check oil MITSUBISHI GALANT 1989 Service Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 88 of 1273

11-38

ENGINE

Rubber

exposed

Tooth missing

and

canvas fiber exposed

lEN0002

Crankshaft

sprocket “B”

Crankshaft

aENzo4

Spacer

Chamfered

6EN009

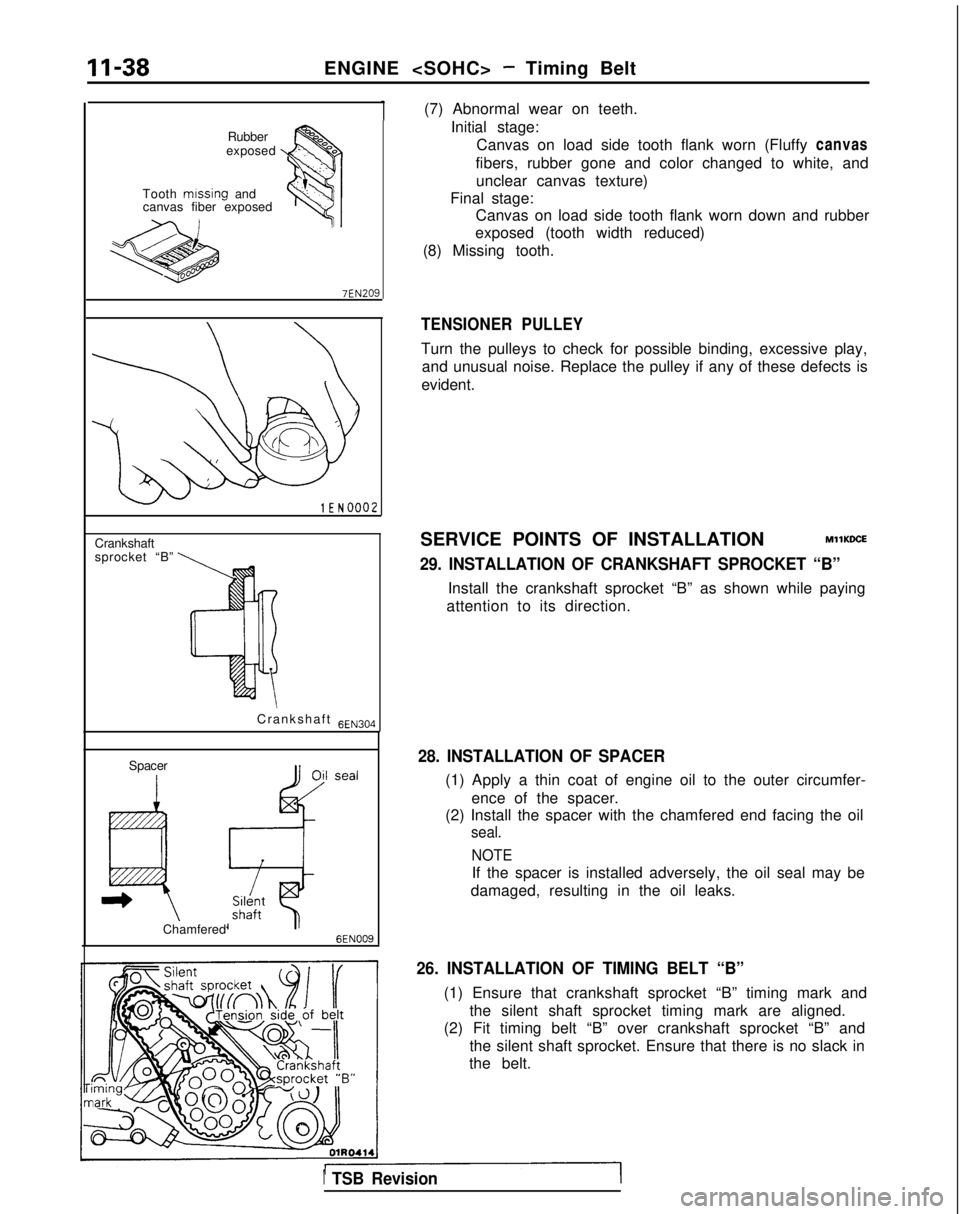

(7) Abnormal wear on teeth.Initial stage:Canvas on load side tooth flank worn (Fluffy canvas

fibers, rubber gone and color changed to white, and unclear canvas texture)

Final stage: Canvas on load side tooth flank worn down and rubber

exposed (tooth width reduced)

(8) Missing tooth.

TENSIONER PULLEY

Turn the pulleys to check for possible binding, excessive play, and unusual noise. Replace the pulley if any of these defects is

evident.

SERVICE POINTS OF INSTALLATION

MllKDCE

29. INSTALLATION OF CRANKSHAFT SPROCKET “B”

Install the crankshaft sprocket “B” as shown while paying

attention to its direction.

28. INSTALLATION OF SPACER

(1) Apply a thin coat of engine oil to the outer circumfer-

ence of the spacer.

(2) Install the spacer with the chamfered end facing the oil

seal.

NOTE

If the spacer is installed adversely, the oil seal may be

damaged, resulting in the oil leaks.

26. INSTALLATION OF TIMING BELT “B”

(1) Ensure that crankshaft sprocket “B” timing mark and the silent shaft sprocket timing mark are aligned.

(2) Fit timing belt “B” over crankshaft sprocket “B” and

the silent shaft sprocket. Ensure that there is no slack in

the belt.

1 TSB Revision

Page 90 of 1273

II-40ENGINE

OlRO372

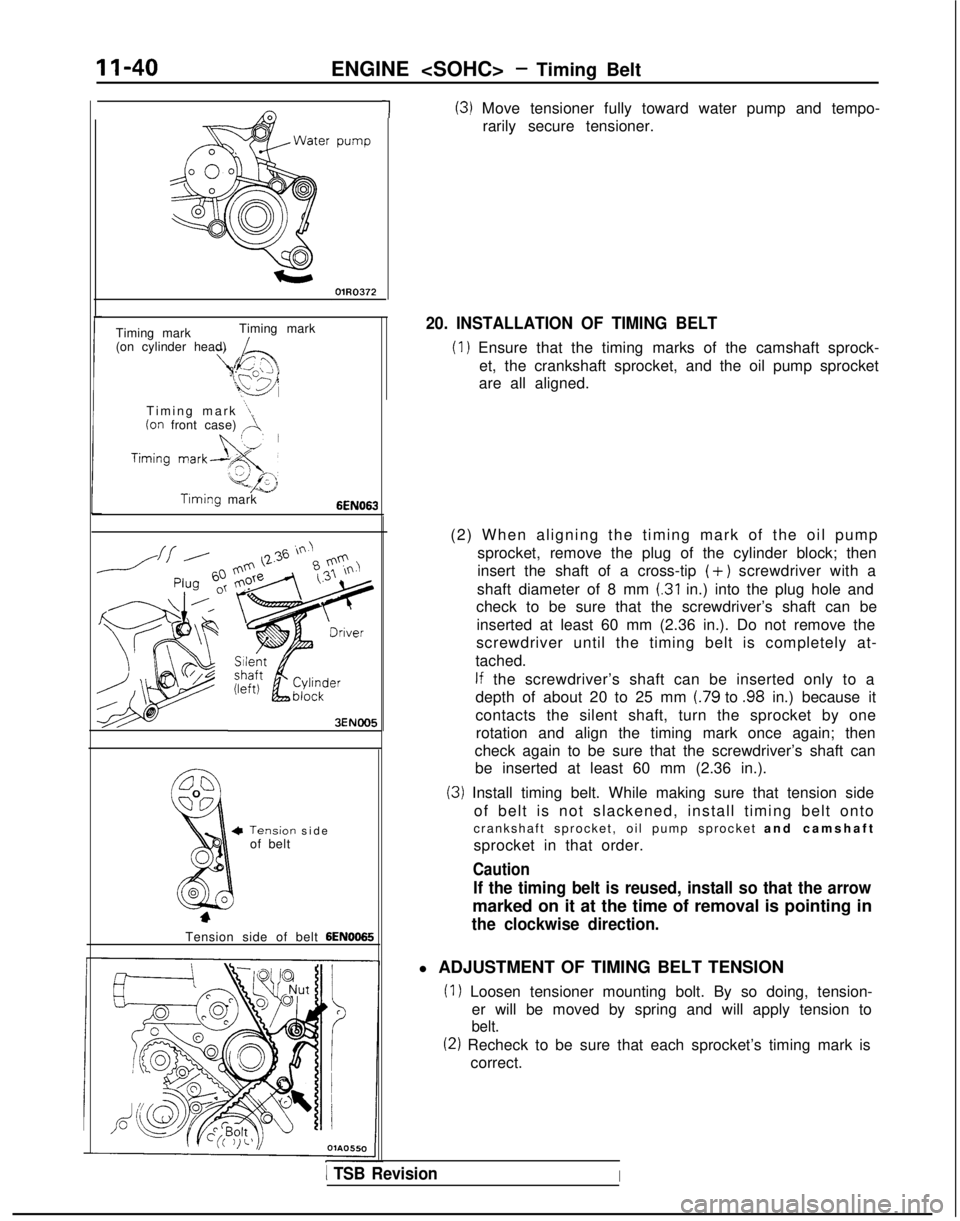

1(3) Move tensioner fully toward water pump and tempo-rarily secure tensioner.

Timing mark Timing mark

(on cylinder head)

Timing mark

“1(on front case) ,A.

Timing mark6EN063

3ENOO5

Tensiorof belt-I sid

e

Tension side of belt

6EN0065

20. INSTALLATION OF TIMING BELT

(1) Ensure that the timing marks of the camshaft sprock- et, the crankshaft sprocket, and the oil pump sprocket

are all aligned.

(2) When aligning the timing mark of the oil pump sprocket, remove the plug of the cylinder block; then

insert the shaft of a cross-tip

(+) screwdriver with a

shaft diameter of 8 mm

(.31 in.) into the plug hole and

check to be sure that the screwdriver’s shaft can be

inserted at least 60 mm (2.36 in.). Do not remove the

screwdriver until the timing belt is completely at-

tached.

If the screwdriver’s shaft can be inserted only to a

depth of about 20 to 25 mm

(.79 to .98 in.) because it

contacts the silent shaft, turn the sprocket by one rotation and align the timing mark once again; then

check again to be sure that the screwdriver’s shaft can be inserted at least 60 mm (2.36 in.).

(3) Install timing belt. While making sure that tension side

of belt is not slackened, install timing belt onto

crankshaft sprocket, oil pump sprocket and camshaf

t

sprocket in that order.

Caution

If the timing belt is reused, install so that the arrow

marked on it at the time of removal is pointing in

the clockwise direction.

l ADJUSTMENT OF TIMING BELT TENSION

(1) Loosen tensioner mounting bolt. By so doing, tension- er will be moved by spring and will apply tension to

belt.

(2) Recheck to be sure that each sprocket’s timing mark iscorrect.

1 TSB RevisionI

Page 91 of 1273

ENGINE

I

I

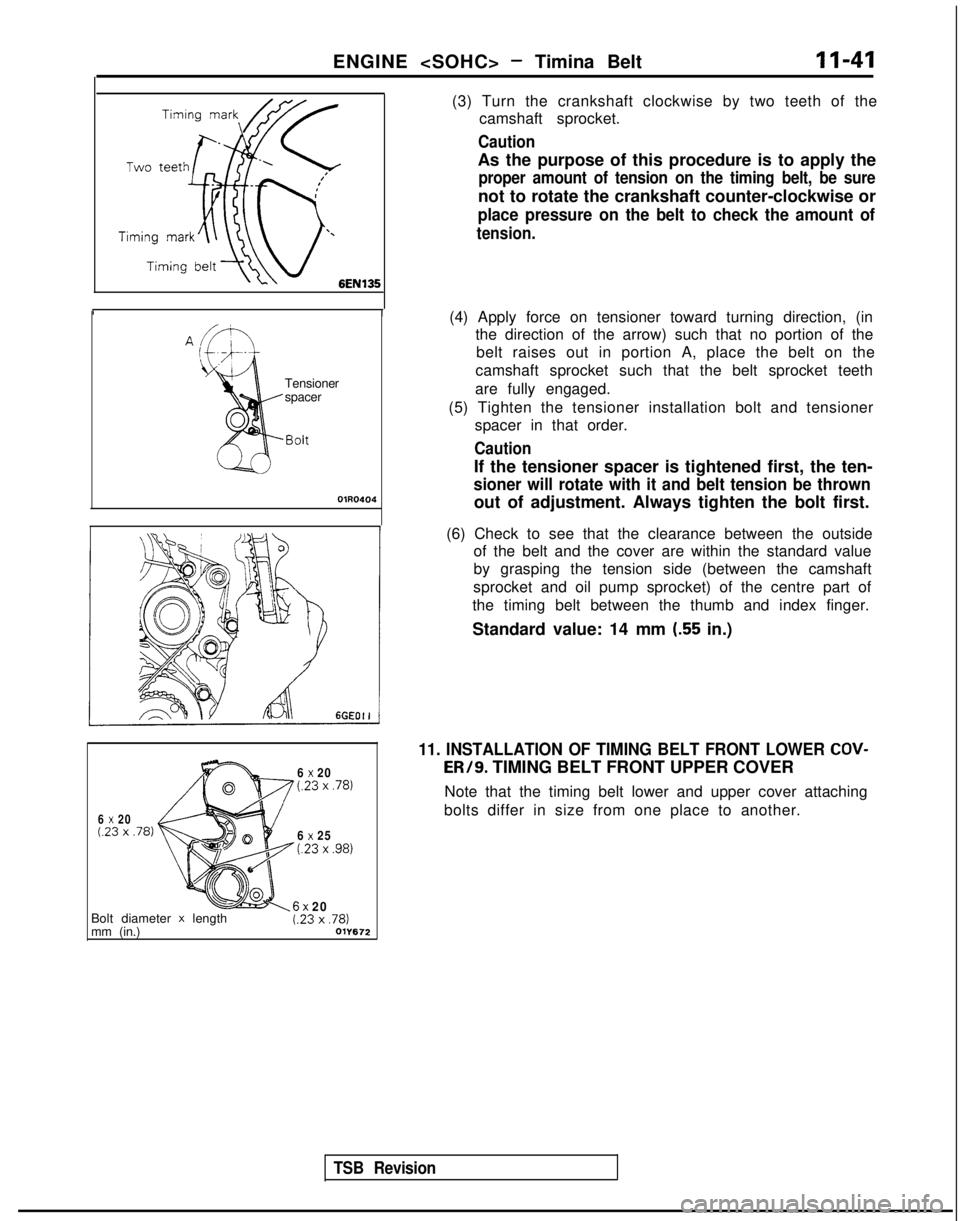

(3) Turn the crankshaft clockwise by two teeth of the

camshaft sprocket.

Caution

As the purpose of this procedure is to apply the

proper amount of tension on the timing belt, be sure

not to rotate the crankshaft counter-clockwise or

place pressure on the belt to check the amount of

tension.

Tensioner

spacer

OlR0404

(4) Apply force on tensioner toward turning direction, (inthe direction of the arrow) such that no portion of the

belt raises out in portion A, place the belt on the

camshaft sprocket such that the belt sprocket teeth

are fully engaged.

(5) Tighten the tensioner installation bolt and tensioner spacer in that order.

Caution

If the tensioner spacer is tightened first, the ten-

sioner will rotate with it and belt tension be thrown

out of adjustment. Always tighten the bolt first.

TSB Revision

(6) Check to see that the clearance between the outside of the belt and the cover are within the standard value

by grasping the tension side (between the camshaft

sprocket and oil pump sprocket) of the centre part of

the timing belt between the thumb and index finger.

Standard value: 14 mm

(.55 in.)

6 x 20(23 x .78)

6 x 20(23 x .78)

6 x 25t.23 x ,981

11. INSTALLATION OF TIMING BELT FRONT LOWER COV- ER/9.

TIMING BELT FRONT UPPER COVER

Note that the timing belt lower and upper cover attaching

bolts differ in size from one place to another.

Bolt diameter

x length

mm (in.)6x 20t.23 x ,781011672

Page 94 of 1273

ENGINE

A Timing

mark

Timingmark

mark

-/Crank&aft swocketOlA0667 lEN0017SERVICE POINTS OF REMOVAL

MllKBDG

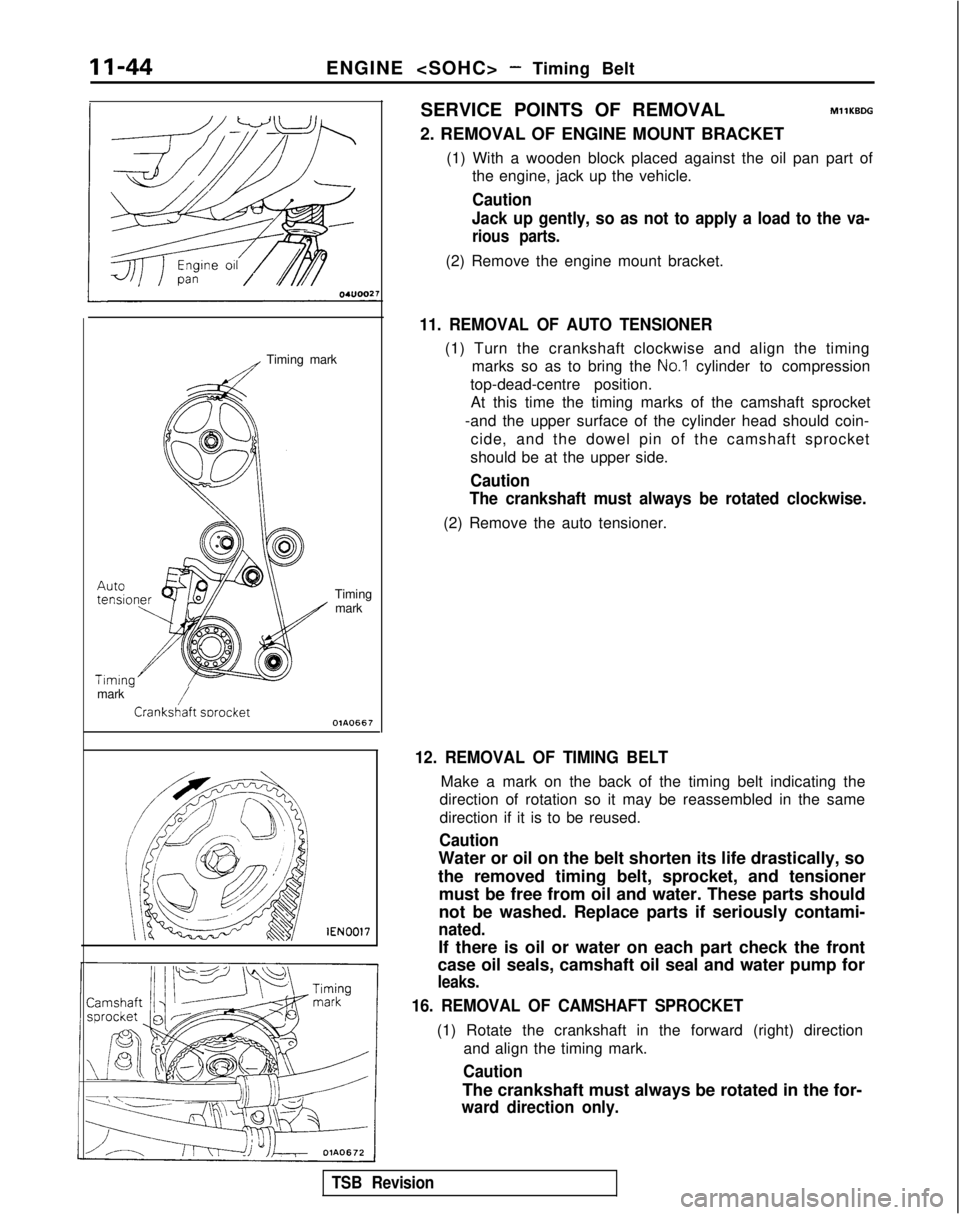

2. REMOVAL OF ENGINE MOUNT BRACKET

(1) With a wooden block placed against the oil pan part ofthe engine, jack up the vehicle.

Caution

Jack up gently, so as not to apply a load to the va-

rious parts.

(2) Remove the engine mount bracket.

11. REMOVAL OF AUTO TENSIONER

(1) Turn the crankshaft clockwise and align the timing marks so as to bring the

No.1 cylinder to compression

top-dead-centre position. At this time the timing marks of the camshaft sprocket

-and the upper surface of the cylinder head should coin- cide, and the dowel pin of the camshaft sprocket

should be at the upper side.

Caution

The crankshaft must always be rotated clockwise.

(2) Remove the auto tensioner.

12. REMOVAL OF TIMING BELT

Make a mark on the back of the timing belt indicating the

direction of rotation so it may be reassembled in the same

direction if it is to be reused.

Caution

Water or oil on the belt shorten its life drastically, so

the removed timing belt, sprocket, and tensioner must be free from oil and water. These parts should

not be washed. Replace parts if seriously contami-

nated.

If there is oil or water on each part check the front

case oil seals, camshaft oil seal and water pump for

leaks.

16. REMOVAL OF CAMSHAFT SPROCKET

(1) Rotate the crankshaft in the forward (right) direction

and align the timing mark.

Caution

The crankshaft must always be rotated in the for-

ward direction only.

TSB Revision

Page 95 of 1273

ENGINE

11-45

sprocket

vlGVO001 MD998754

vlB990767-01

-

&

00B00°

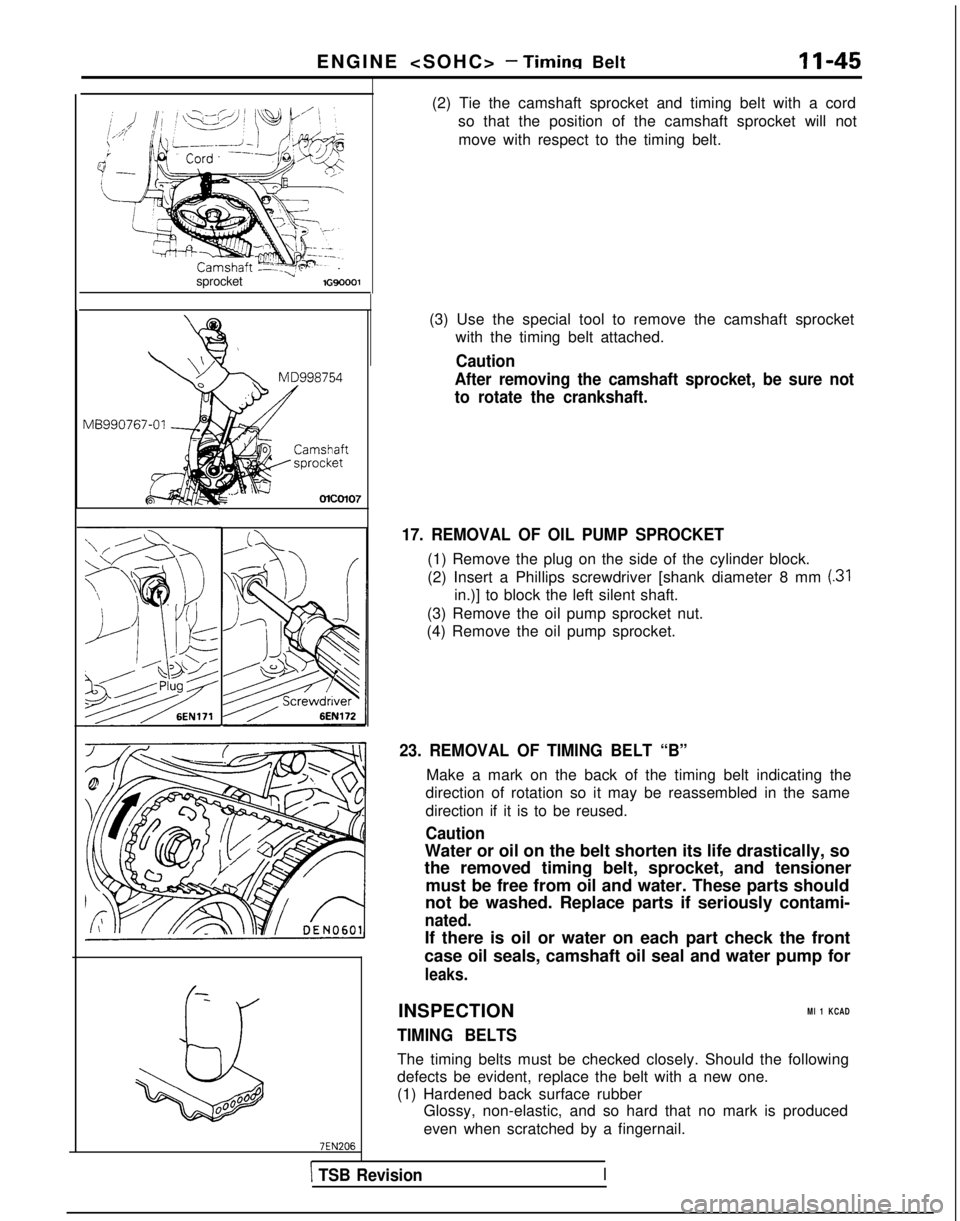

(2) Tie the camshaft sprocket and timing belt with a cord

so that the position of the camshaft sprocket will not

move with respect to the timing belt.

(3) Use the special tool to remove the camshaft sprocket with the timing belt attached.

Caution

After removing the camshaft sprocket, be sure not

to rotate the crankshaft.

17. REMOVAL OF OIL PUMP SPROCKET

(1) Remove the plug on the side of the cylinder block.

(2) Insert a Phillips screwdriver [shank diameter 8 mm

(31

in.)] to block the left silent shaft.

(3) Remove the oil pump sprocket nut.

(4) Remove the oil pump sprocket.

23. REMOVAL OF TIMING BELT “B”

Make a mark on the back of the timing belt indicating the

direction of rotation so it may be reassembled in the same

direction if it is to be reused.

Caution

Water or oil on the belt shorten its life drastically, so

the removed timing belt, sprocket, and tensioner

must be free from oil and water. These parts should

not be washed. Replace parts if seriously contami-

nated.

If there is oil or water on each part check the front

case oil seals, camshaft oil seal and water pump for

leaks.

INSPECTIONMl 1 KCAD

TIMING BELTS

The timing belts must be checked closely. Should the following

defects be evident, replace the belt with a new one.

(1) Hardened back surface rubber Glossy, non-elastic, and so hard that no mark is produced

even when scratched by a fingernail.

\ TSB RevisionI

Page 100 of 1273

ENGINE

Center bolt i\ \

6EN028:

Timina mark

Timingmark

Timing mark

Crankshaft sprocket

OlAO668

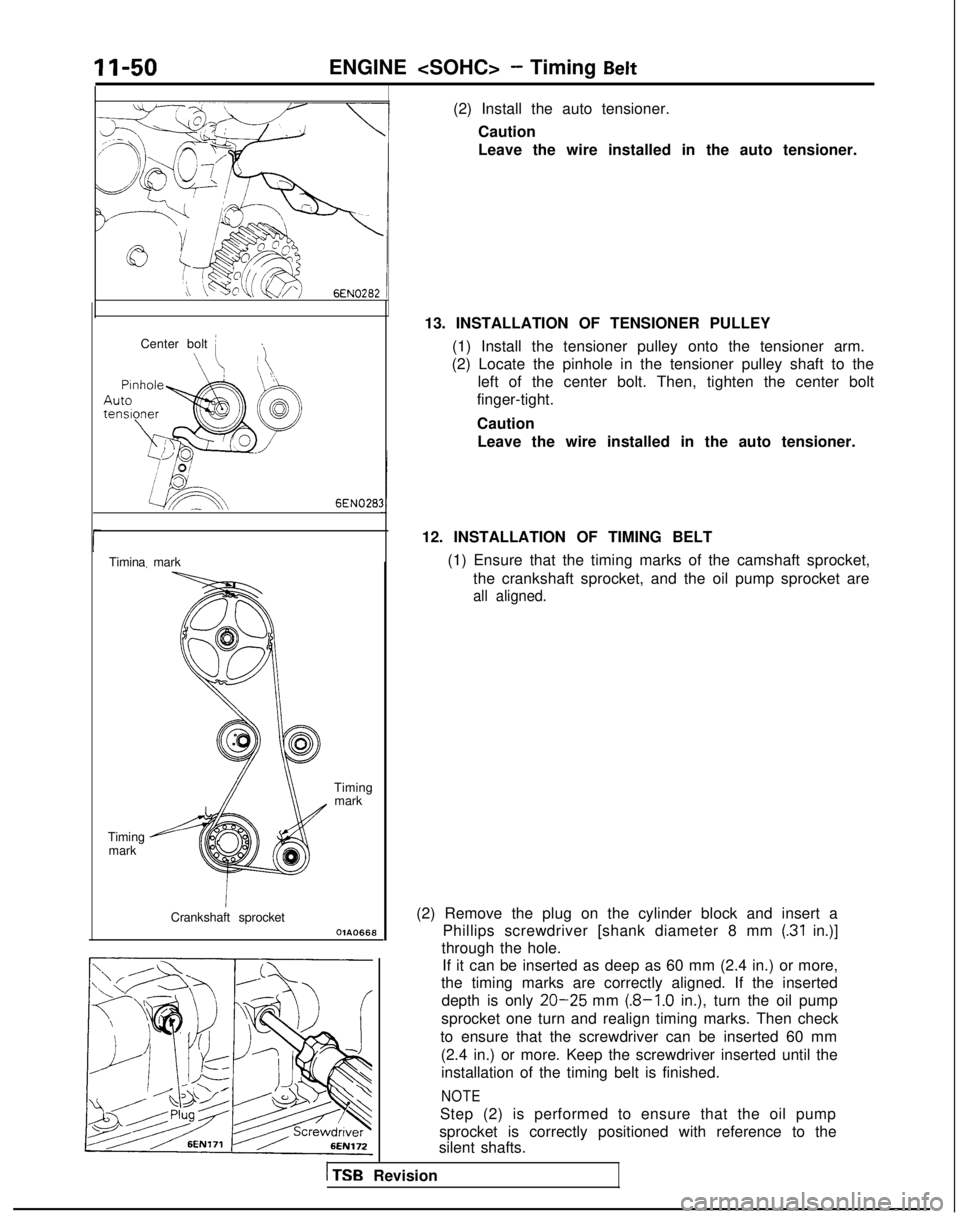

(2) Install the auto tensioner.Caution

Leave the wire installed in the auto tensioner.

13. INSTALLATION OF TENSIONER PULLEY (1) Install the tensioner pulley onto the tensioner arm.

(2) Locate the pinhole in the tensioner pulley shaft to the left of the center bolt. Then, tighten the center bolt

finger-tight.

Caution

Leave the wire installed in the auto tensioner.

12. INSTALLATION OF TIMING BELT (1) Ensure that the timing marks of the camshaft sprocket,the crankshaft sprocket, and the oil pump sprocket are

all aligned.

(2) Remove the plug on the cylinder block and insert a Phillips screwdriver [shank diameter 8 mm

(.31 in.)]

through the hole. If it can be inserted as deep as 60 mm (2.4 in.) or more,

the timing marks are correctly aligned. If the inserted

depth is only

20-25 mm (.8-1.0 in.), turn the oil pump

sprocket one turn and realign timing marks. Then check

to ensure that the screwdriver can be inserted 60 mm (2.4 in.) or more. Keep the screwdriver inserted until theinstallation of the timing belt is finished.

NOTE

Step (2) is performed to ensure that the oil pump

sprocket is correctly positioned with reference to the

silent shafts.

1 TSB Revision

Page 107 of 1273

ENGINE

OlR0340

7EN0393

1SERVICE ADJUSTMENT PROCEDUBFzo

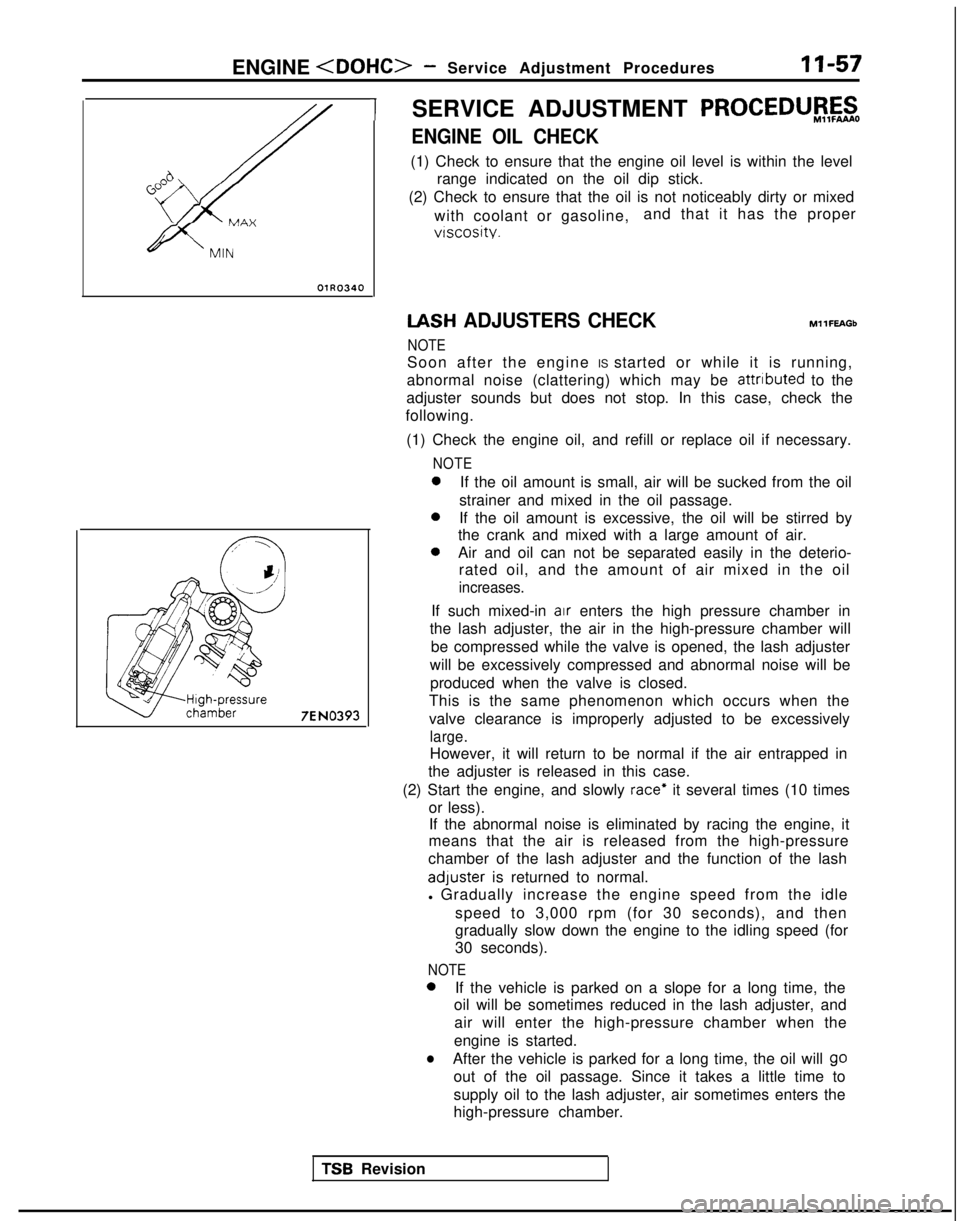

ENGINE OIL CHECK

(1) Check to ensure that the engine oil level is within the level

range indicated on the oil dip stick.

(2) Check to ensure that the oil is not noticeably dirty or mixed

with coolant or gasoline, and that it has the proper

vtscosity. IASH

ADJUSTERS CHECK

NOTE MllFEAGb

Soon after the engine IS started or while it is running,

abnormal noise (clattering) which may be attributed

to the

adjuster sounds but does not stop. In this case, check the

following.

(1) Check the engine oil, and refill or replace oil if necessary.

NOTE 0

If the oil amount is small, air will be sucked from the oil

strainer and mixed in the oil passage. 0

If the oil amount is excessive, the oil will be stirred by

the crank and mixed with a large amount of air. 0

Air and oil can not be separated easily in the deterio-

rated oil, and the amount of air mixed in the oil

increases.

If such mixed-in air enters the high pressure chamber in

the lash adjuster, the air in the high-pressure chamber will

be compressed while the valve is opened, the lash adjuster

will be excessively compressed and abnormal noise will be produced when the valve is closed.

This is the same phenomenon which occurs when the

valve clearance is improperly adjusted to be excessively

large.

However, it will return to be normal if the air entrapped in

the adjuster is released in this case.

(2) Start the engine, and slowly

race* it several times (10 times

or less). If the abnormal noise is eliminated by racing the engine, it

means that the air is released from the high-pressure

chamber of the lash adjuster and the function of the lash adluster

is returned to normal.

l Gradually increase the engine speed from the idle

speed to 3,000 rpm (for 30 seconds), and then

gradually slow down the engine to the idling speed (for

30 seconds).

NOTE 0

If the vehicle is parked on a slope for a long time, the

oil will be sometimes reduced in the lash adjuster, and

air will enter the high-pressure chamber when the

engine is started.

lAfter the vehicle is parked for a long time, the oil will go

out of the oil passage. Since it takes a little time to

supply oil to the lash adjuster, air sometimes enters the

high-pressure chamber.

TSR Revision

Page 109 of 1273

ENGINE

7 Go;;ikv position

switch

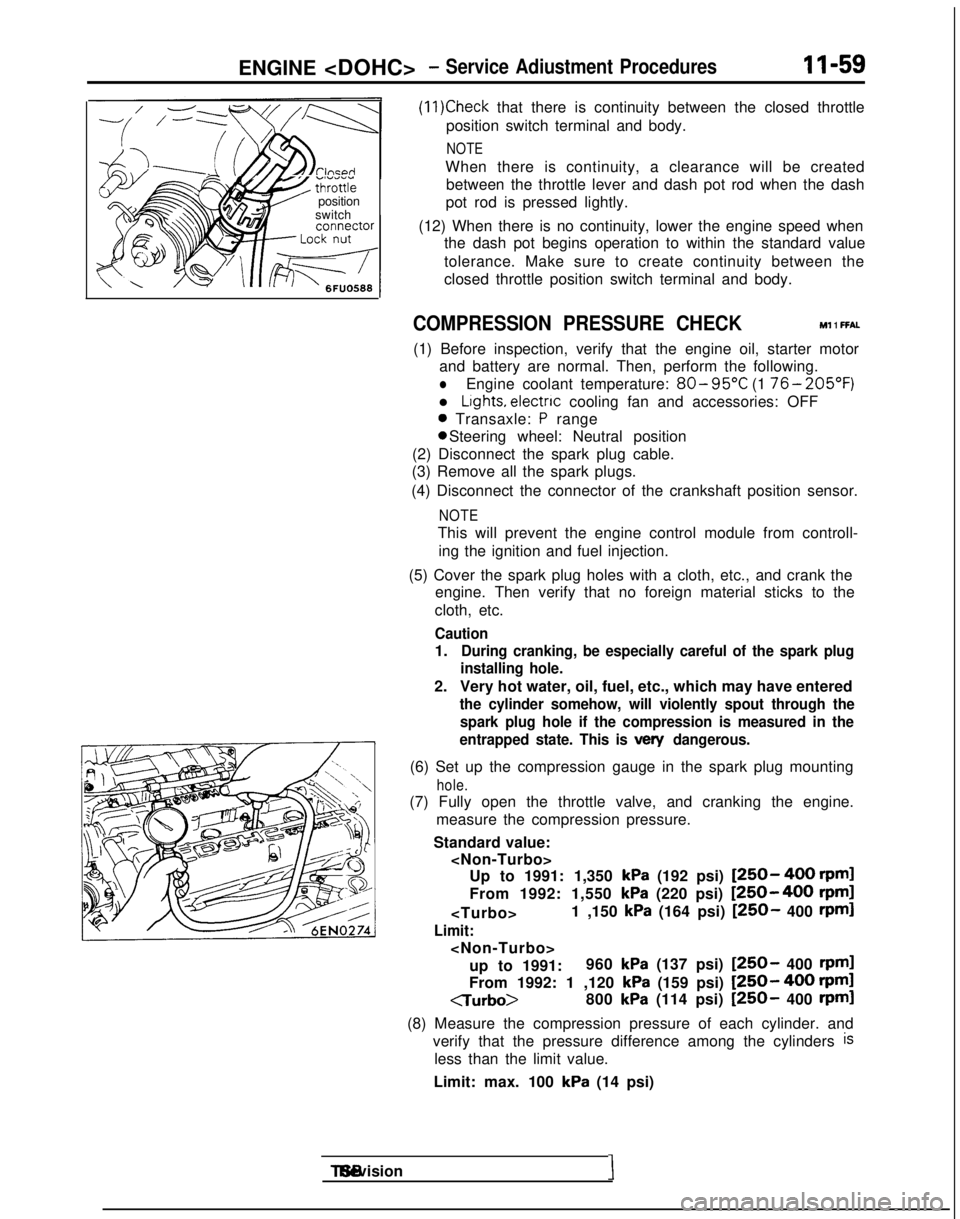

(11)Check that there is continuity between the closed throttle

position switch terminal and body.

NOTE

When there is continuity, a clearance will be created between the throttle lever and dash pot rod when the dash

pot rod is pressed lightly.

(12) When there is no continuity, lower the engine speed when the dash pot begins operation to within the standard value

tolerance. Make sure to create continuity between the

closed throttle position switch terminal and body.

COMPRESSION PRESSURE CHECK Ml 1 FFAL

(1) Before inspection, verify that the engine oil, starter motor

and battery are normal. Then, perform the following.

lEngine coolant temperature: 80- 95°C

(1 76- 205’F)

l Lights, electnc

cooling fan and accessories: OFF

0 Transaxle: P range 0 Steering wheel: Neutral position

(2) Disconnect the spark plug cable.

(3) Remove all the spark plugs.

(4) Disconnect the connector of the crankshaft position sensor.

NOTE

This will prevent the engine control module from controll- ing the ignition and fuel injection.

(5) Cover the spark plug holes with a cloth, etc., and crank the engine. Then verify that no foreign material sticks to the

cloth, etc.

Caution

1.During cranking, be especially careful of the spark plug

installing hole.

2. Very hot water, oil, fuel, etc., which may have entered

the cylinder somehow, will violently spout through the

spark plug hole if the compression is measured in the

entrapped state. This is

vex/ dangerous.

(6) Set up the compression gauge in the spark plug mounting

hole.

(7) Fully open the throttle valve, and cranking the engine.

measure the compression pressure.

Standard value:

kPa (192 psi) [250- 400 rpml

From 1992: 1,550

kPa (220 psi) [250-400 rpm]

Limit:

up to 1991: 960

kPa (137 psi) [250- 400 rpml

From 1992: 1 ,120 kPa (159 psi) [250- 400 rpml

CTurbo>

800

kPa (114 psi) [250- 400 rpml

(8) Measure the compression pressure of each cylinder. and verify that the pressure difference among the cylinders

is

less than the limit value.

Limit: max. 100

kPa (14 psi) TSB Revision

I

Page 110 of 1273

II-60ENGINE

(9) If a cylinder’s compression pressure or pressure differenceis outside the limit, fill a small amount of engine oil through

the spark plug hole and repeat Items (7) and (8) above.

@ If the compression is increased when the oil is filled, the piston

and/or cylinder wall may be worn or

damaged.

@ If the compression is not Increased even though the oil is filled, the valve may be thermally seized, the valve

contact may be improper or pressure may leak at the

gasket. (10)Connect the connector of the crankshaft position sensor.

(1l)lnstall

the spark plug and spark plug cable.

(12)Erase the diagnostic trouble code with the scan tool or re-

connect the battery (-)

cable 10 seconds or more after it

was disconnected.

NOTE

This will erase the memory of the diagnostic trouble code which resulted from disconnection of the crankshaft posi-

tion sensor connector.

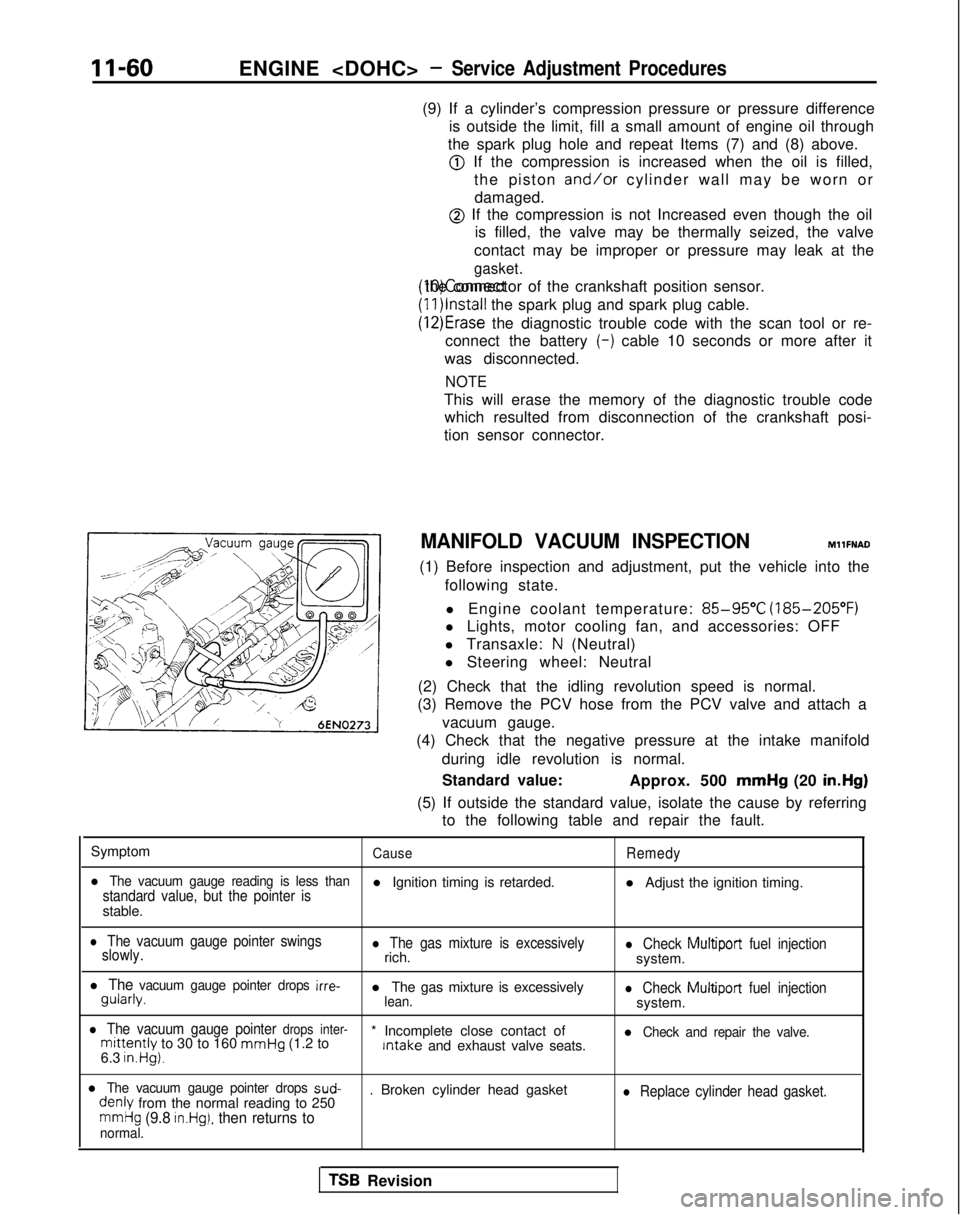

MANIFOLD VACUUM INSPECTION MllFNAD

(1) Before inspection and adjustment, put the vehicle into the following state.

l Engine coolant temperature:

85-95°C (185-205°F)

l Lights, motor cooling fan, and accessories: OFF

l Transaxle:

N (Neutral)

l Steering wheel: Neutral

(2) Check that the idling revolution speed is normal.

(3) Remove the PCV hose from the PCV valve and attach a

vacuum gauge.

(4) Check that the negative pressure at the intake manifold

during idle revolution is normal.

Standard value: Approx. 500 mmHg

(20 in.Hg)

(5) If outside the standard value, isolate the cause by referring to the following table and repair the fault.

Symptom

CauseRemedy

l The vacuum gauge reading is less thanstandard value, but the pointer isl Ignition timing is retarded. l Adjust the ignition timing.

stable.

l The vacuum gauge pointer swings

slowly.l The gas mixture is excessivelyrich.l Check Multiport fuel injectionsystem.

l The vacuum gauge pointer drops irre- gularly.

l The gas mixture is excessively

lean.l Check Multiport

fuel injectionsystem.

l The vacuum gauge pointer drops inter-mittently to 30 to 160 mmHg

(1.2 to * Incomplete close contact of Intake

and exhaust valve seats.l Check and repair the valve.

6.3 in.Hg).

l The vacuum gauge pointer drops sud- denly

from the normal reading to 250 . Broken cylinder head gasketl Replace cylinder head gasket.

mmHg (9.8 in.Hg), then returns tonormal.

TSB Revision

Page 111 of 1273

ENGINE

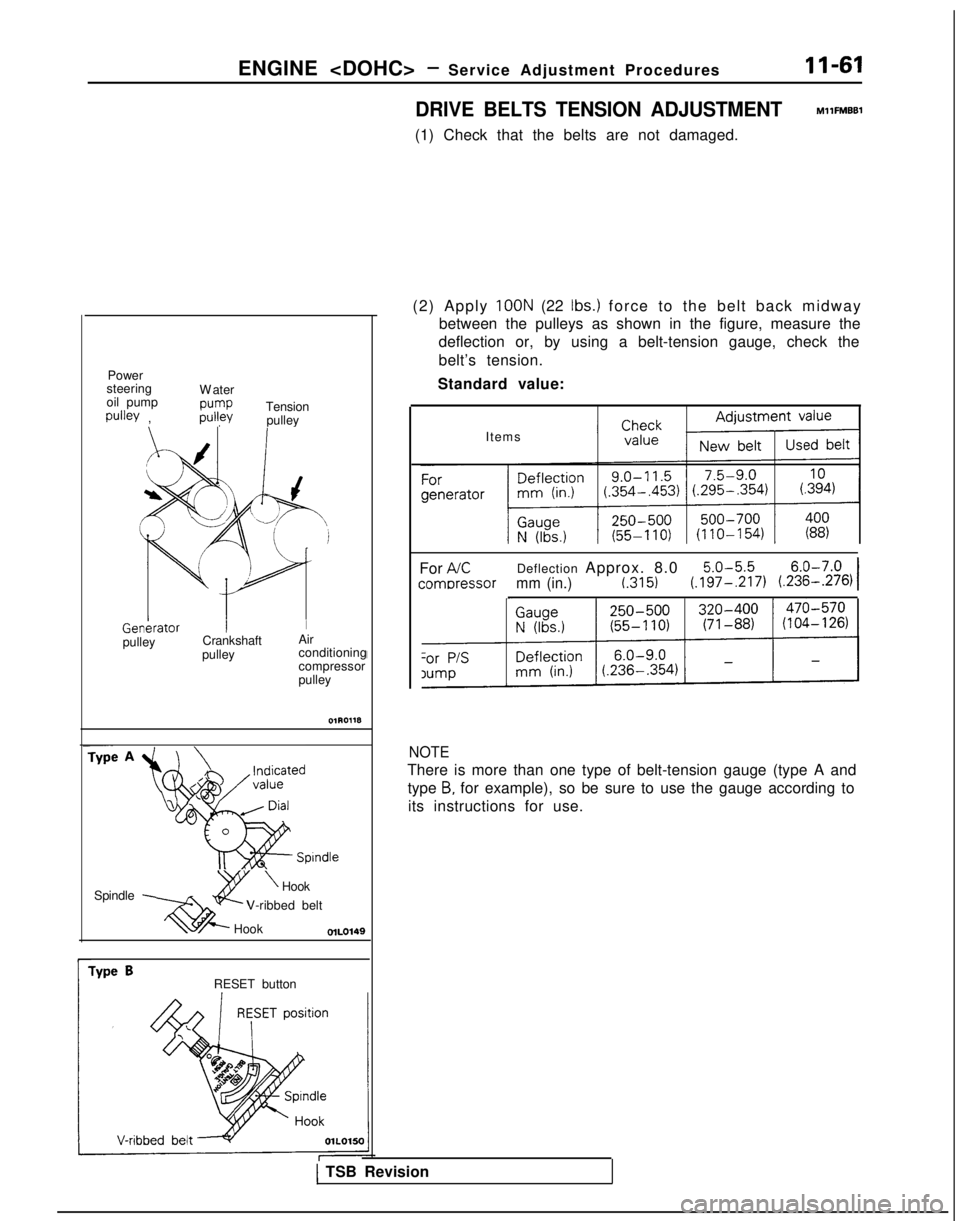

DRIVE BELTS TENSION ADJUSTMENT

MllFMBBl

(1) Check that the belts are not damaged.

Power

steering

oil pump

pulley , W

ater

pump

pulley

Tension

pulley

f /

xI J

b

L ‘d

p1 Genkrator

I

Ipulley

Crankshaft

Air

pulley conditioning

compressor

pulley

Spindle Spindle

2Y

\Hook

xi@--

V-ribbed belt

Hook

r

Type BRESET button (2) Apply

100N (22 Ibs.) force to the belt back midwa

y

between the pulleys as shown in the figure, measure the

deflection or, by using a belt-tension gauge, check the

belt’s tension.

Standard value:

Items

For

AKDeflection Approx. 8.05.0-5.56.0-7.0

comDressormm (in.)t.3151(.197-,217) (.236-.276)I

NOTE

There is more than one type of belt-tension gauge (type A and

type

B, for example), so be sure to use the gauge according to

its instructions for use.

1 TSB Revision