key MITSUBISHI GALANT 1989 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 19 of 1273

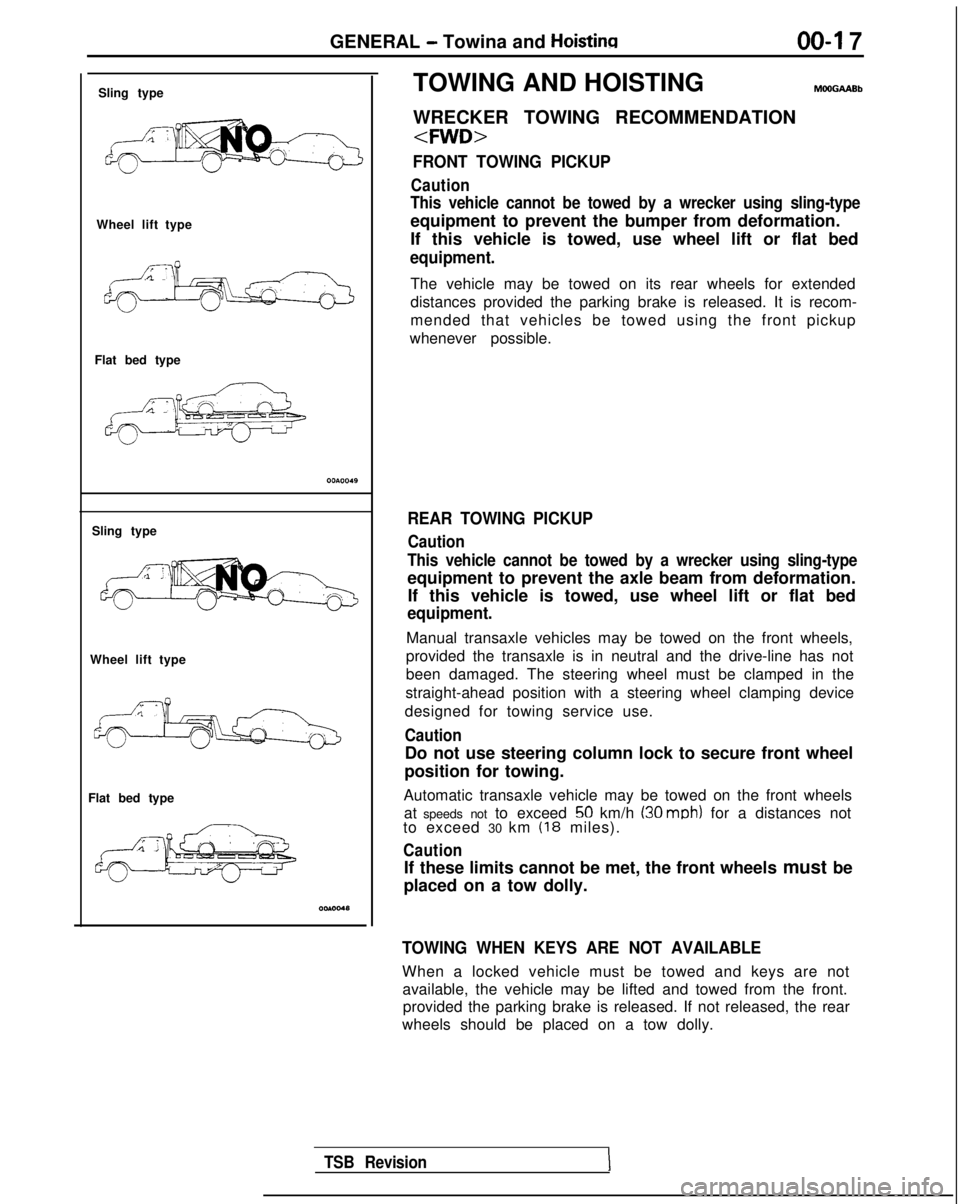

GENERAL - Towina and Hoisting

00-l 7

Sling type

Wheel lift type

Flat bed type

Sling type

Wheel lift type

Flat bed type TOWING AND HOISTING

WRECKER TOWING RECOMMENDATION

FRONT TOWING PICKUP

Caution

This vehicle cannot be towed by a wrecker using sling-type

equipment to prevent the bumper from deformation.

If this vehicle is towed, use wheel lift or flat bed

equipment.

The vehicle may be towed on its rear wheels for extended

distances provided the parking brake is released. It is recom-

mended that vehicles be towed using the front pickup

whenever possible.

REAR TOWING PICKUP

Caution

This vehicle cannot be towed by a wrecker using sling-type

equipment to prevent the axle beam from deformation. If this vehicle is towed, use wheel lift or flat bed

equipment.

Manual transaxle vehicles may be towed on the front wheels,

provided the transaxle is in neutral and the drive-line has not

been damaged. The steering wheel must be clamped in the

straight-ahead position with a steering wheel clamping device

designed for towing service use.

Caution

Do not use steering column lock to secure front wheel

position for towing.

Automatic transaxle vehicle may be towed on the front wheels at speeds not to exceed

50 km/h (30 mob) for a distances not

to exceed 30 km (18 miles).

Caution

If these limits cannot be met, the front wheels must be

placed on a tow dolly.

TOWING WHEN KEYS ARE NOT AVAILABLE

When a locked vehicle must be towed and keys are not available, the vehicle may be lifted and towed from the front.provided the parking brake is released. If not released, the rear

wheels should be placed on a tow dolly.

TSB Revision

Page 84 of 1273

11-34

ENGINE

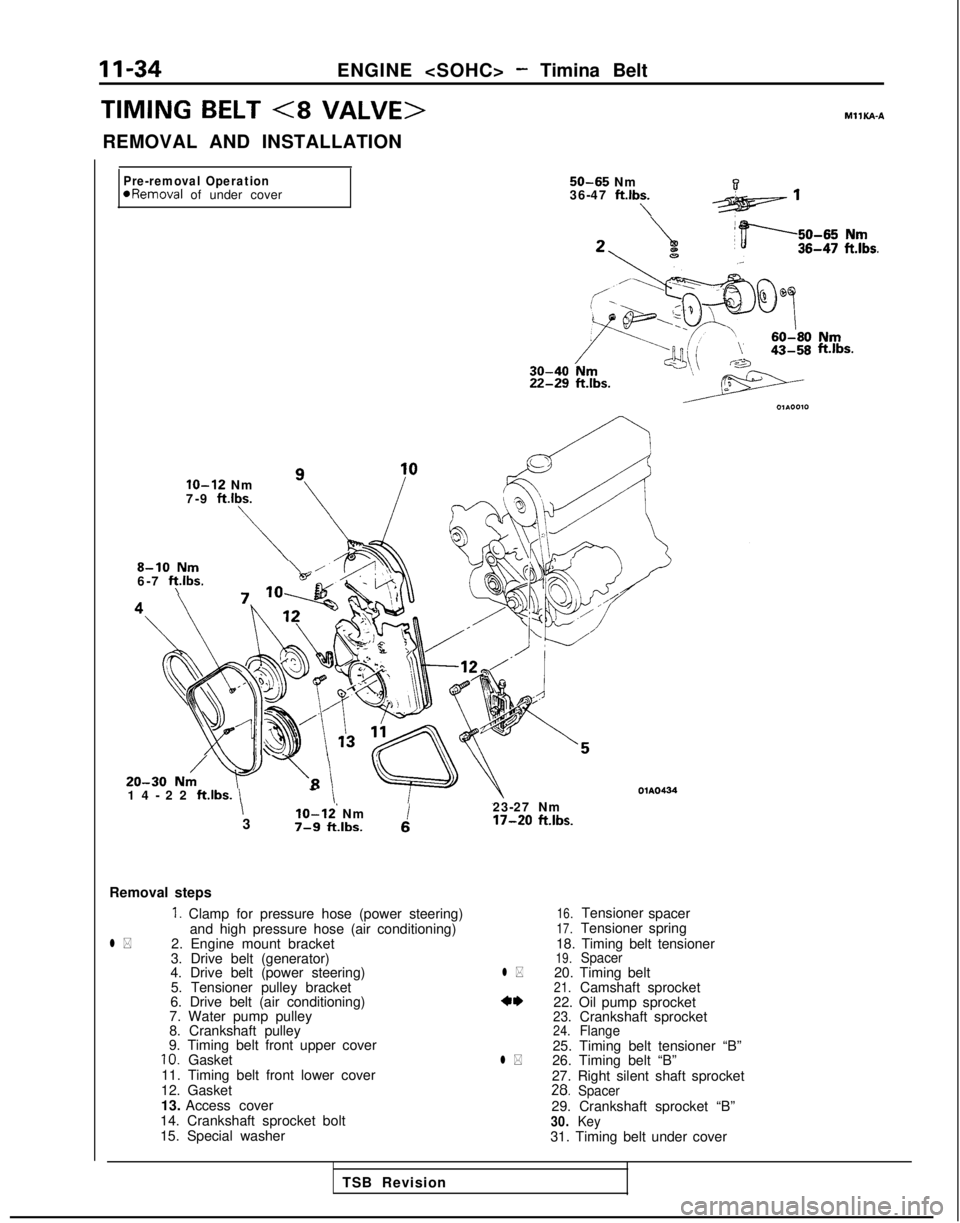

TIMING BELT (8 VALVE>MIlKA-A

REMOVAL AND INSTALLATION

Pre-removal OperationaRemoval of under cover 50-65

Nm

36-47 ftlbs.

\ 22-29

ft.lbs.

ft.lbs.

IO-12 Nm

7-9 ft.lbs. 10

m\../.8-10 N6-7 ft.lbs.\

20-30 N,/ v \R \OlAO43414-22 ft.lbs. \I3

10-12’

Nm7-S ftlbs.

6

23-27 Nm 17-20

ft.lbs.

Removal steps

1. Clamp for pressure hose (power steering)

and high pressure hose (air conditioning)

l *2. Engine mount bracket

3. Drive belt (generator)

4. Drive belt (power steering)

5. Tensioner pulley bracket

6. Drive belt (air conditioning)

7. Water pump pulley

8. Crankshaft pulley

9. Timing belt front upper cover

10. Gasket

11. Timing belt front lower cover

12. Gasket

13. Access cover

14. Crankshaft sprocket bolt

15. Special washer

16.Tensioner spacer17.Tensioner spring

18. Timing belt tensioner

19.Spacerl *20. Timing belt21.Camshaft sprocket*‘I)22. Oil pump sprocket23.24.Crankshaft sprocketFlange25. Timing belt tensioner “B”l *26. Timing belt “B”

27. Right silent shaft sprocket

28.Spacer29. Crankshaft sprocket “B”30.Key31. Timing belt under cover

TSB Revision

Page 85 of 1273

ENGINE

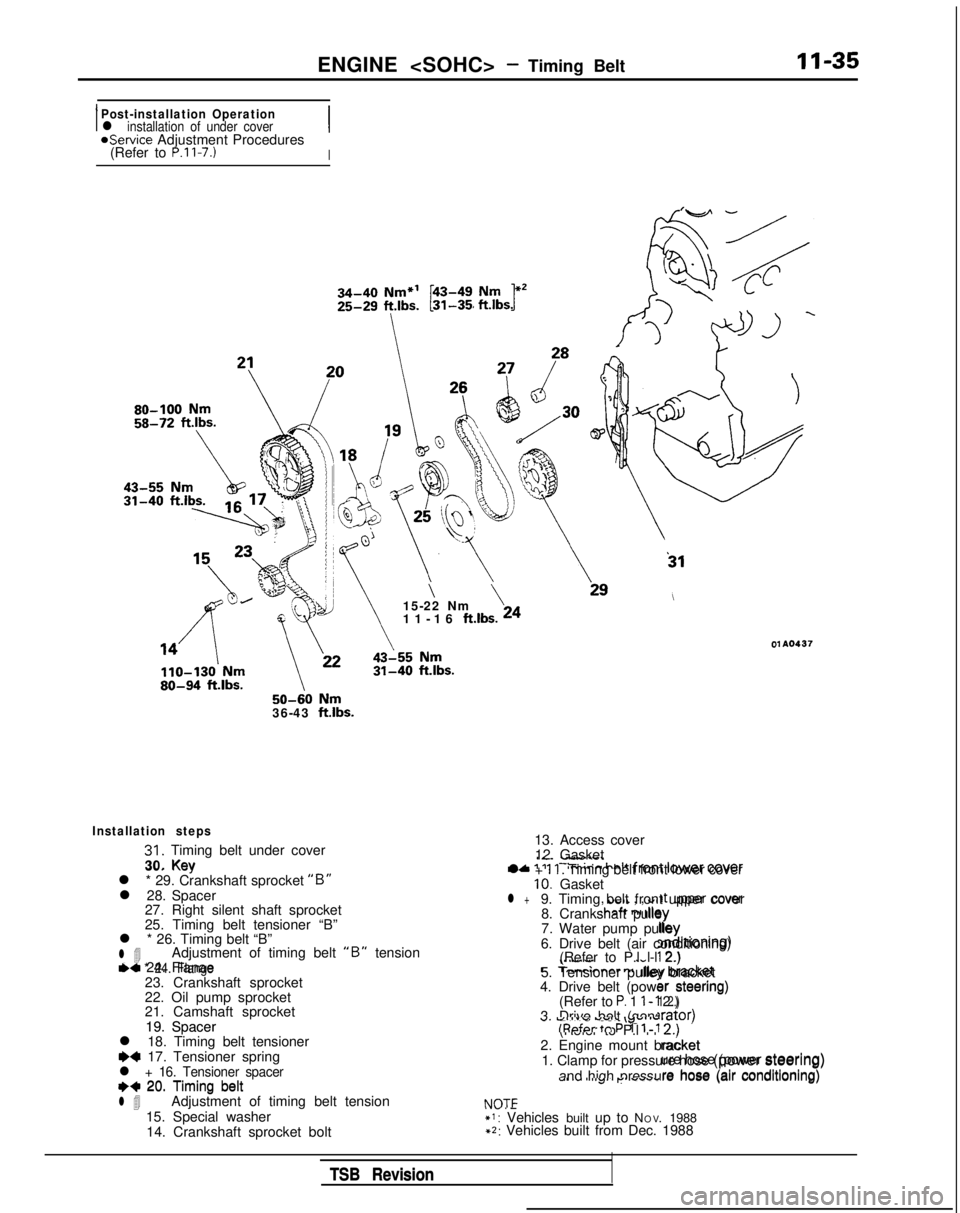

IPost-installation Operationl installation of under coverIaService Adjustment Procedures

(Refer to P.ll-7.)I 50-60

Nm36-43 ftlbs.

31

\\15-22 Nm

11-16 ft.lbs. 24

01 A0437

30. KevIL. -I"..--+A ‘IIT:m;nn halt fmnf lower cover

Installation steps

31. Timing belt under cover

30. Key

l * 29. Crankshaft sprocket

“B”l 28. Spacer 27. Right silent shaft sprocket

25. Timing belt tensioner “B”

l * 26. Timing belt “B”

l 4Adjustment of timing belt “B” tensionl * 24. Flange23. Crankshaft sprocket

22. Oil pump sprocket

21. Camshaft sprocket

19. Spacer

l 18. Timing belt tensioner

~~ 17. Tensioner springl + 16. Tensioner spacer++ 20. Timing beltl 4Adjustment of timing belt tension

15. Special washer 14. Crankshaft sprocket bolt

tic 24. Flanae

, UtiIL , , WI ,t upper cover!hcaft n, dlqy

lb. :;d)rtroning)

\..“.w.

.-c

T-mrinnar r

nliny bracket

er steering)1 2.)

19. Spacer

++ 20. Timing belt13. Access cover

12. Gasket

l +

11. Timing belt front lower cover10. Gasketl +9. Timing belt front upper cover 8. Crankshaft pulley

7. Water pump pulley

6. Drive belt (air conditioning) (Refer to P.l l-l 2.)

5. Tensioner pulley bracket

4. Drive belt (power steering)

(Refer to

P. 1 l-l 2.)

3. Drive belt (generator) (Refer to P.l l-l 2.)

2. Engine mount bracket 1. Clamp for pressure hose (power steering)

and high pressure hose (air conditioning)

NOTE*I: Vehicles built up to N O

V. 1988

+2: Vehicles built from Dec. 1988 lrator)

U. Vll”” ““SC \y”v’ulRpfcw tn P 1 l-l

2.)

racket

NOT=

ure hose (power steering)

s-4, I” I “..J’I p.. .#““.are hose (air conditioning)

TSB Revision

TSB Revision

Page 93 of 1273

ENGINE

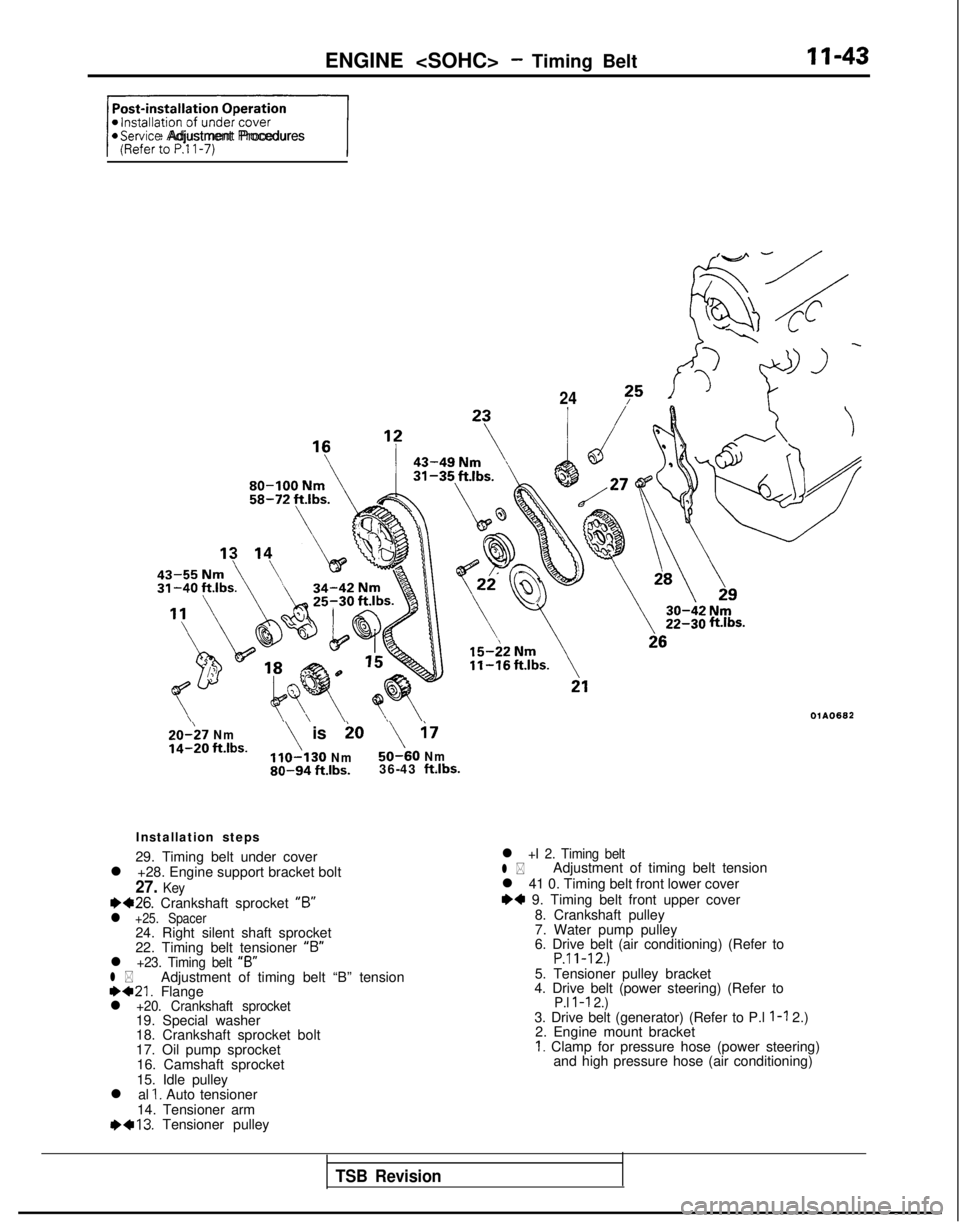

+/@Service Adjustment Procedures

24?5

20-;7 Nmio

14-20 ft.lbs.\ is\ i7

Nm50-60 Nm80-94 ft.lbs.36-43 ft.lbs.

Installation steps

29. Timing belt under cover

l +28. Engine support bracket bolt

27. Keyea26. Crankshaft sprocket “6”l +25. Spacer24. Right silent shaft sprocket

22. Timing belt tensioner “B”

l +23. Timing belt

“B”l *Adjustment of timing belt “B” tension1)421. Flangel +20. Crankshaft sprocket19. Special washer

18. Crankshaft sprocket bolt

17. Oil pump sprocket

16. Camshaft sprocket

15. Idle pulley

l al

1. Auto tensioner

14. Tensioner arm 1)+13.

Tensioner pulley

ftlbs.

OlAO682

l +I 2. Timing beltl *Adjustment of timing belt tension

l 41 0. Timing belt front lower cover

I)+ 9. Timing belt front upper cover 8. Crankshaft pulley

7. Water pump pulley

6. Drive belt (air conditioning) (Refer to

P.ll-12.)5. Tensioner pulley bracket

4. Drive belt (power steering) (Refer to

P.l l-l 2.)3. Drive belt (generator) (Refer to P.l l-l 2.)

2. Engine mount bracket

I. Clamp for pressure hose (power steering) and high pressure hose (air conditioning)

TSB Revision

Page 153 of 1273

FUEL SYSTEM

ON-BOARD DIAGNOSTIC-

The engine control module monitors the input/out-

put signals (some signals at all times and the others

under specified conditions) of the engine control

module.

When it is noticed that an irregularity has continued

for a specified time or longer from when the irregu- lar signal is initially monitored, passing a certain

number, the engine control module judges that an

irregularity has occurred, memorizes the diagnostic

trouble code, and outputs the signal to the on-board

diagnostic output terminal.

There are 15 on-board diagnostic items including

the normal state, and the diagnostic results can be

read out with a voltmeter or scan tool.

Moreover, since memorization of the diagnostic

trouble codes is backed up directly by the battery,

the diagnostic results are memorized even if the ig- nition key is turned off. The diagnostic trouble

codes will, however, be erased when the battery disconnected. In addition, beginning with the engine

control module of

1990 and later models, the diag-

nostic trouble codes are erased by turning on the

ignition switch and sending the diagnostic trouble

code erase signal from the scan tool to the engine

control module.

Caution

If the sensor connector is disconnected with

the ignition switch turned on, the diagnostic

trouble code is memorized. In this case, send

the diagnostic trouble code erase signal from

the scan tool to the engine control module or disconnect the battery terminal (-)

for 10 sec-

onds or more, and the diagnostic memory will

be erased.

The 15 on-board diagnostic items are provided as

follows, and if plural items are activated, they are all

indicated sequentially from the smallest code num-

I---

terminal or the engine control module connector is

uer

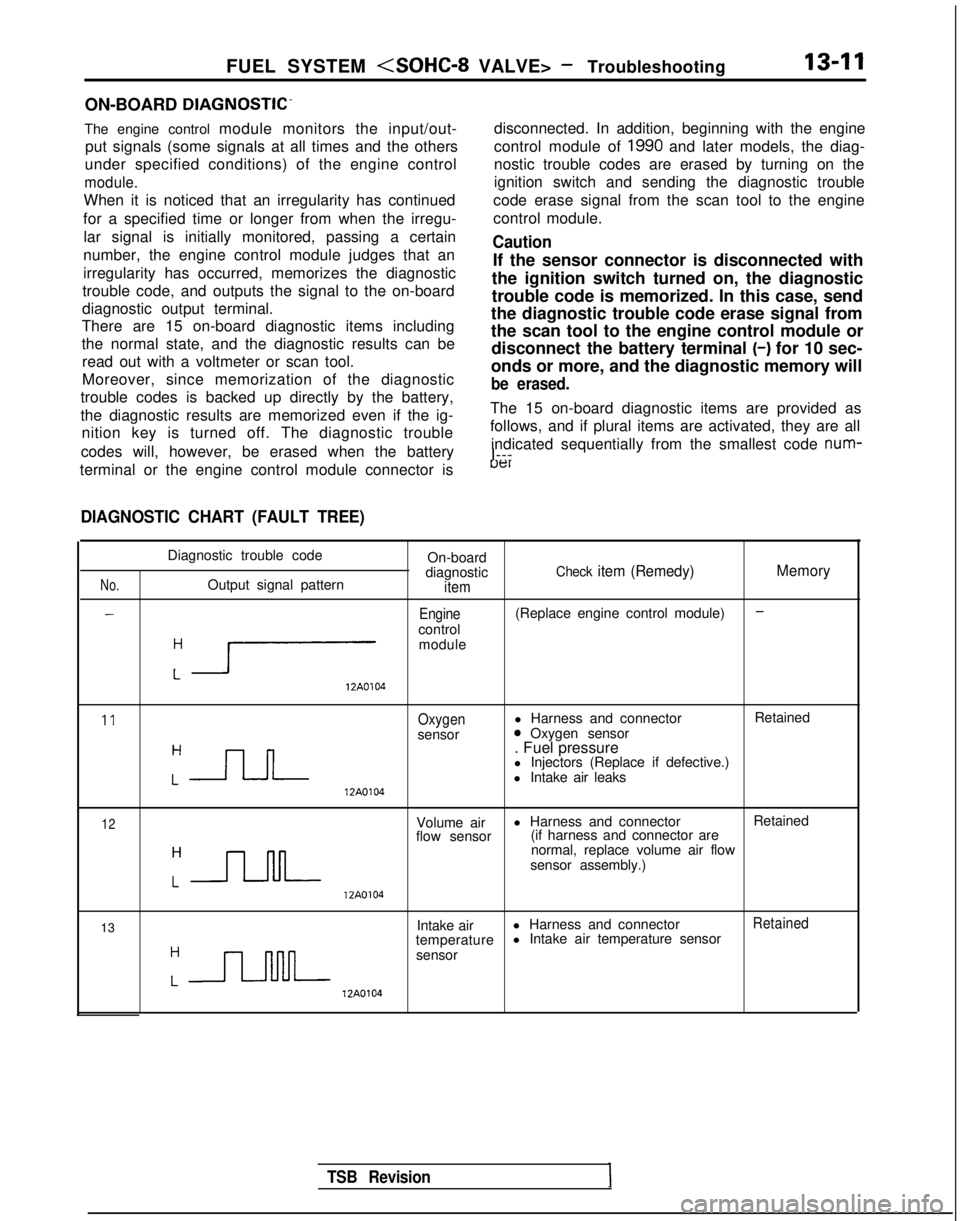

DIAGNOSTIC CHART (FAULT TREE)

No.

-

Diagnostic trouble code On-board

diagnostic

Check item (Remedy) MemoryOutput signal patternitem

-Engine(Replace engine control module)

control

:r

module 12A0104

11Oxygenl Harness and connector

Retained

sensor0 Oxygen sensor

:-JLJ--

. Fuel pressure

l Injectors (Replace if defective.)

l Intake air leaks 12A0104

12Volume air

l Harness and connector

Retained

flow sensor (if harness and connector are

:-JJ-M-

normal, replace volume air flow

sensor assembly.) 12A0104

13 Intake air

l Harness and connector

Retained

temperature l Intake air temperature sensor

:n

sensor 12A0104

TSB Revision

Page 158 of 1273

13-16

FUEL SYSTEM

FAILSAFE/BACK-UP FUNCTIONS LIST

If trouble with any major sensor is detected by the on-board diagnostic,\

the vehicle will be kept in the safe

driving conditions according to the preset control logic.

Trouble item Control content for trouble

Volume air flow Fuel injection timing and ignition timing are determined according to th\

e throttle position

sensor sensor

(TPS) and engine revolution speed signal (crankshaft position sensor signal)\

.

Intake air temperature The control is executed with the suction air temperature regarded as

25°C (77°F).

sensor

Throttle position The fuel injection rate is not increased for acceleration according to t\

he throttle position

sensor

(TPS)sensor signal.

Idle speed control After the idle speed control motor plunger is driven and contracted, the\

idle revolution speed

motor position sensor is not controlled.

Engine coolant The control is executed with the engine coolant temperature regarded as \

8OO.C (176°F).temperature sensor (Even if the sensor signal becomes normal again, the control is continued

until the ignltlon

switch is turned off.)

Camshaft position Simultaneous injection of fuel is executed for all cylinders. (In this \

case, the

No.1 cylinder top

sensor dead center is not detected at all after the ignition key is turned on.)\

Barometric pressure The control is executed with the pressure regarded as 760 mmHg

(30

in.Hg).

sensor

Oxygen sensor Closed loop control of the air/fuel mixture ratio is not executed.

i

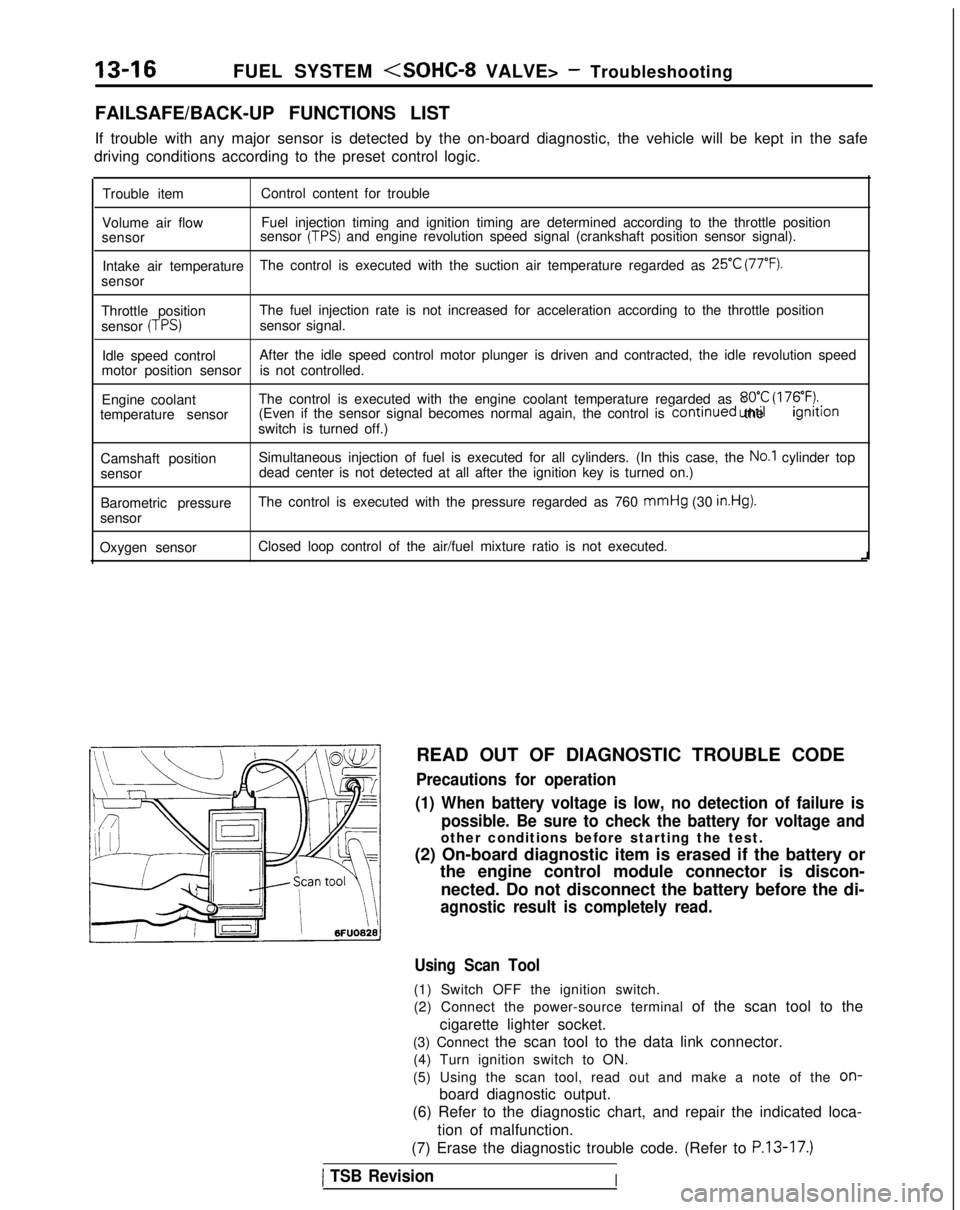

READ OUT OF DIAGNOSTIC TROUBLE CODE

Precautions for operation

(1) When battery voltage is low, no detection of failure is possible. Be sure to check the battery for voltage and

other conditions before starting the test.

(2) On-board diagnostic item is erased if the battery or the engine control module connector is discon-

nected. Do not disconnect the battery before the di-

agnostic result is completely read.

Using Scan Tool

(1) Switch OFF the ignition switch.

(2) Connect the power-source terminal of the scan tool to the

cigarette lighter socket.

(3) Connect the scan tool to the data link connector. (4) Turn ignition switch to ON.

(5) Using the scan tool, read out and make a note of the

on-

board diagnostic output.

(6) Refer to the diagnostic chart, and repair the indicated loca-

tion of malfunction.

(7) Erase the diagnostic trouble code. (Refer to

P.13-17.)

1 TSB RevisionI

Page 159 of 1273

FUEL SYSTEM

\ I\-\\\\\\6FUO807

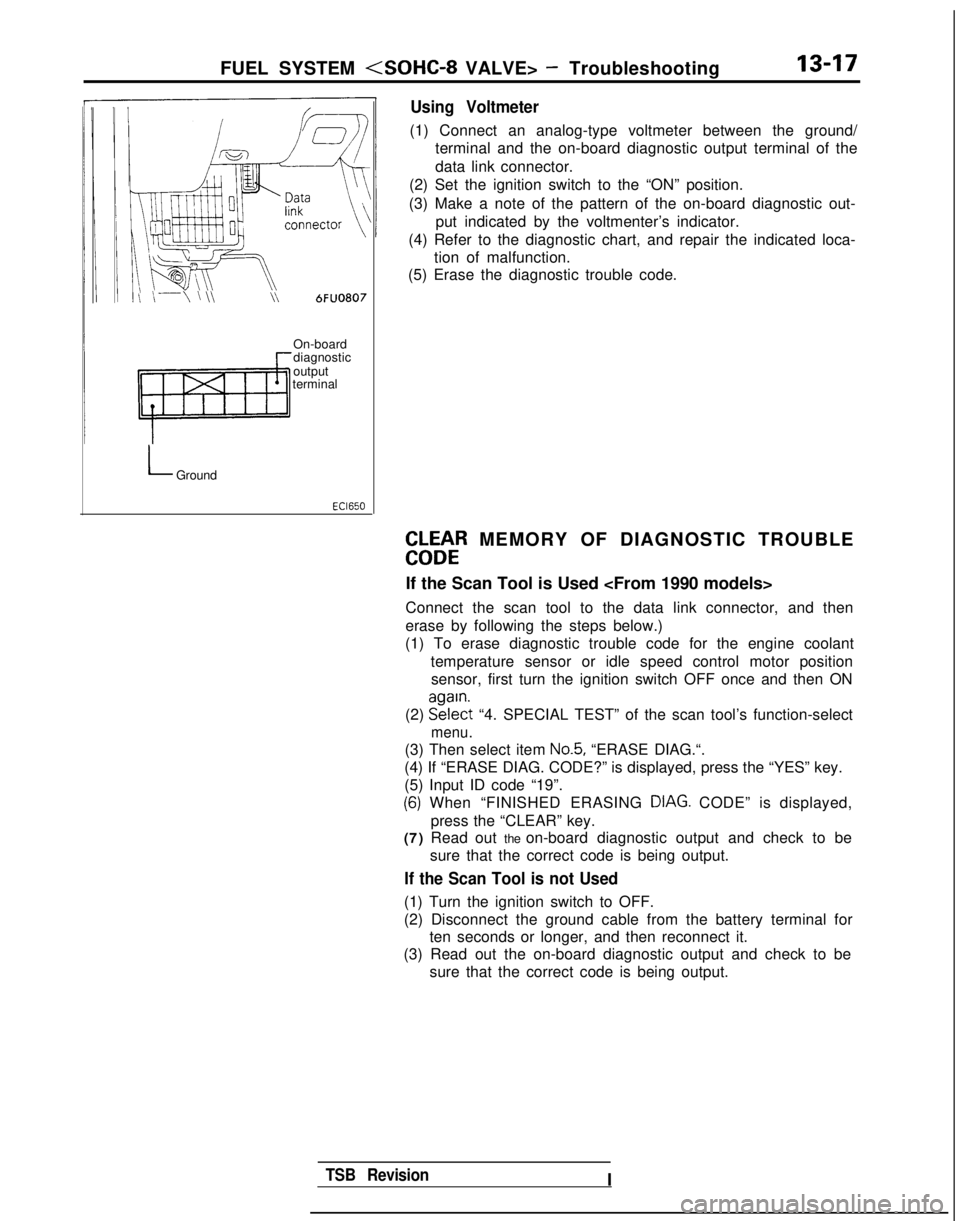

Using Voltmeter

(1) Connect an analog-type voltmeter between the ground/

terminal and the on-board diagnostic output terminal of the

data link connector.

(2) Set the ignition switch to the “ON” position.

(3) Make a note of the pattern of the on-board diagnostic out- put indicated by the voltmenter’s indicator.

(4) Refer to the diagnostic chart, and repair the indicated loca- tion of malfunction.

(5) Erase the diagnostic trouble code.

On-board

diagnostic

output

terminal

LGround

EbLbtR MEMORY OF DIAGNOSTIC TROUBLE

If the Scan Tool is Used

Connect the scan tool to the data link connector, and then

erase by following the steps below.)

(1) To erase diagnostic trouble code for the engine coolant

temperature sensor or idle speed control motor positionsensor, first turn the ignition switch OFF once and then ON

(2) EE?$t

“4. SPECIAL TEST” of the scan tool’s function-select

menu.

(3) Then select item No.5, “ERASE DIAG.“.

(4) If “ERASE DIAG. CODE?” is displayed, press the “YES” k\

ey.

(5) Input ID code “19”.

(6) When “FINISHED ERASING DIAG. CODE” is displayed,> Ipress the “CLEAR” key.

(7) Read out the on-board diagnostic output and check to be

sure that the correct code is being output.

If the Scan Tool is not Used

(1) Turn the ignition switch to OFF.

(2) Disconnect the ground cable from the battery terminal forten seconds or longer, and then reconnect it.

(3) Read out the on-board diagnostic output and check to be

sure that the correct code is being output.

TSB RevisionI

Page 183 of 1273

FUEL SYSTEM

Ciaarette

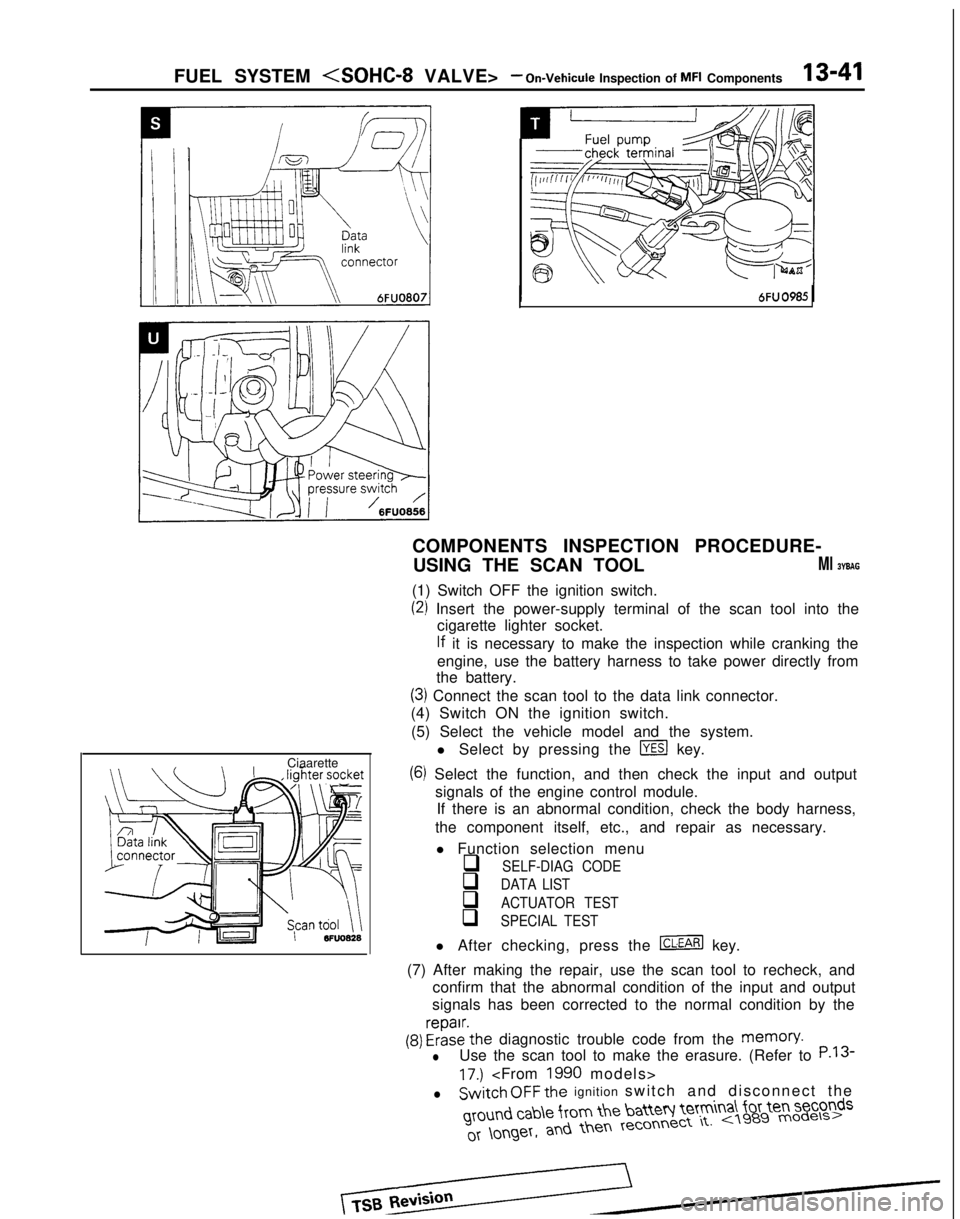

COMPONENTS INSPECTION PROCEDURE-

USING THE SCAN TOOL

Ml BYBAG

(1) Switch OFF the ignition switch.

(2) Insert the power-supply terminal of the scan tool into the cigarette lighter socket.

lf it is necessary to make the inspection while cranking the

engine, use the battery harness to take power directly from

the battery.

(3) Connect the scan tool to the data link connector.

(4) Switch ON the ignition switch.

(5) Select the vehicle model and the system. l Select by pressing the

m key.

(6) Select the function, and then check the input and outputsignals of the engine control module.If there is an abnormal condition, check the body harness,

the component itself, etc., and repair as necessary.

l Function selection menu

q SELF-DIAG CODE

q DATA LIST

q ACTUATOR TEST

q SPECIAL TEST

l After checking, press the m key.

(7) After making the repair, use the scan tool to recheck, and confirm that the abnormal condition of the input and output

signals has been corrected to the normal condition by the

(9) FrizE’the diagnostic trouble code from the memory.

lUse the scan tool to make the erasure. (Refer to P.13

17.)

lSwitch OFF the ignition switch and disconnect the ground

cab\e from the batteq Ie’tm

a\ for ten seconds

Page 263 of 1273

FUEL SYSTEM

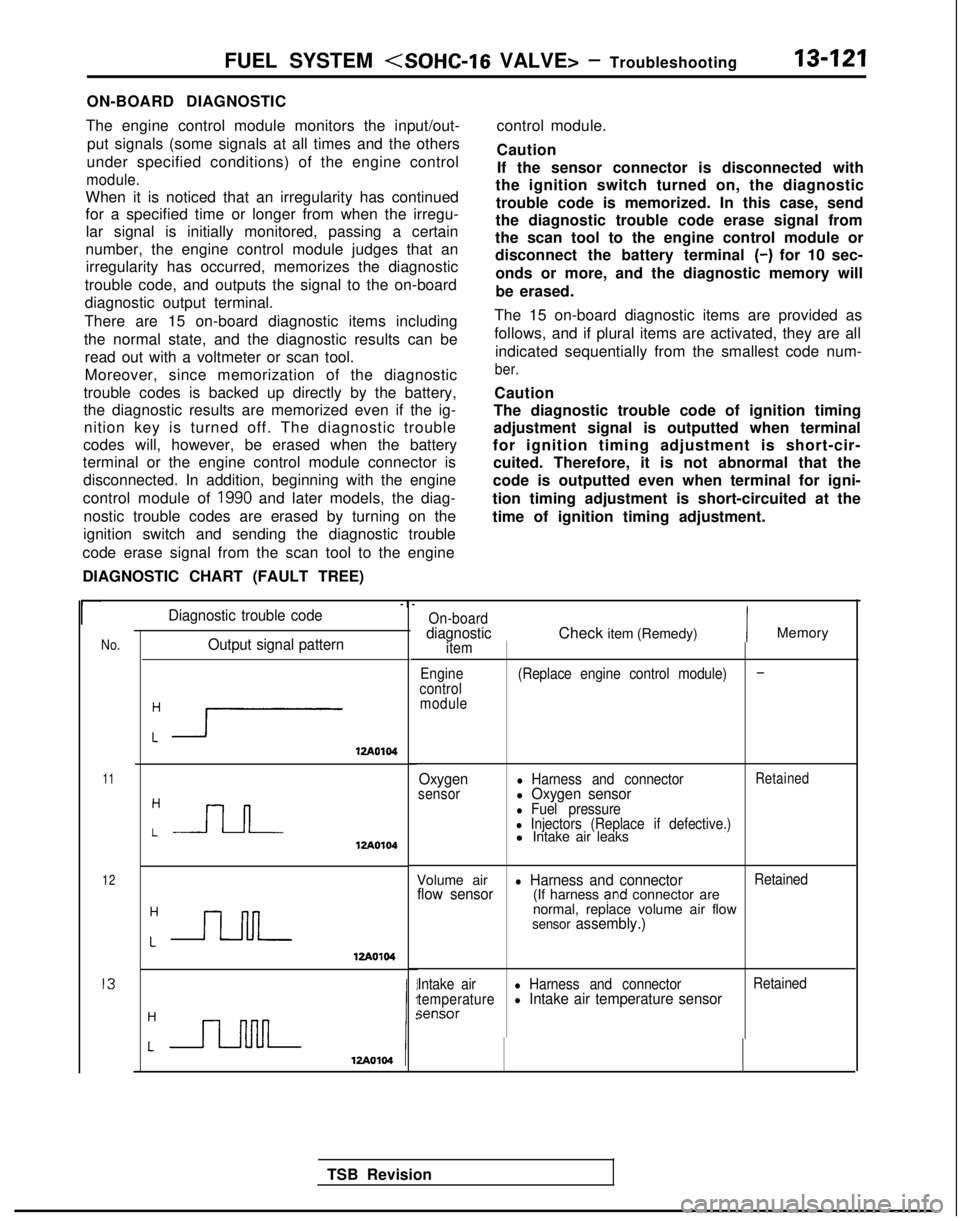

ON-BOARD DIAGNOSTIC

The engine control module monitors the input/out- put signals (some signals at all times and the others

under specified conditions) of the engine control

module.

When it is noticed that an irregularity has continued

for a specified time or longer from when the irregu- lar signal is initially monitored, passing a certain

number, the engine control module judges that an irregularity has occurred, memorizes the diagnostic

trouble code, and outputs the signal to the on-board

diagnostic output terminal.

There are 15 on-board diagnostic items including

the normal state, and the diagnostic results can be read out with a voltmeter or scan tool.

Moreover, since memorization of the diagnostic

trouble codes is backed up directly by the battery,

the diagnostic results are memorized even if the ig- nition key is turned off. The diagnostic trouble

codes will, however, be erased when the battery

terminal or the engine control module connector is

disconnected. In addition, beginning with the engine

control module of

1990 and later models, the diag-

nostic trouble codes are erased by turning on the

ignition switch and sending the diagnostic trouble

code erase signal from the scan tool to the engine

DIAGNOSTIC CHART (FAULT TREE) control module.

Caution

If the sensor connector is disconnected with

the ignition switch turned on, the diagnostic

trouble code is memorized. In this case, send

the diagnostic trouble code erase signal from

the scan tool to the engine control module or

disconnect the battery terminal

(-) for 10 sec-

onds or more, and the diagnostic memory will

be erased.

The 15 on-board diagnostic items are provided as

follows, and if plural items are activated, they are all indicated sequentially from the smallest code num-

ber.

Caution

The diagnostic trouble code of ignition timing

adjustment signal is outputted when terminal

for ignition timing adjustment is short-cir- cuited. Therefore, it is not abnormal that the

code is outputted even when terminal for igni-

tion timing adjustment is short-circuited at the

time of ignition timing adjustment.

r

No.Output signal pattern

:i1zA0104

11

12

I3

:-J-l-J-12Ao104

Diagnostic trouble code-I

-

On-boarddiagnosticitem

Engine

control moduleCheck item (Remedy)IMemory

(Replace engine control module)-

Oxygensensorl Harness and connectorRetainedl Oxygen sensorl Fuel pressurel Injectors (Replace if defective.)l Intake air leaks

Volume air

l Harness and connectorRetainedflow sensor(If harness and connector are

normal, replace volume air flow

sensor assembly.)

Intake airl Harness and connector Retained

temperaturel Intake air temperature sensorsensor

TSB Revision

Page 268 of 1273

13-126FUEL SYSTEM

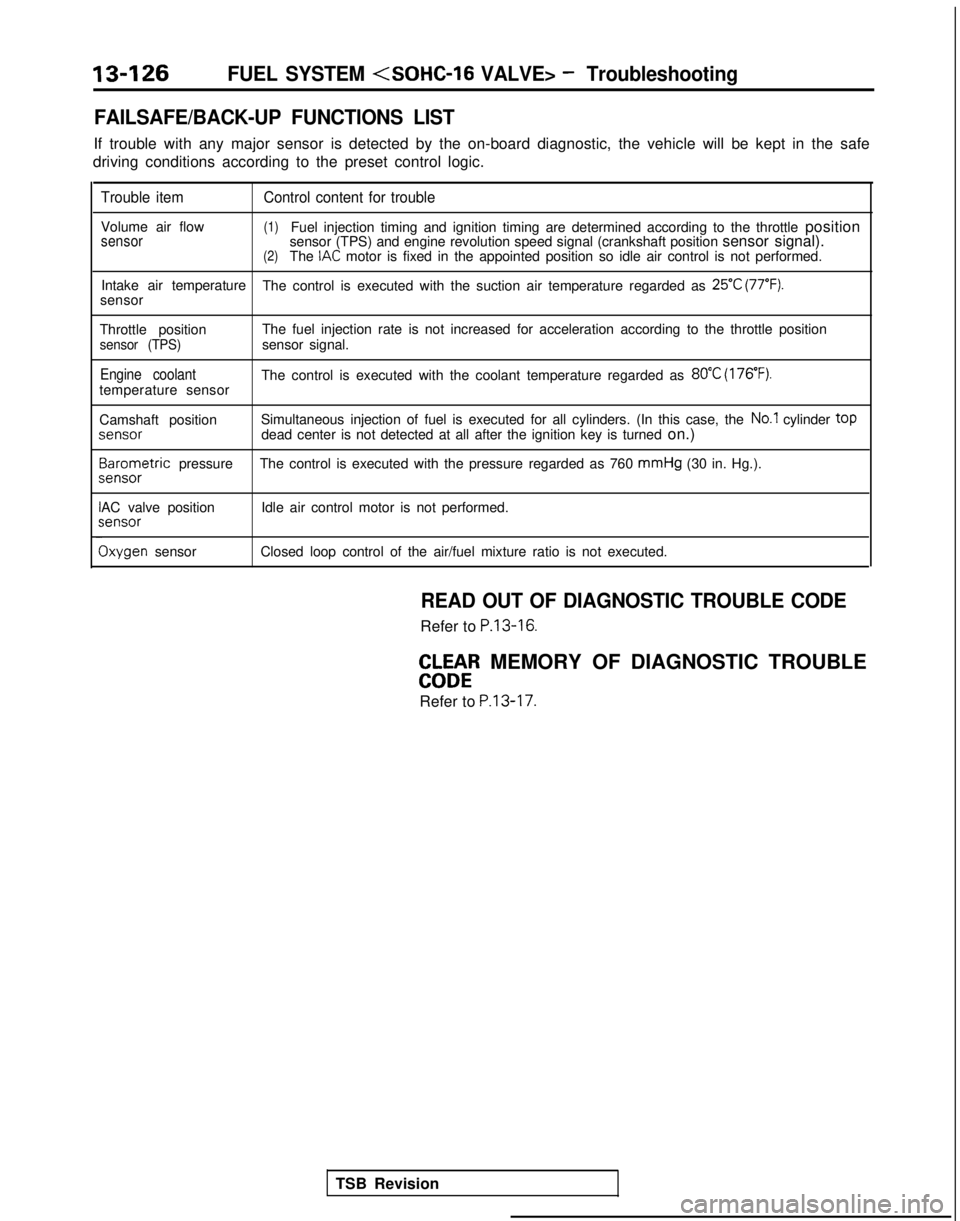

FAILSAFE/BACK-UP FUNCTIONS LIST

If trouble with any major sensor is detected by the on-board diagnostic,\

the vehicle will be kept in the safe

driving conditions according to the preset control logic.

Trouble item Control content for trouble

Volume air flow(1)Fuel injection timing and ignition timing are determined according to th\

e throttle positionsensorsensor (TPS) and engine revolution speed signal (crankshaft position \

sensor signal).(2)The IAC motor is fixed in the appointed position so idle air control is not per\

formed.

Intake air temperature The control is executed with the suction air temperature regarded as

25°C (77°F).sensor

Throttle position The fuel injection rate is not increased for acceleration according to t\

he throttle position

sensor (TPS)sensor signal.

Engine coolantThe control is executed with the coolant temperature regarded as 80°C (176’F).temperature sensor

Camshaft positionSimultaneous injection of fuel is executed for all cylinders. (In this \

case, the

No.1 cylinder top

jenS0r

dead center is not detected at all after the ignition key is turned

on.)3arometric

pressure The control is executed with the pressure regarded as 760 mmHg

(30 in. Hg.).

sensor

AC valve position Idle air control motor is not performed.;ensor

Ixygen sensor

Closed loop control of the air/fuel mixture ratio is not executed.

READ OUT OF DIAGNOSTIC TROUBLE CODE

Refer to P.13-16.

EbW&R MEMORY OF DIAGNOSTIC TROUBLE

Refer to

P.13-17.

TSB Revision