check oil MITSUBISHI GALANT 1989 Service Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 180 of 1273

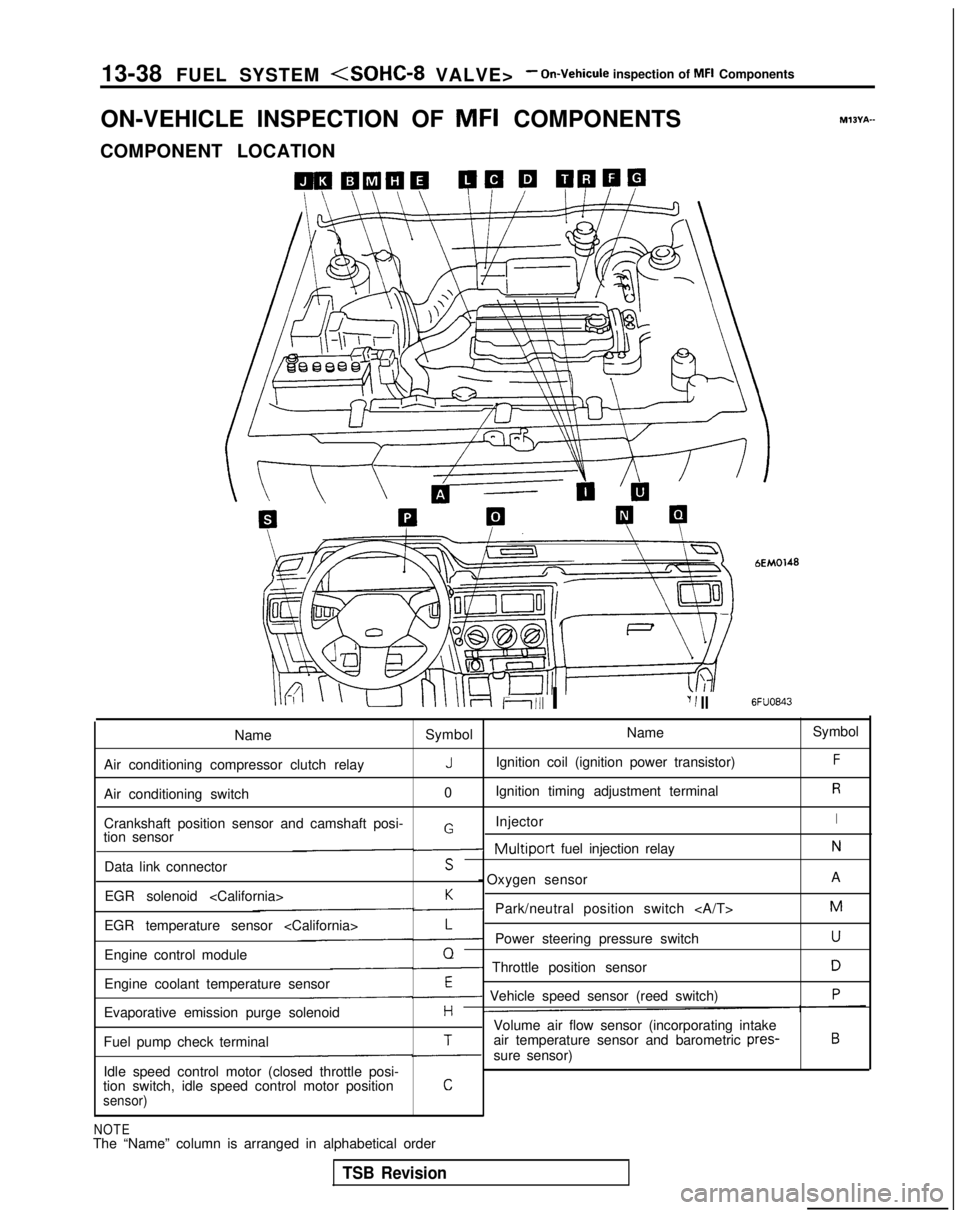

13-38

FUEL SYSTEM

ON-VEHICLE INSPECTION OF MFI

COMPONENTS

COMPONENT LOCATION

Ii111 I‘I 1 II

bEM0148

6FUO843

M?BYA-

Name Symbol Name

Symbol

Air conditioning compressor clutch relay

JIgnition coil (ignition power transistor)F

Air conditioning switch 0Ignition timing adjustment terminalR

Crankshaft position sensor and camshaft posi- InjectorIGtion sensor-Multiport fuel injection relayN

Data link connectorS - Oxygen sensor

A

EGR solenoid

K-Park/neutral position switch M

EGR temperature sensor

L-Power steering pressure switchU

Engine control moduleQ- Throttle position sensorD

Engine coolant temperature sensorE- Vehicle speed sensor (reed switch)P

Evaporative emission purge solenoidHVolume air flow sensor (incorporating intake

Fuel pump check terminalTair temperature sensor and barometric pres-B

-sure sensor)

Idle speed control motor (closed throttle posi-

tion switch, idle speed control motor position

Csensor)

NOTEThe “Name” column is arranged in alphabetical order

TSB Revision

Page 184 of 1273

13-42 FUEL SYSTEM

(9) Switch OFF the ignition switch. (10)Disconnect

the scan tool. (11)Restart

the engine and perform a driving test, etc. to

confirm that the malfunction has been corrected.

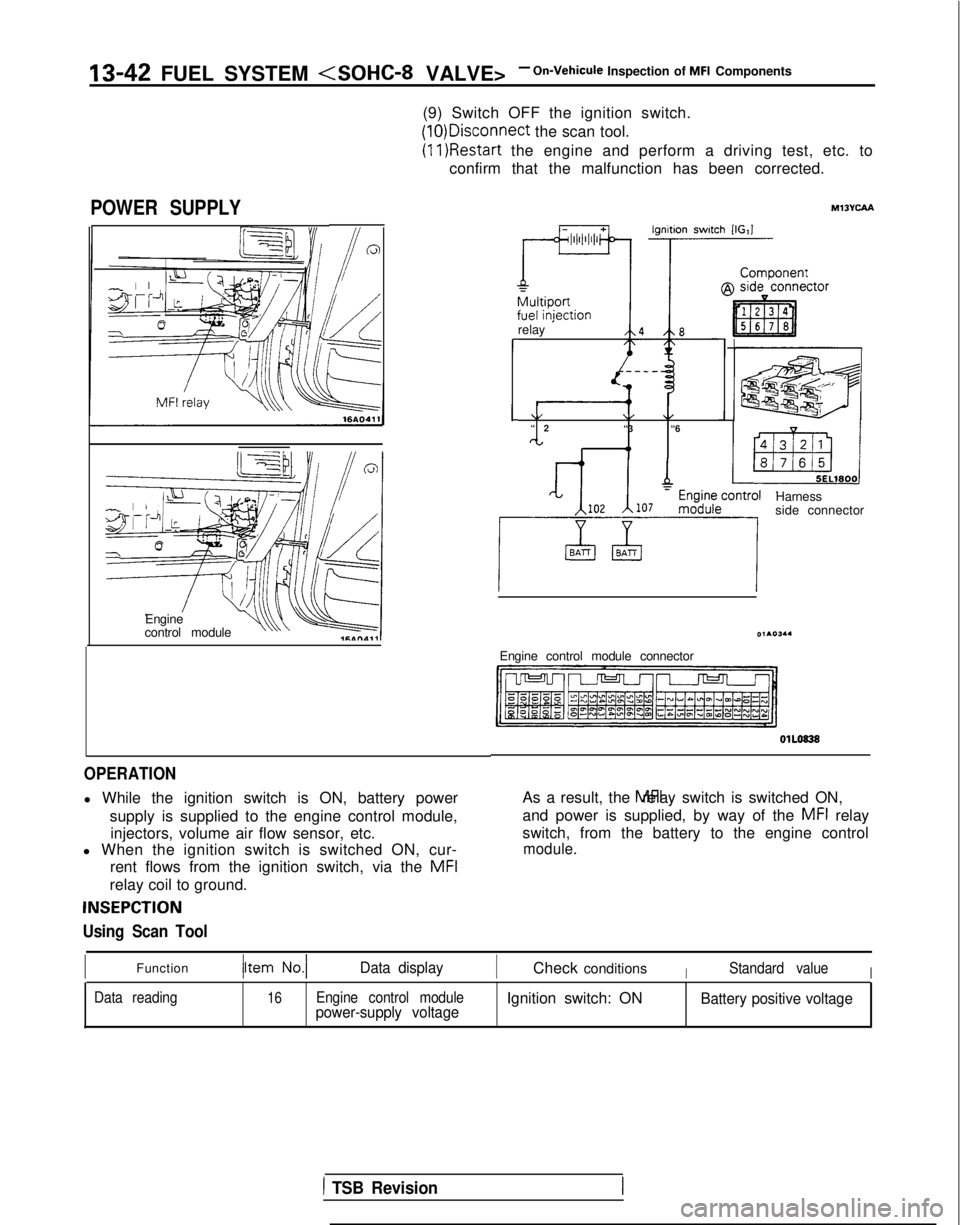

POWER SUPPLY

Engine

control moduleu\\ v

OPERATION

l While the ignition switch is ON, battery power

supply is supplied to the engine control module,injectors, volume air flow sensor, etc.

l When the ignition switch is switched ON, cur-

rent flows from the ignition switch, via the MFI

relay coil to ground.

INSEPCTION

Using Scan Tool

relay ’

\/\/\/“

2

“3 “6

CL I 4,

Harness

side connector

Engine control module connector OlLO838

As a result, the MFI relay switch is switched ON,

and power is supplied, by way of the

MFI relay

switch, from the battery to the engine control

module.

IFunctionData displayICheck conditionsIStandard valueI

Data reading16Engine control modulepower-supply voltageIgnition switch: ONBattery positive voltage

1 TSB Revision

Page 186 of 1273

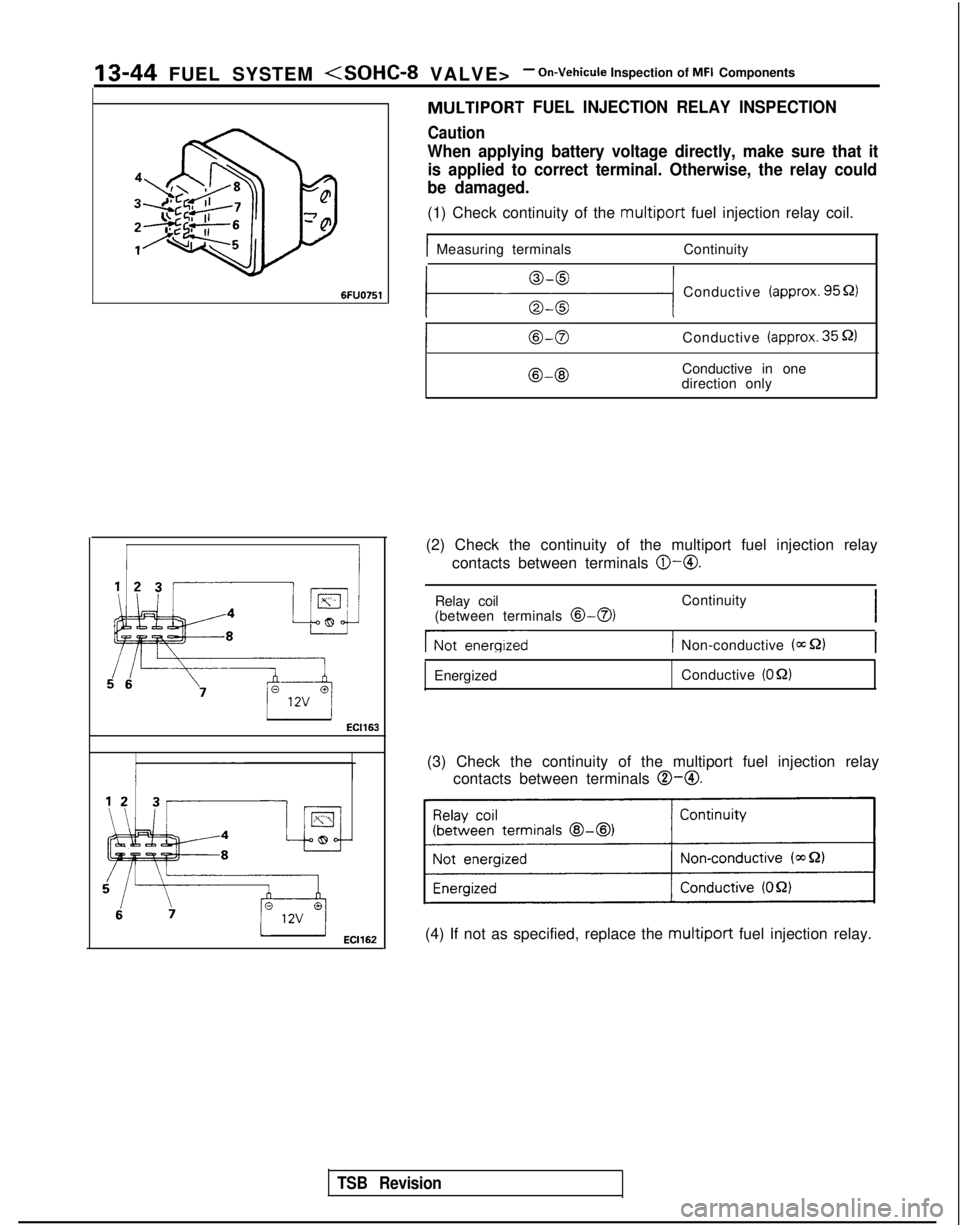

‘13-44 FUEL SYSTEM

EC1163

When applying battery voltage directly, make sure that it

is applied to correct terminal. Otherwise, the relay could

be damaged.

(1) Check continuity of the multiport fuel injection relay coil.

IMeasuring terminals Continuity

MULTIPORT FUEL INJECTION RELAY INSPECTION

Caution

111 Conductive (approx. 9551)

Conductive (approx. 35 52)

@-@IConductive in one

direction only

(2) Check the continuity of the multiport fuel injection relay contacts between terminals

@-@.

TSB Revision

Relay coil

(between terminals @>-a)Continuity

I

Gienergized1 Non-conductive (=S2)

Energized Conductive (OQ)

(3) Check the continuity of the multiport fuel injection relay

contacts between terminals

0-O.

(4) If not as specified, replace the multiport fuel injection relay.

Page 188 of 1273

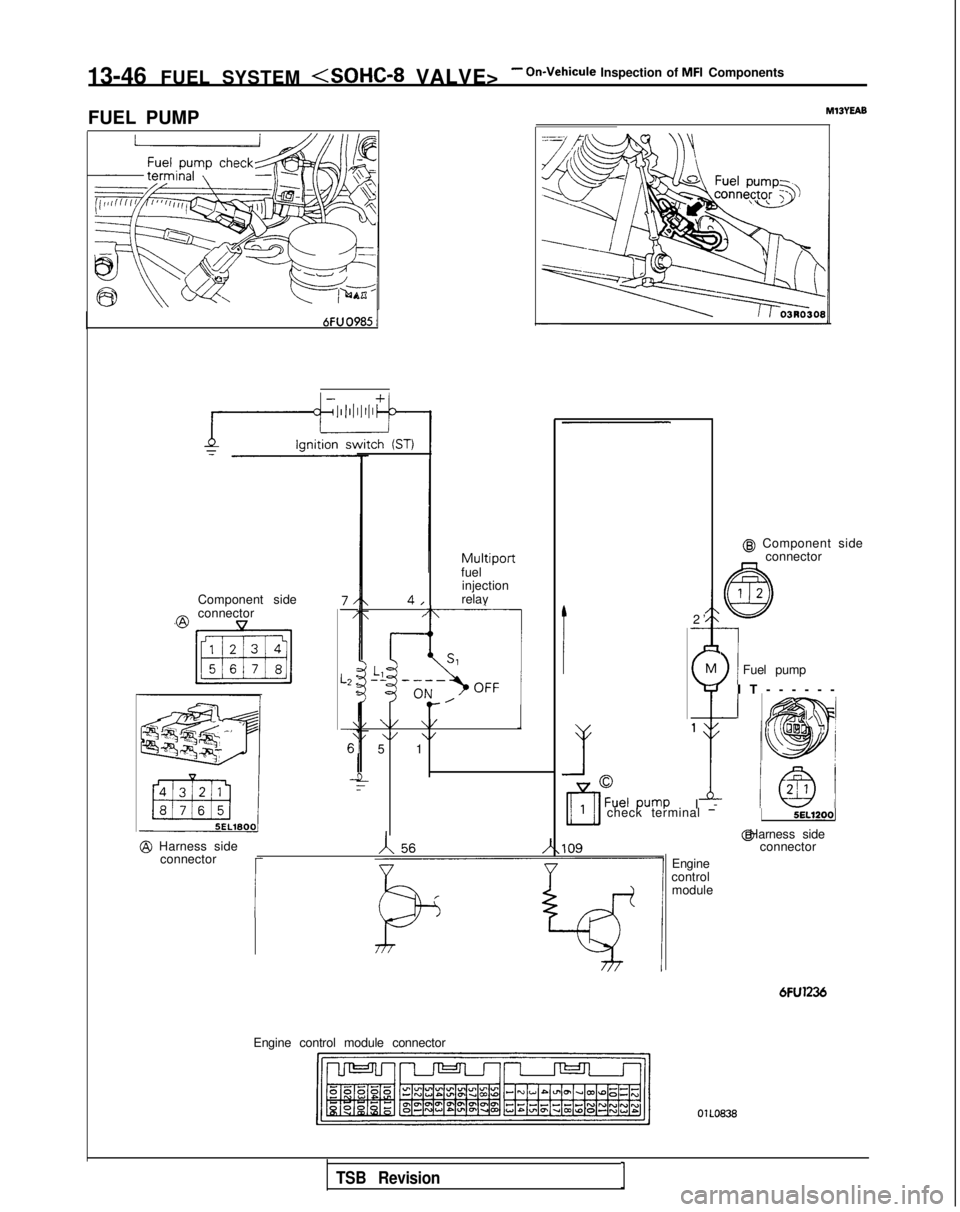

13-46 FUEL SYSTEM

FUEL PUMP

MlBYEAB

@ Component side connector

-

\

1Fuel pump M

$

1

I

-

Multiportfuel

injection

relay

Component side

7/-/

L2 :<

\

6’

_!

4,

@connector,

I-~ i1SlLl”’-------.,\OFF I OIL

,’e-

\/ \/1\/ \/5 1 2

’

-

I

IT-----

-

1!

check terminal -5EL1200j

Engine

control module @ Harness side

connector

@ Harness side

connector

I

6FU1236

Engine control module connector OlLO838

TSB RevisionI

Page 189 of 1273

FUEL SYSTEM

OPERATION

l

Activates the fuel pump during engine cranking

and while the engine is running.

l When the ignition switch is set to the START

position, current flows, by way of the

multiport

fuel injection relay coil, from the ignition switch

to ground. As a result, the

multiport fuel injec-

tion relay switch is switched ON, and the power

for activation of the fuel pump is supplied, by

way of the

multiport fuel injection relay switch,

from the battery to the fuel pump.

INSPECTION

Using Scan tool

l While the engine is running, the engine control

module switches ON the power transistor, after

which current flows to the

multiport fuel injec-

tion relay coil, and the power for activation of

the fuel pump is supplied to the fuel pump.

l When the

multiport fuel injection relay switch is

switched ON, battery voltage is also applied to

the engine control module, and so the engine

control module detects the fact that the power

for activation of the fuel pump is being supplied

to the fuel pump.

Function Item

No.

Actuation Inspection conditions DescriptionNormal condition

Actuator test 07 Actuates fuel

. Engine cranking Hold the return hosePulsation can be felt.

pump, clrcu-

. Fuel pump forced between two fingers

lating fuel. activation

so as to feel the

The inspection pulsation of the

flow-should be conducteding of fuel.

for both of the above conditions. Listen to the pump

Pump sound can besound at a place nearheard.the fuel tank.

Check for continuity of the ground

circuit.

I

. ;E;;,, pumpconnector: Discon-

2

1

Y-

!

Repair theharness.

@El- @ HarnessGround)connector

O~AOZOl3

I

Check for continuity between the fuel

pump and the checking terminal.

connector: Discon-

1

@uide 1

B

0. ;;;;,,

pump

L

Check the fuel pump.

. Apply battery voltage to the check-

ing terminal and operate the pump.

!I:7

OK

connector :1 = 6FUl238

TSB Revision

Page 198 of 1273

13-56 FUEL SYSTEM

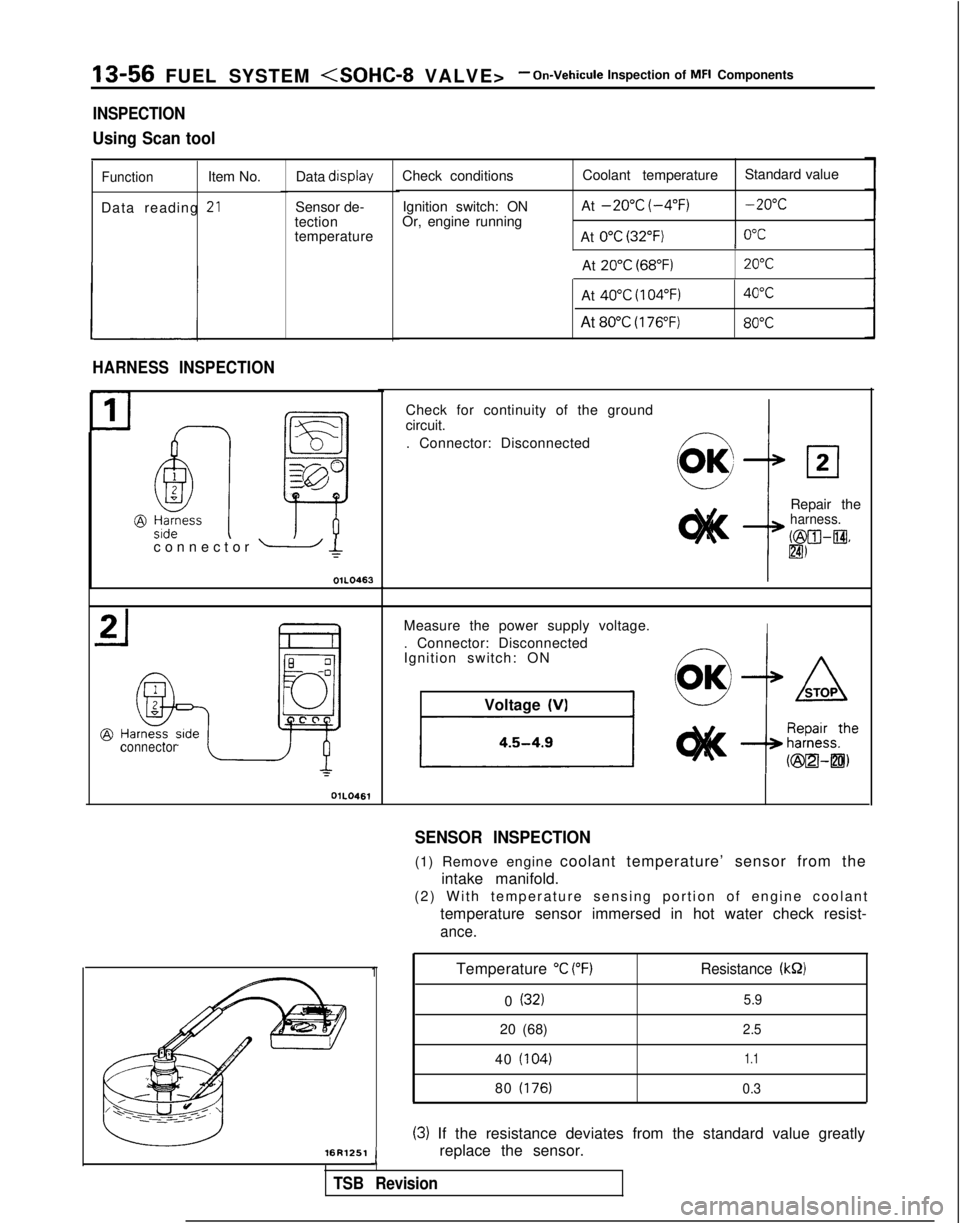

INSPECTION

Using Scan tool

FunctionItem No.

Data reading

-*LI

Data display

Sensor de-

tection

temperature

HARNESS INSPECTION

connector OlLO461Check conditions

Ignition switch: ON

Or, engine running Coolant temperature

Standard value

At

-20°C (-4°F)-20°C

At 0°C (32°F)0°C I

At

20°C (68°F)20°C

connector - Ic

OIL0463L

-16R1251

Temperature “C (“F)Resistance (kS2)

0 (32)5.9

20 (68)2.5

40 (104)1.1

80 (176) 0.3

(3) If the resistance deviates from the standard value greatly

replace the sensor.

J

TSB Revision

At 40°C (104°F)40°C

At 80°C (176°F)80°C

1

Check for continuity of the ground

circuit.

. Connector: Disconnected

Repair the

harness.

b&XII-@.

lm

Measure the power supply voltage.I. Connector: Disconnected

Ignition switch: ONVoltage

(VI

SENSOR INSPECTION

(1) Remove engine coolant temperature’ sensor from the

intake manifold.

(2) With temperature sensing portion of engine coolan

t

temperature sensor immersed in hot water check resist-

ance.

Page 216 of 1273

13-74 FUEL SYSTEM

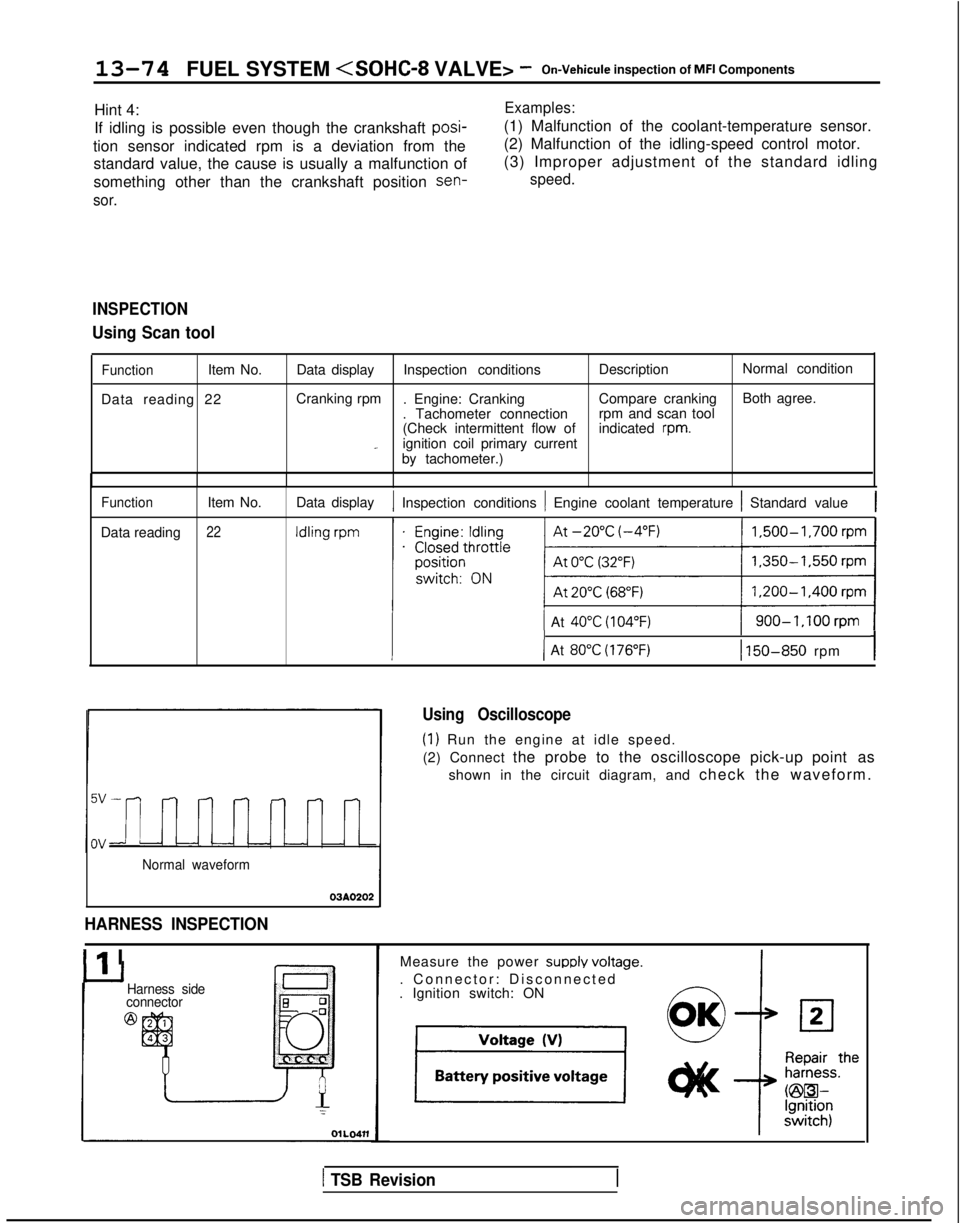

Hint 4:

If idling is possible even though the crankshaft posi-

tion sensor indicated rpm is a deviation from the standard value, the cause is usually a malfunction of

something other than the crankshaft position sen-

sor.

Examples:

(1) Malfunction of the coolant-temperature sensor.

(2) Malfunction of the idling-speed control motor.

(3) Improper adjustment of the standard idling

speed.

INSPECTION

Using Scan tool

FunctionItem No.

Data reading 22 Data display

Inspection conditions DescriptionNormal condition

Cranking rpm . Engine: Cranking Compare crankingBoth agree.

. Tachometer connection rpm and scan tool

(Check intermittent flow of indicated

rpm._ignition coil primary current

by tachometer.)

Function

Data reading Item No.22

Data display1 Inspection conditions 1 Engine coolant temperature 1 Standard value1

1 At 40°C (104°F)1 900-1,100rpm 1

III-I( At 80°C (176°F)1 150-850 rpm

Normal waveform

03AO202

HARNESS INSPECTION

Ilr I

Using Oscilloscope

(1) Run the engine at idle speed.

(2) Connect the probe to the oscilloscope pick-up point as

shown in the circuit diagram, and check the waveform.

Harness side

connector

@

Measure the power SUPPIY voltaoe.

. Connector: Disconnected

-. Ignition switch: ON

1 TSB Revision

Page 224 of 1273

13-82 FUEL SYSTEM

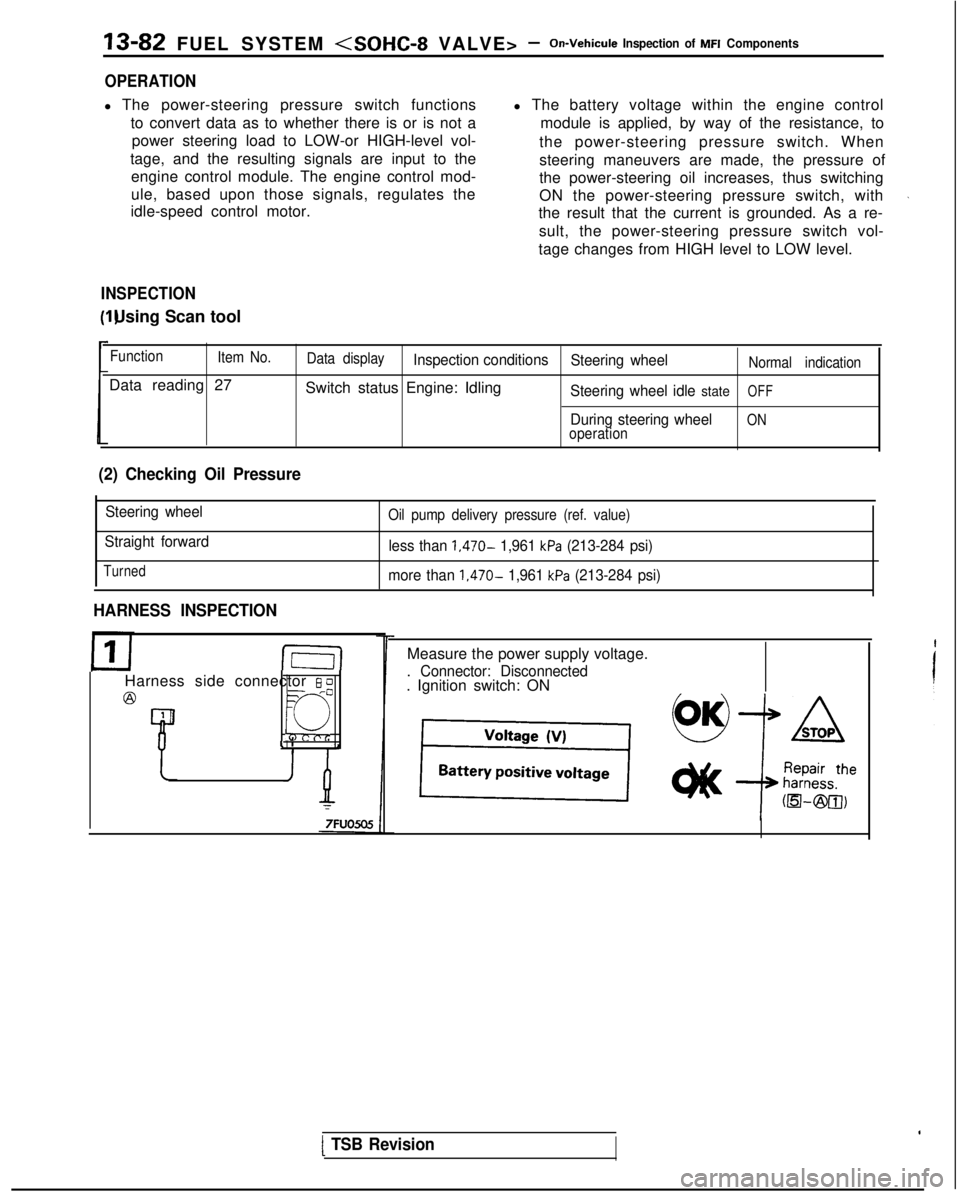

OPERATION

l The power-steering pressure switch functions

to convert data as to whether there is or is not apower steering load to LOW-or HIGH-level vol-

tage, and the resulting signals are input to the engine control module. The engine control mod-

ule, based upon those signals, regulates the

idle-speed control motor. l The battery voltage within the engine control

module is applied, by way of the resistance, to

the power-steering pressure switch. When

steering maneuvers are made, the pressure of

the power-steering oil increases, thus switching

ON the power-steering pressure switch, with

the result that the current is grounded. As a re-

sult, the power-steering pressure switch vol-

tage changes from HIGH level to LOW level.

INSPECTION I) Using Scan tool

Function

Item No.

Data reading 27

Data displayInspection conditions Steering wheelNormal indication

Switch status Engine: IdlingSteering wheel idle stateOFF

During steering wheelONoperation

(2) Checking Oil Pressure

Steering wheel

Straight forward

Turned

Oil pump delivery pressure (ref. value)

less than 1,470- 1,961 kPa (213-284 psi)

more than

1,470- 1,961 kPa (213-284 psi)

HARNESS INSPECTION

I-E-I

Harness side connector 6 0

@=- -0

Q

4 1

Measure the power supply voltage.

. Connector: Disconnected. Ignition switch: ON

[ TSB Revision

Page 232 of 1273

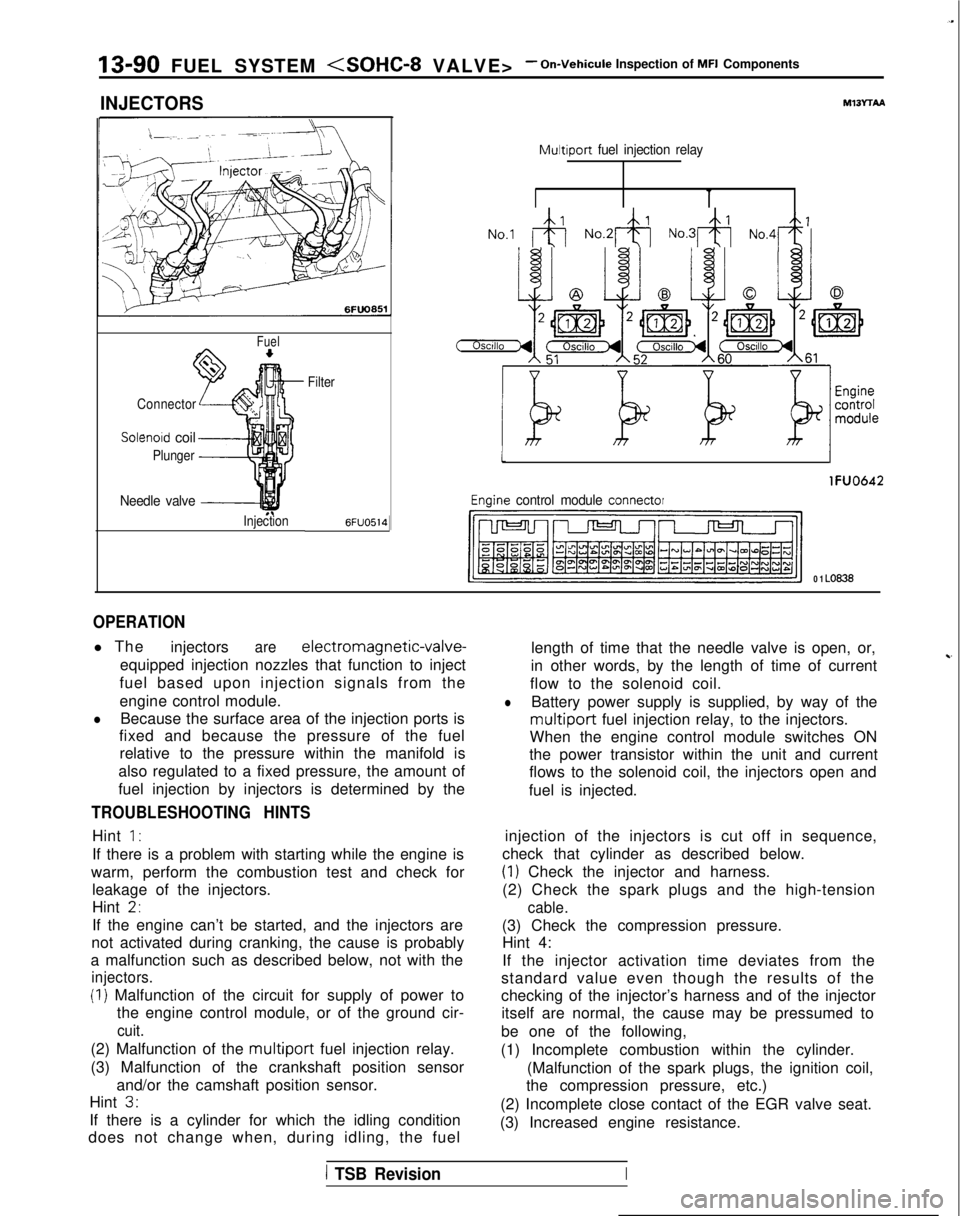

13-90 FUEL SYSTEM

INJECTORS

Fuel

Connector

Solenoid coil

Plunger

Needle valve -----I

InjectionFilter6FUO514

M13rrAA

Multiport

fuel injection relay

No.1 &j No.2& No.3& No,4+

tI

lFUO642

Engine control module connector

CJ=JW=U-I

0 1 LO636

OPERATION

l The

injectorsare electromagnetic-valve-

equipped injection nozzles that function to inject

fuel based upon injection signals from the

engine control module.

lBecause the surface area of the injection ports is

fixed and because the pressure of the fuel

relative to the pressure within the manifold is

also regulated to a fixed pressure, the amount of

fuel injection by injectors is determined by the

TROUBLESHOOTING HINTS

Hint 1:

If there is a problem with starting while the engine is

warm, perform the combustion test and check for leakage of the injectors.

Hint

2,

If the engine can’t be started, and the injectors are

not activated during cranking, the cause is probably

a malfunction such as described below, not with the

injectors.

(I) Malfunction of the circuit for supply of power to the engine control module, or of the ground cir-

cuit.

(2) Malfunction of the multiport fuel injection relay.

(3) Malfunction of the crankshaft position sensor and/or the camshaft position sensor.

Hint

3.

If there is a cylinder for which the idling condition

does not change when, during idling, the fuel length of time that the needle valve is open, or,

in other words, by the length of time of current

~-

flow to the solenoid coil.

lBattery power supply is supplied, by way of the

multiport fuel injection relay, to the injectors.

When the engine control module switches ON

the power transistor within the unit and current

flows to the solenoid coil, the injectors open and

fuel is injected.

injection of the injectors is cut off in sequence,

check that cylinder as described below.

(1) Check the injector and harness.

(2) Check the spark plugs and the high-tension

cable.

(3) Check the compression pressure. Hint 4:

If the injector activation time deviates from the

standard value even though the results of the

checking of the injector’s harness and of the injector itself are normal, the cause may be pressumed to

be one of the following,

(1) Incomplete combustion within the cylinder. (Malfunction of the spark plugs, the ignition coil,

the compression pressure, etc.)

(2) Incomplete close contact of the EGR valve seat.

(3) Increased engine resistance.

1 TSB RevisionI

Page 236 of 1273

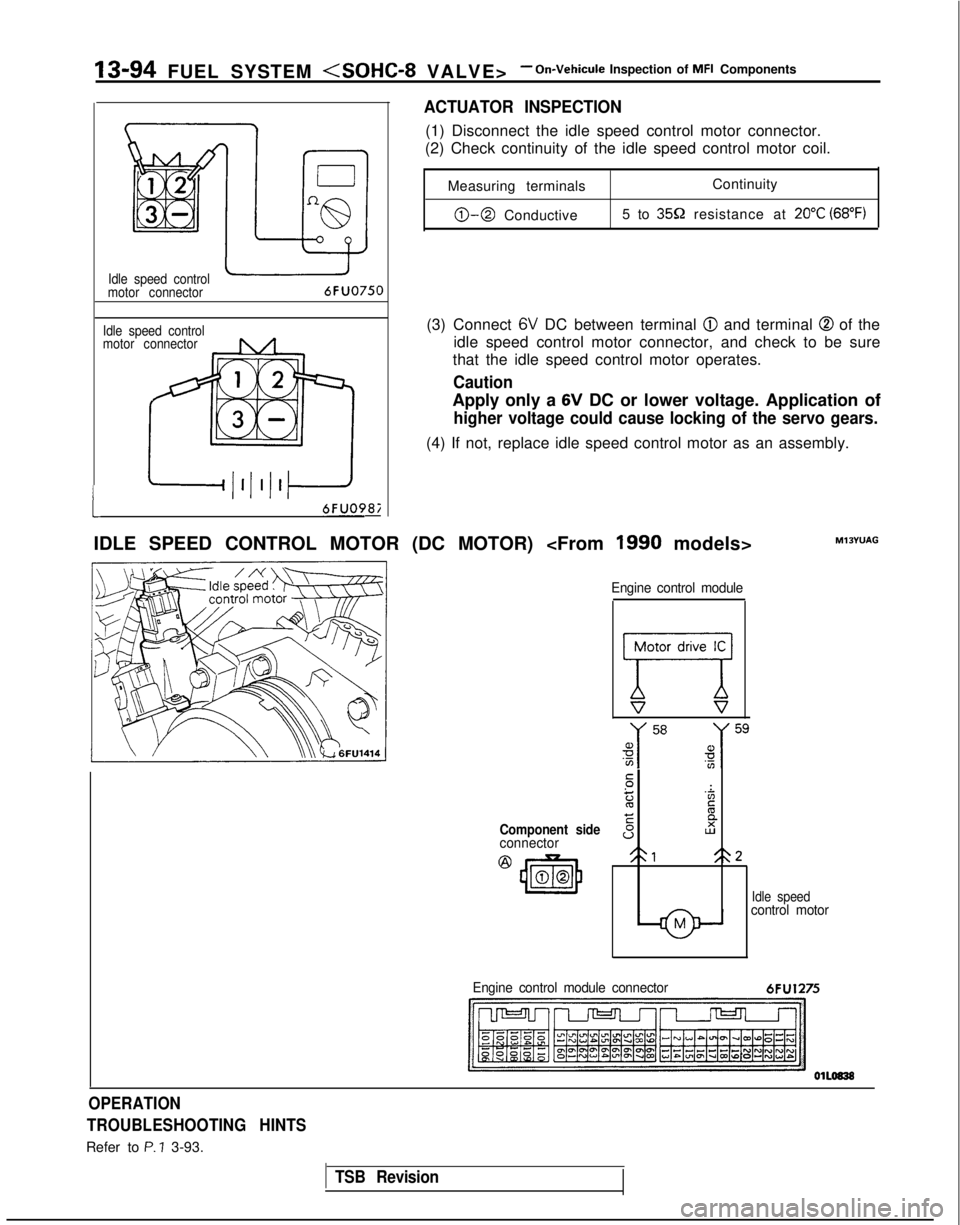

13-94 FUEL SYSTEM

1

Idle speed control

motor connector

Idle speed control

motor connector6FUO750

6FUO9&

ACTUATOR INSPECTION

(1) Disconnect the idle speed control motor connector.

(2) Check continuity of the idle speed control motor coil.

Measuring terminals Continuity

0-0 Conductive

5 to 359 resistance at 20°C (68°F)

(3) Connect 6V DC between terminal @I and terminal @ of the

idle speed control motor connector, and check to be sure

that the idle speed control motor operates.

Caution

Apply only a 6V DC or lower voltage. Application of

higher voltage could cause locking of the servo gears.

(4) If not, replace idle speed control motor as an assembly.

IDLE SPEED CONTROL MOTOR (DC MOTOR)

Component sideconnector

@

43m00

Engine control module

77V s

.-:

z'Zc

EE

sI2

21<\2

Idle speedcontrol motor

MlOYUAG

Engine control module connector

6FU1275

OPERATION

TROUBLESHOOTING HINTS

Refer to P. ? 3-93.

TSB Revision