automatic MITSUBISHI GALANT 1989 Service Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 504 of 1273

13-362AUTO-CRUISE CONTROL SYSTEM - Troubleshooting

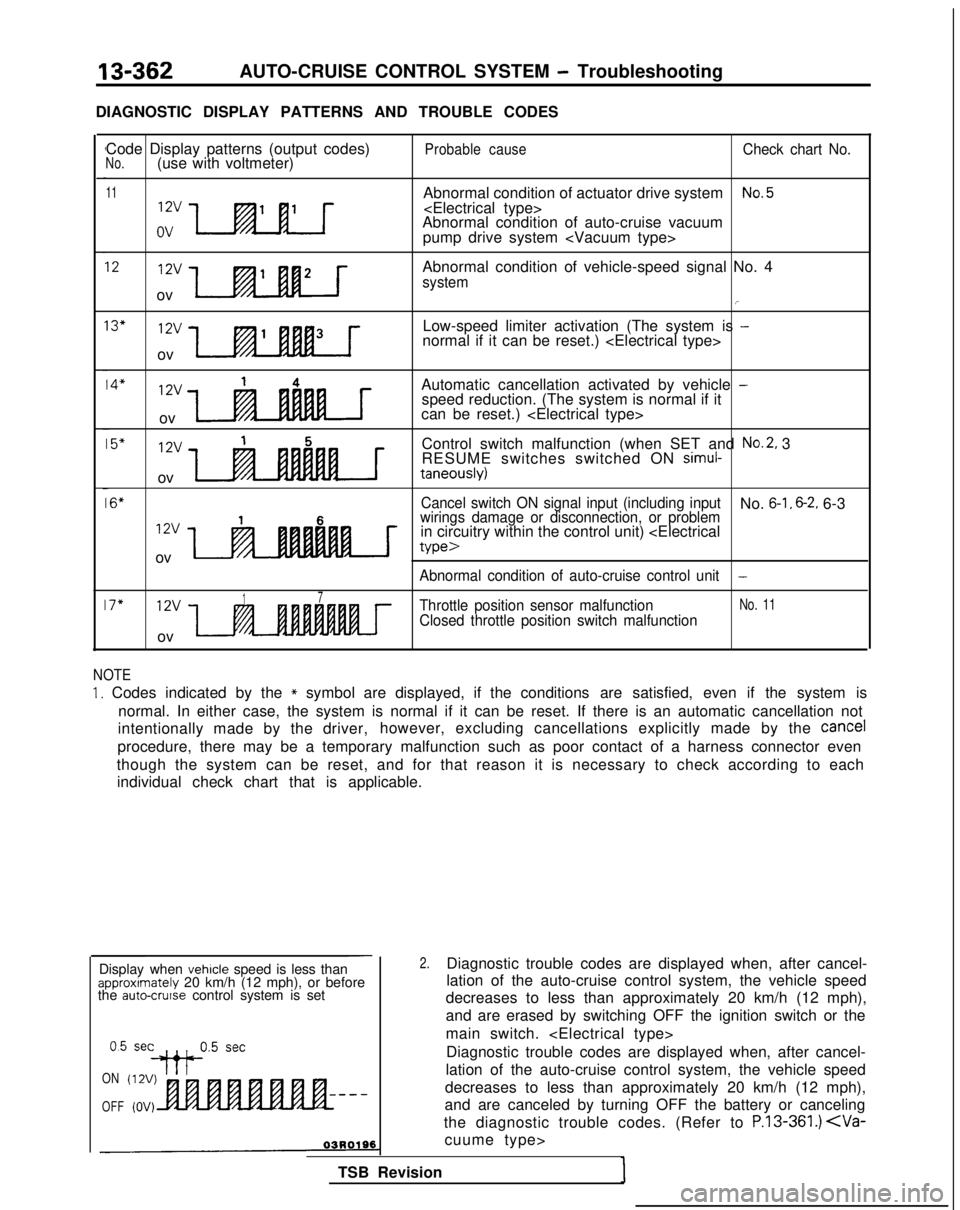

DIAGNOSTIC DISPLAY PATTERNS AND TROUBLE CODES Code Display patterns (output codes)

No.(use with voltmeter)

11

xJa-.tu

Probable causeCheck chart No.

Abnormal condition of actuator drive systemNo.5

Abnormal condition of auto-cruise vacuum

pump drive system

1212vAbnormal condition of vehicle-speed signal No. 4systemov/

13"12vLow-speed limiter activation (The system is -normal if it can be reset.)

ov

14*12v14Automatic cancellation activated by vehicle -speed reduction. (The system is normal if it

ov can be reset.)

15"12v15Control switch malfunction (when SET and No.2, 3

RESUME switches switched ON simul-

ovtaneously)

16"Cancel switch ON signal input (including inputNo. 6-1, 6-2. 6-3

12v16wirings damage or disconnection, or problemin circuitry within the control unit)

we>

Abnormal condition of auto-cruise control unit-

17"12v17Throttle position sensor malfunctionNo. 11

Closed throttle position switch malfunction

ov

NOTE

1. Codes indicated by the * symbol are displayed, if the conditions are satisfied, even if the system is

normal. In either case, the system is normal if it can be reset. If ther\

e is an automatic cancellation not

intentionally made by the driver, however, excluding cancellations explicitly made by the

cancel

procedure, there may be a temporary malfunction such as poor contact of \

a harness connector even

though the system can be reset, and for that reason it is necessary to c\

heck according to each individual check chart that is applicable.

ON

OFF

-

Display when vehicle speed is less thanapproximately 20 km/h (12 mph), or before

the auto-cruise control system is set

0.5 set

++P5 setDiagnostic trouble codes are displayed when, after cancel-

lation of the auto-cruise control system, the vehicle speed

decreases to less than approximately 20 km/h (12 mph),

and are canceled by turning OFF the battery or canceling

the diagnostic trouble codes. (Refer to

P.13-361.)

TSB Revision

2.Diagnostic trouble codes are displayed when, after cancel-

lation of the auto-cruise control system, the vehicle speed

decreases to less than approximately 20 km/h (12 mph),

and are erased by switching OFF the ignition switch or the

main switch.

Page 555 of 1273

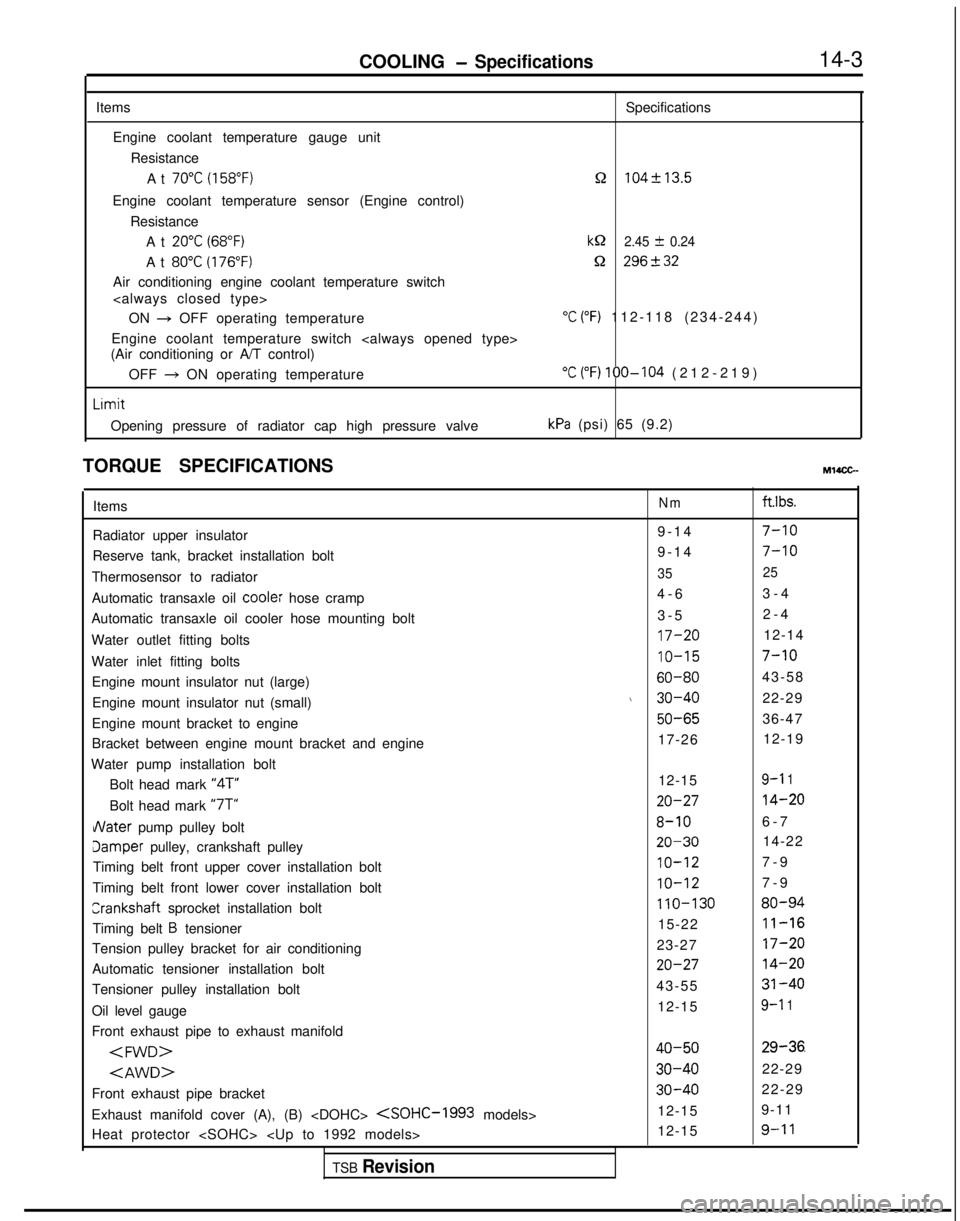

COOLING- Specifications14-3

Items Specifications

Engine coolant temperature gauge unit ResistanceAt

70°C (158°F)n 104f13.5

Engine coolant temperature sensor (Engine control) ResistanceAt

20°C (68°F)kQ 2.45 f 0.24

At 80°C (176°F)Q 296+32

Air conditioning engine coolant temperature switch

ON

+ OFF operating temperature“C (“F) 112-118 (234-244

)

Engine coolant temperature switch

(Air conditioning or A/T control)

OFF

+ ON operating temperature“C (“F) 100-104 (212-219

)

Limit

Opening pressure of radiator cap high pressure valvekPa (psi) 65 (9.2)

TORQUE SPECIFICATIONS

MWCG-

ItemsNm ft.lbs.

Radiator upper insulator 9-14

7-10

Reserve tank, bracket installation bolt9-1

4

7-10

Thermosensor to radiator35

25

Automatic transaxle oil coole: hose cramp 4-

6

3-4

Automatic transaxle oil cooler hose mounting bolt 3-5

2-4

Water outlet fitting bolts

17-2012-14

Water inlet fitting bolts

IO-157-10

Engine mount insulator nut (large)60-8043-58

Engine mount insulator nut (small)

\ 30-4022-29

Engine mount bracket to engine

50-6536-47

Bracket between engine mount bracket and engine 17-26

12-19

Water pump installation bolt Bolt head mark “4T”

12-15

9-l 1

Bolt head mark “7T”20-2714-20

dater pump pulley bolt8-106-

7

Jamper pulley, crankshaft pulley20-3014-22

Timing belt front upper cover installation bolt

IO-127-

9

Timing belt front lower cover installation bolt

IO-127-

9

Crankshaft

sprocket installation bolt

110-13080-94

Timing belt B tensioner 15-2211-16

Tension pulley bracket for air conditioning

23-2717-20

Automatic tensioner installation bolt20-2714-20

Tensioner pulley installation bolt43-5531-40

Oil level gauge 12-159-l 1

Front exhaust pipe to exhaust manifold

Front exhaust pipe bracket

30-4022-29

Exhaust manifold cover (A), (B)

9-11

Heat protector

TSB Revision

Page 557 of 1273

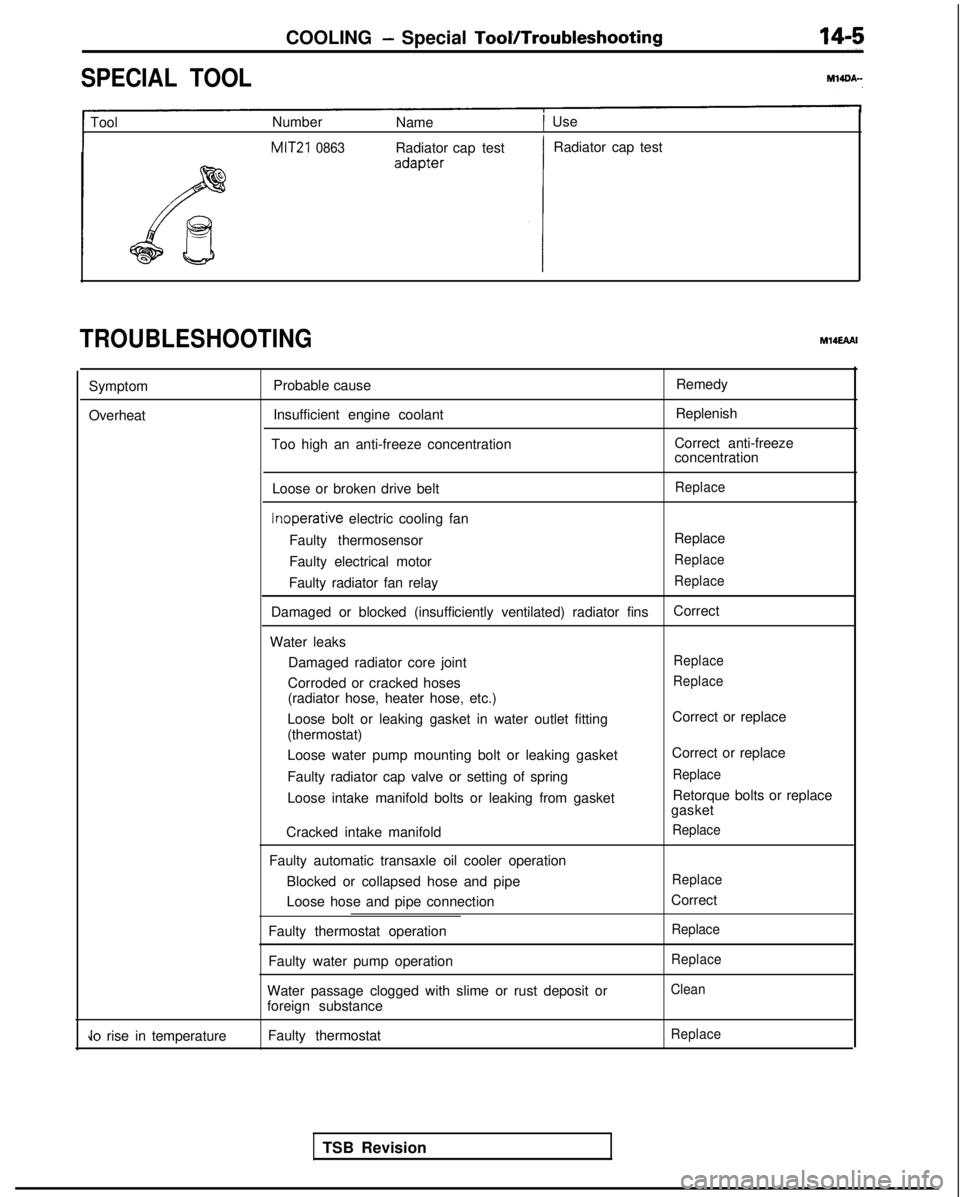

COOLING - Special TooVTroubleshooting

SPECIAL TOOL

1 Tool

Number

Name1 Use

MIT21 0863Radiator cap test Radiator cap test

TROUBLESHOOTINGM14EAAI

Symptom

Overheat Probable cause

Insufficient engine coolant

Too high an anti-freeze concentration Remedy

Replenish

Correct anti-freeze

concentration

Loose or broken drive belt

Replace Inoperative

electric cooling fan

Faulty thermosensor Replace

Faulty electrical motor

Replace

Faulty radiator fan relayReplace

Damaged or blocked (insufficiently ventilated) radiator fins Correct

Water leaks Damaged radiator core joint

Replace

Corroded or cracked hosesReplace

(radiator hose, heater hose, etc.)

Loose bolt or leaking gasket in water outlet fitting

(thermostat)

Loose water pump mounting bolt or leaking gasket

Faulty radiator cap valve or setting of spring

Loose intake manifold bolts or leaking from gasket

Cracked intake manifold

Faulty automatic transaxle oil cooler operation Blocked or collapsed hose and pipe

Loose hose and pipe connection

Faulty thermostat operation

Faulty water pump operation

Water passage clogged with slime or rust deposit or

foreign substance Correct or replace

Correct or replace

Replace

Retorque bolts or replace

gasket

Replace

Replace

Correct

Replace

Replace

Clean

Jo rise in temperature Faulty thermostatReplace

TSB Revision

Page 561 of 1273

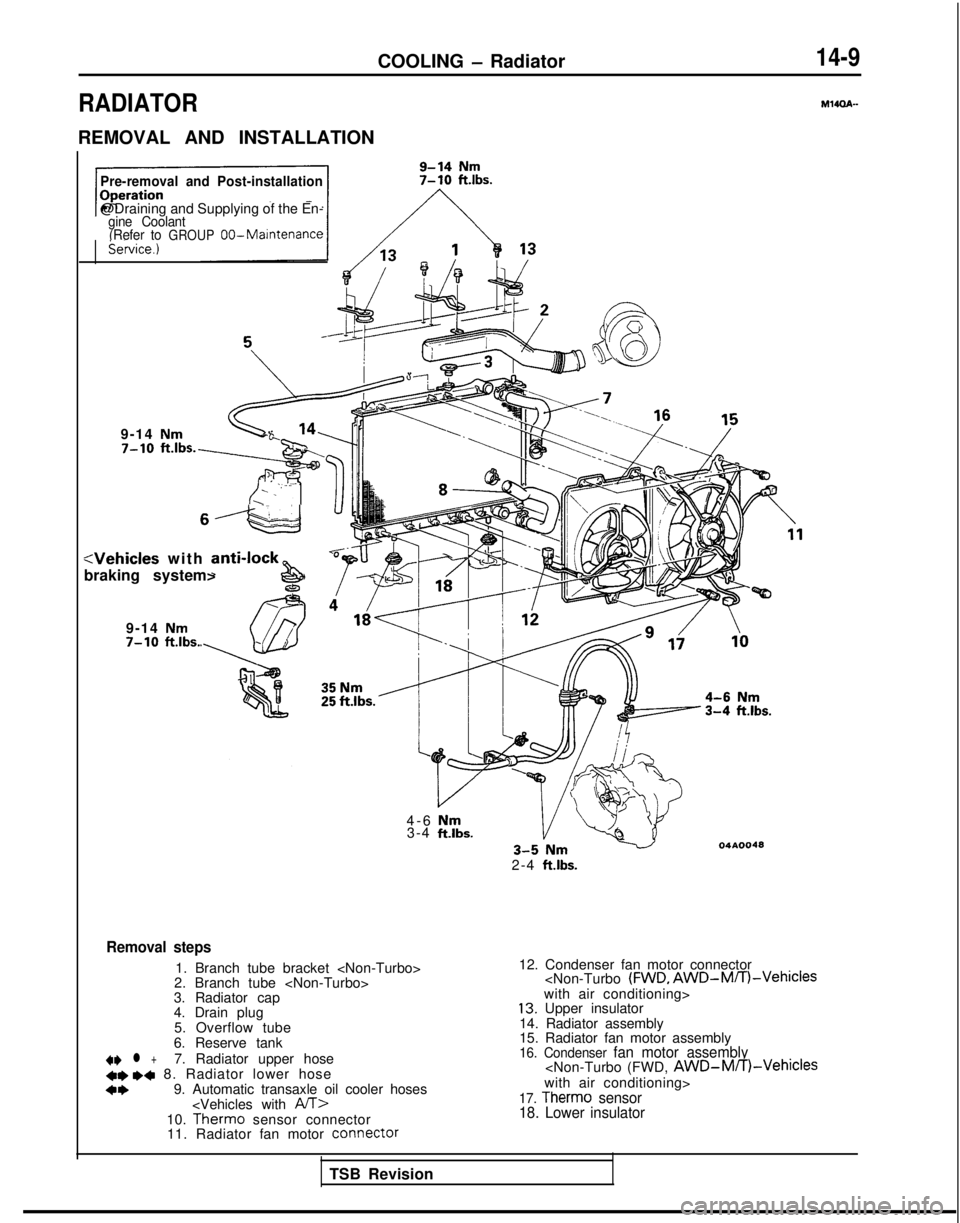

COOLING - Radiator

RADIATOR

REMOVAL AND INSTALLATION

14-9

M14OA-

Pre-removal and Post-installation

@Draining and Supplying of the En-gine Coolant

(Refer toGROUP 00-Maintenancekervice.)

9-14 Nm

(j/-&j

:Vehicles with anti-lock&

braking system>

9-14

Nm7-10 ft.lbs.

4-6 Nm3-4 ftlbs.04AOO48

2-4 ft.lbs.

Removal steps

1. Branch tube bracket

2. Branch tube

3. Radiator cap

4. Drain plug

5. Overflow tube

6. Reserve tank

41) l +7. Radiator upper hose+e ,+ 8. Radiator lower hose

a+9. Automatic transaxle oil cooler hoses

sensor connector

11. Radiator fan motor COnneCtOr12. Condenser fan motor connector

14. Radiator assembly

15. Radiator fan motor assembly

16. Condenser fan motor assembly

18. Lower insulator

TSB Revision

Page 562 of 1273

14-10

COOLING - Radiator

‘I !--.

\

\

I 8005mo20

SERVICE POINTS OF REMOVALMlIOBAH

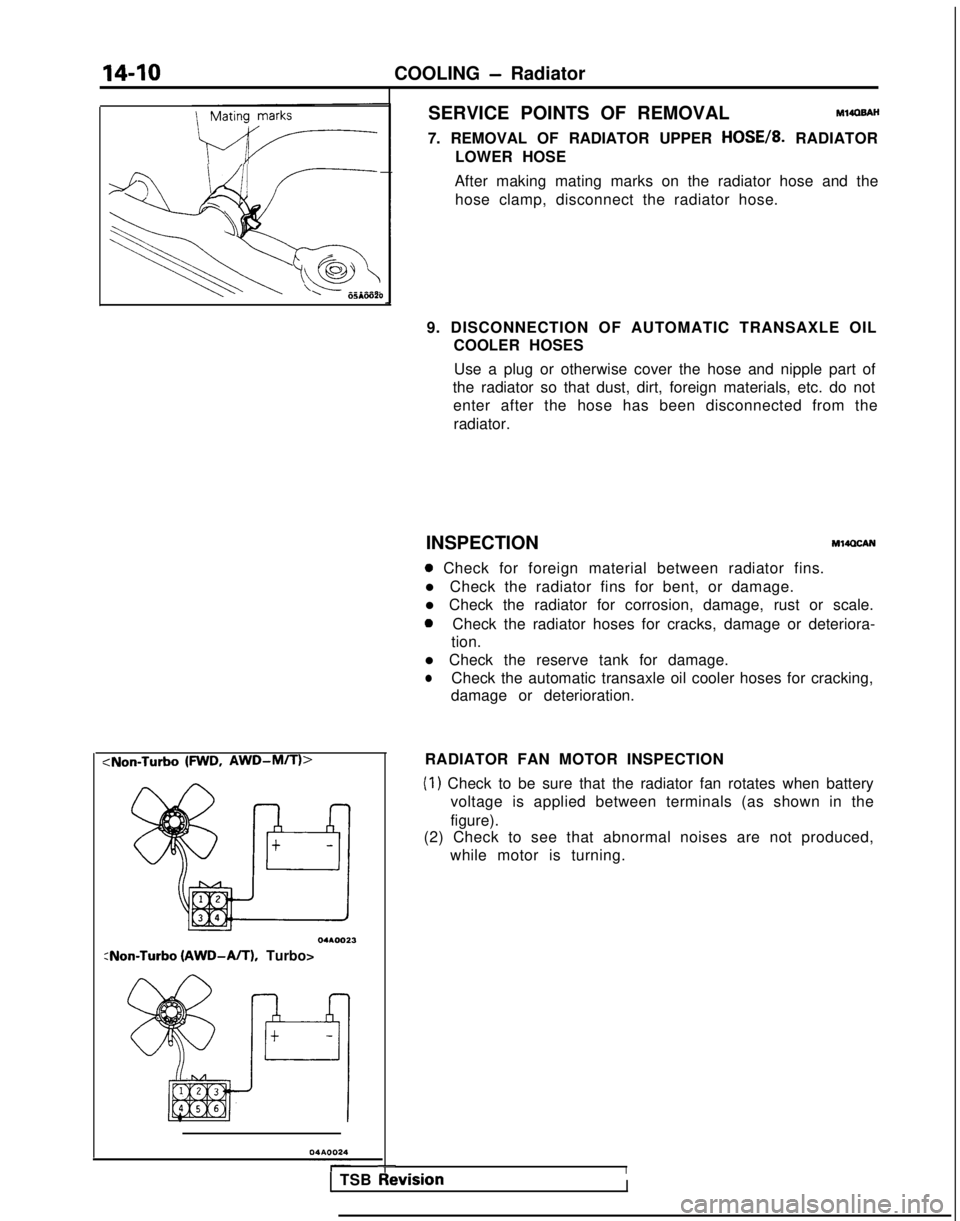

7. REMOVAL OF RADIATOR UPPER HOSE/& RADIATOR

LOWER HOSE

After making mating marks on the radiator hose and the hose clamp, disconnect the radiator hose.

:Non-Turbo (FWD, AWD-M/T)>

04AOO23

:Non-Turbo

(AWD-A/T),

Turbo>

-I- -.1 TSB RevisionI

9. DISCONNECTION OF AUTOMATIC TRANSAXLE OIL

COOLER HOSES

Use a plug or otherwise cover the hose and nipple part of

the radiator so that dust, dirt, foreign materials, etc. do not enter after the hose has been disconnected from the

radiator.

INSPECTION

MWQCAN

a Check for foreign material between radiator fins.

l Check the radiator fins for bent, or damage.

l Check the radiator for corrosion, damage, rust or scale.

aCheck the radiator hoses for cracks, damage or deteriora-

tion.

l Check the reserve tank for damage.

lCheck the automatic transaxle oil cooler hoses for cracking,

damage or deterioration.

RADIATOR FAN MOTOR INSPECTION

(1) Check to be sure that the radiator fan rotates when battery voltage is applied between terminals (as shown in the

figure).

(2) Check to see that abnormal noises are not produced,

while motor is turning.

Page 569 of 1273

COOLING - Water Pump

10-7-

9

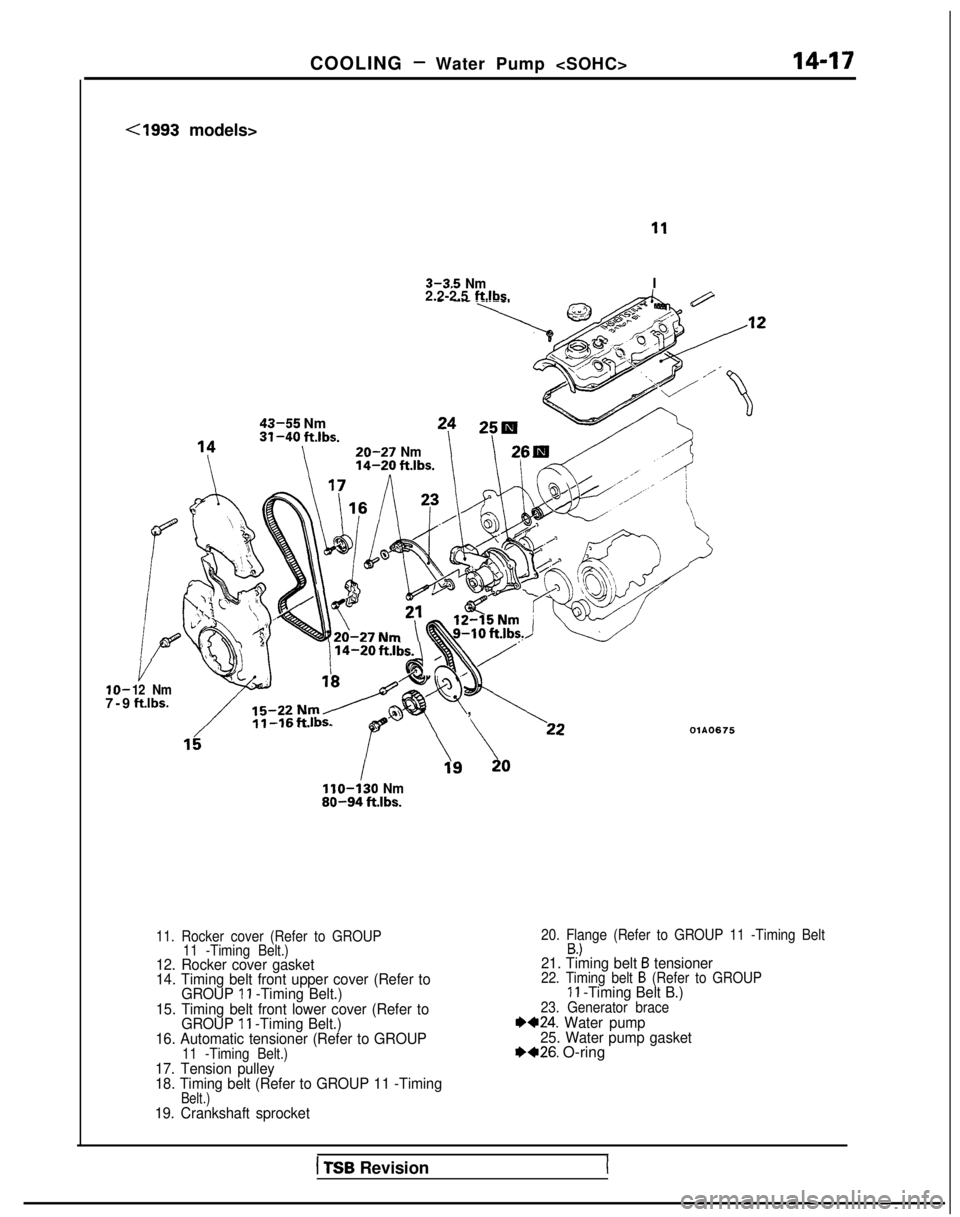

Cl993 models>

43-55 Nm31-40 ftlbs.

\

20-27 Nm14-20 ftlbs.

3-3.5 NmI

2.2-2.5 ftlbs.

y

12 Nm ftlbs.

i,4-2Oft.l;~

Nrn’x@<,I 1-16 ft.lbs.,

OlAO675

I110-130 Nm80-94 ft.lbs.

11. Rocker cover (Refer to GROUP

11 -Timing Belt.)

12. Rocker cover gasket

14. Timing belt front upper cover (Refer to

GROUP

11 -Timing Belt.)

15. Timing belt front lower cover (Refer to GROUP

11 -Timing Belt.)

16. Automatic tensioner (Refer to GROUP

11 -Timing Belt.)17. Tension pulley

18. Timing belt (Refer to GROUP 11 -Timing

Belt.)

20. Flange (Refer to GROUP 11 -Timing Belt

B.121. Timing belt B tensioner22. Timing belt B (Refer to GROUP11 -Timing Belt B.)23. Generator brace+424. Water pump

25. Water pump gasket

++26. O-ring

19. Crankshaft sprocket

1 TSB Revision

Page 572 of 1273

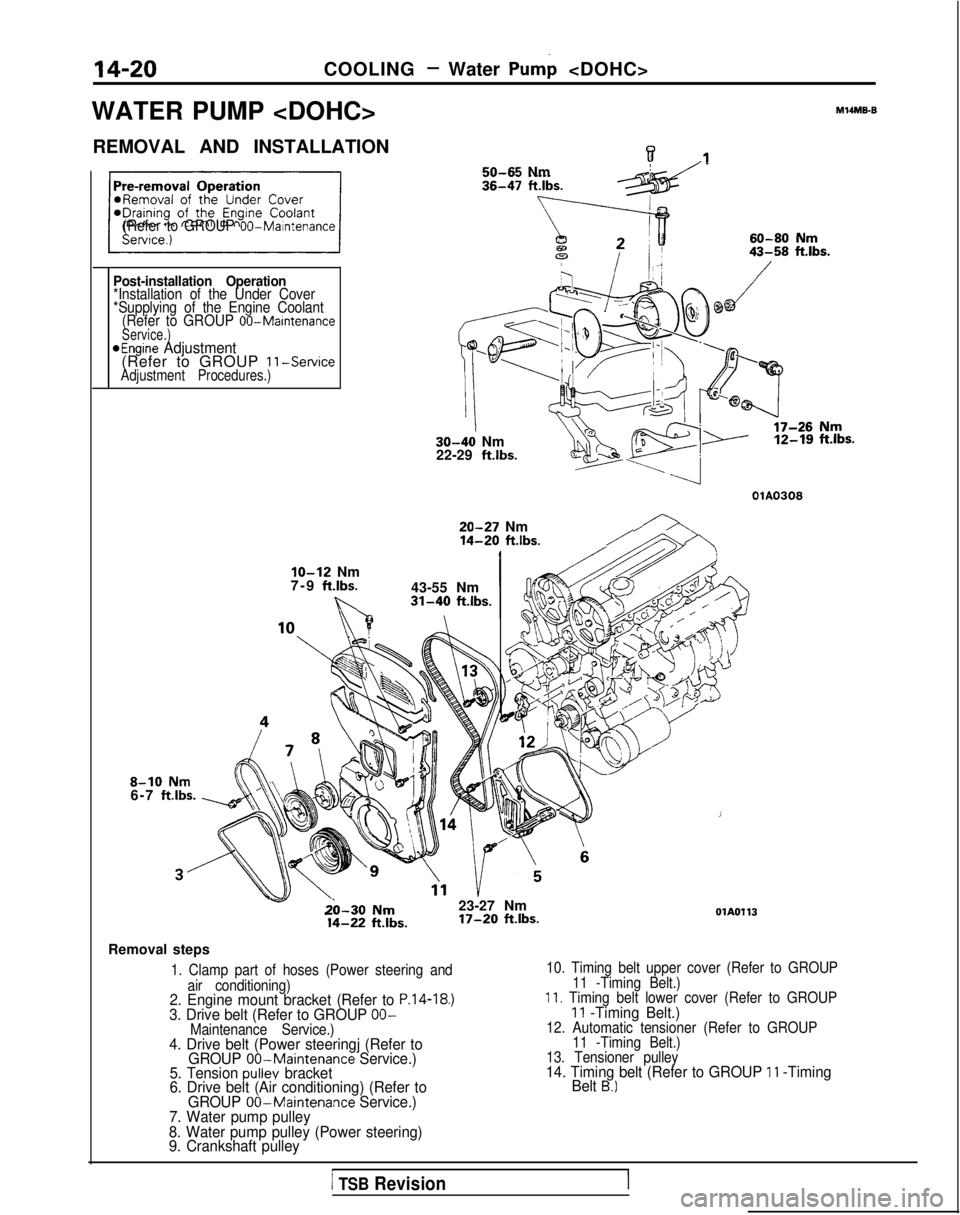

14-20COOLING - Water Pump

WATER PUMP

M14ME6

REMOVAL AND INSTALLATIONw.I50-65 Nm

(Refer to GROUP 00-Maintenance

Post-installation Operation*Installation of the Under Cover

*Supplying of the Engine Coolant (Refer to GROUP

00-MaintenanceService.)aEngine Adjustment(Refer to GROUP 11-ServiceAdjustment Procedures.)

30-40 Nm

22-29 ft.lbs. 12-19

ft.lbs.

OlA0308

20-27 Nm14-20 ft.lbs./

8-10 Nm6-7 ftlbs.

IO-12 Nm

7-9 ft.lbs.

b..

43-55 Nm31-40 ft.lbs.

v&l-30 Nm23-27 Nm 14-22

ftlbs. 17-20

ft.lbs.OlA0113

Removal steps

1. Clamp part of hoses (Power steering and

air conditioning)

2. Engine mount bracket (Refer to P.14-18.)3. Drive belt (Refer to GROUP OO-Maintenance Service.)4. Drive belt (Power steeringj (Refer to GROUP 00-Maintenance Service.)

5. Tension pullev bracket

6. Drive belt (Air conditioning) (Refer to

10. Timing belt upper cover (Refer to GROUP

11 -Timing Belt.)

11. Timing belt lower cover (Refer to GROUP11 -Timing Belt.)12. Automatic tensioner (Refer to GROUP11 -Timing Belt.)

13. Tensioner pulley

14. Timing belt (Refer to GROUP 11 -Timing

Belt B.)

GROUP 00-Maintenance Service.)

7. Water pump pulley

8. Water pump pulley (Power steering)

9. Crankshaft pulley

1 TSB RevisionI

Page 689 of 1273

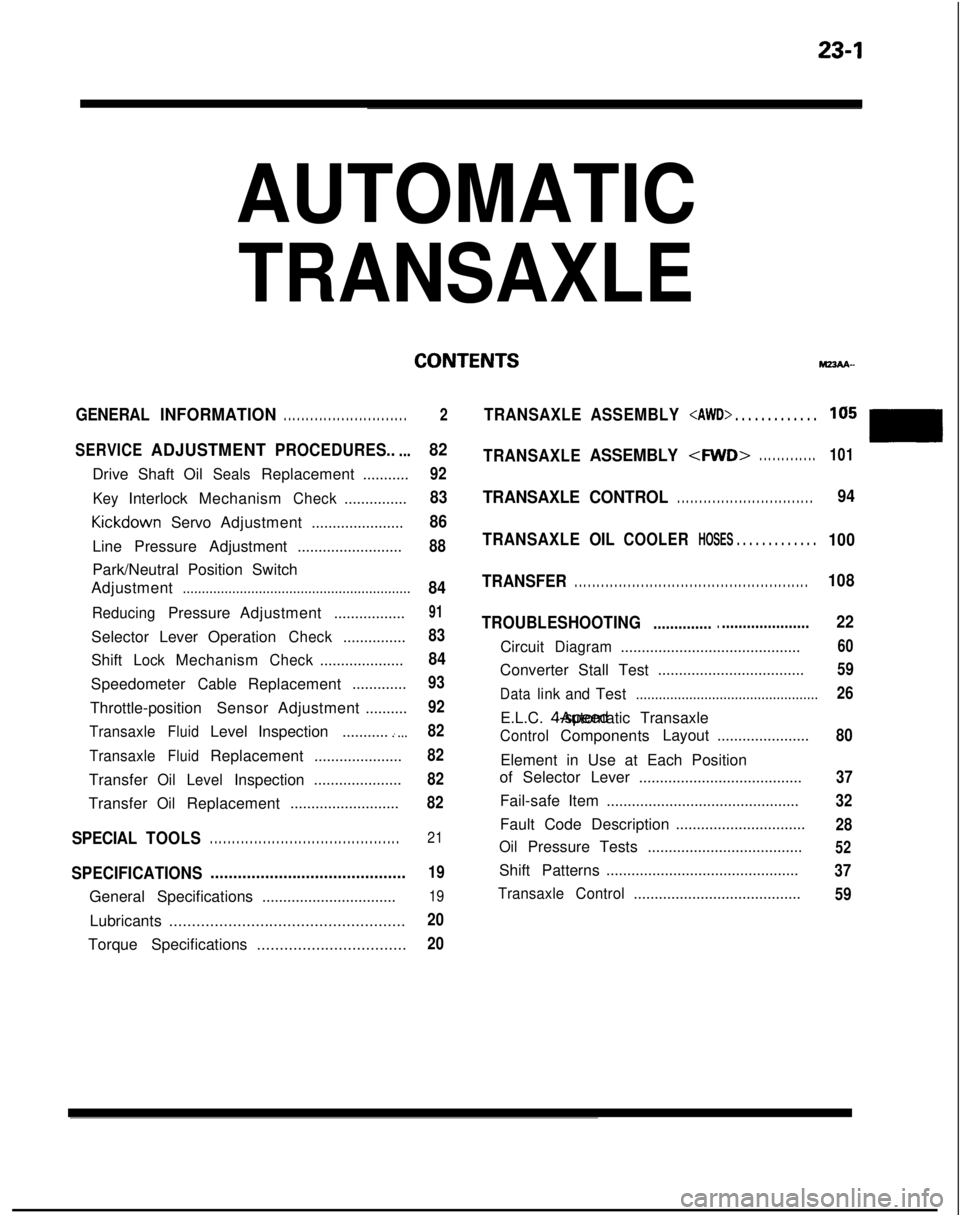

23-1

AUTOMATIC

TRANSAXLE

CONTENTShl23AA-

GENERALINFORMATION. . . . . . . . . . . . . . . . . . . . . . . . . . . .

SERVICEADJUSTMENTPROCEDURES.....

Drive Shaft OilSealsReplacement...........

KeyInterlockMechanismCheck............... Kickdown

ServoAdjustment ......................

Line Pressure Adjustment .........................

Park/Neutral Position Switch

Adjustment

............................................................

ReducingPressure Adjustment .................

Selector LeverOperation

Check...............

Shift

LockMechanismCheck....................

Speedometer

CableReplacement .............

Throttle-position Sensor Adjustment ..........

TransaxleFluidLevelInspection ...........i...

TransaxleFluidReplacement .....................

Transfer

Oil LevelInspection .....................

Transfer

OilReplacement ..........................

SPECIAL

TOOLS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . .21

SPECIFICATIONS ...........................................19

General Specifications

................................19

Lubricants....................................................20

Torque Specifications .................................20

2TRANSAXLEASSEMBLY

82

92

83

86

88

84

91

83

84

93

92

82

82

82

82

TRANSAXLEASSEMBLY

TRANSAXLE CONTROL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

TRANSAXLE OIL

COOLERHOSES . . . . . . . . . . . . .100

TRANSFER

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . .108

TROUBLESHOOTING

....................................

CircuitDiagram...........................................

Converter Stall Test ...................................

Datalink

andTest................................................

E.L.C. 4-speed Automatic Transaxle

ControlComponents

Layout

......................

Element in Use at Each Position

of Selector Lever .......................................

Fail-safe Item ..............................................

Fault Code Description ...............................

OilPressure Tests

.....................................

Shift Patterns ..............................................

Transaxle

Control........................................

22

60

59

26

80

37

32

28

52

37 59

Page 691 of 1273

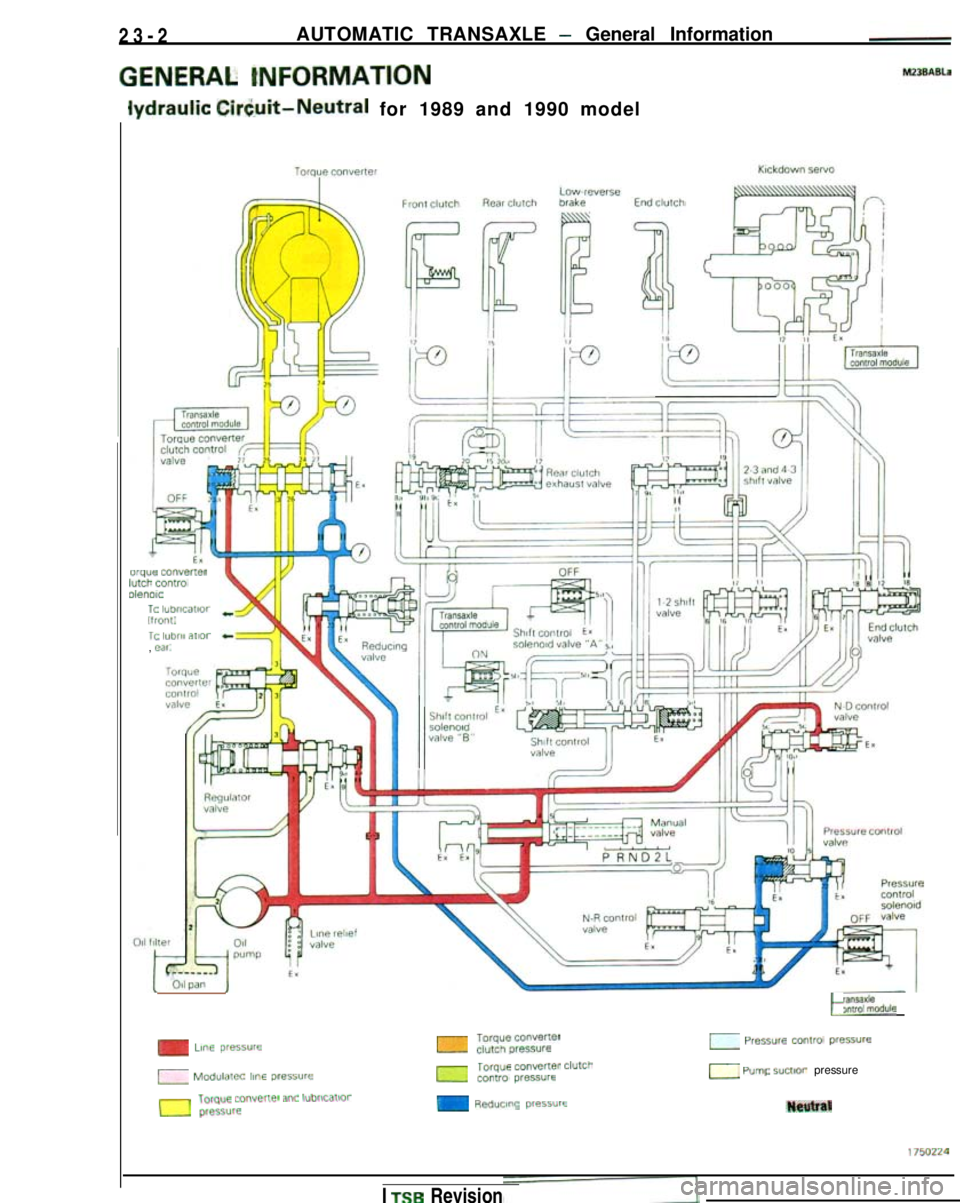

23-2

AUTOMATIC TRANSAXLE - General Information

GENERAL tNFORMATlON

lydraulic CirCuit-Neutral for 1989 and 1990 model

owe Converterl”tCh ControloienoldTO ILiDilCdliUlllfl”llllTO l11111,i .,I,“”, cari

m Ll”P ,ireasure

0

MOd”ldle’i

,

l”biiCJliO”

preiaure

~%d”,,I-

m TOrg”econ”arte‘

ClUtCl3res9”ie0 Ple*s”le

CO”lr”l pressure

0Torque COnvelter ClutchControl pressure0 P”m*

s”~tlon pressure

m Reducing ,11~55118tbsttral

1750224 I

TSB Revision

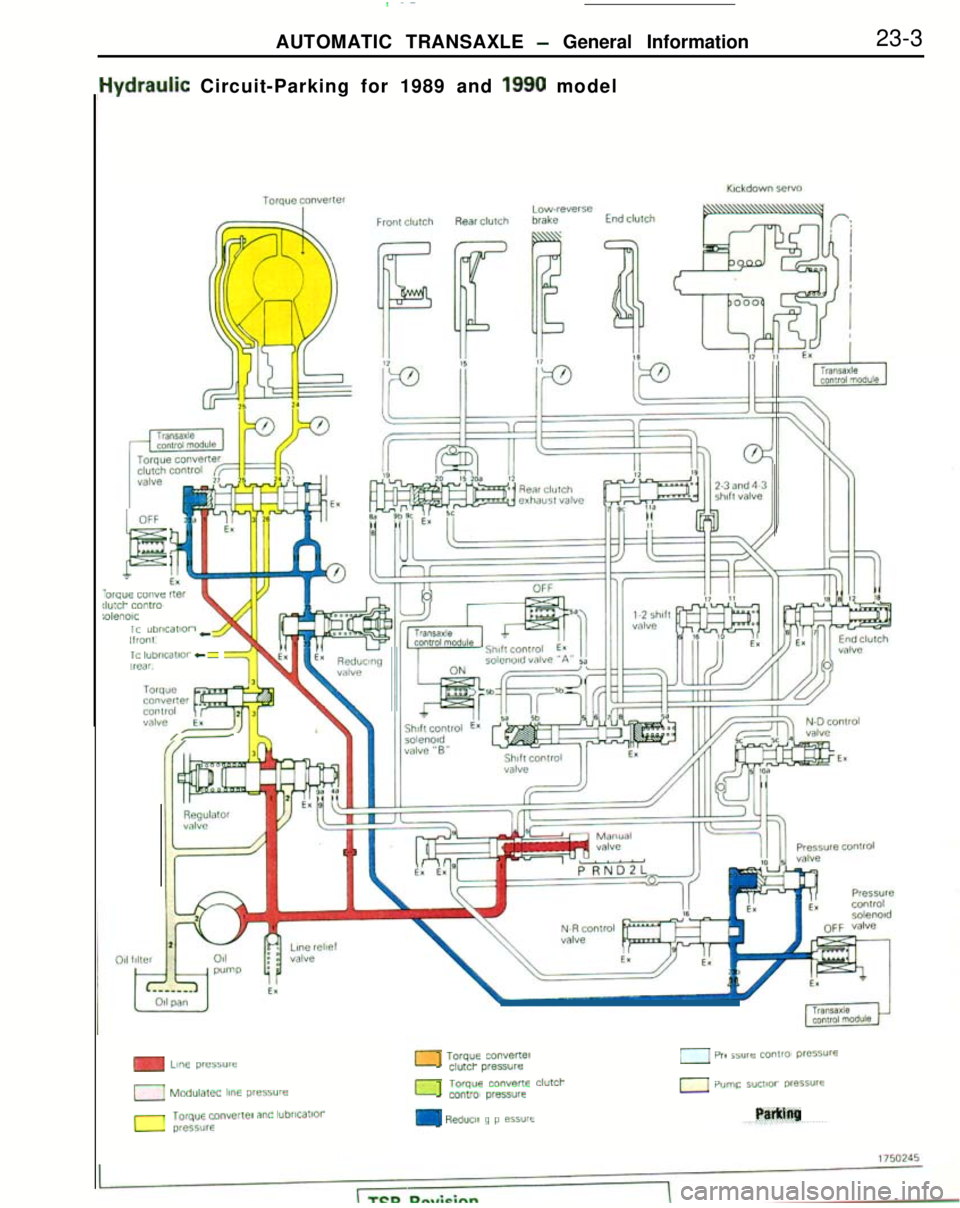

Page 693 of 1273

AUTOMATIC TRANSAXLE - General Information

23-3

iydraulic Circuit-Parking for 1989 and 1990

model

OFF

b@o,c;ue COPYe~i”Wh rnntmdenold1” llllllcdt~on,,W”llTO ,“tmc,ltlnrl c=m,c,,r,

m LN”F pr”,““P

0 Mi!d”l‘lWd IIllS ,>w+5ureTorque ColwCllel arci l”br~ca:l”n0 prelFI;IP

] TorquF “onverter3 P,< ,,l,lD CO”llll we>wrsC’UWh pressue

1T"rq"P convene clutchCO"VOl ples5"le0 P,,,,W F"C!lUll r)lesd~e

1 Reduclr 9 P ess.lrcPNklnp