automatic MITSUBISHI GALANT 1989 Service User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 46 of 1273

GENERAL -Maintenance Service

(1O)Star-t engine and allow to idle for at least two minutes.

Then, with parking brake on, move selector

fever

momentarily to each position, ending in “N” Neutral

position.

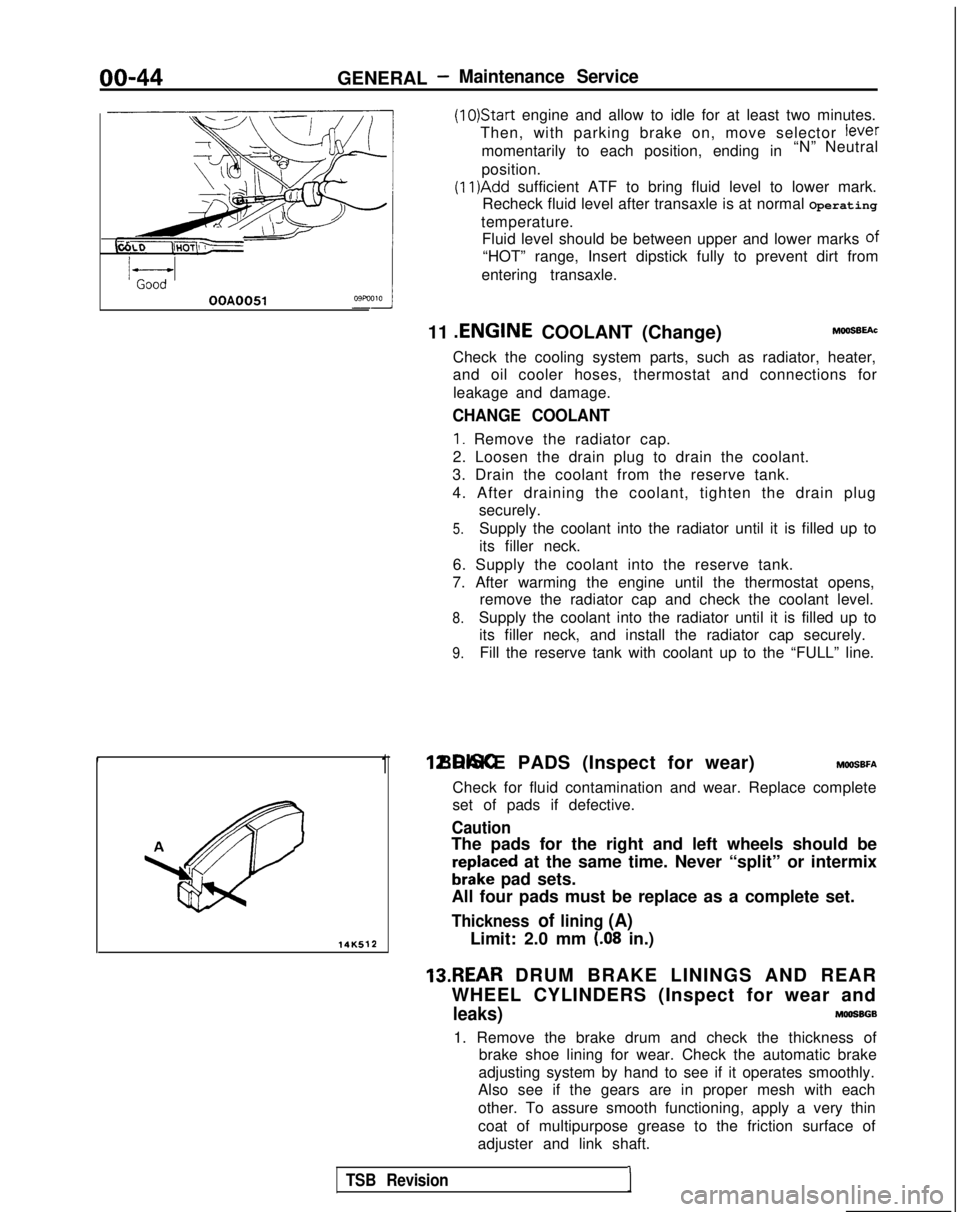

(11)Add sufficient ATF to bring fluid level to lower mark.

Recheck fluid level after transaxle is at normal Operating

temperature. Fluid level should be between upper and lower marks of

“HOT” range, Insert dipstick fully to prevent dirt from

entering transaxle.

OOA0051

11 .ENGINE

COOLANT (Change)MOOSEEAC

Check the cooling system parts, such as radiator, heater,

and oil cooler hoses, thermostat and connections for

leakage and damage.

CHANGE COOLANT

1. Remove the radiator cap.

2. Loosen the drain plug to drain the coolant.

3. Drain the coolant from the reserve tank.

4. After draining the coolant, tighten the drain plug securely.

5.Supply the coolant into the radiator until it is filled up to

its filler neck.

6. Supply the coolant into the reserve tank.

7. After warming the engine until the thermostat opens, remove the radiator cap and check the coolant level.

8.Supply the coolant into the radiator until it is filled up to

its filler neck, and install the radiator cap securely.

9.Fill the reserve tank with coolant up to the “FULL” line.

14K512

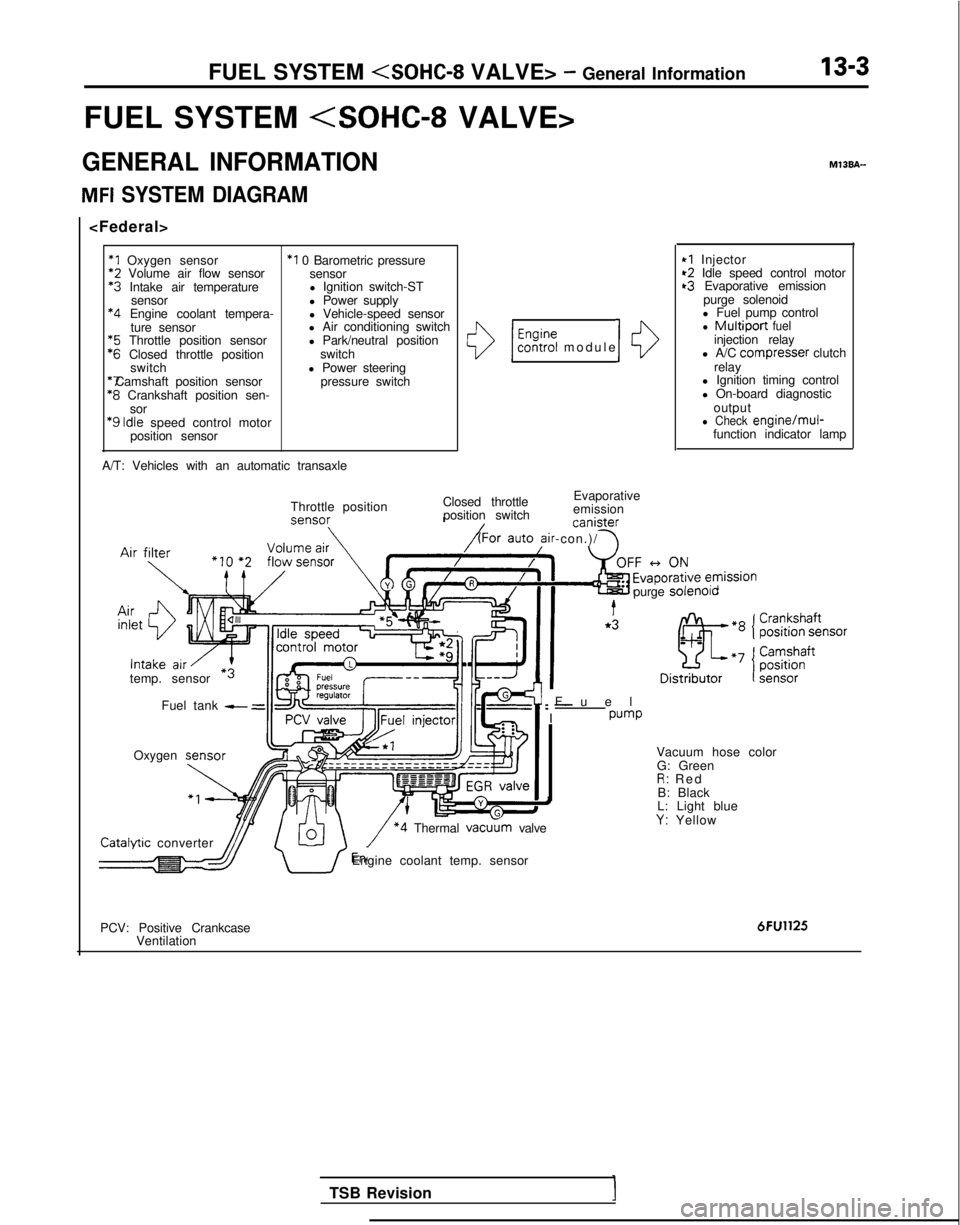

1 12.DISC BRAKE PADS (Inspect for wear) MWSBFA

Check for fluid contamination and wear. Replace complete

set of pads if defective.

Caution

The pads for the right and left wheels should be

reDlaced at the same time. Never “split” or intermix

brkke pad sets.

All four pads must be replace as a complete set.

Thickness of lining (A)

Limit: 2.0 mm (.08 in.)

13.REAR DRUM BRAKE LININGS AND REAR

WHEEL CYLINDERS (Inspect for wear and

leaks)MOOSBGB

1. Remove the brake drum and check the thickness of brake shoe lining for wear. Check the automatic brake

adjusting system by hand to see if it operates smoothly.

Also see if the gears are in proper mesh with each

other. To assure smooth functioning, apply a very thin

coat of multipurpose grease to the friction surface of

adjuster and link shaft.

TSB Revision1

Page 145 of 1273

FUEL SYSTEM

FUEL SYSTEM

GENERAL INFORMATION

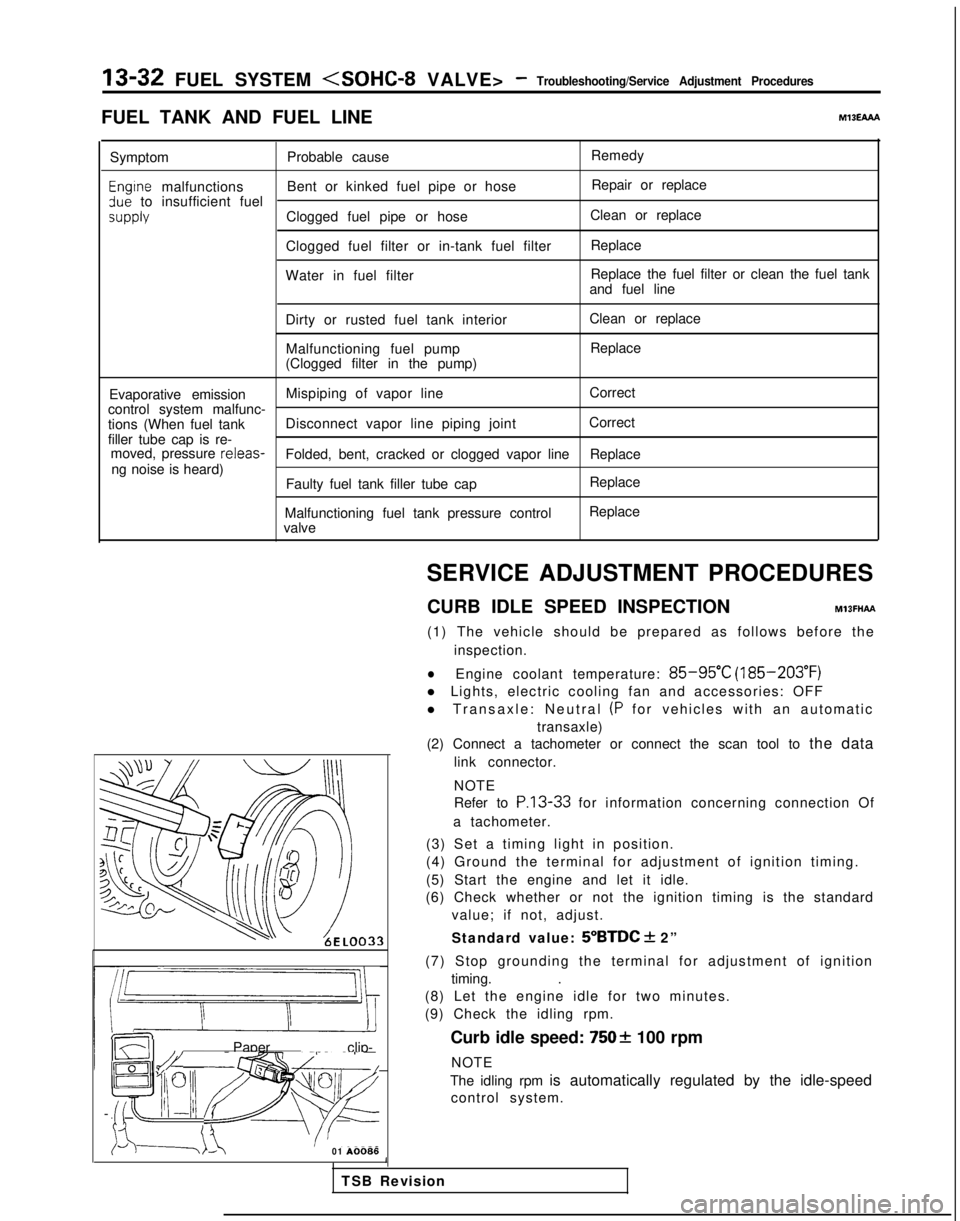

MFI SYSTEM DIAGRAM

*1 Oxygen sensor

*2

Volume air flow sensor *3

Intake air temperature

sensor *4

Engine coolant tempera-

ture sensor *5

Throttle position sensor *6

Closed throttle position

switch *7 Camshaft position sensor

*8

Crankshaft position sen-

sor

‘9 Idle

speed control motor

position sensor

*I 0 Barometric pressure sensor

l Ignition switch-ST

l Power supply

l Vehicle-speed sensor

l Air conditioning switch

l Park/neutral position

switch

l Power steering pressure switch

A/T: Vehicles with an automatic transaxle

()/ $%?i modul

e

Closed throttle Evaporative

position switch emission canister

ir-con.)/ \

10

Throttle position

temp. sensor Fuel tank

- =

Oxygen M13BA-

I

*I Injector~2 Idle speed control motort3 Evaporative emission

purge solenoid

l Fuel pump control

l Multiport fuelinjection relay

l A/C compresser clutch

relay

l Ignition timing control

l On-board diagnostic

output

l Check engine/mul-function indicator lamp

Fue

l

: -

I

pump

purge

solenolo Catalvtic

converter

\/ *4 Thermal vacu

G: Green

R: Re

d

B: Black

L: Light blue

Y: Yellow

dJJ/ U’Engine coolant temp. sensor

PCV: Positive Crankcase Ventilation

6FU1125

TSB Revision

Page 174 of 1273

13-32

FUEL SYSTEM

FUEL TANK AND FUEL LINEMlBEAAA

Symptom Probable cause Remedy

Engtne malfunctions

Bent or kinked fuel pipe or hose Repair or replace3ue to insufficient fuel

SUPPlYClogged fuel pipe or hoseClean or replace

Clogged fuel filter or in-tank fuel filter Replace

Water in fuel filter Replace the fuel filter or clean the fuel tank

and fuel line

Dirty or rusted fuel tank interior Malfunctioning fuel pump

(Clogged filter in the pump) Clean or replace

Replace

Evaporative emission Mispiping of vapor line

Correct

control system malfunc-

tions (When fuel tank Disconnect vapor line piping joint Correct

filler tube cap is re- moved, pressure releas-

Folded, bent, cracked or clogged vapor line Replace

ng noise is heard) Faulty fuel tank filler tube cap

Malfunctioning fuel tank pressure control

valve Replace

Replace

LL

m ~~ : Paper clip-

F l!;“I /yFp- -

izd--_7-01

A0086SERVICE ADJUSTMENT PROCEDURES

CURB IDLE SPEED INSPECTION

MlBFHAFt

(1) The vehicle should be prepared as follows before the inspection.

lEngine coolant temperature: 85-95°C (185-203°F)

l Lights, electric cooling fan and accessories: OFF

l Transaxle: Neutral

(P for vehicles with an automatic

transaxle)

(2) Connect a tachometer or connect the scan tool to the data

link connector.

NOTE

Refer to

P.13-33 for information concerning connection Of

a tachometer.

(3) Set a timing light in position.

(4) Ground the terminal for adjustment of ignition timing.

(5) Start the engine and let it idle.

(6) Check whether or not the ignition timing is the standard

value; if not, adjust.

Standard value:

5”BTDC + 2”

(7) Stop grounding the terminal for adjustment of ignition timing. .

(8) Let the engine idle for two minutes.

(9) Check the idling rpm.

Curb idle speed:

7502 100 rpm

NOTE

The idling rpm is automatically regulated by the idle-speed control system.

1

TSB Revision

Page 175 of 1273

FUEL SYSTEM

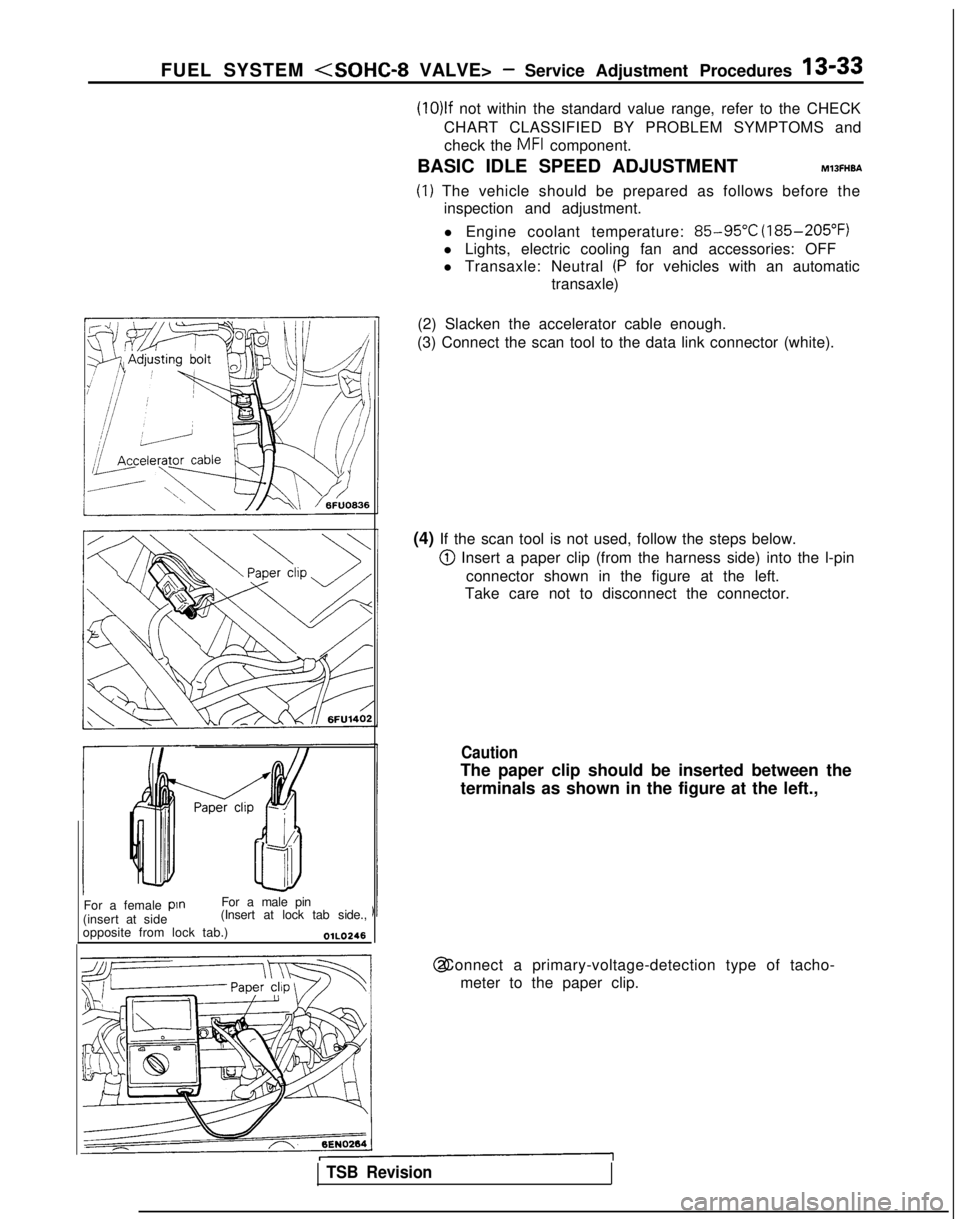

For a female

pin

For a male pin

(insert at side (Insert at lock tab side.,

opposite from lock tab.)

OlLO246

(10)lf not within the standard value range, refer to the CHECK

CHART CLASSIFIED BY PROBLEM SYMPTOMS and check the

MFI component.

BASIC IDLE SPEED ADJUSTMENT

MlBFHBA

(1) The vehicle should be prepared as follows before the inspection and adjustment.

l Engine coolant temperature:

85-95°C (185-205°F)

l Lights, electric cooling fan and accessories: OFF

l Transaxle: Neutral

(P for vehicles with an automatic

transaxle)

(2) Slacken the accelerator cable enough.

(3) Connect the scan tool to the data link connector (white).

(4) If the scan tool is not used, follow the steps below.

@I Insert a paper clip (from the harness side) into the l-pin connector shown in the figure at the left.

Take care not to disconnect the connector.

Caution

The paper clip should be inserted between the

terminals as shown in the figure at the left., @ Connect a primary-voltage-detection type of tacho-

meter to the paper clip.

TSB Revision

Page 200 of 1273

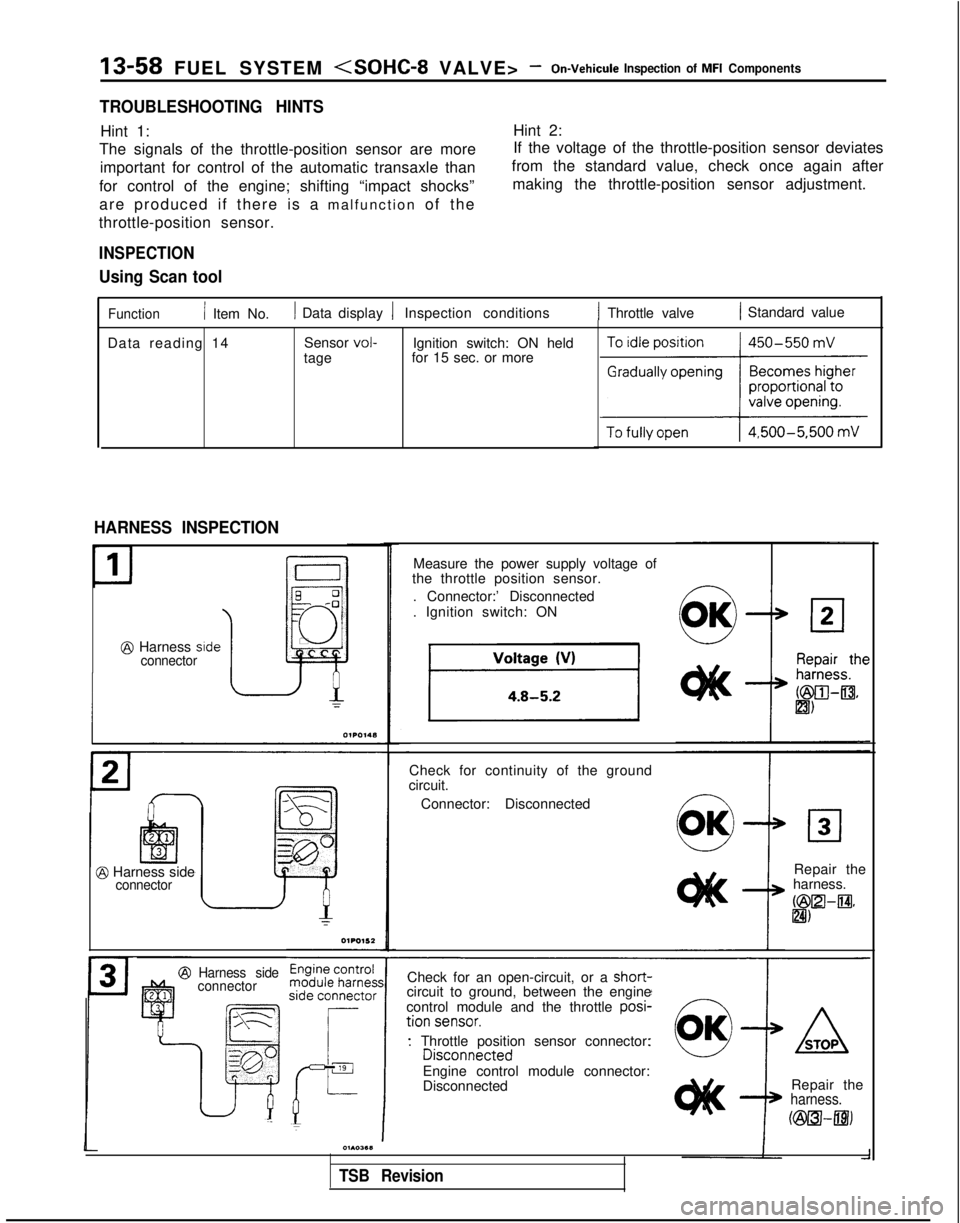

13-58 FUEL SYSTEM

TROUBLESHOOTING HINTS

Hint 1:Hint 2:

The signals of the throttle-position sensor are more If the voltage of the throttle-position sensor deviates

important for control of the automatic transaxle than from the standard value, check once again after

for control of the engine; shifting “impact shocks” making the throttle-position sensor adjustment.

are produced if there is a malfunction of the

throttle-position sensor.

INSPECTION

Using Scan tool

Function/ Item No.1 Data display 1 Inspection conditions1 Throttle valve1 Standard value

Data reading 14 Sensor

vol-tageIgnition switch: ON held

for 15 sec. or more

HARNESS INSPECTION

E q-0

JJ ~

@ Harness side0

connector

@ Harness sideconnector

Harness side

connector

Measure the power supply voltage of

the throttle position sensor.

. Connector:’ Disconnected

. Ignition switch: ON

Check for continuity of the ground

circuit.

Connector: Disconnected

Repair the

harness.

bZilZl-m* &I)

Check for an open-circuit, or a short-

circuit to ground, between the engine

control module and the throttle posi-

. Throttle position sensor connector: Engine control module connector:

Disconnected Repair the

harness.

Fi&TUI-mj

01103611

TSB Revision

Page 203 of 1273

FUEL SYSTEM

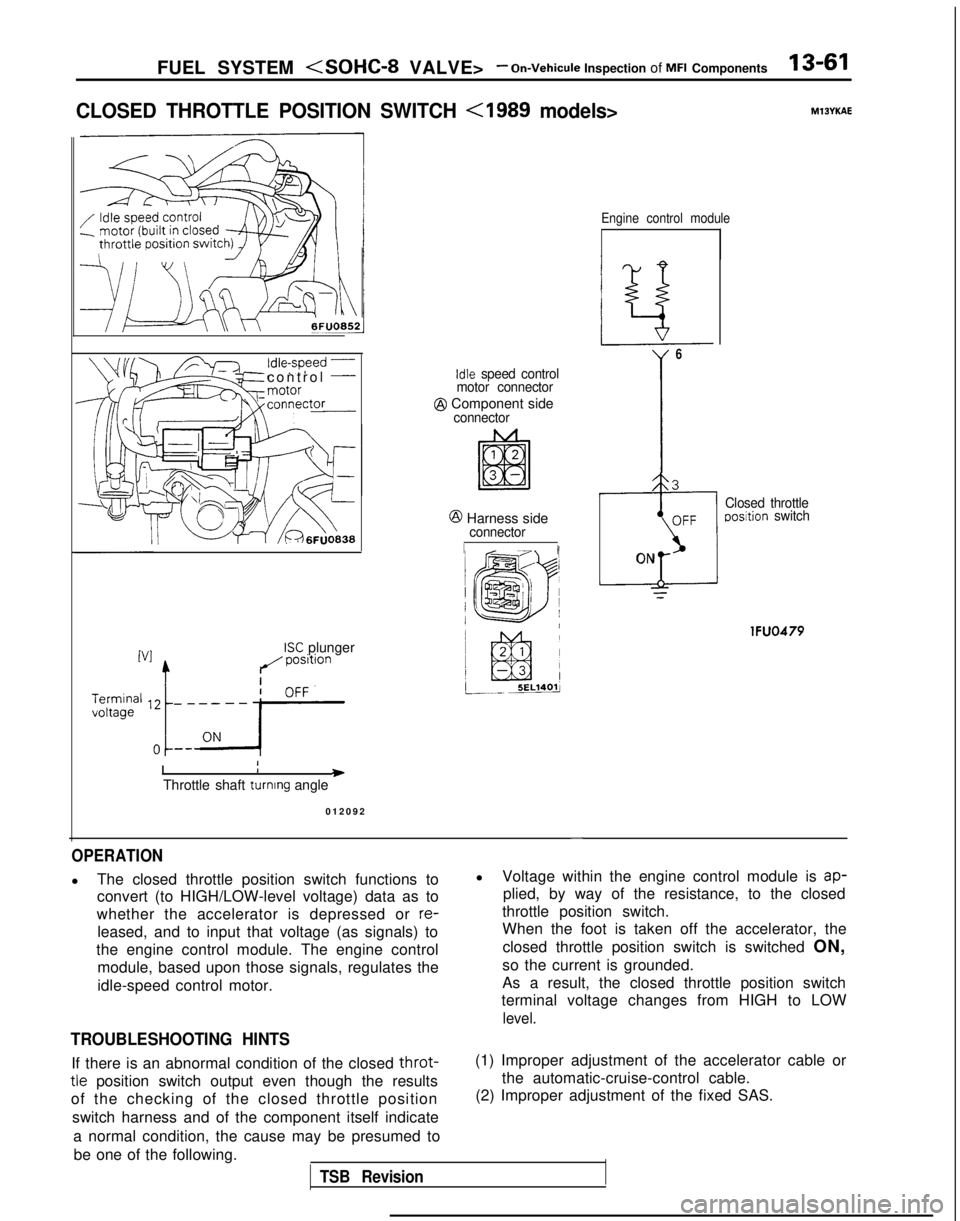

CLOSED THROTTLE POSITION SWITCH

control -Idle speed control

motor connector

@ Component sideconnector

@ Harness sideconnector

II

ISC plunger

_---__

III*Throttle shaft turning angle

01209

2

-

Engine control module

1

6

3

OFF

aI

ON

-z

Closed throttleDosition switch

lFUO479

OPERATION

l

The closed throttle position switch functions to

convert (to HIGH/LOW-level voltage) data as to

whether the accelerator is depressed or

re-

leased, and to input that voltage (as signals) to

the engine control module. The engine control module, based upon those signals, regulates the

idle-speed control motor.

TROUBLESHOOTING HINTS

l Voltage within the engine control module is ap-

plied, by way of the resistance, to the closed

throttle position switch.

When the foot is taken off the accelerator, the

closed throttle position switch is switched ON,

so the current is grounded.

As a result, the closed throttle position switch

terminal voltage changes from HIGH to LOW

level.

If there is an abnormal condition of the closed throt-

tle position switch output even though the results

of the checking of the closed throttle position

switch harness and of the component itself indicate

a normal condition, the cause may be presumed tobe one of the following.

TSB Revision

(1) Improper adjustment of the accelerator cable or the automatic-cruise-control cable.

(2) Improper adjustment of the fixed SAS.

Page 275 of 1273

FUEL SYSTEM

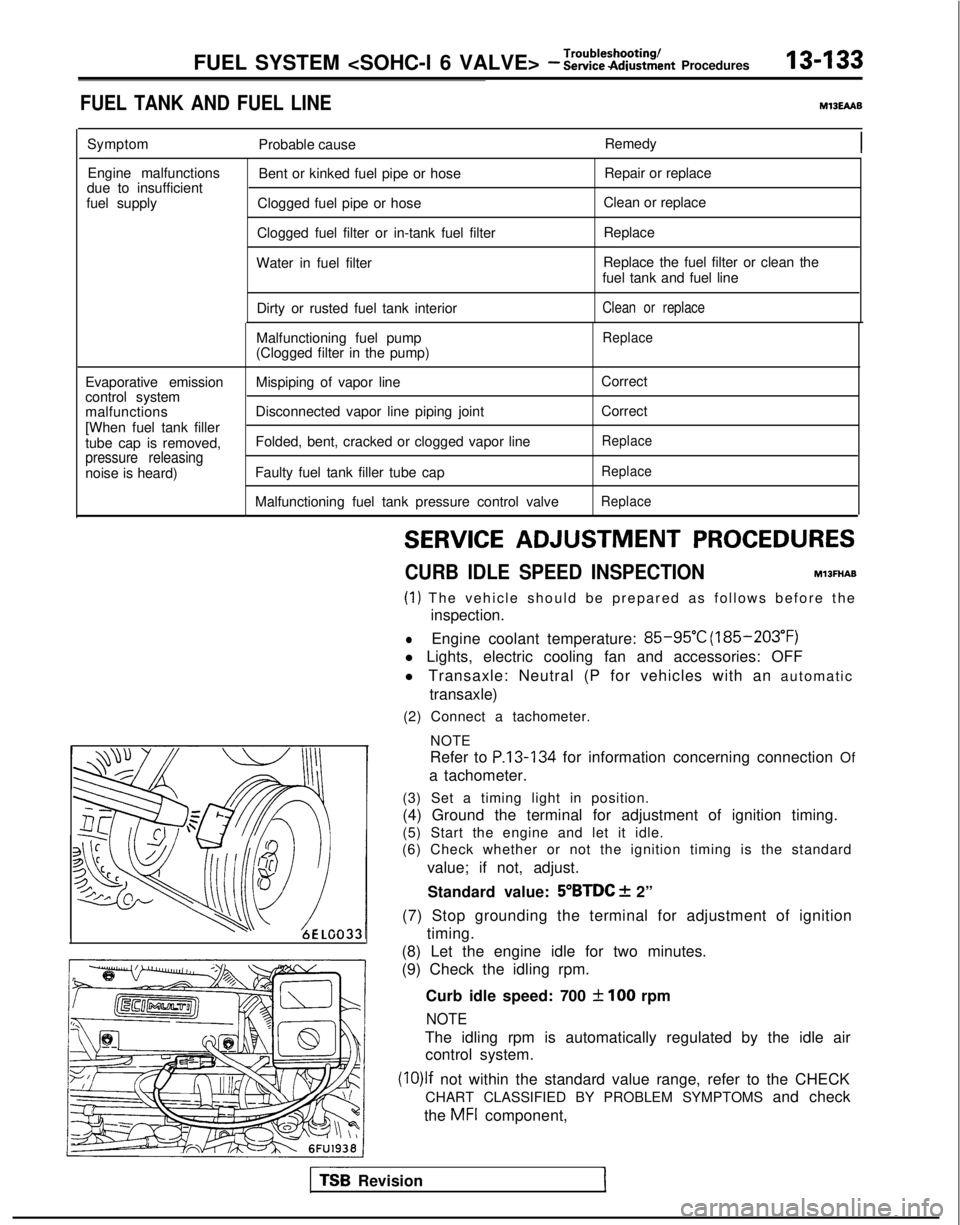

FUEL TANK AND FUEL LINEMIBEAAB

Symptom

Probable cause Remedy

Engine malfunctions

due to insufficient

fuel supply Bent or kinked fuel pipe or hose

Clogged fuel pipe or hose

Clogged fuel filter or in-tank fuel filter

Water in fuel filter Repair or replace

Clean or replace

Replace

Replace the fuel filter or clean the

fuel tank and fuel line

Dirty or rusted fuel tank interior

Clean or replace

Malfunctioning fuel pump

(Clogged filter in the pump)Replace

Evaporative emission

control system

malfunctions

[When fuel tank filler

tube cap is removed,

pressure releasingnoise is heard) Mispiping of vapor line

Disconnected vapor line piping joint

Folded, bent, cracked or clogged vapor line

Faulty fuel tank filler tube cap

Malfunctioning fuel tank pressure control valve Correct

Correct

Replace

Replace

Replace

SERVICE ADJUSTMENT

PROCEDURES

CURB IDLE SPEED INSPECTIONhll3MAE

(1) The vehicle should be prepared as follows before th

e

inspection.

lEngine coolant temperature: 85-95°C (185-203°F)

l Lights, electric cooling fan and accessories: OFF

l Transaxle: Neutral (P for vehicles with an automatic

transaxle)

(2) Connect a tachometer.

NOTE

Refer to

P.13-134 for information concerning connection Of

a tachometer.

(3) Set a timing light in position.

(4) Ground the terminal for adjustment of ignition timing.

(5) Start the engine and let it idle.

(6) Check whether or not the ignition timing is the standard

value; if not, adjust.

Standard value:

5”BTDC f 2”

(7) Stop grounding the terminal for adjustment of ignition timing.

(8) Let the engine idle for two minutes.

(9) Check the idling rpm.

Curb idle speed: 700

31100 rpm

NOTE

The idling rpm is automatically regulated by the idle aircontrol system.

(lO)lf not within the standard value range, refer to the CHECK

CHART CLASSIFIED BY PROBLEM SYMPTOMS and check

the

MFI component,

TS6 Revision1

Page 300 of 1273

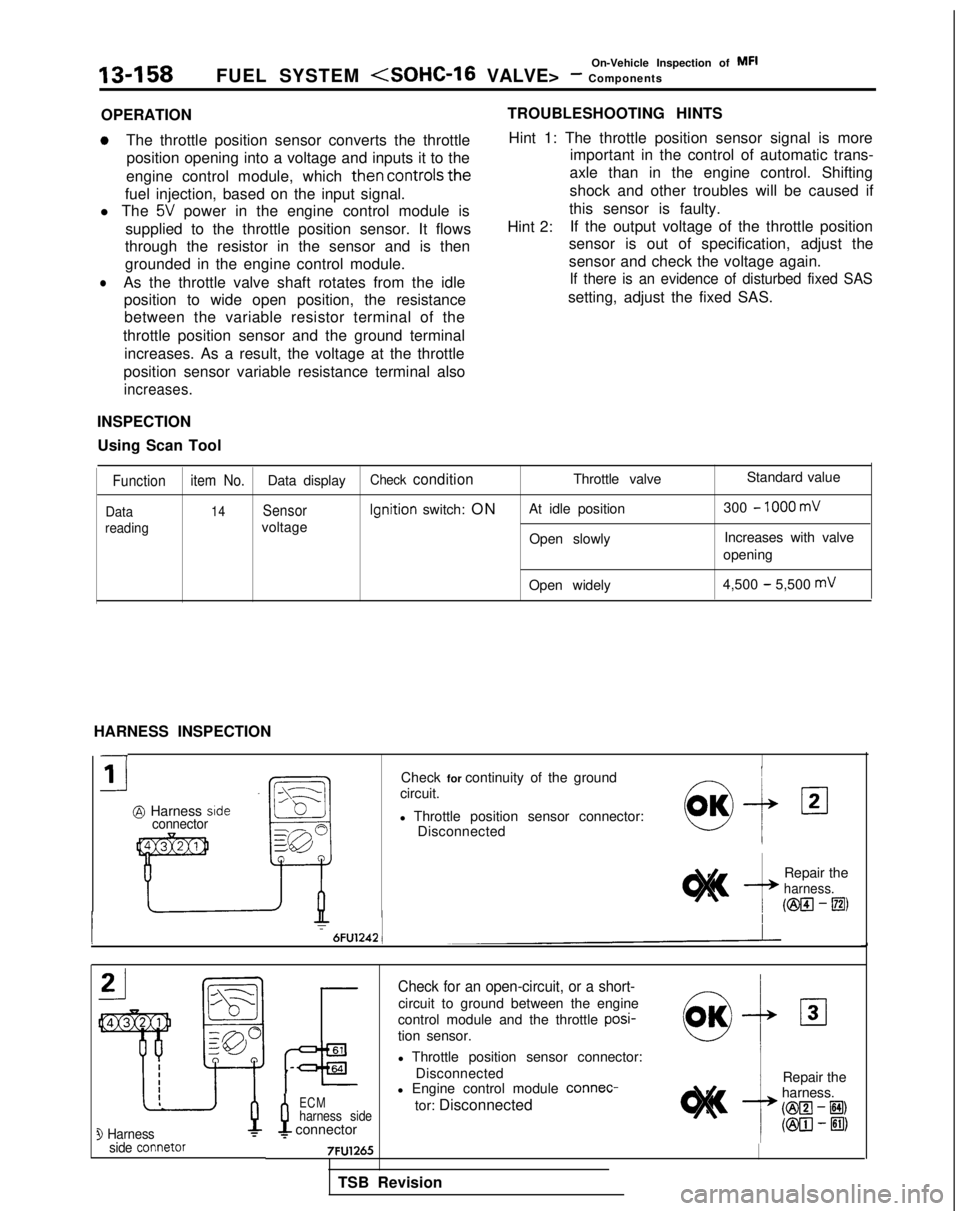

On-Vehicle Inspection of MFI

13-158FUEL SYSTEM (SOHC-16 VALVE> - Components

OPERATION

aThe throttle position sensor converts the throttle position opening into a voltage and inputs it to the

engine control module, which

then controls

the

fuel injection, based on the input signal.

l The

5V power in the engine control module is

supplied to the throttle position sensor. It flows

through the resistor in the sensor and is then

grounded in the engine control module.

lAs the throttle valve shaft rotates from the idle position to wide open position, the resistancebetween the variable resistor terminal of the

throttle position sensor and the ground terminal increases. As a result, the voltage at the throttle

position sensor variable resistance terminal also

increases.

INSPECTION

Using Scan Tool TROUBLESHOOTING HINTS

Hint 1: The throttle position sensor signal is more important in the control of automatic trans-

axle than in the engine control. Shifting

shock and other troubles will be caused if

this sensor is faulty.

Hint 2: If the output voltage of the throttle position

sensor is out of specification, adjust the

sensor and check the voltage again.

If there is an evidence of disturbed fixed SAS

setting, adjust the fixed SAS.

Function item No.Data displayCheck conditionThrottle valve Standard value

Data14Sensor Ignition

switch: ON At idle position 300 - 1000 mV

readingvoltage

Open slowlyIncreases with valve

opening

Open widely 4,500

- 5,500 mV

HARNESS INSPECTION

-

i1

@ Harness sideconnector

Check for continuity of the ground

circuit.

l Throttle position sensor connector: Disconnected

Repair the

harness.

(ml-m

3 Harnessside connetor

P

ECMharness sidef connector

Check for an open-circuit, or a short-

circuit to ground between the engine

control module and the throttle posi-

tion sensor.

l Throttle position sensor connector:

Disconnected

l Engine control module connec-

tor: Disconnected Repair the

harness. @El

- El)

(@III-ElII

TSB Revision

Page 387 of 1273

FUEL SYSTEM

cl989 models> -a’i\.-upI t

SERVICE ADJUSTMENT PROCEDURES

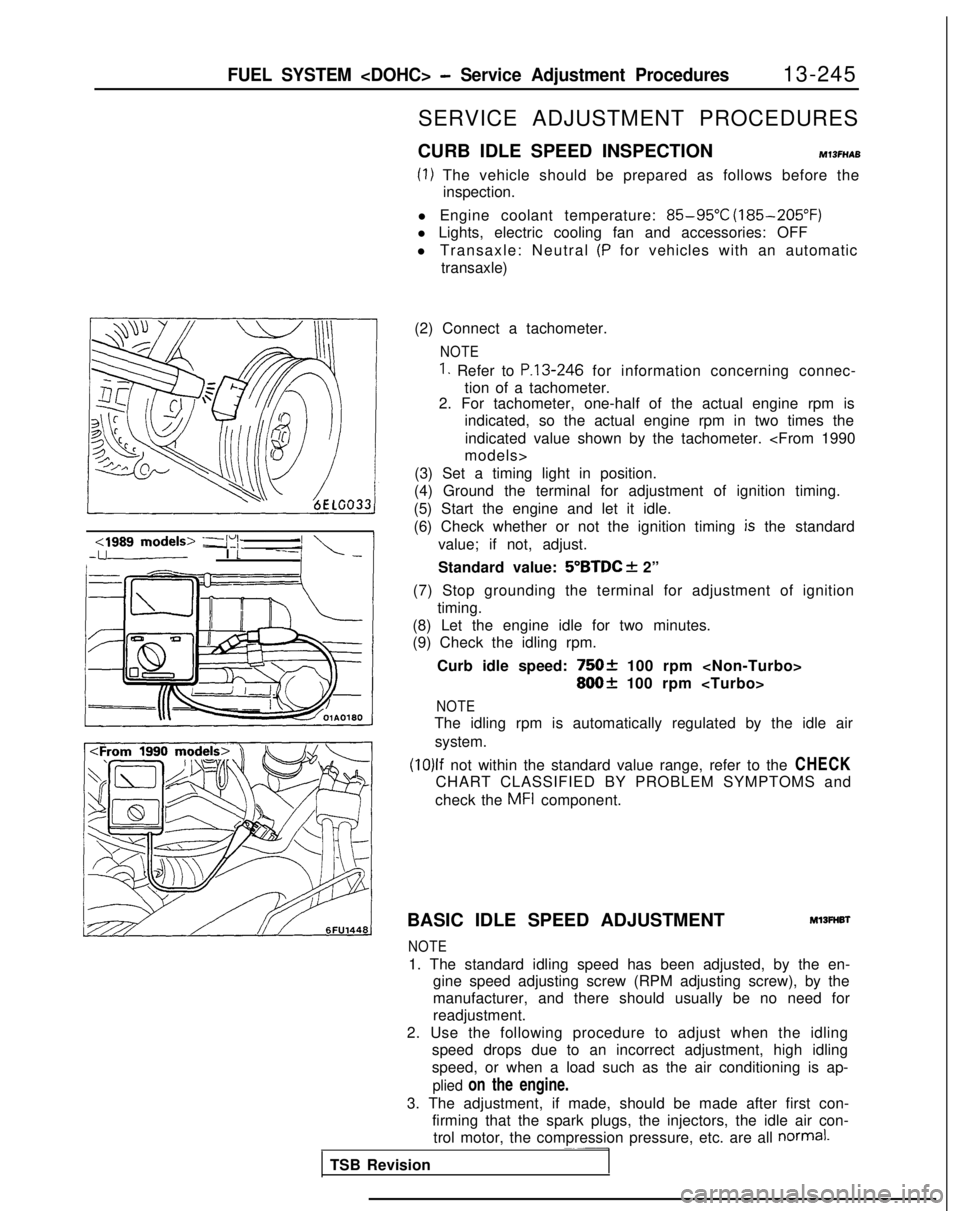

CURB IDLE SPEED INSPECTION

MlSFHAB

(1) The vehicle should be prepared as follows before the inspection.

l Engine coolant temperature:

85-95°C (185-205°F)

l Lights, electric cooling fan and accessories: OFF

l Transaxle: Neutral

(P for vehicles with an automatic

transaxle)

(2) Connect a tachometer.

NOTE

1. Refer to P.13-246 for information concerning connec-

tion of a tachometer.

2. For tachometer, one-half of the actual engine rpm is

indicated, so the actual engine rpm in two times the

indicated value shown by the tachometer.

(3) Set a timing light in position.

(4) Ground the terminal for adjustment of ignition timing.

(5) Start the engine and let it idle.

(6) Check whether or not the ignition timing

is the standard

value; if not, adjust.

Standard value:

5”BTDC f 2”

(7) Stop grounding the terminal for adjustment of ignition timing.

(8) Let the engine idle for two minutes.

(9) Check the idling rpm.

Curb idle speed:

75Ok 100 rpm

800+ 100 rpm

NOTE

The idling rpm is automatically regulated by the idle airsystem.

(10)lf not within the standard value range, refer to the CHECK

CHART CLASSIFIED BY PROBLEM SYMPTOMS and

check the

MFI component.

BASIC IDLE SPEED ADJUSTMENT

Ml3FHBl

NOTE

1. The standard idling speed has been adjusted, by the en- gine speed adjusting screw (RPM adjusting screw), by the

manufacturer, and there should usually be no need for

readjustment.

2. Use the following procedure to adjust when the idling speed drops due to an incorrect adjustment, high idling

speed, or when a load such as the air conditioning is ap-

plied on the engine.

3. The adjustment, if made, should be made after first con- firming that the spark plugs, the injectors, the idle air con-trol motor, the compression pressure, etc. are all

normal.~~-

TSB Revision

Page 388 of 1273

13-246FUEL SYSTEM

17k&---,!E~,~~/iY I

(1) The vehicle should be prepared as follows before the

inspection and adjustment.

l Engine coolant temperature:

85-95°C (185-205°F)

l Lights, electric cooling fan and accessories: OFF l Transaxle: Neutral (P for vehicles with an automatic transaxle)

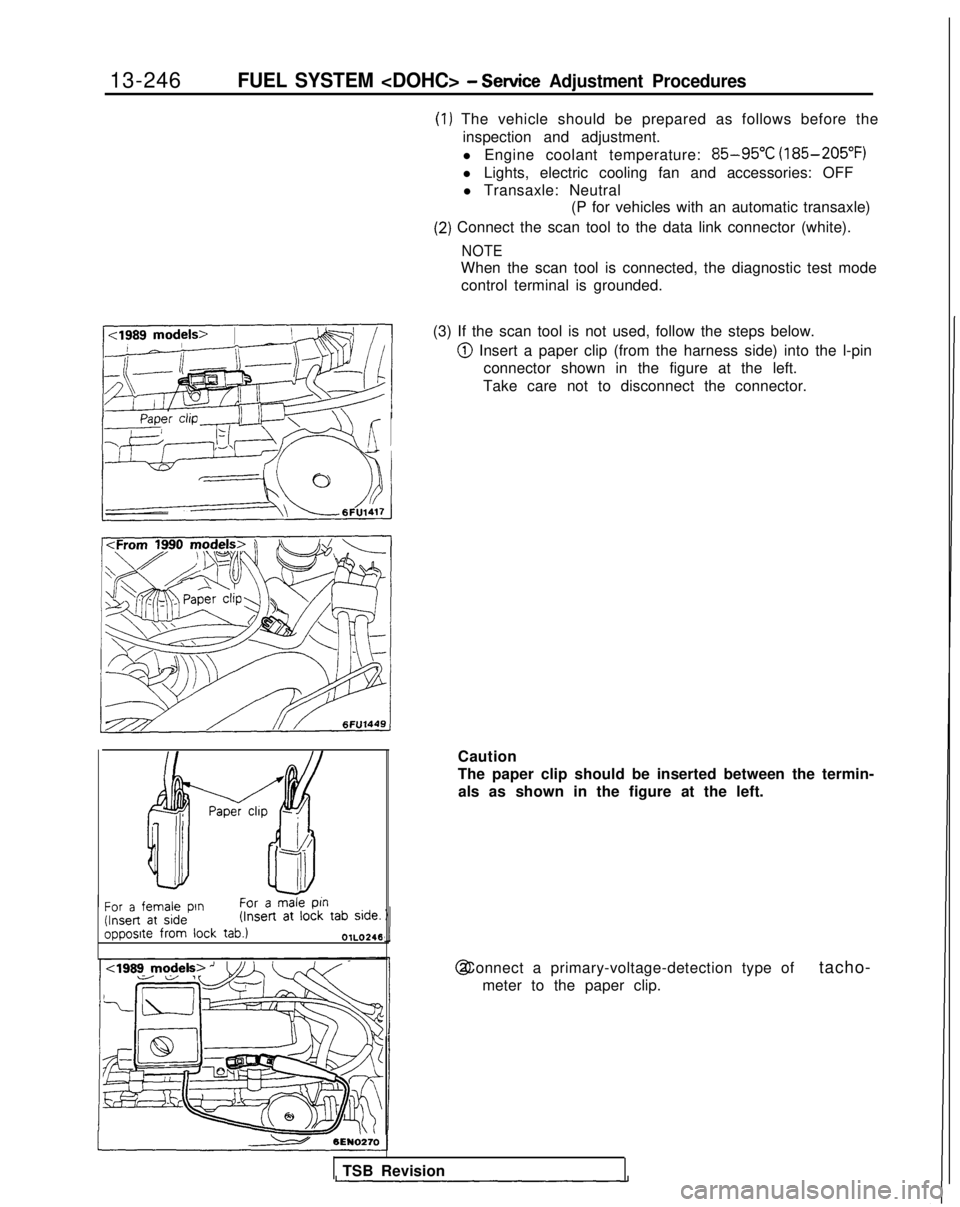

(2) Connect the scan tool to the data link connector (white).

NOTE

When the scan tool is connected, the diagnostic test mode

control terminal is grounded.

(3) If the scan tool is not used, follow the steps below.

@ Insert a paper clip (from the harness side) into the l-pin connector shown in the figure at the left.

Take care not to disconnect the connector.

/ Paper chp -

f!f--i!t

Ah

-II

For a female pin

For a male

ptn (Insert

at side (Insert

at

lock tab side.

opposite from

lock

tab.)OlL0246

Caution

The paper clip should be inserted between the termin-

als as shown in the figure at the left. @ Connect a primary-voltage-detection type of

tacho-

meter to the paper clip.

TSB Revision