automatic MITSUBISHI GALANT 1989 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 1253 of 1273

SERVICE BRAKES - G-Sensor

G-SENSOR

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Op

*Removal and Installation of Floor

Con-

(Refer to GROUP

52-Floor Console.)l Removal and Installation of Trunk

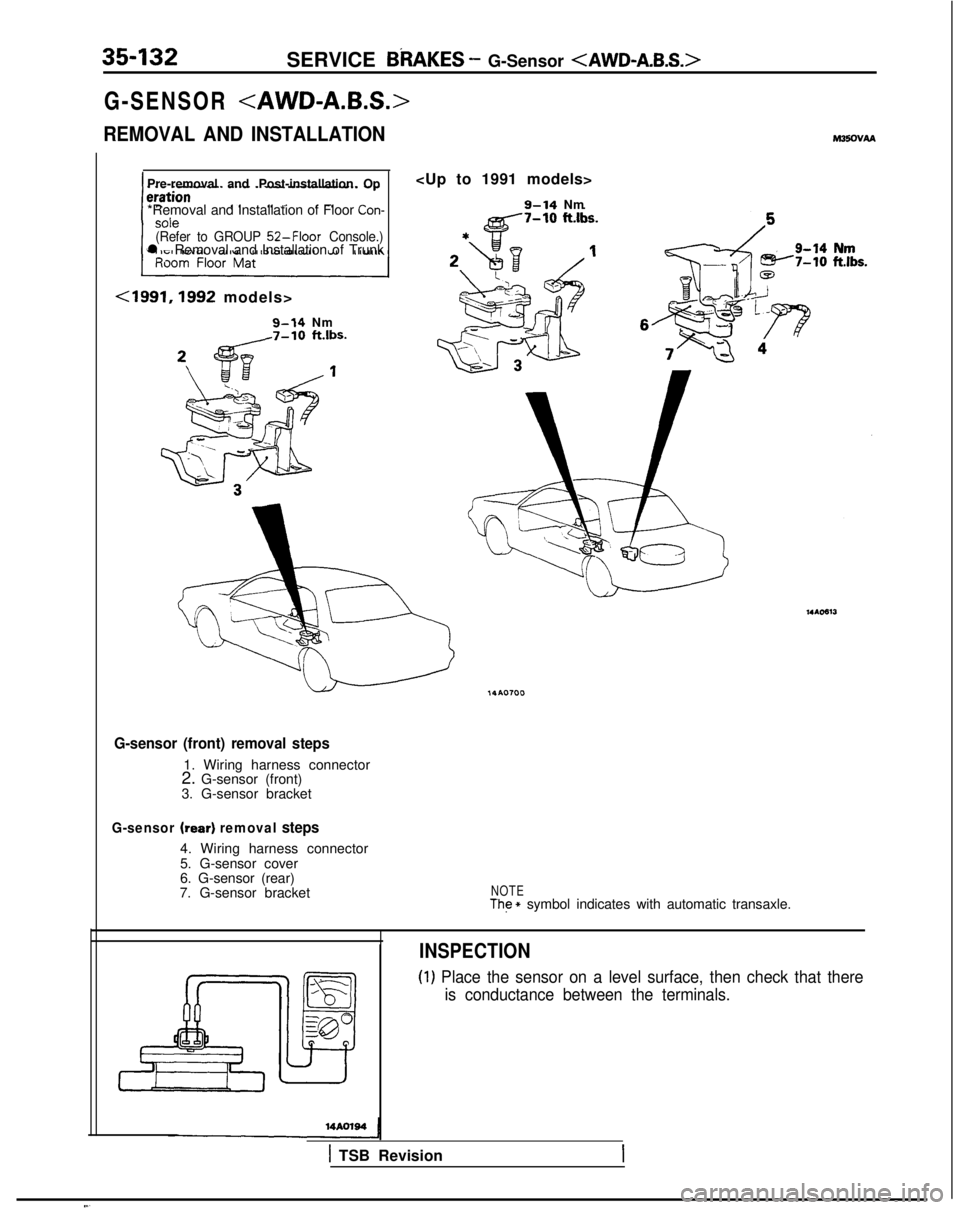

<1991,1992 models>

g-14 Nm

M35OVAA

9-14 Nm

G-sensor (front) removal steps

1. Wiring harness connector

2. G-sensor (front)

3. G-sensor bracket

G-sensor (rear) removal steps

4. Wiring harness connector

5. G-sensor cover

6. G-sensor (rear)

7. G-sensor bracket

NOTEThe * symbol indicates with automatic transaxle.

INSPECTION

(1) Place the sensor on a level surface, then check that there

is conductance between the terminals.

1 TSB Revision

Page 1257 of 1273

36-2PARKING BRAKES - Specifications/Troubleshooting/Service Adjustment Procedures

SPECIFICATIONS

GENERAL SPECIFICATIONS

ItemsSpecifications

TypeMechanical brake acting on rear wheels

Parking brake lever typeLever type

Cable arrangementV-type

SERVICE SPECIFICATION

Items

Standard value

Parking brake lever stroke Specifications5-7 notches

TROUBLESHOOTING

Symptom

Probable cause Remedy

Poor parking brake

function +Worn brake pad Poor condition of brake pad surface Replace

Parking brake cable sticking

Auto-adjuster malfunction Adjust

Excessive parking brake lever stroke

Adjust the parking brake lever

stroke or check the parking

brake cable arrangement

I

i

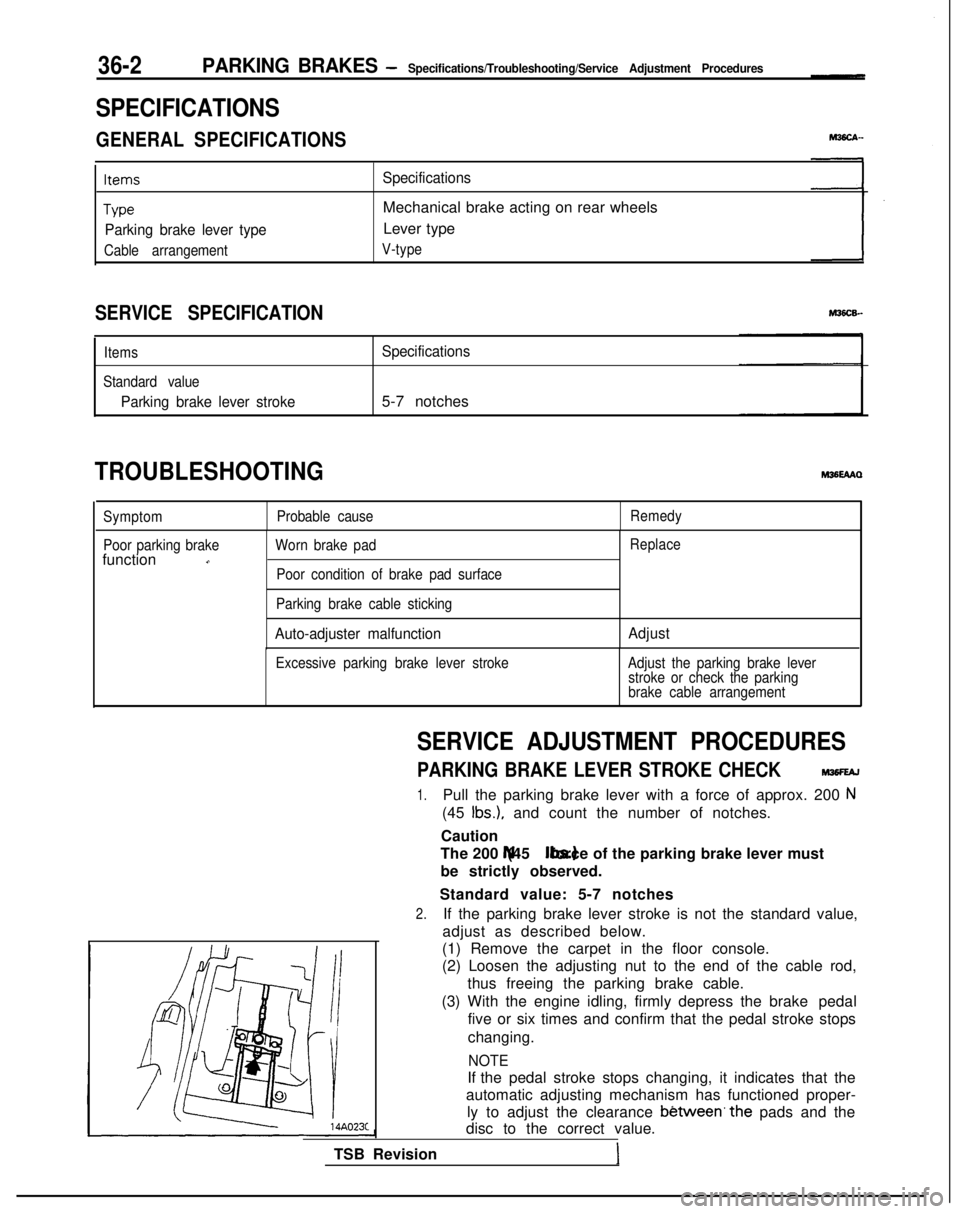

!14A023C

SERVICE ADJUSTMENT PROCEDURES

PARKING BRAKE LEVER STROKE CHECKM~~FEAJ

1.Pull the parking brake lever with a force of approx. 200 N

(45 Ibs.), and count the number of notches.

Caution

The 200 N (45 Ibs.) force of the parking brake lever must

be strictly observed.

Standard value: 5-7 notches

2.If the parking brake lever stroke is not the standard value,

adjust as described below.

(1) Remove the carpet in the floor console.

(2) Loosen the adjusting nut to the end of the cable rod,

thus freeing the parking brake cable.

(3) With the engine idling, firmly depress the brake pedal

five or six times and confirm that the pedal stroke stops

changing.

NOTE

If the pedal stroke stops changing, it indicates that the

automatic adjusting mechanism has functioned proper- ly to adjust the clearance

b&ween’the pads and the

disc to the correct value.

TSB Revision

Page 1258 of 1273

PARKING BRAKES - Service Adiustment Procedures36-3

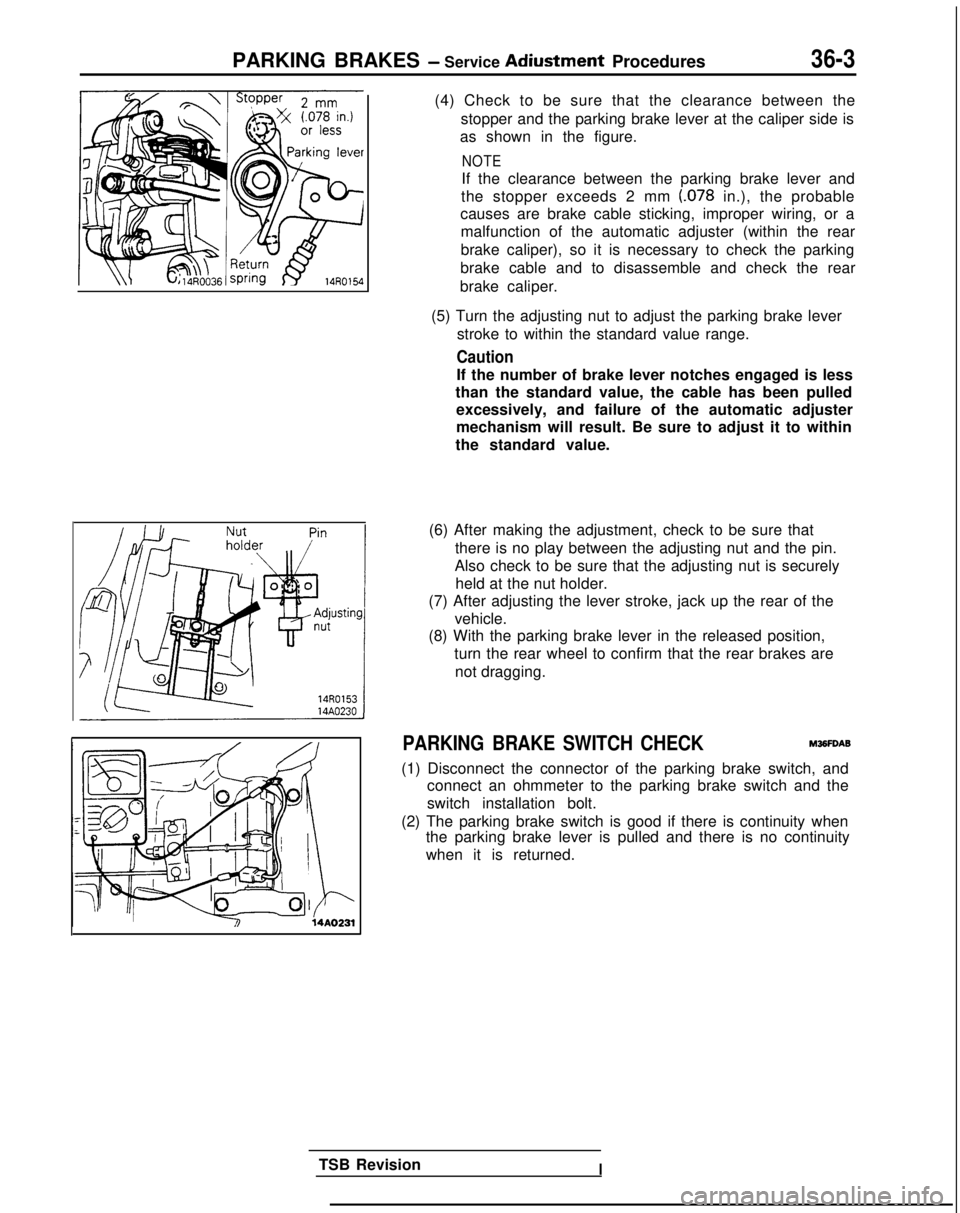

(4) Check to be sure that the clearance between the

stopper and the parking brake lever at the caliper side is

as shown in the figure.

NOTE

If the clearance between the parking brake lever and

the stopper exceeds 2 mm

(078 in.), the probable

causes are brake cable sticking, improper wiring, or a

malfunction of the automatic adjuster (within the rear

brake caliper), so it is necessary to check the parking

brake cable and to disassemble and check the rear

brake caliper.

(5) Turn the adjusting nut to adjust the parking brake lever stroke to within the standard value range.

Caution

If the number of brake lever notches engaged is less

than the standard value, the cable has been pulled excessively, and failure of the automatic adjuster

mechanism will result. Be sure to adjust it to within

the standard value.

(6) After making the adjustment, check to be sure that there is no play between the adjusting nut and the pin.

Also check to be sure that the adjusting nut is securely held at the nut holder.

(7) After adjusting the lever stroke, jack up the rear of the

vehicle.

(8) With the parking brake lever in the released position,

turn the rear wheel to confirm that the rear brakes are

not dragging.

PARKING BRAKE SWITCH CHECK M3SFDAB

(1) Disconnect the connector of the parking brake switch, and connect an ohmmeter to the parking brake switch and the

switch installation bolt.

(2) The parking brake switch is good if there is continuity when the parking brake lever is pulled and there is no continuity

when it is returned.

TSB Revision

I

Page 1261 of 1273

36-6PARKING BRAKES - Parking Brake Cable

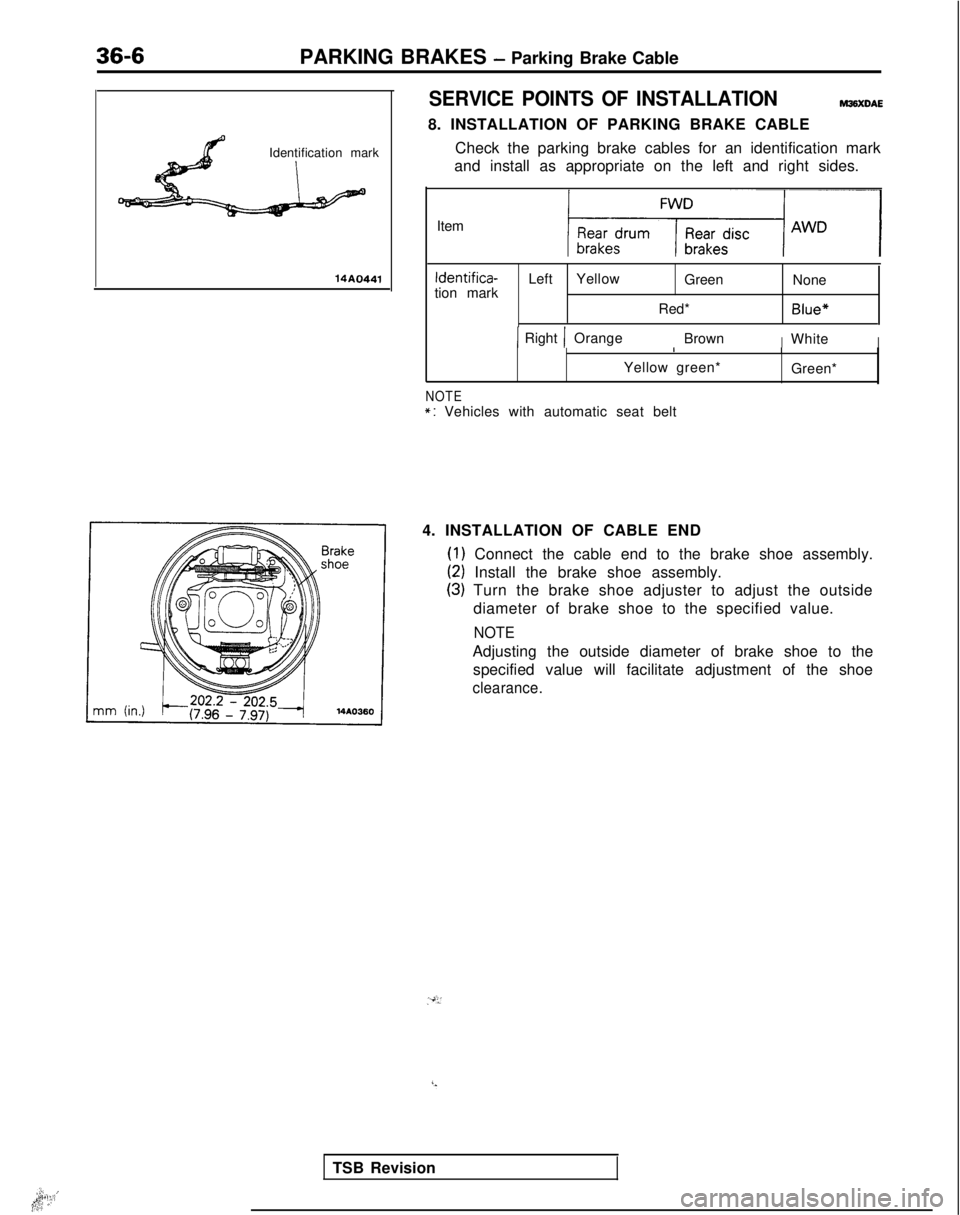

Identification mark

14A0441

SERVICE POINTS OF INSTALLATIONWXDAE

8. INSTALLATION OF PARKING BRAKE CABLE Check the parking brake cables for an identification mark

and install as appropriate on the left and right sides.

Item Identifica-

tion mark Left

Yellow

Green None

Red*

Blue*

1 Right 1 Orange BrownIWhiteI I

Yellow green* I

Green*

NOTE*: Vehicles with automatic seat belt

4. INSTALLATION OF CABLE END

(1) Connect the cable end to the brake shoe assembly.

(2) Install the brake shoe assembly.

(3) Turn the brake shoe adjuster to adjust the outside diameter of brake shoe to the specified value.

NOTE

Adjusting the outside diameter of brake shoe to thespecified value will facilitate adjustment of the shoe

clearance. .‘,,

I.**i:,1;q ,.’

TSB Revision

Page 1262 of 1273

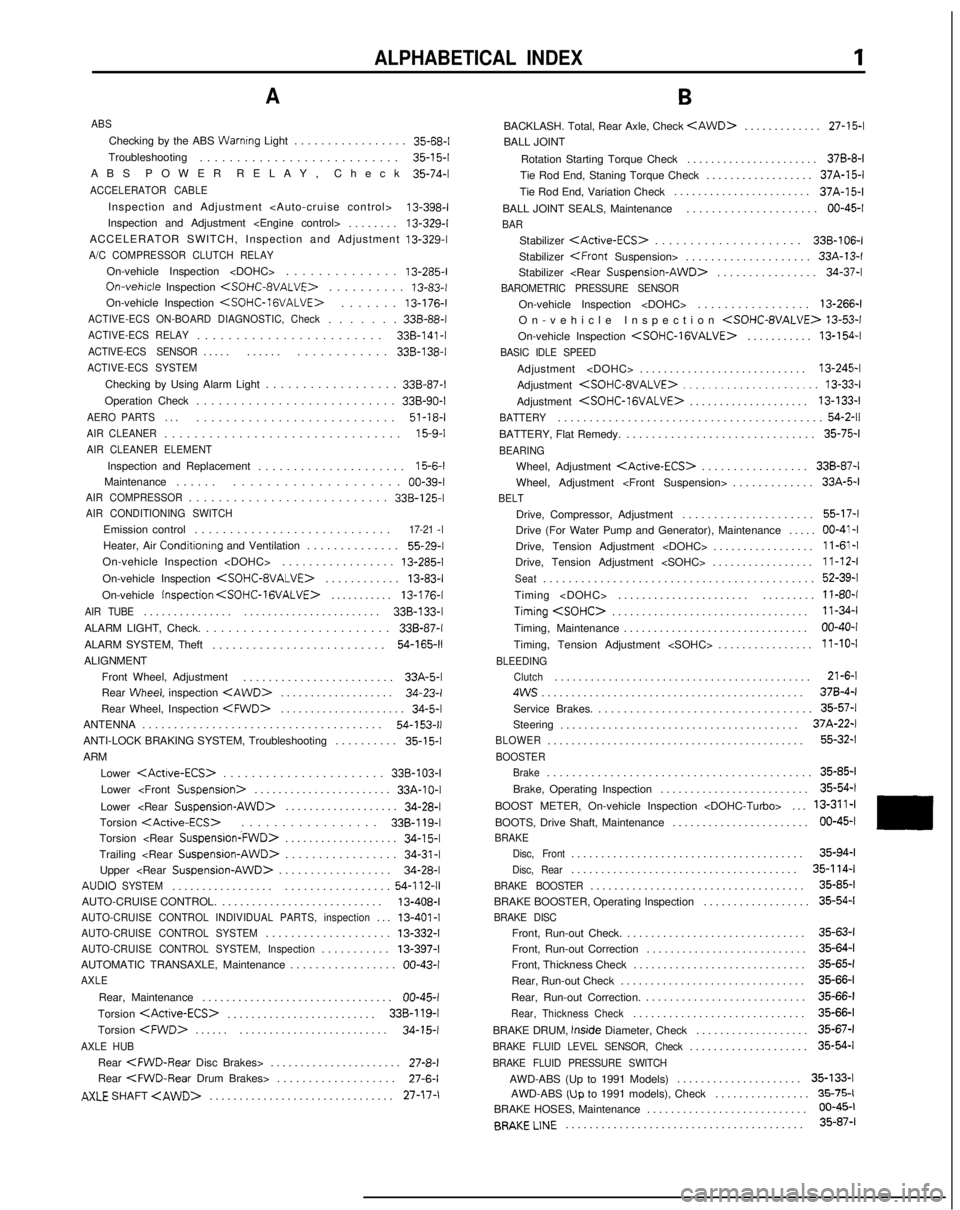

ALPHABETICAL INDEX1

A

ABS

Checking by the ABS Warnrng Light................

. 35-68-l

Troubleshooting ...........................

35-l 5-l

ABS POWER RELAY, Chec

k 35-74-l

ACCELERATOR CABLE

Inspection and Adjustment

13-398-l

Inspection and Adjustment

ACCELERATOR SWITCH, Inspection and Adjustment 13-329-I

A/C COMPRESSOR CLUTCH RELAY

On-vehicle Inspection

.............

. 13-285-l

On-vehrcle

Inspection

. 13-83-t

On-vehicle Inspection

. 13-176-l

ACTIVE-ECS ON-BOARD DIAGNOSTIC, Check......

. 338-88-I

ACTIVE-ECS RELAY.......................

. 338-141

-I

ACTIVE-ECS SENSOR....

.

...... ............ 338-138-I

ACTIVE-ECS SYSTEM

Checking by Using Alarm Light

.................

. 338-87-I

Operation Check ........................... 338-90-I

AERO PARTS..

.

........................... 51-18-l

AIR CLEANER...............................

. 15-9-I

AIR CLEANER ELEMENT

Inspection and Replacement

....................

. 15-6-l

Maintenance .......................... 00-39-l

AIR COMPRESSOR..........................

. 338-125-I

AIR CONDITIONING SWITCH

Emission control

...........................

.

17-21 -I

Heater, Air

Conditionrng

and Ventilation .............. 55-29-l

On-vehicle Inspection

On-vehicle Inspection

. 13-83-l

On-vehicle Inspection

. 13-176-l

AIR TUBE..............

.

....................... 338-133-I

ALARM LIGHT, Check. ......................... 338-87-I

ALARM SYSTEM, Theft ..........................

54-165-11

ALIGNMENT

Front Wheel, Adjustment .......................

. 33A-5-l

Rear

Wheel, inspection

. 34-23-l

Rear Wheel, Inspection

. 34-5-l

ANTENNA ......................................

54-153-11

ANTI-LOCK BRAKING SYSTEM, Troubleshooting .........

.

35-15-1

ARM

Lower

. 338-103-I

Lower

.

33A-10-I

Lower

................... 34-28-l

Torsion

.

338-l 19-l

Torsion

...................34-l 5-lTrailing

................. 34-31-l

Upper

.................. 34-28-l

AUDIO

SYSTEM................

.

.................

54-l 12-11

AUTO-CRUISE CONTROL. ..........................

. 13-408-I

AUTO-CRUISE CONTROL INDIVIDUAL PARTS, inspection..

. 13-401-I

AUTO-CRUISE CONTROL SYSTEM...................

. 13-332-l

AUTO-CRUISE CONTROL SYSTEM, Inspection..........

. 13-397-l

AUTOMATIC TRANSAXLE, Maintenance ................. 00-43-I

AXLE

Rear, Maintenance

...............................

. 00-45-I

Torsion

.

338-l 19-l

Torsion

.

......................... 34-15-l

AXLE HUB

Rear

Rear CFWD-Rear

Drum Brakes> ................... 27-6-l

AXLE SHAFT

.

27-17-1

B

BACKLASH. Total, Rear Axle, Check

. 27-15-l

BALL JOINT

Rotation Starting Torque Check ...................... 378-8-I

Tie Rod End, Staning Torque Check .................. 37A-15-l

Tie Rod End, Variation Check ....................... 37A-15-l

BALL JOINT SEALS, Maintenance ..................... 00-45-I

BAR

Stabilizer

. 338-106-I

Stabilizer

. 33A-13-l

Stabilizer

. 34-37-l

BAROMETRIC PRESSURE SENSOR

On-vehicle Inspection

................

. 13-266-l

On-vehicle Inspection

On-vehicle Inspection

. 13-154-l

BASIC IDLE SPEED

Adjustment

...........................

. 13-245-l

Adjustment

Adjustment

. 13-133-l

BATTERY.........................................

.

54-2-11

BATTERY, Flat Remedy.

.............................

. 35-75-l

BEARING

Wheel, Adjustment

. 338-87-I

Wheel, Adjustment

BELT

Drive, Compressor, Adjustment

....................

. 55-17-l

Drive (For Water Pump and Generator), Maintenance ..... 00-41-I

Drive, Tension Adjustment

Drive, Tension Adjustment

Seat..........................................

. 52-39-l

Timing

Timing

. 11-34-l

Timing, Maintenance ............................... 00-40-I

Timing, Tension Adjustment

BLEEDING

Clutch

..........................................

. 21-6-l

4ws...........................................

. 370-4-I

Service Brakes. .................................. 35-57-l

Steering ........................................ 37A-22-l

BLOWER..........................................

. 55-32-l

BOOSTER

Brake

.........................................

. 35-85-l

Brake, Operating Inspection ......................... 35-54-l

BOOST METER, On-vehicle Inspection

BOOTS, Drive Shaft, Maintenance ....................... 00-45-I

BRAKE

Disc, Front

......................................

. 35-94-l

Disc, Rear.....................................

.

35-l 14-l

BRAKE BOOSTER

...................................

. 35-85-l

BRAKE BOOSTER, Operating Inspection .................. 35-54-l

BRAKE DISC

Front, Run-out Check.

.............................

. 35-63-l

Front, Run-out Correction ........................... 35-64-l

Front, Thickness Check ............................. 35-65-l

Rear, Run-out Check ............................... 35-66-l

Rear, Run-out Correction. ........................... 35-66-l

Rear, Thickness Check............................

. 35-66-l

BRAKE DRUM, tnside

Diameter, Check ................... 35-67-l

BRAKE FLUID LEVEL SENSOR, Check...................

. 35-54-l

BRAKE FLUID PRESSURE SWITCH

AWD-ABS (Up to 1991 Models)

....................

.

35-133-l

AWD-ABS

(Up to 1991 models), Check ...............

. 35-75-l

BRAKE HOSES, Maintenance ........................... 06-45-t

BRAKELINE

........................................

35-87-l

Page 1271 of 1273