height adjustment MITSUBISHI GALANT 1989 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 253 of 1273

FUEL SYSTEM

03R0297

Vapor hose

mmin.)Fillerhose

i2.l

B

3FOO7

A

1

Flare nut

Skure side

03Yo43

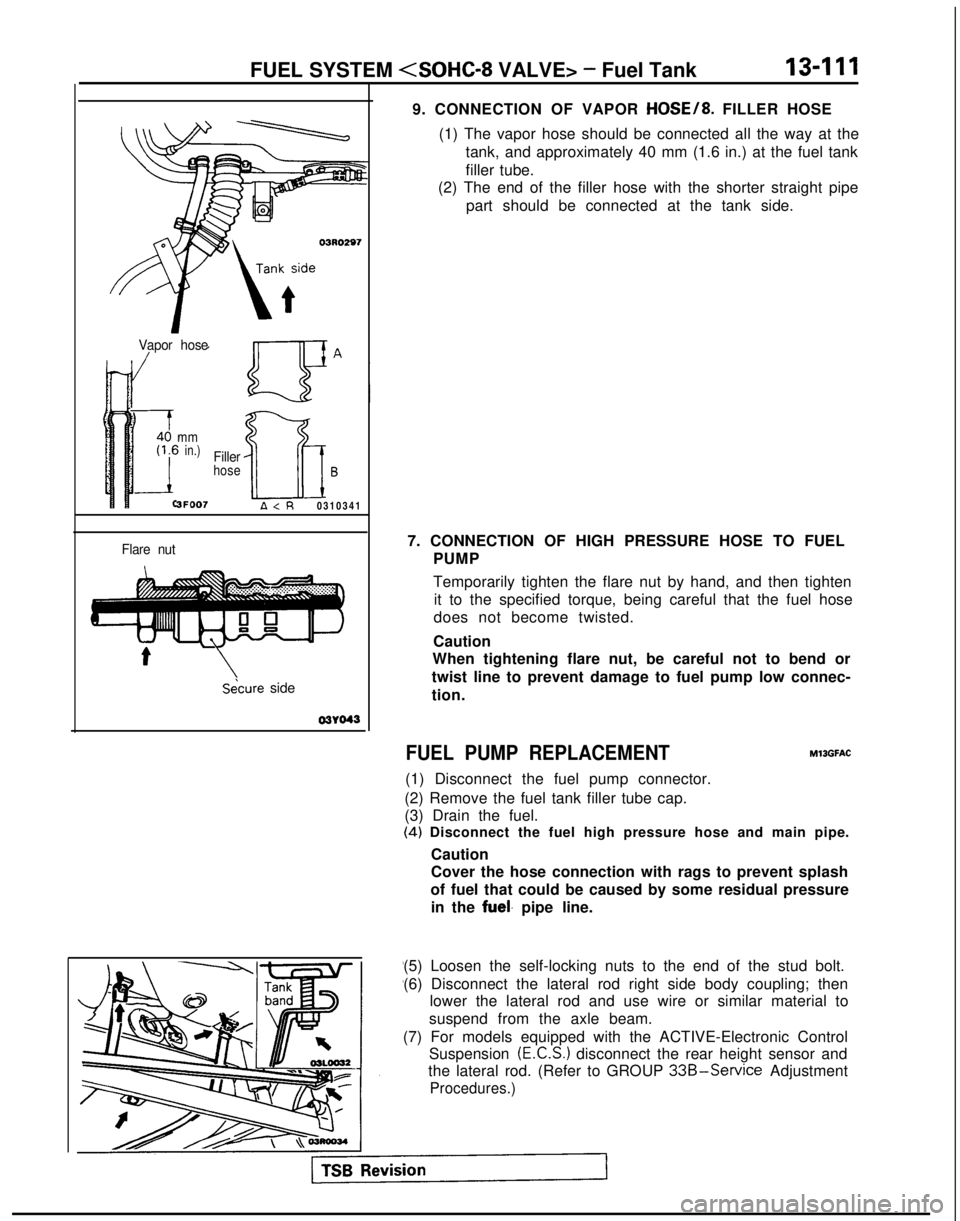

9. CONNECTION OF VAPOR HOSE/8. FILLER HOSE

(1) The vapor hose should be connected all the way at the tank, and approximately 40 mm (1.6 in.) at the fuel tank

filler tube.

(2) The end of the filler hose with the shorter straight pipe

part should be connected at the tank side.

7. CONNECTION OF HIGH PRESSURE HOSE TO FUEL PUMP

Temporarily tighten the flare nut by hand, and then tightenit to the specified torque, being careful that the fuel hose

does not become twisted.

Caution

When tightening flare nut, be careful not to bend or

twist line to prevent damage to fuel pump low connec-

tion.

FUEL PUMP REPLACEMENT

(1) Disconnect the fuel pump connector.

(2) Remove the fuel tank filler tube cap.

(3) Drain the fuel. MllGFAC

(4)

Disconnect the fuel high pressure hose and main pipe.

Caution

Cover the hose connection with rags to prevent splash

of fuel that could be caused by some residual pressure in the

fuel. pipe line.

(5) Loosen the self-locking nuts to the end of the stud bolt.

(6) Disconnect the lateral rod right side body coupling; then lower the lateral rod and use wire or similar material to

suspend from the axle beam.

(7) For models equipped with the ACTIVE-Electronic Control Suspension

(E.C.S.) disconnect the rear height sensor and

the lateral rod. (Refer to GROUP

33B-Service Adjustment

Procedures.)

Page 254 of 1273

13-112FUEL SYSTEM

03L0018

QcD ua .

CFa

cc

0c aa0u0aa

Positioning projection

03L0009

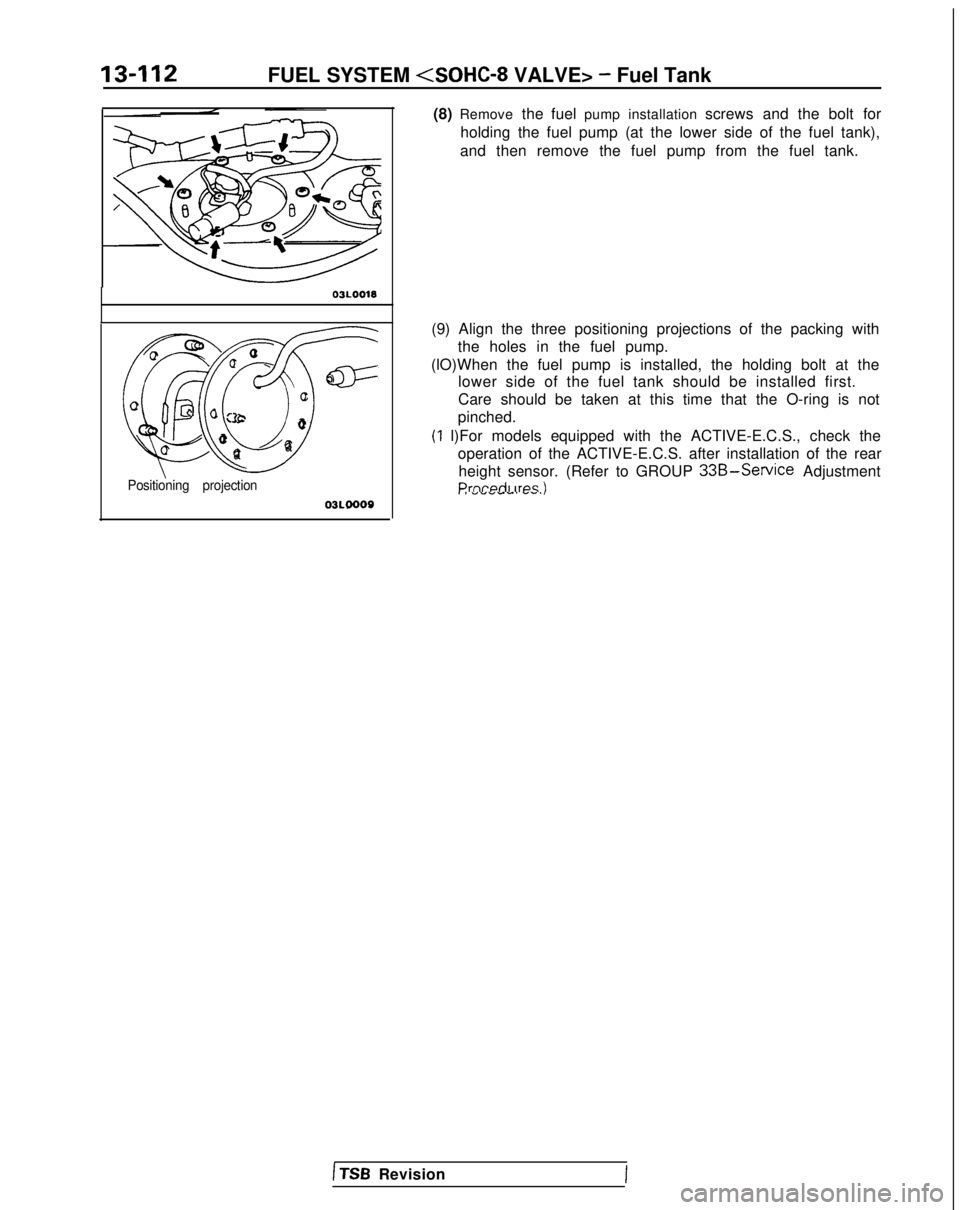

(8) Remove

the fuel pump installation screws and the bolt for

holding the fuel pump (at the lower side of the fuel tank),

and then remove the fuel pump from the fuel tank.

(9) Align the three positioning projections of the packing with the holes in the fuel pump.

(lO)When the fuel pump is installed, the holding bolt at the lower side of the fuel tank should be installed first.

Care should be taken at this time that the O-ring is not

pinched.

(1 l)For models equipped with the ACTIVE-E.C.S., check the operation of the ACTIVE-E.C.S. after installation of the rearheight sensor. (Refer to GROUP

33B-Service AdjustmentPrnrwiI irps II I ““VW-. W.S.,

1 TSB Revision

Page 462 of 1273

13-320FUEL SYSTEM

03RO297

V/apor hose

mmin.)

3FOO7

Filler

hoseB

A

\Secure side 03YO43

Ll

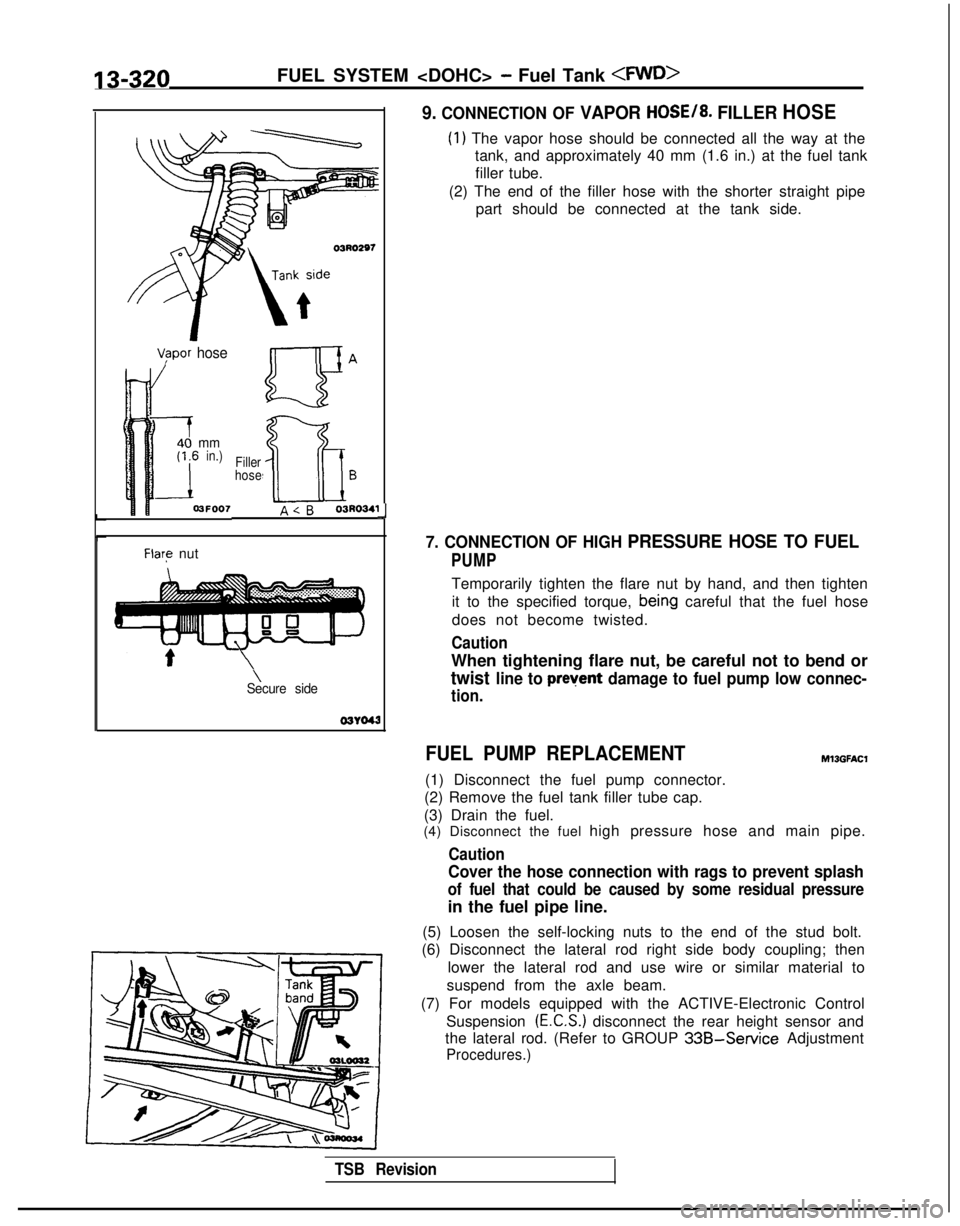

9. CONNECTION OF VAPOR HOSE/8. FILLER HOSE

(1) The vapor hose should be connected all the way at the

tank, and approximately 40 mm (1.6 in.) at the fuel tank

filler tube.

(2) The end of the filler hose with the shorter straight pipe part should be connected at the tank side.

7. CONNECTION OF HIGH PRESSURE HOSE TO FUEL

PUMP

Temporarily tighten the flare nut by hand, and then tighten

it to the specified torque,

bein,g careful that the fuel hose

does not become twisted.

Caution

When tightening flare nut, be careful not to bend or

twist line to prevent damage to fuel pump low connec-

tion.

FUEL PUMP REPLACEMENT

(1) Disconnect the fuel pump connector.

(2) Remove the fuel tank filler tube cap.

(3) Drain the fuel.

Ml3GFAt.X

(4) Disconnect the fuel high pressure hose and main pipe.

Caution

Cover the hose connection with rags to prevent splash

of fuel that could be caused by some residual pressure

in the fuel pipe line.

(5) Loosen the self-locking nuts to the end of the stud bolt.

(6) Disconnect the lateral rod right side body coupling; then

lower the lateral rod and use wire or similar material to

suspend from the axle beam.

(7) For models equipped with the ACTIVE-Electronic Control Suspension

(E.C.S.) disconnect the rear height sensor and

the lateral rod. (Refer to GROUP

33B-Service Adjustment

Procedures.)

TSB Revision

Page 463 of 1273

FUEL SYSTEM

I03LOO18

-

QGB ua \

a=

C-CT

0a

c oc3i20’0Qaa

Positidning projection

03L0000

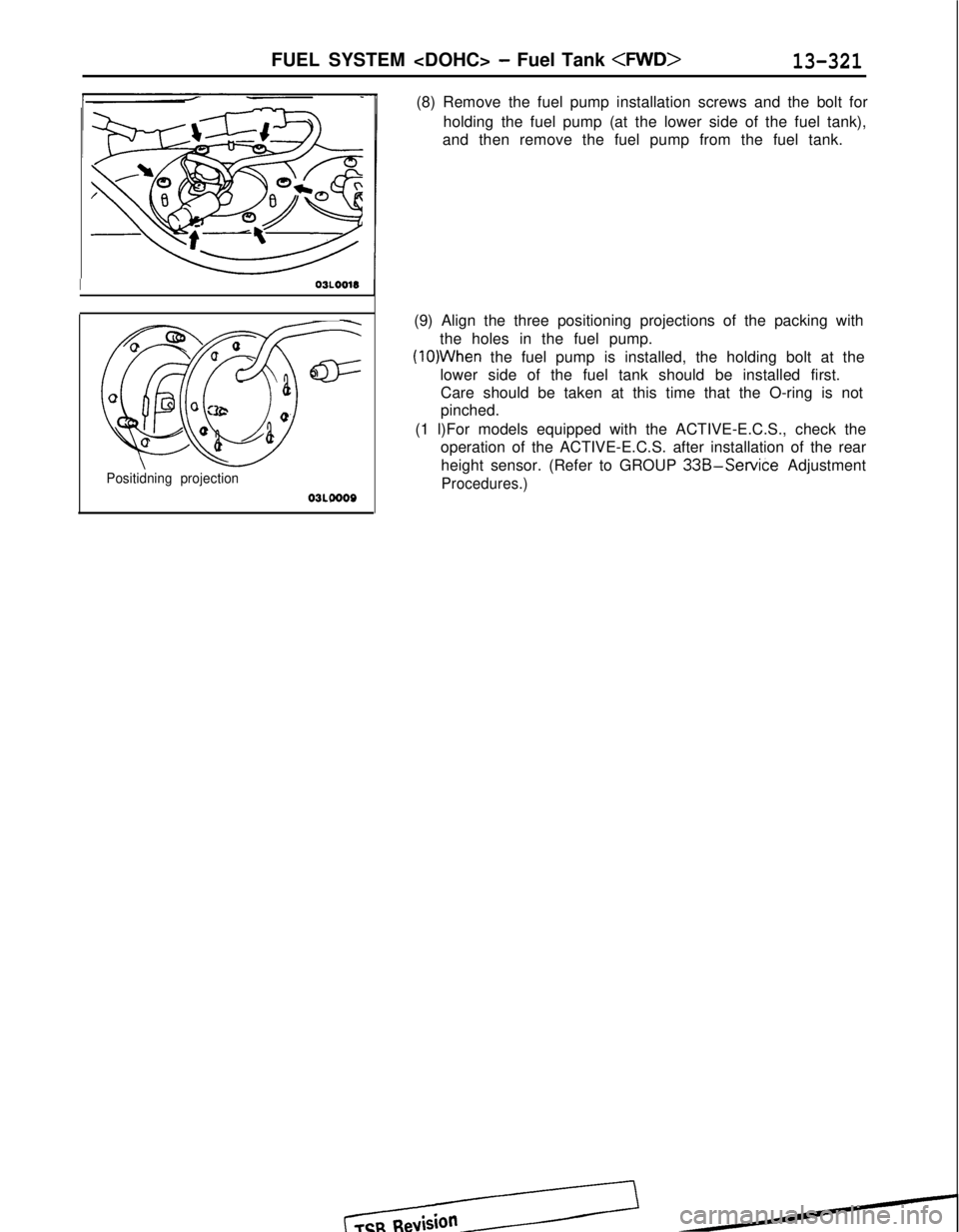

(8) Remove the fuel pump installation screws and the bolt for

holding the fuel pump (at the lower side of the fuel tank),

and then remove the fuel pump from the fuel tank.

(9) Align the three positioning projections of the packing with the holes in the fuel pump.

(lO)When the fuel pump is installed, the holding bolt at the

lower side of the fuel tank should be installed first. Care should be taken at this time that the O-ring is not

pinched.

(1 l)For models equipped with the ACTIVE-E.C.S., check the operation of the ACTIVE-E.C.S. after installation of the rear

height sensor. (Refer to GROUP

33B-Service Adjustment

Procedures.)

Page 655 of 1273

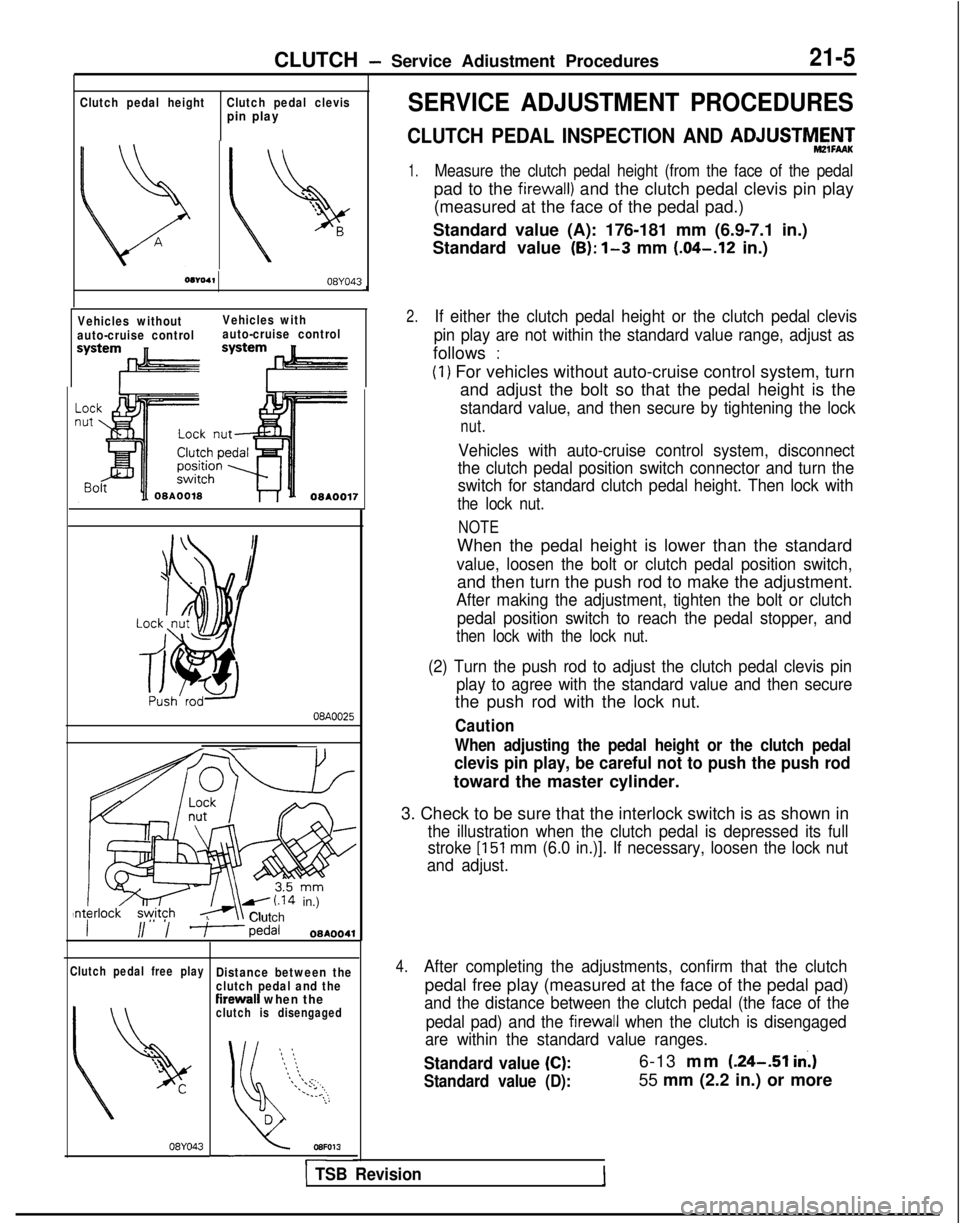

CLUTCH - Service Adiustment Procedures21-5

Clutch pedal height

Clutch pedal clevispin play

08104,08YO43

Vehicles without

auto-cruise control Vehicles with

auto-cruise control

08A0025

IL\\A- i.14

in.)Nnt,erlock s.y,ityh ,

Clutch

II/ / ?--pedal08AOO41

Clutch pedal free play

08YO43

Distance between the

clutch pedal and the

firewall when theclutch is disengaged

‘5 :: :

*\\\ ;.,

\.

.-‘.* ..,.--. . .:,

eir-

.;

D

l3sFO13

SERVICE ADJUSTMENT PROCEDURES

CLUTCH PEDAL INSPECTION AND ADJUSTM&‘+d+d

1.Measure the clutch pedal height (from the face of the pedal

pad to the firewall) and the clutch pedal clevis pin play

(measured at the face of the pedal pad.)

Standard value (A): 176-181 mm (6.9-7.1 in.)

Standard value

(B): l-3 mm (.04-.12

in.)

2.If either the clutch pedal height or the clutch pedal clevis

pin play are not within the standard value range, adjust as

follows :

(1) For vehicles without auto-cruise control system, turn and adjust the bolt so that the pedal height is the

standard value, and then secure by tightening the lock

nut.

Vehicles with auto-cruise control system, disconnect

the clutch pedal position switch connector and turn the

switch for standard clutch pedal height. Then lock with

the lock nut.

NOTE

When the pedal height is lower than the standard

value, loosen the bolt or clutch pedal position switch,

and then turn the push rod to make the adjustment.

After making the adjustment, tighten the bolt or clutch

pedal position switch to reach the pedal stopper, and

then lock with the lock nut.

(2) Turn the push rod to adjust the clutch pedal clevis pin play to agree with the standard value and then secure

the push rod with the lock nut.

Caution

When adjusting the pedal height or the clutch pedal

clevis pin play, be careful not to push the push rod

toward the master cylinder.

3. Check to be sure that the interlock switch is as shown in

the illustration when the clutch pedal is depressed its full

stroke

[I51 mm (6.0 in.)]. If necessary, loosen the lock nut

and adjust.

4.After completing the adjustments, confirm that the clutch

pedal free play (measured at the face of the pedal pad)

and the distance between the clutch pedal (the face of the

pedal pad) and the

firewall when the clutch is disengaged

are within the standard value ranges.

Standard value (C):6-13 mm (.24--51 in.)

Standard value (D):55 mm (2.2 in.) or more

1 TSB Revision

Page 889 of 1273

REAR AXLE

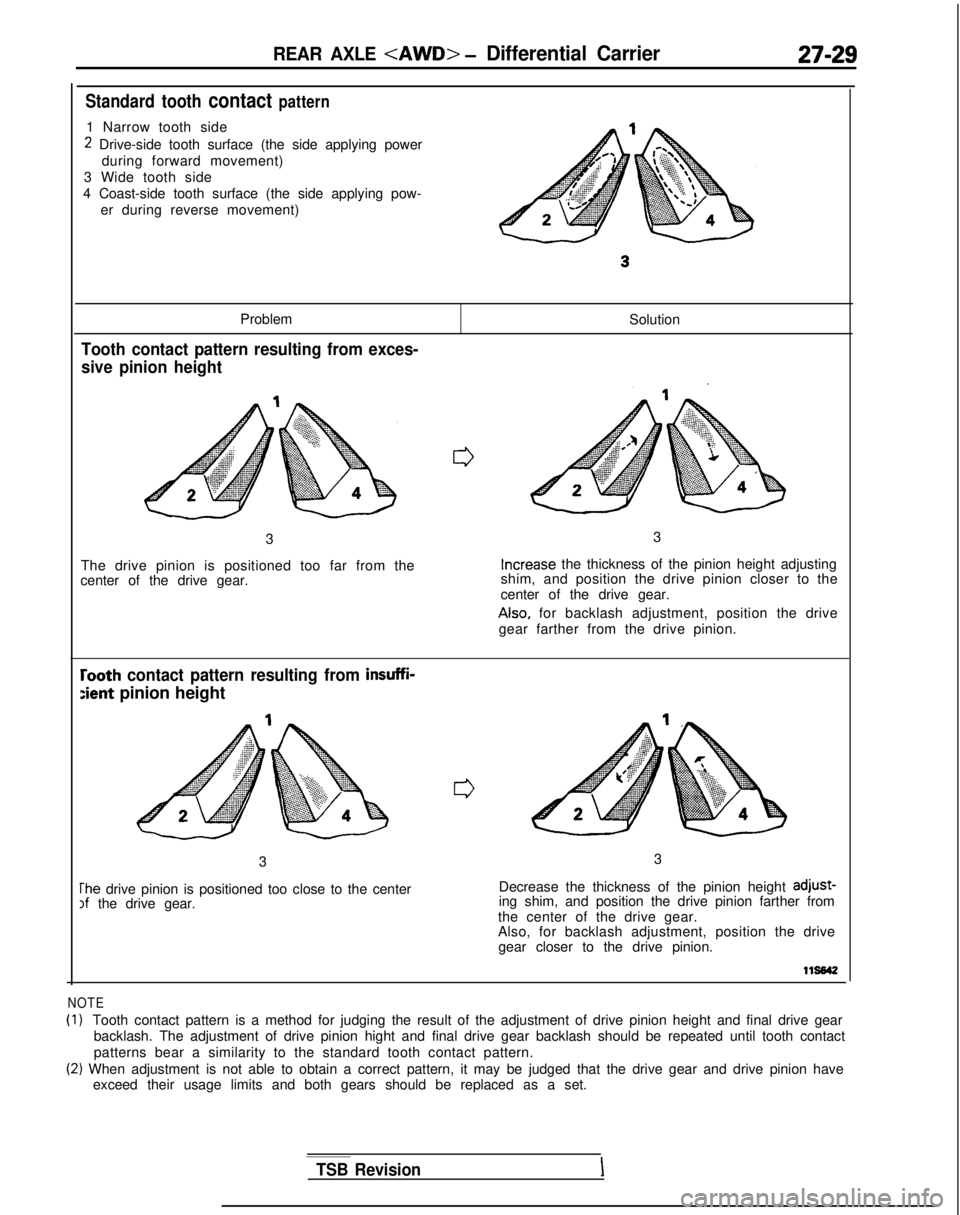

Standard tooth contact pattern

1 Narrow tooth side

2 Drive-side tooth surface (the side applying powerduring forward movement)

3 Wide tooth side

4 Coast-side tooth surface (the side applying pow- er during reverse movement)

Problem

Tooth contact pattern resulting from exces-

sive pinion height

Solution

3

The drive pinion is positioned too far from the

center of the drive gear. 3Increase

the thickness of the pinion height adjusting

shim, and position the drive pinion closer to the

center of the drive gear. Also,

for backlash adjustment, position the drive

gear farther from the drive pinion.

rooth contact pattern resulting from insuffi-

:ient pinion height

3

The drive pinion is positioned too close to the centerIf the drive gear. 3

Decrease the thickness of the pinion height adjust-

ing shim, and position the drive pinion farther from

the center of the drive gear.

Also, for backlash adjustment, position the drive gear closer to the drive pinion.

lls642

NOTE

(1)Tooth contact pattern is a method for judging the result of the adjustme\

nt of drive pinion height and final drive gear

backlash. The adjustment of drive pinion hight and final drive gear back\

lash should be repeated until tooth contact

patterns bear a similarity to the standard tooth contact pattern.

(2) When adjustment is not able to obtain a correct pattern, it may be judg\

ed that the drive gear and drive pinion have exceed their usage limits and both gears should be replaced as a set.

TSB RevisionI

Page 890 of 1273

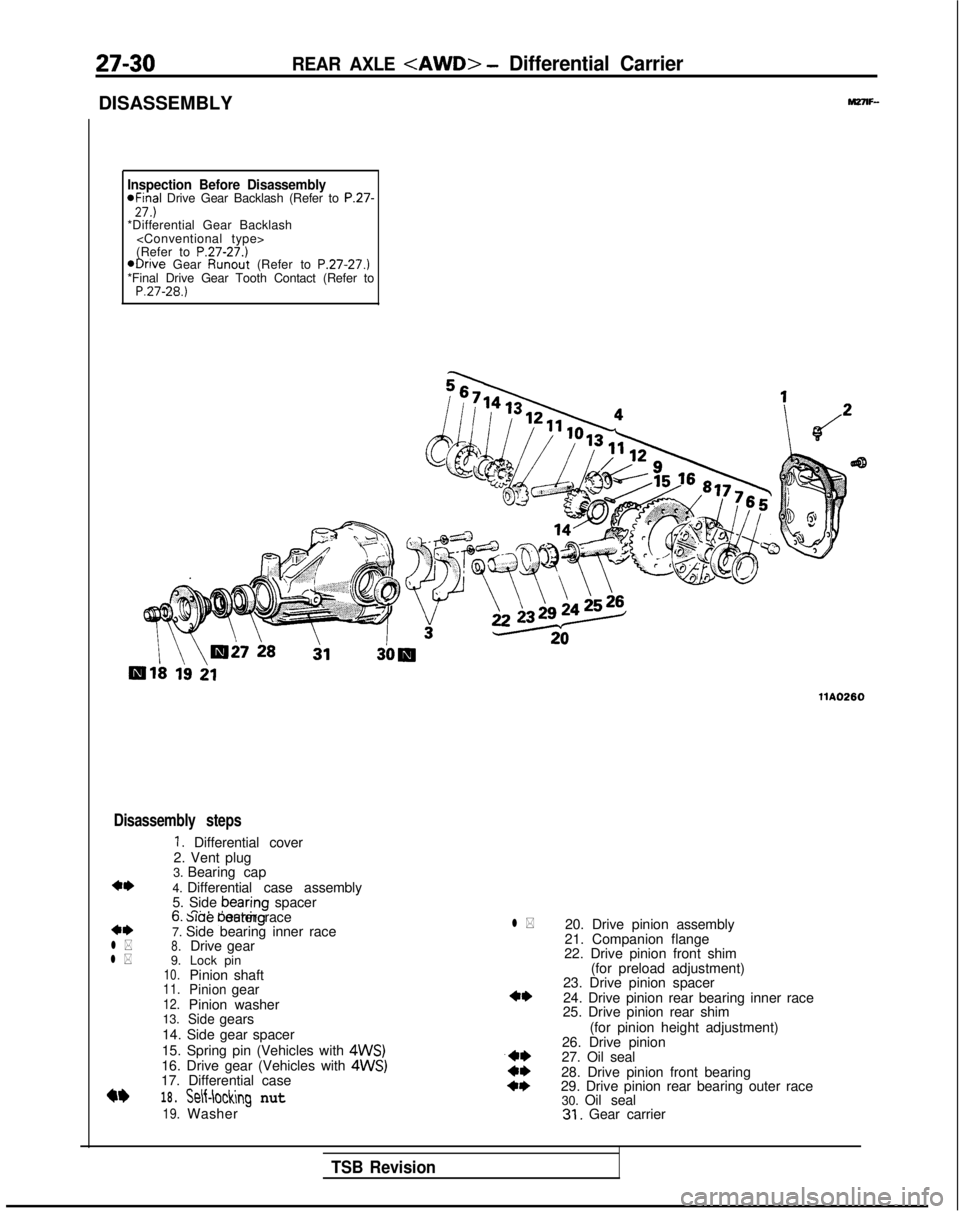

27-30

DISASSEMBLY

REAR AXLE

Inspection Before Disassembly*Final Drive Gear Backlash (Refer to P.27-27.)*Differential Gear Backlash

(Refer to

P.27-27.)@Drive Gear Runout

(Refer to P.27-27.)

*Final Drive Gear Tooth Contact (Refer to

P.27-28.)

llA0260

Disassembly steps

1. Differential cover

2. Vent plug

**l *

l *

3. Bearing cap

4. Differential case assembly

5. Side bearing

spacer

n n.* I0. slae oeanng outer race

7. Side bearing inner race

8.Drive

9. gear

10.Lock pin

Pinion shaft

11.Pinion12.gear

Pinion washer

13.

Sidegears

14. Side gear spacer

15. Spring pin (Vehicles with

4WS)16. Drive gear (Vehicles with 4WS)17. Differential case

18.

19.

Self-loclhg nut

Washer

l *20. Drive pinion assembly

21. Companion flange

22. Drive pinion front shim

(for preload adjustment)

23. Drive pinion spacer

24. Drive pinion rear bearing inner race

25. Drive pinion rear shim

(for pinion height adjustment)

26. Drive pinion

27. Oil seal

28. Drive pinion front bearing

29. Drive pinion rear bearing outer race 30. Oil seal

31. Gear carrier

TSB Revision

Page 893 of 1273

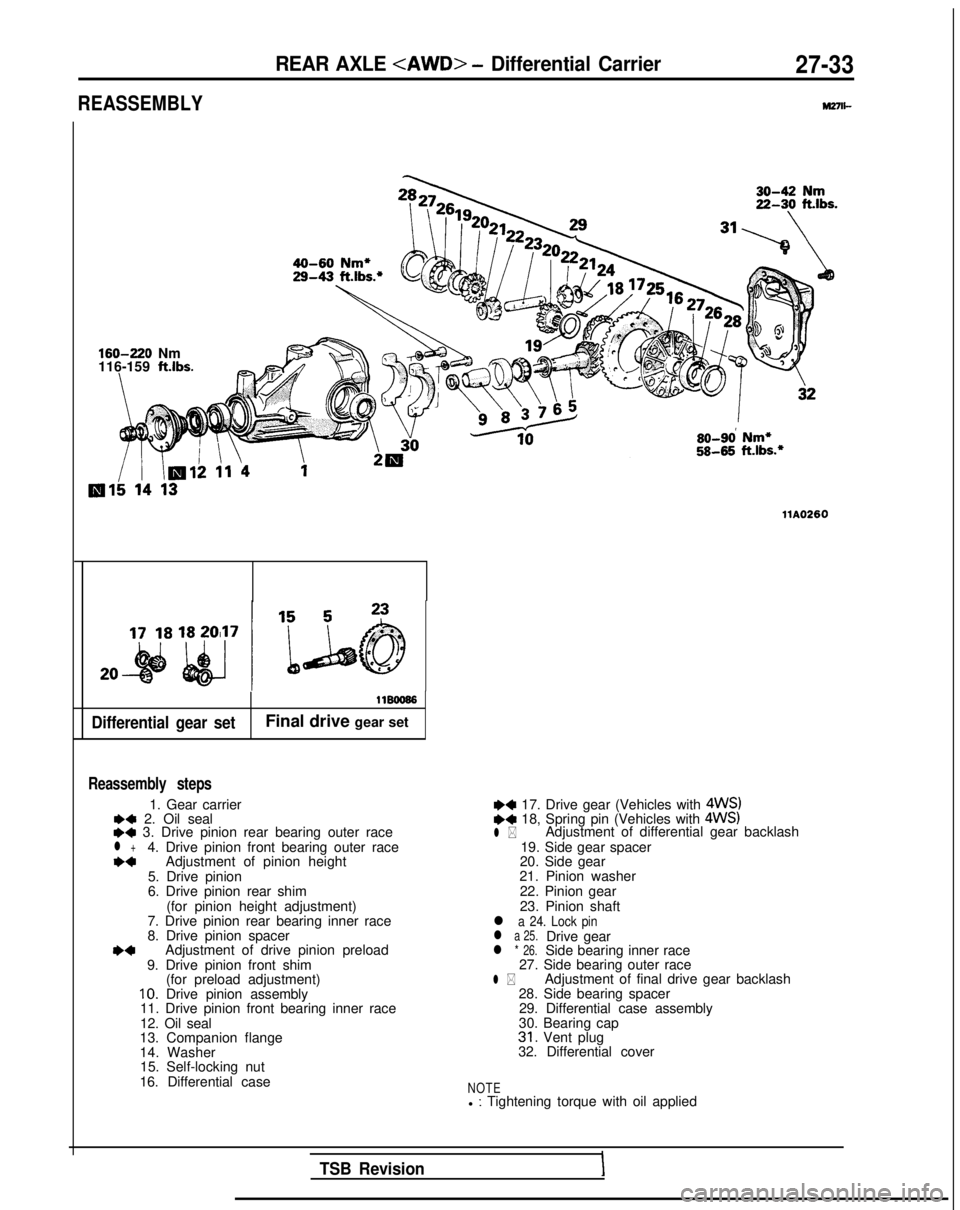

REASSEMBLY

REAR AXLE

M27n-

160-220

Nm

116-159

ft.lbs.

Differential gear set

11BOO66

Final drive gear set

Reassembly steps

1. Gear carrier*a 2. Oil seal++ 3. Drive pinion rear bearing outer racel +4. Drive pinion front bearing outer race*aAdjustment of pinion height

5. Drive pinion

6. Drive pinion rear shim (for pinion height adjustment)

7. Drive pinion rear bearing inner race

8. Drive pinion spacer

*aAdjustment of drive pinion preload

9. Drive pinion front shim (for preload adjustment)

10. Drive pinion assembly

11. Drive pinion front bearing inner race

12. Oil seal

13. Companion flange

14. Washer 15. Self-locking nut

16. Differential case so-9d

Nm*

5845

ft.lbs.*

llA0260

~~ 17. Drive gear (Vehicles with 4WS)e+ 18, Spring pin (Vehicles with 4WS)l *Adjustment of differential gear backlash

19. Side gear spacer

20. Side gear

21. Pinion washer

22. Pinion gear

23. Pinion shaft

l a 24. Lock pinl a 25.Drive gearl * 26.Side bearing inner race

27. Side bearing outer race

l *Adjustment of final drive gear backlash

28. Side bearing spacer 29. Differential case assembly

30. Bearing cap

31. Vent plug

32. Differential cover

NOTEl : Tightening torque with oil applied

TSB RevisionI

Page 895 of 1273

REAR AXLE

IllK610

90938-o 1

llY181

llY182

MB990905-4-C

MIT216335

MIT216336

MB990905-2-01

u-

MB990905l-01

llW616

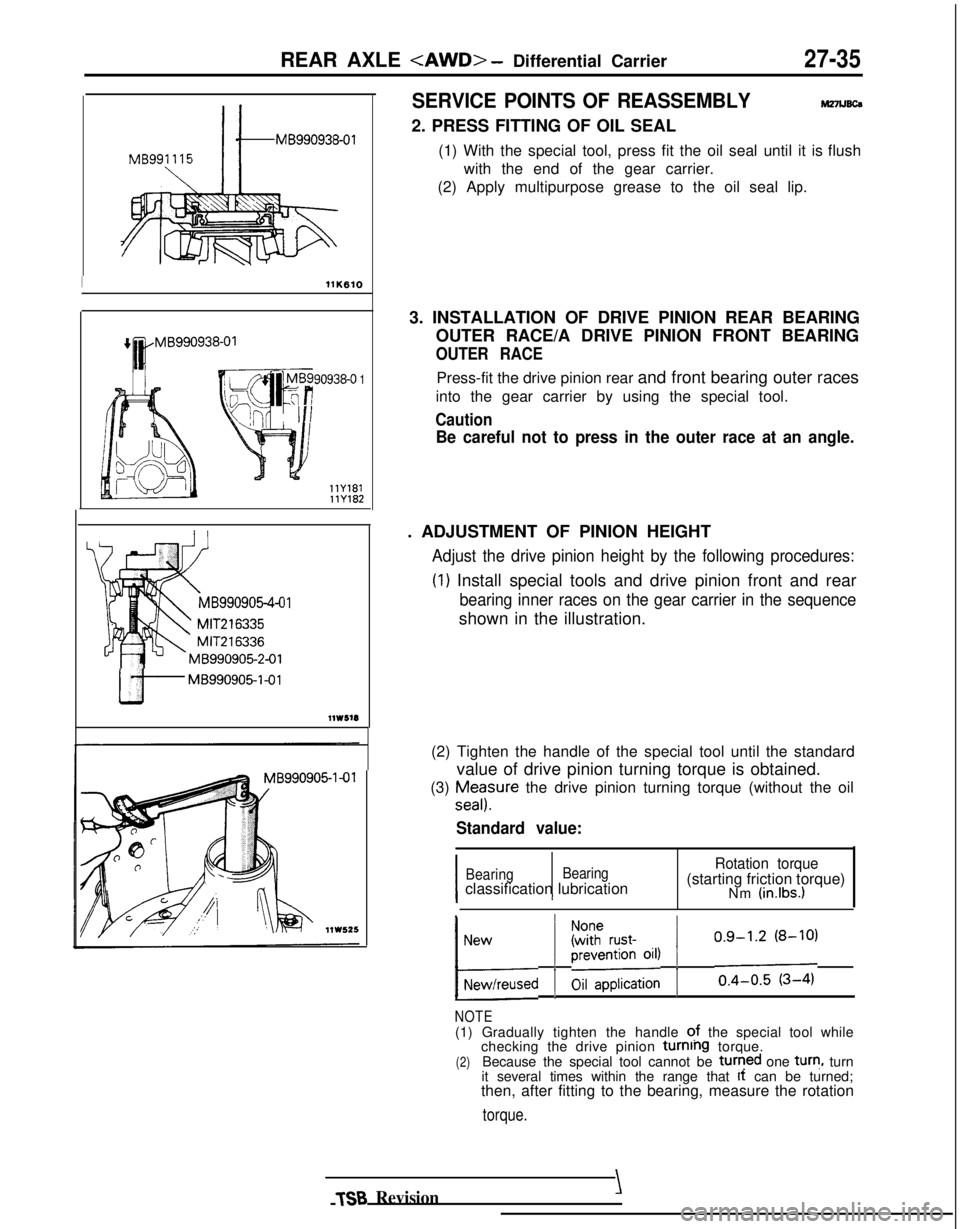

SERVICE POINTS OF REASSEMBLYM27lJ6c6

2. PRESS FITTING OF OIL SEAL

(1) With the special tool, press fit the oil seal until it iswith the end of the gear carrier.

(2) Apply multipurpose grease to the oil seal lip. flush

3. INSTALLATION OF DRIVE PINION REAR BEARING OUTER RACE/A DRIVE PINION FRONT BEARING

OUTER RACE

Press-fit the drive pinion rear and front bearing outer races

into the gear carrier by using the special tool.

Caution

Be careful not to press in the outer race at an angle.

. ADJUSTMENT OF PINION HEIGHT

Adjust the drive pinion height by the following procedures: (I)

Install special tools and drive pinion front and rear

bearing inner races on the gear carrier in the sequence

shown in the illustration.

(2) Tighten the handle of the special tool until the standard value of drive pinion turning torque is obtained.

(3)

Ea;sure the drive pinion turning torque (without the oil

Standard value:

I I

Bearing BearingRotation torque

classification lubrication (starting friction torque)

Nm (in.lbs.)

I,;,r,used 1 EJi!x%;; 1/;;;;y;-;

NOTE(1) Gradually tighten the handle ?f the special tool while

checking the drive pinion turning torque.(2)Because the special tool cannot be turqed one tur?,

turn

it several times within the range that It

can be turned;

then, after fitting to the bearing, measure the rotation

torque.

TSB Revision\

Page 940 of 1273

339-l

ACTIVE-ELECTRONIC

CONTROL

SUSPENSION

ACTIVE-ECS RELAY......................................141

ACTIVE-ECSSENSOR.................................. 138

AIRCOMPRESSOR.......................................125

AIR TUBE.......................................................133

CONTROLUNIT............................................ 140

HEIGHT SENSOR ..........................................

135

INDICATORASSEMBLY............................... 140

LATERALROD...............................................117

LOWER

ARM.................................................103

REAR

SUSPENSION ASSEMBLY................114

RESERVETANK............................................ 122

SERVICE ADJUSTMENT PROCEDURES.....86

Alarm Light Check.....................................87

Checking by On-board Diagnostic ..............88

FrontWheelAlignment .............................. 86

G sensor Output Voltage Check ...............96

High-pressure Switch

(High-pressure Tank Side)

Actuation Pressure Check

.......................... 94

Hub End Play Inspection ...........................86 M33AA-

Low-pressure Switch

(Low-pressure Tank Side)

Actuation

PressureCheck . . . . . . . . . . . . . . . . . . . . . . . . .95

Normal Vehicle Height Check and

Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . . . . . . . .88

Rolling Diaphragm Check . . . . . . . . . . .._.............. 89

System Checking by Using Alarm

Light

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . . . . .87

System OperationCheck . . . . . . . . . . . . . . . . . . . . . . . . . . .90

Wheel Bearing Adjustment . . . . . . . . . .

.._........... 87

SHOCKABSORBER ASSEMBLY. . . . . . . . . . . . . . . . .110

SOLENOIDVALVEANDDRYER . . . . . . . . . . . . . . . . .127

SPECIAL TOOLS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . .7

SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . .2

GeneralSpecifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

ServiceSpecifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . .3

TorqueSpecifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

STABILIZER BAR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . .106

STRUT ASSEMBLY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . .97

TORSION AXLE AND ARM

ASSEMBLY. . . . . . . . ..*.........................................119,

TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10