belt MITSUBISHI LANCER 2005 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 105 of 788

IGNITION SYSTEM

ENGINE ELECTRICAL16-41

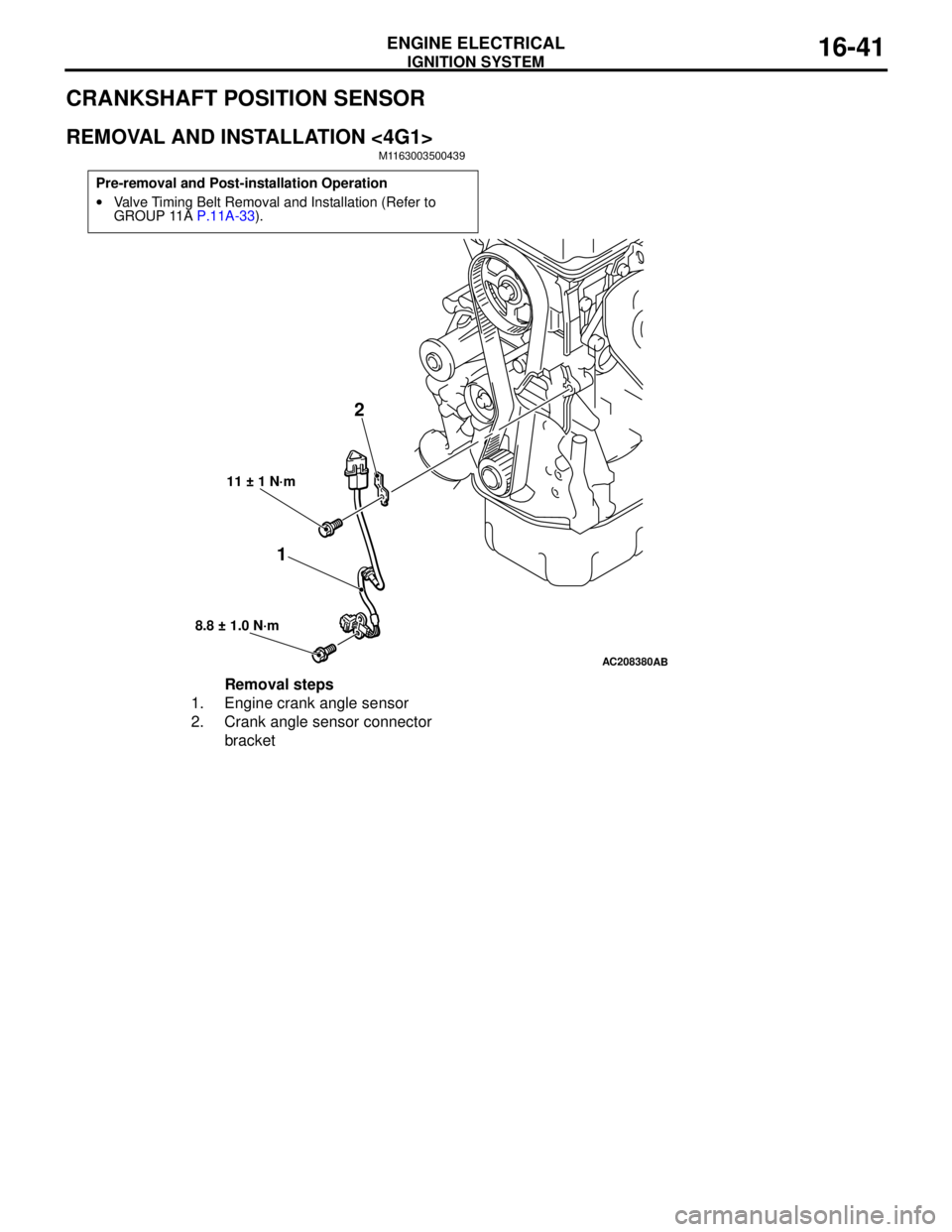

CRANKSHAFT POSITION SENSOR

REMOVAL AND INSTALLATION <4G1>

M1163003500439

Pre-removal and Post-installation Operation

•Valve Timing Belt Removal and Installation (Refer to

GROUP 11A P.11A-33).

AC208380AB

12

11 ± 1 N·m

8.8 ± 1.0 N·m

Removal steps

1. Engine crank angle sensor

2. Crank angle sensor connector

bracket

Page 106 of 788

IGNITION SYSTEM

ENGINE ELECTRICAL16-42

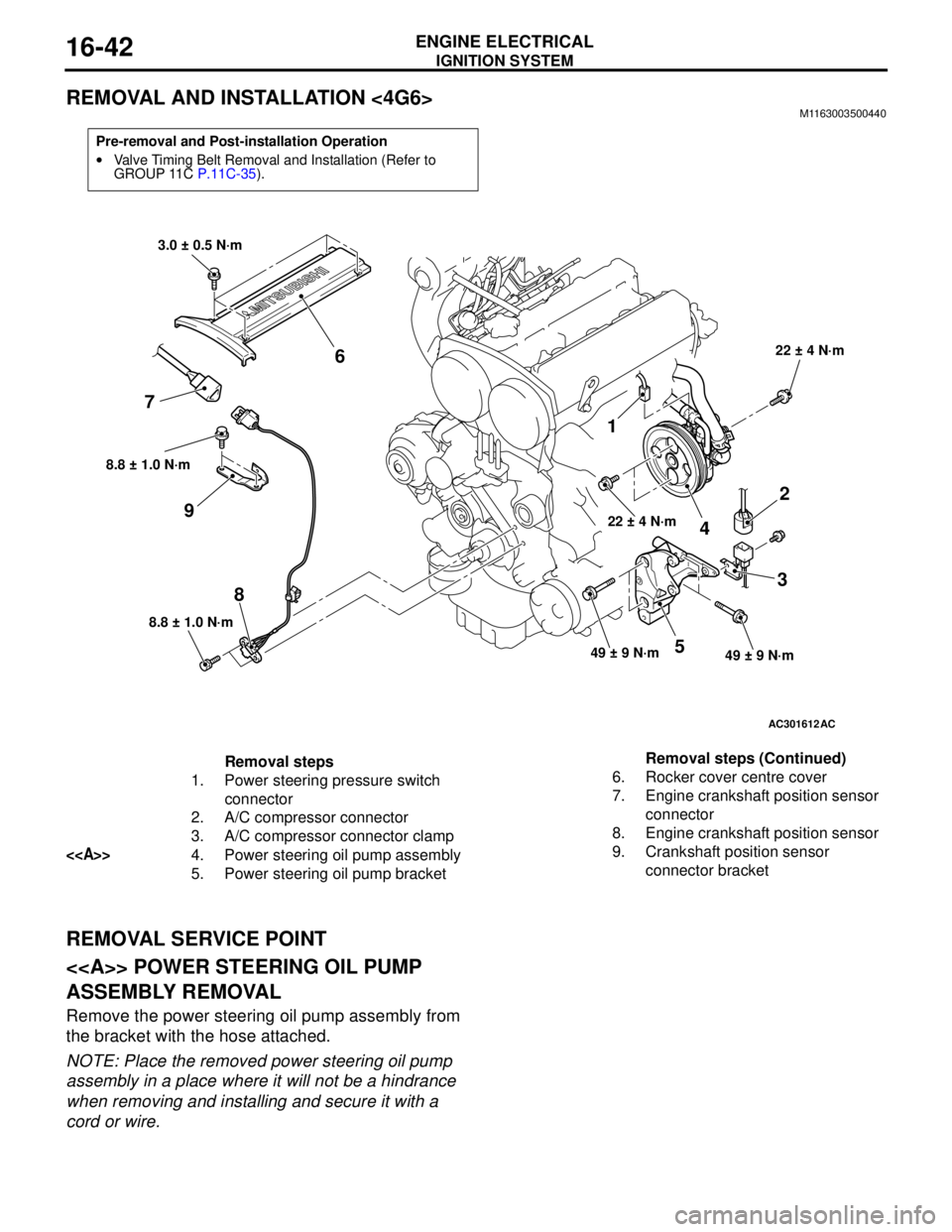

REMOVAL AND INSTALLATION <4G6>M1163003500440

REMOVAL SERVICE POINT

<> POWER STEERING OIL PUMP

ASSEMBLY REMOVAL

Remove the power steering oil pump assembly from

the bracket with the hose attached.

NOTE: Place the removed power steering oil pump

assembly in a place where it will not be a hindrance

when removing and installing and secure it with a

cord or wire.

Pre-removal and Post-installation Operation

•Valve Timing Belt Removal and Installation (Refer to

GROUP 11C P.11C-35).

AC301612

8.8 ± 1.0 N·m

8

8.8 ± 1.0 N·m

9

1

22 ± 4 N·m

4

2

3

49 ± 9 N·m49 ± 9 N·m5

22 ± 4 N·m

3.0 ± 0.5 N·m

6

7

AC

Removal steps

1. Power steering pressure switch

connector

2. A/C compressor connector

3. A/C compressor connector clamp

<>4. Power steering oil pump assembly

5. Power steering oil pump bracket6. Rocker cover centre cover

7. Engine crankshaft position sensor

connector

8. Engine crankshaft position sensor

9. Crankshaft position sensor

connector bracket Removal steps (Continued)

Page 235 of 788

37-1

GROUP 37

POWER STEERING

CONTENTS

GENERAL INFORMATION . . . . . . . .37-3

SERVICE SPECIFICATIONS . . . . . . .37-6

LUBRICANTS . . . . . . . . . . . . . . . . . .37-7

SEALANTS . . . . . . . . . . . . . . . . . . . .37-7

SPECIAL TOOLS . . . . . . . . . . . . . . . .37-8

ON-VEHICLE SERVICE . . . . . . . . . . .37-11

STEERING WHEEL FREE PLAY

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37-11

STEERING ANGLE CHECK . . . . . . . . . . . . 37-11

TIE ROD END BALL JOINT TURNING

TORQUE CHECK . . . . . . . . . . . . . . . . . . . . 37-12

STATIONARY STEERING EFFORT

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37-12

STEERING WHEEL RETURN TO

CENTRE CHECK . . . . . . . . . . . . . . . . . . . . 37-13DRIVE BELT TENSION CHECK . . . . . . . . . 37-13

FLUID LEVEL CHECK . . . . . . . . . . . . . . . . 37-13

FLUID REPLACEMENT . . . . . . . . . . . . . . . 37-13

POWER STEERING SYSTEM AIR

BLEEDING . . . . . . . . . . . . . . . . . . . . . . . . . 37-13

OIL PUMP PRESSURE TEST . . . . . . . . . . 37-14

POWER STEERING PRESSURE

SWITCH CHECK . . . . . . . . . . . . . . . . . . . . . 37-15

TIE ROD END BALL JOINT DUST COVER

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37-15

STEERING COLUMN SHAFT

ASSEMBLY SHOCK ABSORBING

MECHANISM CHECK . . . . . . . . . . . . . . . . . 37-15

STEERING WHEEL* . . . . . . . . . . . . . .37-17

REMOVAL AND INSTALLATION

REMOVAL AND INSTALLATION

Continued on next page

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING

•Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to

personal injury or death to service personnel (from inadvertent firing of the air bag) or to the driver and

paassenger (from rendering the SRS inoperative).

•Service or maintenance of any SRS component or SRS-related component must be performed only at an

authorized MITSUBISHI dealer.

•MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B - Supplemental

Restraint System (SRS) before beginning any service or maintenance of any component of the SRS or any

SRS-related component.

NOTE

The SRS includes the following components: SRS air bag control unit, SRS warning light, front impact sensors, air bag module,

clock spring, and interconnecting wiring. Other SRS-related components (that may have to be removed/installed in connection

with SRS service or maintenance) are indicated in the table of contents by an asterisk (*).

Page 247 of 788

ON-VEHICLE SERVICE

POWER STEERING37-13

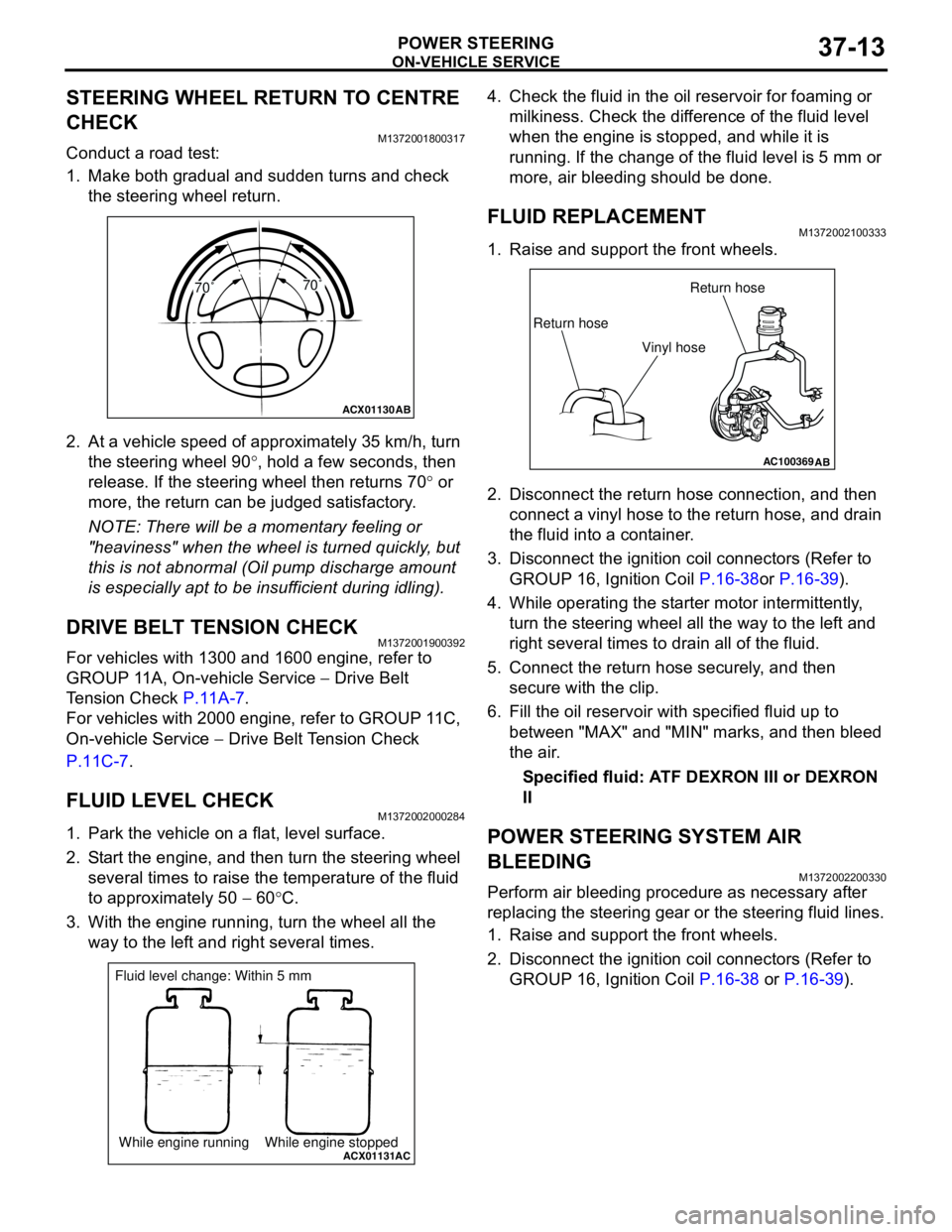

STEERING WHEEL RETURN TO CENTRE

CHECK

M1372001800317

Conduct a road test:

1. Make both gradual and sudden turns and check

the steering wheel return.

2. At a vehicle speed of approximately 35 km/h, turn

the steering wheel 90°, hold a few seconds, then

release. If the steering wheel then returns 70° or

more, the return can be judged satisfactory.

NOTE: There will be a momentary feeling or

"heaviness" when the wheel is turned quickly, but

this is not abnormal (Oil pump discharge amount

is especially apt to be insufficient during idling).

DRIVE BELT TENSION CHECKM1372001900392

For vehicles with 1300 and 1600 engine, refer to

GROUP 11A, On-vehicle Service − Drive Belt

Tension Check P.11A-7.

For vehicles with 2000 engine, refer to GROUP 11C,

On-vehicle Service − Drive Belt Tension Check

P.11C-7.

FLUID LEVEL CHECKM1372002000284

1. Park the vehicle on a flat, level surface.

2. Start the engine, and then turn the steering wheel

several times to raise the temperature of the fluid

to approximately 50 − 60°C.

3. With the engine running, turn the wheel all the

way to the left and right several times.4. Check the fluid in the oil reservoir for foaming or

milkiness. Check the difference of the fluid level

when the engine is stopped, and while it is

running. If the change of the fluid level is 5 mm or

more, air bleeding should be done.

FLUID REPLACEMENTM1372002100333

1. Raise and support the front wheels.

2. Disconnect the return hose connection, and then

connect a vinyl hose to the return hose, and drain

the fluid into a container.

3. Disconnect the ignition coil connectors (Refer to

GROUP 16, Ignition Coil P.16-38or P.16-39).

4. While operating the starter motor intermittently,

turn the steering wheel all the way to the left and

right several times to drain all of the fluid.

5. Connect the return hose securely, and then

secure with the clip.

6. Fill the oil reservoir with specified fluid up to

between "MAX" and "MIN" marks, and then bleed

the air.

Specified fluid: ATF DEXRON III or DEXRON

II

POWER STEERING SYSTEM AIR

BLEEDING

M1372002200330

Perform air bleeding procedure as necessary after

replacing the steering gear or the steering fluid lines.

1. Raise and support the front wheels.

2. Disconnect the ignition coil connectors (Refer to

GROUP 16, Ignition Coil P.16-38 or P.16-39).

ACX01130

AB

70˚70˚

ACX01131While engine running While engine stoppedAC

Fluid level change: Within 5 mm

AC100369AB

Return hoseReturn hose

Vinyl hose

Page 271 of 788

POWER STEERING OIL PUMP ASSEMBLY

POWER STEERING37-37

POWER STEERING OIL PUMP ASSEMBLY

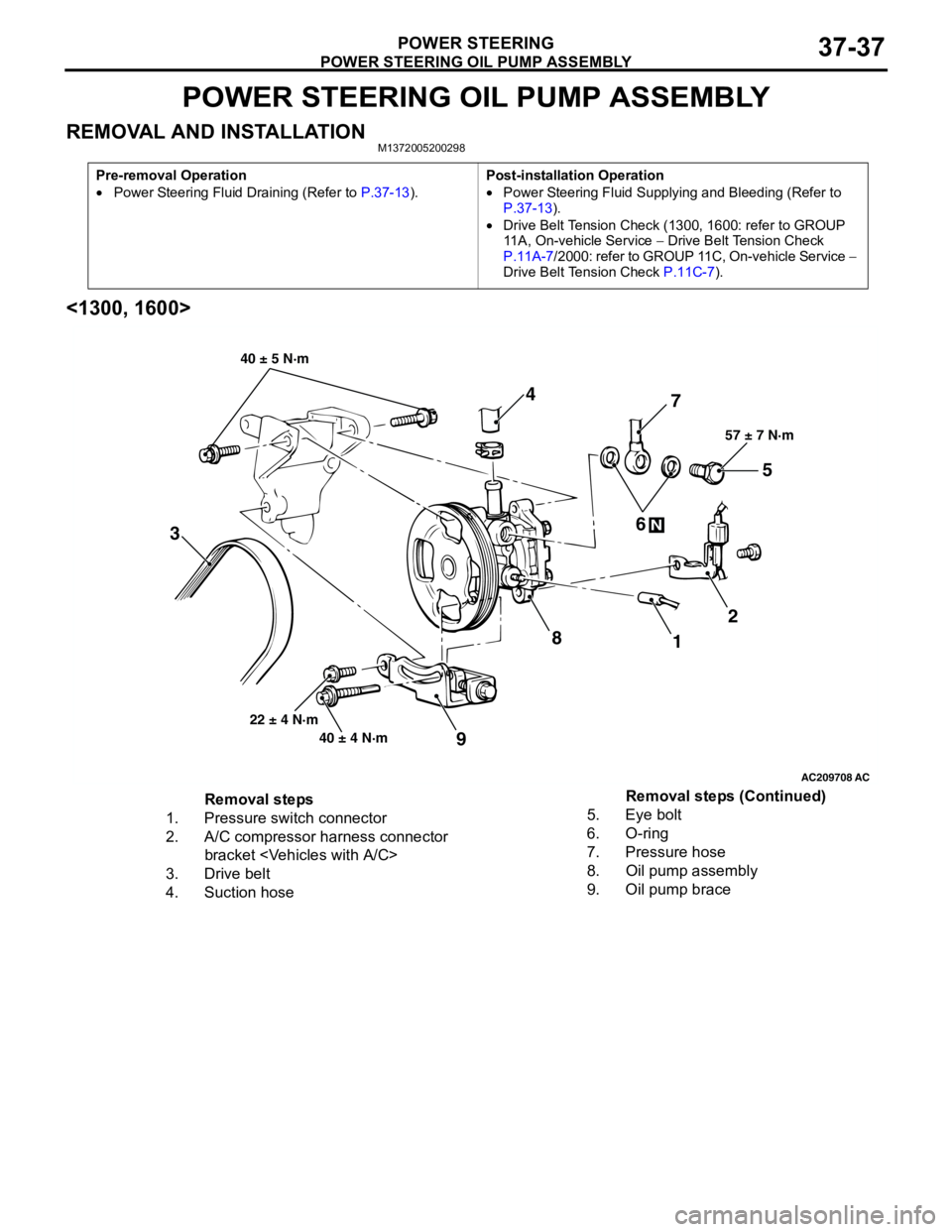

REMOVAL AND INSTALLATIONM1372005200298

<1300, 1600>

Pre-removal Operation

•Power Steering Fluid Draining (Refer to P.37-13).Post-installation Operation

•Power Steering Fluid Supplying and Bleeding (Refer to

P.37-13).

•Drive Belt Tension Check (1300, 1600: refer to GROUP

11A, On-vehicle Service − Drive Belt Tension Check

P.11A-7/2000: refer to GROUP 11C, On-vehicle Service −

Drive Belt Tension Check P.11C-7).

AC209708

87

12 34

5

6

57 ± 7 N·m

40 ± 4 N·m 22 ± 4 N·m

N

9

40 ± 5 N·m

AC

Removal steps

1. Pressure switch connector

2. A/C compressor harness connector

bracket

3. Drive belt

4. Suction hose5. Eye bolt

6. O-ring

7. Pressure hose

8. Oil pump assembly

9. Oil pump braceRemoval steps (Continued)

Page 272 of 788

POWER STEERING OIL PUMP ASSEMBLY

POWER STEERING37-38

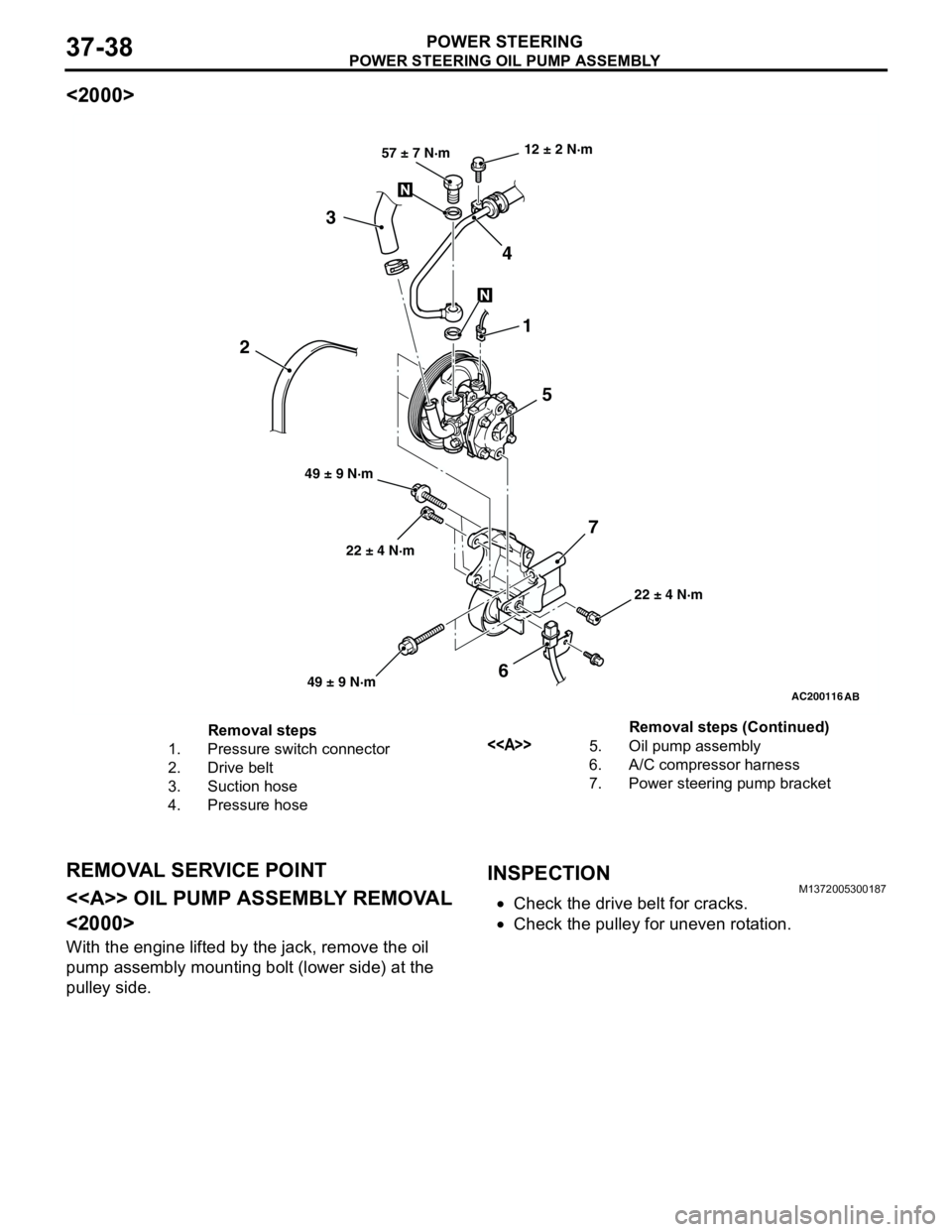

<2000>

REMOVAL SERVICE POINT

<> OIL PUMP ASSEMBLY REMOVAL

<2000>

With the engine lifted by the jack, remove the oil

pump assembly mounting bolt (lower side) at the

pulley side.

INSPECTIONM1372005300187

•Check the drive belt for cracks.

•Check the pulley for uneven rotation.

AC200116

AB

22 ± 4 N·m 12 ± 2 N·m

22 ± 4 N·m 49 ± 9 N·m57 ± 7 N·m

1

5 4 3

6 2

7

49 ± 9 N·m

Removal steps

1. Pressure switch connector

2. Drive belt

3. Suction hose

4. Pressure hose<>5. Oil pump assembly

6. A/C compressor harness

7. Power steering pump bracketRemoval steps (Continued)

Page 311 of 788

DOOR

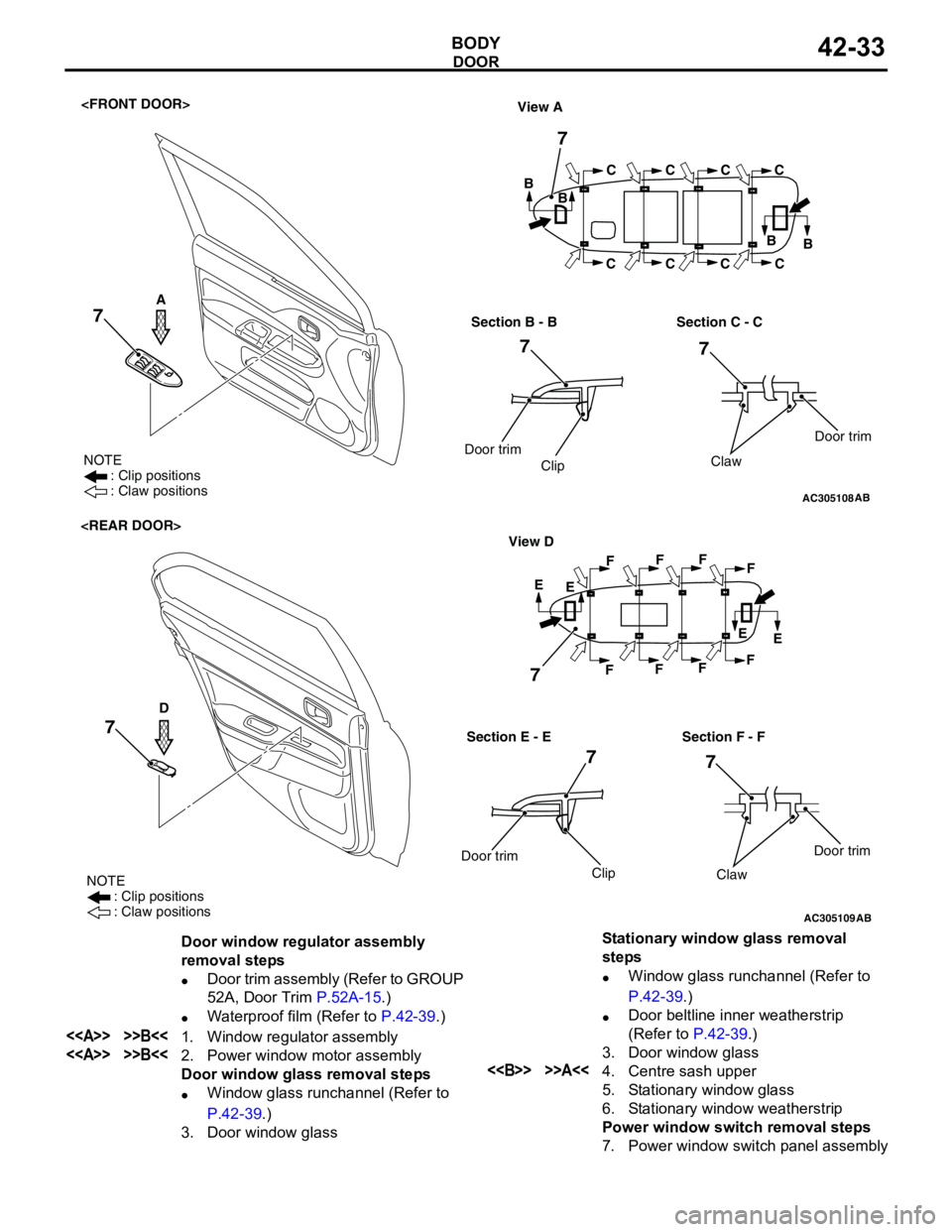

BODY42-33

AC305108

NOTE

: Clip positions

: Claw positions

View A

B

B

B

B C

CC

CC

CC

C

Section B - B

Door trim

ClipSection C - C

AB

Door trim

Claw

7

7

7 7

A

AC305109

NOTE

: Clip positions

: Claw positions

E

E

E

E F

FF

FF

FF

F

Section E - EView D

Door trim

ClipSection F - F

Door trim

Claw

D

7

7 7

AB

7

Door window regulator assembly

removal steps

•Door trim assembly (Refer to GROUP

52A, Door Trim P.52A-15.)

•Waterproof film (Refer to P.42-39.)

<> >>B<<1. Window regulator assembly

<> >>B<<2. Power window motor assembly

Door window glass removal steps

•Window glass runchannel (Refer to

P.42-39.)

3. Door window glassStationary window glass removal

steps

•Window glass runchannel (Refer to

P.42-39.)

•Door beltline inner weatherstrip

(Refer to P.42-39.)

3. Door window glass<> >>A<<4. Centre sash upper

5. Stationary window glass

6. Stationary window weatherstrip

Power window switch removal steps

7. Power window switch panel assembly

Page 317 of 788

DOOR

BODY42-39

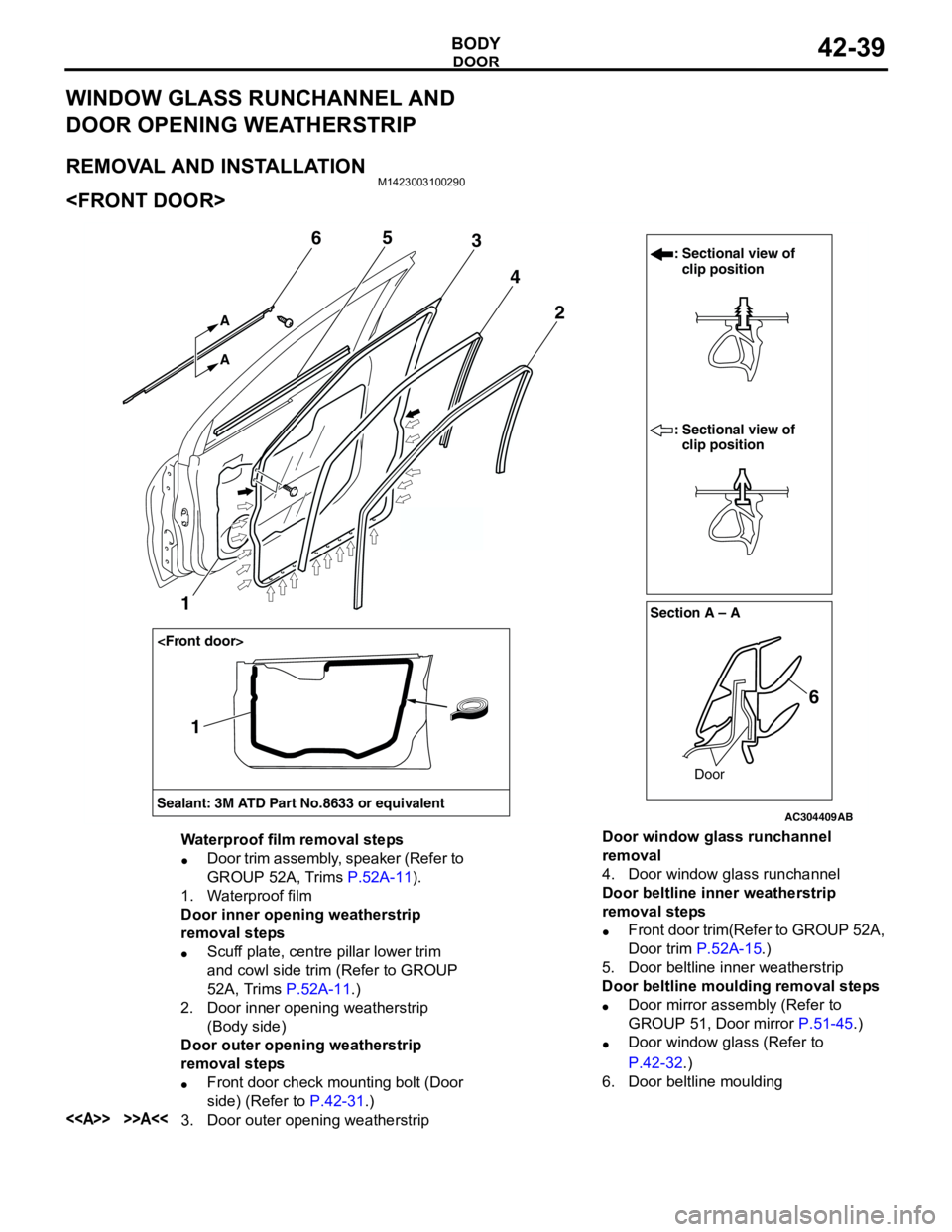

WINDOW GLASS RUNCHANNEL AND

DOOR OPENING WEATHERSTRIP

REMOVAL AND INSTALLATIONM1423003100290

AC304409AB

Section A – A

Sealant: 3M ATD Part No.8633 or equivalentDoor

: Sectional view of

clip position

: Sectional view of

clip position

6 2

1

4

365

A A

1

Waterproof film removal steps

•Door trim assembly, speaker (Refer to

GROUP 52A, Trims P.52A-11).

1. Waterproof film

Door inner opening weatherstrip

removal steps

•Scuff plate, centre pillar lower trim

and cowl side trim (Refer to GROUP

52A, Trims P.52A-11.)

2. Door inner opening weatherstrip

(Body side)

Door outer opening weatherstrip

removal steps

•Front door check mounting bolt (Door

side) (Refer to P.42-31.)

<> >>A<<3. Door outer opening weatherstripDoor window glass runchannel

removal

4. Door window glass runchannel

Door beltline inner weatherstrip

removal steps

•Front door trim(Refer to GROUP 52A,

Door trim P.52A-15.)

5. Door beltline inner weatherstrip

Door beltline moulding removal steps

•Door mirror assembly (Refer to

GROUP 51, Door mirror P.51-45.)

•Door window glass (Refer to

P.42-32.)

6. Door beltline moulding

Page 318 of 788

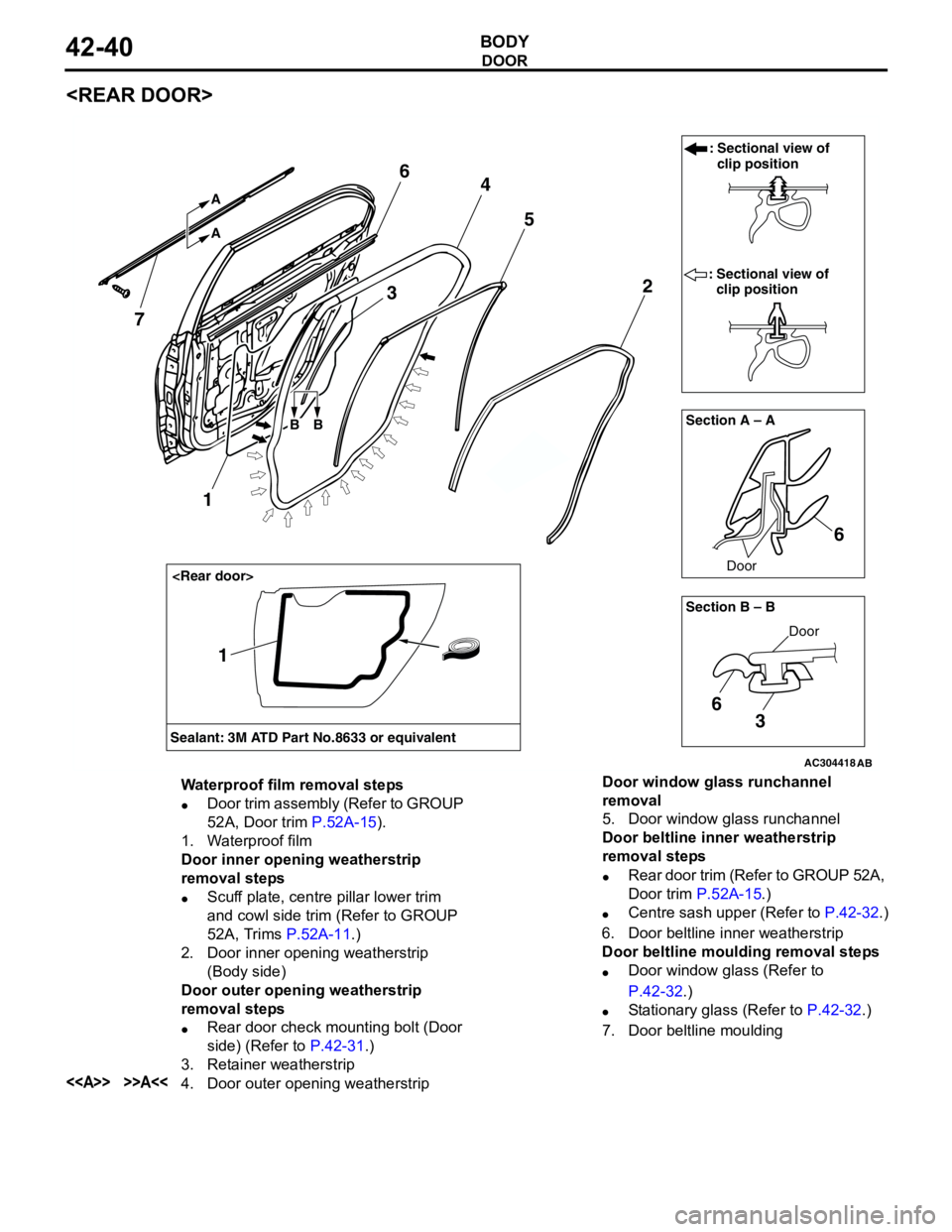

DOOR

BODY42-40

AC304418AB

Section A – A

Door

: Sectional view of

clip position

: Sectional view of

clip position

6 2 4

5

7

A A

3

Section B – B

Door

6

3

6

BB

Sealant: 3M ATD Part No.8633 or equivalent

1

1

Waterproof film removal steps

•Door trim assembly (Refer to GROUP

52A, Door trim P.52A-15).

1. Waterproof film

Door inner opening weatherstrip

removal steps

•Scuff plate, centre pillar lower trim

and cowl side trim (Refer to GROUP

52A, Trims P.52A-11.)

2. Door inner opening weatherstrip

(Body side)

Door outer opening weatherstrip

removal steps

•Rear door check mounting bolt (Door

side) (Refer to P.42-31.)

3. Retainer weatherstrip

<> >>A<<4. Door outer opening weatherstripDoor window glass runchannel

removal

5. Door window glass runchannel

Door beltline inner weatherstrip

removal steps

•Rear door trim (Refer to GROUP 52A,

Door trim P.52A-15.)

•Centre sash upper (Refer to P.42-32.)

6. Door beltline inner weatherstrip

Door beltline moulding removal steps

•Door window glass (Refer to

P.42-32.)

•Stationary glass (Refer to P.42-32.)

7. Door beltline moulding

Page 486 of 788

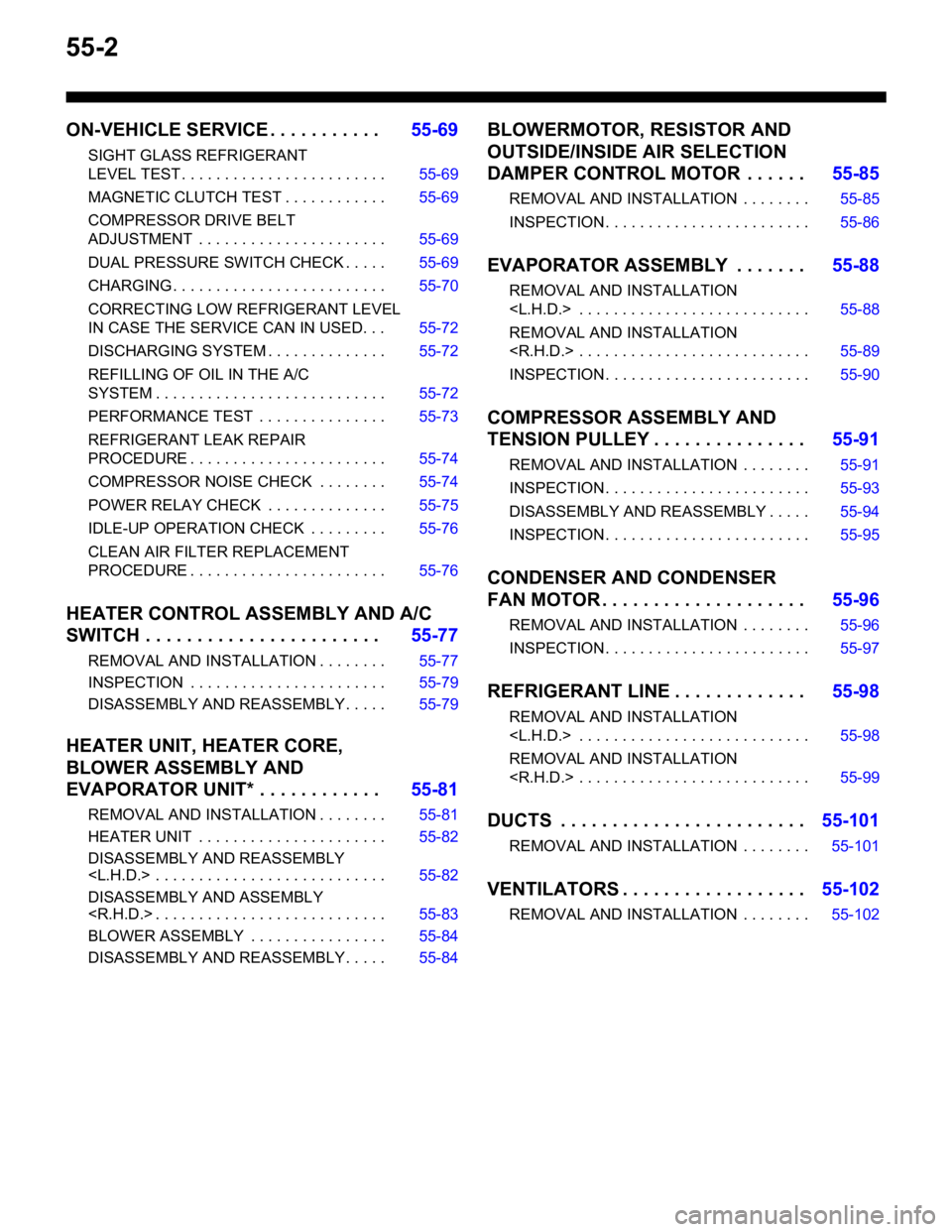

55-2

ON-VEHICLE SERVICE . . . . . . . . . . .55-69

SIGHT GLASS REFRIGERANT

LEVEL TEST . . . . . . . . . . . . . . . . . . . . . . . . 55-69

MAGNETIC CLUTCH TEST . . . . . . . . . . . . 55-69

COMPRESSOR DRIVE BELT

ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . 55-69

DUAL PRESSURE SWITCH CHECK . . . . . 55-69

CHARGING . . . . . . . . . . . . . . . . . . . . . . . . . 55-70

CORRECTING LOW REFRIGERANT LEVEL

IN CASE THE SERVICE CAN IN USED. . . 55-72

DISCHARGING SYSTEM . . . . . . . . . . . . . . 55-72

REFILLING OF OIL IN THE A/C

SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . 55-72

PERFORMANCE TEST . . . . . . . . . . . . . . . 55-73

REFRIGERANT LEAK REPAIR

PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . 55-74

COMPRESSOR NOISE CHECK . . . . . . . . 55-74

POWER RELAY CHECK . . . . . . . . . . . . . . 55-75

IDLE-UP OPERATION CHECK . . . . . . . . . 55-76

CLEAN AIR FILTER REPLACEMENT

PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . 55-76

HEATER CONTROL ASSEMBLY AND A/C

SWITCH . . . . . . . . . . . . . . . . . . . . . . .55-77

REMOVAL AND INSTALLATION . . . . . . . . 55-77

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . 55-79

DISASSEMBLY AND REASSEMBLY . . . . . 55-79

HEATER UNIT, HEATER CORE,

BLOWER ASSEMBLY AND

EVAPORATOR UNIT* . . . . . . . . . . . .55-81

REMOVAL AND INSTALLATION . . . . . . . . 55-81

HEATER UNIT . . . . . . . . . . . . . . . . . . . . . . 55-82

DISASSEMBLY AND REASSEMBLY

DISASSEMBLY AND ASSEMBLY

BLOWER ASSEMBLY . . . . . . . . . . . . . . . . 55-84

DISASSEMBLY AND REASSEMBLY . . . . . 55-84

BLOWERMOTOR, RESISTOR AND

OUTSIDE/INSIDE AIR SELECTION

DAMPER CONTROL MOTOR . . . . . .55-85

REMOVAL AND INSTALLATION . . . . . . . . 55-85

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 55-86

EVAPORATOR ASSEMBLY . . . . . . .55-88

REMOVAL AND INSTALLATION

REMOVAL AND INSTALLATION

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 55-90

COMPRESSOR ASSEMBLY AND

TENSION PULLEY . . . . . . . . . . . . . . .55-91

REMOVAL AND INSTALLATION . . . . . . . . 55-91

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 55-93

DISASSEMBLY AND REASSEMBLY . . . . . 55-94

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 55-95

CONDENSER AND CONDENSER

FAN MOTOR . . . . . . . . . . . . . . . . . . . .55-96

REMOVAL AND INSTALLATION . . . . . . . . 55-96

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 55-97

REFRIGERANT LINE . . . . . . . . . . . . .55-98

REMOVAL AND INSTALLATION

REMOVAL AND INSTALLATION

DUCTS . . . . . . . . . . . . . . . . . . . . . . . .55-101

REMOVAL AND INSTALLATION . . . . . . . . 55-101

VENTILATORS . . . . . . . . . . . . . . . . . .55-102

REMOVAL AND INSTALLATION . . . . . . . . 55-102