oil pressure MITSUBISHI LANCER 2005 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 106 of 788

IGNITION SYSTEM

ENGINE ELECTRICAL16-42

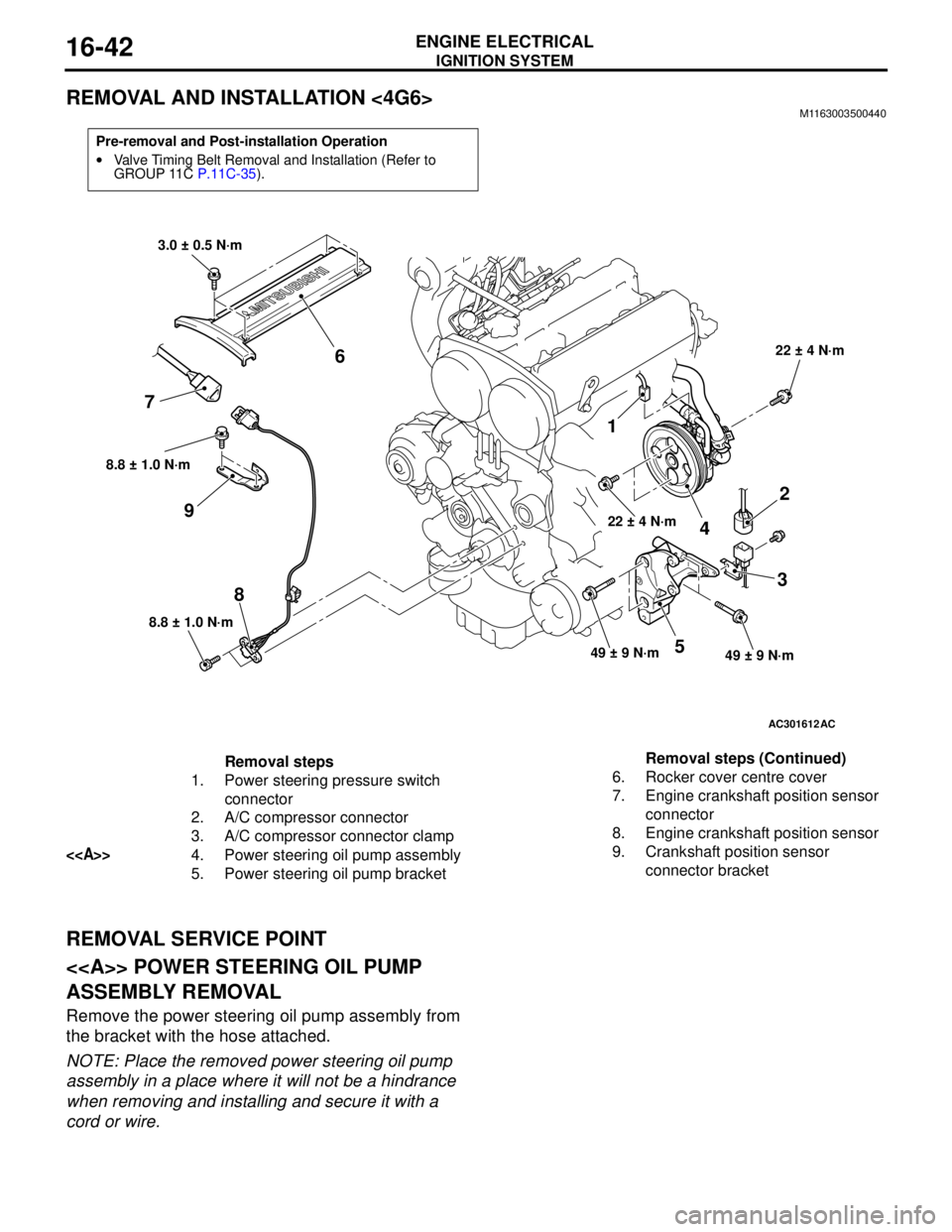

REMOVAL AND INSTALLATION <4G6>M1163003500440

REMOVAL SERVICE POINT

<> POWER STEERING OIL PUMP

ASSEMBLY REMOVAL

Remove the power steering oil pump assembly from

the bracket with the hose attached.

NOTE: Place the removed power steering oil pump

assembly in a place where it will not be a hindrance

when removing and installing and secure it with a

cord or wire.

Pre-removal and Post-installation Operation

•Valve Timing Belt Removal and Installation (Refer to

GROUP 11C P.11C-35).

AC301612

8.8 ± 1.0 N·m

8

8.8 ± 1.0 N·m

9

1

22 ± 4 N·m

4

2

3

49 ± 9 N·m49 ± 9 N·m5

22 ± 4 N·m

3.0 ± 0.5 N·m

6

7

AC

Removal steps

1. Power steering pressure switch

connector

2. A/C compressor connector

3. A/C compressor connector clamp

<>4. Power steering oil pump assembly

5. Power steering oil pump bracket6. Rocker cover centre cover

7. Engine crankshaft position sensor

connector

8. Engine crankshaft position sensor

9. Crankshaft position sensor

connector bracket Removal steps (Continued)

Page 148 of 788

DRIVE SHAFT ASSEMBLY

FRONT AXLE26-16

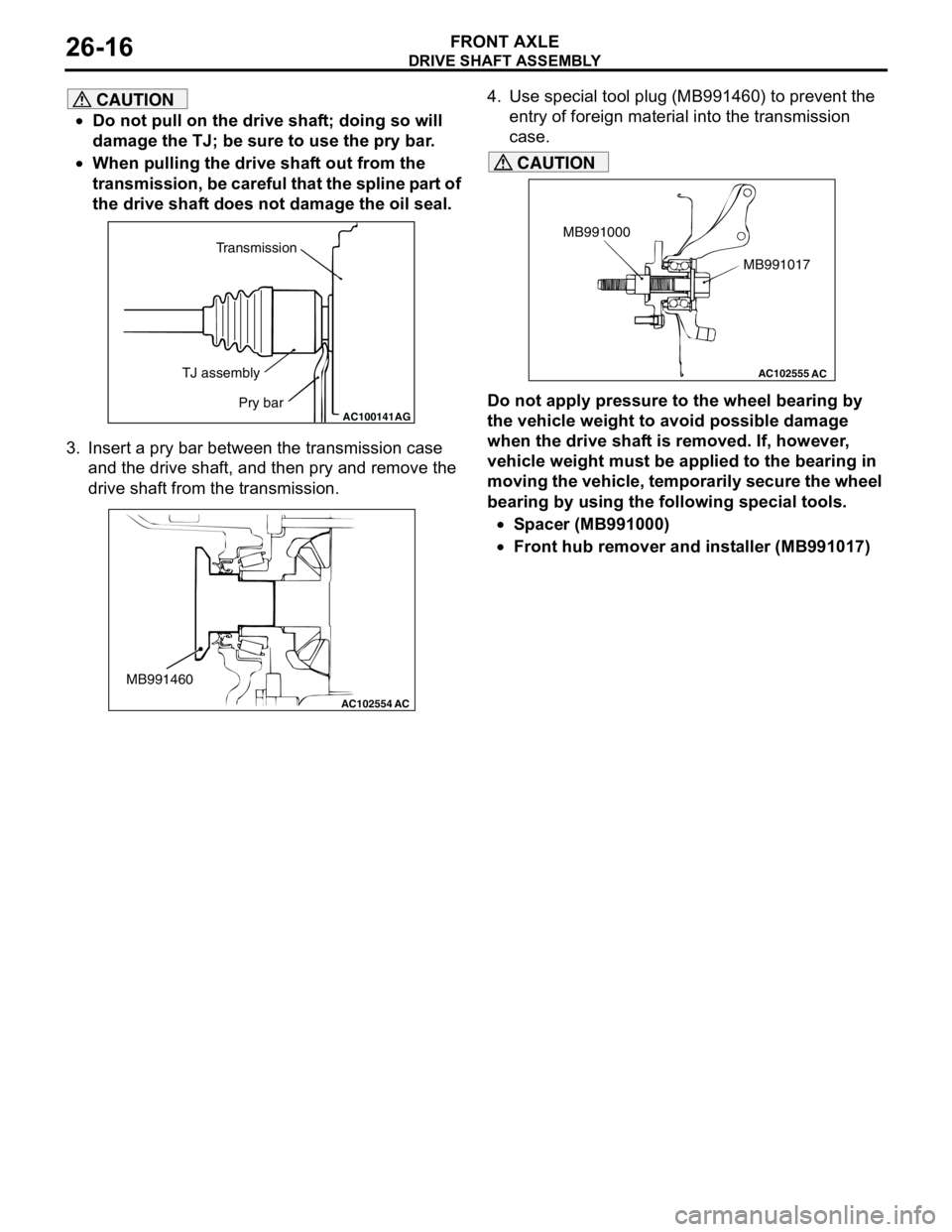

CAUTION

•Do not pull on the drive shaft; doing so will

damage the TJ; be sure to use the pry bar.

•When pulling the drive shaft out from the

transmission, be careful that the spline part of

the drive shaft does not damage the oil seal.

3. Insert a pry bar between the transmission case

and the drive shaft, and then pry and remove the

drive shaft from the transmission.4. Use special tool plug (MB991460) to prevent the

entry of foreign material into the transmission

case.

CAUTION

Do not apply pressure to the wheel bearing by

the vehicle weight to avoid possible damage

when the drive shaft is removed. If, however,

vehicle weight must be applied to the bearing in

moving the vehicle, temporarily secure the wheel

bearing by using the following special tools.

•Spacer (MB991000)

•Front hub remover and installer (MB991017)AC100141

Transmission

TJ assembly

Pry bar

AG

AC102554

MB991460

AC

AC102555

AC

MB991017 MB991000

Page 235 of 788

37-1

GROUP 37

POWER STEERING

CONTENTS

GENERAL INFORMATION . . . . . . . .37-3

SERVICE SPECIFICATIONS . . . . . . .37-6

LUBRICANTS . . . . . . . . . . . . . . . . . .37-7

SEALANTS . . . . . . . . . . . . . . . . . . . .37-7

SPECIAL TOOLS . . . . . . . . . . . . . . . .37-8

ON-VEHICLE SERVICE . . . . . . . . . . .37-11

STEERING WHEEL FREE PLAY

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37-11

STEERING ANGLE CHECK . . . . . . . . . . . . 37-11

TIE ROD END BALL JOINT TURNING

TORQUE CHECK . . . . . . . . . . . . . . . . . . . . 37-12

STATIONARY STEERING EFFORT

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37-12

STEERING WHEEL RETURN TO

CENTRE CHECK . . . . . . . . . . . . . . . . . . . . 37-13DRIVE BELT TENSION CHECK . . . . . . . . . 37-13

FLUID LEVEL CHECK . . . . . . . . . . . . . . . . 37-13

FLUID REPLACEMENT . . . . . . . . . . . . . . . 37-13

POWER STEERING SYSTEM AIR

BLEEDING . . . . . . . . . . . . . . . . . . . . . . . . . 37-13

OIL PUMP PRESSURE TEST . . . . . . . . . . 37-14

POWER STEERING PRESSURE

SWITCH CHECK . . . . . . . . . . . . . . . . . . . . . 37-15

TIE ROD END BALL JOINT DUST COVER

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37-15

STEERING COLUMN SHAFT

ASSEMBLY SHOCK ABSORBING

MECHANISM CHECK . . . . . . . . . . . . . . . . . 37-15

STEERING WHEEL* . . . . . . . . . . . . . .37-17

REMOVAL AND INSTALLATION

REMOVAL AND INSTALLATION

Continued on next page

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING

•Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to

personal injury or death to service personnel (from inadvertent firing of the air bag) or to the driver and

paassenger (from rendering the SRS inoperative).

•Service or maintenance of any SRS component or SRS-related component must be performed only at an

authorized MITSUBISHI dealer.

•MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B - Supplemental

Restraint System (SRS) before beginning any service or maintenance of any component of the SRS or any

SRS-related component.

NOTE

The SRS includes the following components: SRS air bag control unit, SRS warning light, front impact sensors, air bag module,

clock spring, and interconnecting wiring. Other SRS-related components (that may have to be removed/installed in connection

with SRS service or maintenance) are indicated in the table of contents by an asterisk (*).

Page 237 of 788

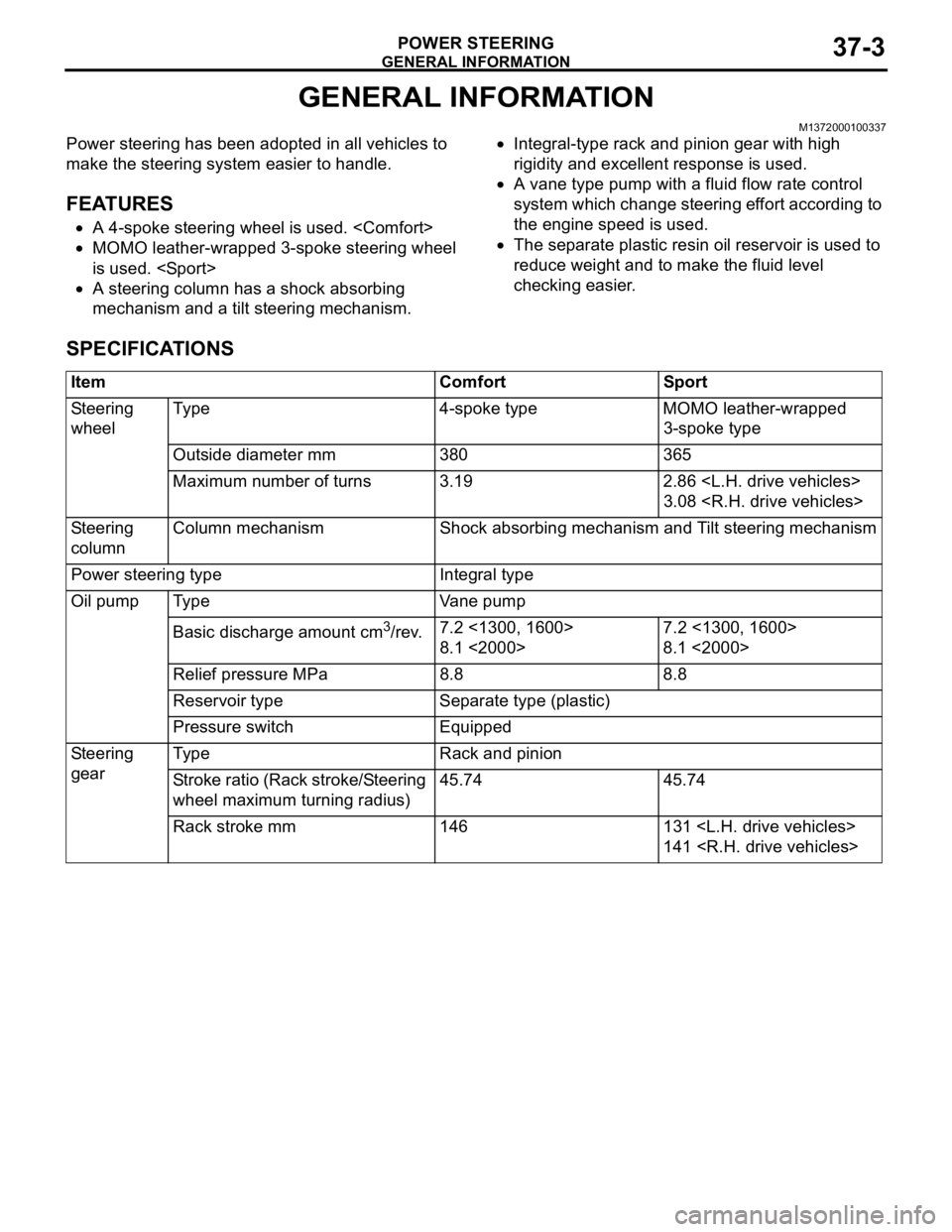

GENERAL INFORMATION

POWER STEERING37-3

GENERAL INFORMATION

M1372000100337

Power steering has been adopted in all vehicles to

make the steering system easier to handle.

FEATURES

•A 4-spoke steering wheel is used.

•MOMO leather-wrapped 3-spoke steering wheel

is used.

•A steering column has a shock absorbing

mechanism and a tilt steering mechanism.•Integral-type rack and pinion gear with high

rigidity and excellent response is used.

•A vane type pump with a fluid flow rate control

system which change steering effort according to

the engine speed is used.

•The separate plastic resin oil reservoir is used to

reduce weight and to make the fluid level

checking easier.

SPECIFICATIONS

Item Comfort Sport

Steering

wheelType 4-spoke type MOMO leather-wrapped

3-spoke type

Outside diameter mm 380 365

Maximum number of turns 3.19 2.86

3.08

Steering

columnColumn mechanism Shock absorbing mechanism and Tilt steering mechanism

Power steering type Integral type

Oil pump Type Vane pump

Basic discharge amount cm

3/rev.7.2 <1300, 1600>

8.1 <2000>7.2 <1300, 1600>

8.1 <2000>

Relief pressure MPa 8.8 8.8

Reservoir type Separate type (plastic)

Pressure switch Equipped

Steering

gearType Rack and pinion

Stroke ratio (Rack stroke/Steering

wheel maximum turning radius)45.74 45.74

Rack stroke mm 146 131

141

Page 238 of 788

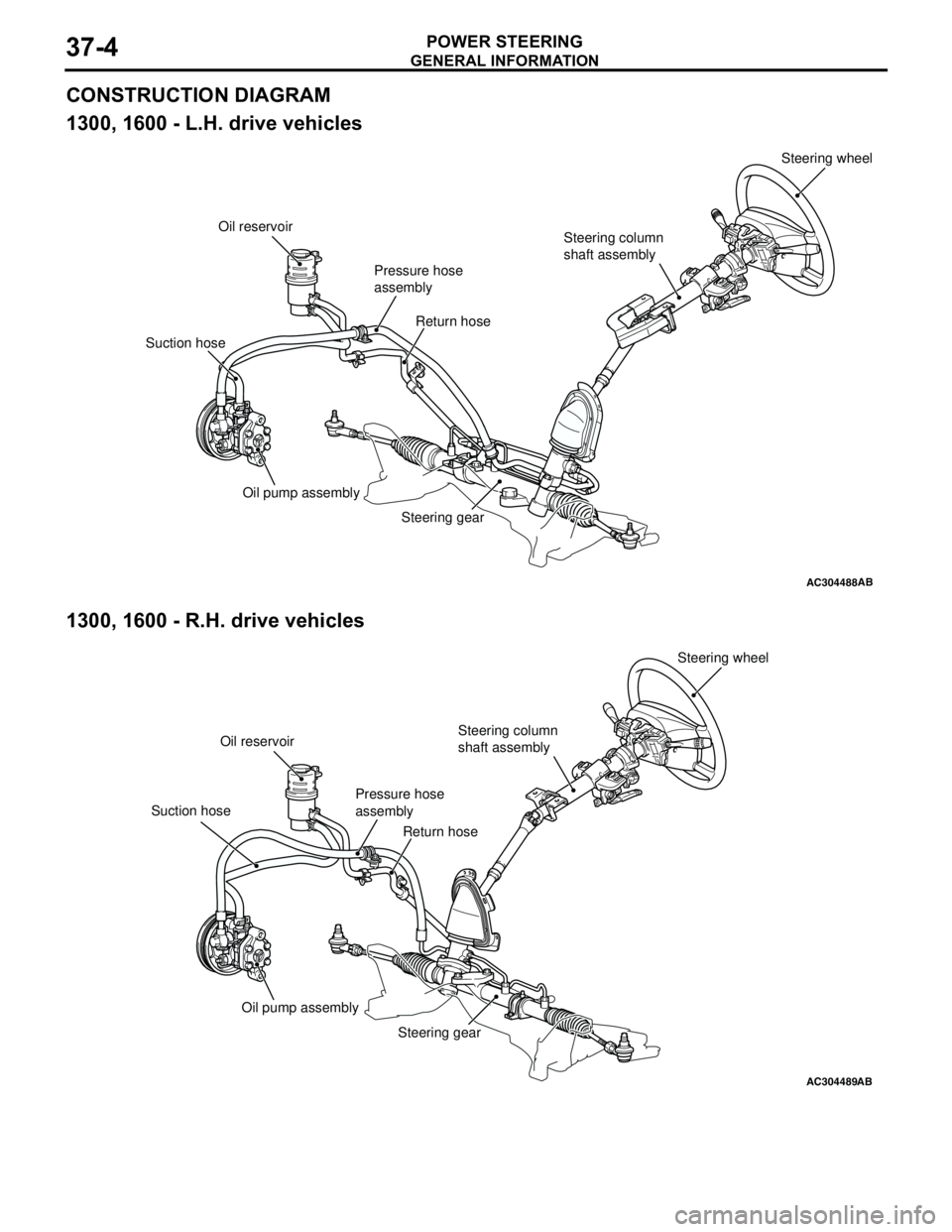

GENERAL INFORMATION

POWER STEERING37-4

CONSTRUCTION DIAGRAM

1300, 1600 - L.H. drive vehicles

1300, 1600 - R.H. drive vehicles

AC304488AB

Steering wheel

Steering column

shaft assembly

Pressure hose

assembly Oil reservoir

Suction hoseReturn hose

Oil pump assembly

Steering gear

AC304489AB

Steering wheel

Steering column

shaft assembly

Pressure hose

assembly Oil reservoir

Suction hose

Return hose

Oil pump assembly

Steering gear

Page 239 of 788

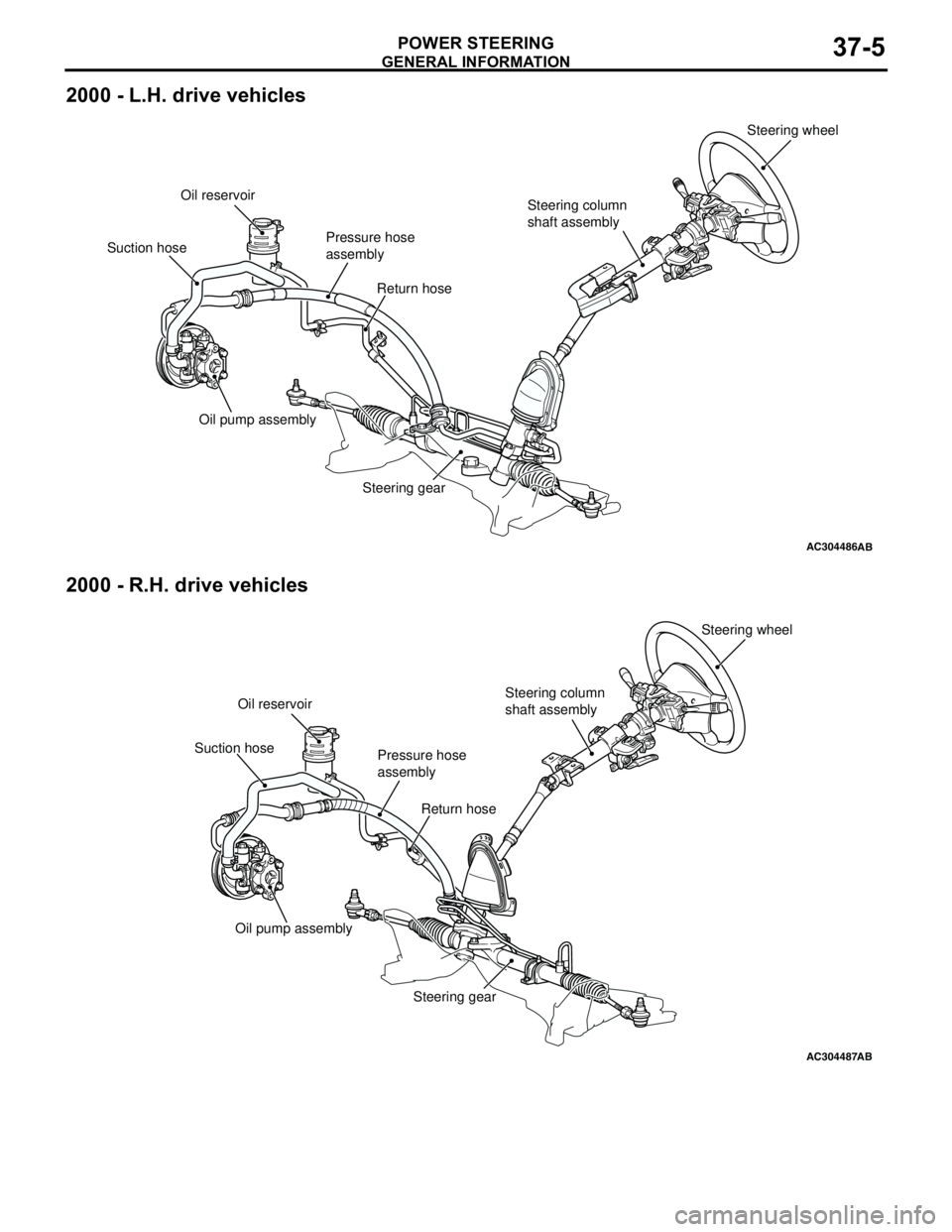

GENERAL INFORMATION

POWER STEERING37-5

2000 - L.H. drive vehicles

2000 - R.H. drive vehicles

AC304486AB

Steering wheel

Steering column

shaft assembly

Pressure hose

assembly Oil reservoir

Suction hose

Return hose

Oil pump assembly

Steering gear

AC304487AB

Steering wheel

Steering column

shaft assembly

Pressure hose

assembly Oil reservoir

Suction hose

Return hose

Oil pump assembly

Steering gear

Page 240 of 788

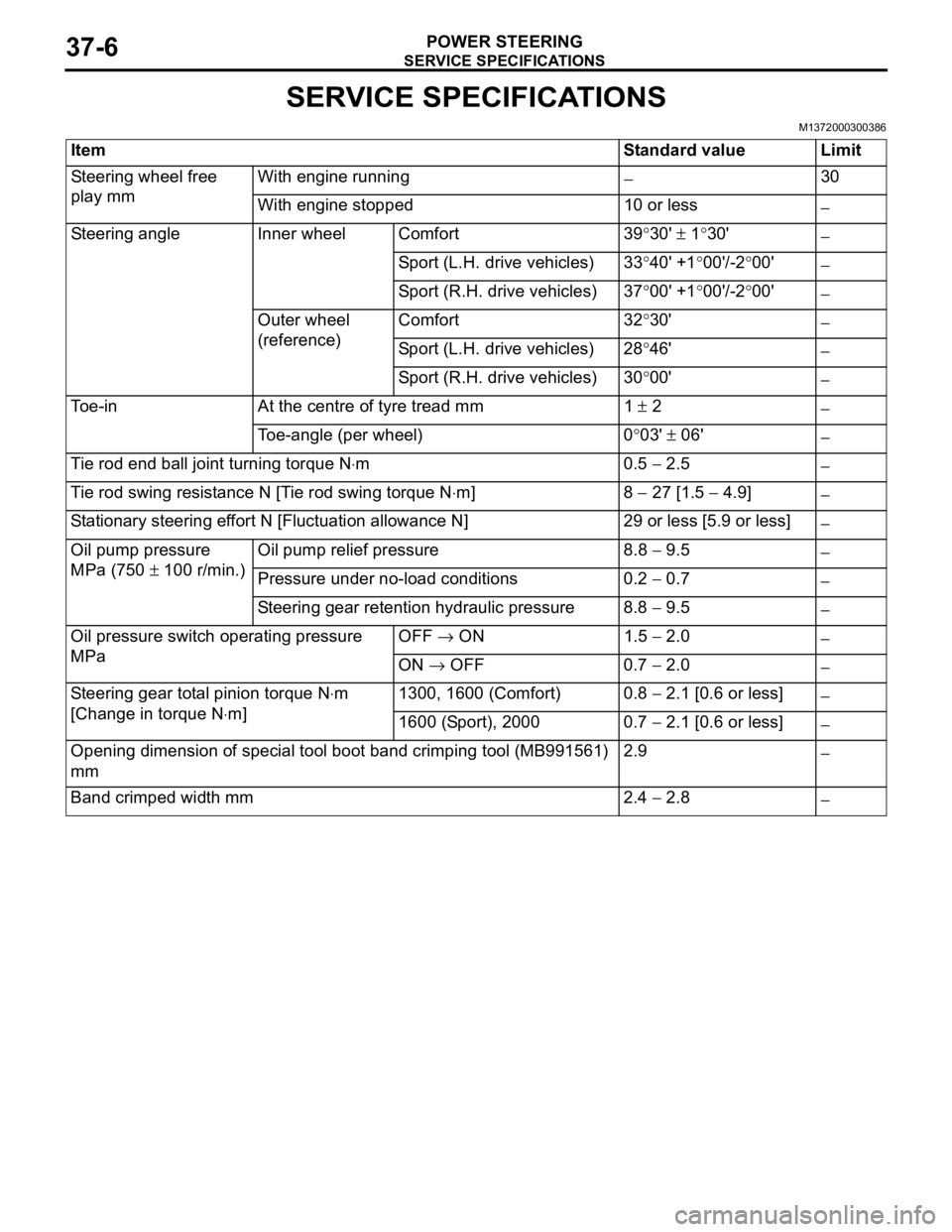

SERVICE SPECIFICATIONS

POWER STEERING37-6

SERVICE SPECIFICATIONS

M1372000300386

Item Standard value Limit

Steering wheel free

play mmWith engine running

−30

With engine stopped 10 or less

−

Steering angle Inner wheel Comfort 39°30' ± 1°30'

−

Sport (L.H. drive vehicles) 33°40' +1°00'/-2°00'

−

Sport (R.H. drive vehicles) 37°00' +1°00'/-2°00'

−

Outer wheel

(reference)Comfort 32°30'

−

Sport (L.H. drive vehicles) 28°46'

−

Sport (R.H. drive vehicles) 30°00'

−

Toe-in At the centre of tyre tread mm 1 ± 2

−

Toe-angle (per wheel) 0°03' ± 06'

−

Tie rod end ball joint turning torque N⋅m0.5 − 2.5

−

Tie rod swing resistance N [Tie rod swing torque N⋅m] 8 − 27 [1.5 − 4.9]

−

Stationary steering effort N [Fluctuation allowance N] 29 or less [5.9 or less]

−

Oil pump pressure

MPa (750 ± 100 r/min.)Oil pump relief pressure 8.8 − 9.5

−

Pressure under no-load conditions 0.2 − 0.7

−

Steering gear retention hydraulic pressure 8.8 − 9.5

−

Oil pressure switch operating pressure

MPaOFF → ON 1.5 − 2.0

−

ON → OFF 0.7 − 2.0

−

Steering gear total pinion torque N⋅m

[Change in torque N⋅m]1300, 1600 (Comfort) 0.8 − 2.1 [0.6 or less]

−

1600 (Sport), 2000 0.7 − 2.1 [0.6 or less]

−

Opening dimension of special tool boot band crimping tool (MB991561)

mm2.9

−

Band crimped width mm 2.4 − 2.8

−

Page 242 of 788

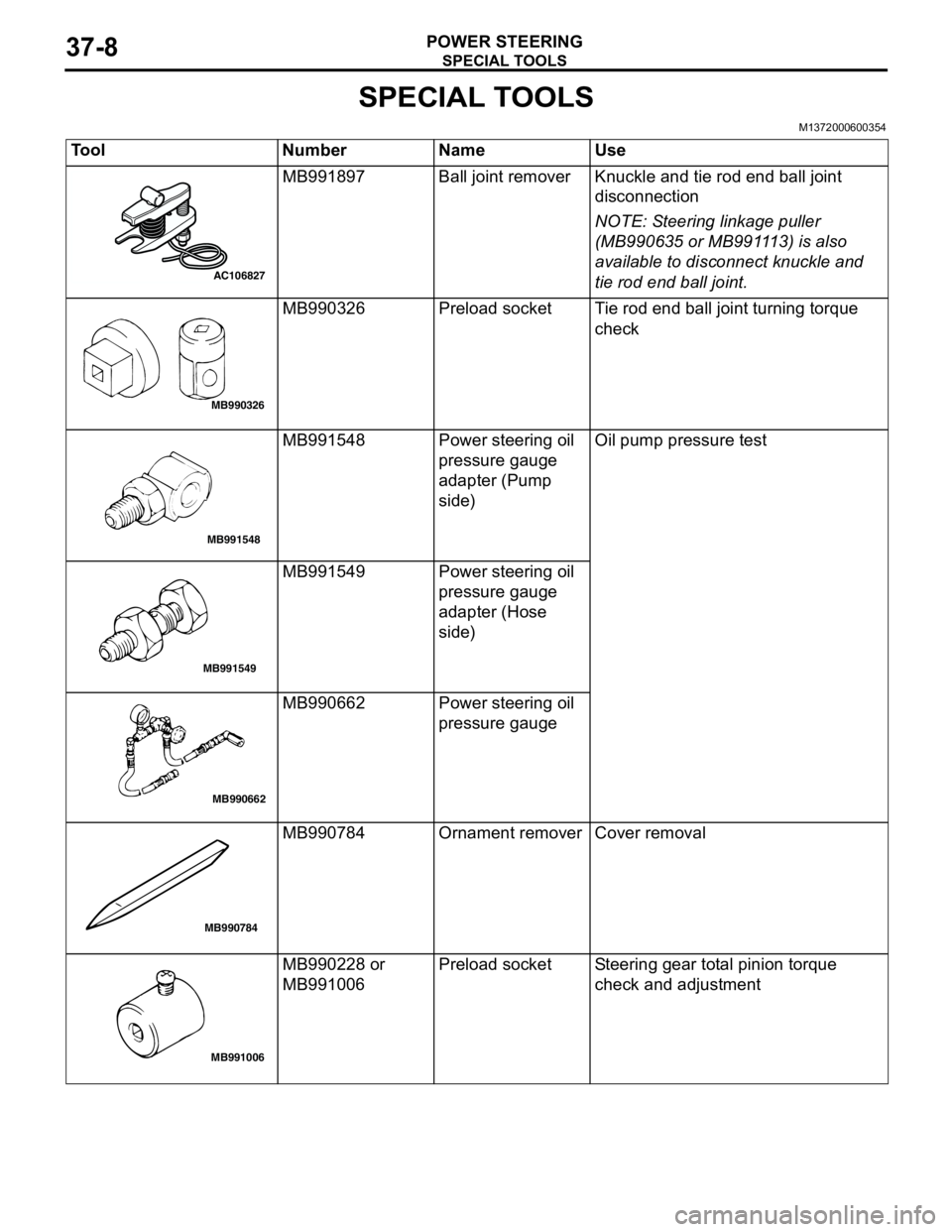

SPECIAL TOOLS

POWER STEERING37-8

SPECIAL TOOLS

M1372000600354

Tool Number Name Use

MB991897 Ball joint remover Knuckle and tie rod end ball joint

disconnection

NOTE: Steering linkage puller

(MB990635 or MB991113) is also

available to disconnect knuckle and

tie rod end ball joint.

MB990326 Preload socket Tie rod end ball joint turning torque

check

MB991548 Power steering oil

pressure gauge

adapter (Pump

side)Oil pump pressure test

MB991549 Power steering oil

pressure gauge

adapter (Hose

side)

MB990662 Power steering oil

pressure gauge

MB990784 Ornament remover Cover removal

MB990228 or

MB991006Preload socket Steering gear total pinion torque

check and adjustment

AC106827

MB990326

MB991548

MB991549

MB990662

MB990784

MB991006

Page 248 of 788

ON-VEHICLE SERVICE

POWER STEERING37-14

CAUTION

Perform air bleeding only while cranking the

engine. If air bleeding is performed while the

engine is running, air could enter the fluid.

During air bleeding, refill the steering fluid

supply so that the level never falls below the

"MIN" mark on the oil reservoir.

3. Turn the steering wheel all the way to the left and

right five or six times while using the starter motor

to crank the engine intermittently several times

(for 15 to 20 seconds).

4. Connect the ignition coil connectors (Refer to

GROUP 16, Ignition Coil P.16-38 or P.16-39).

5. Start the engine (idling).

6. Turn the steering wheel to the left and right until

there are no air bubbles in the oil reservoir.

7. Confirm that the fluid is not milky, and that the

level is between "MAX" and "MIN" marks.

8. Confirm that there is very little change in the fluid

level when the steering wheel is turned left and

right.

CAUTION

If the fluid level rises suddenly after the engine is

stopped, the air has not been completely bled. If

air bleeding is not complete, there will be

abnormal noises from the pump and the

flow-control valve, and this condition could

cause reduce the life of the power steering

components.

9. Confirm that the change in the fluid level is no

more than 5 mm when the engine is stopped and

when it is running.

10.If the change of the fluid level is 5 mm or more,

the air has not been completely bled from the

system. The air bleeding procedure must be

repeated.

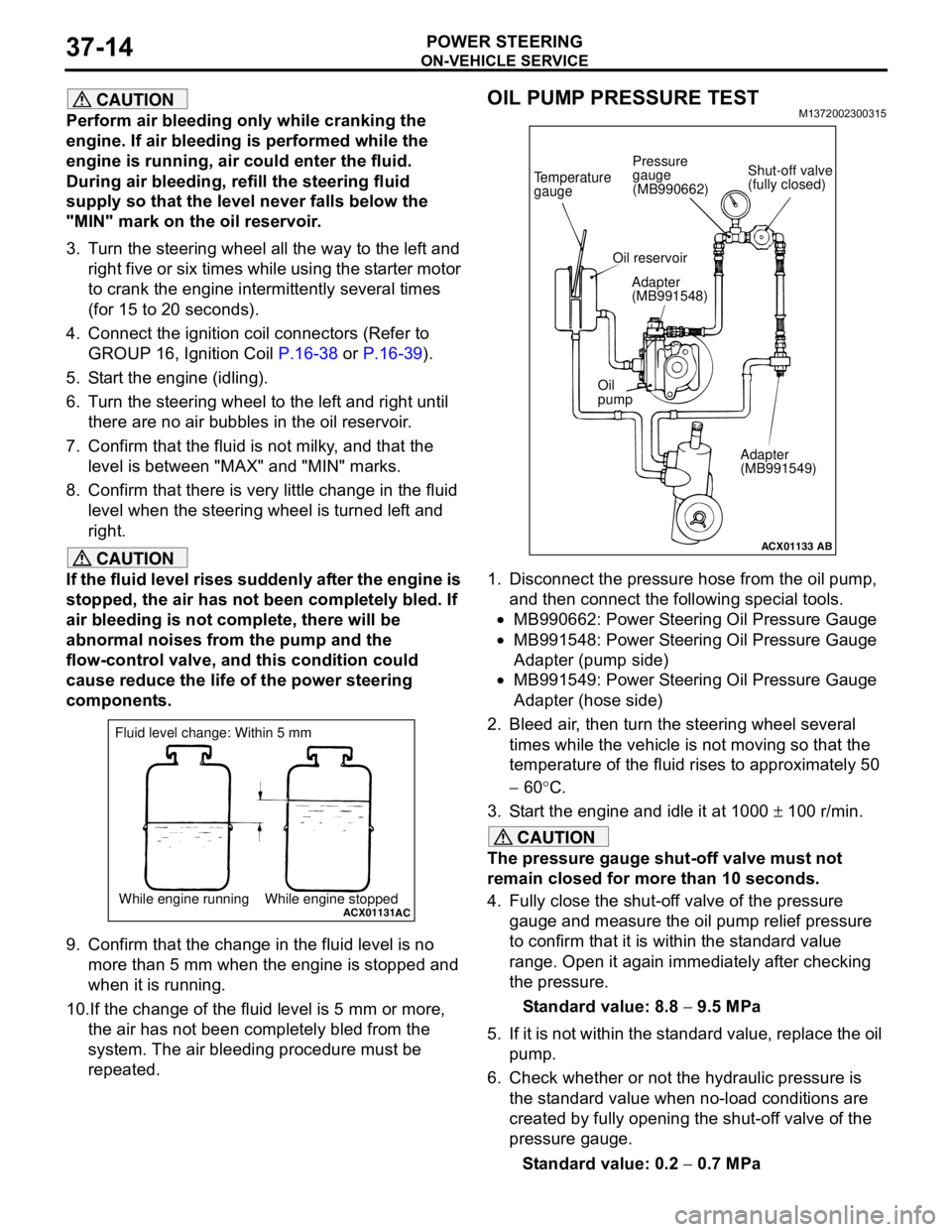

OIL PUMP PRESSURE TESTM1372002300315

1. Disconnect the pressure hose from the oil pump,

and then connect the following special tools.

•MB990662: Power Steering Oil Pressure Gauge

•MB991548: Power Steering Oil Pressure Gauge

Adapter (pump side)

•MB991549: Power Steering Oil Pressure Gauge

Adapter (hose side)

2. Bleed air, then turn the steering wheel several

times while the vehicle is not moving so that the

temperature of the fluid rises to approximately 50

− 60°C.

3. Start the engine and idle it at 1000 ± 100 r/min.

CAUTION

The pressure gauge shut-off valve must not

remain closed for more than 10 seconds.

4. Fully close the shut-off valve of the pressure

gauge and measure the oil pump relief pressure

to confirm that it is within the standard value

range. Open it again immediately after checking

the pressure.

Standard value: 8.8 − 9.5 MPa

5. If it is not within the standard value, replace the oil

pump.

6. Check whether or not the hydraulic pressure is

the standard value when no-load conditions are

created by fully opening the shut-off valve of the

pressure gauge.

Standard value: 0.2 − 0.7 MPa

ACX01131While engine running While engine stoppedAC

Fluid level change: Within 5 mm

ACX01133

Temperature

gauge

Oil reservoir

Adapter

(MB991548)

Oil

pump

Adapter

(MB991549)

AB

Shut-off valve

(fully closed) Pressure

gauge

(MB990662)

Page 249 of 788

ON-VEHICLE SERVICE

POWER STEERING37-15

7. If it is not within the standard value, the probable

cause is a malfunction of the oil line or steering

gear, so check these parts and repair as

necessary.

8. Turn the steering wheel all the way to the left or

right; then check whether or not the retention

hydraulic pressure is the standard value.

Standard value: 8.8 − 9.5 MPa

9. If not the standard value, overhaul the steering

gear. Remeasure fluid pressure.

10. Remove the special tools, and then tighten the

pressure hose to the specified torque.

Tightening torque: 57 ± 7 N⋅m

11. Bleed the system (Refer to P.37-13).

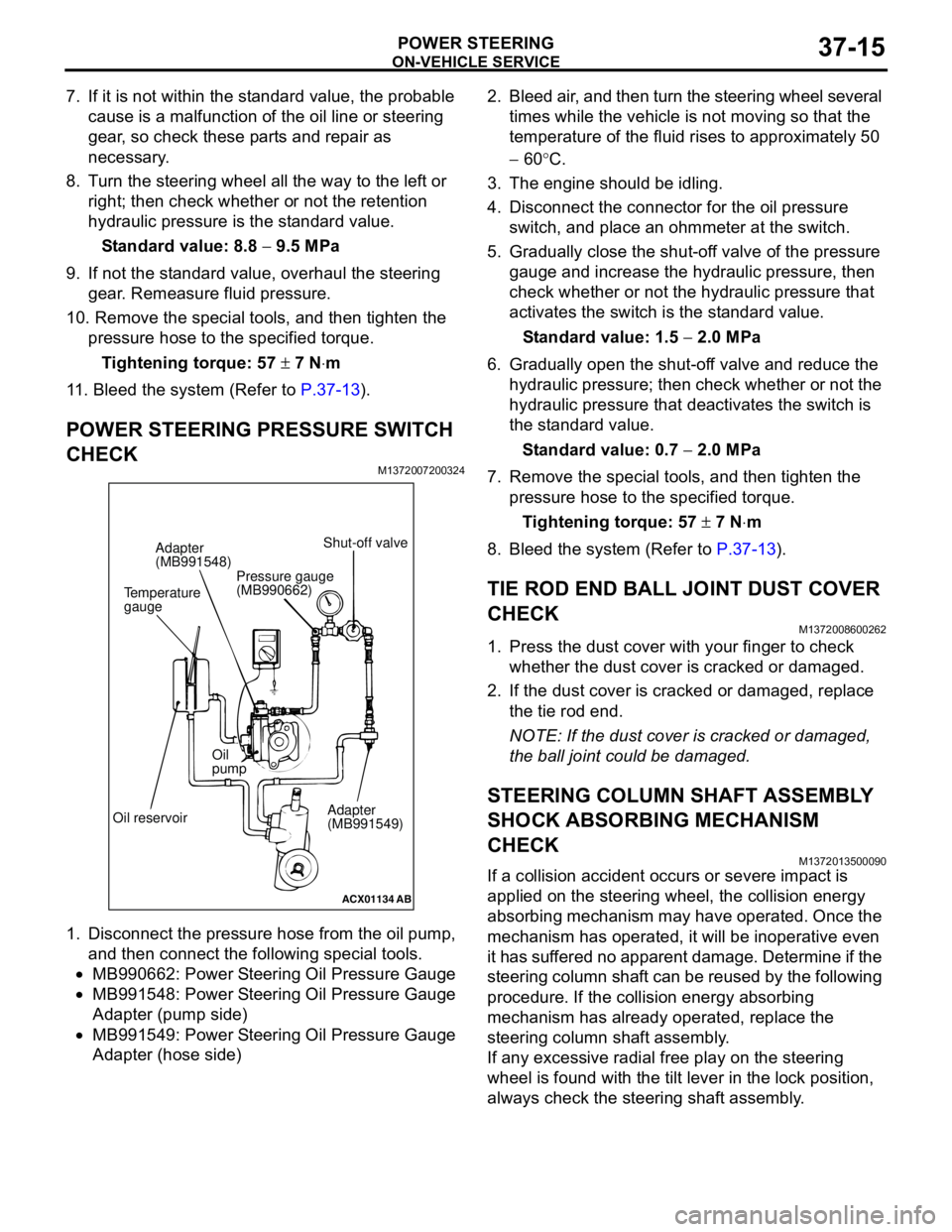

POWER STEERING PRESSURE SWITCH

CHECK

M1372007200324

1. Disconnect the pressure hose from the oil pump,

and then connect the following special tools.

•MB990662: Power Steering Oil Pressure Gauge

•MB991548: Power Steering Oil Pressure Gauge

Adapter (pump side)

•MB991549: Power Steering Oil Pressure Gauge

Adapter (hose side)2. Bleed air, and then turn the steering wheel several

times while the vehicle is not moving so that the

temperature of the fluid rises to approximately 50

− 60°C.

3. The engine should be idling.

4. Disconnect the connector for the oil pressure

switch, and place an ohmmeter at the switch.

5. Gradually close the shut-off valve of the pressure

gauge and increase the hydraulic pressure, then

check whether or not the hydraulic pressure that

activates the switch is the standard value.

Standard value: 1.5 − 2.0 MPa

6. Gradually open the shut-off valve and reduce the

hydraulic pressure; then check whether or not the

hydraulic pressure that deactivates the switch is

the standard value.

Standard value: 0.7 − 2.0 MPa

7. Remove the special tools, and then tighten the

pressure hose to the specified torque.

Tightening torque: 57 ± 7 N⋅m

8. Bleed the system (Refer to P.37-13).

TIE ROD END BALL JOINT DUST COVER

CHECK

M1372008600262

1. Press the dust cover with your finger to check

whether the dust cover is cracked or damaged.

2. If the dust cover is cracked or damaged, replace

the tie rod end.

NOTE: If the dust cover is cracked or damaged,

the ball joint could be damaged.

STEERING COLUMN SHAFT ASSEMBLY

SHOCK ABSORBING MECHANISM

CHECK

M1372013500090

If a collision accident occurs or severe impact is

applied on the steering wheel, the collision energy

absorbing mechanism may have operated. Once the

mechanism has operated, it will be inoperative even

it has suffered no apparent damage. Determine if the

steering column shaft can be reused by the following

procedure. If the collision energy absorbing

mechanism has already operated, replace the

steering column shaft assembly.

If any excessive radial free play on the steering

wheel is found with the tilt lever in the lock position,

always check the steering shaft assembly.

ACX01134

AB

Temperature

gaugeAdapter

(MB991548)

Oil reservoirOil

pump

Adapter

(MB991549) Shut-off valve

Pressure gauge

(MB990662)