fuel MITSUBISHI LANCER 2005 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 419 of 788

COMBINATION METER ASSEMBLY

CHASSIS ELECTRICAL54A-31

TROUBLESHOOTING

SYMPTOM CHARTM1543007201086

MB991223

A: MB991219

B: MB991220

C: MB991221

D: MB991222Harness set

A: Test harness

B: LED harness

C: LED harness

adapter

D: ProbeMaking voltage and

resistance measurements

during troubleshooting

A: Connect pin contact

pressure inspection

B: Power circuit inspection

C: Power circuit inspection

D: Commercial tester

connection Tool Number Name Use

MB991223

A

B

C

D

AC

Symptom Inspection

procedure No.Reference page

Speedometer does not work (the other meters work).

P.54A-32

Speedometer does not work (the other meters work). 2

P.54A-37

Tachometer does not work (the other meters work). 3

P.54A-44

Fuel gauge does not work (the other meters work). 4

P.54A-48

Engine coolant temperature gauge does not work (the other

meters work).5

P.54A-51

Combination meters does not work (the instruments do not

work).6

P.54A-54

Page 436 of 788

COMBINATION METER ASSEMBLY

CHASSIS ELECTRICAL54A-48

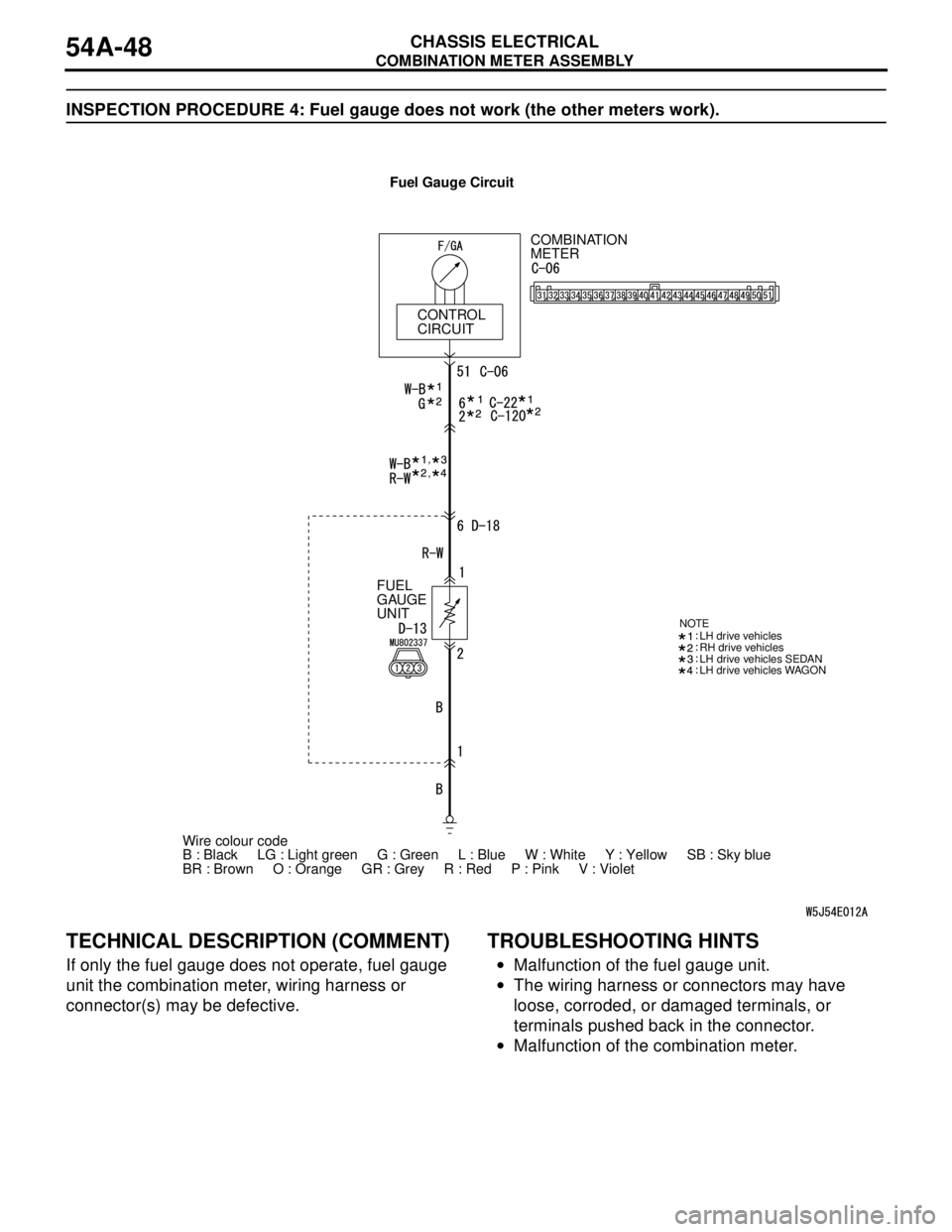

INSPECTION PROCEDURE 4: Fuel gauge does not work (the other meters work).

TECHNICAL DESCRIPTION (COMMENT)

If only the fuel gauge does not operate, fuel gauge

unit the combination meter, wiring harness or

connector(s) may be defective.

TROUBLESHOOTING HINTS

•Malfunction of the fuel gauge unit.

•The wiring harness or connectors may have

loose, corroded, or damaged terminals, or

terminals pushed back in the connector.

•Malfunction of the combination meter.

COMBINATION

METER

CONTROL

CIRCUIT

FUEL

GAUGE

UNIT

LH drive vehicles SEDAN

LH drive vehicles WAGON NOTE

LH drive vehicles

RH drive vehicles

,,

Wire colour code

B : Black LG : Light green G : Green L : Blue W : White Y : Yellow SB : Sky blue

BR : Brown O : Orange GR : Grey R : Red P : Pink V : VioletFuel Gauge Circuit

Page 437 of 788

COMBINATION METER ASSEMBLY

CHASSIS ELECTRICAL54A-49

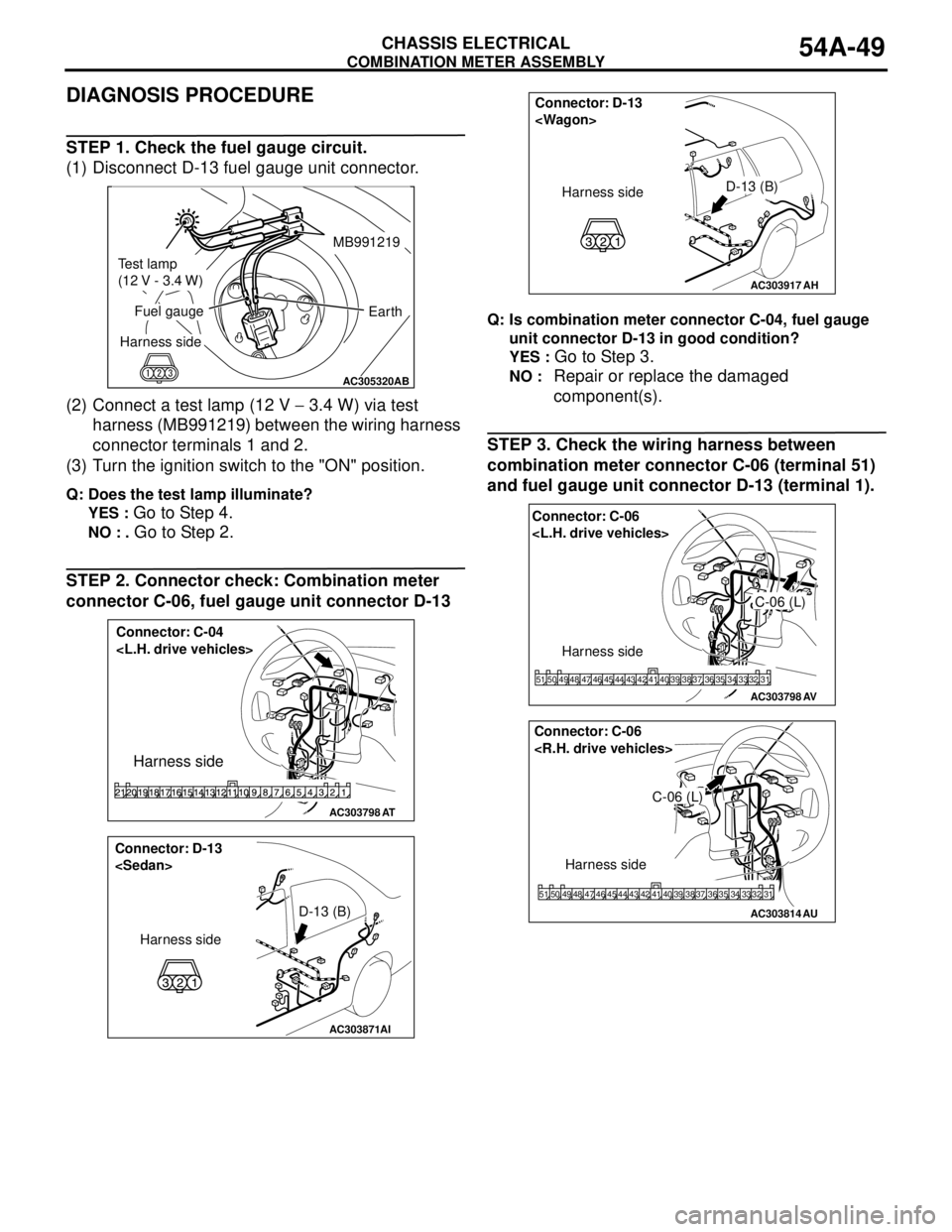

DIAGNOSIS PROCEDURE

STEP 1. Check the fuel gauge circuit.

(1) Disconnect D-13 fuel gauge unit connector.

(2) Connect a test lamp (12 V − 3.4 W) via test

harness (MB991219) between the wiring harness

connector terminals 1 and 2.

(3) Turn the ignition switch to the "ON" position.

Q: Does the test lamp illuminate?

YES :

Go to Step 4.

NO : . Go to Step 2.

STEP 2. Connector check: Combination meter

connector C-06, fuel gauge unit connector D-13

Q: Is combination meter connector C-04, fuel gauge

unit connector D-13 in good condition?

YES :

Go to Step 3.

NO : Repair or replace the damaged

component(s).

STEP 3. Check the wiring harness between

combination meter connector C-06 (terminal 51)

and fuel gauge unit connector D-13 (terminal 1).

AC305320

AB

Test lamp

(12 V - 3.4 W)

MB991219

Harness side

Fuel gauge

Earth

AC303798

Connector: C-04

Harness side

AT

AC303871

Connector: D-13

Harness sideD-13 (B)

AI

AC303917

D-13 (B) Connector: D-13

Harness side

AH

AC303798

Connector: C-06

Harness side

C-06 (L)

31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51

AV

AC303814AU

Connector: C-06

Harness side

31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51

C-06 (L)

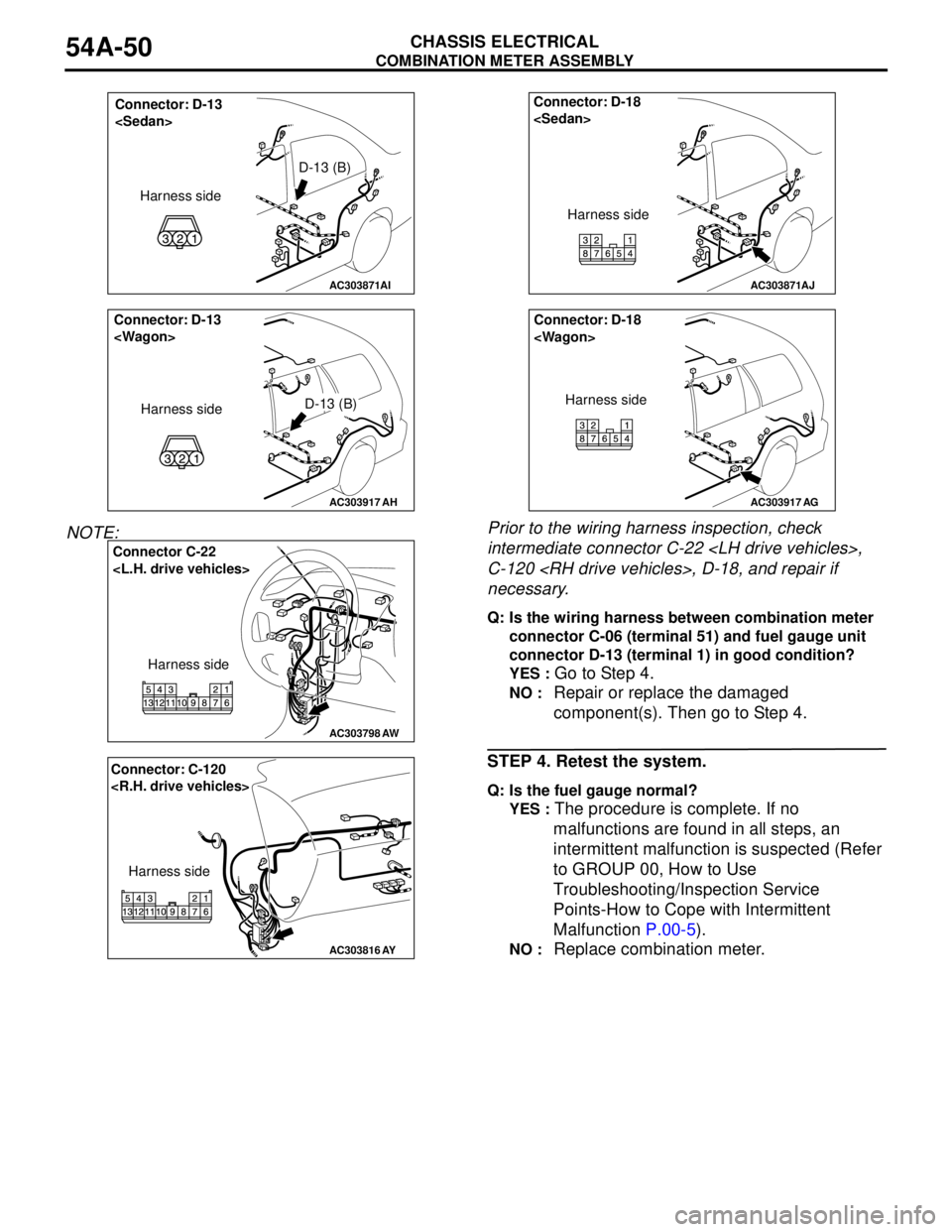

Page 438 of 788

COMBINATION METER ASSEMBLY

CHASSIS ELECTRICAL54A-50

NOTE: Prior to the wiring harness inspection, check

intermediate connector C-22

C-120

necessary.

Q: Is the wiring harness between combination meter

connector C-06 (terminal 51) and fuel gauge unit

connector D-13 (terminal 1) in good condition?

YES :

Go to Step 4.

NO : Repair or replace the damaged

component(s). Then go to Step 4.

STEP 4. Retest the system.

Q: Is the fuel gauge normal?

YES :

The procedure is complete. If no

malfunctions are found in all steps, an

intermittent malfunction is suspected (Refer

to GROUP 00, How to Use

Troubleshooting/Inspection Service

Points-How to Cope with Intermittent

Malfunction P.00-5).

NO : Replace combination meter.

AC303871

Connector: D-13

Harness sideD-13 (B)

AI

AC303917

D-13 (B) Connector: D-13

Harness side

AH

AC303798

Harness side Connector C-22

AW

AC303816AY

Connector: C-120

Harness side

AC303871

Connector: D-18

AJ

Harness side

AC303917

Connector: D-18

Harness side

AG

Page 439 of 788

COMBINATION METER ASSEMBLY

CHASSIS ELECTRICAL54A-51

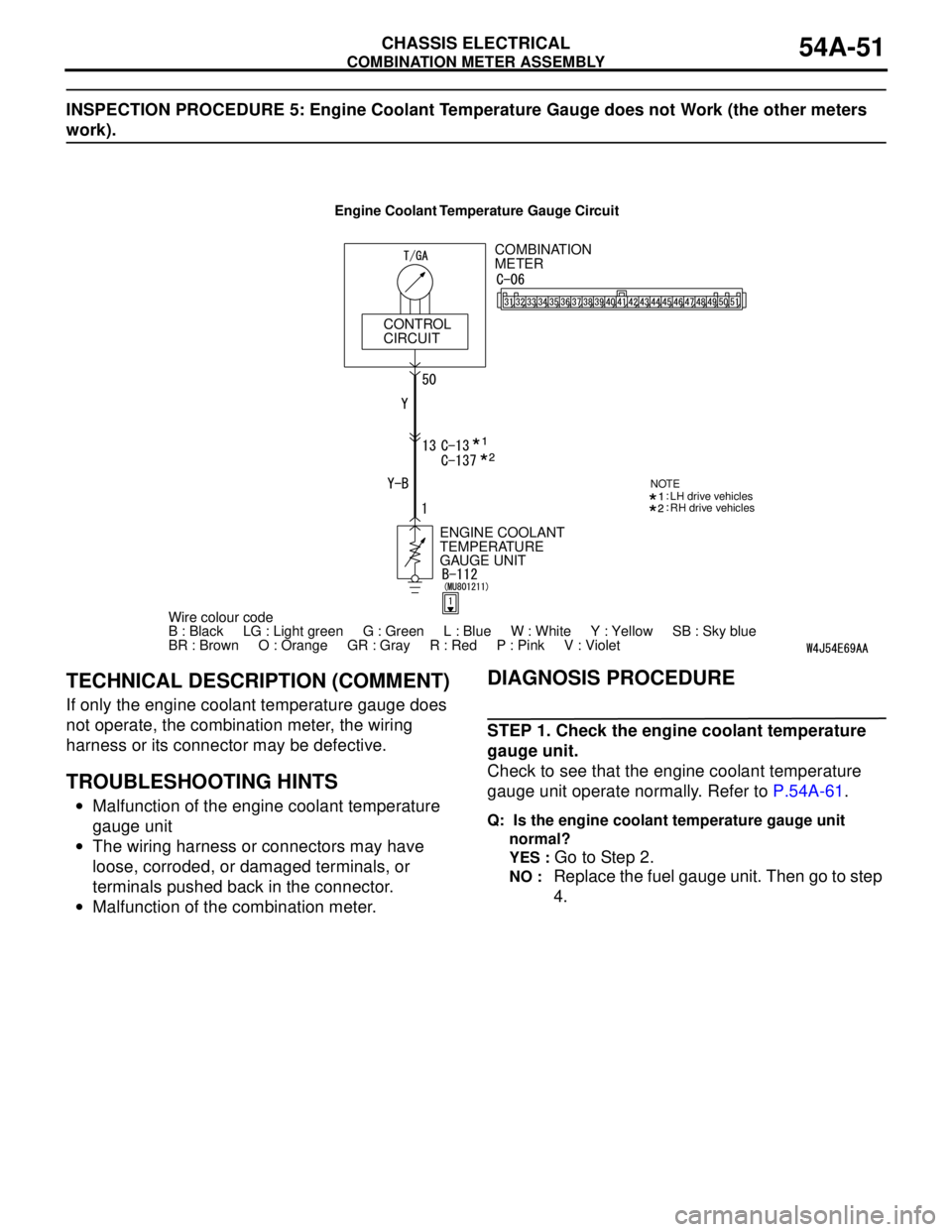

INSPECTION PROCEDURE 5: Engine Coolant Temperature Gauge does not Work (the other meters

work).

TECHNICAL DESCRIPTION (COMMENT)

If only the engine coolant temperature gauge does

not operate, the combination meter, the wiring

harness or its connector may be defective.

TROUBLESHOOTING HINTS

•Malfunction of the engine coolant temperature

gauge unit

•The wiring harness or connectors may have

loose, corroded, or damaged terminals, or

terminals pushed back in the connector.

•Malfunction of the combination meter.

DIAGNOSIS PROCEDURE

STEP 1. Check the engine coolant temperature

gauge unit.

Check to see that the engine coolant temperature

gauge unit operate normally. Refer to P.54A-61.

Q: Is the engine coolant temperature gauge unit

normal?

YES :

Go to Step 2.

NO : Replace the fuel gauge unit. Then go to step

4.

COMBINATION

METER

CONTROL

CIRCUIT

Wire colour code

B : Black LG : Light green G : Green L : Blue W : White Y : Yellow SB : Sky blue

BR : Brown O : Orange GR : Gray R : Red P : Pink V : Violet ENGINE COOLANT

TEMPERATURE

GAUGE UNIT

NOTELH drive vehicles

RH drive vehicles

Engine Coolant Temperature Gauge Circuit

Page 449 of 788

COMBINATION METER ASSEMBLY

CHASSIS ELECTRICAL54A-61

NOTE: For tachometer check, use an external

high quality inductive tachometer.

2. Compare the readings of the vehicle tachometer

and the external tachometer at every engine

speed, and check if the variations are within the

standard values.

Standard values:

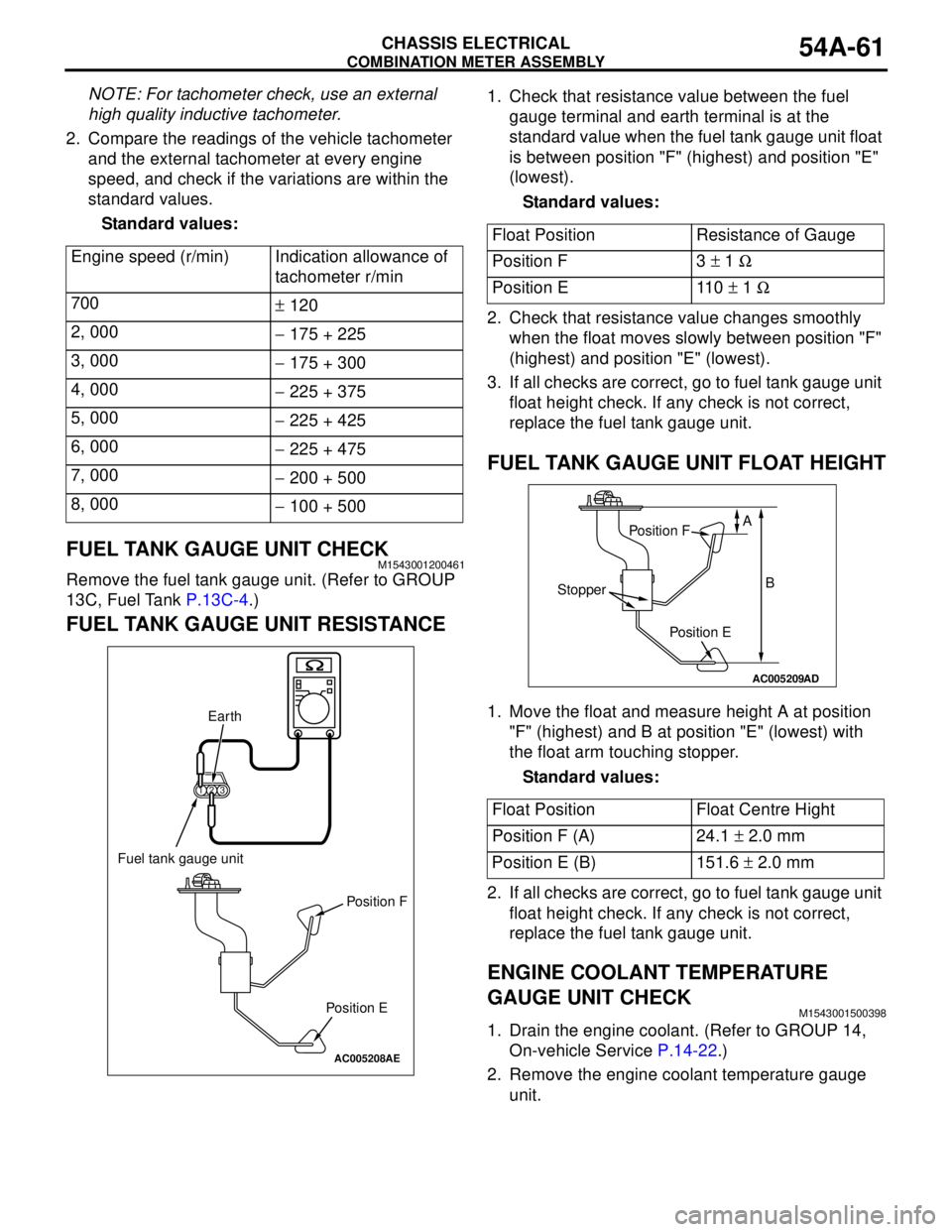

FUEL TANK GAUGE UNIT CHECKM1543001200461

Remove the fuel tank gauge unit. (Refer to GROUP

13C, Fuel Tank P.13C-4.)

FUEL TANK GAUGE UNIT RESISTANCE

1. Check that resistance value between the fuel

gauge terminal and earth terminal is at the

standard value when the fuel tank gauge unit float

is between position "F" (highest) and position "E"

(lowest).

Standard values:

2. Check that resistance value changes smoothly

when the float moves slowly between position "F"

(highest) and position "E" (lowest).

3. If all checks are correct, go to fuel tank gauge unit

float height check. If any check is not correct,

replace the fuel tank gauge unit.

FUEL TANK GAUGE UNIT FLOAT HEIGHT

1. Move the float and measure height A at position

"F" (highest) and B at position "E" (lowest) with

the float arm touching stopper.

Standard values:

2. If all checks are correct, go to fuel tank gauge unit

float height check. If any check is not correct,

replace the fuel tank gauge unit.

ENGINE COOLANT TEMPERATURE

GAUGE UNIT CHECK

M1543001500398

1. Drain the engine coolant. (Refer to GROUP 14,

On-vehicle Service P.14-22.)

2. Remove the engine coolant temperature gauge

unit. Engine speed (r/min) Indication allowance of

tachometer r/min

700

± 120

2, 000

− 175 + 225

3, 000

− 175 + 300

4, 000

− 225 + 375

5, 000

− 225 + 425

6, 000

− 225 + 475

7, 000

− 200 + 500

8, 000

− 100 + 500

AC005208

123

AE

Fuel tank gauge unit

Earth

Position F

Position E

Float Position Resistance of Gauge

Position F 3 ± 1 Ω

Position E 110 ± 1 Ω

Float Position Float Centre Hight

Position F (A) 24.1 ± 2.0 mm

Position E (B) 151.6 ± 2.0 mm

AC005209

AD

Position F

Position E

Stopper

A

B

Page 452 of 788

COMBINATION METER ASSEMBLY

CHASSIS ELECTRICAL54A-64

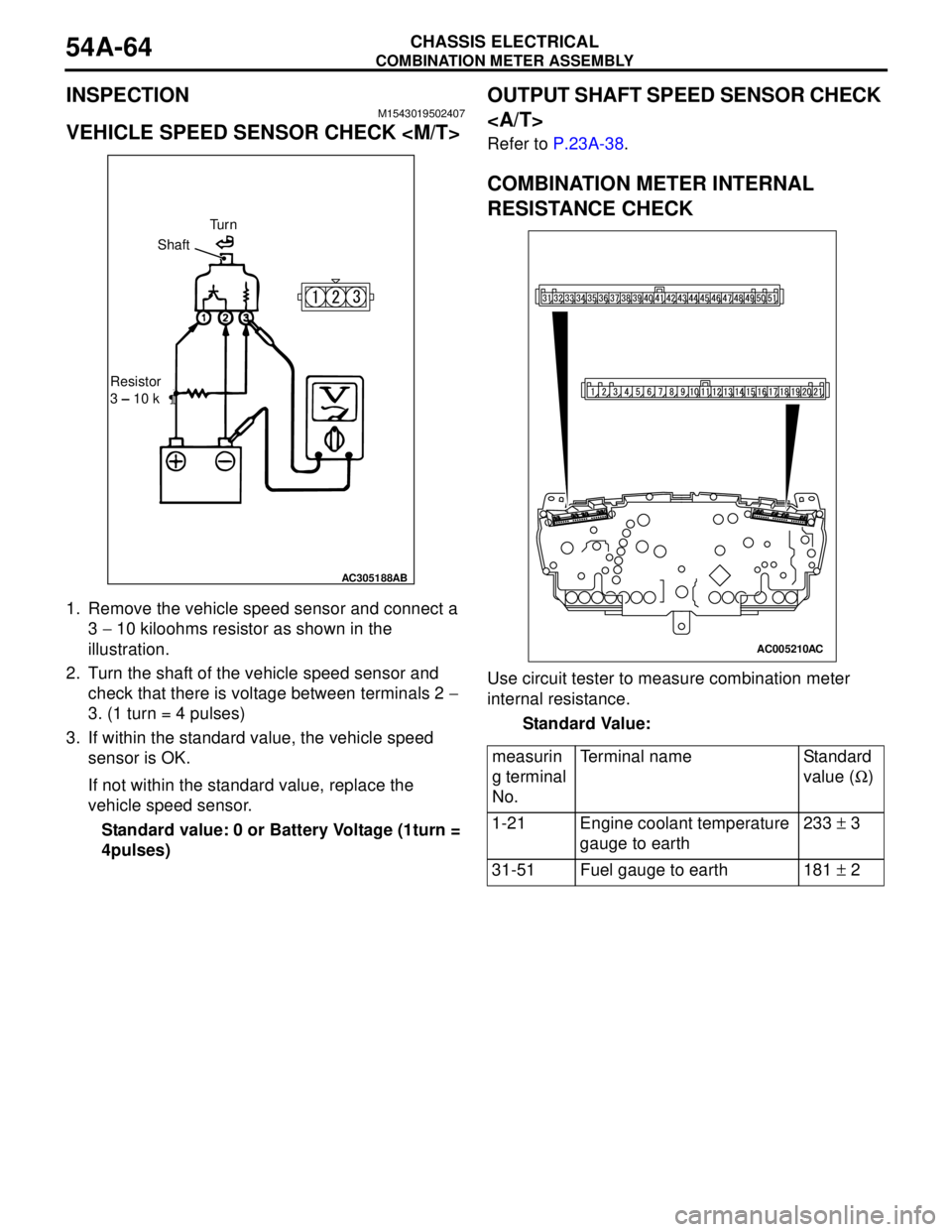

INSPECTIONM1543019502407

VEHICLE SPEED SENSOR CHECK

1. Remove the vehicle speed sensor and connect a

3 − 10 kiloohms resistor as shown in the

illustration.

2. Turn the shaft of the vehicle speed sensor and

check that there is voltage between terminals 2 −

3. (1 turn = 4 pulses)

3. If within the standard value, the vehicle speed

sensor is OK.

If not within the standard value, replace the

vehicle speed sensor.

Standard value: 0 or Battery Voltage (1turn =

4pulses)

OUTPUT SHAFT SPEED SENSOR CHECK

Refer to P.23A-38.

COMBINATION METER INTERNAL

RESISTANCE CHECK

Use circuit tester to measure combination meter

internal resistance.

Standard Value:

AC305188AB

Tu r n

Shaft

Resistor

3 – 10 k¶

measurin

g terminal

No.Terminal name Standard

value (Ω)

1-21 Engine coolant temperature

gauge to earth233 ± 3

31-51 Fuel gauge to earth 181 ± 2

AC005210AC

Page 454 of 788

HEADLAMP

CHASSIS ELECTRICAL54A-66

HEADLAMP

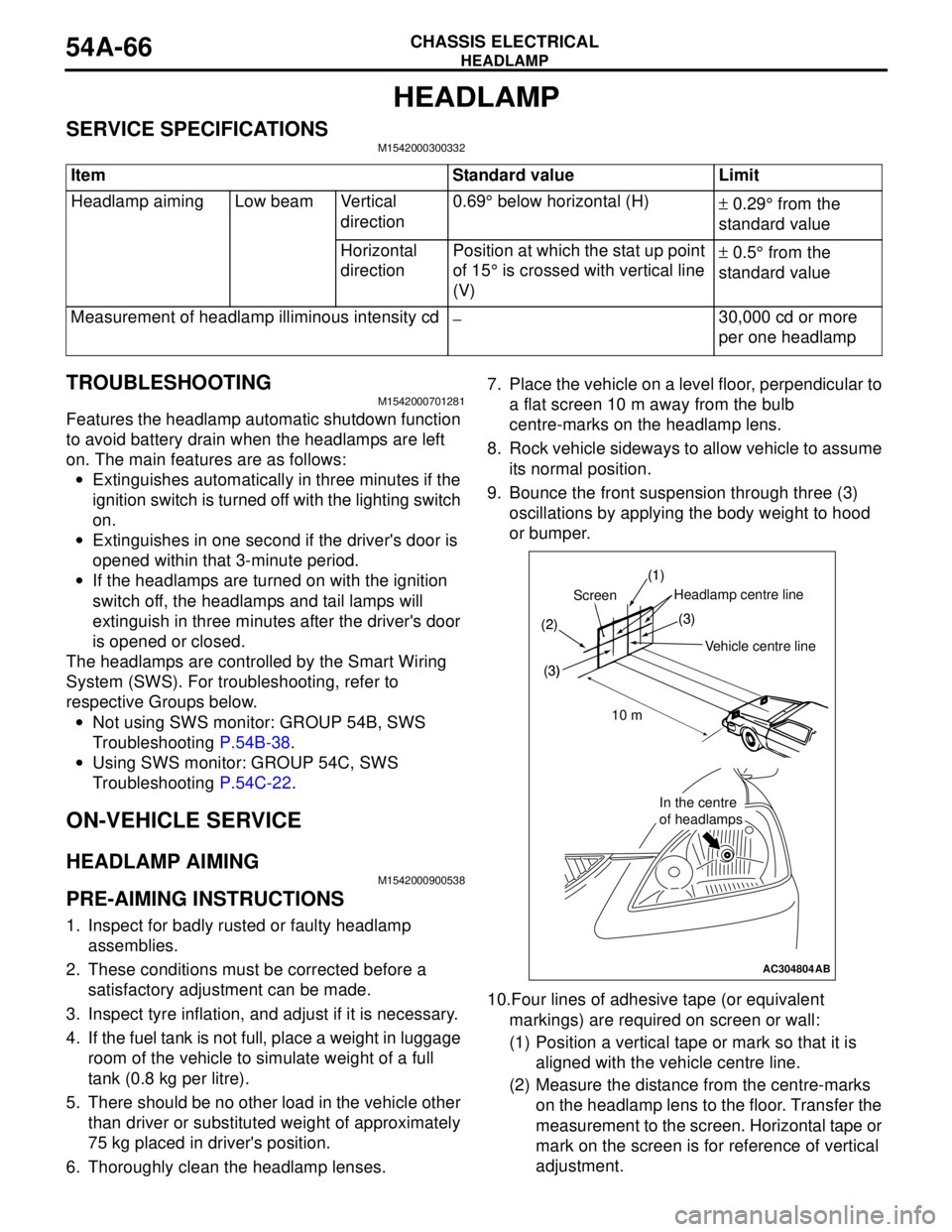

SERVICE SPECIFICATIONSM1542000300332

TROUBLESHOOTING M1542000701281

Features the headlamp automatic shutdown function

to avoid battery drain when the headlamps are left

on. The main features are as follows:

•Extinguishes automatically in three minutes if the

ignition switch is turned off with the lighting switch

on.

•Extinguishes in one second if the driver's door is

opened within that 3-minute period.

•If the headlamps are turned on with the ignition

switch off, the headlamps and tail lamps will

extinguish in three minutes after the driver's door

is opened or closed.

The headlamps are controlled by the Smart Wiring

System (SWS). For troubleshooting, refer to

respective Groups below.

•Not using SWS monitor: GROUP 54B, SWS

Troubleshooting P.54B-38.

•Using SWS monitor: GROUP 54C, SWS

Troubleshooting P.54C-22.

ON-VEHICLE SERVICE

HEADLAMP AIMING

M1542000900538

PRE-AIMING INSTRUCTIONS

1. Inspect for badly rusted or faulty headlamp

assemblies.

2. These conditions must be corrected before a

satisfactory adjustment can be made.

3. Inspect tyre inflation, and adjust if it is necessary.

4. If the fuel tank is not full, place a weight in luggage

room of the vehicle to simulate weight of a full

tank (0.8 kg per litre).

5. There should be no other load in the vehicle other

than driver or substituted weight of approximately

75 kg placed in driver's position.

6. Thoroughly clean the headlamp lenses.7. Place the vehicle on a level floor, perpendicular to

a flat screen 10 m away from the bulb

centre-marks on the headlamp lens.

8. Rock vehicle sideways to allow vehicle to assume

its normal position.

9. Bounce the front suspension through three (3)

oscillations by applying the body weight to hood

or bumper.

10.Four lines of adhesive tape (or equivalent

markings) are required on screen or wall:

(1) Position a vertical tape or mark so that it is

aligned with the vehicle centre line.

(2) Measure the distance from the centre-marks

on the headlamp lens to the floor. Transfer the

measurement to the screen. Horizontal tape or

mark on the screen is for reference of vertical

adjustment. Item Standard value Limit

Headlamp aiming Low beam Vertical

direction0.69° below horizontal (H)

± 0.29° from the

standard value

Horizontal

directionPosition at which the stat up point

of 15° is crossed with vertical line

(V)± 0.5° from the

standard value

Measurement of headlamp illiminous intensity cd

−30,000 cd or more

per one headlamp

AC304804

(1)

(2)

(3)

Headlamp centre line

Vehicle crntre line Screen

(3)

10 m

In the centre

of headlamps

(1)

(2)

(3)(3)

In the centre

of headlamps

AB

Vehicle centre line

ScreenHeadlamp centre line

10 m

Page 591 of 788

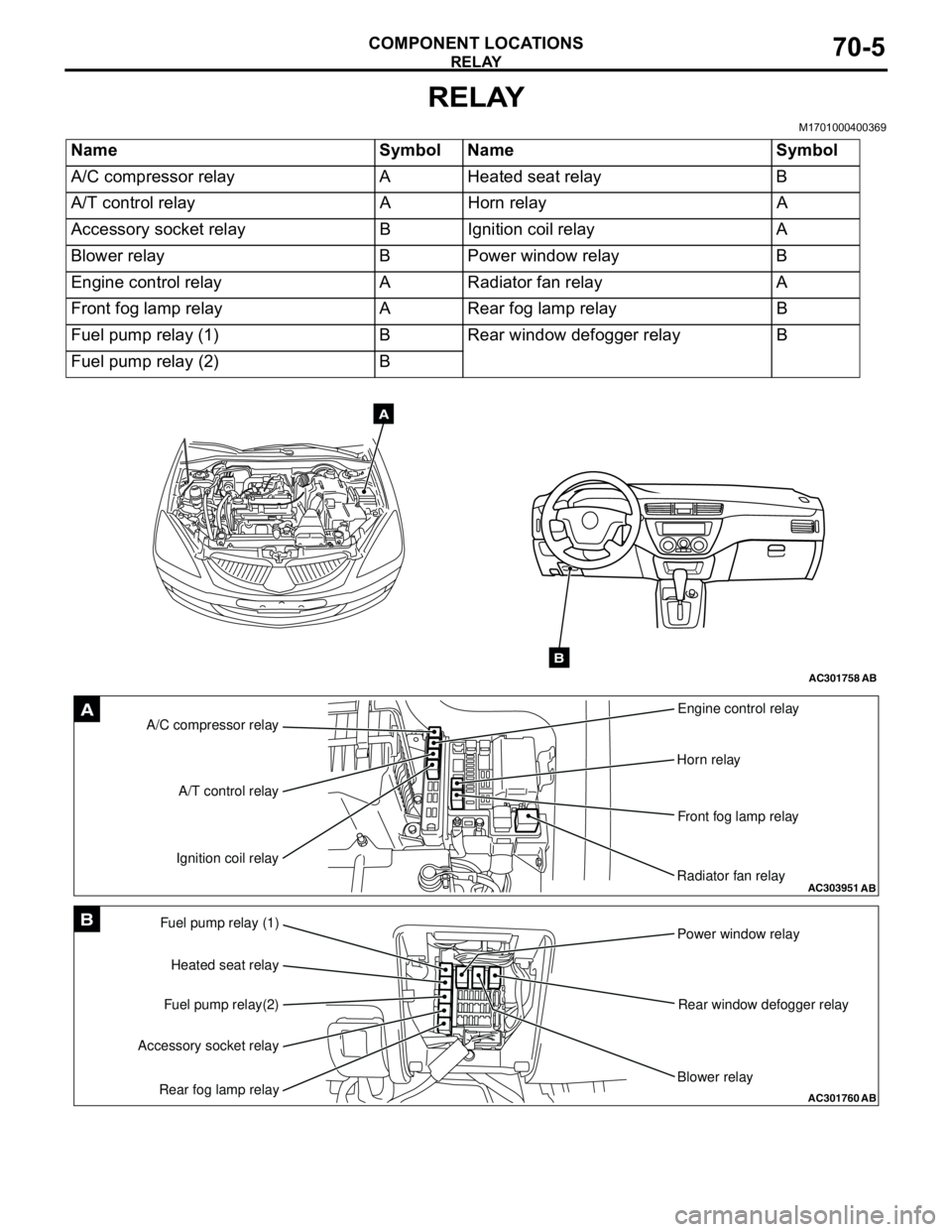

RELAY

COMPONENT LOCATIONS70-5

RELAY

M1701000400369

Name Symbol Name Symbol

A/C compressor relay A Heated seat relay B

A/T control relay A Horn relay A

Accessory socket relay B Ignition coil relay A

Blower relay B Power window relay B

Engine control relay A Radiator fan relay A

Front fog lamp relay A Rear fog lamp relay B

Fuel pump relay (1) B Rear window defogger relay B

Fuel pump relay (2) B

AC301758AB

A

B

AC303951AB

A/C compressor relayEngine control relay

Horn relay

Front fog lamp relay

Radiator fan relay A/T control relay

Ignition coil relayA

AC301760

Fuel pump relay (1)

Power window relay

Rear window defogger relay

Blower relay Heated seat relay

Fuel pump relay(2)

Accessory socket relay

Rear fog lamp relayAB

B

Page 608 of 788

OVERALL CONFIGURATION DIAGRAM

CONFIGURATION DIAGRAMS80-2

OVERALL CONFIGURATION DIAGRAM

OVERALL WIRING DIAGRAM

NOTE: .

1. This illustration shows only major wiring harnesses.

2. *: also equipped at the right side.

AC301175

AB

Front wiring

harness (RH)Control wiring

harnessInstrument panel

wiring harnessRoof wiring

harnessFloor wiring

harness (RH)

Battery wiring

harnessFront wiring

harness (LH)Front door

wiring harness Floor wiring

harness (LH)Fuel wiring

harnessRear door

wiring harness

Front bumper

wiring harness

Rear bumper

wiring harness

**