ABS MITSUBISHI LANCER 2005 Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 250 of 788

ON-VEHICLE SERVICE

POWER STEERING37-16

WARNING

•If the vehicle continues to be driven after

the collision absorbing mechanism has

operated, the steering column shaft may

be damaged while it is in use.

•If there is a slack in the one-way capsule,

do not attempt to repair it but replace the

steering column shaft assembly.

Inspection Procedure

1. Remove the lower and upper column covers.

CAUTION

Do not release the tilt lever until the steering

column has been installed to complete this

inspection procedure.

2. Ensure that the tilt lever is in the lock position.

NOTE: If not, place the tilt lever in the lock

position.

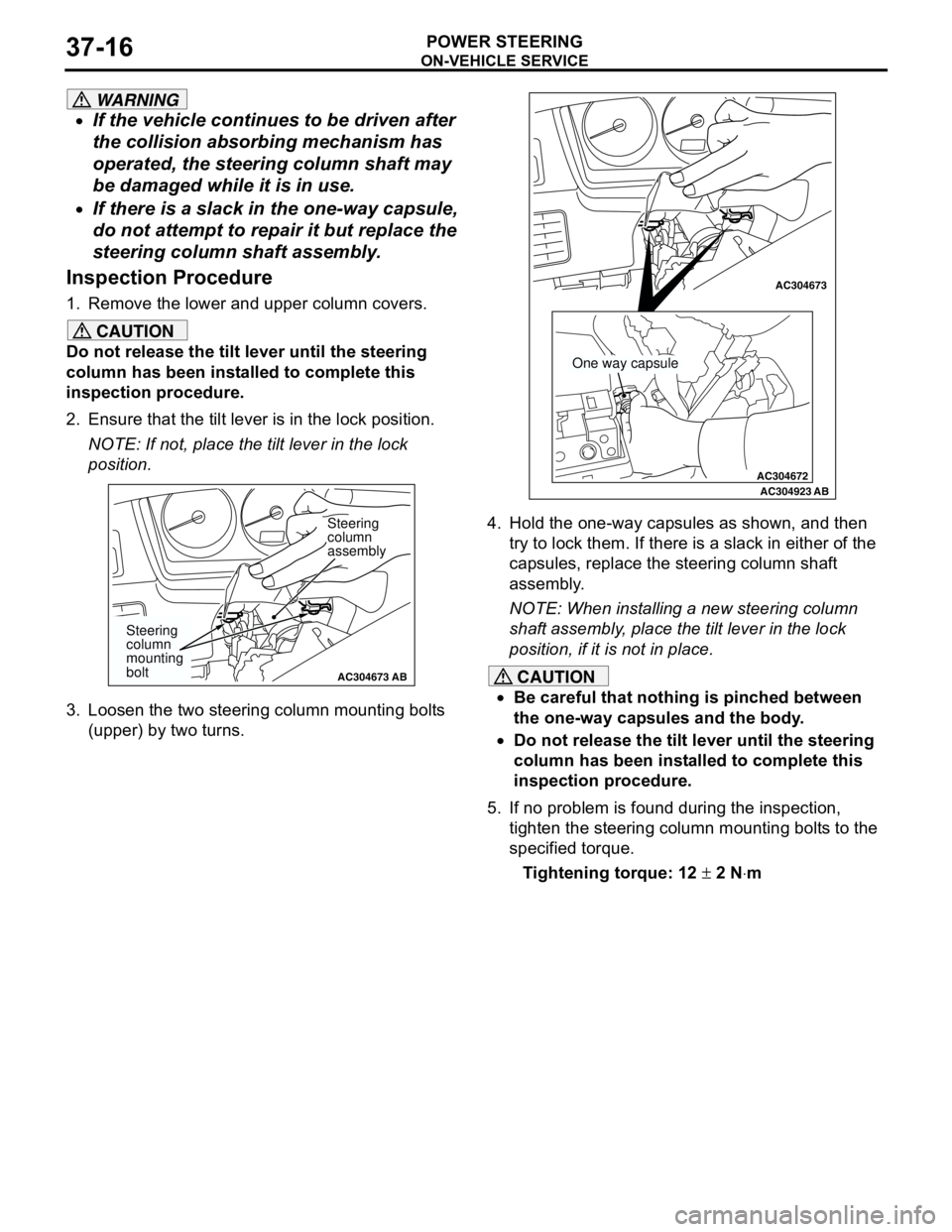

3. Loosen the two steering column mounting bolts

(upper) by two turns.4. Hold the one-way capsules as shown, and then

try to lock them. If there is a slack in either of the

capsules, replace the steering column shaft

assembly.

NOTE: When installing a new steering column

shaft assembly, place the tilt lever in the lock

position, if it is not in place.

CAUTION

•Be careful that nothing is pinched between

the one-way capsules and the body.

•Do not release the tilt lever until the steering

column has been installed to complete this

inspection procedure.

5. If no problem is found during the inspection,

tighten the steering column mounting bolts to the

specified torque.

Tightening torque: 12 ± 2 N⋅m

AC304673AC304673

Steering

column

assembly

AB

Steering

column

mounting

bolt

AC304672

AC304673AC304673

AC304923AB

One way capsule

Page 255 of 788

STEERING SHAFT

POWER STEERING37-21

STEERING SHAFT

REMOVAL AND INSTALLATIONM1372011500113

WARNING

Before removing the steering wheel and air bag module assembly, refer to GROUP 52B,

Service Precautions (P.52B-5) and Air Bag Module and Clock Spring (P.52B-210).

REMOVAL SERVICE POINT

<> STEERING COLUMN SHAFT

ASSEMBLY REMOVAL

CAUTION

The tilt lever should be held in the lock position

until the steering column shaft is installed to the

vehicle. If the steering column is removed with

the tilt lever released, or the tilt lever is released

after the steering column shaft was removed from the vehicle, the steering column can not be

reinstalled correctly. If the steering column is

installed incorrectly, the collision energy

absorbing mechanism may be damaged.

1. Ensure that the tilt lever is in the lock position, and

remove the steering column mounting bolts.

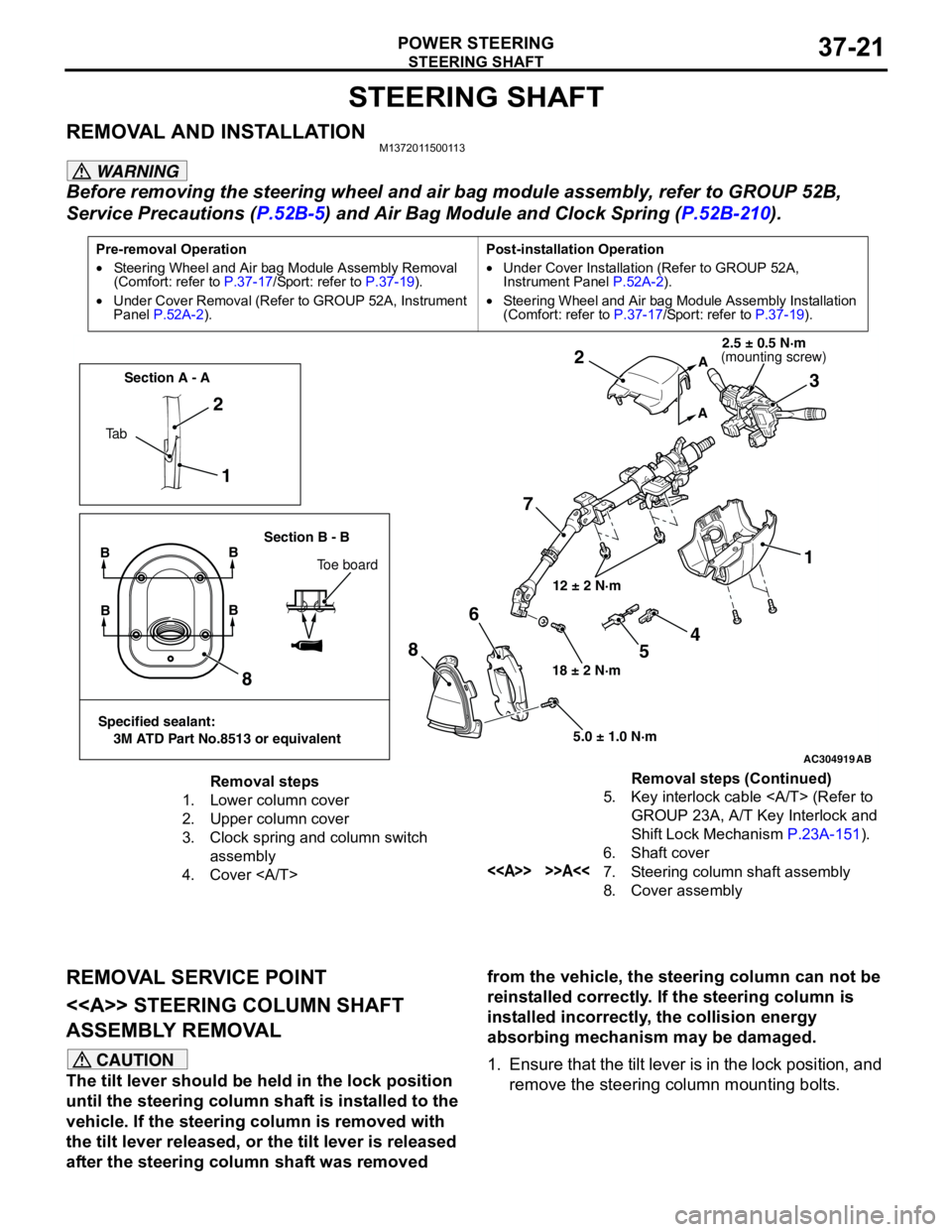

Pre-removal Operation

•Steering Wheel and Air bag Module Assembly Removal

(Comfort: refer to P.37-17/Sport: refer to P.37-19).

•Under Cover Removal (Refer to GROUP 52A, Instrument

Panel P.52A-2).Post-installation Operation

•Under Cover Installation (Refer to GROUP 52A,

Instrument Panel P.52A-2).

•Steering Wheel and Air bag Module Assembly Installation

(Comfort: refer to P.37-17/Sport: refer to P.37-19).

AC304919AB

12 ± 2 N·m

18 ± 2 N·m

5.0 ± 1.0 N·m

1 2

73 2

1

8

86

A

A

Ta bSection A - A

Section B - B

BB

Toe board

Specified sealant:

3M ATD Part No.8513 or equivalent

BB

4

5

(mounting screw)2.5 ± 0.5 N·m

Removal steps

1. Lower column cover

2. Upper column cover

3. Clock spring and column switch

assembly

4. Cover 5. Key interlock cable (Refer to

GROUP 23A, A/T Key Interlock and

Shift Lock Mechanism P.23A-151).

6. Shaft cover

<> >>A<<7. Steering column shaft assembly

8. Cover assemblyRemoval steps (Continued)

Page 256 of 788

STEERING SHAFT

POWER STEERING37-22

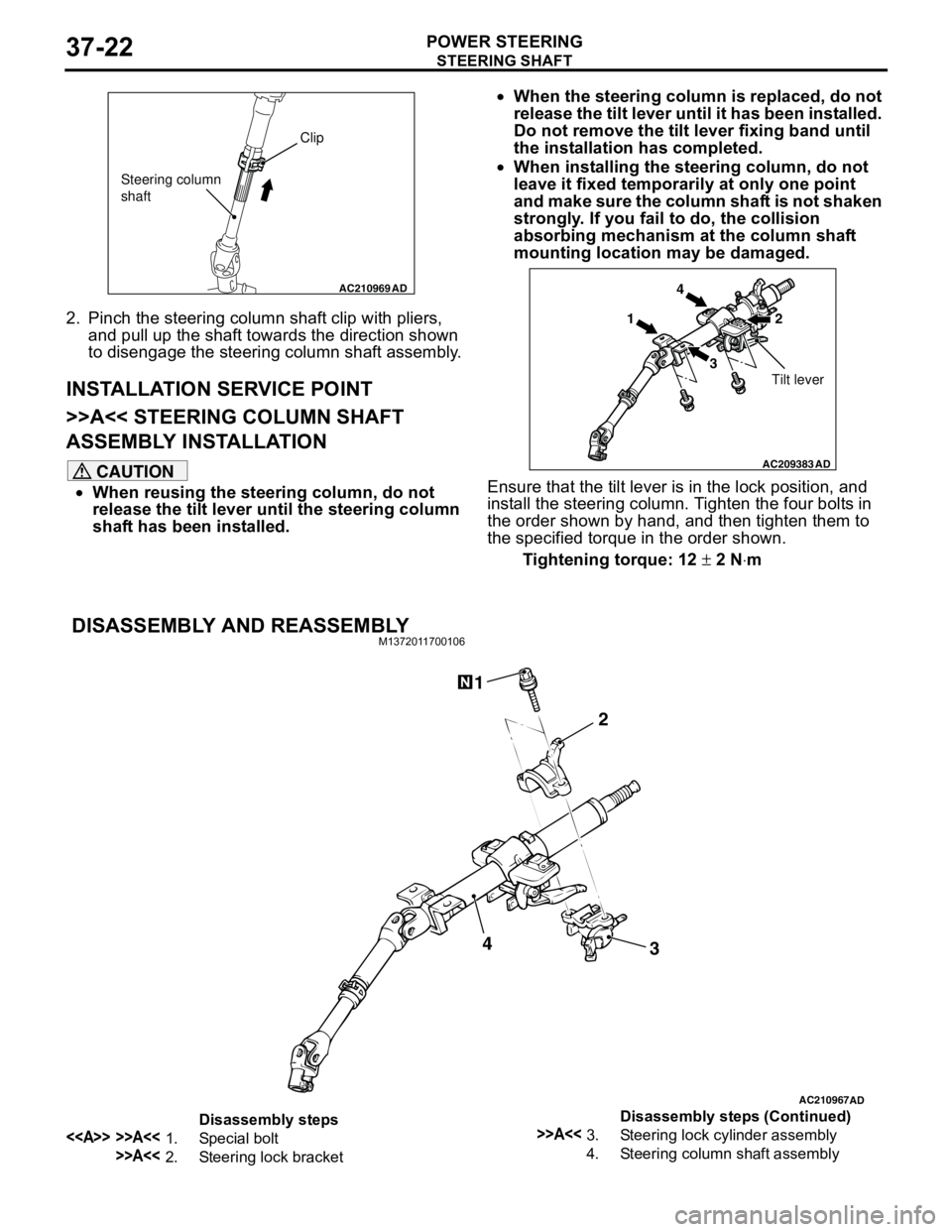

2. Pinch the steering column shaft clip with pliers,

and pull up the shaft towards the direction shown

to disengage the steering column shaft assembly.

INSTALLATION SERVICE POINT

>>A<< STEERING COLUMN SHAFT

ASSEMBLY INSTALLATION

CAUTION

•When reusing the steering column, do not

release the tilt lever until the steering column

shaft has been installed.•When the steering column is replaced, do not

release the tilt lever until it has been installed.

Do not remove the tilt lever fixing band until

the installation has completed.

•When installing the steering column, do not

leave it fixed temporarily at only one point

and make sure the column shaft is not shaken

strongly. If you fail to do, the collision

absorbing mechanism at the column shaft

mounting location may be damaged.

Ensure that the tilt lever is in the lock position, and

install the steering column. Tighten the four bolts in

the order shown by hand, and then tighten them to

the specified torque in the order shown.

Tightening torque: 12 ± 2 N⋅m

DISASSEMBLY AND REASSEMBLYM1372011700106

AC210969AD

Clip

Steering column

shaft

AC209383

AD

14

32

Tilt lever

AC210967AD

3 2 14

Disassembly steps

<> >>A<<1. Special bolt

>>A<<2. Steering lock bracket

>>A<<3. Steering lock cylinder assembly

4. Steering column shaft assemblyDisassembly steps (Continued)

Page 293 of 788

WINDOW GLASS

BODY42-15

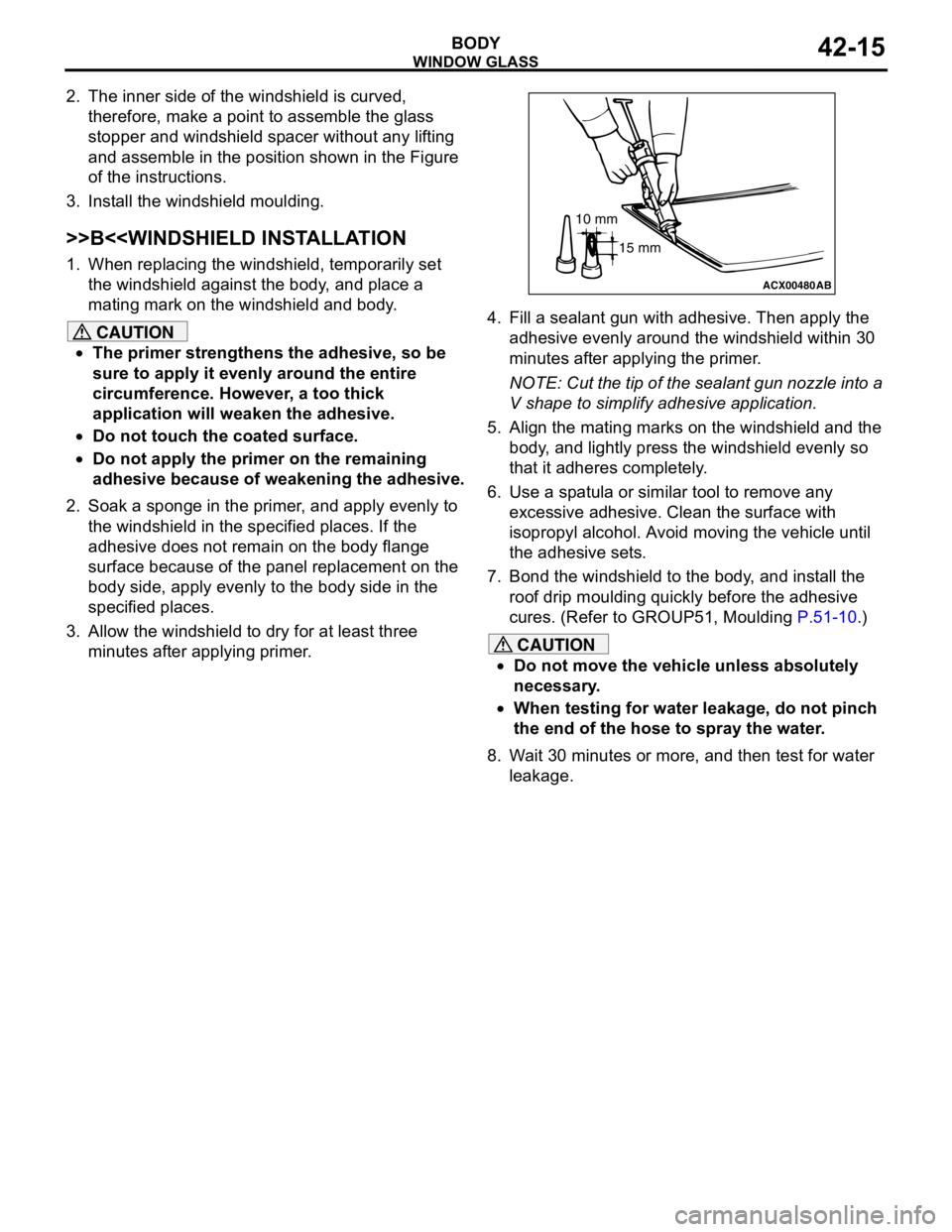

2. The inner side of the windshield is curved,

therefore, make a point to assemble the glass

stopper and windshield spacer without any lifting

and assemble in the position shown in the Figure

of the instructions.

3. Install the windshield moulding.

>>B<

the windshield against the body, and place a

mating mark on the windshield and body.

CAUTION

•The primer strengthens the adhesive, so be

sure to apply it evenly around the entire

circumference. However, a too thick

application will weaken the adhesive.

•Do not touch the coated surface.

•Do not apply the primer on the remaining

adhesive because of weakening the adhesive.

2. Soak a sponge in the primer, and apply evenly to

the windshield in the specified places. If the

adhesive does not remain on the body flange

surface because of the panel replacement on the

body side, apply evenly to the body side in the

specified places.

3. Allow the windshield to dry for at least three

minutes after applying primer.4. Fill a sealant gun with adhesive. Then apply the

adhesive evenly around the windshield within 30

minutes after applying the primer.

NOTE: Cut the tip of the sealant gun nozzle into a

V shape to simplify adhesive application.

5. Align the mating marks on the windshield and the

body, and lightly press the windshield evenly so

that it adheres completely.

6. Use a spatula or similar tool to remove any

excessive adhesive. Clean the surface with

isopropyl alcohol. Avoid moving the vehicle until

the adhesive sets.

7. Bond the windshield to the body, and install the

roof drip moulding quickly before the adhesive

cures. (Refer to GROUP51, Moulding P.51-10.)

CAUTION

•Do not move the vehicle unless absolutely

necessary.

•When testing for water leakage, do not pinch

the end of the hose to spray the water.

8. Wait 30 minutes or more, and then test for water

leakage.

ACX00480

10 mm

15 mm

AB

Page 566 of 788

HEATER UNIT, HEATER CORE, BLOWER ASSEMBLY AND EVAPORATOR UNIT

HEATER, AIR CONDITIONER AND VENTILATION55-82

REMOVAL SERVICE POINT

<> FLEXIBLE SUCTION HOSE AND

LIQUID PIPE B DISCONNECTION

CAUTION

As the compressor oil and receiver are highly

moisture absorbent, use a non-porous material

to plug the hose and nipples.

To prevent the entry of dust or other foreign bodies,

plug the dismantled hose and the nipples of the

expansion valves.

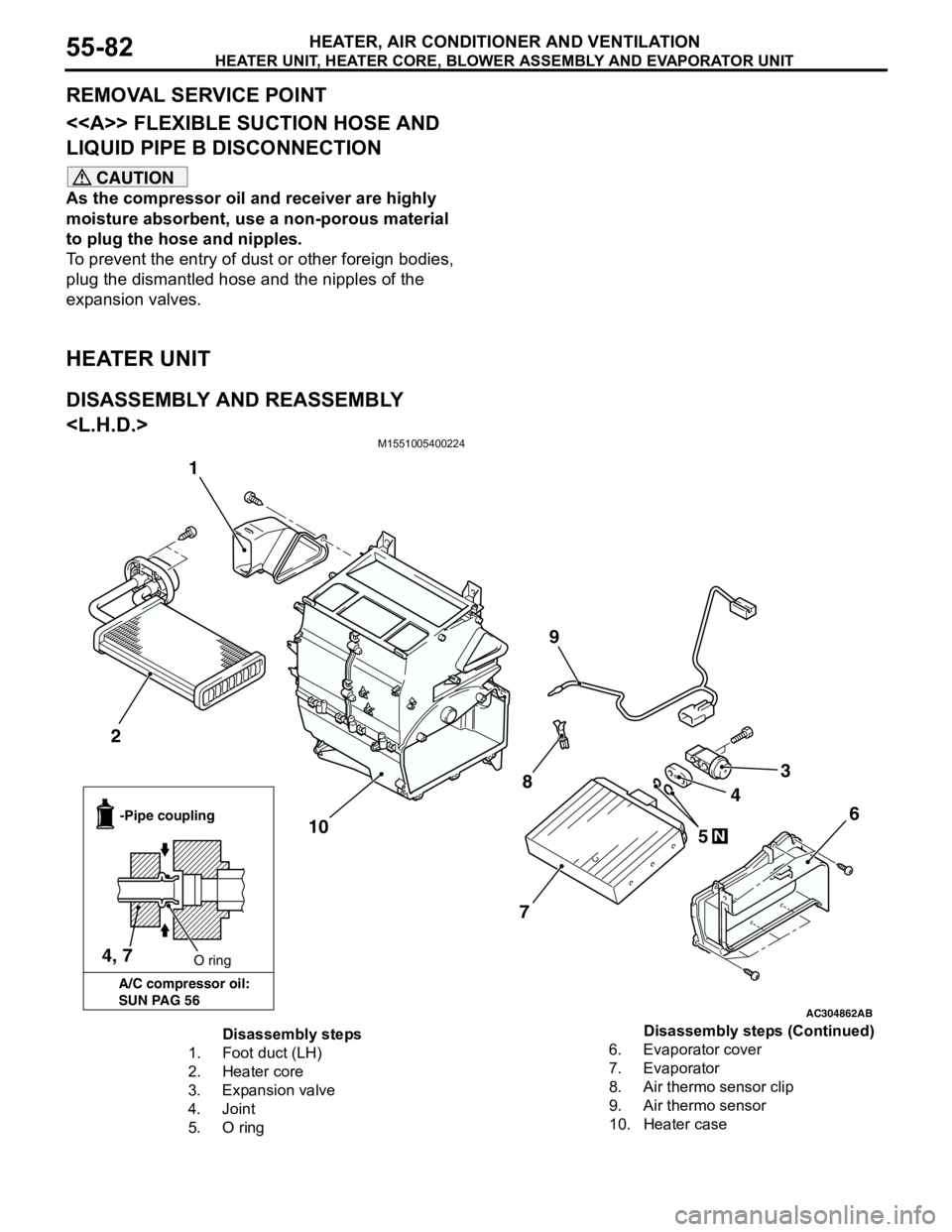

HEATER UNIT

DISASSEMBLY AND REASSEMBLY

M1551005400224

AC304862

1

2

3

4

5

6

7

8

9

10

AB

4, 7O ring -Pipe coupling

A/C compressor oil:

SUN PAG 56

N

Disassembly steps

1. Foot duct (LH)

2. Heater core

3. Expansion valve

4. Joint

5. O ring6. Evaporator cover

7. Evaporator

8. Air thermo sensor clip

9. Air thermo sensor

10. Heater caseDisassembly steps (Continued)

Page 572 of 788

EVAPORATOR ASSEMBLY

HEATER, AIR CONDITIONER AND VENTILATION55-88

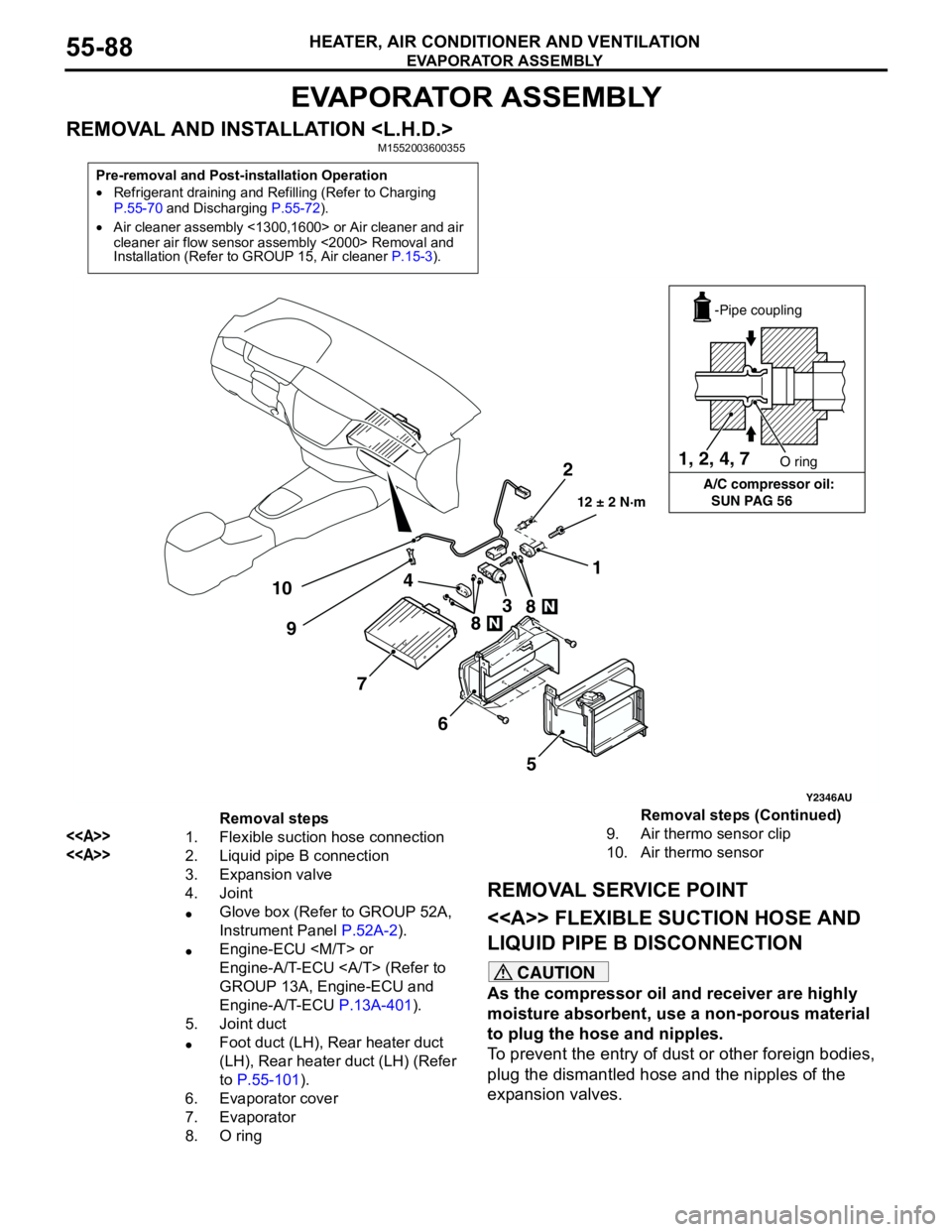

EVAPORATOR ASSEMBLY

REMOVAL AND INSTALLATION

REMOVAL SERVICE POINT

<> FLEXIBLE SUCTION HOSE AND

LIQUID PIPE B DISCONNECTION

CAUTION

As the compressor oil and receiver are highly

moisture absorbent, use a non-porous material

to plug the hose and nipples.

To prevent the entry of dust or other foreign bodies,

plug the dismantled hose and the nipples of the

expansion valves.

Pre-removal and Post-installation Operation

•Refrigerant draining and Refilling (Refer to Charging

P.55-70 and Discharging P.55-72).

•Air cleaner assembly <1300,1600> or Air cleaner and air

cleaner air flow sensor assembly <2000> Removal and

Installation (Refer to GROUP 15, Air cleaner P.15-3).

Y2346AU

1, 2, 4, 7

A/C compressor oil:

SUN PAG 56O ring

-Pipe coupling

2

101

3 4

7

6

5 98

8

12 ± 2 N·m

Removal steps

<>1. Flexible suction hose connection

<>2. Liquid pipe B connection

3. Expansion valve

4. Joint

•Glove box (Refer to GROUP 52A,

Instrument Panel P.52A-2).

•Engine-ECU

Engine-A/T-ECU (Refer to

GROUP 13A, Engine-ECU and

Engine-A/T-ECU P.13A-401).

5. Joint duct

•Foot duct (LH), Rear heater duct

(LH), Rear heater duct (LH) (Refer

to P.55-101).

6. Evaporator cover

7. Evaporator

8. O ring 9. Air thermo sensor clip

10. Air thermo sensorRemoval steps (Continued)

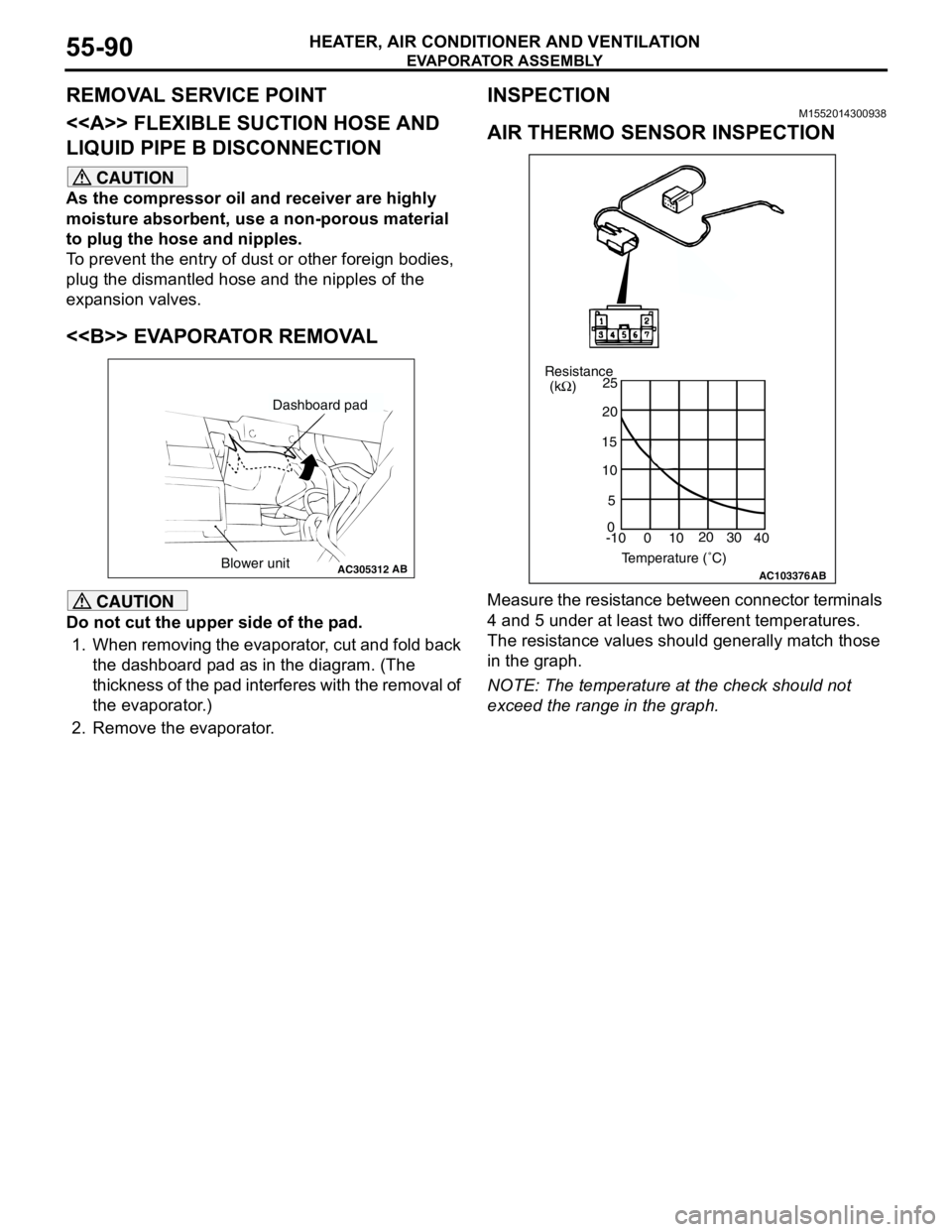

Page 574 of 788

Page 576 of 788

Page 581 of 788

CONDENSER AND CONDENSER FAN MOTOR

HEATER, AIR CONDITIONER AND VENTILATION55-97

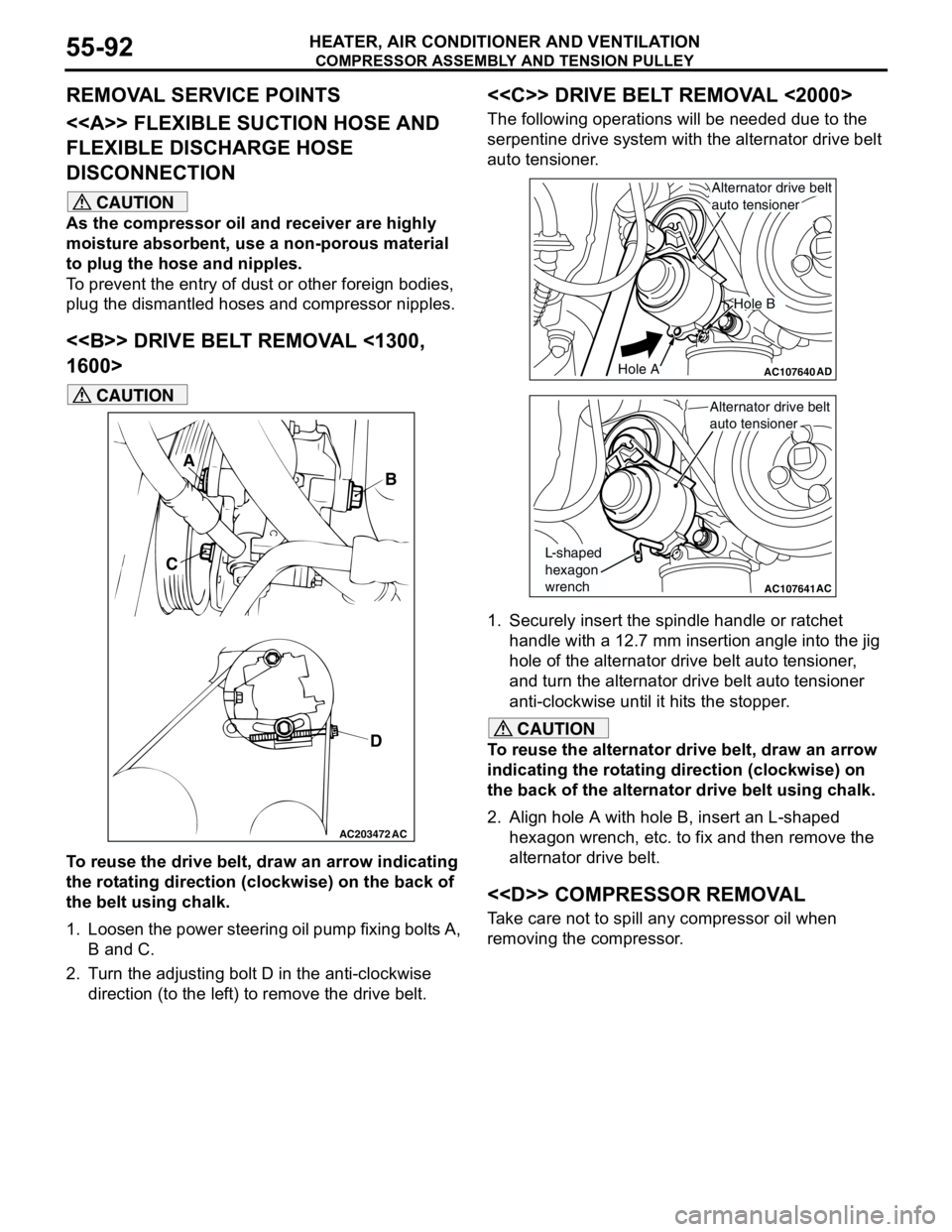

REMOVAL SERVICE POINT

<> FLEXIBLE SUCTION HOSE AND

LIQUID PIPE A DISCONNECTION

CAUTION

As the compressor oil and receiver are highly

moisture absorbent, use a non-porous material

to plug the hose and nipples.

To prevent the entry of dust or other foreign bodies,

plug the dismantled hose and condenser assembly

nipples.

INSTALLATION SERVICE POINT

>>A<< CONDENSER INSTALLATION

When replacing the condenser, refill it with a

specified amount of compressor oil and install it. (to

the vehicle).

Compressor oil: SUN PAG 56

Quantity: 15 mL

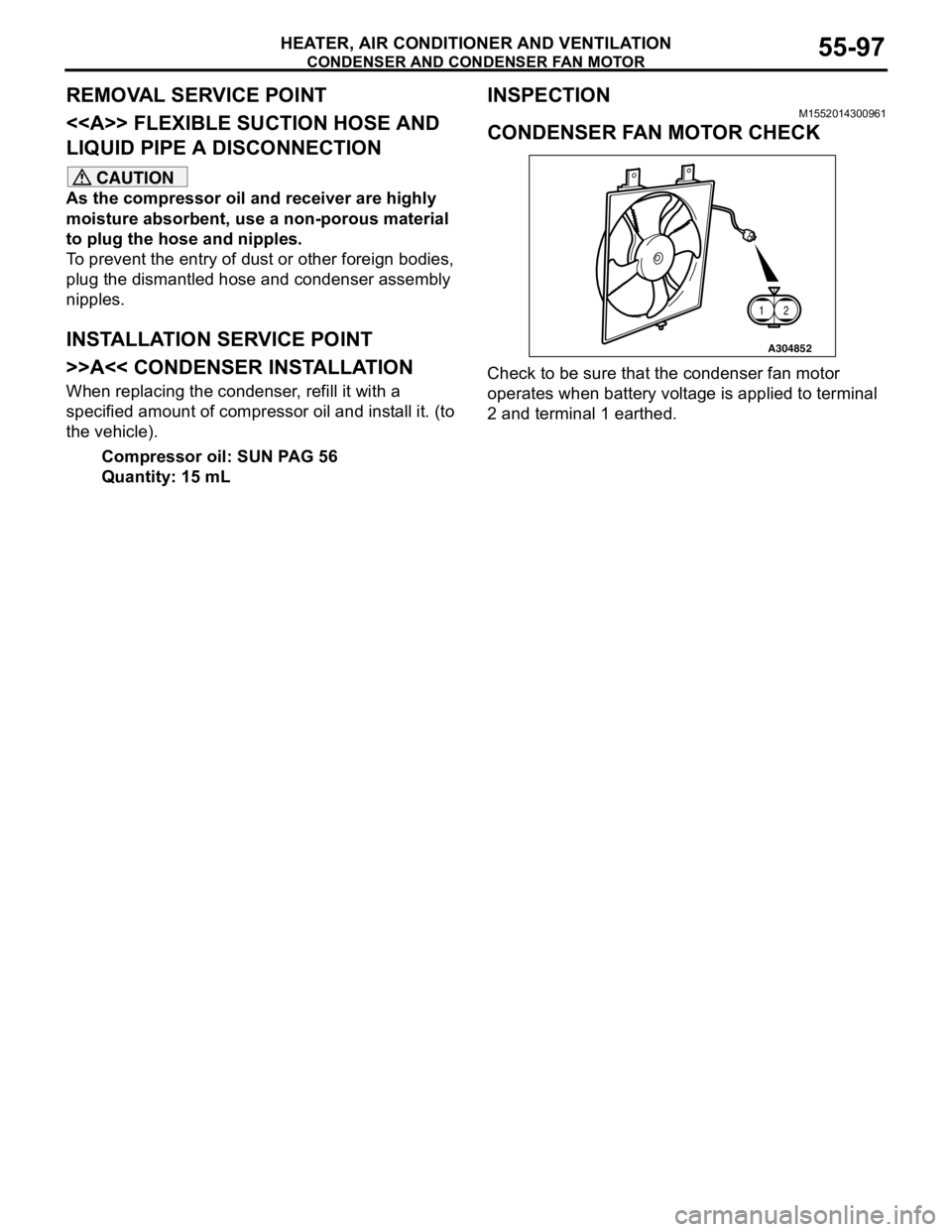

INSPECTIONM1552014300961

CONDENSER FAN MOTOR CHECK

Check to be sure that the condenser fan motor

operates when battery voltage is applied to terminal

2 and terminal 1 earthed.

A304852

12

Page 583 of 788

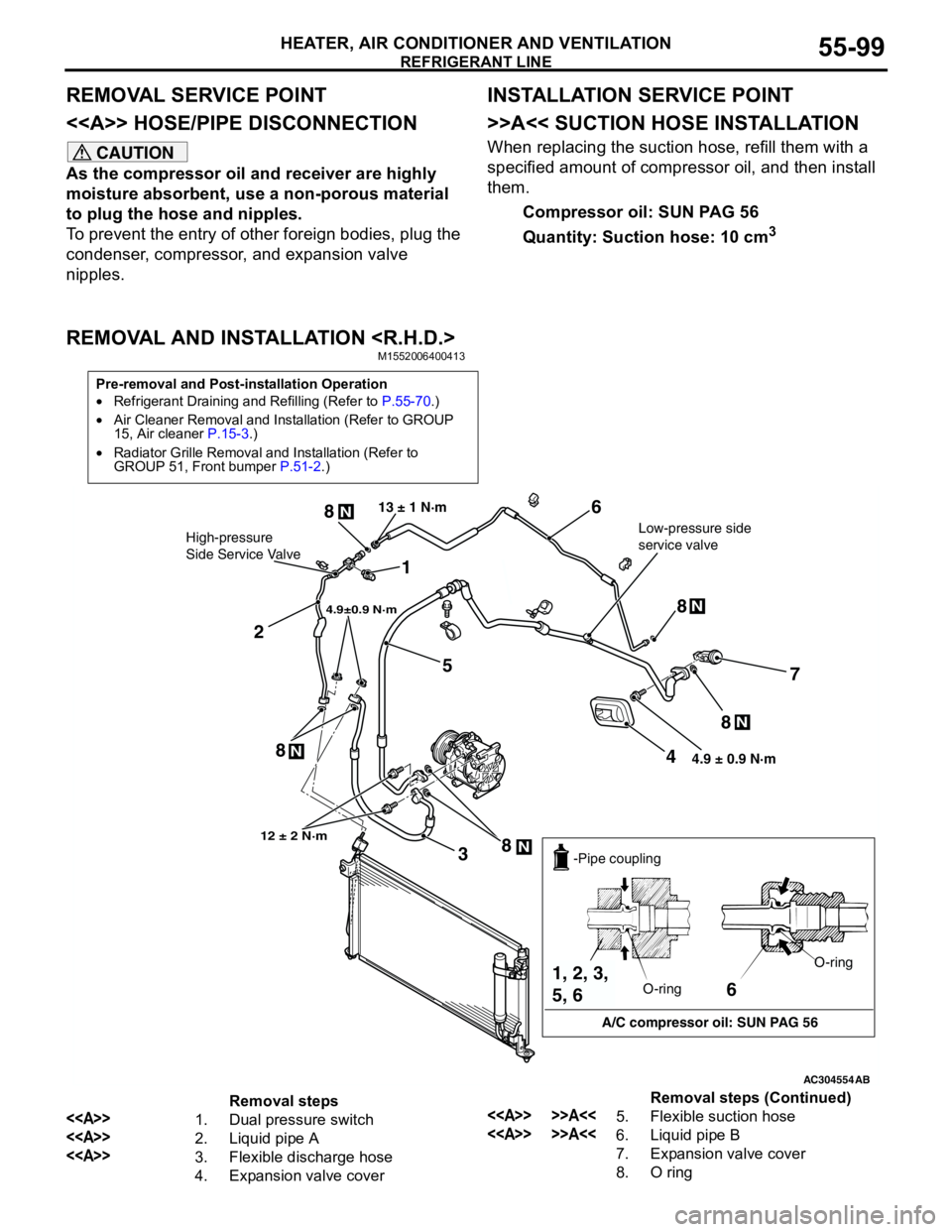

REFRIGERANT LINE

HEATER, AIR CONDITIONER AND VENTILATION55-99

REMOVAL SERVICE POINT

<> HOSE/PIPE DISCONNECTION

CAUTION

As the compressor oil and receiver are highly

moisture absorbent, use a non-porous material

to plug the hose and nipples.

To prevent the entry of other foreign bodies, plug the

condenser, compressor, and expansion valve

nipples.

INSTALLATION SERVICE POINT

>>A<< SUCTION HOSE INSTALLATION

When replacing the suction hose, refill them with a

specified amount of compressor oil, and then install

them.

Compressor oil: SUN PAG 56

Quantity: Suction hose: 10 cm

3

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

•Refrigerant Draining and Refilling (Refer to P.55-70.)

•Air Cleaner Removal and Installation (Refer to GROUP

15, Air cleaner P.15-3.)

•Radiator Grille Removal and Installation (Refer to

GROUP 51, Front bumper P.51-2.)

AC304554

1

2

3

4

5

6

7

8N

8N

8N

N8 8

N

4.9±0.9 N·m

Low-pressure side

service valve 13 ± 1 N·mHigh-pressure

Side Service Valve

12 ± 2 N·m

4.9 ± 0.9 N·m

AB

6

A/C compressor oil: SUN PAG 56 -Pipe coupling

O-ringO-ring

1, 2, 3,

5, 6

Removal steps

<>1. Dual pressure switch

<>2. Liquid pipe A

<>3. Flexible discharge hose

4. Expansion valve cover

<> >>A<<5. Flexible suction hose

<> >>A<<6. Liquid pipe B

7. Expansion valve cover

8. O ringRemoval steps (Continued)