torque MITSUBISHI LANCER 2005 Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 243 of 788

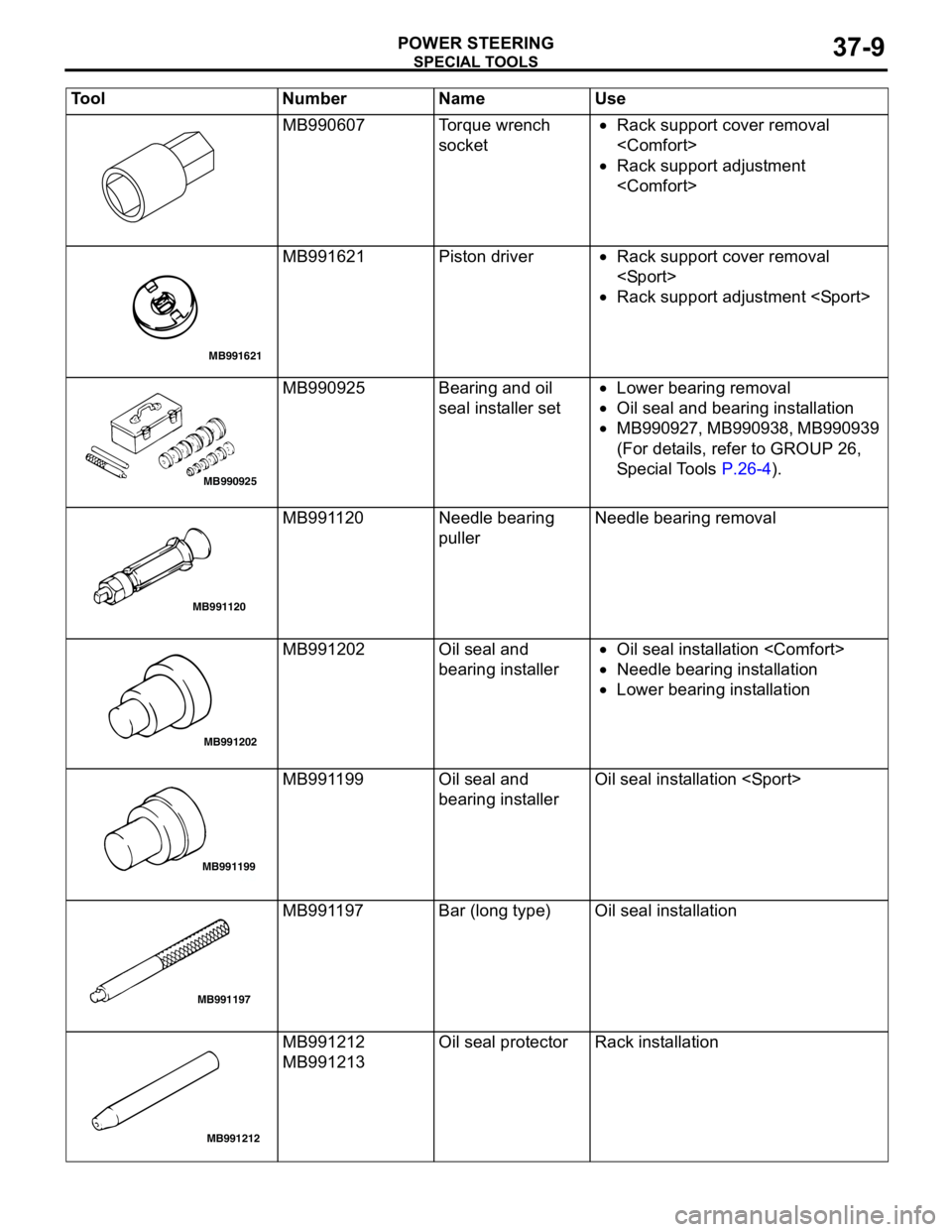

SPECIAL TOOLS

POWER STEERING37-9

MB990607 Torque wrench

socket•Rack support cover removal

•Rack support adjustment

MB991621 Piston driver•Rack support cover removal

•Rack support adjustment

MB990925 Bearing and oil

seal installer set•Lower bearing removal

•Oil seal and bearing installation

•MB990927, MB990938, MB990939

(For details, refer to GROUP 26,

Special Tools P.26-4).

MB991120 Needle bearing

pullerNeedle bearing removal

MB991202 Oil seal and

bearing installer•Oil seal installation

•Needle bearing installation

•Lower bearing installation

MB991199 Oil seal and

bearing installerOil seal installation

MB991197 Bar (long type) Oil seal installation

MB991212

MB991213Oil seal protector Rack installation Tool Number Name Use

MB991621

MB990925

MB991120

MB991202

MB991199

AB

MB991197

MB991212

Page 244 of 788

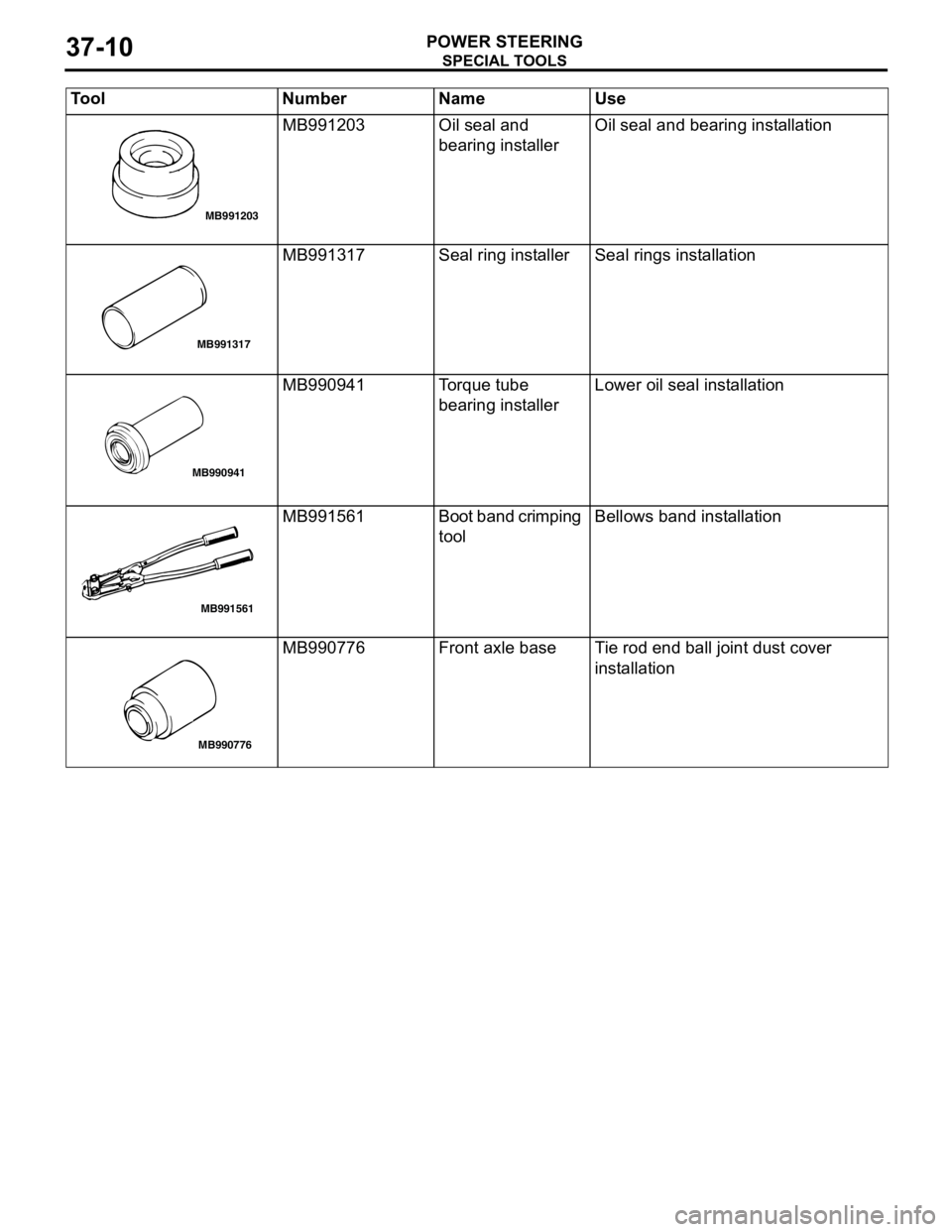

SPECIAL TOOLS

POWER STEERING37-10

MB991203 Oil seal and

bearing installerOil seal and bearing installation

MB991317 Seal ring installer Seal rings installation

MB990941 Torque tube

bearing installerLower oil seal installation

MB991561 Boot band crimping

toolBellows band installation

MB990776 Front axle base Tie rod end ball joint dust cover

installation Tool Number Name Use

MB991203

MB991317

MB990941

MB991561

MB990776

Page 245 of 788

ON-VEHICLE SERVICE

POWER STEERING37-11

ON-VEHICLE SERVICE

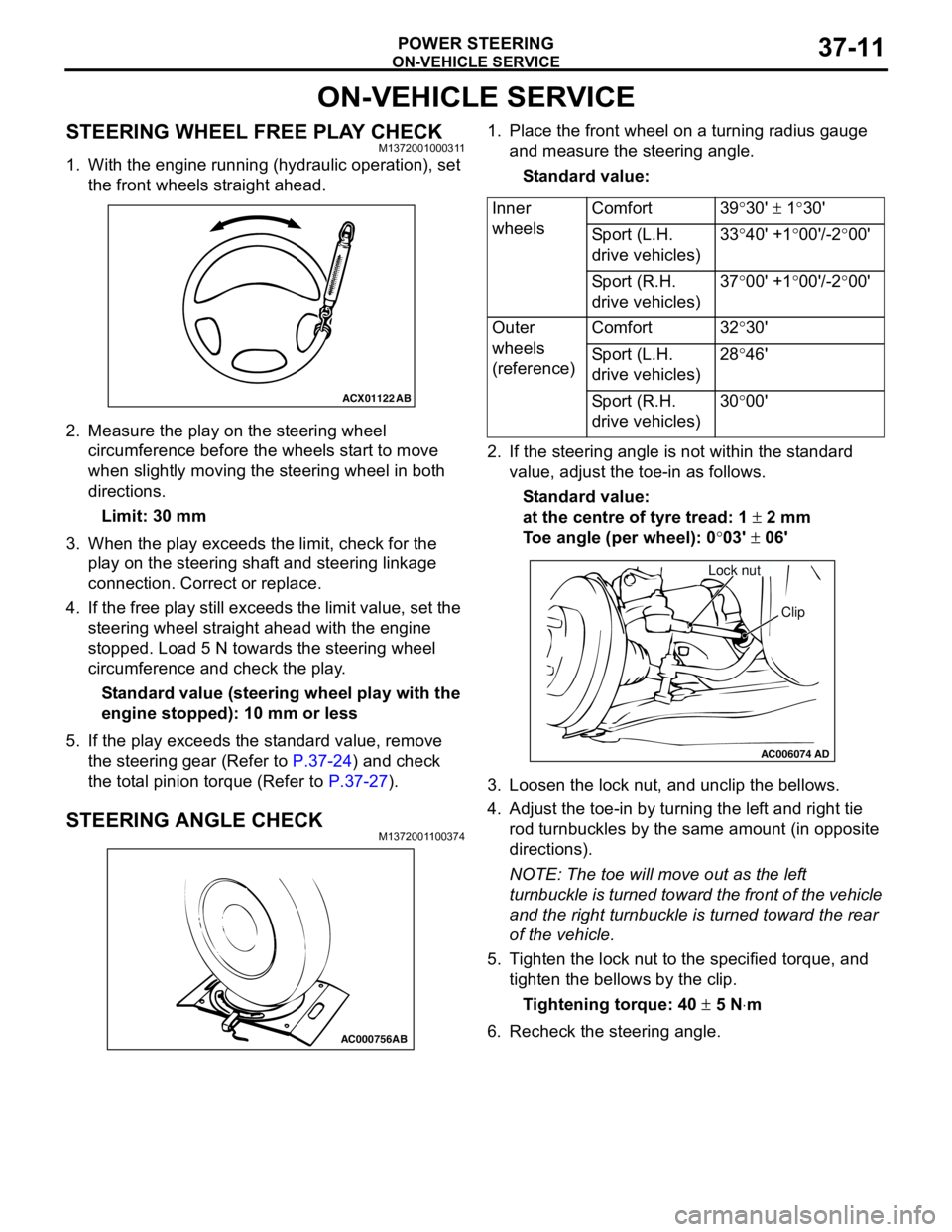

STEERING WHEEL FREE PLAY CHECKM1372001000311

1. With the engine running (hydraulic operation), set

the front wheels straight ahead.

2. Measure the play on the steering wheel

circumference before the wheels start to move

when slightly moving the steering wheel in both

directions.

Limit: 30 mm

3. When the play exceeds the limit, check for the

play on the steering shaft and steering linkage

connection. Correct or replace.

4. If the free play still exceeds the limit value, set the

steering wheel straight ahead with the engine

stopped. Load 5 N towards the steering wheel

circumference and check the play.

Standard value (steering wheel play with the

engine stopped): 10 mm or less

5. If the play exceeds the standard value, remove

the steering gear (Refer to P.37-24) and check

the total pinion torque (Refer to P.37-27).

STEERING ANGLE CHECKM1372001100374

1. Place the front wheel on a turning radius gauge

and measure the steering angle.

Standard value:

2. If the steering angle is not within the standard

value, adjust the toe-in as follows.

Standard value:

at the centre of tyre tread: 1 ± 2 mm

Toe angle (per wheel): 0°03' ± 06'

3. Loosen the lock nut, and unclip the bellows.

4. Adjust the toe-in by turning the left and right tie

rod turnbuckles by the same amount (in opposite

directions).

NOTE: The toe will move out as the left

turnbuckle is turned toward the front of the vehicle

and the right turnbuckle is turned toward the rear

of the vehicle.

5. Tighten the lock nut to the specified torque, and

tighten the bellows by the clip.

Tightening torque: 40 ± 5 N⋅m

6. Recheck the steering angle.

ACX01122

AB

AC000756AB

Inner

wheelsComfort 39°30' ± 1°30'

Sport (L.H.

drive vehicles)33°40' +1°00'/-2°00'

Sport (R.H.

drive vehicles)37°00' +1°00'/-2°00'

Outer

wheels

(reference)Comfort 32°30'

Sport (L.H.

drive vehicles)28°46'

Sport (R.H.

drive vehicles)30°00'

AC006074AD

Lock nut

Clip

Page 246 of 788

ON-VEHICLE SERVICE

POWER STEERING37-12

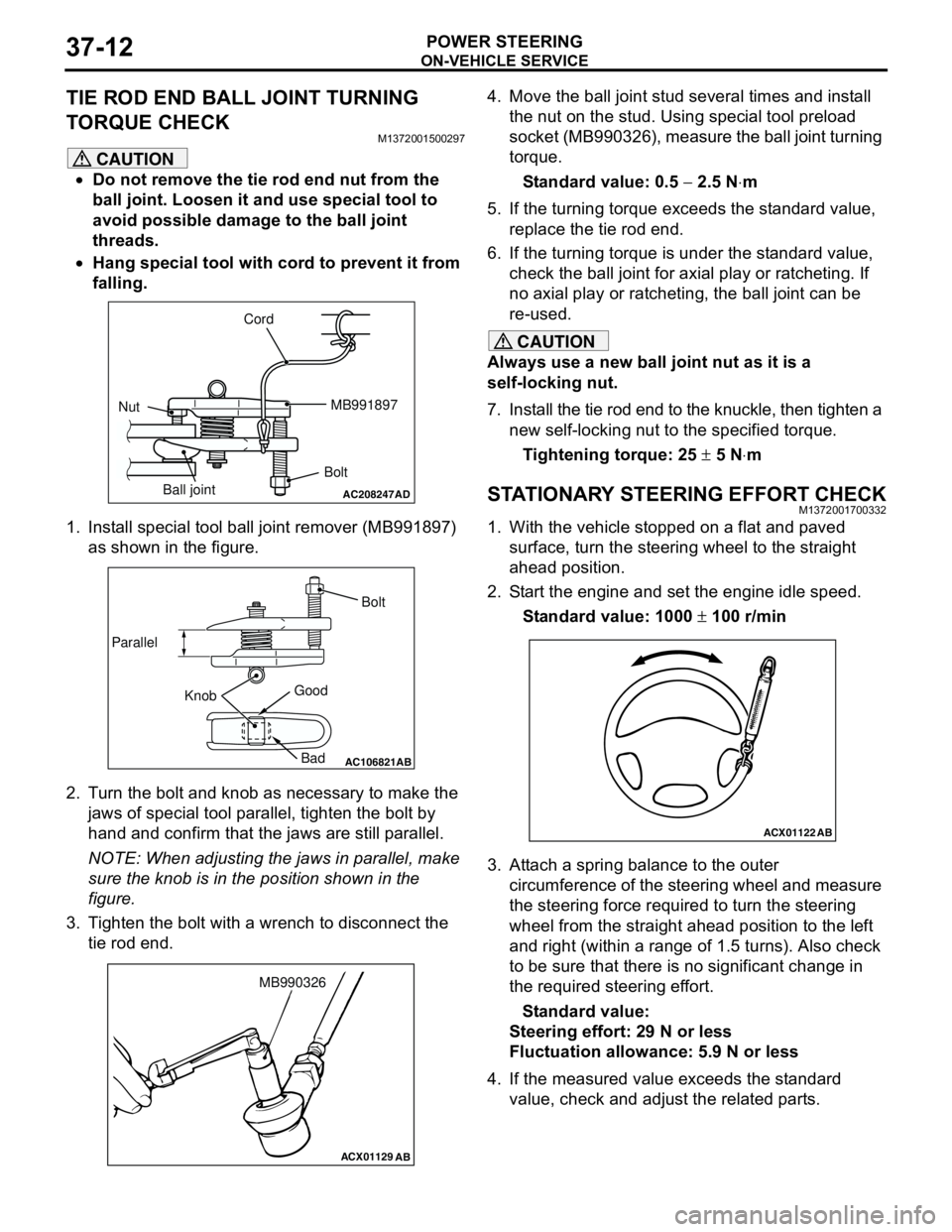

TIE ROD END BALL JOINT TURNING

TORQUE CHECK

M1372001500297

CAUTION

•Do not remove the tie rod end nut from the

ball joint. Loosen it and use special tool to

avoid possible damage to the ball joint

threads.

•Hang special tool with cord to prevent it from

falling.

1. Install special tool ball joint remover (MB991897)

as shown in the figure.

2. Turn the bolt and knob as necessary to make the

jaws of special tool parallel, tighten the bolt by

hand and confirm that the jaws are still parallel.

NOTE: When adjusting the jaws in parallel, make

sure the knob is in the position shown in the

figure.

3. Tighten the bolt with a wrench to disconnect the

tie rod end.4. Move the ball joint stud several times and install

the nut on the stud. Using special tool preload

socket (MB990326), measure the ball joint turning

torque.

Standard value: 0.5 − 2.5 N⋅m

5. If the turning torque exceeds the standard value,

replace the tie rod end.

6. If the turning torque is under the standard value,

check the ball joint for axial play or ratcheting. If

no axial play or ratcheting, the ball joint can be

re-used.

CAUTION

Always use a new ball joint nut as it is a

self-locking nut.

7. Install the tie rod end to the knuckle, then tighten a

new self-locking nut to the specified torque.

Tightening torque: 25 ± 5 N⋅m

STATIONARY STEERING EFFORT CHECKM1372001700332

1. With the vehicle stopped on a flat and paved

surface, turn the steering wheel to the straight

ahead position.

2. Start the engine and set the engine idle speed.

Standard value: 1000 ± 100 r/min

3. Attach a spring balance to the outer

circumference of the steering wheel and measure

the steering force required to turn the steering

wheel from the straight ahead position to the left

and right (within a range of 1.5 turns). Also check

to be sure that there is no significant change in

the required steering effort.

Standard value:

Steering effort: 29 N or less

Fluctuation allowance: 5.9 N or less

4. If the measured value exceeds the standard

value, check and adjust the related parts.

AC208247AD

Cord

BoltMB991897

Nut

Ball joint

AC106821

Knob ParallelBolt

Good

Bad

AB

ACX01129

AB

MB990326

ACX01122

AB

Page 249 of 788

ON-VEHICLE SERVICE

POWER STEERING37-15

7. If it is not within the standard value, the probable

cause is a malfunction of the oil line or steering

gear, so check these parts and repair as

necessary.

8. Turn the steering wheel all the way to the left or

right; then check whether or not the retention

hydraulic pressure is the standard value.

Standard value: 8.8 − 9.5 MPa

9. If not the standard value, overhaul the steering

gear. Remeasure fluid pressure.

10. Remove the special tools, and then tighten the

pressure hose to the specified torque.

Tightening torque: 57 ± 7 N⋅m

11. Bleed the system (Refer to P.37-13).

POWER STEERING PRESSURE SWITCH

CHECK

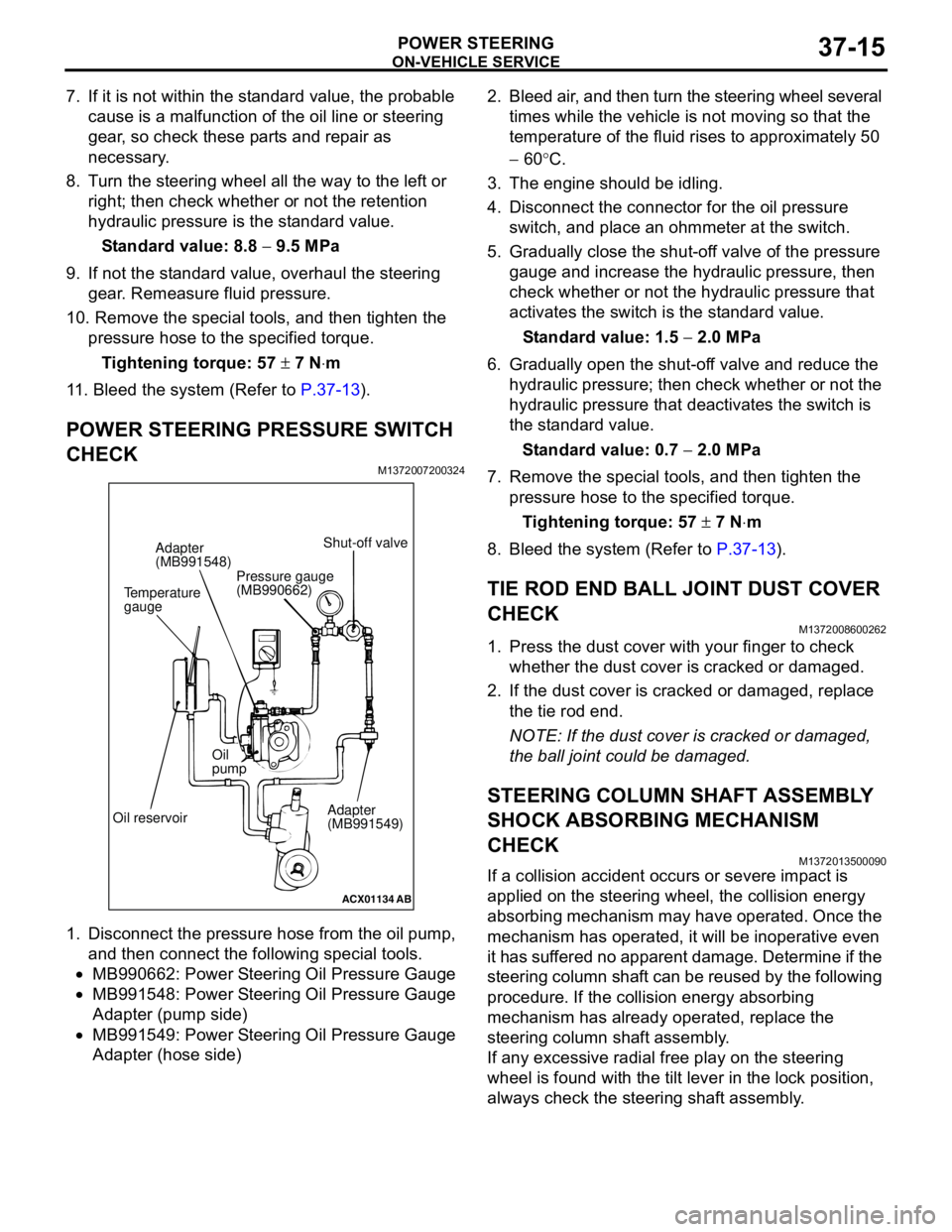

M1372007200324

1. Disconnect the pressure hose from the oil pump,

and then connect the following special tools.

•MB990662: Power Steering Oil Pressure Gauge

•MB991548: Power Steering Oil Pressure Gauge

Adapter (pump side)

•MB991549: Power Steering Oil Pressure Gauge

Adapter (hose side)2. Bleed air, and then turn the steering wheel several

times while the vehicle is not moving so that the

temperature of the fluid rises to approximately 50

− 60°C.

3. The engine should be idling.

4. Disconnect the connector for the oil pressure

switch, and place an ohmmeter at the switch.

5. Gradually close the shut-off valve of the pressure

gauge and increase the hydraulic pressure, then

check whether or not the hydraulic pressure that

activates the switch is the standard value.

Standard value: 1.5 − 2.0 MPa

6. Gradually open the shut-off valve and reduce the

hydraulic pressure; then check whether or not the

hydraulic pressure that deactivates the switch is

the standard value.

Standard value: 0.7 − 2.0 MPa

7. Remove the special tools, and then tighten the

pressure hose to the specified torque.

Tightening torque: 57 ± 7 N⋅m

8. Bleed the system (Refer to P.37-13).

TIE ROD END BALL JOINT DUST COVER

CHECK

M1372008600262

1. Press the dust cover with your finger to check

whether the dust cover is cracked or damaged.

2. If the dust cover is cracked or damaged, replace

the tie rod end.

NOTE: If the dust cover is cracked or damaged,

the ball joint could be damaged.

STEERING COLUMN SHAFT ASSEMBLY

SHOCK ABSORBING MECHANISM

CHECK

M1372013500090

If a collision accident occurs or severe impact is

applied on the steering wheel, the collision energy

absorbing mechanism may have operated. Once the

mechanism has operated, it will be inoperative even

it has suffered no apparent damage. Determine if the

steering column shaft can be reused by the following

procedure. If the collision energy absorbing

mechanism has already operated, replace the

steering column shaft assembly.

If any excessive radial free play on the steering

wheel is found with the tilt lever in the lock position,

always check the steering shaft assembly.

ACX01134

AB

Temperature

gaugeAdapter

(MB991548)

Oil reservoirOil

pump

Adapter

(MB991549) Shut-off valve

Pressure gauge

(MB990662)

Page 250 of 788

ON-VEHICLE SERVICE

POWER STEERING37-16

WARNING

•If the vehicle continues to be driven after

the collision absorbing mechanism has

operated, the steering column shaft may

be damaged while it is in use.

•If there is a slack in the one-way capsule,

do not attempt to repair it but replace the

steering column shaft assembly.

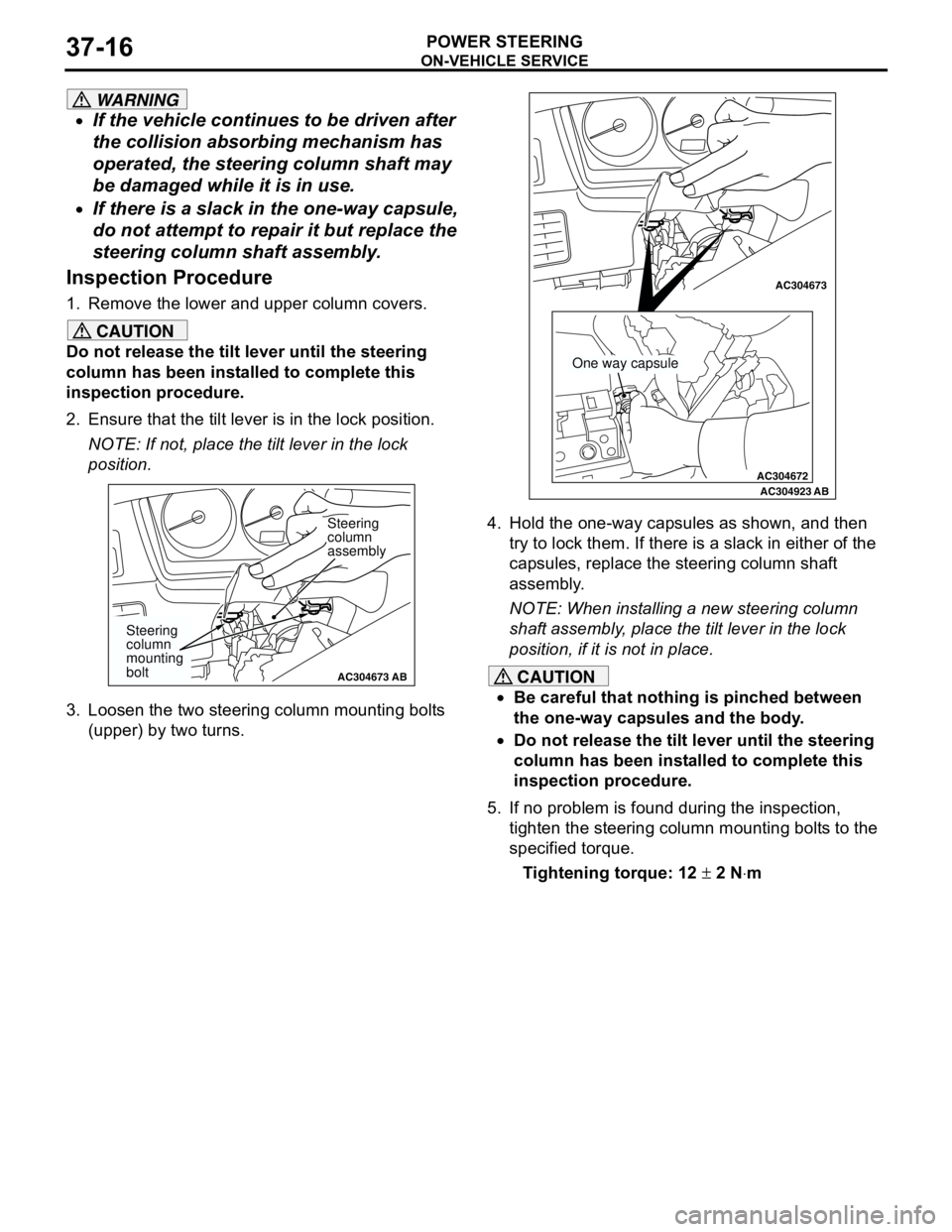

Inspection Procedure

1. Remove the lower and upper column covers.

CAUTION

Do not release the tilt lever until the steering

column has been installed to complete this

inspection procedure.

2. Ensure that the tilt lever is in the lock position.

NOTE: If not, place the tilt lever in the lock

position.

3. Loosen the two steering column mounting bolts

(upper) by two turns.4. Hold the one-way capsules as shown, and then

try to lock them. If there is a slack in either of the

capsules, replace the steering column shaft

assembly.

NOTE: When installing a new steering column

shaft assembly, place the tilt lever in the lock

position, if it is not in place.

CAUTION

•Be careful that nothing is pinched between

the one-way capsules and the body.

•Do not release the tilt lever until the steering

column has been installed to complete this

inspection procedure.

5. If no problem is found during the inspection,

tighten the steering column mounting bolts to the

specified torque.

Tightening torque: 12 ± 2 N⋅m

AC304673AC304673

Steering

column

assembly

AB

Steering

column

mounting

bolt

AC304672

AC304673AC304673

AC304923AB

One way capsule

Page 256 of 788

STEERING SHAFT

POWER STEERING37-22

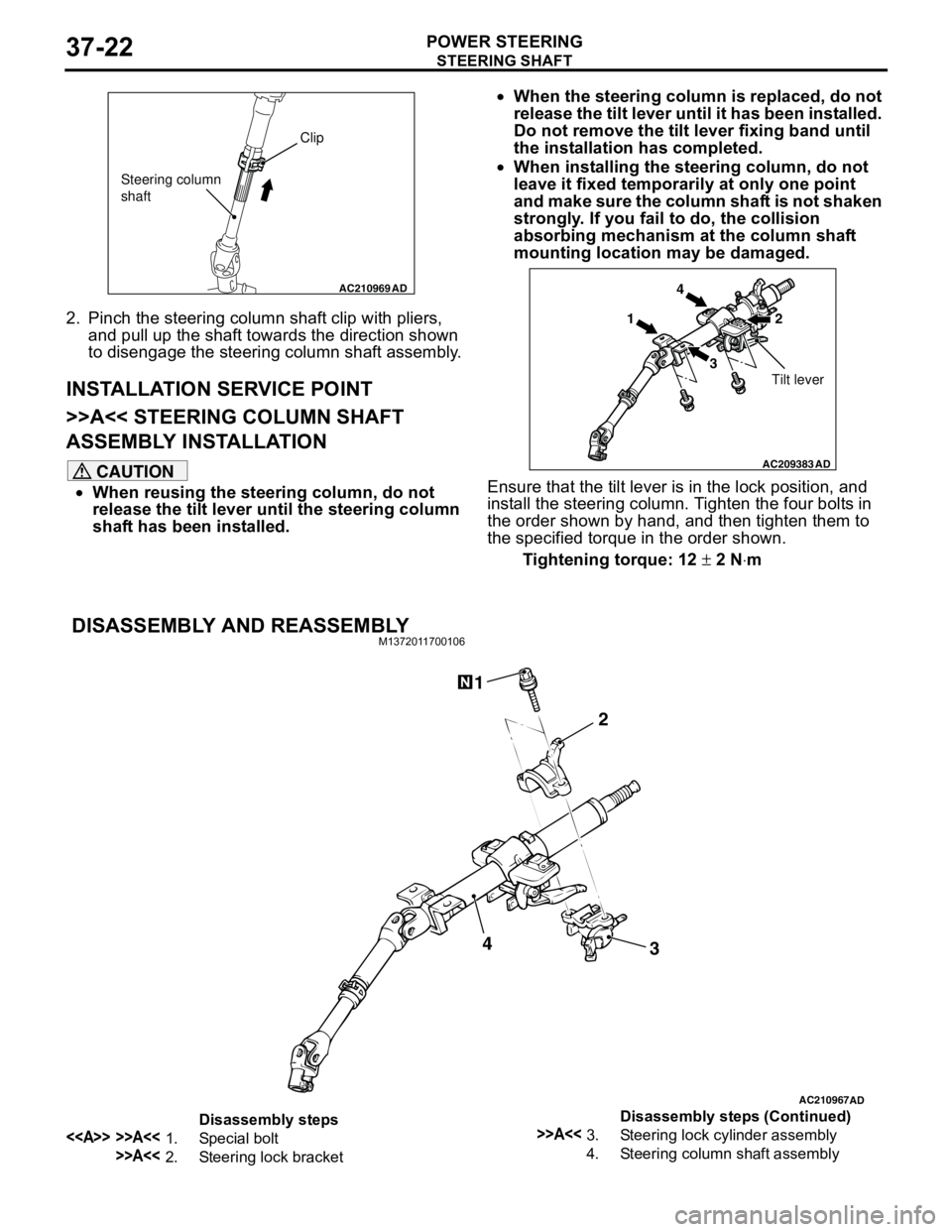

2. Pinch the steering column shaft clip with pliers,

and pull up the shaft towards the direction shown

to disengage the steering column shaft assembly.

INSTALLATION SERVICE POINT

>>A<< STEERING COLUMN SHAFT

ASSEMBLY INSTALLATION

CAUTION

•When reusing the steering column, do not

release the tilt lever until the steering column

shaft has been installed.•When the steering column is replaced, do not

release the tilt lever until it has been installed.

Do not remove the tilt lever fixing band until

the installation has completed.

•When installing the steering column, do not

leave it fixed temporarily at only one point

and make sure the column shaft is not shaken

strongly. If you fail to do, the collision

absorbing mechanism at the column shaft

mounting location may be damaged.

Ensure that the tilt lever is in the lock position, and

install the steering column. Tighten the four bolts in

the order shown by hand, and then tighten them to

the specified torque in the order shown.

Tightening torque: 12 ± 2 N⋅m

DISASSEMBLY AND REASSEMBLYM1372011700106

AC210969AD

Clip

Steering column

shaft

AC209383

AD

14

32

Tilt lever

AC210967AD

3 2 14

Disassembly steps

<> >>A<<1. Special bolt

>>A<<2. Steering lock bracket

>>A<<3. Steering lock cylinder assembly

4. Steering column shaft assemblyDisassembly steps (Continued)

Page 260 of 788

POWER STEERING GEAR BOX AND LINKAGE

POWER STEERING37-26

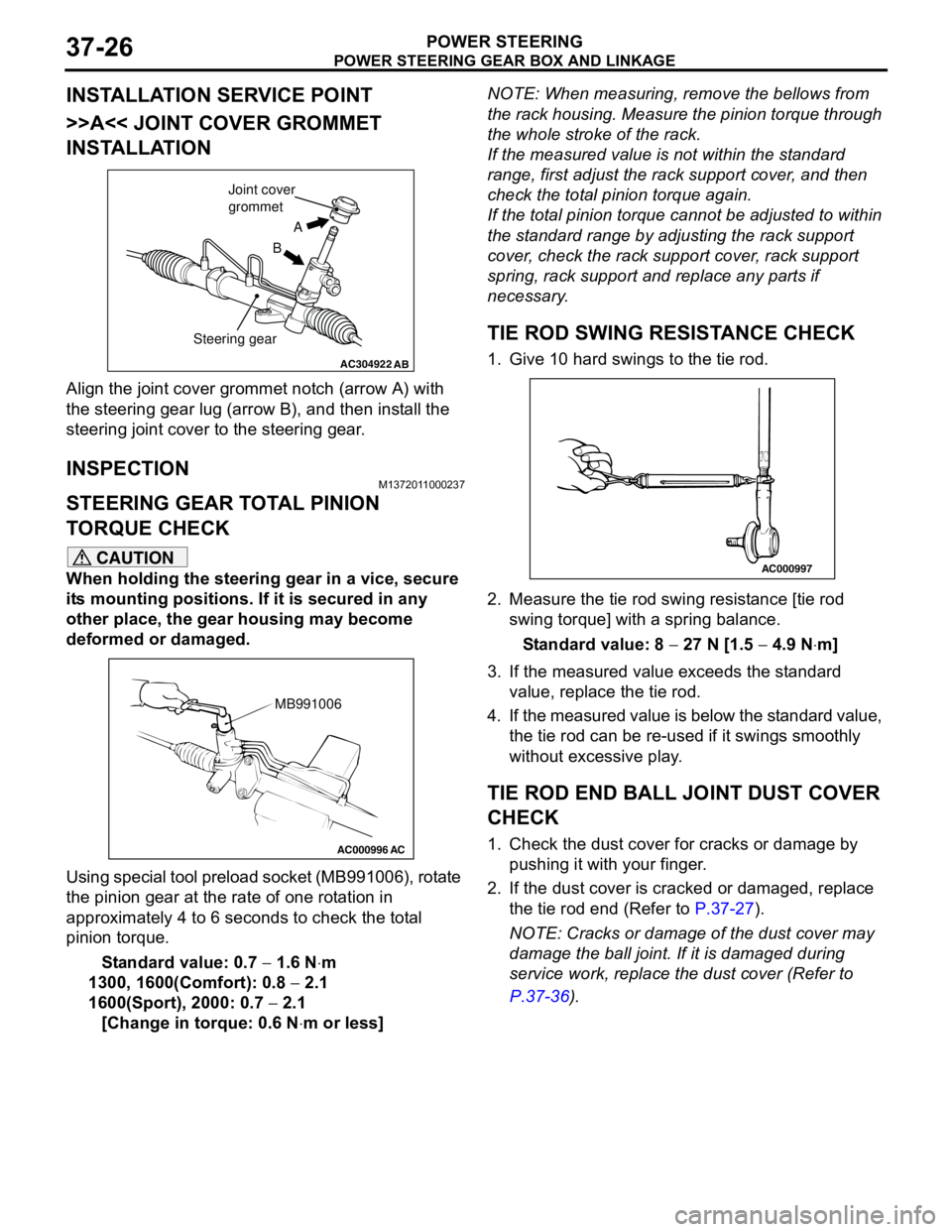

INSTALLATION SERVICE POINT

>>A<< JOINT COVER GROMMET

INSTALLATION

Align the joint cover grommet notch (arrow A) with

the steering gear lug (arrow B), and then install the

steering joint cover to the steering gear.

INSPECTIONM1372011000237

STEERING GEAR TOTAL PINION

TORQUE CHECK

CAUTION

When holding the steering gear in a vice, secure

its mounting positions. If it is secured in any

other place, the gear housing may become

deformed or damaged.

Using special tool preload socket (MB991006), rotate

the pinion gear at the rate of one rotation in

approximately 4 to 6 seconds to check the total

pinion torque.

Standard value: 0.7 − 1.6 N⋅m

1300, 1600(Comfort): 0.8 − 2.1

1600(Sport), 2000: 0.7 − 2.1

[Change in torque: 0.6 N⋅m or less]NOTE: When measuring, remove the bellows from

the rack housing. Measure the pinion torque through

the whole stroke of the rack.

If the measured value is not within the standard

range, first adjust the rack support cover, and then

check the total pinion torque again.

If the total pinion torque cannot be adjusted to within

the standard range by adjusting the rack support

cover, check the rack support cover, rack support

spring, rack support and replace any parts if

necessary.

TIE ROD SWING RESISTANCE CHECK

1. Give 10 hard swings to the tie rod.

2. Measure the tie rod swing resistance [tie rod

swing torque] with a spring balance.

Standard value: 8 − 27 N [1.5 − 4.9 N⋅m]

3. If the measured value exceeds the standard

value, replace the tie rod.

4. If the measured value is below the standard value,

the tie rod can be re-used if it swings smoothly

without excessive play.

TIE ROD END BALL JOINT DUST COVER

CHECK

1. Check the dust cover for cracks or damage by

pushing it with your finger.

2. If the dust cover is cracked or damaged, replace

the tie rod end (Refer to P.37-27).

NOTE: Cracks or damage of the dust cover may

damage the ball joint. If it is damaged during

service work, replace the dust cover (Refer to

P.37-36).

AC304922AB

A

B Joint cover

grommet

Steering gear

AC000996 AC

MB991006

AC000997

Page 261 of 788

POWER STEERING GEAR BOX AND LINKAGE

POWER STEERING37-27

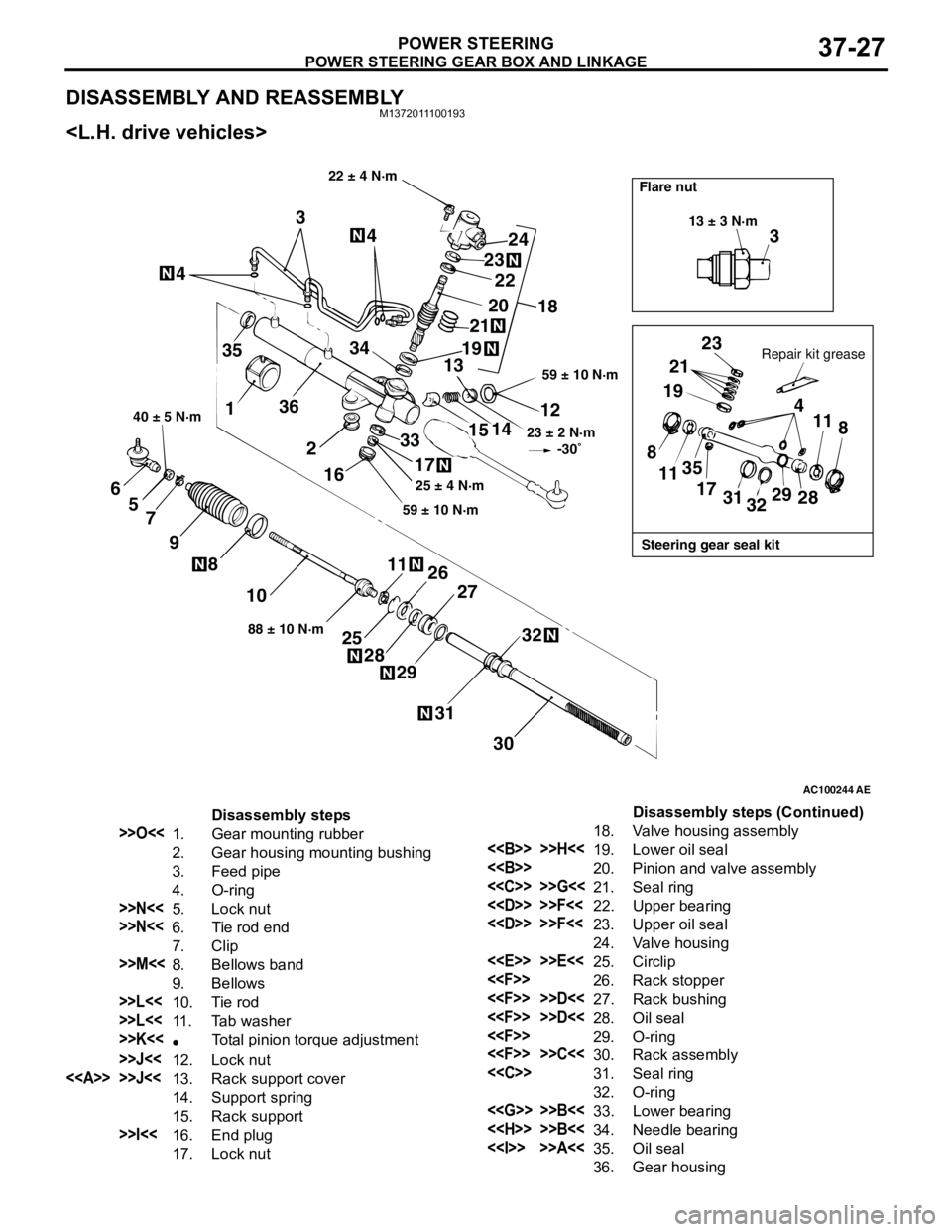

DISASSEMBLY AND REASSEMBLYM1372011100193

AC100244AE

3

13 ± 3 N·m

Steering gear seal kit Flare nut

Repair kit grease

23

21

19

4

11

8

28 29

32 31 17 35

11 8

22 ± 4 N·m

59 ± 10 N·m

23 ± 2 N·m

-30˚

12

14

15

33

17

59 ± 10 N·m25 ± 4 N·m

18 24

23

20

19

2122

13 344

4

3

35

136

2

16

30 31

32

27

29 28

2526 1188 ± 10 N·m

10 8

9 7 5 6

40 ± 5 N·m

Disassembly steps

>>O<<1. Gear mounting rubber

2. Gear housing mounting bushing

3. Feed pipe

4. O-ring

>>N<<5. Lock nut

>>N<<6. Tie rod end

7. Clip

>>M<<8. Bellows band

9. Bellows

>>L<<10. Tie rod

>>L<<11. Tab washer

>>K<<•Total pinion torque adjustment

>>J<<12. Lock nut

<> >>J<<13. Rack support cover

14. Support spring

15. Rack support

>>I<<16. End plug

17. Lock nut18. Valve housing assembly

<> >>H<<19. Lower oil seal

<>20. Pinion and valve assembly

<

<

<

24. Valve housing

<

<

<

<

<

<

<

32. O-ring

<

<

<> >>A<<35. Oil seal

36. Gear housingDisassembly steps (Continued)

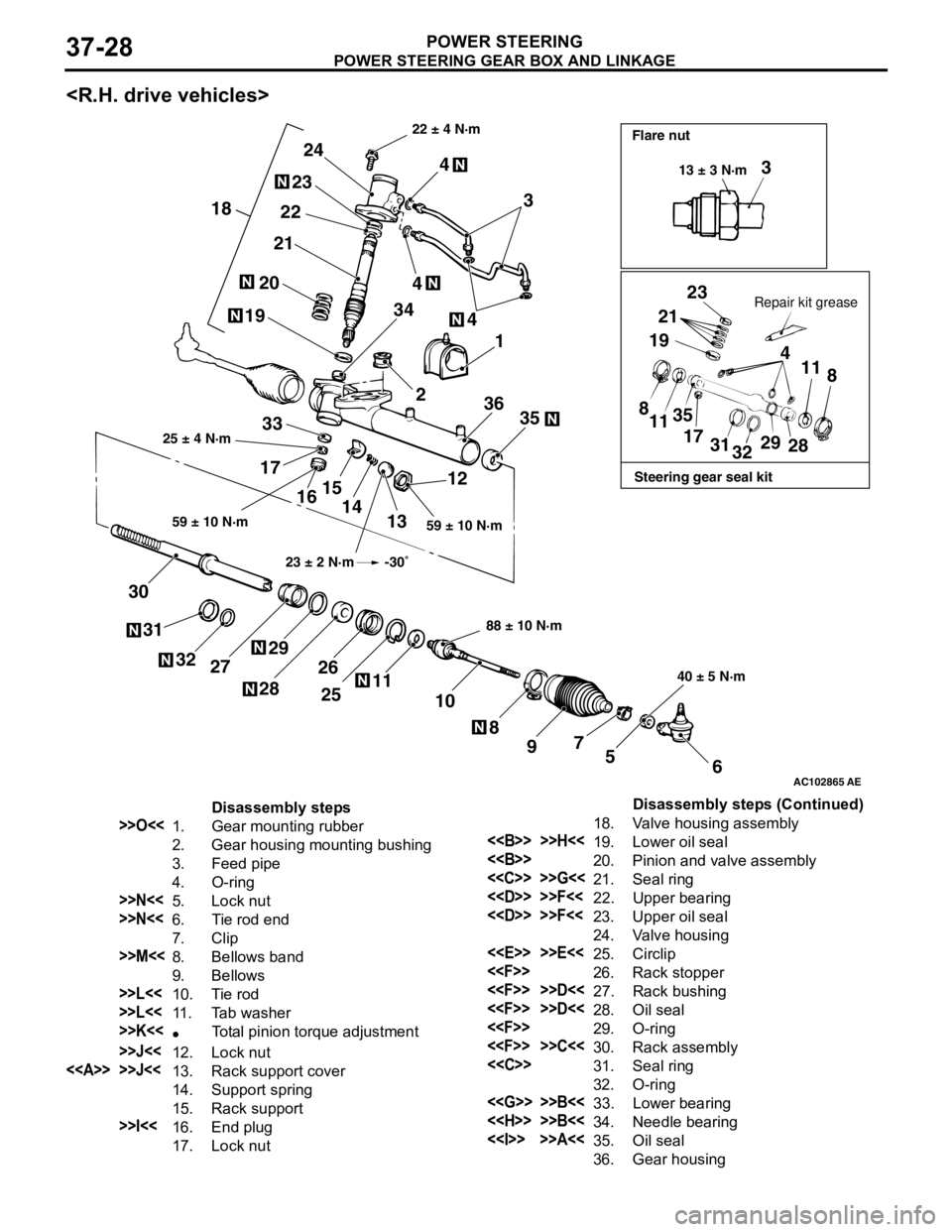

Page 262 of 788

POWER STEERING GEAR BOX AND LINKAGE

POWER STEERING37-28

AC102865

3

23

21

19

4

11

8

8

1135

17

31

3229

28

6 5 7

9 8 10 11

25 26

2829

27 32 31 3012

13 14 15

16 173335 361 4

2 3444

3 24

23

22

21

20

19

18

AE

Steering gear seal kit Flare nut

Repair kit grease 22 ± 4 N·m

59 ± 10 N·m 25 ± 4 N·m

88 ± 10 N·m

40 ± 5 N·m 59 ± 10 N·m13 ± 3 N·m

23 ± 2 N·m -30˚

Disassembly steps

>>O<<1. Gear mounting rubber

2. Gear housing mounting bushing

3. Feed pipe

4. O-ring

>>N<<5. Lock nut

>>N<<6. Tie rod end

7. Clip

>>M<<8. Bellows band

9. Bellows

>>L<<10. Tie rod

>>L<<11. Tab washer

>>K<<•Total pinion torque adjustment

>>J<<12. Lock nut

<> >>J<<13. Rack support cover

14. Support spring

15. Rack support

>>I<<16. End plug

17. Lock nut18. Valve housing assembly

<> >>H<<19. Lower oil seal

<>20. Pinion and valve assembly

<

<

<

24. Valve housing

<

<

<

<

<

<

<

32. O-ring

<

<

<> >>A<<35. Oil seal

36. Gear housingDisassembly steps (Continued)