steering MITSUBISHI LANCER 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 1 of 788

GROUP INDEX

00General . . . . . . . . . . . . . . . . . . . . . . . .

11Engine. . . . . . . . . . . . . . . . . . . . . . . . .

12Engine Lubrication . . . . . . . . . . . . . .

13Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . .

14Engine Cooling . . . . . . . . . . . . . . . . .

15Intake and Exhaust . . . . . . . . . . . . . .

16Engine Electrical . . . . . . . . . . . . . . . .

17Engine and Emission Control . . . . .

21Clutch . . . . . . . . . . . . . . . . . . . . . . . . .

22Manual Transmission . . . . . . . . . . . .

23Automatic Transmission. . . . . . . . . .

26Front Axle . . . . . . . . . . . . . . . . . . . . . .

27Rear Axle . . . . . . . . . . . . . . . . . . . . . .

31Wheel and Tyre . . . . . . . . . . . . . . . . .

32Power Plant Mount . . . . . . . . . . . . . .

33Front Suspension . . . . . . . . . . . . . . .

34Rear Suspension . . . . . . . . . . . . . . . .

35Service Brakes . . . . . . . . . . . . . . . . . .

36Parking Brakes . . . . . . . . . . . . . . . . .

37Power Steering . . . . . . . . . . . . . . . . .

42Body . . . . . . . . . . . . . . . . . . . . . . . . . .

51Exterior . . . . . . . . . . . . . . . . . . . . . . . .

52 . . . . . . . . . .

54Chassis Electrical . . . . . . . . . . . . . . .

55 . . . . . . .

70Component Locations. . . . . . . . . . . .

80Configration Diagrams . . . . . . . . . . .

90Circuit Diagrams . . . . . . . . . . . . . . . .

LANCER /

LANCER WAGON

WORKSHOP MANUAL

FOREWORD

This Workshop manual contains procedures for

service mechanics, including removal, disassembly,

inspection, adjustment, reassembly and installation.

Use the following manuals in combination with this

manual as required.

TECHNICAL INFORMATION MANUAL

PYME0302

PYME0302-A

WORKSHOP MANUAL

CHASSIS GROUP PWME0302

BODY REPAIR MANUAL

PBME0302

PBME0302-A

PARTS CATALOGUE

B606K005A_

All information, illustrations and product descriptions

contained in this manual are current as at the time of

publication. We, however, reserve the right to make

changes at any time without prior notice or obligation.

Mitsubishi Motors Corporation May 2004

Heater, Air Conditioner and

Ventilation Interior and Supplemental

Restraint System (SRS)

Page 76 of 788

CHARGING SYSTEM

ENGINE ELECTRICAL16-12

ALTERNATOR ASSEMBLY

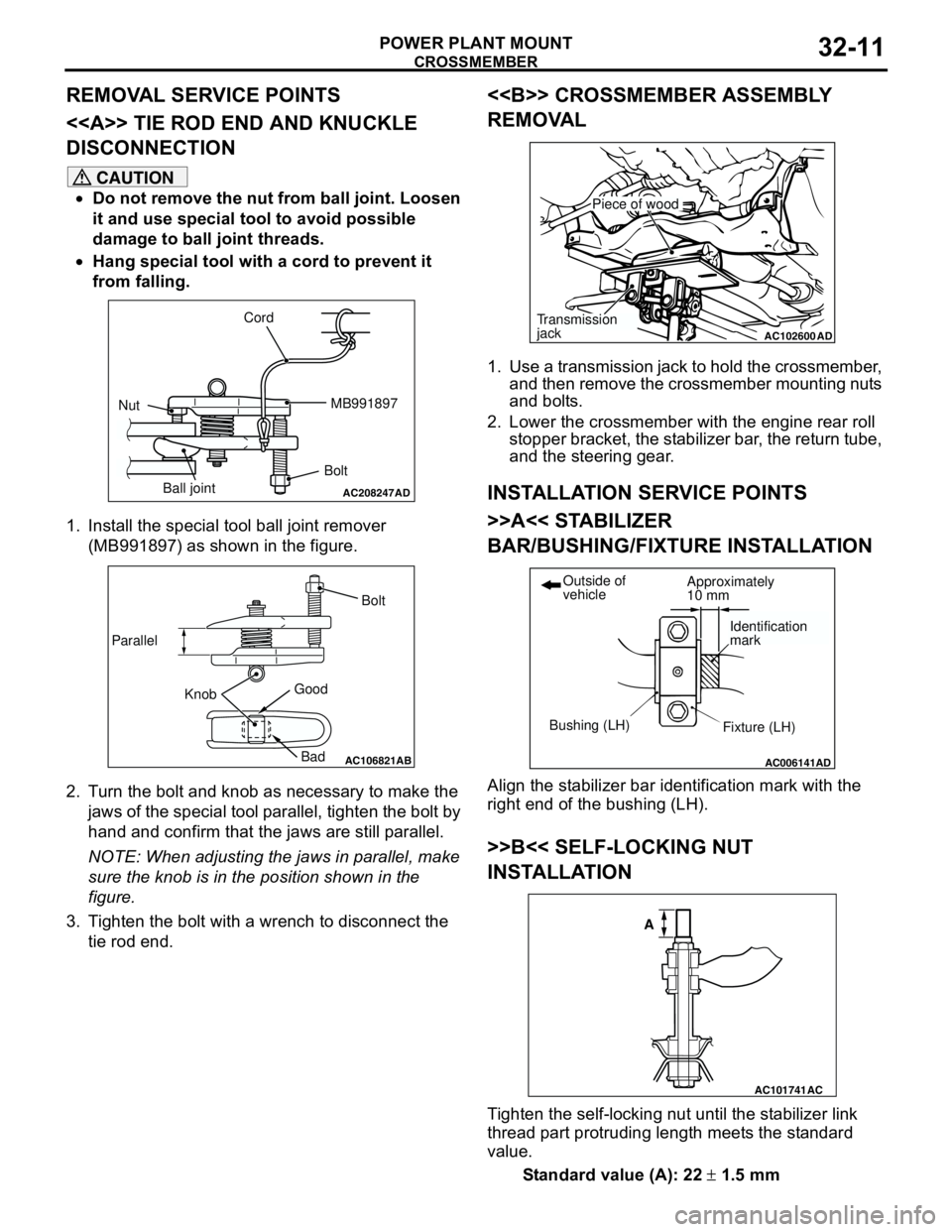

REMOVAL AND INSTALLATION <4G1>M1161001400548

REMOVAL SERVICE POINT

<> ALTERNATOR ASSEMBLY

REMOVAL

Remove the alternator assembly from above the

vehicle.

Pre-removal Operation

•Under Cover Removal

•Drive Belt Removal (Refer to GROUP 11A - Crankshaft

Pulley P.11A-16).Post-installation Operation

•Drive Belt Installation (Refer to GROUP 11A - Crankshaft

Pulley P.11A-16).

•Drive Belt Tension Adjustment (Refer to GROUP 11A -

On-vehicle Service P.11A-7).

•Under Cover Installation

AC303729

1

2

4

3

44 ± 10 N·m

23 ± 2 N·m

24 ± 3 N·m12 ± 2 N·m

AB

Removal steps

1. Power steering pressure hose

clamp

2. Alternator connector and terminal3. Alternator adjusting brace

<>4. Alternator assemblyRemoval steps (Continued)

Page 106 of 788

IGNITION SYSTEM

ENGINE ELECTRICAL16-42

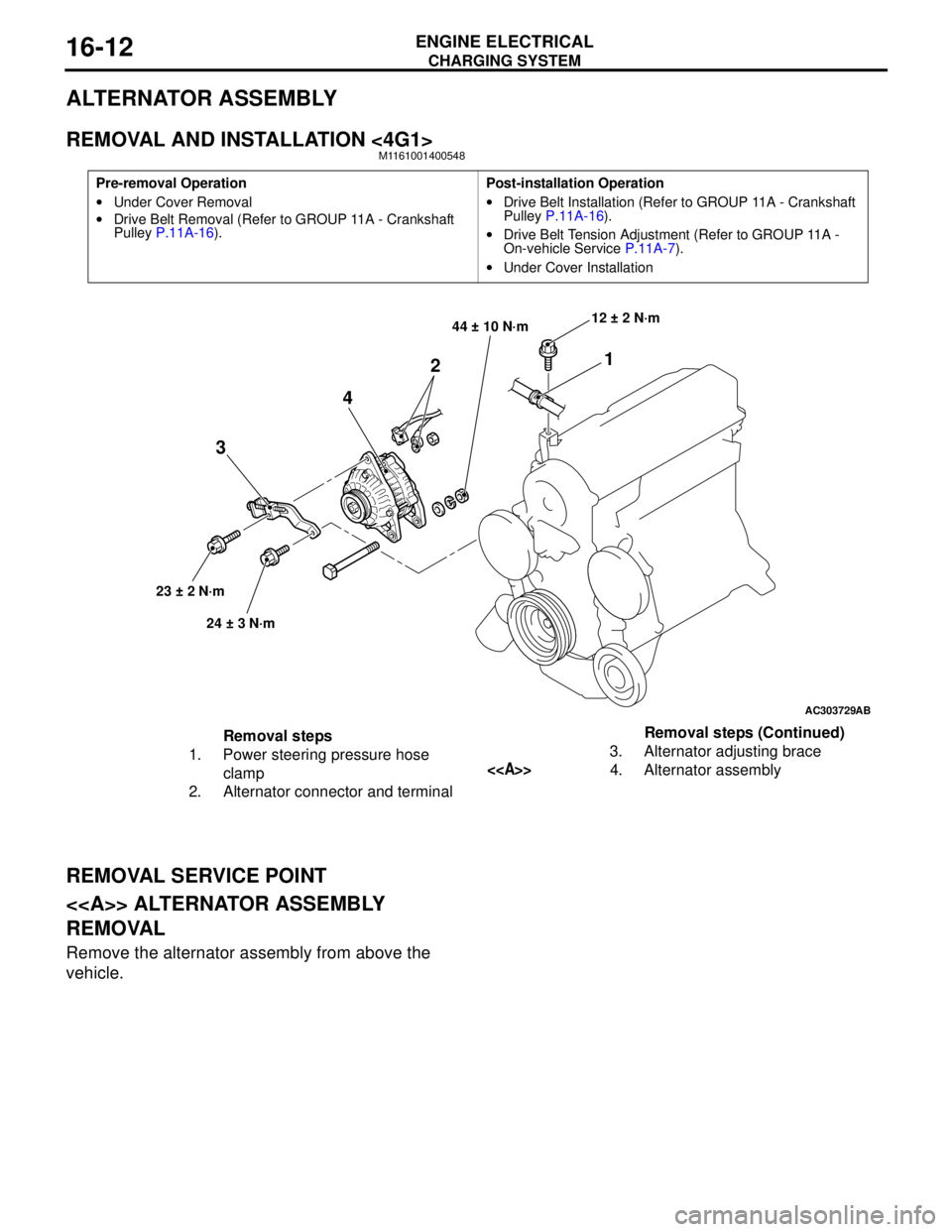

REMOVAL AND INSTALLATION <4G6>M1163003500440

REMOVAL SERVICE POINT

<> POWER STEERING OIL PUMP

ASSEMBLY REMOVAL

Remove the power steering oil pump assembly from

the bracket with the hose attached.

NOTE: Place the removed power steering oil pump

assembly in a place where it will not be a hindrance

when removing and installing and secure it with a

cord or wire.

Pre-removal and Post-installation Operation

•Valve Timing Belt Removal and Installation (Refer to

GROUP 11C P.11C-35).

AC301612

8.8 ± 1.0 N·m

8

8.8 ± 1.0 N·m

9

1

22 ± 4 N·m

4

2

3

49 ± 9 N·m49 ± 9 N·m5

22 ± 4 N·m

3.0 ± 0.5 N·m

6

7

AC

Removal steps

1. Power steering pressure switch

connector

2. A/C compressor connector

3. A/C compressor connector clamp

<>4. Power steering oil pump assembly

5. Power steering oil pump bracket6. Rocker cover centre cover

7. Engine crankshaft position sensor

connector

8. Engine crankshaft position sensor

9. Crankshaft position sensor

connector bracket Removal steps (Continued)

Page 136 of 788

SPECIAL TOOLS

FRONT AXLE26-4

SPECIAL TOOLS

M1261000600375

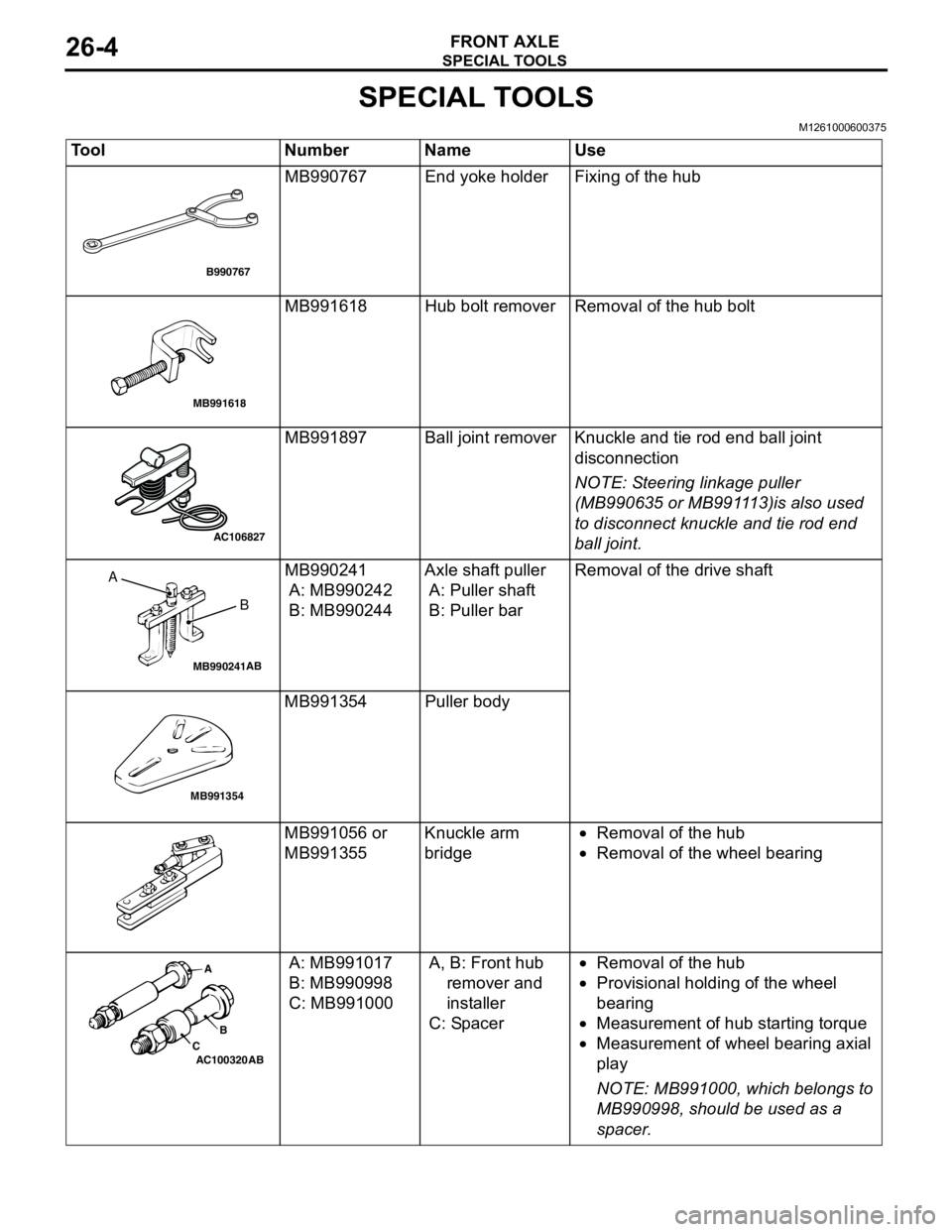

Tool Number Name Use

MB990767 End yoke holder Fixing of the hub

MB991618 Hub bolt remover Removal of the hub bolt

MB991897 Ball joint remover Knuckle and tie rod end ball joint

disconnection

NOTE: Steering linkage puller

(MB990635 or MB991113)is also used

to disconnect knuckle and tie rod end

ball joint.

MB990241

A: MB990242

B: MB990244Axle shaft puller

A: Puller shaft

B: Puller barRemoval of the drive shaft

MB991354 Puller body

MB991056 or

MB991355Knuckle arm

bridge•Removal of the hub

•Removal of the wheel bearing

A: MB991017

B: MB990998

C: MB991000A, B: Front hub

remover and

installer

C: Spacer•Removal of the hub

•Provisional holding of the wheel

bearing

•Measurement of hub starting torque

•Measurement of wheel bearing axial

play

NOTE: MB991000, which belongs to

MB990998, should be used as a

spacer.

B990767

MB991618

AC106827

MB990241AB

A

B

MB991354

AC100320 ABA

B

C

Page 166 of 788

TROUBLESHOOTING

WHEEL AND TYRE31-4

WHEEL BALANCE ACCURACYM1311001700247

PURPOSE

This section contains tips and procedures for

achieving accurate wheel balance. Steering wheel

vibration and/or body shake can result if any of these

procedures are not carefully observed.

1. Wheels and tyres must be properly mounted on a

balancer in order to achieve correct balance.

Centring the wheel on the shaft of the balancer is

essential for proper mounting.

2. Off-the-car wheel balancers must be calibrated

periodically to ensure good balancing results. An

inaccurately calibrated balancer could cause

unnecessary replacement of tyres, shocks,

suspension components, or steering components.

Check your balancer's calibration approximately

every 100 balances. Your wheel balancer's

instruction manual should include calibration

procedures. If the calibration procedures specifically

for your balancer are missing, use the generic steps

in this section for zero calibration, static balance, and

dynamic balance checks. The wheel balancer

calibration checks are also described in the

flowchart. (Refer to P.31-6).

PROCEDURE

1. Confirm that the balancer's cone and the wheel

mounting cone are undamaged and free of dirt

and rust.

2. On this vehicle, the wheel's centre hole on the

hub side has a chamfered edge. Use a

back-mounting cone on your wheel balancer to

centre the wheel on the balancer shaft.

3. Install a wheel mounting cone. The appropriate

size cone for this vehicle is 67.0 mm.

4. Before balancing the wheel, remove any wheel

weights from both sides. Also check both sides for

any damage.

5. When installing wheel weights, hammer them at a

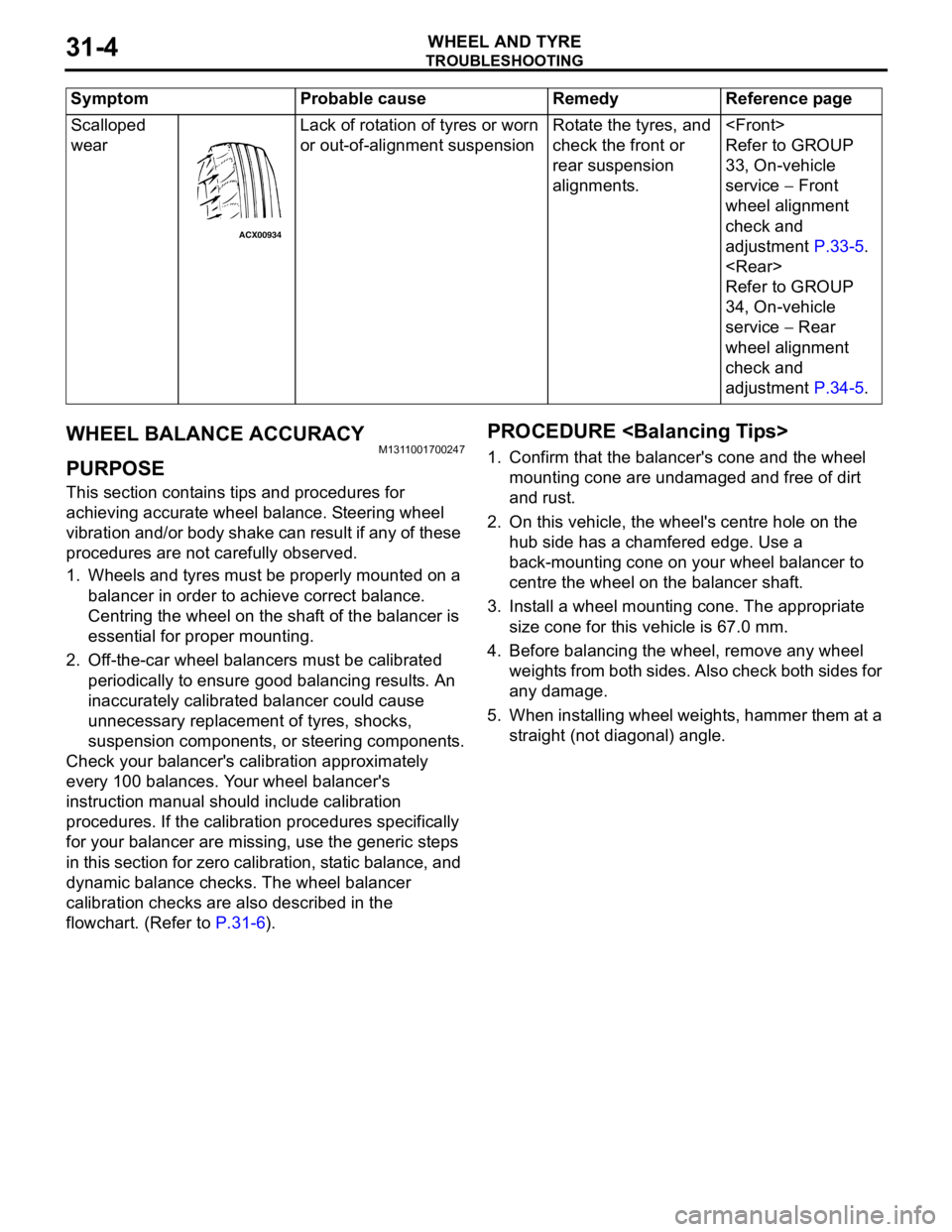

straight (not diagonal) angle. Scalloped

wearLack of rotation of tyres or worn

or out-of-alignment suspensionRotate the tyres, and

check the front or

rear suspension

alignments.

Refer to GROUP

33, On-vehicle

service − Front

wheel alignment

check and

adjustment P.33-5.

Refer to GROUP

34, On-vehicle

service − Rear

wheel alignment

check and

adjustment P.34-5. Symptom Probable cause Remedy Reference page

ACX00934

Page 173 of 788

SERVICE SPECIFICATION

POWER PLANT MOUNT32-3

SERVICE SPECIFICATION

M1321000300333

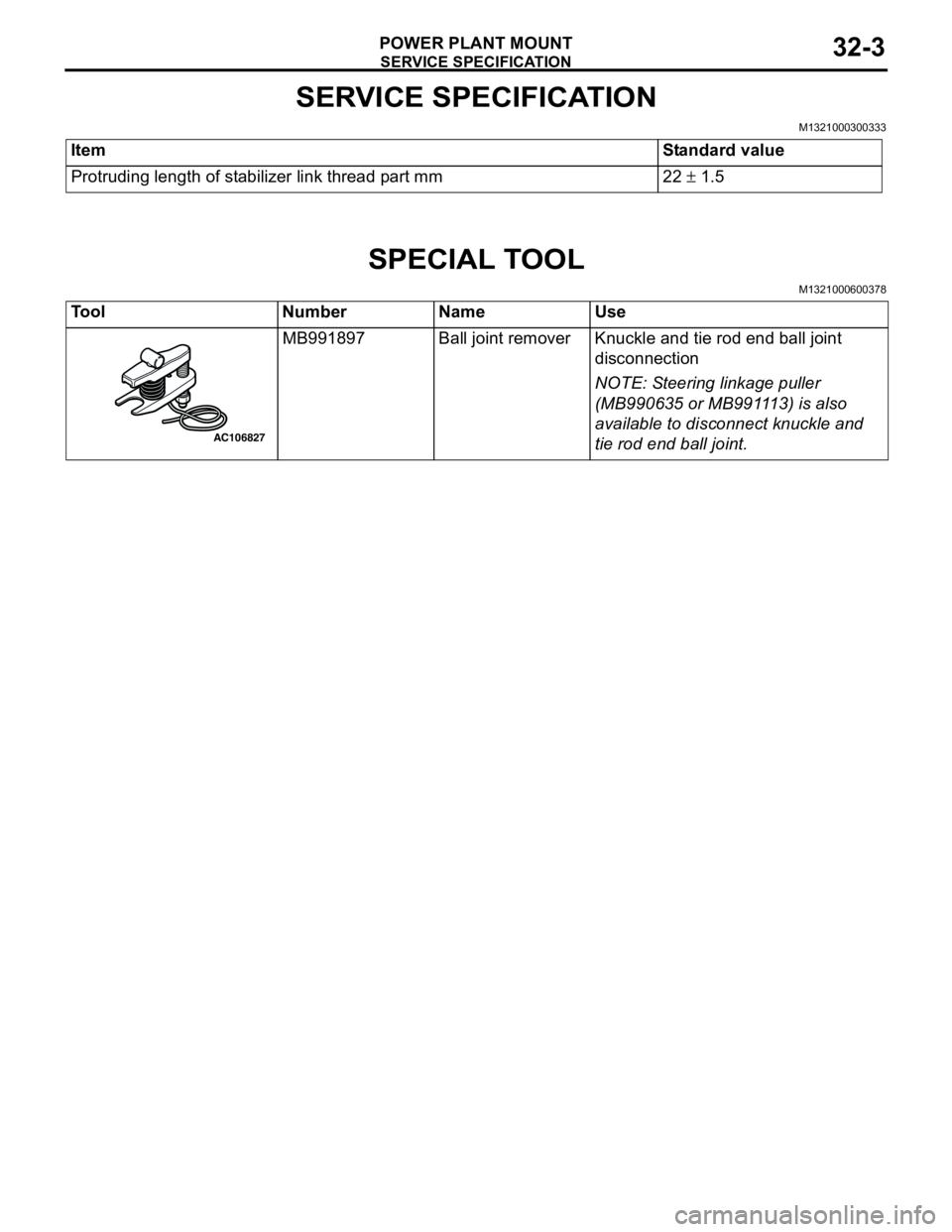

SPECIAL TOOL

M1321000600378

ItemStandard value

Protruding length of stabilizer link thread part mm 22 ± 1.5

Tool Number Name Use

MB991897 Ball joint remover Knuckle and tie rod end ball joint

disconnection

NOTE: Steering linkage puller

(MB990635 or MB991113) is also

available to disconnect knuckle and

tie rod end ball joint.

AC106827

Page 178 of 788

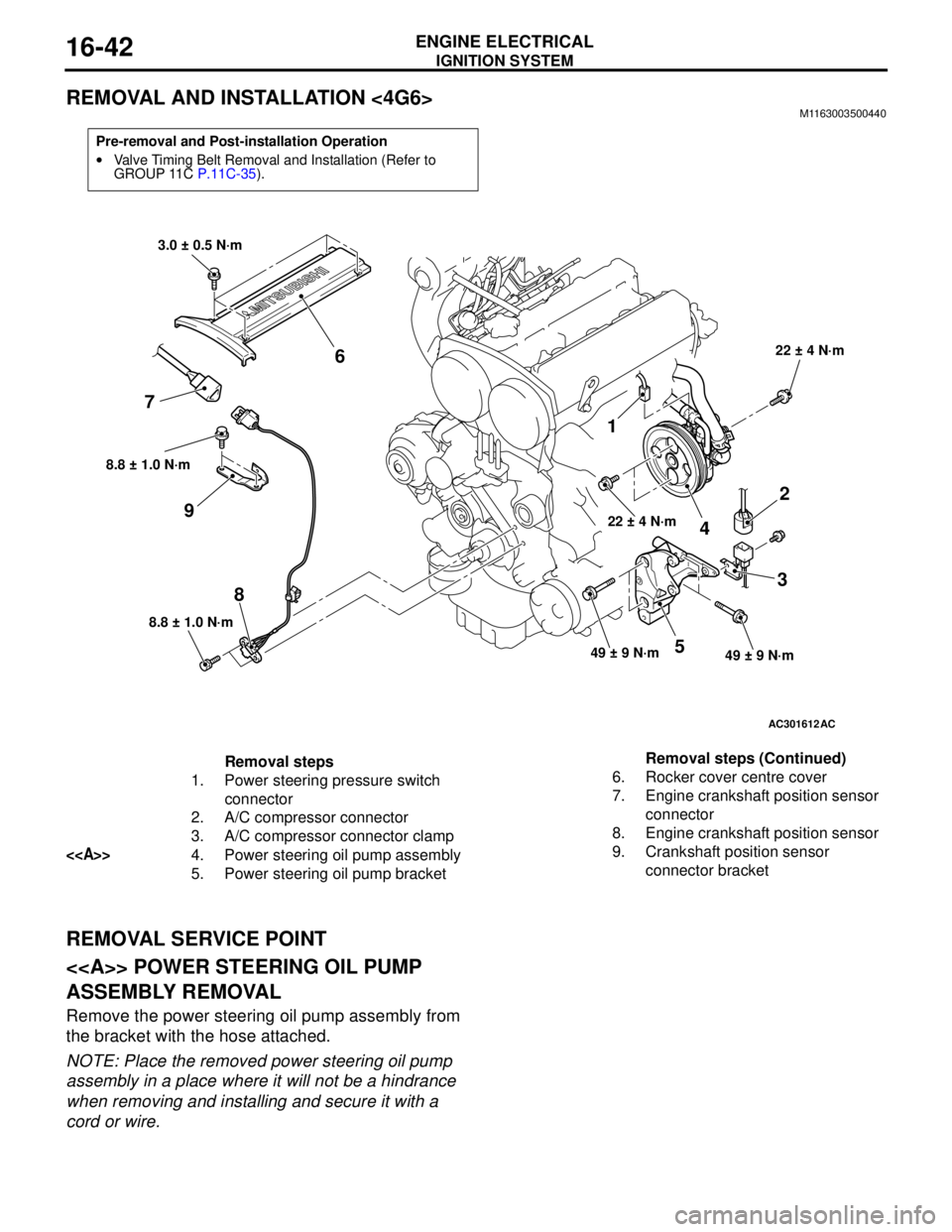

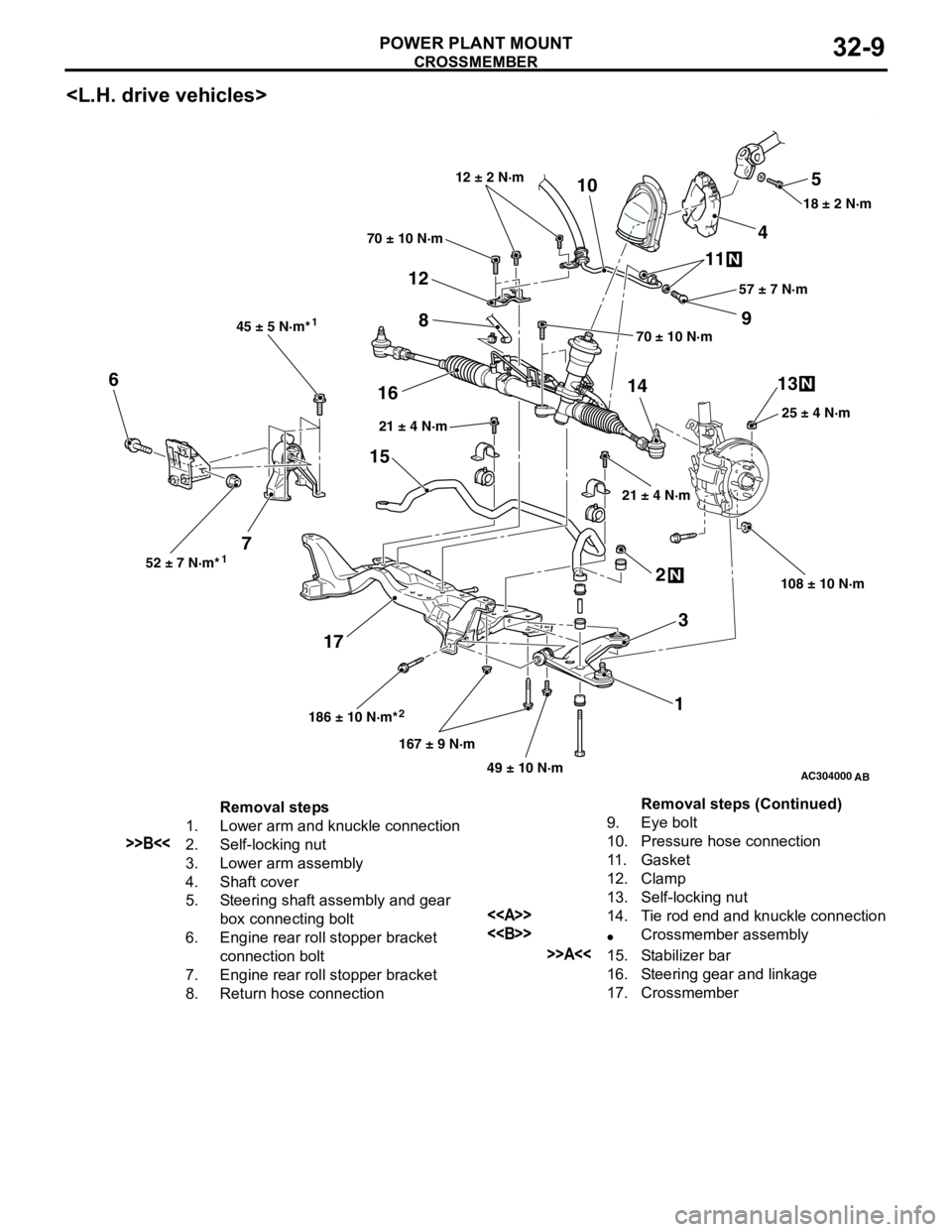

CROSSMEMBER

POWER PLANT MOUNT32-8

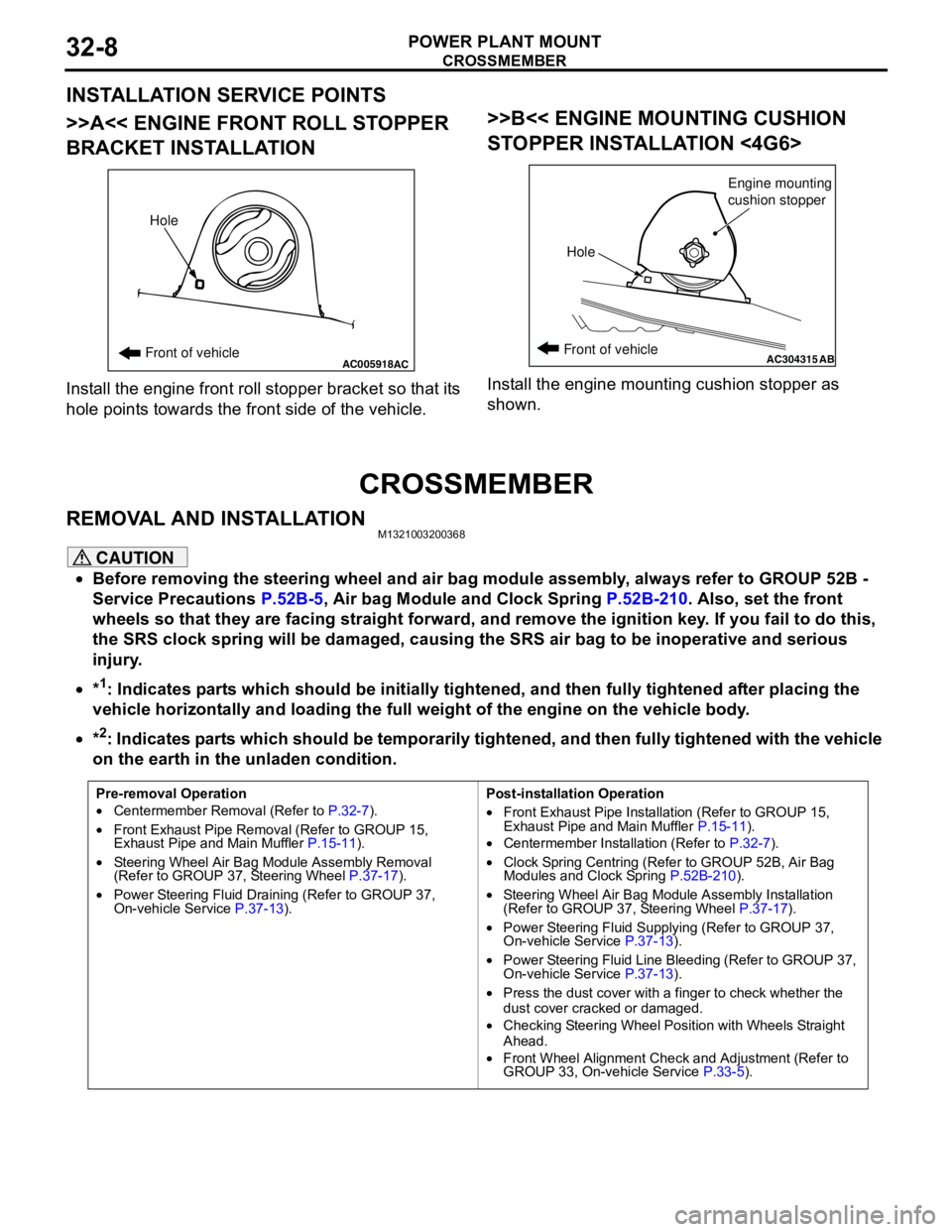

INSTALLATION SERVICE POINTS

>>A<< ENGINE FRONT ROLL STOPPER

BRACKET INSTALLATION

Install the engine front roll stopper bracket so that its

hole points towards the front side of the vehicle.

>>B<< ENGINE MOUNTING CUSHION

STOPPER INSTALLATION <4G6>

Install the engine mounting cushion stopper as

shown.

CROSSMEMBER

REMOVAL AND INSTALLATIONM1321003200368

CAUTION

•Before removing the steering wheel and air bag module assembly, always refer to GROUP 52B -

Service Precautions P.52B-5, Air bag Module and Clock Spring P.52B-210. Also, set the front

wheels so that they are facing straight forward, and remove the ignition key. If you fail to do this,

the SRS clock spring will be damaged, causing the SRS air bag to be inoperative and serious

injury.

•*

1: Indicates parts which should be initially tightened, and then fully tightened after placing the

vehicle horizontally and loading the full weight of the engine on the vehicle body.

•*

2: Indicates parts which should be temporarily tightened, and then fully tightened with the vehicle

on the earth in the unladen condition.

AC005918Front of vehicleHoleACAC304315ABFront of vehicle

HoleEngine mounting

cushion stopper

Pre-removal Operation

•Centermember Removal (Refer to P.32-7).

•Front Exhaust Pipe Removal (Refer to GROUP 15,

Exhaust Pipe and Main Muffler P.15-11).

•Steering Wheel Air Bag Module Assembly Removal

(Refer to GROUP 37, Steering Wheel P.37-17).

•Power Steering Fluid Draining (Refer to GROUP 37,

On-vehicle Service P.37-13).Post-installation Operation

•Front Exhaust Pipe Installation (Refer to GROUP 15,

Exhaust Pipe and Main Muffler P.15-11).

•Centermember Installation (Refer to P.32-7).

•Clock Spring Centring (Refer to GROUP 52B, Air Bag

Modules and Clock Spring P.52B-210).

•Steering Wheel Air Bag Module Assembly Installation

(Refer to GROUP 37, Steering Wheel P.37-17).

•Power Steering Fluid Supplying (Refer to GROUP 37,

On-vehicle Service P.37-13).

•Power Steering Fluid Line Bleeding (Refer to GROUP 37,

On-vehicle Service P.37-13).

•Press the dust cover with a finger to check whether the

dust cover cracked or damaged.

•Checking Steering Wheel Position with Wheels Straight

Ahead.

•Front Wheel Alignment Check and Adjustment (Refer to

GROUP 33, On-vehicle Service P.33-5).

Page 179 of 788

CROSSMEMBER

POWER PLANT MOUNT32-9

AC304000

108 ± 10 N·m 25 ± 4 N·m 18 ± 2 N·m

70 ± 10 N·m

21 ± 4 N·m 21 ± 4 N·m

186 ± 10 N·m*

167 ± 9 N·m

49 ± 10 N·m 52 ± 7 N·m*45 ± 5 N·m*

70 ± 10 N·m57 ± 7 N·m 12 ± 2 N·m

5

4 10

9 11

8

12

1413 6

716

15

172

3

1

N

N

N

2 11

AB

Removal steps

1. Lower arm and knuckle connection

>>B<<2. Self-locking nut

3. Lower arm assembly

4. Shaft cover

5. Steering shaft assembly and gear

box connecting bolt

6. Engine rear roll stopper bracket

connection bolt

7. Engine rear roll stopper bracket

8. Return hose connection9. Eye bolt

10. Pressure hose connection

11. Gasket

12. Clamp

13. Self-locking nut

<>14. Tie rod end and knuckle connection

<>•Crossmember assembly

>>A<<15. Stabilizer bar

16. Steering gear and linkage

17. CrossmemberRemoval steps (Continued)

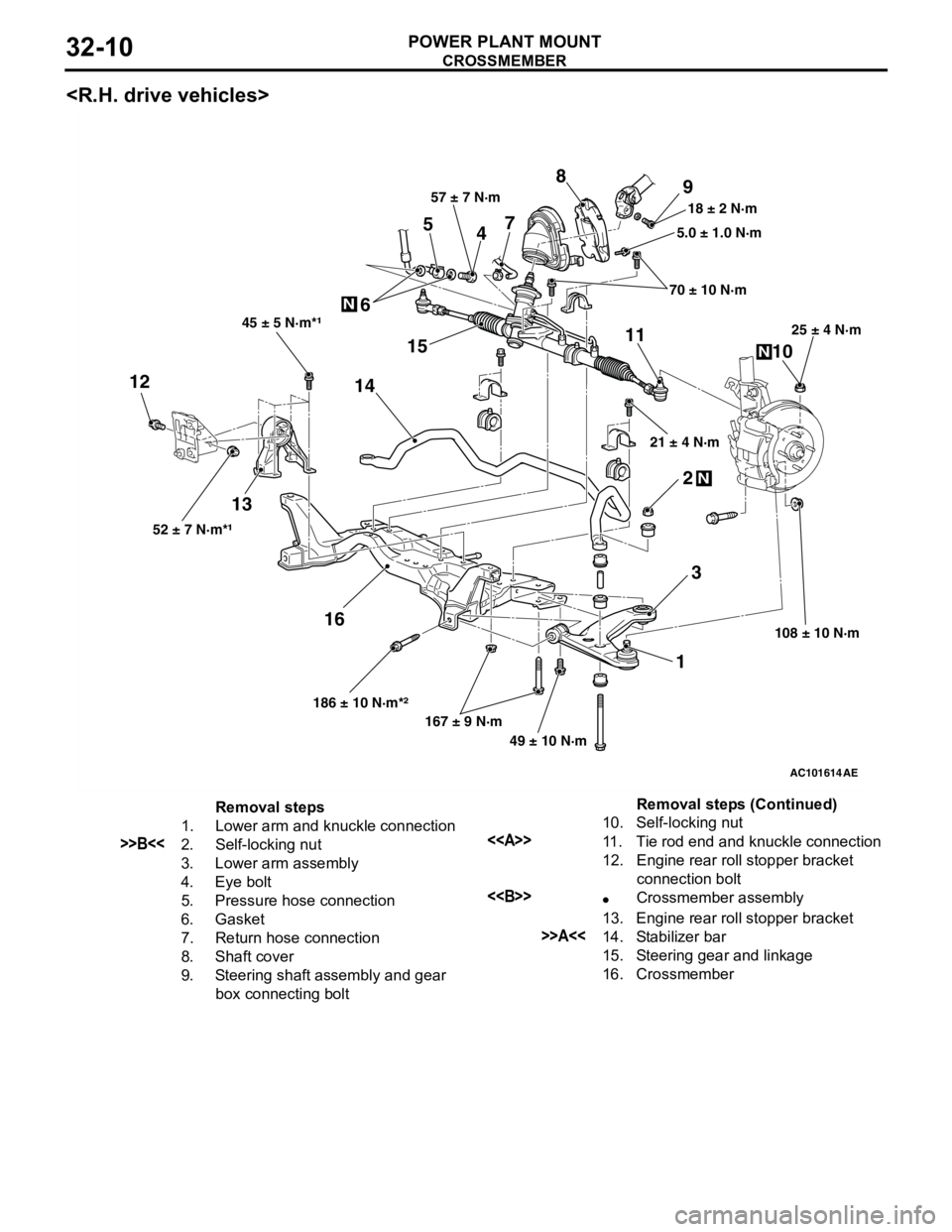

Page 180 of 788

CROSSMEMBER

POWER PLANT MOUNT32-10

AC101614

12

3 4 5

678

9

10 11

12

131415

16

45 ± 5 N·m*¹

52 ± 7 N·m*¹

186 ± 10 N·m*²

167 ± 9 N·m

49 ± 10 N·m108 ± 10 N·m 25 ± 4 N·m

21 ± 4 N·m 70 ± 10 N·m 5.0 ± 1.0 N·m 18 ± 2 N·m 57 ± 7 N·m

N

N

N

AE

Removal steps

1. Lower arm and knuckle connection

>>B<<2. Self-locking nut

3. Lower arm assembly

4. Eye bolt

5. Pressure hose connection

6. Gasket

7. Return hose connection

8. Shaft cover

9. Steering shaft assembly and gear

box connecting bolt10. Self-locking nut<>11. Tie rod end and knuckle connection

12. Engine rear roll stopper bracket

connection bolt

<>•Crossmember assembly

13. Engine rear roll stopper bracket

>>A<<14. Stabilizer bar

15. Steering gear and linkage

16. CrossmemberRemoval steps (Continued)

Page 181 of 788