ect MITSUBISHI LANCER 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 560 of 788

ON-VEHICLE SERVICE

HEATER, AIR CONDITIONER AND VENTILATION55-76

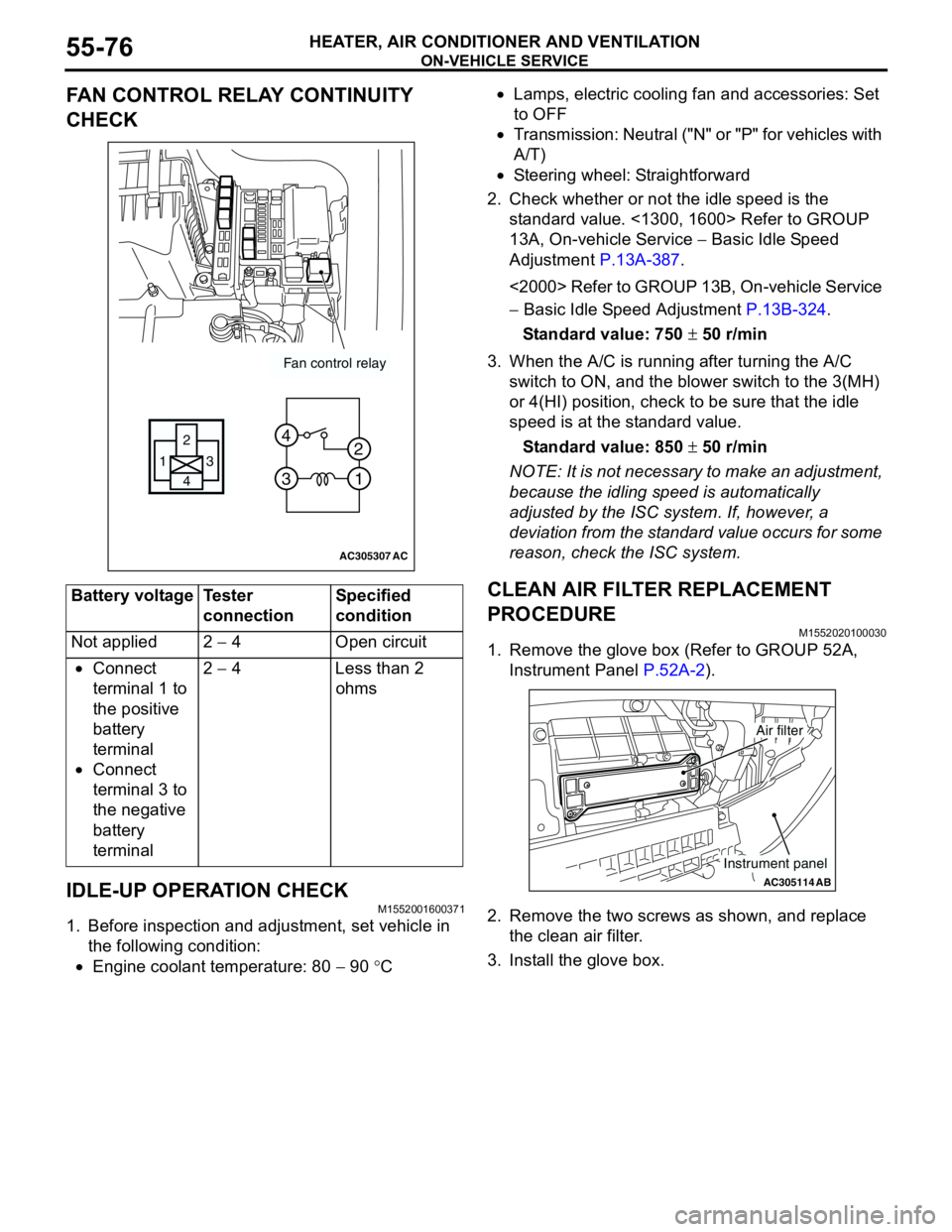

FAN CONTROL RELAY CONTINUITY

CHECK

IDLE-UP OPERATION CHECK

M1552001600371

1. Before inspection and adjustment, set vehicle in

the following condition:

•Engine coolant temperature: 80 − 90 °C•Lamps, electric cooling fan and accessories: Set

to OFF

•Transmission: Neutral ("N" or "P" for vehicles with

A/T)

•Steering wheel: Straightforward

2. Check whether or not the idle speed is the

standard value. <1300, 1600> Refer to GROUP

13A, On-vehicle Service − Basic Idle Speed

Adjustment P.13A-387.

<2000> Refer to GROUP 13B, On-vehicle Service

− Basic Idle Speed Adjustment P.13B-324.

Standard value: 750 ± 50 r/min

3. When the A/C is running after turning the A/C

switch to ON, and the blower switch to the 3(MH)

or 4(HI) position, check to be sure that the idle

speed is at the standard value.

Standard value: 850 ± 50 r/min

NOTE: It is not necessary to make an adjustment,

because the idling speed is automatically

adjusted by the ISC system. If, however, a

deviation from the standard value occurs for some

reason, check the ISC system.

CLEAN AIR FILTER REPLACEMENT

PROCEDURE

M1552020100030

1. Remove the glove box (Refer to GROUP 52A,

Instrument Panel P.52A-2).

2. Remove the two screws as shown, and replace

the clean air filter.

3. Install the glove box. Battery voltage Tester

connectionSpecified

condition

Not applied 2 − 4 Open circuit

•Connect

terminal 1 to

the positive

battery

terminal

•Connect

terminal 3 to

the negative

battery

terminal2 − 4 Less than 2

ohms

AC305307

Fan control relay

13

4 2

3 4

1 2

AC

AC305114AB

Air filter

Instrument panel

Page 561 of 788

HEATER CONTROL ASSEMBLY AND A/C SWITCH

HEATER, AIR CONDITIONER AND VENTILATION55-77

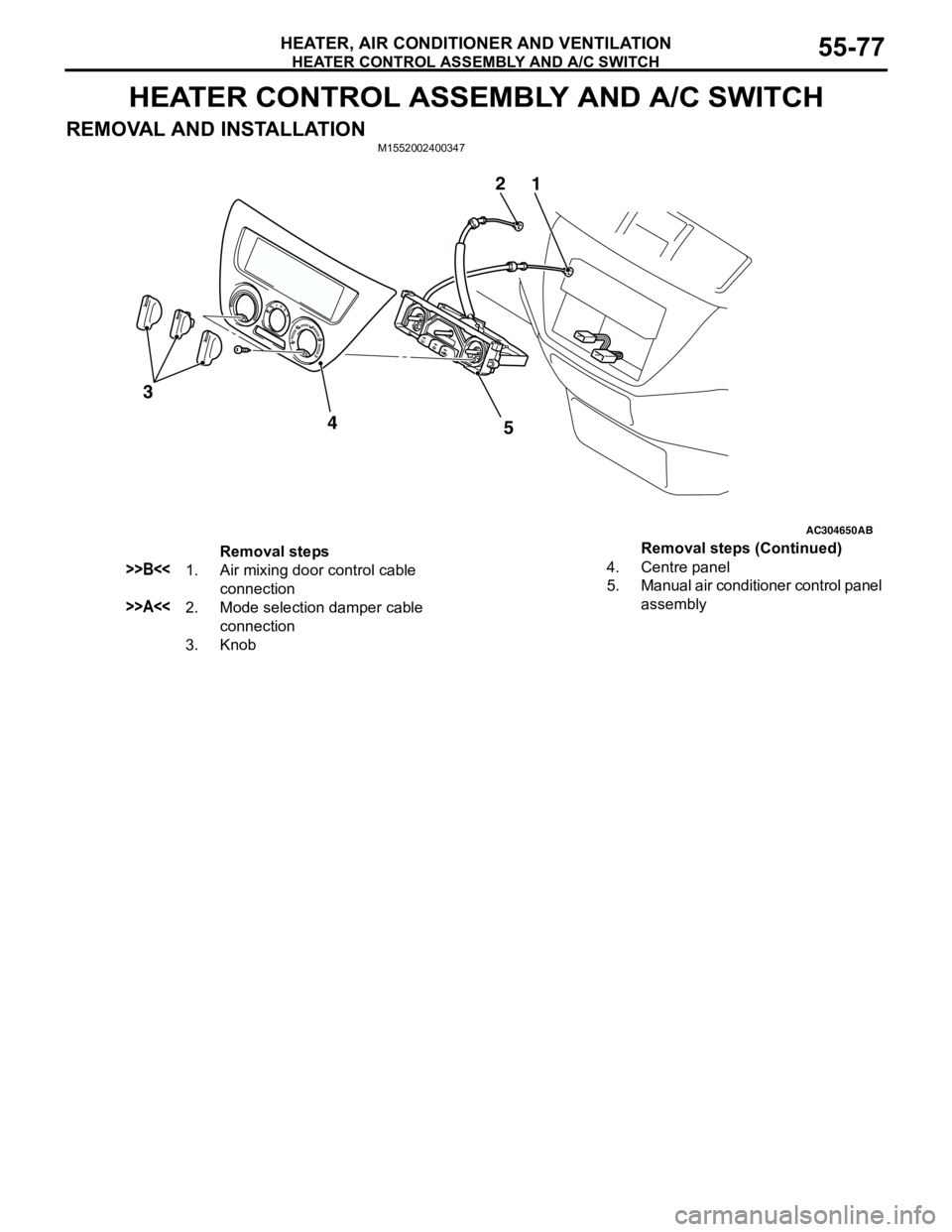

HEATER CONTROL ASSEMBLY AND A/C SWITCH

REMOVAL AND INSTALLATIONM1552002400347

AC304650

1 2

3

4

5

AB

Removal steps

>>B<<1. Air mixing door control cable

connection

>>A<<2. Mode selection damper cable

connection

3. Knob4. Centre panel

5. Manual air conditioner control panel

assembly Removal steps (Continued)

Page 562 of 788

HEATER CONTROL ASSEMBLY AND A/C SWITCH

HEATER, AIR CONDITIONER AND VENTILATION55-78

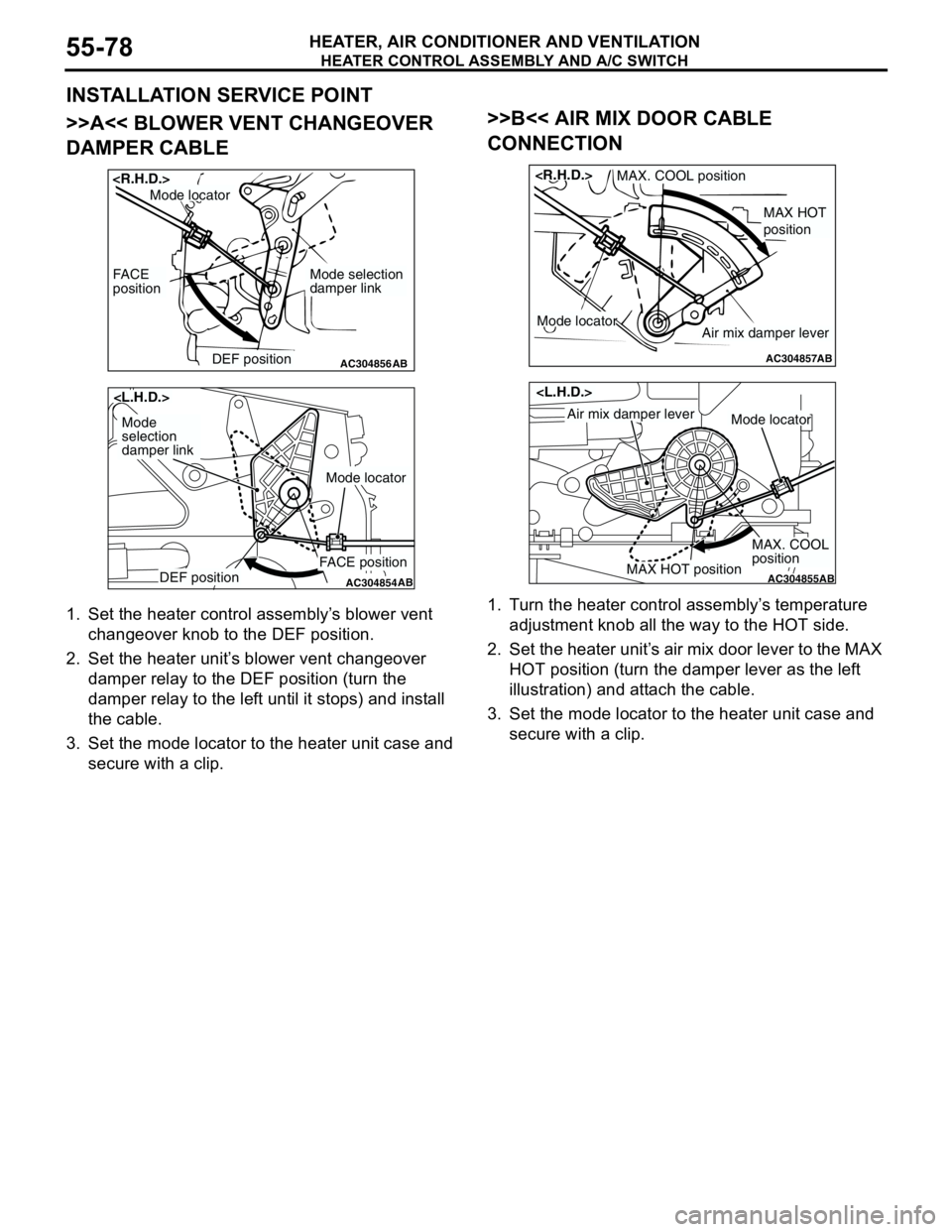

INSTALLATION SERVICE POINT

>>A<< BLOWER VENT CHANGEOVER

DAMPER CABLE

1. Set the heater control assembly’s blower vent

changeover knob to the DEF position.

2. Set the heater unit’s blower vent changeover

damper relay to the DEF position (turn the

damper relay to the left until it stops) and install

the cable.

3. Set the mode locator to the heater unit case and

secure with a clip.

>>B<< AIR MIX DOOR CABLE

CONNECTION

1. Turn the heater control assembly’s temperature

adjustment knob all the way to the HOT side.

2. Set the heater unit’s air mix door lever to the MAX

HOT position (turn the damper lever as the left

illustration) and attach the cable.

3. Set the mode locator to the heater unit case and

secure with a clip.

AC304856DEF position

FACE

position

AB

Mode selection

damper link

Mode locator

AC304854DEF positionFACE position

AB

Mode

selection

damper link

Mode locator

AC304857

MAX HOT

position

MAX. COOL position

AB

Air mix damper leverMode locator

AC304855MAX HOT position

MAX. COOL

position

AB

Air mix damper leverMode locator

Page 563 of 788

HEATER CONTROL ASSEMBLY AND A/C SWITCH

HEATER, AIR CONDITIONER AND VENTILATION55-79

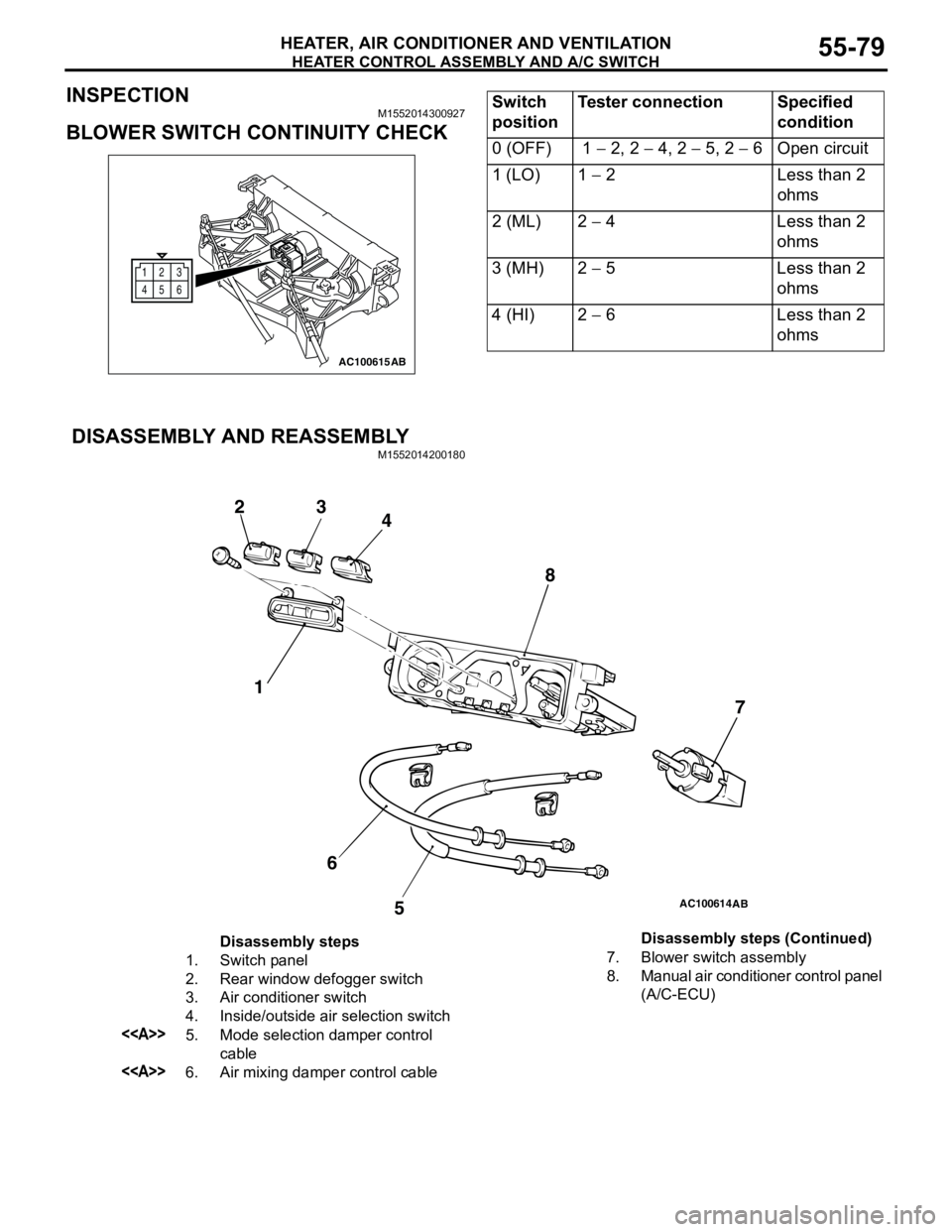

INSPECTIONM1552014300927

BLOWER SWITCH CONTINUITY CHECK

DISASSEMBLY AND REASSEMBLY

M1552014200180

12

6 3

45

AC100615AB

Switch

positionTester connection Specified

condition

0 (OFF) 1 − 2, 2 − 4, 2 − 5, 2 − 6 Open circuit

1 (LO) 1 − 2 Less than 2

ohms

2 (ML) 2 − 4 Less than 2

ohms

3 (MH) 2 − 5 Less than 2

ohms

4 (HI) 2 − 6 Less than 2

ohms

AC100614

1 23

4

5 67 8

AB

Disassembly steps

1. Switch panel

2. Rear window defogger switch

3. Air conditioner switch

4. Inside/outside air selection switch

<>5. Mode selection damper control

cable

<>6. Air mixing damper control cable7. Blower switch assembly

8. Manual air conditioner control panel

(A/C-ECU) Disassembly steps (Continued)

Page 564 of 788

HEATER CONTROL ASSEMBLY AND A/C SWITCH

HEATER, AIR CONDITIONER AND VENTILATION55-80

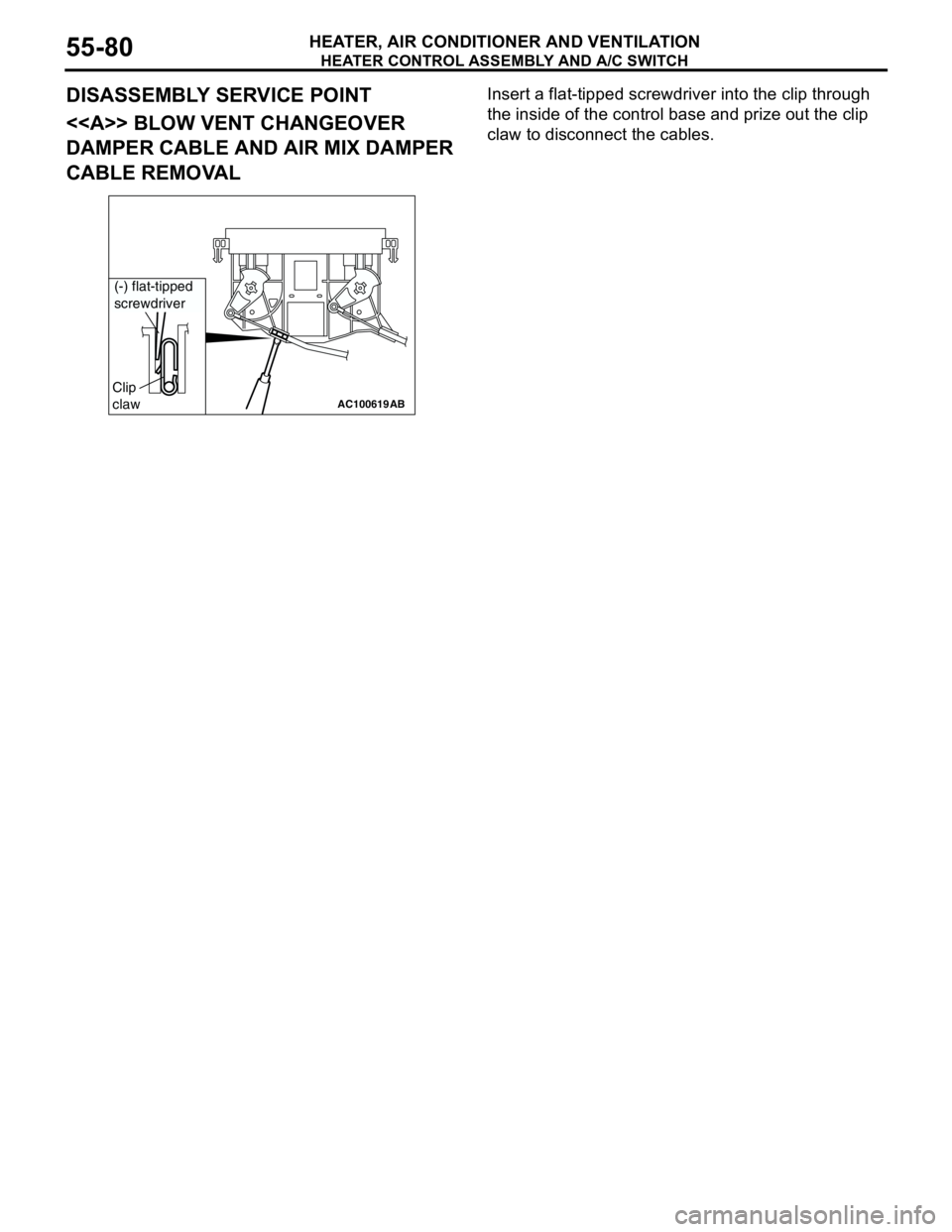

DISASSEMBLY SERVICE POINT

<> BLOW VENT CHANGEOVER

DAMPER CABLE AND AIR MIX DAMPER

CABLE REMOVALInsert a flat-tipped screwdriver into the clip through

the inside of the control base and prize out the clip

claw to disconnect the cables.

AC100619

AB

Clip

claw

(-) flat-tipped

screwdriver

Page 565 of 788

HEATER UNIT, HEATER CORE, BLOWER ASSEMBLY AND EVAPORATOR UNIT

HEATER, AIR CONDITIONER AND VENTILATION55-81

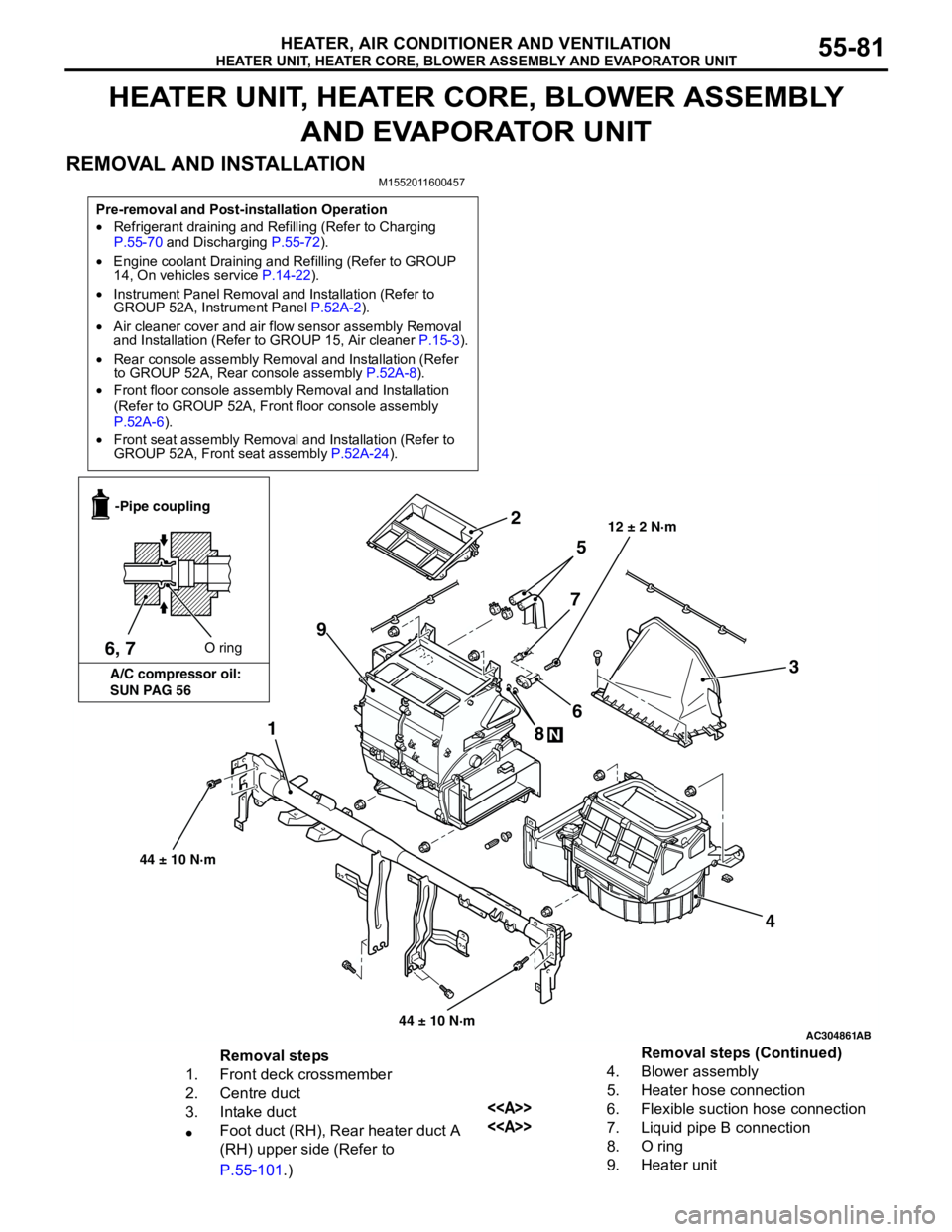

HEATER UNIT, HEATER CORE, BLOWER ASSEMBLY

AND EVAPORATOR UNIT

REMOVAL AND INSTALLATION

M1552011600457

Pre-removal and Post-installation Operation

•Refrigerant draining and Refilling (Refer to Charging

P.55-70 and Discharging P.55-72).

•Engine coolant Draining and Refilling (Refer to GROUP

14, On vehicles service P.14-22).

•Instrument Panel Removal and Installation (Refer to

GROUP 52A, Instrument Panel P.52A-2).

•Air cleaner cover and air flow sensor assembly Removal

and Installation (Refer to GROUP 15, Air cleaner P.15-3).

•Rear console assembly Removal and Installation (Refer

to GROUP 52A, Rear console assembly P.52A-8).

•Front floor console assembly Removal and Installation

(Refer to GROUP 52A, Front floor console assembly

P.52A-6).

•Front seat assembly Removal and Installation (Refer to

GROUP 52A, Front seat assembly P.52A-24).

AC304861

1

2

3

4 5

6

7

8

N

9

AB

12 ± 2 N·m

6, 7O ring -Pipe coupling

A/C compressor oil:

SUN PAG 56

44 ± 10 N·m

44 ± 10 N·m

Removal steps

1. Front deck crossmember

2. Centre duct

3. Intake duct

•Foot duct (RH), Rear heater duct A

(RH) upper side (Refer to

P.55-101.)4. Blower assembly

5. Heater hose connection

<>6. Flexible suction hose connection

<>7. Liquid pipe B connection

8. O ring

9. Heater unitRemoval steps (Continued)

Page 566 of 788

HEATER UNIT, HEATER CORE, BLOWER ASSEMBLY AND EVAPORATOR UNIT

HEATER, AIR CONDITIONER AND VENTILATION55-82

REMOVAL SERVICE POINT

<> FLEXIBLE SUCTION HOSE AND

LIQUID PIPE B DISCONNECTION

CAUTION

As the compressor oil and receiver are highly

moisture absorbent, use a non-porous material

to plug the hose and nipples.

To prevent the entry of dust or other foreign bodies,

plug the dismantled hose and the nipples of the

expansion valves.

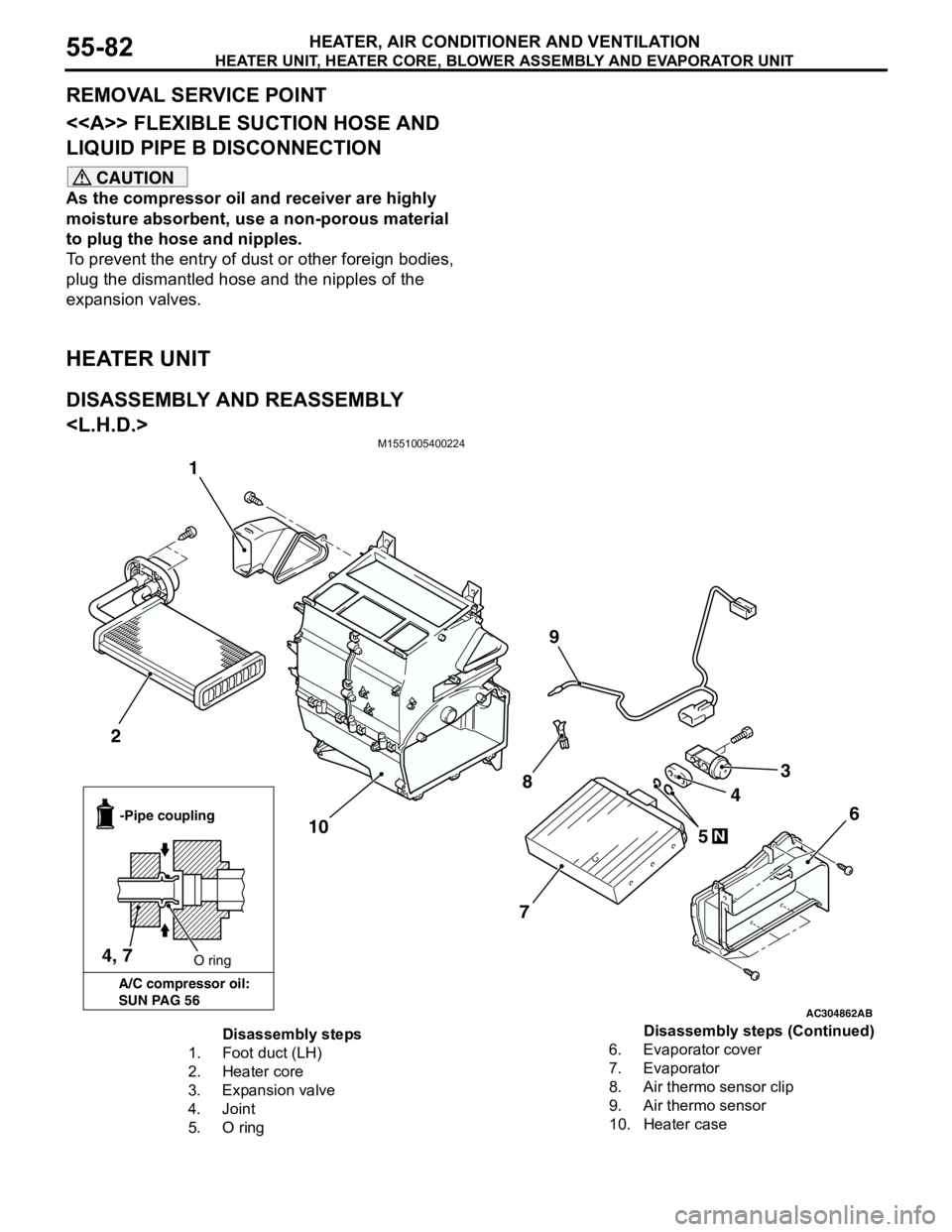

HEATER UNIT

DISASSEMBLY AND REASSEMBLY

M1551005400224

AC304862

1

2

3

4

5

6

7

8

9

10

AB

4, 7O ring -Pipe coupling

A/C compressor oil:

SUN PAG 56

N

Disassembly steps

1. Foot duct (LH)

2. Heater core

3. Expansion valve

4. Joint

5. O ring6. Evaporator cover

7. Evaporator

8. Air thermo sensor clip

9. Air thermo sensor

10. Heater caseDisassembly steps (Continued)

Page 568 of 788

HEATER UNIT, HEATER CORE, BLOWER ASSEMBLY AND EVAPORATOR UNIT

HEATER, AIR CONDITIONER AND VENTILATION55-84

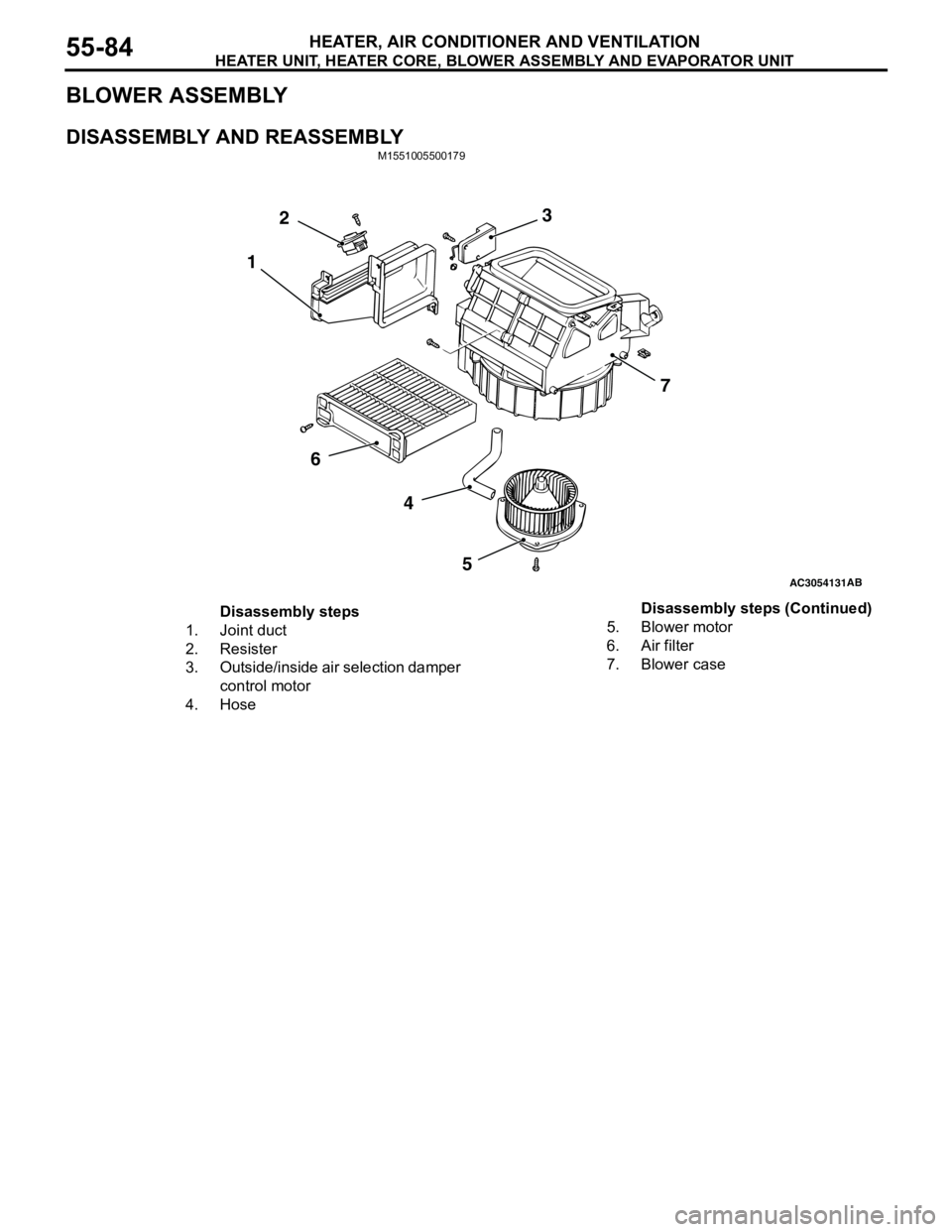

BLOWER ASSEMBLY

DISASSEMBLY AND REASSEMBLYM1551005500179

AC3054131AB

3

4

57

6

12

Disassembly steps

1. Joint duct

2. Resister

3. Outside/inside air selection damper

control motor

4. Hose5. Blower motor

6. Air filter

7. Blower caseDisassembly steps (Continued)

Page 569 of 788

BLOWERMOTOR, RESISTOR AND OUTSIDE/ INSIDE AIR SELECTION DAMPER CONTROL MOTOR

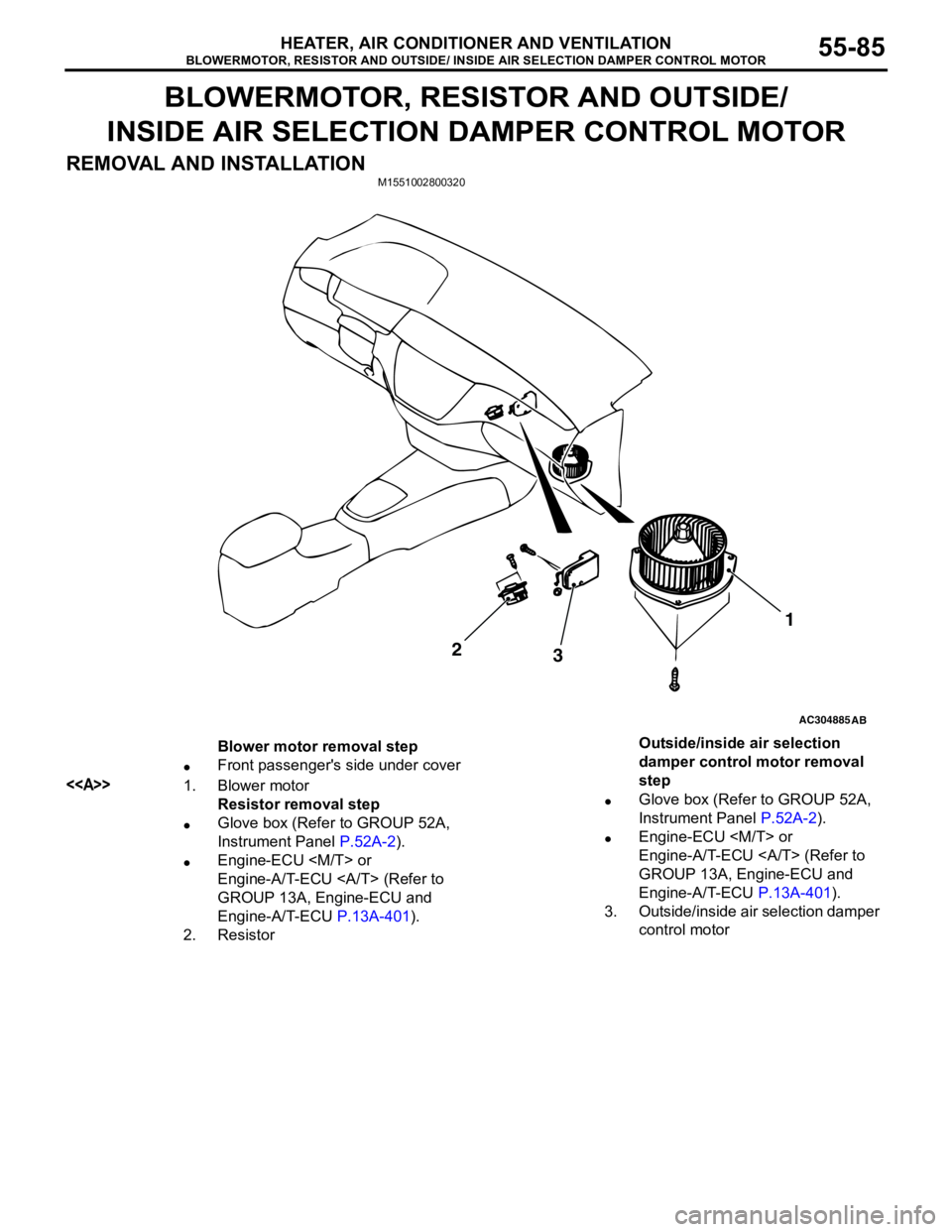

HEATER, AIR CONDITIONER AND VENTILATION55-85

BLOWERMOTOR, RESISTOR AND OUTSIDE/

INSIDE AIR SELECTION DAMPER CONTROL MOTOR

REMOVAL AND INSTALLATION

M1551002800320

AC304885AB

2

31

Blower motor removal step

•Front passenger's side under cover

<>1. Blower motor

Resistor removal step

•Glove box (Refer to GROUP 52A,

Instrument Panel P.52A-2).

•Engine-ECU

Engine-A/T-ECU (Refer to

GROUP 13A, Engine-ECU and

Engine-A/T-ECU P.13A-401).

2. ResistorOutside/inside air selection

damper control motor removal

step

•Glove box (Refer to GROUP 52A,

Instrument Panel P.52A-2).

•Engine-ECU

Engine-A/T-ECU (Refer to

GROUP 13A, Engine-ECU and

Engine-A/T-ECU P.13A-401).

3. Outside/inside air selection damper

control motor

Page 570 of 788

BLOWERMOTOR, RESISTOR AND OUTSIDE/ INSIDE AIR SELECTION DAMPER CONTROL MOTOR

HEATER, AIR CONDITIONER AND VENTILATION55-86

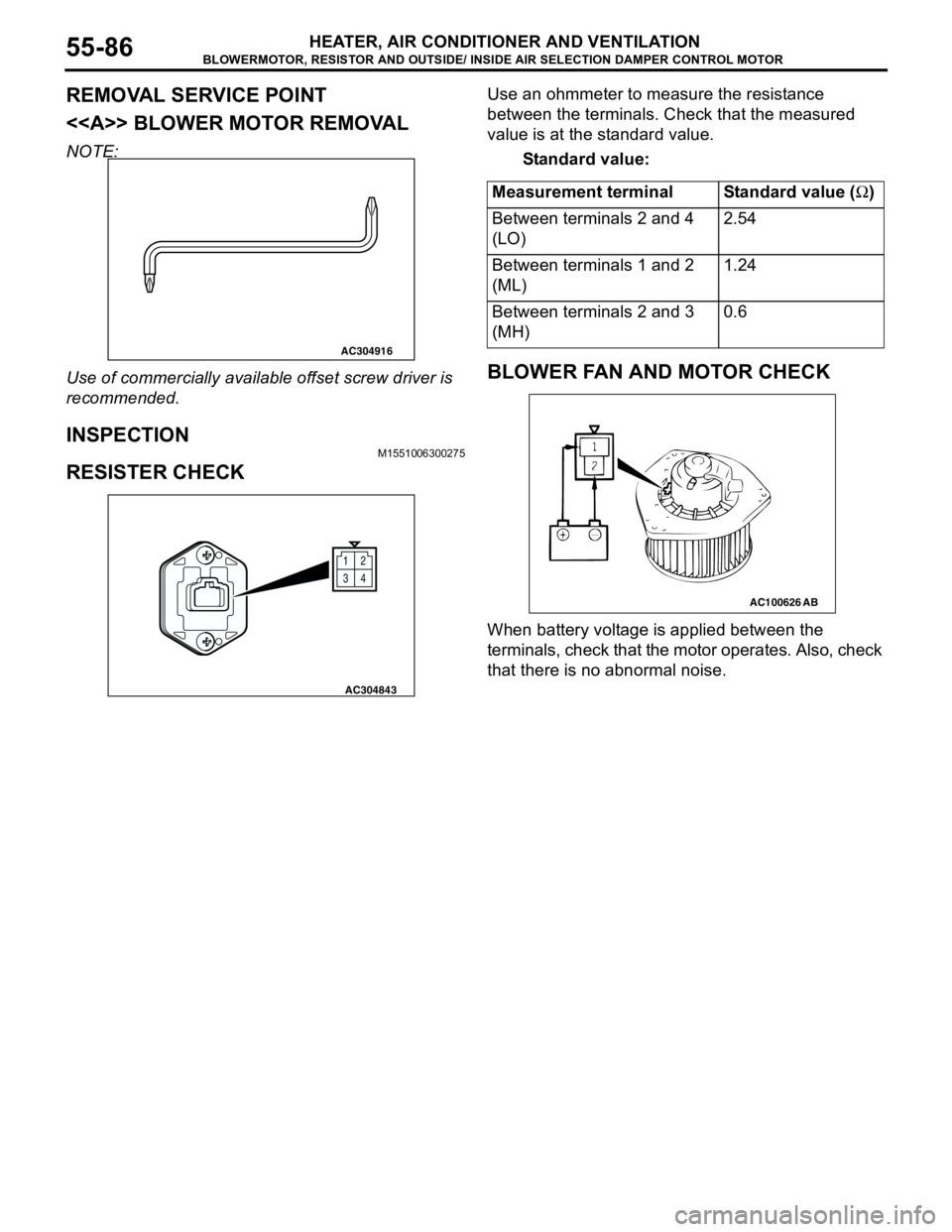

REMOVAL SERVICE POINT

<> BLOWER MOTOR REMOVAL

NOTE:

Use of commercially available offset screw driver is

recommended.

INSPECTIONM1551006300275

RESISTER CHECK

Use an ohmmeter to measure the resistance

between the terminals. Check that the measured

value is at the standard value.

Standard value:

BLOWER FAN AND MOTOR CHECK

When battery voltage is applied between the

terminals, check that the motor operates. Also, check

that there is no abnormal noise.

AC304916

12

34

AC304843

Measurement terminal Standard value (Ω)

Between terminals 2 and 4

(LO)2.54

Between terminals 1 and 2

(ML)1.24

Between terminals 2 and 3

(MH)0.6

AC100626AB