air condition MITSUBISHI LANCER 2005 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 438 of 788

COMBINATION METER ASSEMBLY

CHASSIS ELECTRICAL54A-50

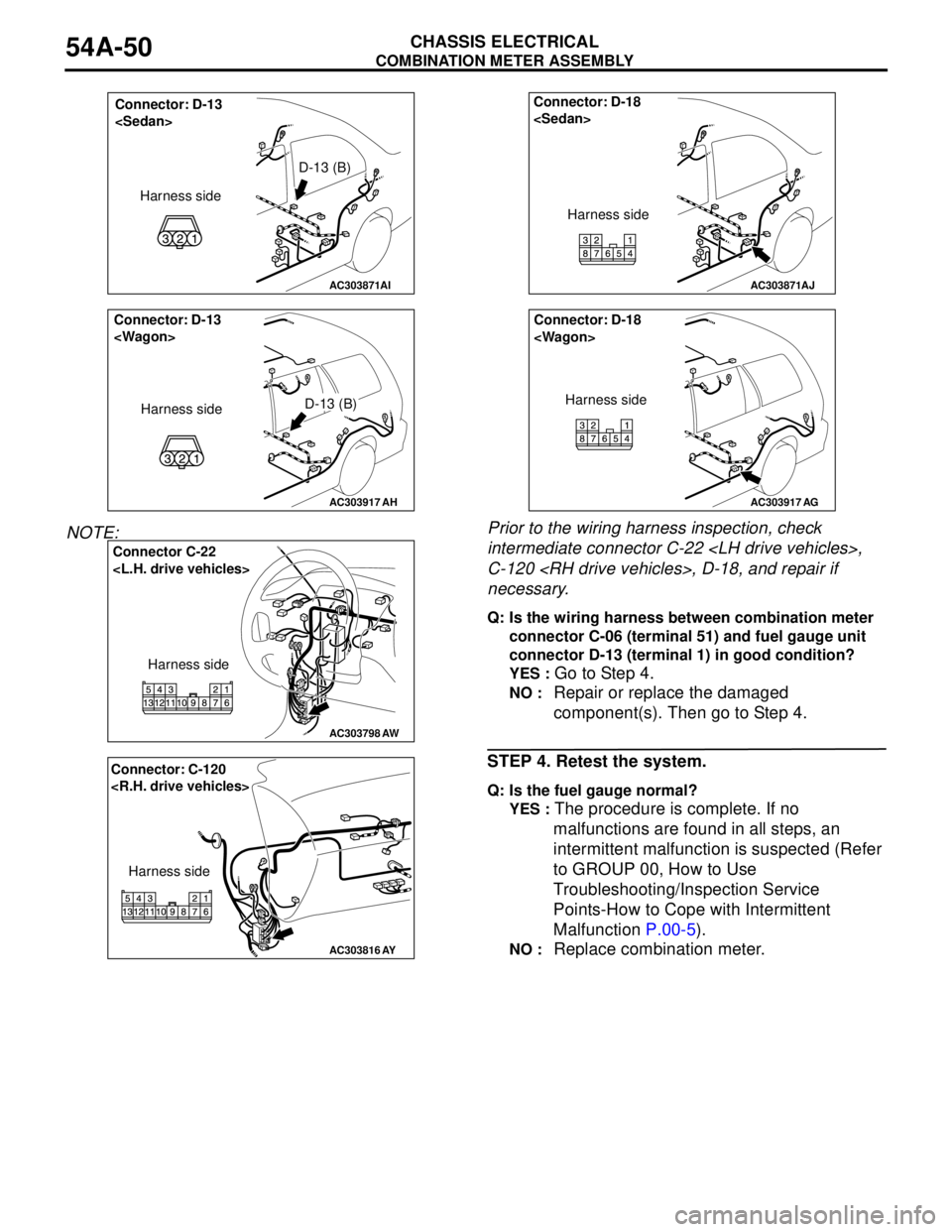

NOTE: Prior to the wiring harness inspection, check

intermediate connector C-22

C-120

necessary.

Q: Is the wiring harness between combination meter

connector C-06 (terminal 51) and fuel gauge unit

connector D-13 (terminal 1) in good condition?

YES :

Go to Step 4.

NO : Repair or replace the damaged

component(s). Then go to Step 4.

STEP 4. Retest the system.

Q: Is the fuel gauge normal?

YES :

The procedure is complete. If no

malfunctions are found in all steps, an

intermittent malfunction is suspected (Refer

to GROUP 00, How to Use

Troubleshooting/Inspection Service

Points-How to Cope with Intermittent

Malfunction P.00-5).

NO : Replace combination meter.

AC303871

Connector: D-13

Harness sideD-13 (B)

AI

AC303917

D-13 (B) Connector: D-13

Harness side

AH

AC303798

Harness side Connector C-22

AW

AC303816AY

Connector: C-120

Harness side

AC303871

Connector: D-18

AJ

Harness side

AC303917

Connector: D-18

Harness side

AG

Page 440 of 788

COMBINATION METER ASSEMBLY

CHASSIS ELECTRICAL54A-52

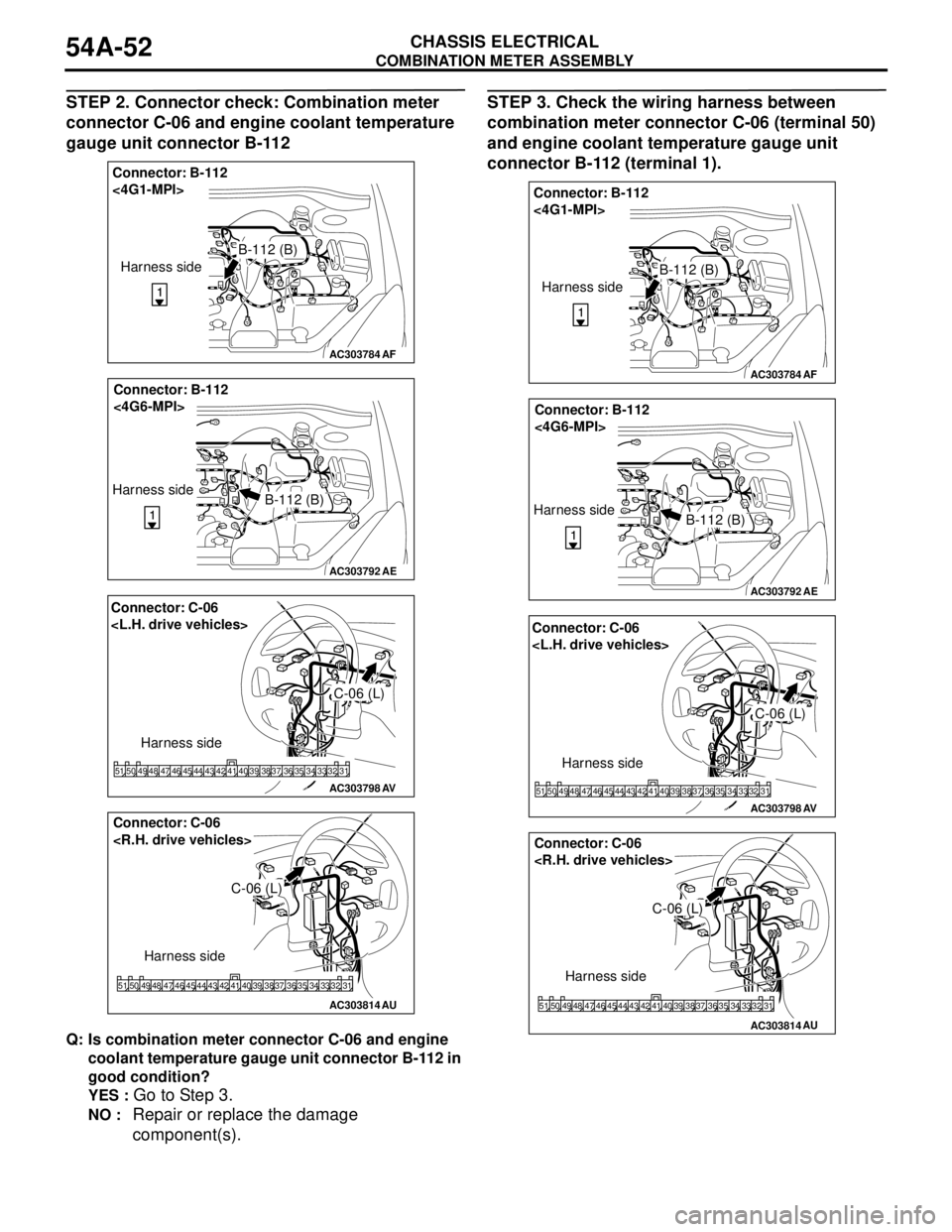

STEP 2. Connector check: Combination meter

connector C-06 and engine coolant temperature

gauge unit connector B-112

Q: Is combination meter connector C-06 and engine

coolant temperature gauge unit connector B-112 in

good condition?

YES :

Go to Step 3.

NO : Repair or replace the damage

component(s).

STEP 3. Check the wiring harness between

combination meter connector C-06 (terminal 50)

and engine coolant temperature gauge unit

connector B-112 (terminal 1).

AC303784

Connector: B-112

<4G1-MPI>

Harness side

B-112 (B)

AF

AC303792

AE

Connector: B-112

<4G6-MPI>

B-112 (B) Harness side

AC303798

Connector: C-06

Harness side

C-06 (L)

31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51

AV

AC303814AU

Connector: C-06

Harness side

31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51

C-06 (L)

AC303784

Connector: B-112

<4G1-MPI>

Harness side

B-112 (B)

AF

AC303792

AE

Connector: B-112

<4G6-MPI>

B-112 (B) Harness side

AC303798

Connector: C-06

Harness side

C-06 (L)

31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51

AV

AC303814AU

Connector: C-06

Harness side

31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51

C-06 (L)

Page 441 of 788

COMBINATION METER ASSEMBLY

CHASSIS ELECTRICAL54A-53

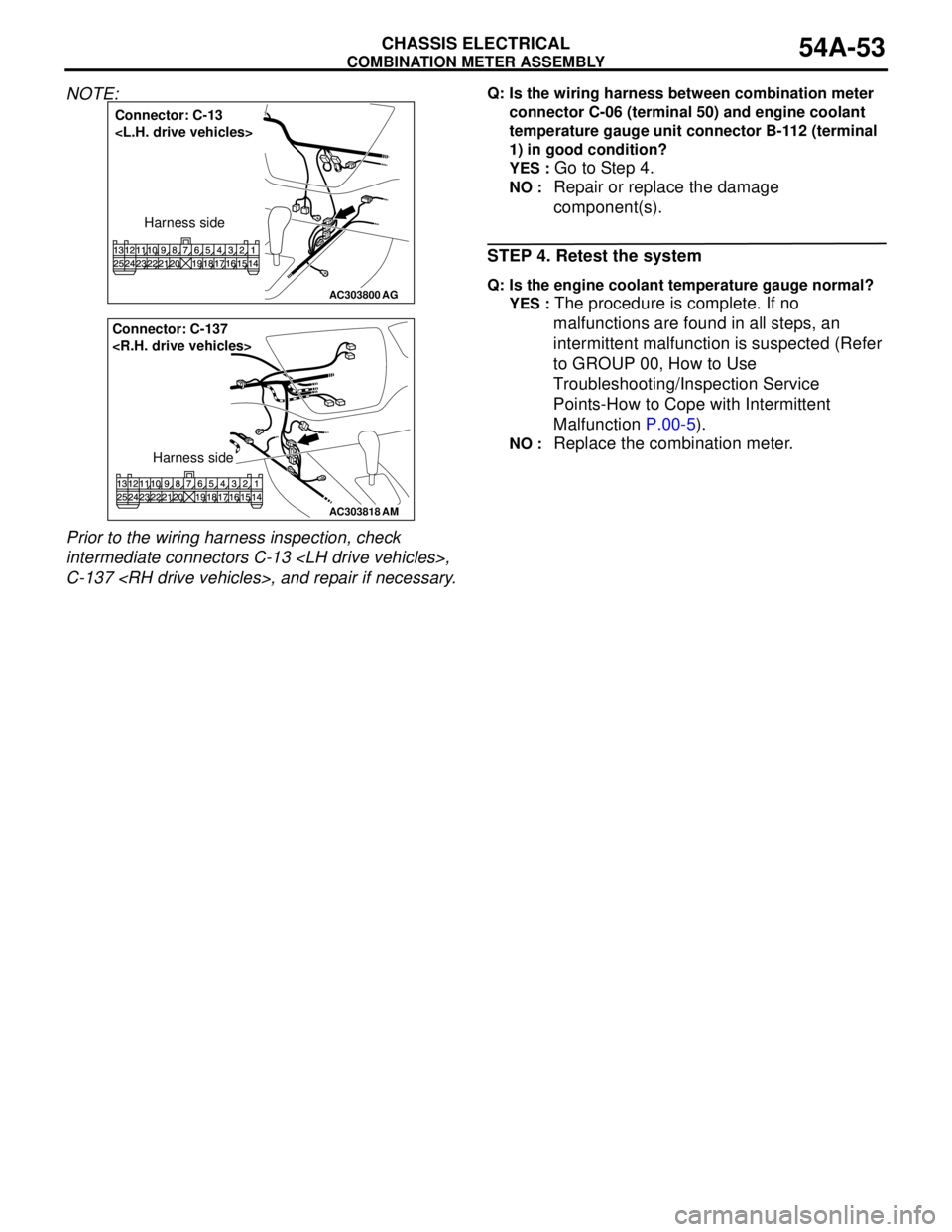

NOTE:

Prior to the wiring harness inspection, check

intermediate connectors C-13

C-137

connector C-06 (terminal 50) and engine coolant

temperature gauge unit connector B-112 (terminal

1) in good condition?

YES :

Go to Step 4.

NO : Repair or replace the damage

component(s).

STEP 4. Retest the system

Q: Is the engine coolant temperature gauge normal?

YES :

The procedure is complete. If no

malfunctions are found in all steps, an

intermittent malfunction is suspected (Refer

to GROUP 00, How to Use

Troubleshooting/Inspection Service

Points-How to Cope with Intermittent

Malfunction P.00-5).

NO : Replace the combination meter.

AC303800

Connector: C-13

Harness side

AG

AC303818

AM

Connector: C-137

Harness side

Page 443 of 788

COMBINATION METER ASSEMBLY

CHASSIS ELECTRICAL54A-55

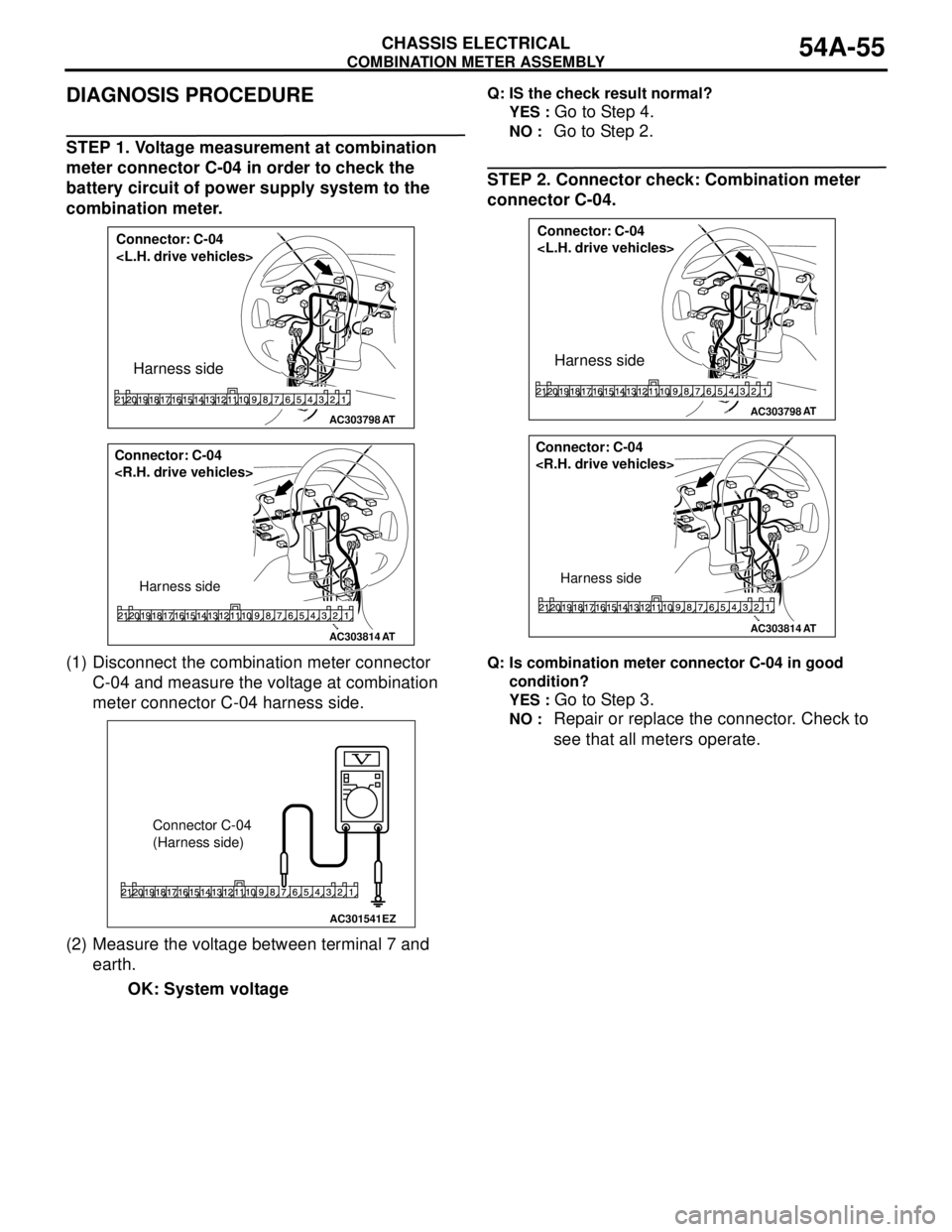

DIAGNOSIS PROCEDURE

STEP 1. Voltage measurement at combination

meter connector C-04 in order to check the

battery circuit of power supply system to the

combination meter.

(1) Disconnect the combination meter connector

C-04 and measure the voltage at combination

meter connector C-04 harness side.

(2) Measure the voltage between terminal 7 and

earth.

OK: System voltage

Q: IS the check result normal?

YES :

Go to Step 4.

NO : Go to Step 2.

STEP 2. Connector check: Combination meter

connector C-04.

Q: Is combination meter connector C-04 in good

condition?

YES :

Go to Step 3.

NO : Repair or replace the connector. Check to

see that all meters operate.

AC303798

Connector: C-04

Harness side

AT

AC303814

Connector: C-04

Harness side

AT

AC301541

Connector C-04

(Harness side)

EZ

AC303798

Connector: C-04

Harness side

AT

AC303814

Connector: C-04

Harness side

AT

Page 444 of 788

COMBINATION METER ASSEMBLY

CHASSIS ELECTRICAL54A-56

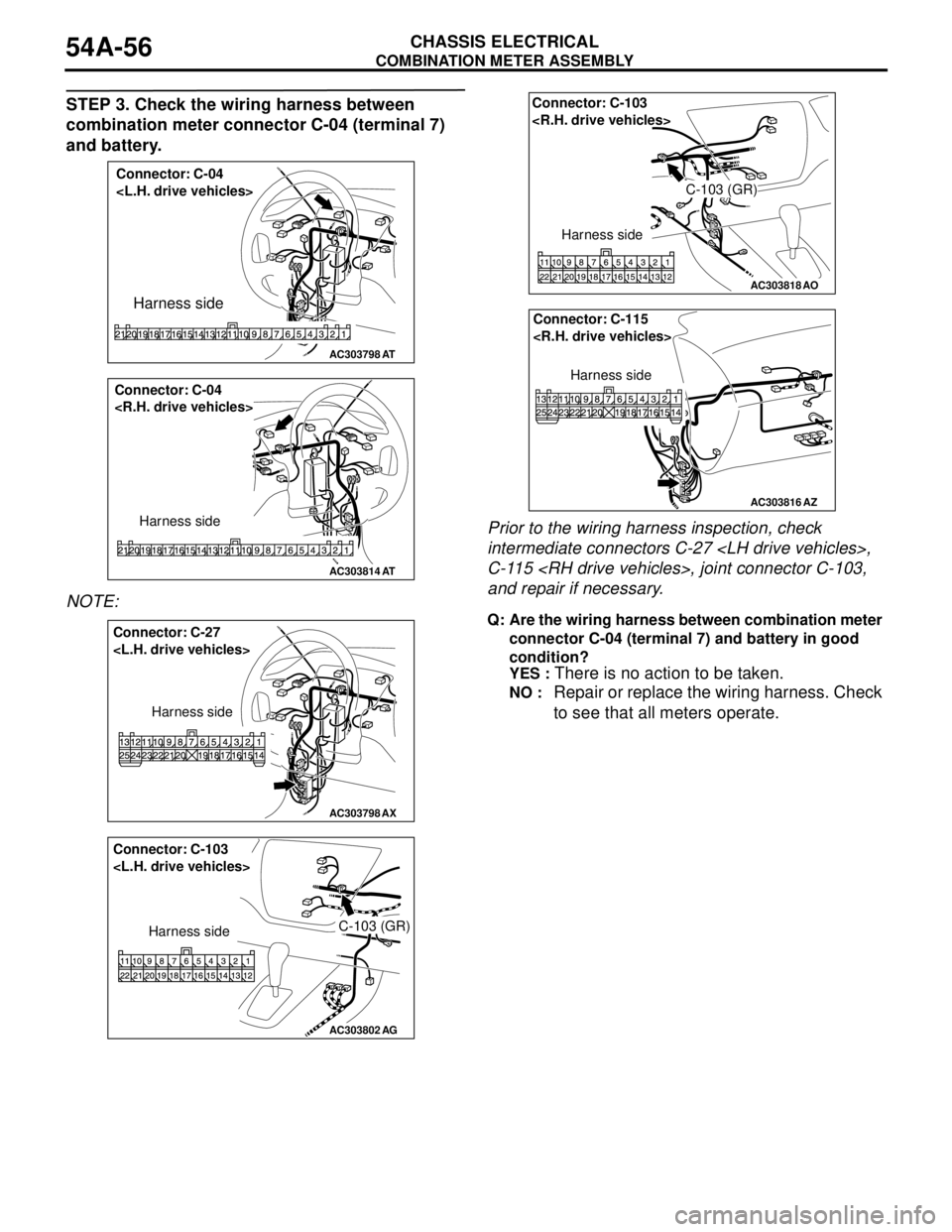

STEP 3. Check the wiring harness between

combination meter connector C-04 (terminal 7)

and battery.

NOTE: .Prior to the wiring harness inspection, check

intermediate connectors C-27

C-115

and repair if necessary.

Q: Are the wiring harness between combination meter

connector C-04 (terminal 7) and battery in good

condition?

YES :

There is no action to be taken.

NO : Repair or replace the wiring harness. Check

to see that all meters operate.

AC303798

Connector: C-04

Harness side

AT

AC303814

Connector: C-04

Harness side

AT

AC303798AX

Connector: C-27

Harness side

AC303802

Connector: C-103

Harness sideC-103 (GR)

AG

AC303818

AO

Connector: C-103

Harness side

C-103 (GR)

AC303816

Connector: C-115

Harness side

AZ

Page 445 of 788

COMBINATION METER ASSEMBLY

CHASSIS ELECTRICAL54A-57

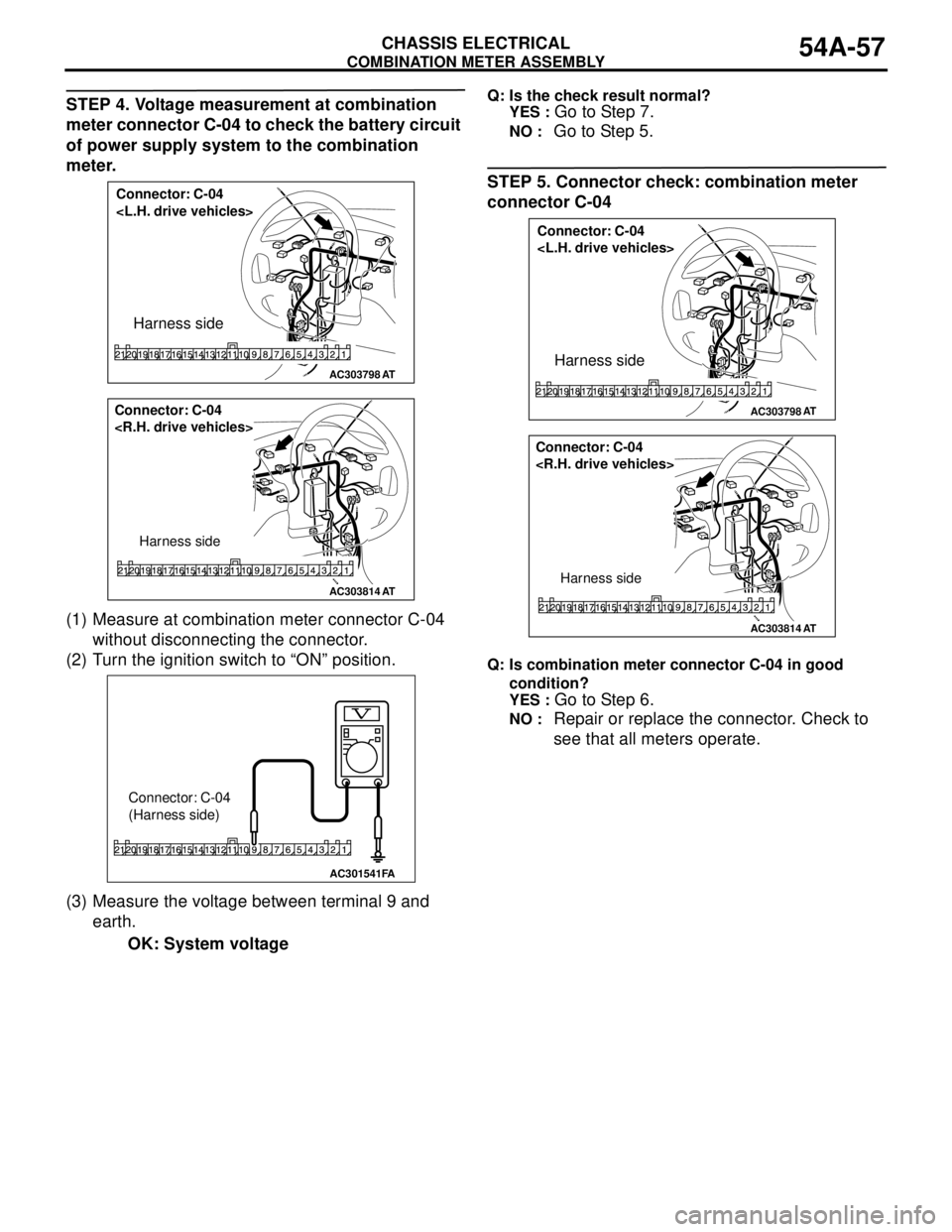

STEP 4. Voltage measurement at combination

meter connector C-04 to check the battery circuit

of power supply system to the combination

meter.

(1) Measure at combination meter connector C-04

without disconnecting the connector.

(2) Turn the ignition switch to “ON” position.

(3) Measure the voltage between terminal 9 and

earth.

OK: System voltageQ: Is the check result normal?

YES :

Go to Step 7.

NO : Go to Step 5.

STEP 5. Connector check: combination meter

connector C-04

Q: Is combination meter connector C-04 in good

condition?

YES :

Go to Step 6.

NO : Repair or replace the connector. Check to

see that all meters operate.

AC303798

Connector: C-04

Harness side

AT

AC303814

Connector: C-04

Harness side

AT

AC301541

Connector: C-04

(Harness side)

FA

AC303798

Connector: C-04

Harness side

AT

AC303814

Connector: C-04

Harness side

AT

Page 446 of 788

COMBINATION METER ASSEMBLY

CHASSIS ELECTRICAL54A-58

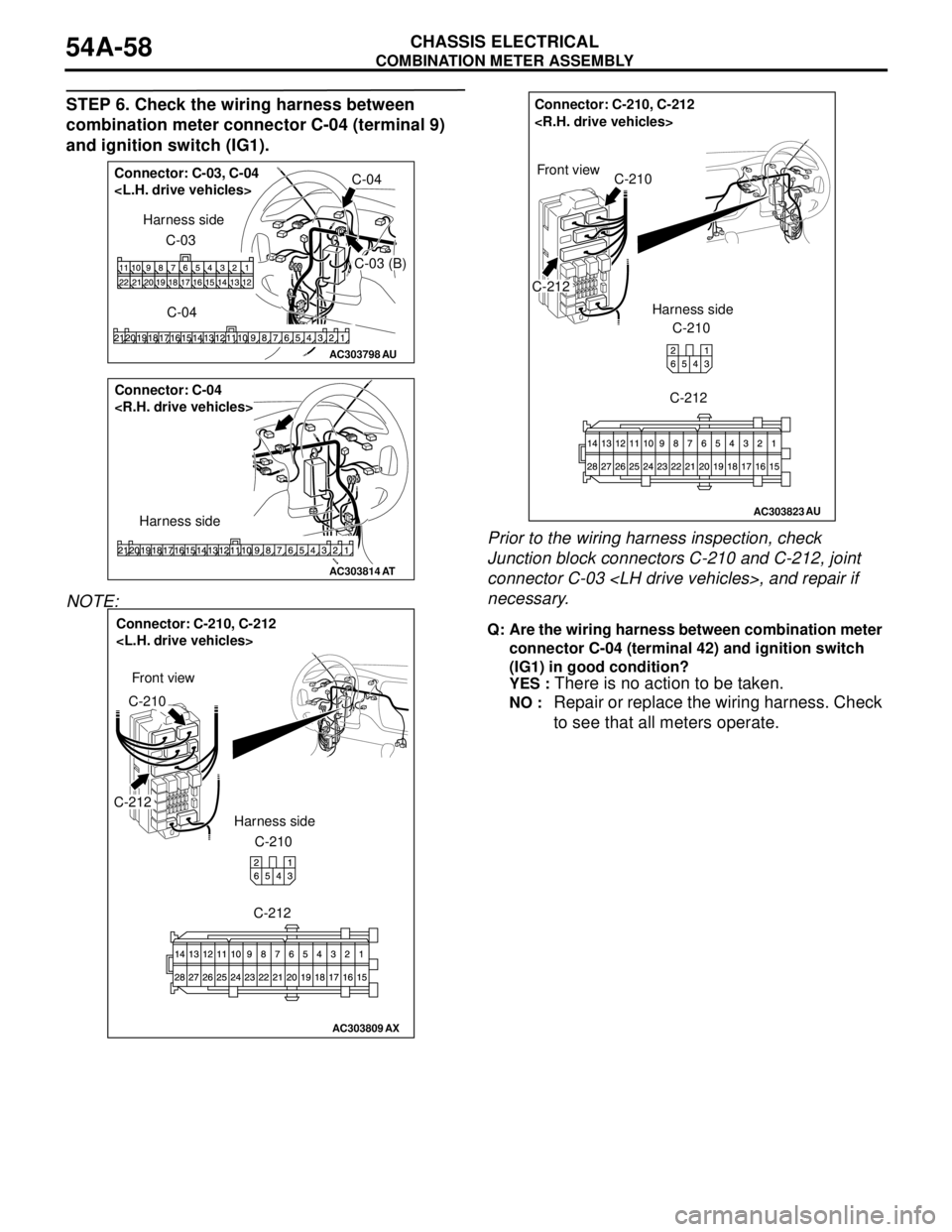

STEP 6. Check the wiring harness between

combination meter connector C-04 (terminal 9)

and ignition switch (IG1).

NOTE: Prior to the wiring harness inspection, check

Junction block connectors C-210 and C-212, joint

connector C-03

necessary.

Q: Are the wiring harness between combination meter

connector C-04 (terminal 42) and ignition switch

(IG1) in good condition?

YES :

There is no action to be taken.

NO : Repair or replace the wiring harness. Check

to see that all meters operate.

AC303798AU

Connector: C-03, C-04

C-03 (B)

C-04 C-03 Harness side

AC303814

Connector: C-04

Harness side

AT

AC303809

Connector: C-210, C-212

C-212

C-210

C-210 Harness side

C-212

AX

Front view

AC303823

Connector: C-210, C-212

C-210

C-212Front view

Harness side

C-210

C-212

AU

Page 447 of 788

COMBINATION METER ASSEMBLY

CHASSIS ELECTRICAL54A-59

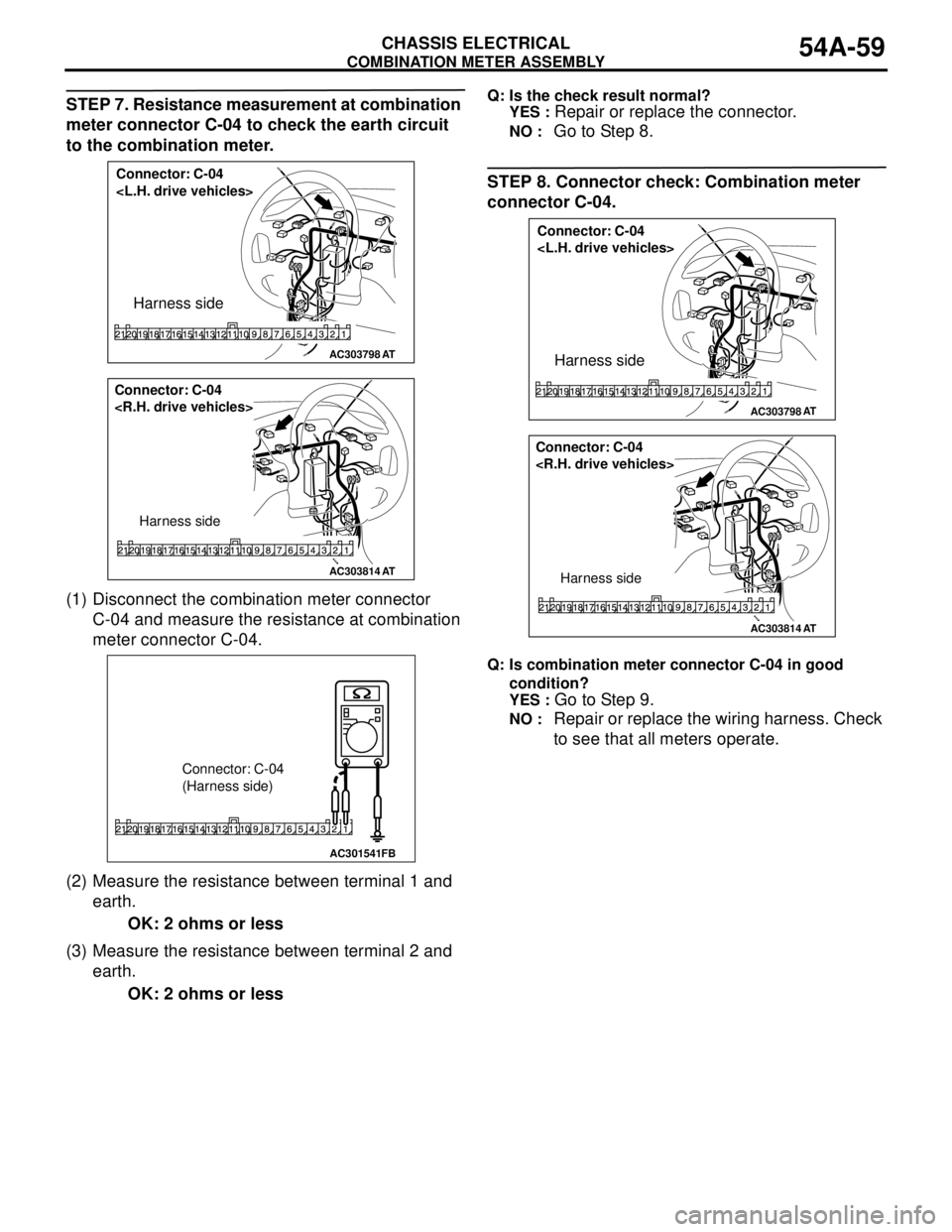

STEP 7. Resistance measurement at combination

meter connector C-04 to check the earth circuit

to the combination meter.

(1) Disconnect the combination meter connector

C-04 and measure the resistance at combination

meter connector C-04.

(2) Measure the resistance between terminal 1 and

earth.

OK: 2 ohms or less

(3) Measure the resistance between terminal 2 and

earth.

OK: 2 ohms or lessQ: Is the check result normal?

YES :

Repair or replace the connector.

NO : Go to Step 8.

STEP 8. Connector check: Combination meter

connector C-04.

Q: Is combination meter connector C-04 in good

condition?

YES :

Go to Step 9.

NO : Repair or replace the wiring harness. Check

to see that all meters operate.

AC303798

Connector: C-04

Harness side

AT

AC303814

Connector: C-04

Harness side

AT

AC301541FB

Connector: C-04

(Harness side)

AC303798

Connector: C-04

Harness side

AT

AC303814

Connector: C-04

Harness side

AT

Page 448 of 788

COMBINATION METER ASSEMBLY

CHASSIS ELECTRICAL54A-60

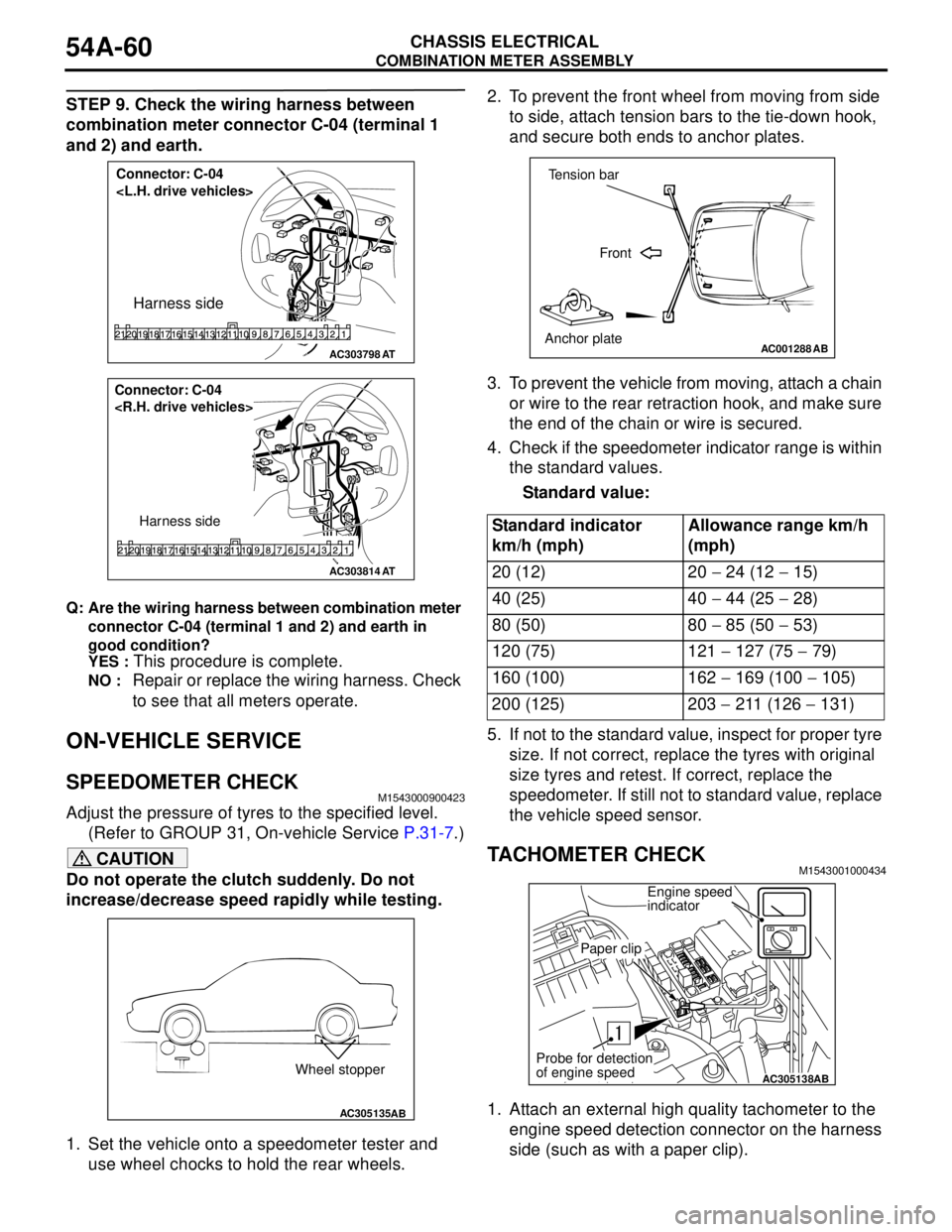

STEP 9. Check the wiring harness between

combination meter connector C-04 (terminal 1

and 2) and earth.

Q: Are the wiring harness between combination meter

connector C-04 (terminal 1 and 2) and earth in

good condition?

YES :

This procedure is complete.

NO : Repair or replace the wiring harness. Check

to see that all meters operate.

ON-VEHICLE SERVICE

SPEEDOMETER CHECKM1543000900423

Adjust the pressure of tyres to the specified level.

(Refer to GROUP 31, On-vehicle Service P.31-7.)

CAUTION

Do not operate the clutch suddenly. Do not

increase/decrease speed rapidly while testing.

1. Set the vehicle onto a speedometer tester and

use wheel chocks to hold the rear wheels.2. To prevent the front wheel from moving from side

to side, attach tension bars to the tie-down hook,

and secure both ends to anchor plates.

3. To prevent the vehicle from moving, attach a chain

or wire to the rear retraction hook, and make sure

the end of the chain or wire is secured.

4. Check if the speedometer indicator range is within

the standard values.

Standard value:

5. If not to the standard value, inspect for proper tyre

size. If not correct, replace the tyres with original

size tyres and retest. If correct, replace the

speedometer. If still not to standard value, replace

the vehicle speed sensor.

TACHOMETER CHECKM1543001000434

1. Attach an external high quality tachometer to the

engine speed detection connector on the harness

side (such as with a paper clip).

AC303798

Connector: C-04

Harness side

AT

AC303814

Connector: C-04

Harness side

AT

AC305135AB

Wheel stopper

Standard indicator

km/h (mph)Allowance range km/h

(mph)

20 (12) 20 − 24 (12 − 15)

40 (25) 40 − 44 (25 − 28)

80 (50) 80 − 85 (50 − 53)

120 (75) 121 − 127 (75 − 79)

160 (100) 162 − 169 (100 − 105)

200 (125) 203 − 211 (126 − 131)

AC001288

Tension bar

Front

Anchor plate

AB

AC305138AB

Engine speed

indicator

Paper clip

Probe for detection

of engine speed

Page 474 of 788

HAZARD WARNING LAMP SWITCH

CHASSIS ELECTRICAL54A-86

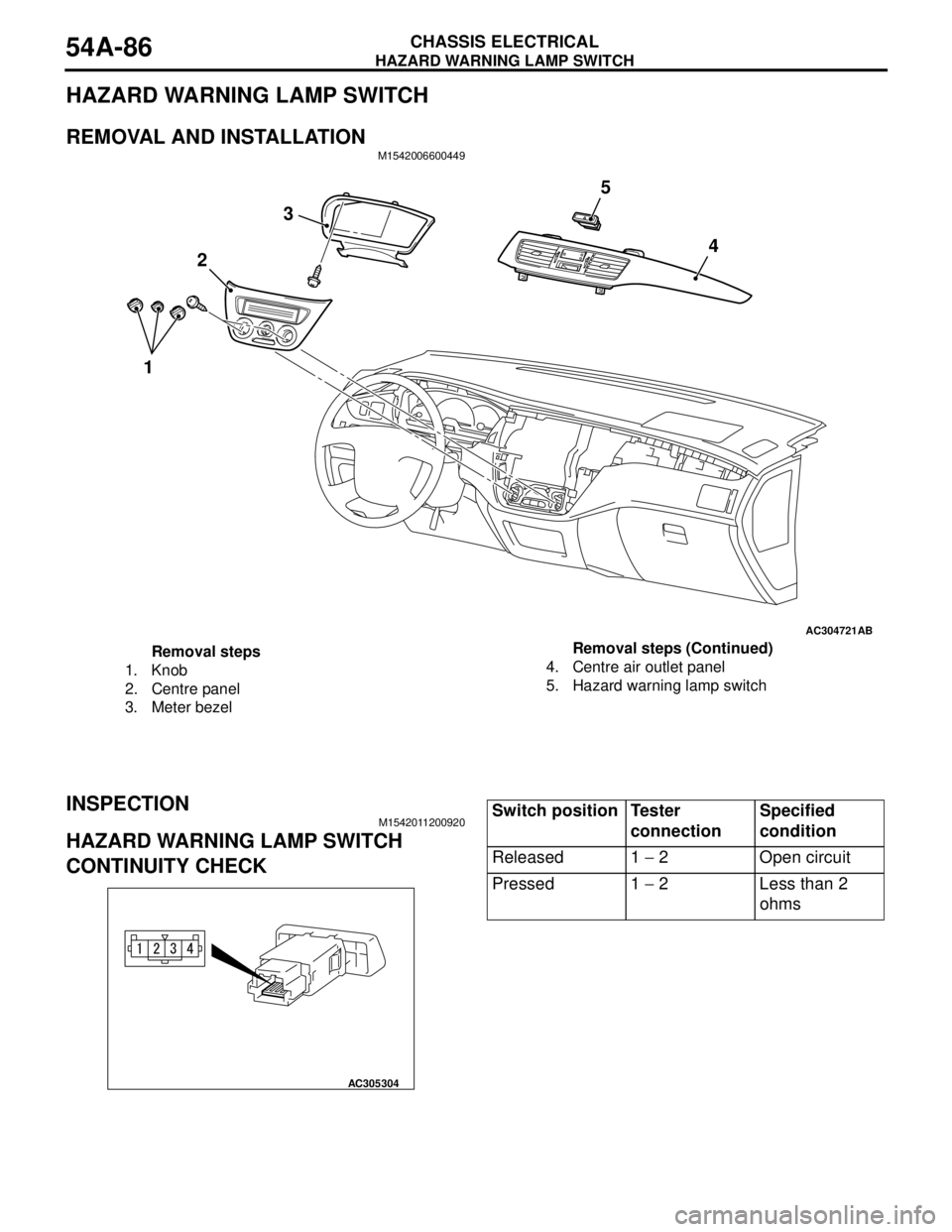

HAZARD WARNING LAMP SWITCH

REMOVAL AND INSTALLATIONM1542006600449

INSPECTIONM1542011200920

HAZARD WARNING LAMP SWITCH

CONTINUITY CHECK

AC304721AB

3

4

2

15

Removal steps

1. Knob

2. Centre panel

3. Meter bezel4. Centre air outlet panel

5. Hazard warning lamp switchRemoval steps (Continued)

AC305304

Switch position Tester

connectionSpecified

condition

Released 1 − 2 Open circuit

Pressed 1 − 2 Less than 2

ohms