washer fluid MITSUBISHI LANCER 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 146 of 788

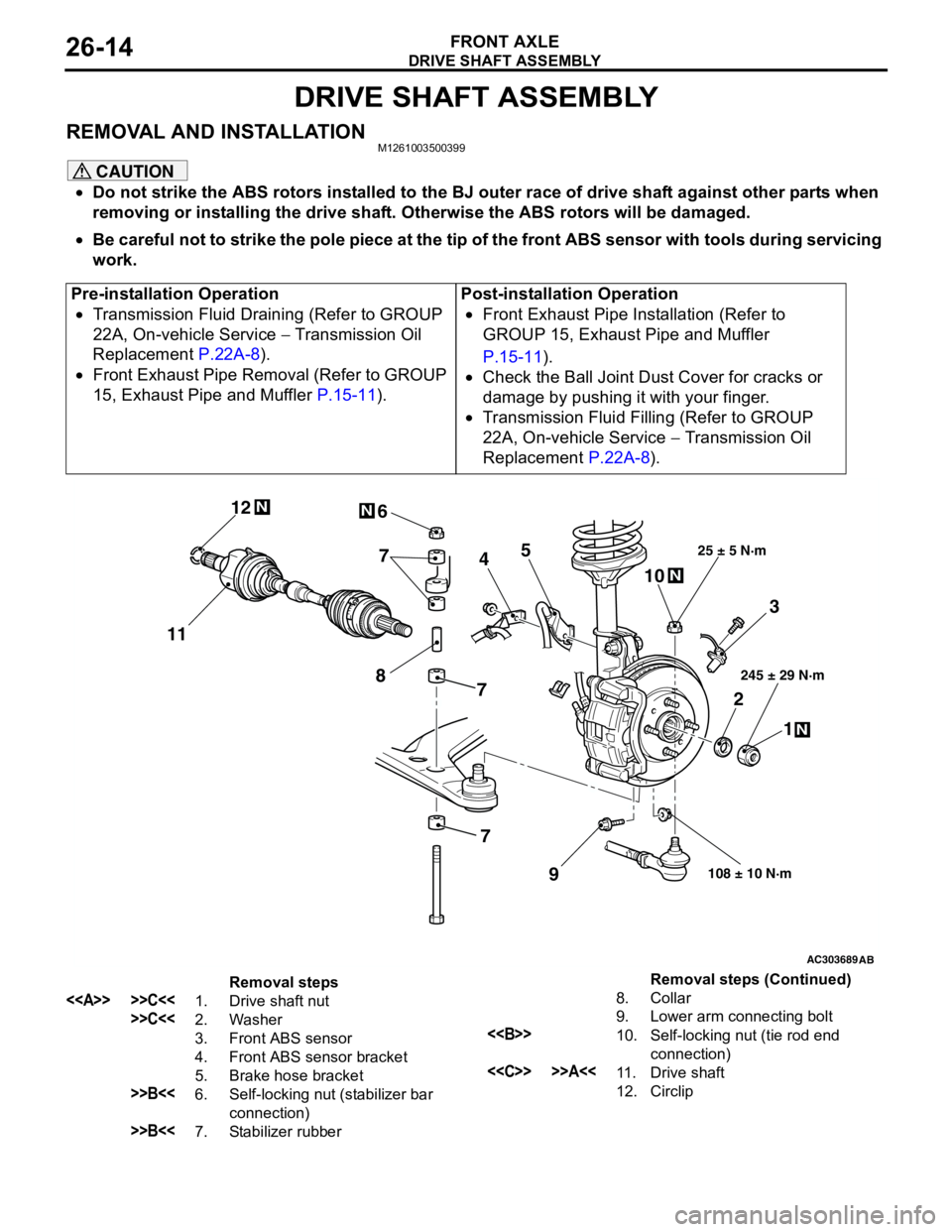

DRIVE SHAFT ASSEMBLY

FRONT AXLE26-14

DRIVE SHAFT ASSEMBLY

REMOVAL AND INSTALLATIONM1261003500399

CAUTION

•Do not strike the ABS rotors installed to the BJ outer race of drive shaft against other parts when

removing or installing the drive shaft. Otherwise the ABS rotors will be damaged.

•Be careful not to strike the pole piece at the tip of the front ABS sensor with tools during servicing

work.

Pre-installation Operation

•Transmission Fluid Draining (Refer to GROUP

22A, On-vehicle Service − Transmission Oil

Replacement P.22A-8).

•Front Exhaust Pipe Removal (Refer to GROUP

15, Exhaust Pipe and Muffler P.15-11).Post-installation Operation

•Front Exhaust Pipe Installation (Refer to

GROUP 15, Exhaust Pipe and Muffler

P.15-11).

•Check the Ball Joint Dust Cover for cracks or

damage by pushing it with your finger.

•Transmission Fluid Filling (Refer to GROUP

22A, On-vehicle Service − Transmission Oil

Replacement P.22A-8).

AC303689AB

9

N

N

NN

10 7

4

3

2

1

25 ± 5 N·m

245 ± 29 N·m

108 ± 10 N·m

8

5 6

1112

7

7

Removal steps

<> >>C<<1. Drive shaft nut

>>C<<2. Washer

3. Front ABS sensor

4. Front ABS sensor bracket

5. Brake hose bracket

>>B<<6. Self-locking nut (stabilizer bar

connection)

>>B<<7. Stabilizer rubber8. Collar

9. Lower arm connecting bolt

<>10. Self-locking nut (tie rod end

connection)

<

12. CirclipRemoval steps (Continued)

Page 364 of 788

WINDSHIELD WIPER AND WASHER

EXTERIOR51-26

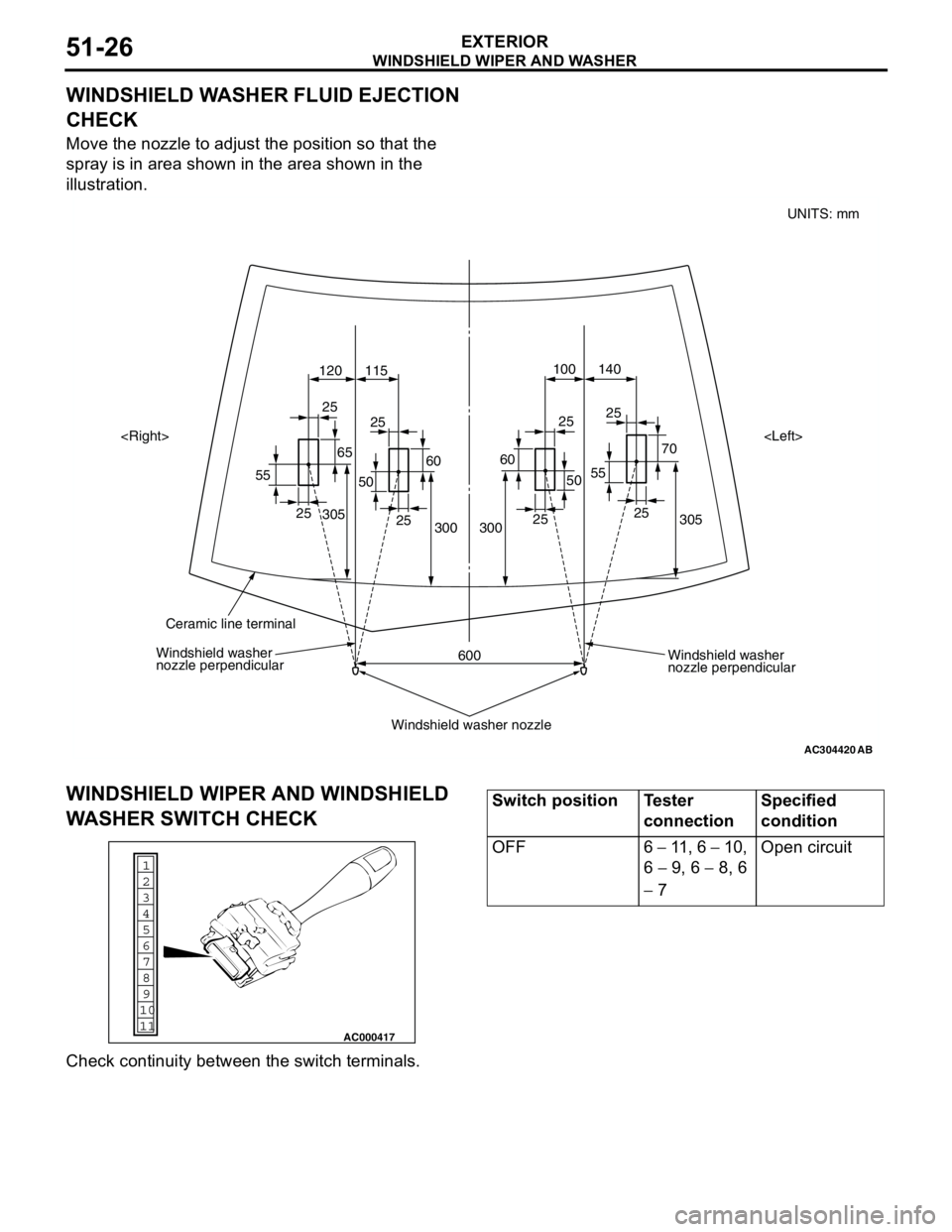

WINDSHIELD WASHER FLUID EJECTION

CHECK

Move the nozzle to adjust the position so that the

spray is in area shown in the area shown in the

illustration.

WINDSHIELD WIPER AND WINDSHIELD

WASHER SWITCH CHECK

Check continuity between the switch terminals.

AC304420

305 70 25

55140 100

120 115

305

300

600 300252525

25

25

25 25

55

6560

50

60

50

AB

Windshield washer

nozzle perpendicular Windshield washer

nozzle perpendicular

Windshield washer nozzle

Ceramic line terminal

UNITS: mm

1

6

8

11 109 7

5 4

3

2

AC000417

Switch position Tester

connectionSpecified

condition

OFF 6 − 11 , 6 − 10,

6 − 9, 6 − 8, 6

− 7Open circuit

Page 369 of 788

REAR WIPER AND WASHER

EXTERIOR51-31

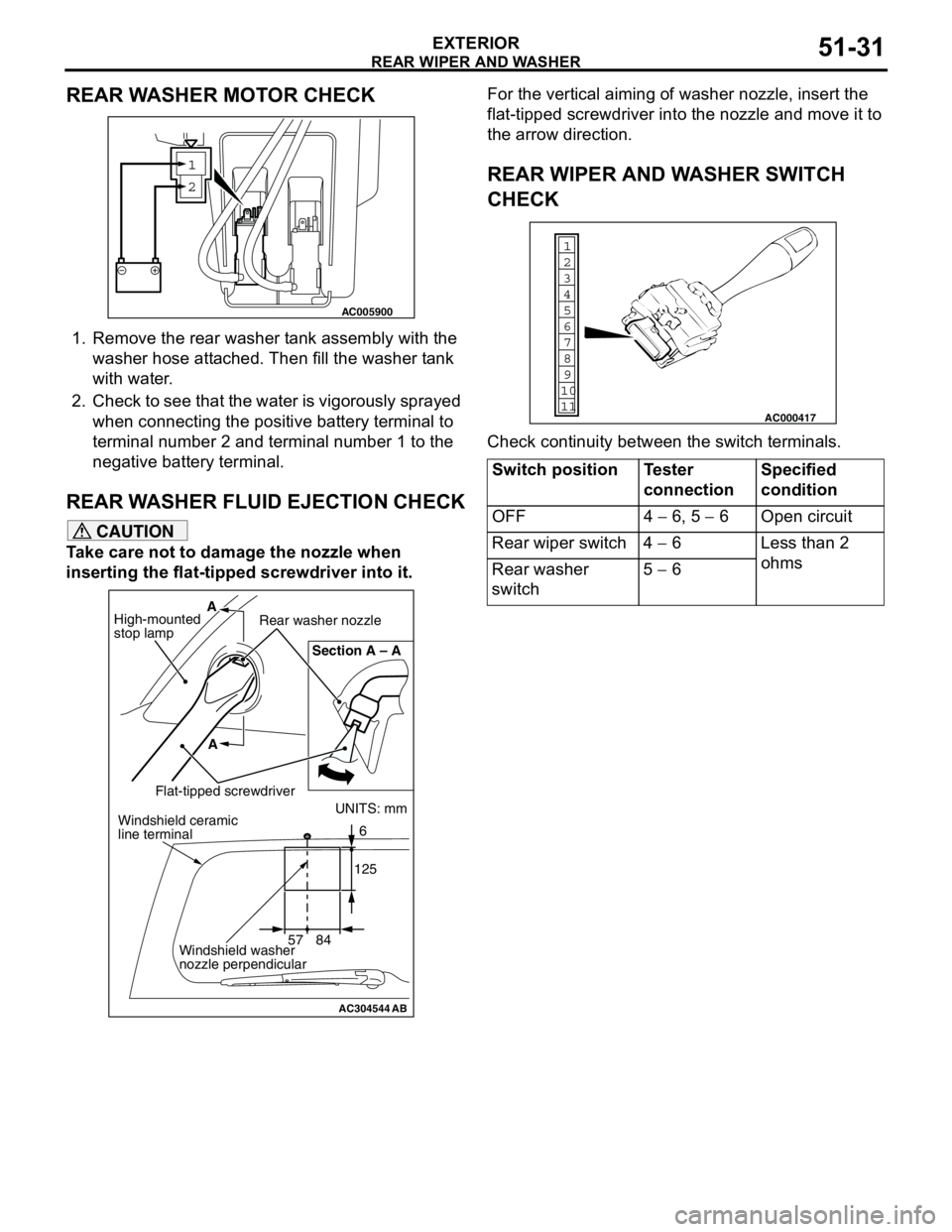

REAR WASHER MOTOR CHECK

1. Remove the rear washer tank assembly with the

washer hose attached. Then fill the washer tank

with water.

2. Check to see that the water is vigorously sprayed

when connecting the positive battery terminal to

terminal number 2 and terminal number 1 to the

negative battery terminal.

REAR WASHER FLUID EJECTION CHECK

CAUTION

Take care not to damage the nozzle when

inserting the flat-tipped screwdriver into it.For the vertical aiming of washer nozzle, insert the

flat-tipped screwdriver into the nozzle and move it to

the arrow direction.

REAR WIPER AND WASHER SWITCH

CHECK

Check continuity between the switch terminals.

1

2

AC005900

AC304544AB

UNITS: mm

57 841256 Section A – A

A A

High-mounted

stop lampRear washer nozzle

Flat-tipped screwdriverWindshield ceramic

line terminal

Windshield washer

nozzle perpendicular

Switch position Tester

connectionSpecified

condition

OFF 4 − 6, 5 − 6 Open circuit

Rear wiper switch 4 − 6 Less than 2

ohms

Rear washer

switch5 − 6

1

6

8

11 109 7

5 4

3

2

AC000417

Page 370 of 788

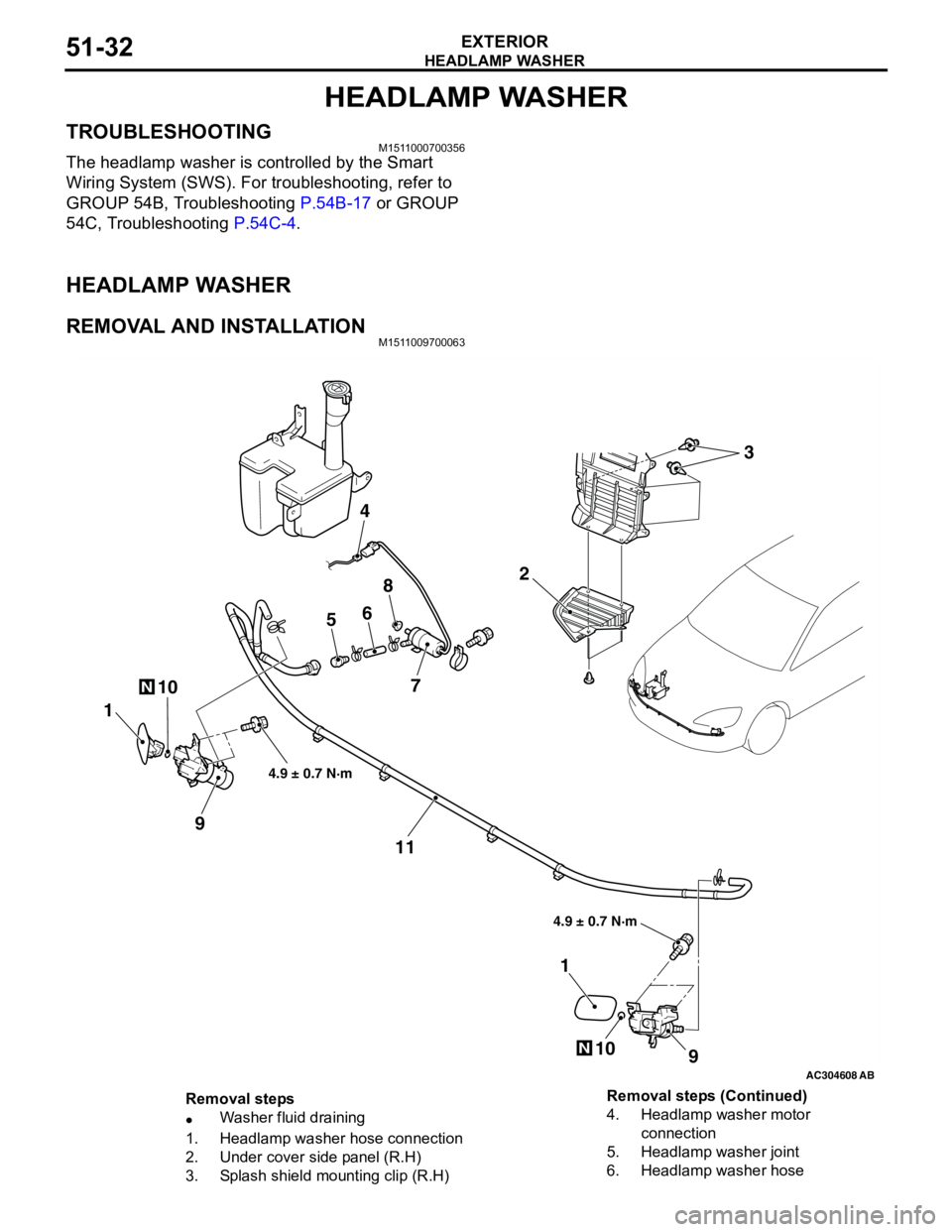

HEADLAMP WASHER

EXTERIOR51-32

HEADLAMP WASHER

TROUBLESHOOTINGM1511000700356

The headlamp washer is controlled by the Smart

Wiring System (SWS). For troubleshooting, refer to

GROUP 54B, Troubleshooting P.54B-17 or GROUP

54C, Troubleshooting P.54C-4.

HEADLAMP WASHER

REMOVAL AND INSTALLATIONM1511009700063

AC304608AB

10N

2

4

56

8

7

1

9

11

9

1

10N

4.9 ± 0.7 N·m 4.9 ± 0.7 N·m

3

Removal steps

•Washer fluid draining

1. Headlamp washer hose connection

2. Under cover side panel (R.H)

3. Splash shield mounting clip (R.H)4. Headlamp washer motor

connection

5. Headlamp washer joint

6. Headlamp washer hose Removal steps (Continued)

Page 729 of 788

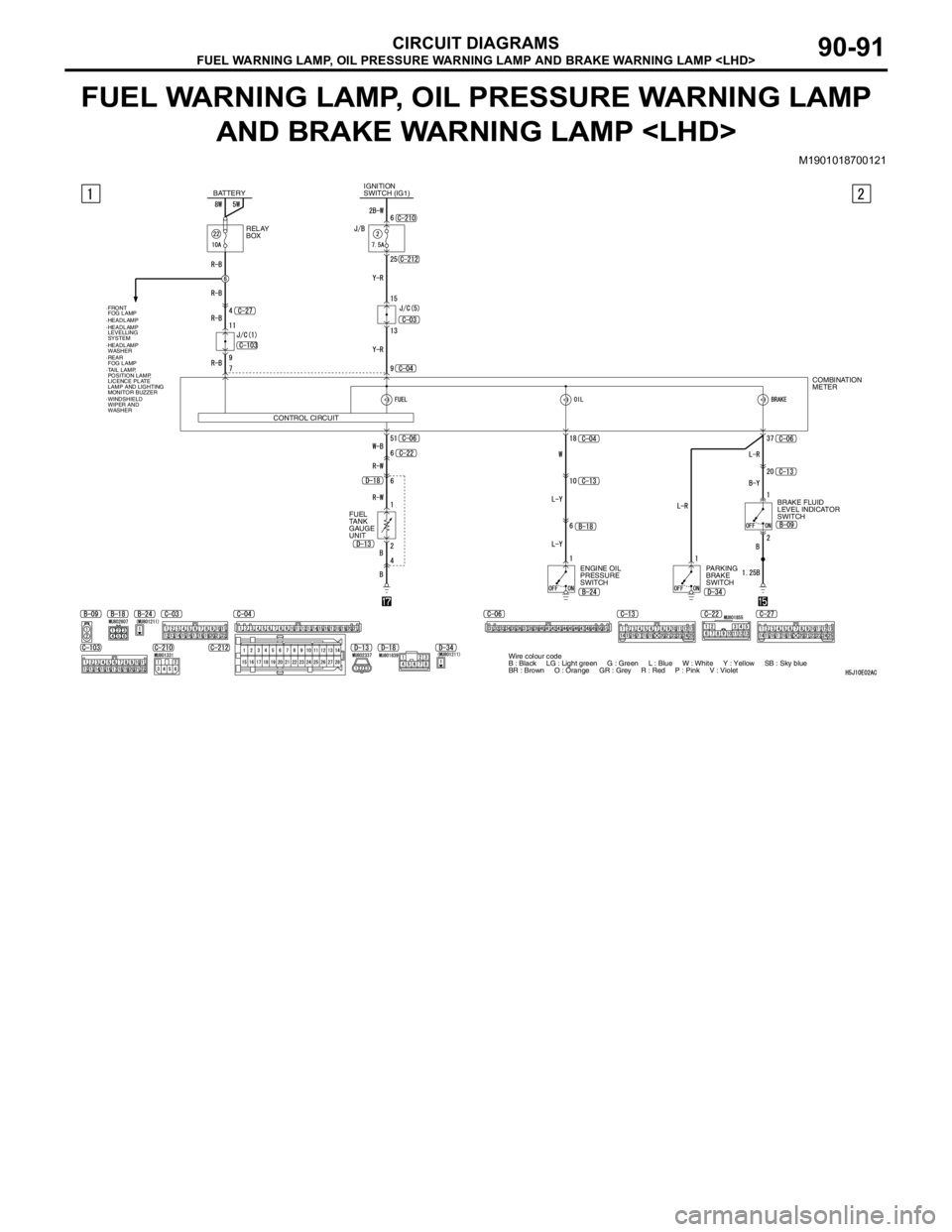

FUEL WARNING LAMP, OIL PRESSURE WARNING LAMP AND BRAKE WARNING LAMP

CIRCUIT DIAGRAMS90-91

FUEL WARNING LAMP, OIL PRESSURE WARNING LAMP

AND BRAKE WARNING LAMP

M1901018700121

BATTERYIGNITION

SWITCH (IG1)

RELAY

BOX

CONTROL CIRCUIT

·FRONT

FOG LAMP

·TAIL LAMP,

POSITION LAMP,

LICENCE PLATE

LAMP AND LIGHTING

MONITOR BUZZER ·HEADLAMP

·WINDSHIELD

WIPER AND

WASHER ·REAR

FOG LAMP ·HEADLAMP

LEVELLING

SYSTEM

FUEL

TANK

GAUGE

UNIT

·HEADLAMP

WASHER

COMBINATION

METER

BRAKE FLUID

LEVEL INDICATOR

SWITCH

ENGINE OIL

PRESSURE

SWITCHPARKING

BRAKE

SWITCH

Wire colour code

B : Black LG : Light green G : Green L : Blue W : White Y : Yellow SB : Sky blue

BR : Brown O : Orange GR : Grey R : Red P : Pink V : Violet

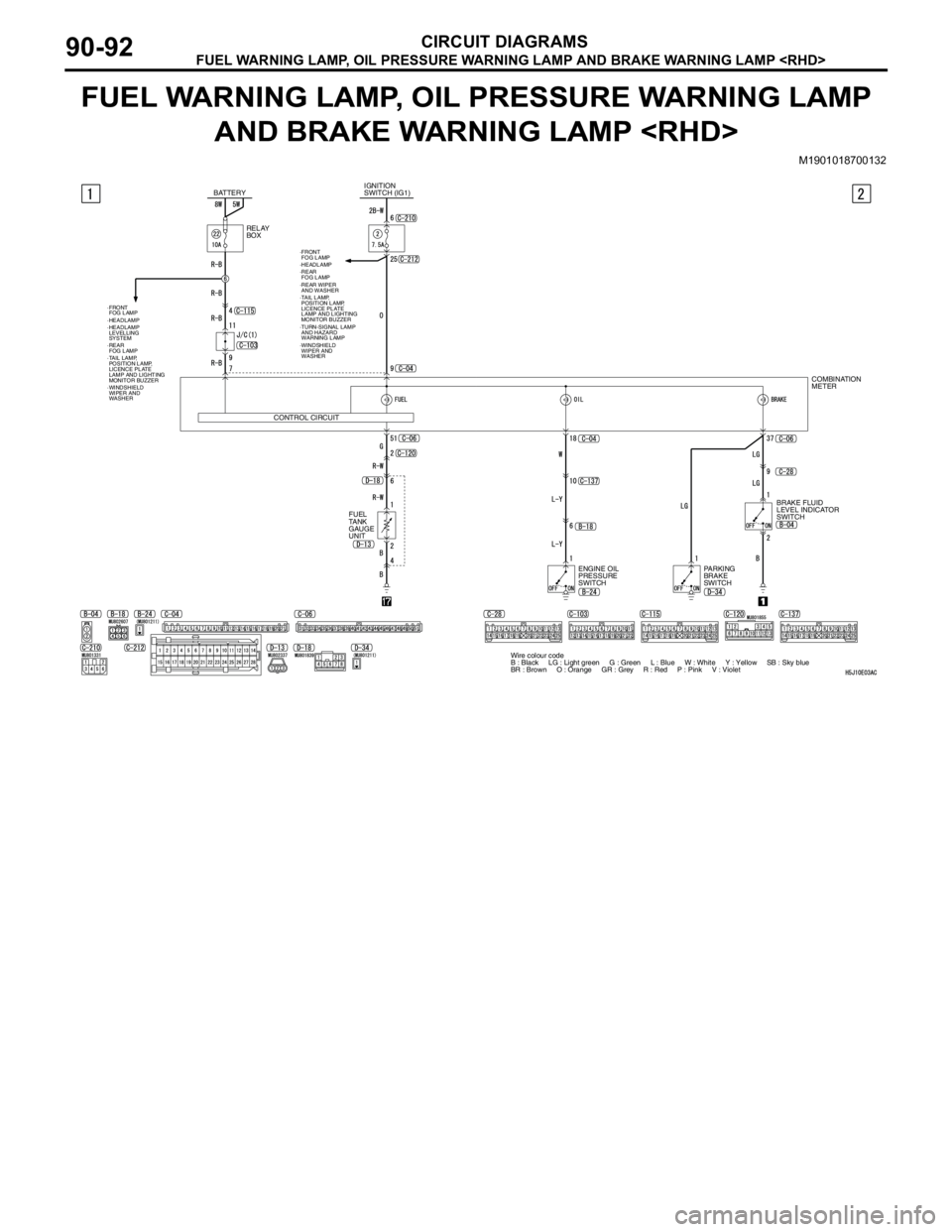

Page 730 of 788

FUEL WARNING LAMP, OIL PRESSURE WARNING LAMP AND BRAKE WARNING LAMP

CIRCUIT DIAGRAMS90-92

FUEL WARNING LAMP, OIL PRESSURE WARNING LAMP

AND BRAKE WARNING LAMP

M1901018700132

Wire colour code

B : Black LG : Light green G : Green L : Blue W : White Y : Yellow SB : Sky blue

BR : Brown O : Orange GR : Grey R : Red P : Pink V : Violet COMBINATION

METER

BRAKE FLUID

LEVEL INDICATOR

SWITCH

ENGINE OIL

PRESSURE

SWITCHPARKING

BRAKE

SWITCH RELAY

BOX BATTERYIGNITION

SWITCH (IG1)

CONTROL CIRCUIT

·FRONT

FOG LAMP

·TAIL LAMP,

POSITION LAMP,

LICENCE PLATE

LAMP AND LIGHTING

MONITOR BUZZER ·HEADLAMP

·WINDSHIELD

WIPER AND

WASHER ·REAR

FOG LAMP

·TURN-SIGNAL LAMP

AND HAZARD

WARNING LAMP

FUEL

TANK

GAUGE

UNIT

·REAR WIPER

AND WASHER

·FRONT

FOG LAMP

·TAIL LAMP,

POSITION LAMP,

LICENCE PLATE

LAMP AND LIGHTING

MONITOR BUZZER ·HEADLAMP

·WINDSHIELD

WIPER AND

WASHER ·REAR

FOG LAMP ·HEADLAMP

LEVELLING

SYSTEM