light MITSUBISHI LANCER 2005 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 513 of 788

TROUBLESHOOTING

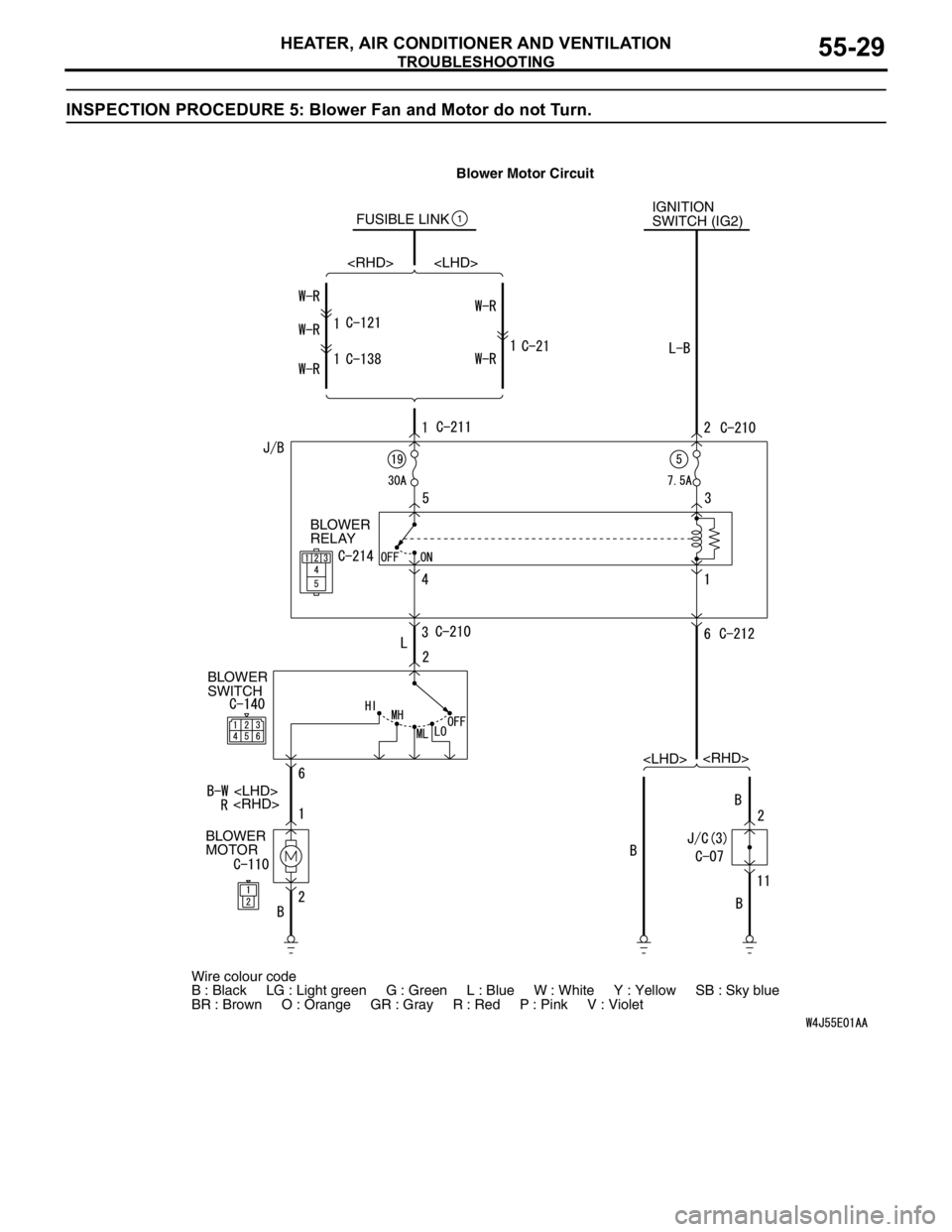

HEATER, AIR CONDITIONER AND VENTILATION55-29

INSPECTION PROCEDURE 5: Blower Fan and Motor do not Turn.

FUSIBLE LINK1IGNITION

SWITCH (IG2)

BLOWER

RELAY

BLOWER

SWITCH

BLOWER

MOTOR

Wire colour code

B : Black LG : Light green G : Green L : Blue W : White Y : Yellow SB : Sky blue

BR : Brown O : Orange GR : Gray R : Red P : Pink V : Violet

Page 523 of 788

TROUBLESHOOTING

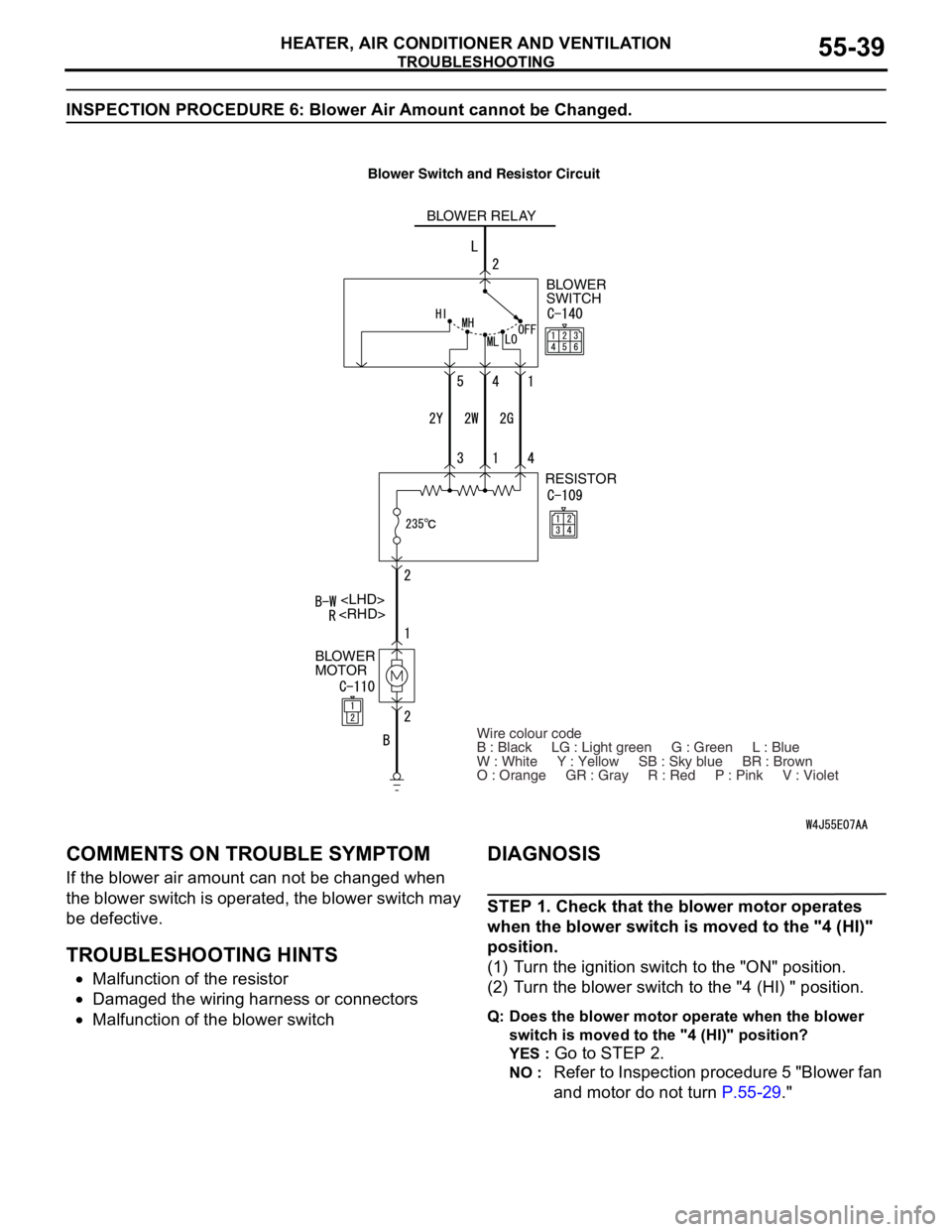

HEATER, AIR CONDITIONER AND VENTILATION55-39

INSPECTION PROCEDURE 6: Blower Air Amount cannot be Changed.

COMMENTS ON TROUBLE SYMPTOM

If the blower air amount can not be changed when

the blower switch is operated, the blower switch may

be defective.

TROUBLESHOOTING HINTS

•Malfunction of the resistor

•Damaged the wiring harness or connectors

•Malfunction of the blower switch

DIAGNOSIS

STEP 1. Check that the blower motor operates

when the blower switch is moved to the "4 (HI)"

position.

(1) Turn the ignition switch to the "ON" position.

(2) Turn the blower switch to the "4 (HI) " position.

Q: Does the blower motor operate when the blower

switch is moved to the "4 (HI)" position?

YES :

Go to STEP 2.

NO : Refer to Inspection procedure 5 "Blower fan

and motor do not turn P.55-29."

BLOWER RELAY

BLOWER

SWITCH

RESISTOR

BLOWER

MOTOR

Wire colour code

B : Black LG : Light green G : Green L : Blue

W : White Y : Yellow SB : Sky blue BR : Brown

O : Orange GR : Gray R : Red P : Pink V : Violet

Page 526 of 788

TROUBLESHOOTING

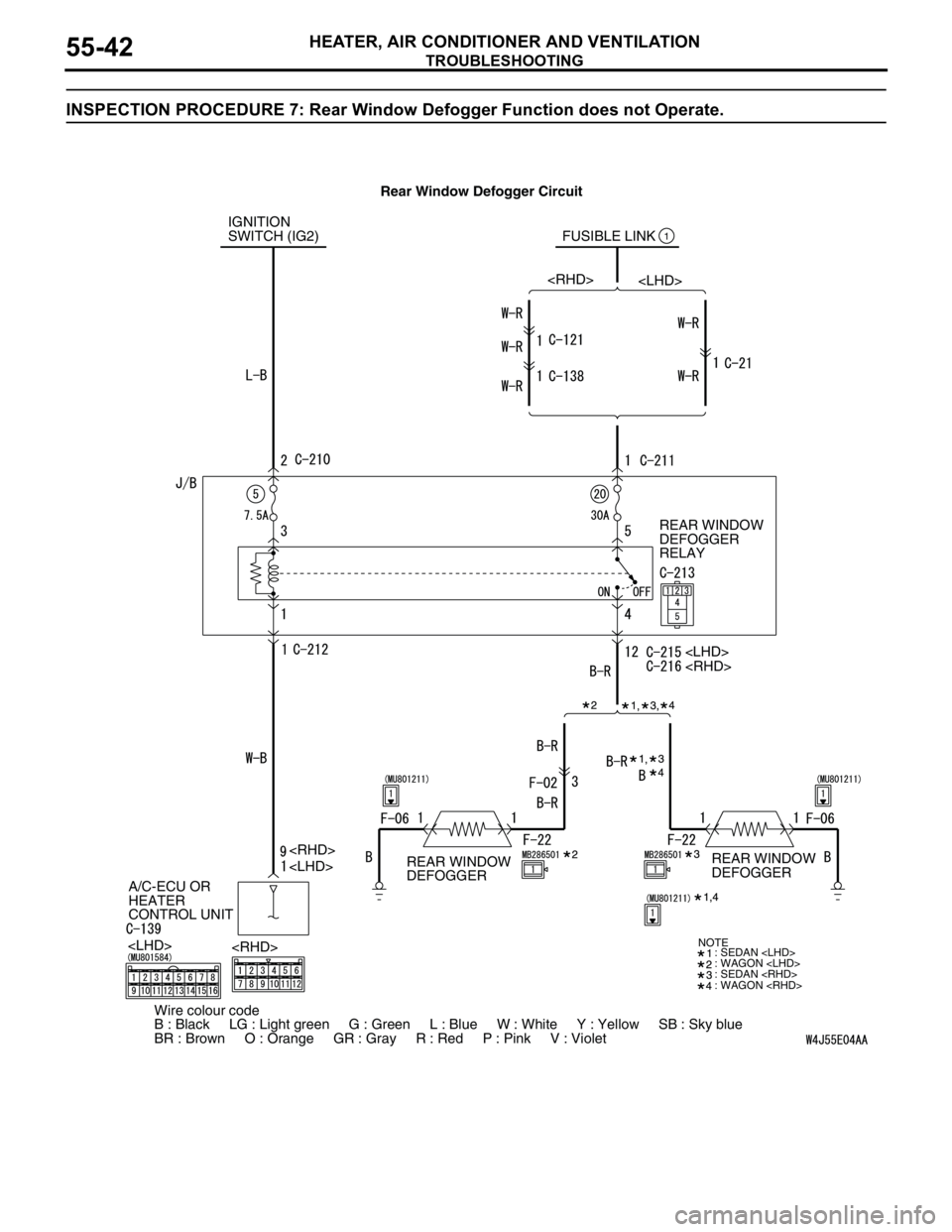

HEATER, AIR CONDITIONER AND VENTILATION55-42

INSPECTION PROCEDURE 7: Rear Window Defogger Function does not Operate.

IGNITION

SWITCH (IG2) FUSIBLE LINK

REAR WINDOW

DEFOGGER

RELAY

A/C-ECU OR

HEATER

CONTROL UNIT1

: SEDAN

: WAGON

: SEDAN

: WAGON

Wire colour code

B : Black LG : Light green G : Green L : Blue W : White Y : Yellow SB : Sky blue

BR : Brown O : Orange GR : Gray R : Red P : Pink V : Violet

NOTE

REAR WINDOW

DEFOGGERREAR WINDOW

DEFOGGER Rear Window Defogger Circuit

Page 537 of 788

TROUBLESHOOTING

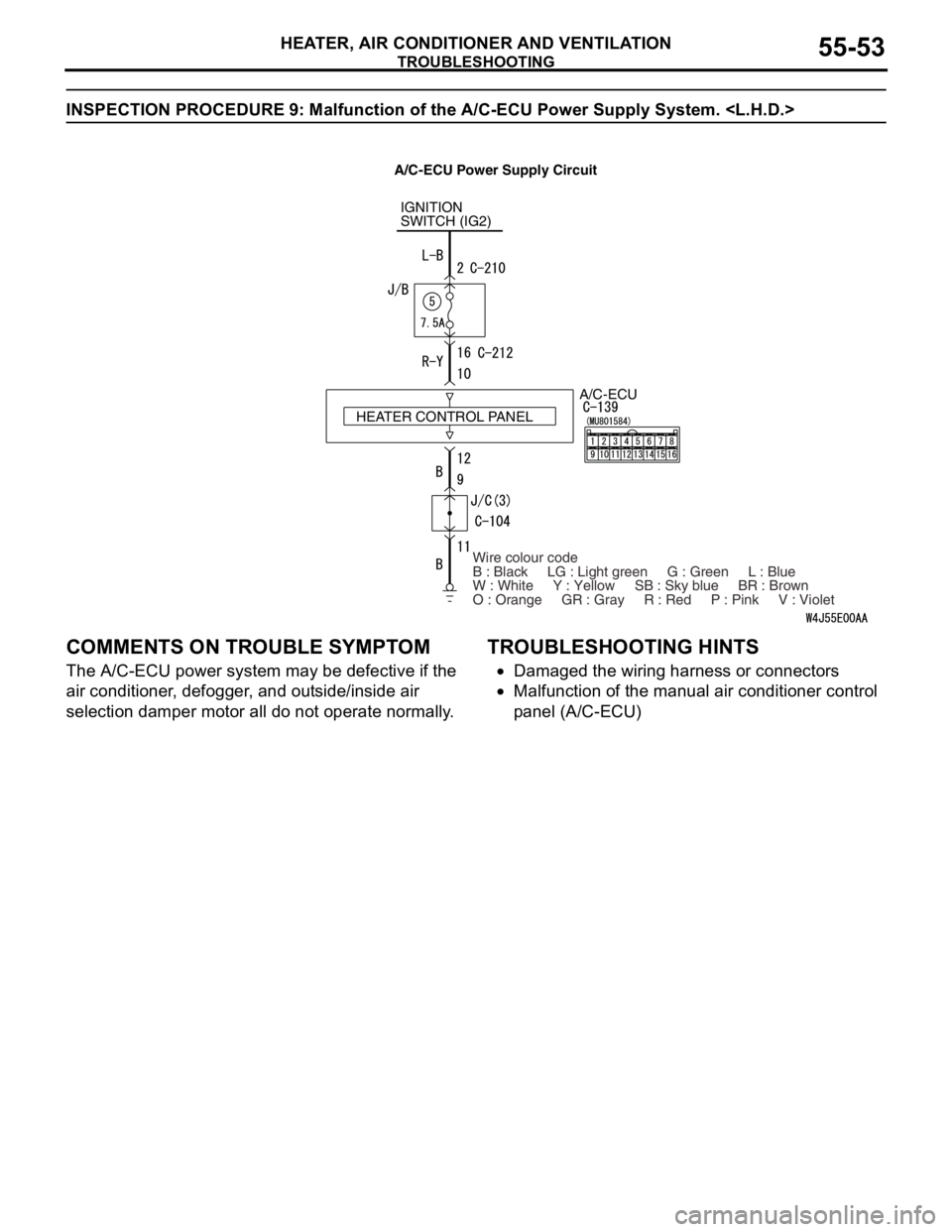

HEATER, AIR CONDITIONER AND VENTILATION55-53

INSPECTION PROCEDURE 9: Malfunction of the A/C-ECU Power Supply System.

COMMENTS ON TROUBLE SYMPTOM

The A/C-ECU power system may be defective if the

air conditioner, defogger, and outside/inside air

selection damper motor all do not operate normally.

TROUBLESHOOTING HINTS

•Damaged the wiring harness or connectors

•Malfunction of the manual air conditioner control

panel (A/C-ECU)

IGNITION

SWITCH (IG2)

A/C-ECU

Wire colour code

B : Black LG : Light green G : Green L : Blue

W : White Y : Yellow SB : Sky blue BR : Brown

O : Orange GR : Gray R : Red P : Pink V : Violet HEATER CONTROL PANEL

A/C-ECU Power Supply Circuit

Page 540 of 788

TROUBLESHOOTING

HEATER, AIR CONDITIONER AND VENTILATION55-56

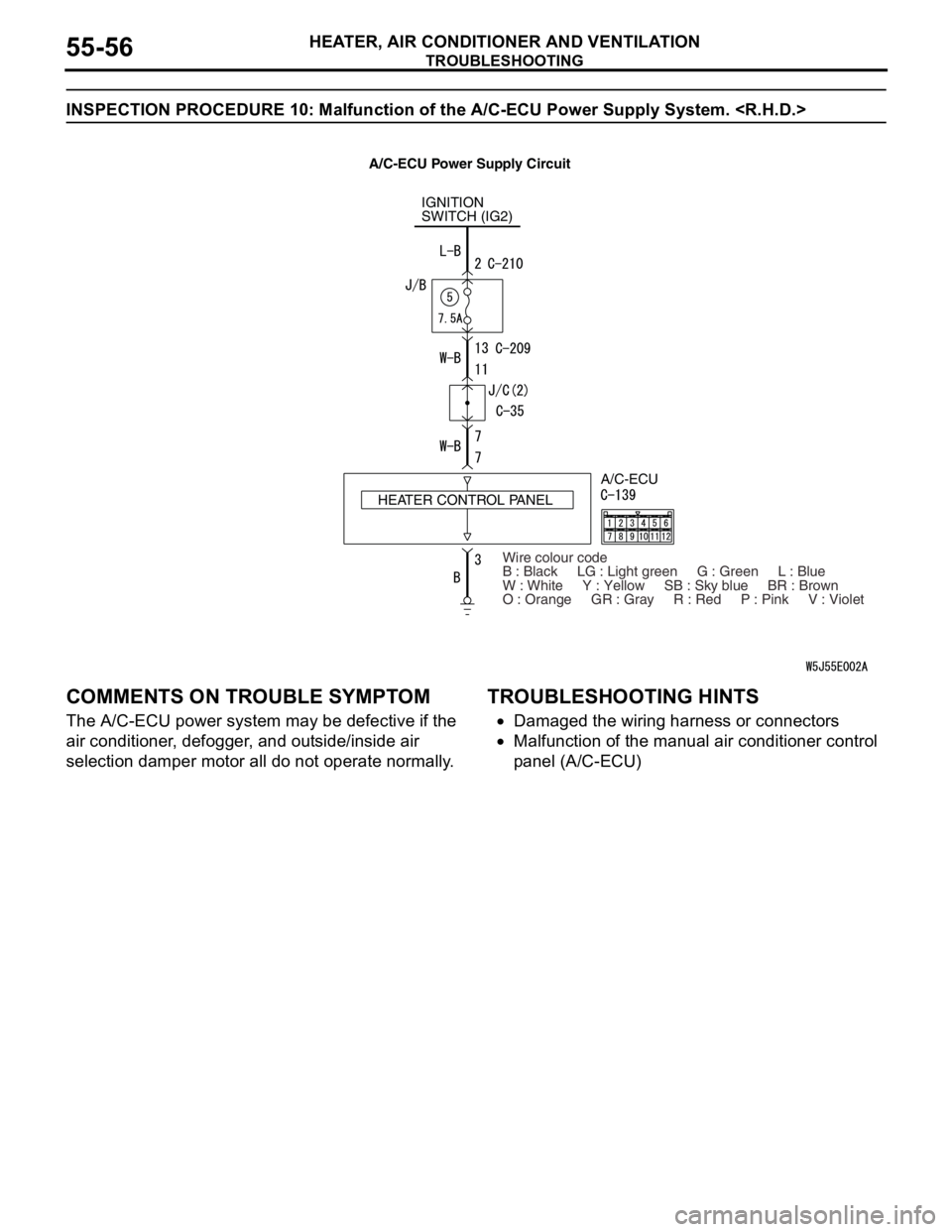

INSPECTION PROCEDURE 10: Malfunction of the A/C-ECU Power Supply System.

COMMENTS ON TROUBLE SYMPTOM

The A/C-ECU power system may be defective if the

air conditioner, defogger, and outside/inside air

selection damper motor all do not operate normally.

TROUBLESHOOTING HINTS

•Damaged the wiring harness or connectors

•Malfunction of the manual air conditioner control

panel (A/C-ECU)

IGNITION

SWITCH (IG2)

HEATER CONTROL PANELA/C-ECU

Wire colour code

B : Black LG : Light green G : Green L : Blue

W : White Y : Yellow SB : Sky blue BR : Brown

O : Orange GR : Gray R : Red P : Pink V : Violet

A/C-ECU Power Supply Circuit

Page 543 of 788

TROUBLESHOOTING

HEATER, AIR CONDITIONER AND VENTILATION55-59

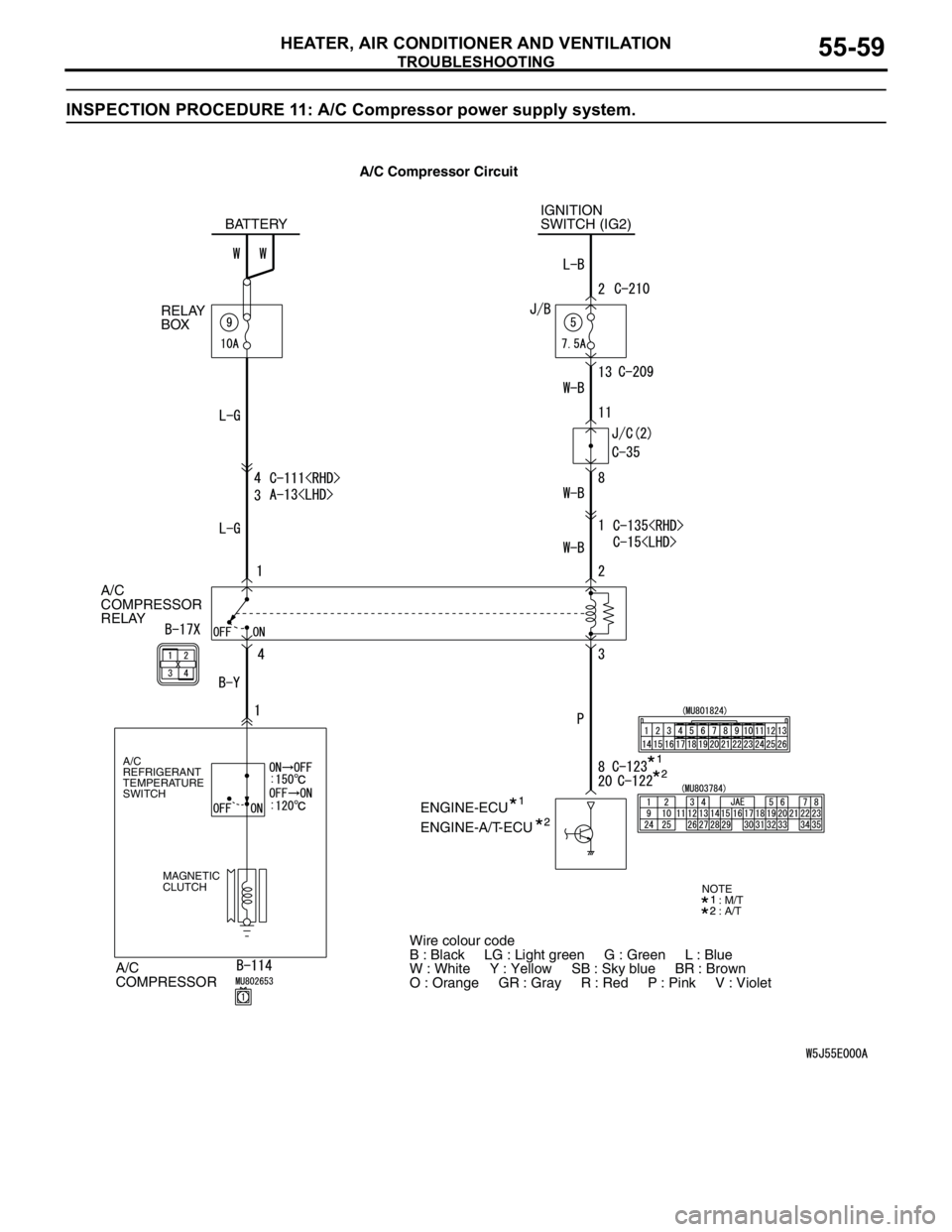

INSPECTION PROCEDURE 11: A/C Compressor power supply system.

A/C

COMPRESSOR

RELAY

A/C

COMPRESSOR

A/C

REFRIGERANT

TEMPERATURE

SWITCH

MAGNETIC

CLUTCH

IGNITION

SWITCH (IG2)

ENGINE-ECU BATTERY

RELAY

BOX

ENGINE-A/T-ECU

Wire colour code

B : Black LG : Light green G : Green L : Blue

W : White Y : Yellow SB : Sky blue BR : Brown

O : Orange GR : Gray R : Red P : Pink V : Violet

: M/T

: A/TNOTE

A/C Compressor Circuit

Page 551 of 788

TROUBLESHOOTING

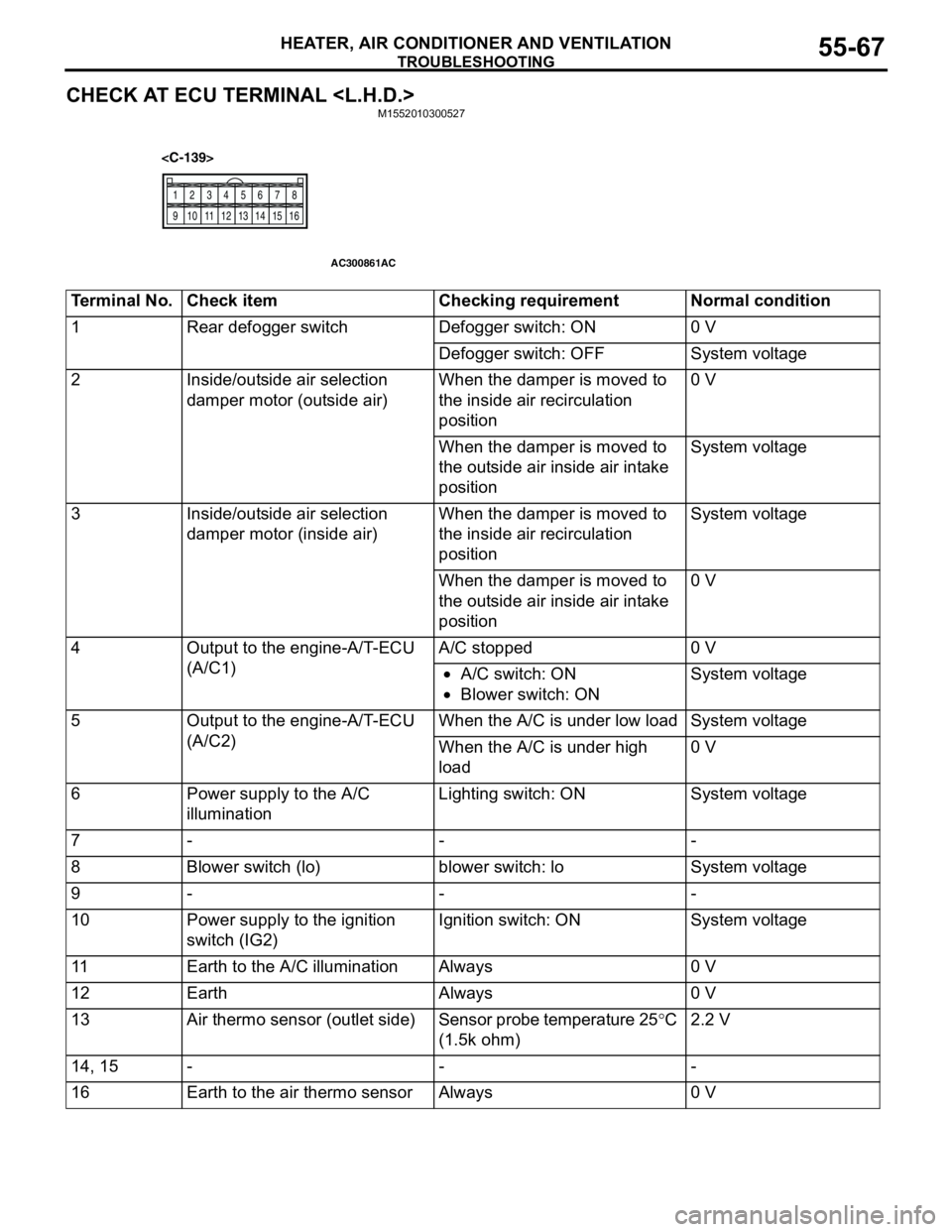

HEATER, AIR CONDITIONER AND VENTILATION55-67

CHECK AT ECU TERMINAL

12

345

678

9 10111213141516

AC300861AC

Terminal No. Check item Checking requirement Normal condition

1 Rear defogger switch Defogger switch: ON 0 V

Defogger switch: OFF System voltage

2 Inside/outside air selection

damper motor (outside air)When the damper is moved to

the inside air recirculation

position0 V

When the damper is moved to

the outside air inside air intake

positionSystem voltage

3 Inside/outside air selection

damper motor (inside air)When the damper is moved to

the inside air recirculation

positionSystem voltage

When the damper is moved to

the outside air inside air intake

position0 V

4 Output to the engine-A/T-ECU

(A/C1)A/C stopped 0 V

•A/C switch: ON

•Blower switch: ONSystem voltage

5 Output to the engine-A/T-ECU

(A/C2)When the A/C is under low load System voltage

When the A/C is under high

load0 V

6 Power supply to the A/C

illuminationLighting switch: ON System voltage

7---

8 Blower switch (lo) blower switch: lo System voltage

9---

10 Power supply to the ignition

switch (IG2)Ignition switch: ON System voltage

11 Earth to the A/C illumination Always 0 V

12 Earth Always 0 V

13 Air thermo sensor (outlet side) Sensor probe temperature 25°C

(1.5k ohm)2.2 V

14, 15 - - -

16 Earth to the air thermo sensor Always 0 V

Page 552 of 788

TROUBLESHOOTING

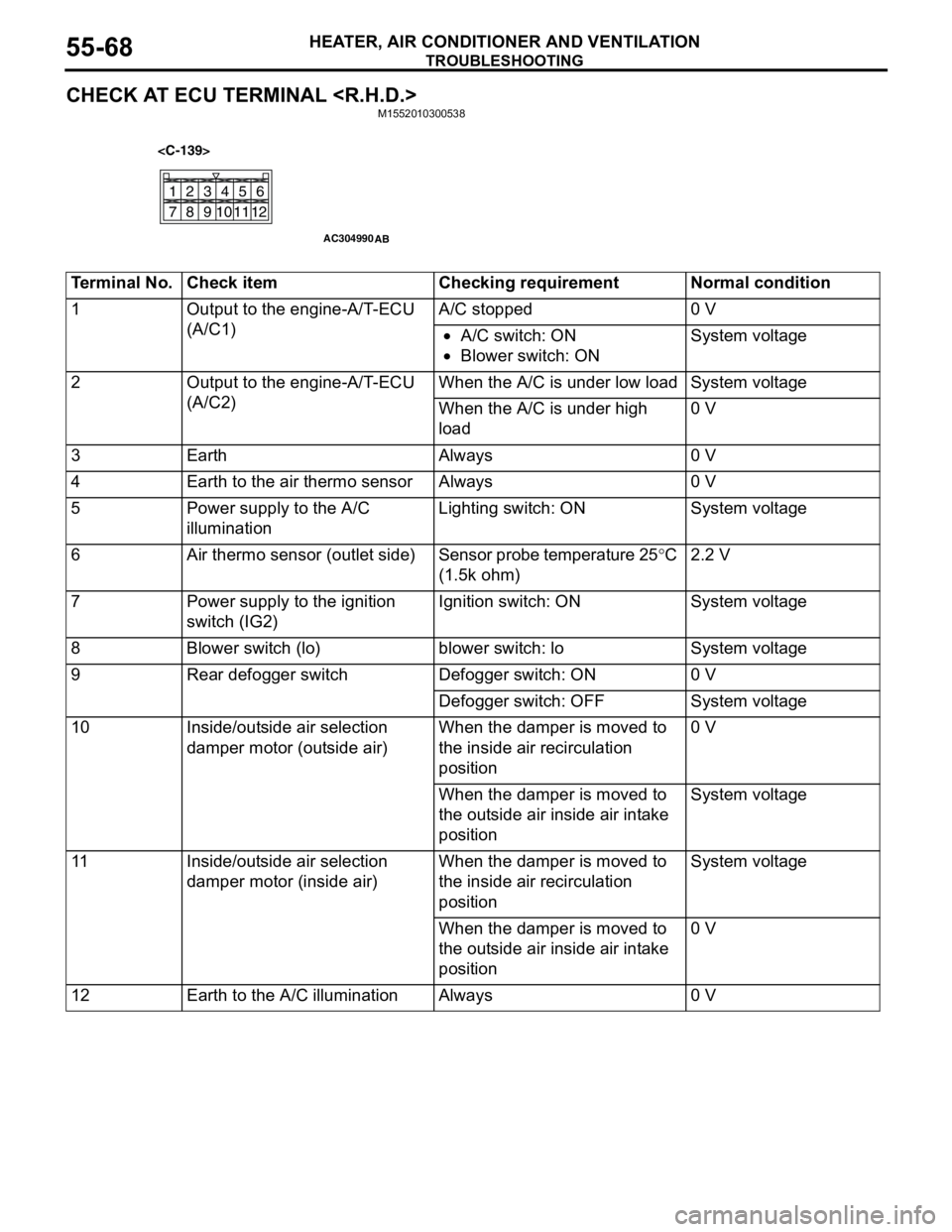

HEATER, AIR CONDITIONER AND VENTILATION55-68

CHECK AT ECU TERMINAL

21

78

6 534

11

10912

AC304990

AB

Terminal No. Check item Checking requirement Normal condition

1 Output to the engine-A/T-ECU

(A/C1)A/C stopped 0 V

•A/C switch: ON

•Blower switch: ONSystem voltage

2 Output to the engine-A/T-ECU

(A/C2)When the A/C is under low load System voltage

When the A/C is under high

load0 V

3 Earth Always 0 V

4 Earth to the air thermo sensor Always 0 V

5 Power supply to the A/C

illuminationLighting switch: ON System voltage

6 Air thermo sensor (outlet side) Sensor probe temperature 25°C

(1.5k ohm)2.2 V

7 Power supply to the ignition

switch (IG2)Ignition switch: ON System voltage

8 Blower switch (lo) blower switch: lo System voltage

9 Rear defogger switch Defogger switch: ON 0 V

Defogger switch: OFF System voltage

10 Inside/outside air selection

damper motor (outside air)When the damper is moved to

the inside air recirculation

position0 V

When the damper is moved to

the outside air inside air intake

positionSystem voltage

11 Inside/outside air selection

damper motor (inside air)When the damper is moved to

the inside air recirculation

positionSystem voltage

When the damper is moved to

the outside air inside air intake

position0 V

12 Earth to the A/C illumination Always 0 V

Page 557 of 788

ON-VEHICLE SERVICE

HEATER, AIR CONDITIONER AND VENTILATION55-73

PERFORMANCE TEST M1552001400355

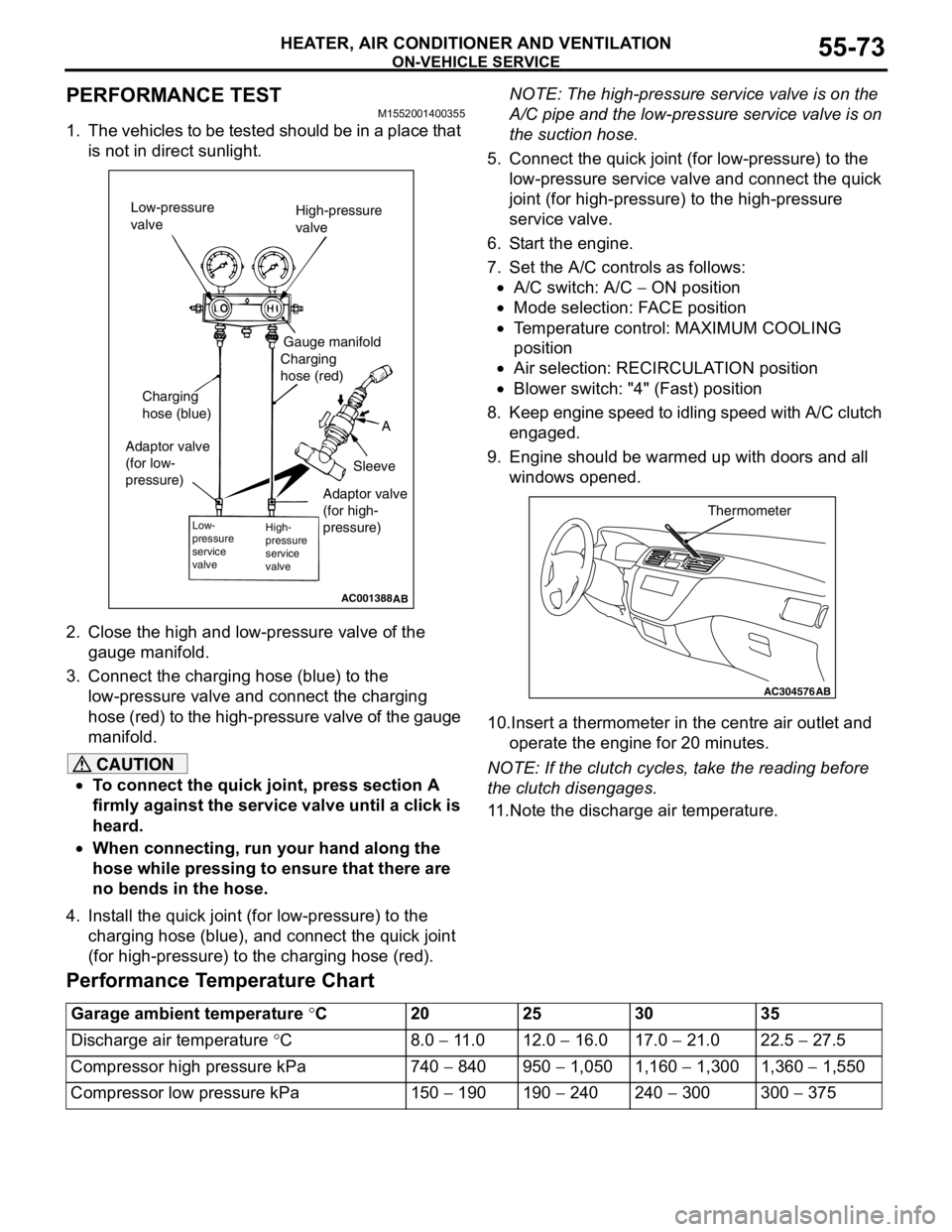

1. The vehicles to be tested should be in a place that

is not in direct sunlight.

2. Close the high and low-pressure valve of the

gauge manifold.

3. Connect the charging hose (blue) to the

low-pressure valve and connect the charging

hose (red) to the high-pressure valve of the gauge

manifold.

CAUTION

•To connect the quick joint, press section A

firmly against the service valve until a click is

heard.

•When connecting, run your hand along the

hose while pressing to ensure that there are

no bends in the hose.

4. Install the quick joint (for low-pressure) to the

charging hose (blue), and connect the quick joint

(for high-pressure) to the charging hose (red).NOTE: The high-pressure service valve is on the

A/C pipe and the low-pressure service valve is on

the suction hose.

5. Connect the quick joint (for low-pressure) to the

low-pressure service valve and connect the quick

joint (for high-pressure) to the high-pressure

service valve.

6. Start the engine.

7. Set the A/C controls as follows:

•A/C switch: A/C − ON position

•Mode selection: FACE position

•Temperature control: MAXIMUM COOLING

position

•Air selection: RECIRCULATION position

•Blower switch: "4" (Fast) position

8. Keep engine speed to idling speed with A/C clutch

engaged.

9. Engine should be warmed up with doors and all

windows opened.

10.Insert a thermometer in the centre air outlet and

operate the engine for 20 minutes.

NOTE: If the clutch cycles, take the reading before

the clutch disengages.

11.Note the discharge air temperature.

Performance Temperature Chart

AC001388

Low-pressure

valveHigh-pressure

valve

Gauge manifold

Charging

hose (red)

A

Sleeve Charging

hose (blue)

Adaptor valve

(for low-

pressure)

Low-

pressure

service

valveHigh-

pressure

service

valve

AB

Adaptor valve

(for high-

pressure)

AC304576

Thermometer

AB

Garage ambient temperature °C20 25 30 35

Discharge air temperature °C8.0 − 11.0 12.0 − 16.0 17.0 − 21.0 22.5 − 27.5

Compressor high pressure kPa 740 − 840 950 − 1,050 1,160 − 1,300 1,360 − 1,550

Compressor low pressure kPa 150 − 190 190 − 240 240 − 300 300 − 375

Page 579 of 788

COMPRESSOR ASSEMBLY AND TENSION PULLEY

HEATER, AIR CONDITIONER AND VENTILATION55-95

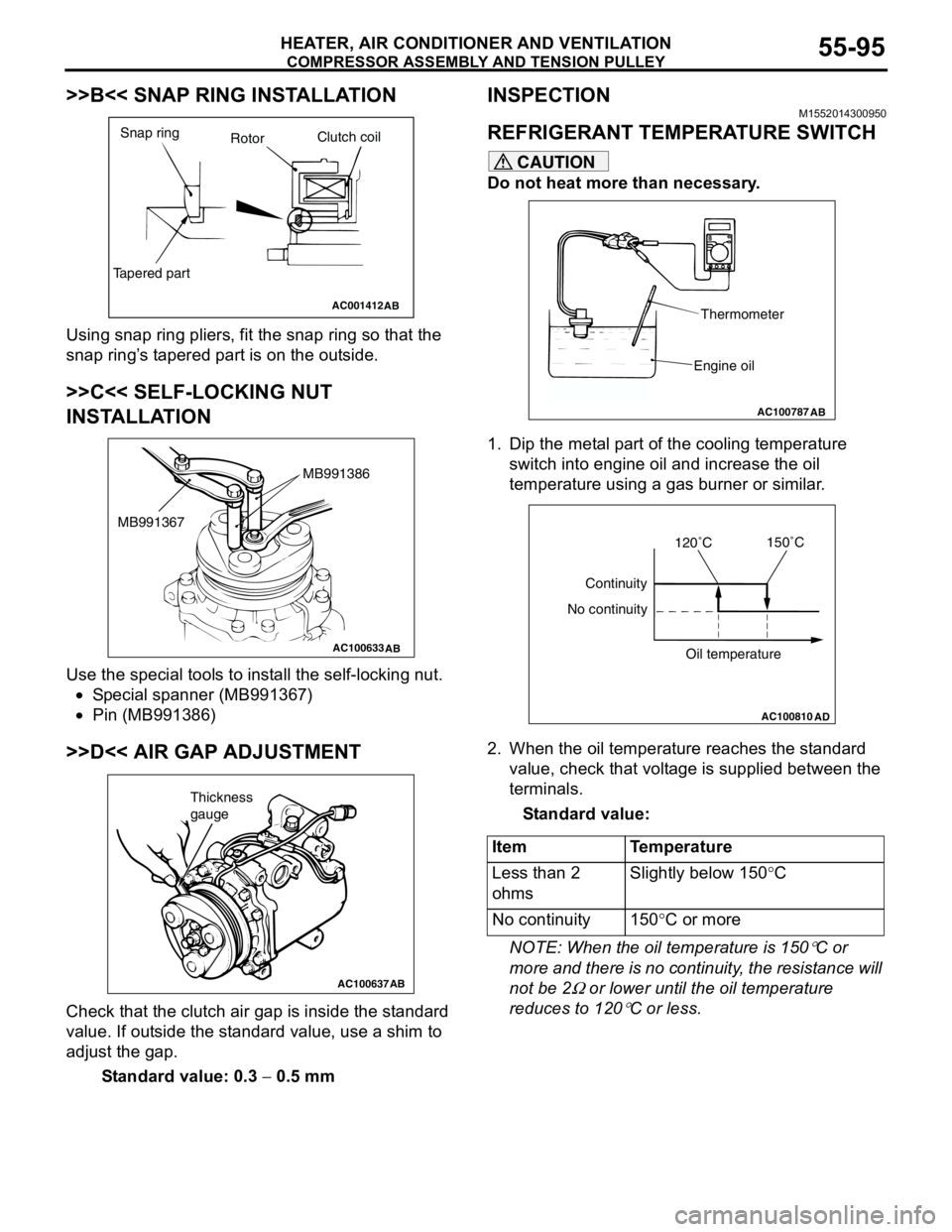

>>B<< SNAP RING INSTALLATION

Using snap ring pliers, fit the snap ring so that the

snap ring’s tapered part is on the outside.

>>C<< SELF-LOCKING NUT

INSTALLATION

Use the special tools to install the self-locking nut.

•Special spanner (MB991367)

•Pin (MB991386)

>>D<< AIR GAP ADJUSTMENT

Check that the clutch air gap is inside the standard

value. If outside the standard value, use a shim to

adjust the gap.

Standard value: 0.3 − 0.5 mm

INSPECTIONM1552014300950

REFRIGERANT TEMPERATURE SWITCH

CAUTION

Do not heat more than necessary.

1. Dip the metal part of the cooling temperature

switch into engine oil and increase the oil

temperature using a gas burner or similar.

2. When the oil temperature reaches the standard

value, check that voltage is supplied between the

terminals.

Standard value:

NOTE: When the oil temperature is 150

°C or

more and there is no continuity, the resistance will

not be 2

Ω or lower until the oil temperature

reduces to 120

°C or less.

AC001412

Snap ring

RotorClutch coil

Tapered part

AB

AC100633AB

MB991386

MB991367

AC100637AB

Thickness

gauge

Item Temperature

Less than 2

ohmsSlightly below 150°C

No continuity 150°C or more

AC100787

Thermometer

Engine oil

AB

AC100810

Continuity

No continuity

Oil temperature

AD

120˚C150˚C