54b MITSUBISHI LANCER 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 304 of 788

DOOR

BODY42-26

TROUBLESHOOTINGM1423000700312

The door system is controlled by the Smart Wiring

System (SWS). For troubleshooting, refer to GROUP

54B, Troubleshooting P.54B-17 or GROUP 54C,

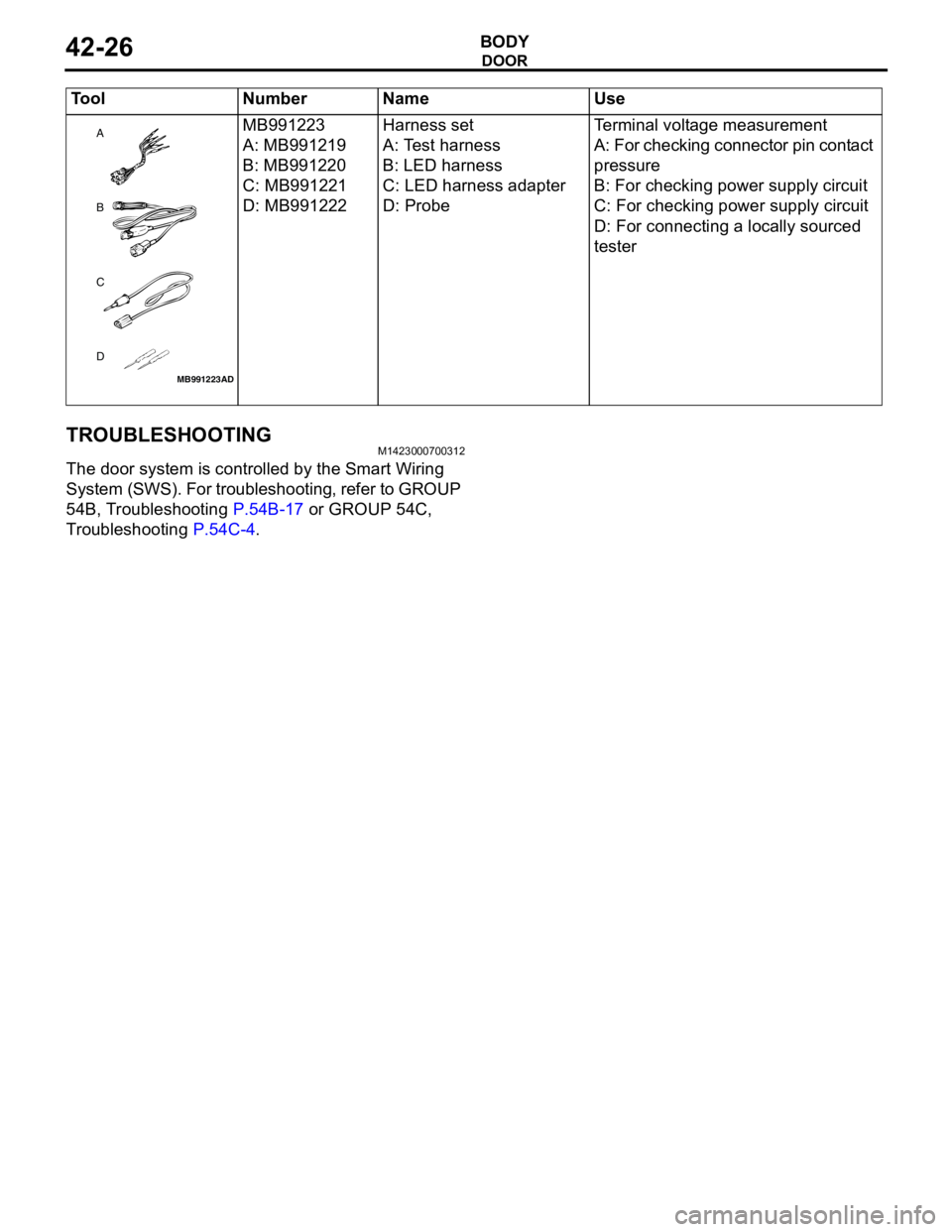

Troubleshooting P.54C-4. MB991223

A: MB991219

B: MB991220

C: MB991221

D: MB991222Harness set

A: Test harness

B: LED harness

C: LED harness adapter

D: ProbeTerminal voltage measurement

A: For checking connector pin contact

pressure

B: For checking power supply circuit

C: For checking power supply circuit

D: For connecting a locally sourced

tester Tool Number Name Use

MB991223

A

D C

B

AD

Page 307 of 788

DOOR

BODY42-29

3. If the operation current is outside the standard

value, refer to GROUP 54B, Troubleshooting

P.54B-17, refer to GROUP 54C, Troubleshooting

P.54C-4.

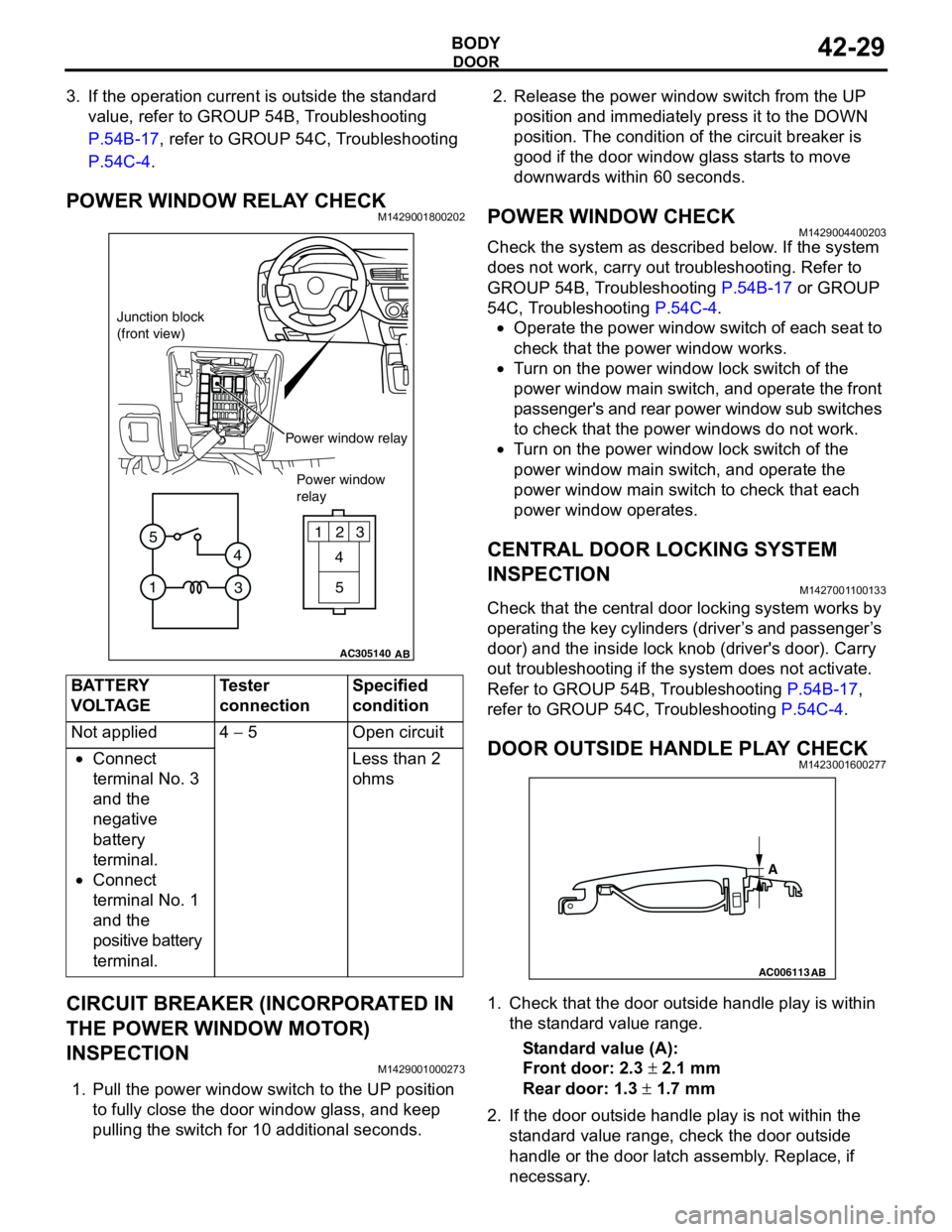

POWER WINDOW RELAY CHECKM1429001800202

CIRCUIT BREAKER (INCORPORATED IN

THE POWER WINDOW MOTOR)

INSPECTION

M1429001000273

1. Pull the power window switch to the UP position

to fully close the door window glass, and keep

pulling the switch for 10 additional seconds.2. Release the power window switch from the UP

position and immediately press it to the DOWN

position. The condition of the circuit breaker is

good if the door window glass starts to move

downwards within 60 seconds.

POWER WINDOW CHECKM1429004400203

Check the system as described below. If the system

does not work, carry out troubleshooting. Refer to

GROUP 54B, Troubleshooting P.54B-17 or GROUP

54C, Troubleshooting P.54C-4.

•Operate the power window switch of each seat to

check that the power window works.

•Turn on the power window lock switch of the

power window main switch, and operate the front

passenger's and rear power window sub switches

to check that the power windows do not work.

•Turn on the power window lock switch of the

power window main switch, and operate the

power window main switch to check that each

power window operates.

CENTRAL DOOR LOCKING SYSTEM

INSPECTION

M1427001100133

Check that the central door locking system works by

operating the key cylinders (driver’s and passenger’s

door) and the inside lock knob (driver's door). Carry

out troubleshooting if the system does not activate.

Refer to GROUP 54B, Troubleshooting P.54B-17,

refer to GROUP 54C, Troubleshooting P.54C-4.

DOOR OUTSIDE HANDLE PLAY CHECKM1423001600277

1. Check that the door outside handle play is within

the standard value range.

Standard value (A):

Front door: 2.3 ± 2.1 mm

Rear door: 1.3 ± 1.7 mm

2. If the door outside handle play is not within the

standard value range, check the door outside

handle or the door latch assembly. Replace, if

necessary. BATTERY

VOLTAGETester

connectionSpecified

condition

Not applied 4 − 5 Open circuit

•Connect

terminal No. 3

and the

negative

battery

terminal.

•Connect

terminal No. 1

and the

positive battery

terminal.Less than 2

ohms

AC305140

123

4

5

1

3 4 5

AB

Junction block

(front view)

Power window relay

Power window

relay

AC006113

AB

A

Page 324 of 788

TA I L G AT E

BODY42-46

TA I L G AT E

SERVICE SPECIFICATIONSM1421000300288

SEALANTSM1424000500098

SPECIAL TOOLM1424000600170

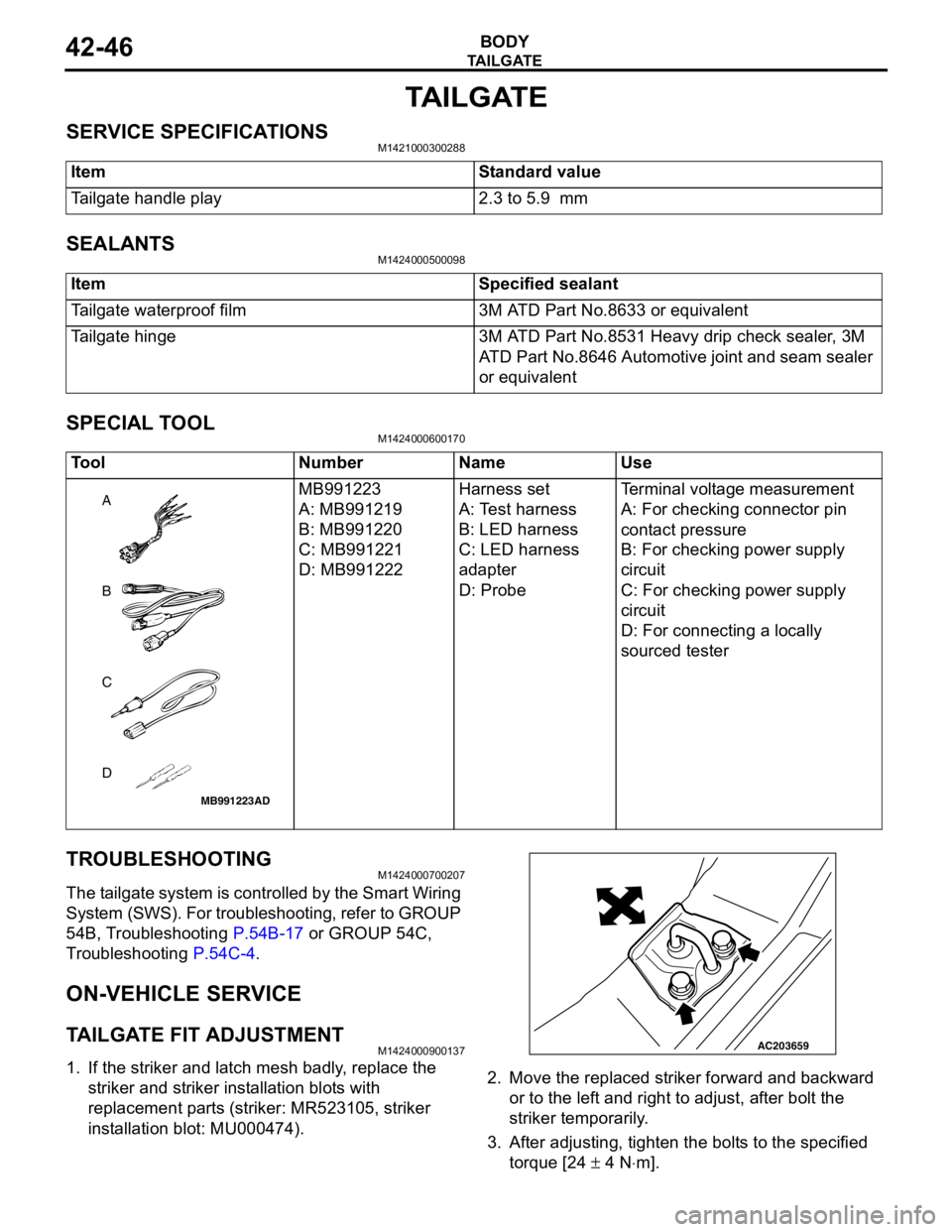

TROUBLESHOOTINGM1424000700207

The tailgate system is controlled by the Smart Wiring

System (SWS). For troubleshooting, refer to GROUP

54B, Troubleshooting P.54B-17 or GROUP 54C,

Troubleshooting P.54C-4.

ON-VEHICLE SERVICE

TAILGATE FIT ADJUSTMENTM1424000900137

1. If the striker and latch mesh badly, replace the

striker and striker installation blots with

replacement parts (striker: MR523105, striker

installation blot: MU000474).2. Move the replaced striker forward and backward

or to the left and right to adjust, after bolt the

striker temporarily.

3. After adjusting, tighten the bolts to the specified

torque [24 ± 4 N⋅m]. Item Standard value

Tailgate handle play 2.3 to 5.9 mm

Item Specified sealant

Tailgate waterproof film 3M ATD Part No.8633 or equivalent

Tailgate hinge 3M ATD Part No.8531 Heavy drip check sealer, 3M

ATD Part No.8646 Automotive joint and seam sealer

or equivalent

Tool Number Name Use

MB991223

A: MB991219

B: MB991220

C: MB991221

D: MB991222Harness set

A: Test harness

B: LED harness

C: LED harness

adapter

D: ProbeTerminal voltage measurement

A: For checking connector pin

contact pressure

B: For checking power supply

circuit

C: For checking power supply

circuit

D: For connecting a locally

sourced tester

MB991223

A

D C

B

AD

AC203659

Page 331 of 788

KEYLESS ENTRY SYSTEM

BODY42-53

TROUBLESHOOTINGM1428000700287

The keyless entry system is controlled by the Smart

Wiring System (SWS). For troubleshooting, refer to

GROUP 54B, Troubleshooting P.54B-17 or GROUP

54C, Troubleshooting P.54C-4.

ON-VEHICLE SERVICE

KEYLESS ENTRY SYSTEM CHECKM1428001400096

Check the system as described below. If the system

does not work, carry out troubleshooting. Refer to

GROUP 54B, Troubleshooting P.54B-17, refer to

GROUP 54C, Troubleshooting P.54C-4.

•Operate the transmitter to check that the doors

and tailgate can be locked and unlocked.

•Operate the transmitter to check that the

answerback function works in response to door

and tailgate

NOTE: The adjustment function allows you to

change the answerback setting as follows. Prior

to that check, confirm which setting is activated.

.

•The hazard warning lamps flash twice when

locked and once when unlocked. The room

lamp flashes twice when locked and

illuminates for 15 seconds when unlocked.

•The hazard warning lamps do not flash when

locked and flash once when unlocked. The

room lamp flashes twice when locked and

illuminates for 15 seconds when unlocked.

•The hazard warning lamps flash twice when

locked and do not flash when unlocked. The

room lamp flashes twice when locked and

illuminates for 15 seconds when unlocked.

•The hazard warning lamps do not flash when

both locked and unlocked. The room lamp

flashes twice when locked and illuminates for

15 seconds when unlocked.

KEYLESS ENTRY SYSTEM TIMER LOCK

FUNCTION INSPECTION

M1428004000138

Push the transmitter unlock button and check to see

that the doors and tailgate

seconds. If it doesn't, then execute troubleshooting

remedies. Refer to GROUP 54B, Troubleshooting

P.54B-17, refer to GROUP 54C, Troubleshooting

P.54C-4.

ENABLING/DISABLING THE

ANSWERBACK FUNCTION

M1428003200214

If the keyless entry system locks or unlocks the

doors, the room lamp flashes or illuminates, the

hazard warning lamp flashes (hazard answerback

function). The hazard answerback function can be

enabled or disabled according to the following

procedure:

ENABLING/DISABLING THE HAZARD

ANSWERBACK FUNCTION

The hazard answerback function can be enabled or

disabled by one of the two following procedures.

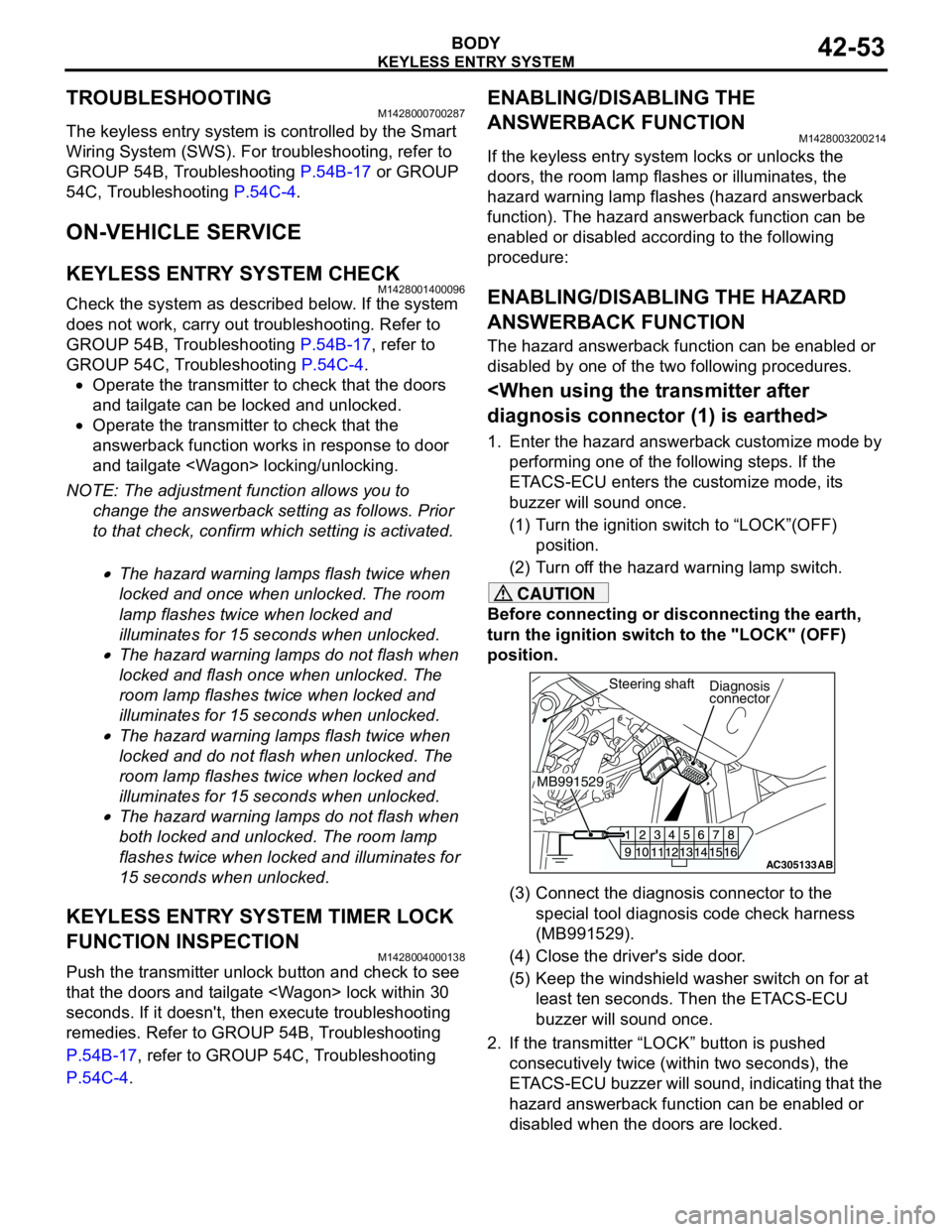

1. Enter the hazard answerback customize mode by

performing one of the following steps. If the

ETACS-ECU enters the customize mode, its

buzzer will sound once.

(1) Turn the ignition switch to “LOCK”(OFF)

position.

(2) Turn off the hazard warning lamp switch.

CAUTION

Before connecting or disconnecting the earth,

turn the ignition switch to the "LOCK" (OFF)

position.

(3) Connect the diagnosis connector to the

special tool diagnosis code check harness

(MB991529).

(4) Close the driver's side door.

(5) Keep the windshield washer switch on for at

least ten seconds. Then the ETACS-ECU

buzzer will sound once.

2. If the transmitter “LOCK” button is pushed

consecutively twice (within two seconds), the

ETACS-ECU buzzer will sound, indicating that the

hazard answerback function can be enabled or

disabled when the doors are locked.

AC305133AB

Diagnosis

connector

MB991529Steering shaft

Page 360 of 788

WINDSHIELD WIPER AND WASHER

EXTERIOR51-22

SERVICE SPECIFICATIONM1511000300325

TROUBLESHOOTINGM1511000700323

The windshield wiper and washer are controlled by

the Smart Wiring System (SWS). For

troubleshooting, refer to GROUP 54B,

Troubleshooting P.54B-17 or GROUP 54C,

Troubleshooting P.54C-4.

NOTE: Even when the ETACS-ECU has failed, the

windshield wiper can work at low speed as fail-safe

mode. (Normally, the windshield wiper operates

when the ignition switch is at the "ACC" position. But,

if it enters the fail-safe mode, the wiper can operate

only when the ignition switch is at the "ON" position.)

ON-VEHICLE SERVICEM1511000800461

WINDSHIELD INTERMITTENT WIPER

INSPECTION

1. If the windshield intermittent wiper interval

adjusting knob is operated, the wiper interval

should change.

2. Holding the windshield intermittent wiper interval

adjusting knob, input the simulated vehicle speed

with MUT-II MB991502 and check that the wiper

interval changes as the vehicle speed changes.

3. If not, carry out the troubleshooting (Refer to

GROUP 54B, Troubleshooting P.54B-17 or

GROUP 54C, Troubleshooting P.54C-4). ItemStandard value

Windshield wiper blade park position mm 34 ± 5

Page 366 of 788

REAR WIPER AND WASHER

EXTERIOR51-28

REAR WIPER AND WASHER

GENERAL INFORMATIONM1511000100525

REAR WIPER AND WASHER OPERATION

Rear Wiper Operation

•If the rear wiper and washer switch is turned to

"INT" position with the ignition switch at "ACC" or

"ON" position, the ETACS-ECU turns ON the rear

wiper drive signal for three seconds

(approximately two cycles), then 7.4 seconds

later the intermittent motion operates every eight

seconds. If the selector lever is moved to the "R"

position when the rear wiper and washer switch is

turned to the "INT" position and the ignition

switch is at the "ACC" or "ON" position, the inhibitor switch "R" turns ON. One second later,

the ETACS-ECU turns ON the rear wiper drive

signal for three seconds (approximately two

cycles). Then, 7.4 seconds later, the intermittent

motion of eight seconds' cycle is restored.

Rear Washer Operation

•If the rear wiper and washer switch is turned to

the ON (washer) position with the ignition switch

at the "ACC" or "ON" position, the rear washer

ON signal is sent to the ETACS-ECU, causing the

rear wiper signal to turn on after 0.3 second. After

the rear washer switch signal turns off, the rear

wiper signal turns off in three seconds. If the rear

washer switch is turned to the ON position while

the rear wiper is in intermittent mode, the rear

washer works for that period when the washer

switch remains on. Then the rear wipers return to

the intermittent mode.

SERVICE SPECIFICATIONM1511000300336

TROUBLESHOOTINGM1511000700334

The rear wiper and washer are controlled by the

Smart Wiring System (SWS). For troubleshooting,

refer to GROUP 54B, Troubleshooting P.54B-17 or

GROUP 54C, Troubleshooting P.54C-4.

ON-VEHICLE SERVICEM1511000800472

CHECK OF REAR WIPER OPERATION

WHEN SELECTOR LEVER IS AT THE "R"

POSITION

1. When the selector lever is moved to the "R"

position with the rear wiper switch at the "INT"

position, the wiper should operate twice or three

times at low speed after approximately one

second.

2. If not, carry out the troubleshooting (Refer to

GROUP 54B, Troubleshooting P.54B-17 or

GROUP 54C, Troubleshooting P.54C-4). ItemStandard value

Rear wiper blade park position mm 42 ± 5

Page 370 of 788

HEADLAMP WASHER

EXTERIOR51-32

HEADLAMP WASHER

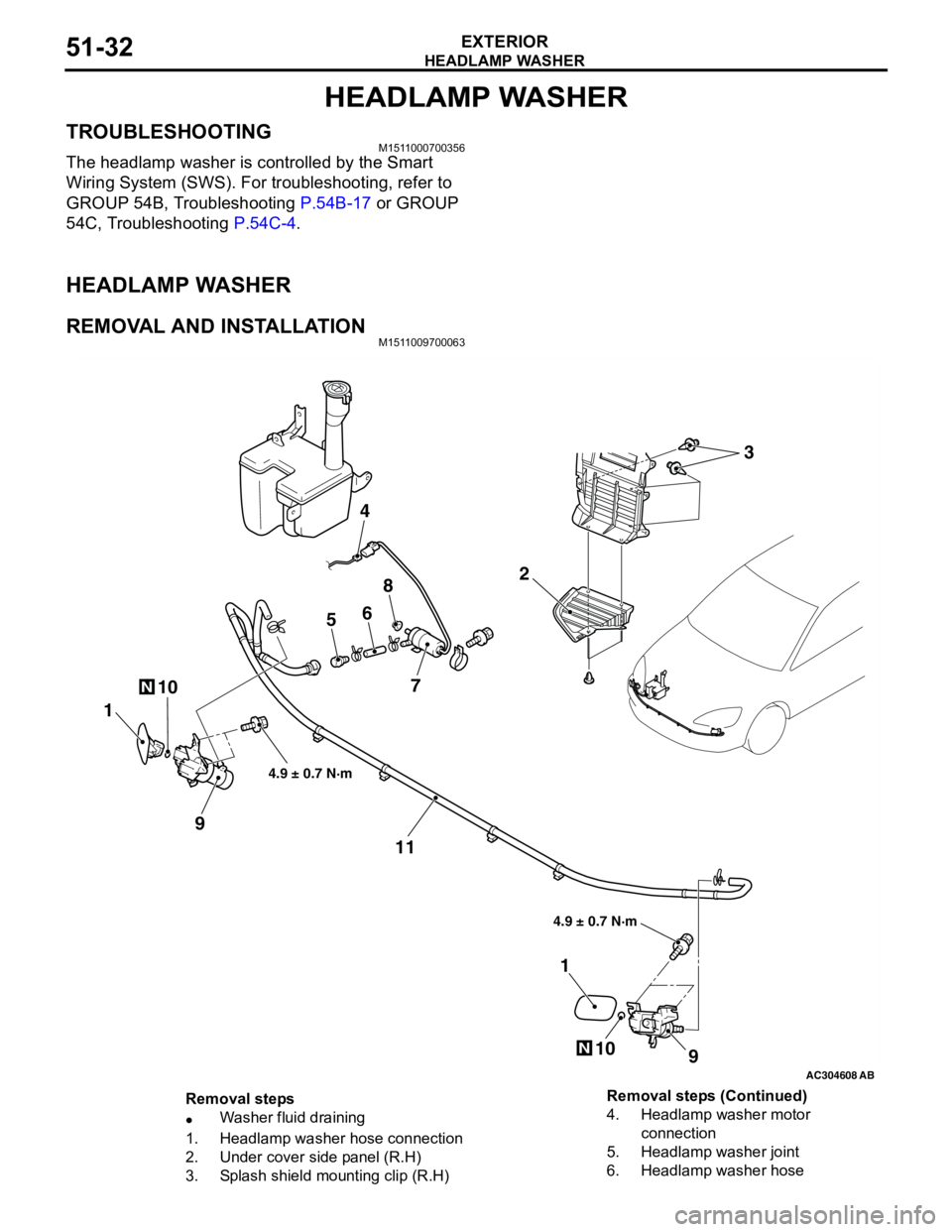

TROUBLESHOOTINGM1511000700356

The headlamp washer is controlled by the Smart

Wiring System (SWS). For troubleshooting, refer to

GROUP 54B, Troubleshooting P.54B-17 or GROUP

54C, Troubleshooting P.54C-4.

HEADLAMP WASHER

REMOVAL AND INSTALLATIONM1511009700063

AC304608AB

10N

2

4

56

8

7

1

9

11

9

1

10N

4.9 ± 0.7 N·m 4.9 ± 0.7 N·m

3

Removal steps

•Washer fluid draining

1. Headlamp washer hose connection

2. Under cover side panel (R.H)

3. Splash shield mounting clip (R.H)4. Headlamp washer motor

connection

5. Headlamp washer joint

6. Headlamp washer hose Removal steps (Continued)

Page 397 of 788

IGNITION SWITCH

CHASSIS ELECTRICAL54A-9

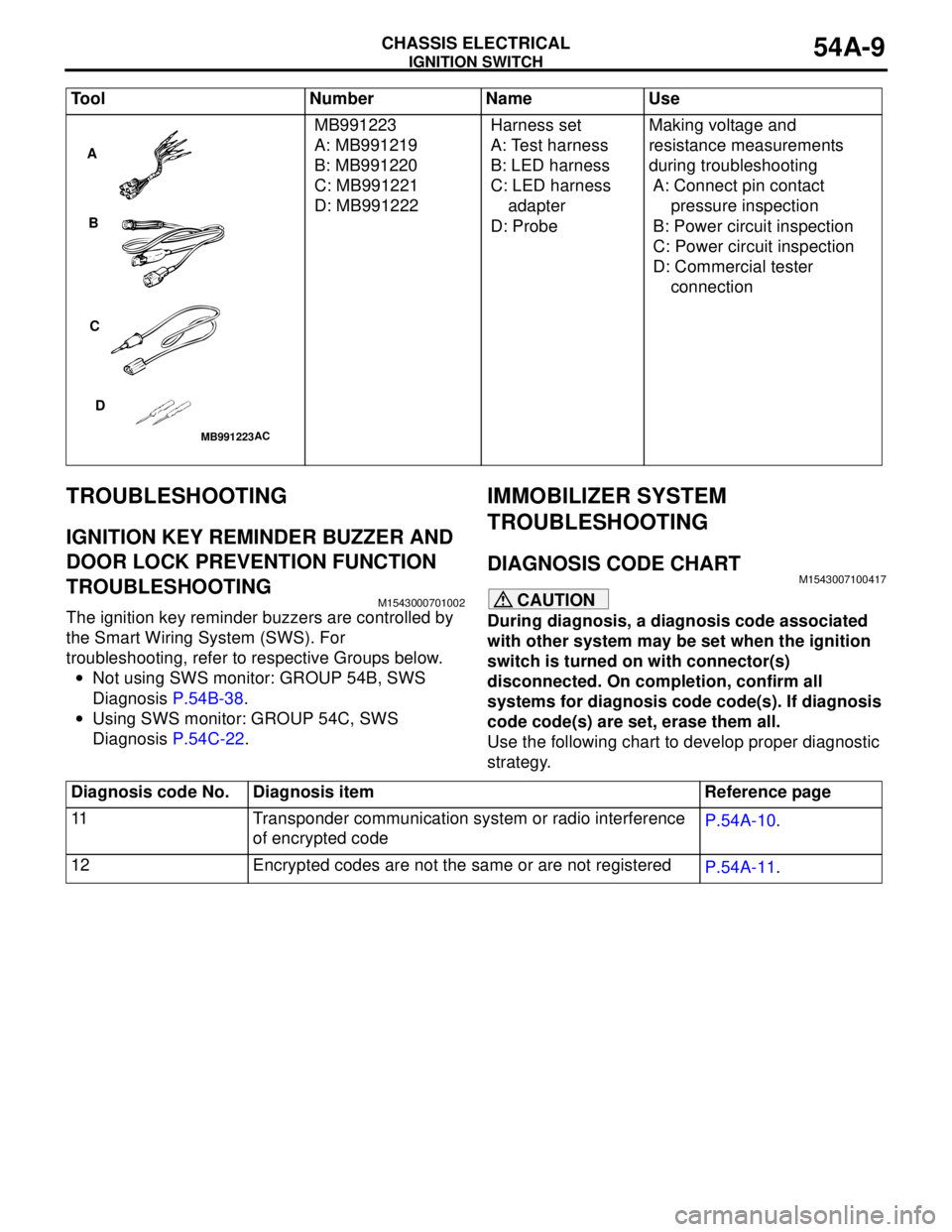

TROUBLESHOOTING

IGNITION KEY REMINDER BUZZER AND

DOOR LOCK PREVENTION FUNCTION

TROUBLESHOOTING

M1543000701002

The ignition key reminder buzzers are controlled by

the Smart Wiring System (SWS). For

troubleshooting, refer to respective Groups below.

•Not using SWS monitor: GROUP 54B, SWS

Diagnosis P.54B-38.

•Using SWS monitor: GROUP 54C, SWS

Diagnosis P.54C-22.

IMMOBILIZER SYSTEM

TROUBLESHOOTING

DIAGNOSIS CODE CHARTM1543007100417

CAUTION

During diagnosis, a diagnosis code associated

with other system may be set when the ignition

switch is turned on with connector(s)

disconnected. On completion, confirm all

systems for diagnosis code code(s). If diagnosis

code code(s) are set, erase them all.

Use the following chart to develop proper diagnostic

strategy. MB991223

A: MB991219

B: MB991220

C: MB991221

D: MB991222Harness set

A: Test harness

B: LED harness

C: LED harness

adapter

D: ProbeMaking voltage and

resistance measurements

during troubleshooting

A: Connect pin contact

pressure inspection

B: Power circuit inspection

C: Power circuit inspection

D: Commercial tester

connection Tool Number Name Use

MB991223

A

B

C

D

AC

Diagnosis code No. Diagnosis item Reference page

11 Transponder communication system or radio interference

of encrypted codeP.54A-10.

12 Encrypted codes are not the same or are not registered

P.54A-11.

Page 454 of 788

HEADLAMP

CHASSIS ELECTRICAL54A-66

HEADLAMP

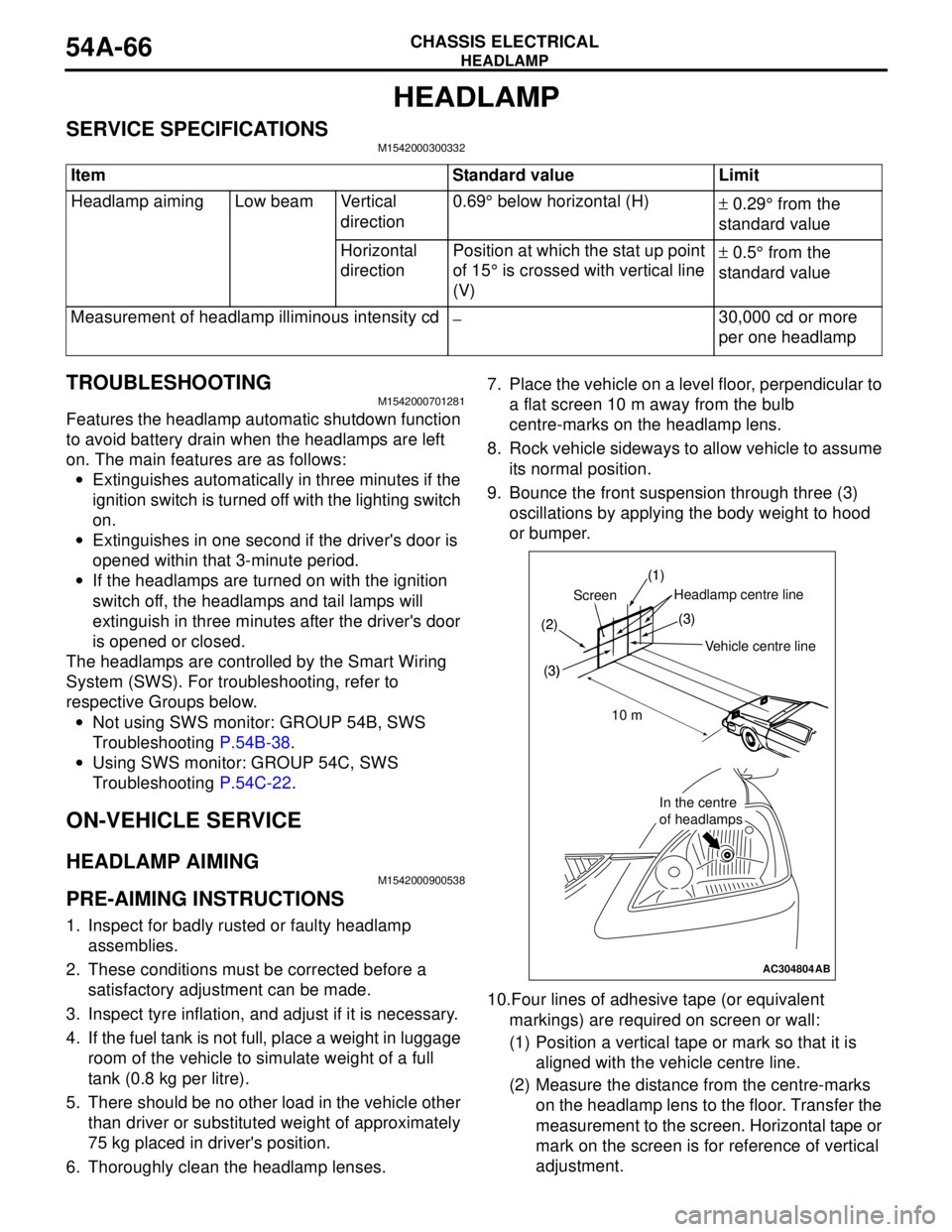

SERVICE SPECIFICATIONSM1542000300332

TROUBLESHOOTING M1542000701281

Features the headlamp automatic shutdown function

to avoid battery drain when the headlamps are left

on. The main features are as follows:

•Extinguishes automatically in three minutes if the

ignition switch is turned off with the lighting switch

on.

•Extinguishes in one second if the driver's door is

opened within that 3-minute period.

•If the headlamps are turned on with the ignition

switch off, the headlamps and tail lamps will

extinguish in three minutes after the driver's door

is opened or closed.

The headlamps are controlled by the Smart Wiring

System (SWS). For troubleshooting, refer to

respective Groups below.

•Not using SWS monitor: GROUP 54B, SWS

Troubleshooting P.54B-38.

•Using SWS monitor: GROUP 54C, SWS

Troubleshooting P.54C-22.

ON-VEHICLE SERVICE

HEADLAMP AIMING

M1542000900538

PRE-AIMING INSTRUCTIONS

1. Inspect for badly rusted or faulty headlamp

assemblies.

2. These conditions must be corrected before a

satisfactory adjustment can be made.

3. Inspect tyre inflation, and adjust if it is necessary.

4. If the fuel tank is not full, place a weight in luggage

room of the vehicle to simulate weight of a full

tank (0.8 kg per litre).

5. There should be no other load in the vehicle other

than driver or substituted weight of approximately

75 kg placed in driver's position.

6. Thoroughly clean the headlamp lenses.7. Place the vehicle on a level floor, perpendicular to

a flat screen 10 m away from the bulb

centre-marks on the headlamp lens.

8. Rock vehicle sideways to allow vehicle to assume

its normal position.

9. Bounce the front suspension through three (3)

oscillations by applying the body weight to hood

or bumper.

10.Four lines of adhesive tape (or equivalent

markings) are required on screen or wall:

(1) Position a vertical tape or mark so that it is

aligned with the vehicle centre line.

(2) Measure the distance from the centre-marks

on the headlamp lens to the floor. Transfer the

measurement to the screen. Horizontal tape or

mark on the screen is for reference of vertical

adjustment. Item Standard value Limit

Headlamp aiming Low beam Vertical

direction0.69° below horizontal (H)

± 0.29° from the

standard value

Horizontal

directionPosition at which the stat up point

of 15° is crossed with vertical line

(V)± 0.5° from the

standard value

Measurement of headlamp illiminous intensity cd

−30,000 cd or more

per one headlamp

AC304804

(1)

(2)

(3)

Headlamp centre line

Vehicle crntre line Screen

(3)

10 m

In the centre

of headlamps

(1)

(2)

(3)(3)

In the centre

of headlamps

AB

Vehicle centre line

ScreenHeadlamp centre line

10 m

Page 459 of 788

FOG LAMP

CHASSIS ELECTRICAL54A-71

FOG LAMP

SERVICE SPECIFICATIONM1542000300343

SPECIAL TOOLM1542000600894

TROUBLESHOOTINGM1542000701292

When the front fog lamp switch is turned to ON with

the tail lamp or the headlamp on (the tail lamp switch

or the headlamp switch is ON), the fog lamp relay

turns on, and the fog lamps will illuminate.

If the tail lamps or the headlamps are turned off with

the lighting switch OFF while the fog lamps are on,

the front fog lamps turn off at the same time to

prevent unattended operation.

If the tail lamps are turned off by the headlamp

automatic shutdown function, the fog lamps turn off

at the same time. However, if the tail lamps illuminate

again, the fog lamps do not.

The front fog lamps are controlled by the Smart

Wiring System (SWS). For troubleshooting, refer to

respective Groups below.

•Not using SWS monitor: GROUP 54B, SWS

Troubleshooting P.54B-38.

•Using SWS monitor: GROUP 54C, SWS

Troubleshooting P.54C-22.

ON-VEHICLE SERVICE

FRONT FOG LAMP AIMING CHECKM1542001100438

After setting the vehicles to the following condition,

adjust the front fog lamp aiming.

•Check that the tyre inflation pressure is at the

value indicated on the tyre pressure labels.

•Set the vehicle to the unladen condition and park

it on a level surface.

•Have a single person (approximately 75 kg) sit in

the driver’s seat.•Run the engine at a speed of 2000 r/min to fully

charge the battery.

Turn on the front fog lamps and check that the

illumination is within the standard value range.

Standard value: Illuminates to within 40

metres

CAUTION

For the fog lamp which is not being measured,

disconnect that fog lamp’s connector if possible

so that it does not illuminate while carrying out

the adjustment. Furthermore, make sure that the

light axis does not get shifted when

re-connecting the connector.

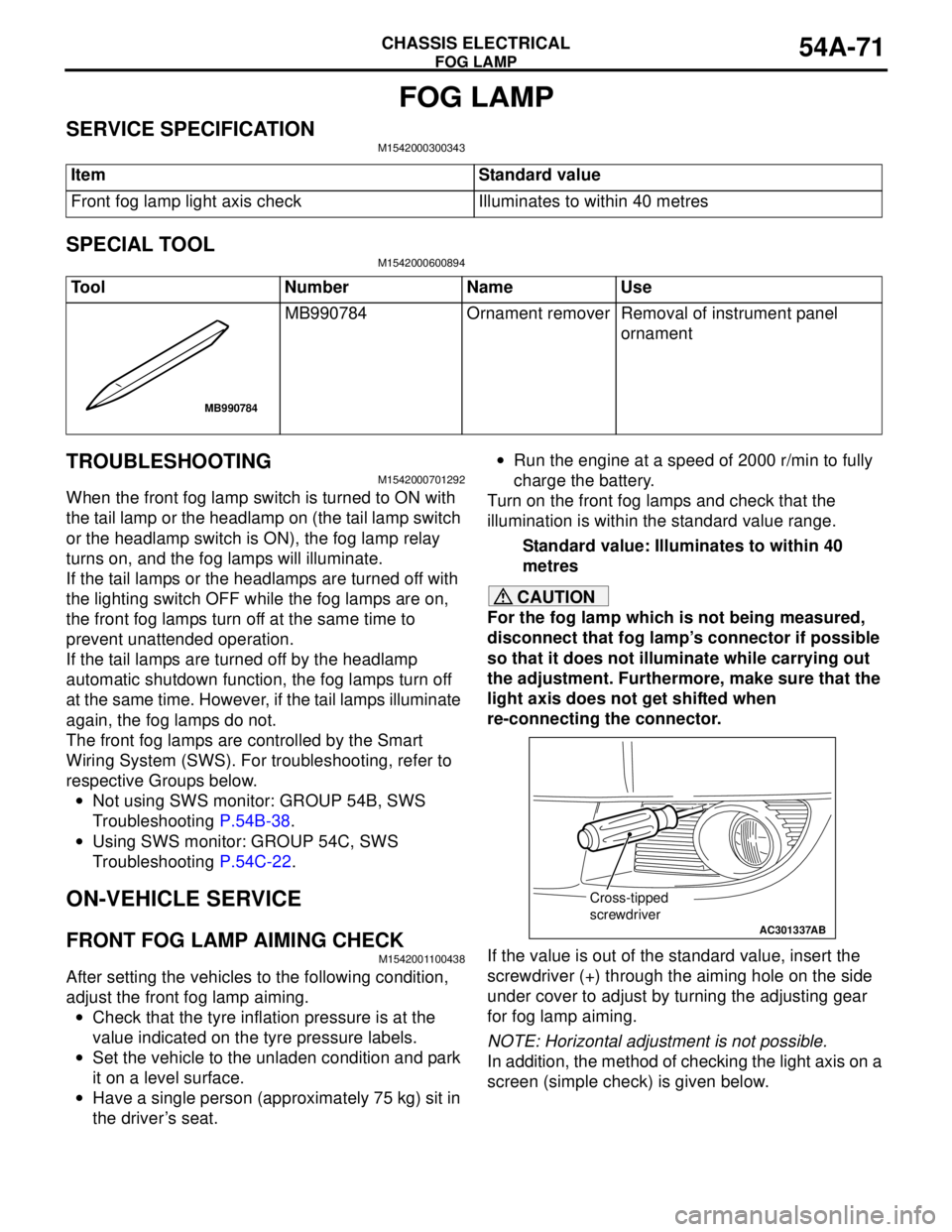

If the value is out of the standard value, insert the

screwdriver (+) through the aiming hole on the side

under cover to adjust by turning the adjusting gear

for fog lamp aiming.

NOTE: Horizontal adjustment is not possible.

In addition, the method of checking the light axis on a

screen (simple check) is given below. Item Standard value

Front fog lamp light axis check Illuminates to within 40 metres

Tool Number Name Use

MB990784 Ornament remover Removal of instrument panel

ornament

MB990784

AC301337

Cross-tipped

screwdriver

AB