engine oil capacity MITSUBISHI LANCER 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 16 of 788

GENERAL INFORMATION

ENGINE COOLING14-2

GENERAL INFORMATION

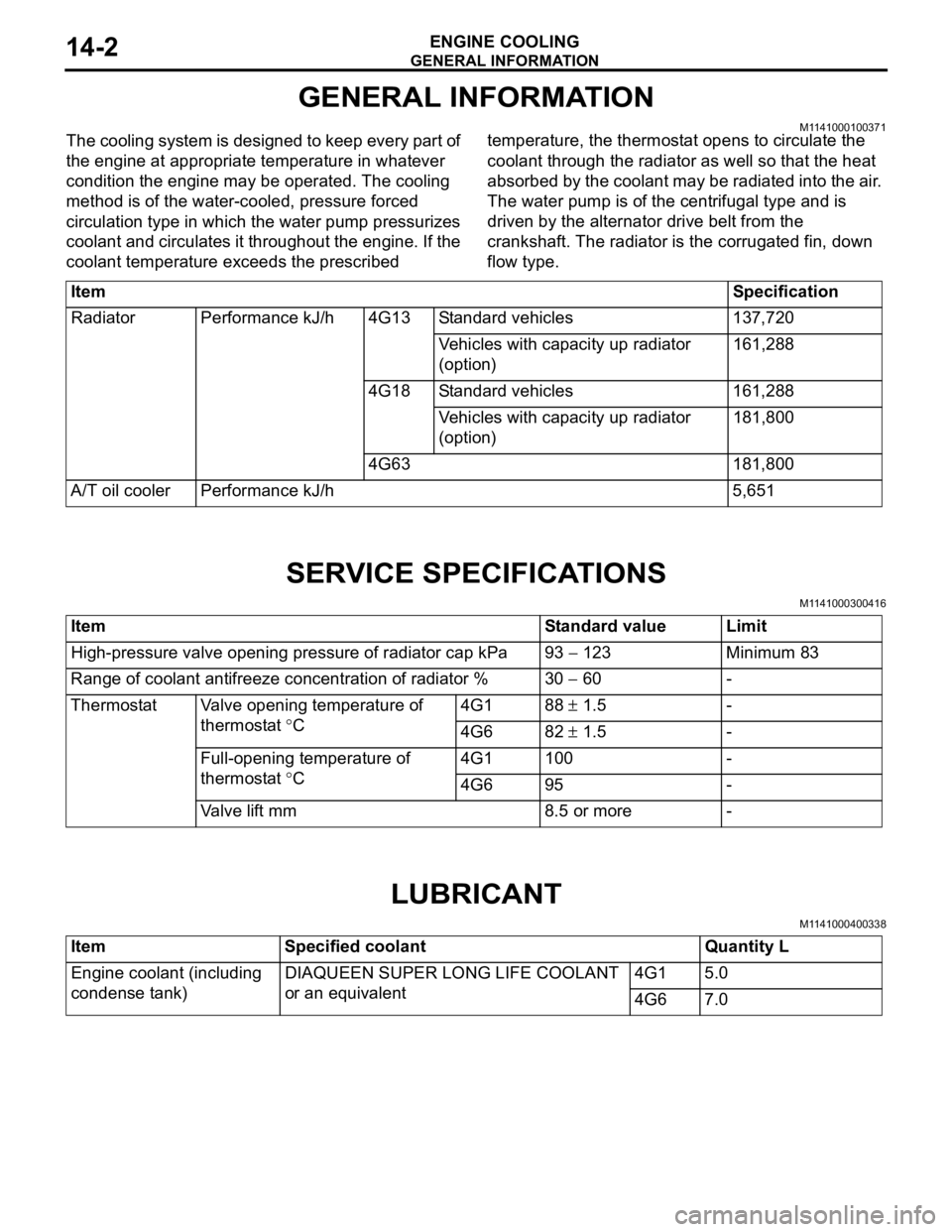

M1141000100371The cooling system is designed to keep every part of

the engine at appropriate temperature in whatever

condition the engine may be operated. The cooling

method is of the water-cooled, pressure forced

circulation type in which the water pump pressurizes

coolant and circulates it throughout the engine. If the

coolant temperature exceeds the prescribed temperature, the thermostat opens to circulate the

coolant through the radiator as well so that the heat

absorbed by the coolant may be radiated into the air.

The water pump is of the centrifugal type and is

driven by the alternator drive belt from the

crankshaft. The radiator is the corrugated fin, down

flow type.

SERVICE SPECIFICATIONS

M1141000300416

LUBRICANT

M1141000400338

ItemSpecification

Radiator Performance kJ/h 4G13 Standard vehicles 137,720

Vehicles with capacity up radiator

(option)161,288

4G18 Standard vehicles 161,288

Vehicles with capacity up radiator

(option)181,800

4G63 181,800

A/T oil cooler Performance kJ/h 5,651

Item Standard value Limit

High-pressure valve opening pressure of radiator cap kPa 93 − 123 Minimum 83

Range of coolant antifreeze concentration of radiator % 30 − 60 -

Thermostat Valve opening temperature of

thermostat °C4G1 88 ± 1.5 -

4G6 82 ± 1.5 -

Full-opening temperature of

thermostat °C4G1 100 -

4G6 95 -

Valve lift mm 8.5 or more -

Item Specified coolant Quantity L

Engine coolant (including

condense tank)DIAQUEEN SUPER LONG LIFE COOLANT

or an equivalent4G1 5.0

4G6 7.0

Page 558 of 788

ON-VEHICLE SERVICE

HEATER, AIR CONDITIONER AND VENTILATION55-74

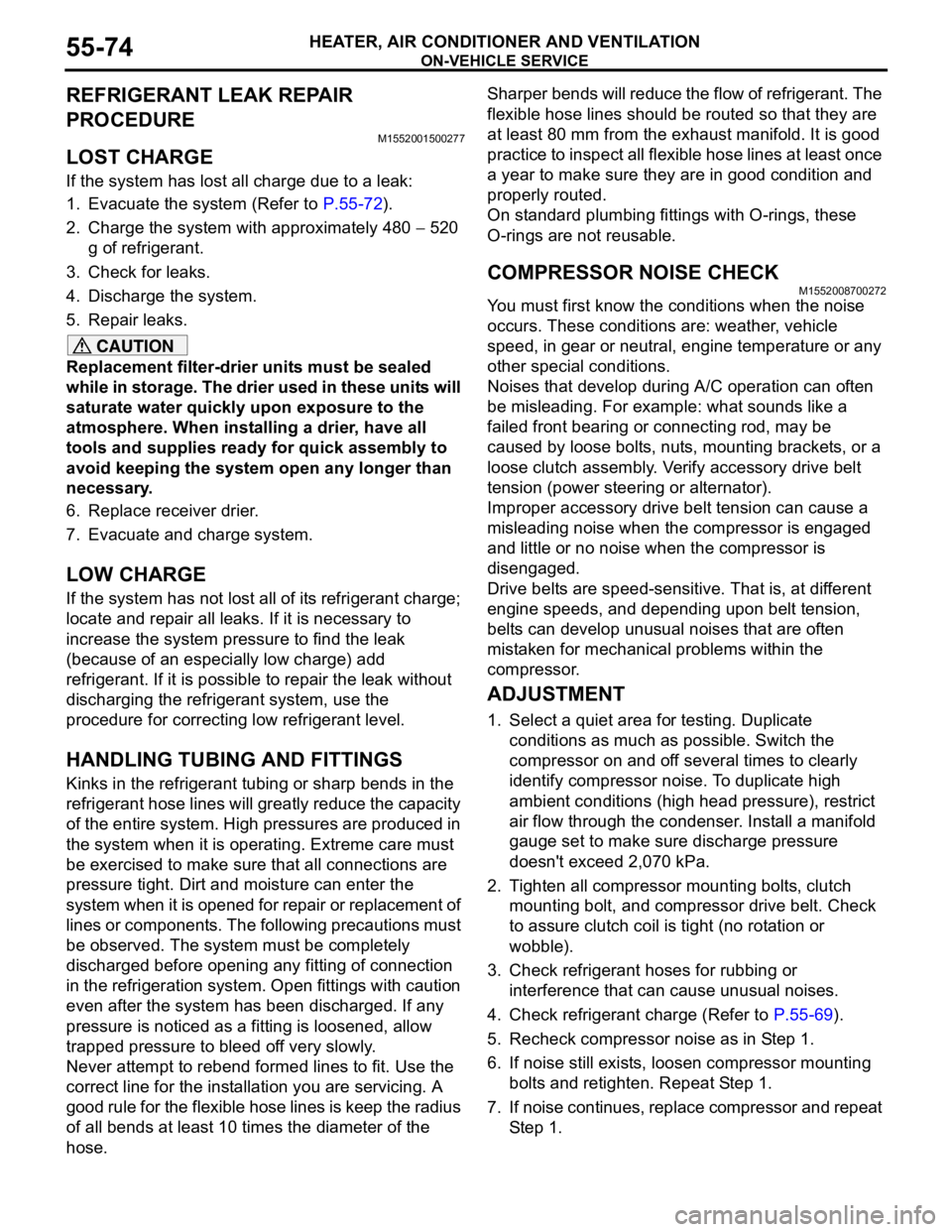

REFRIGERANT LEAK REPAIR

PROCEDURE

M1552001500277

LOST CHARGE

If the system has lost all charge due to a leak:

1. Evacuate the system (Refer to P.55-72).

2. Charge the system with approximately 480 − 520

g of refrigerant.

3. Check for leaks.

4. Discharge the system.

5. Repair leaks.

CAUTION

Replacement filter-drier units must be sealed

while in storage. The drier used in these units will

saturate water quickly upon exposure to the

atmosphere. When installing a drier, have all

tools and supplies ready for quick assembly to

avoid keeping the system open any longer than

necessary.

6. Replace receiver drier.

7. Evacuate and charge system.

LOW CHARGE

If the system has not lost all of its refrigerant charge;

locate and repair all leaks. If it is necessary to

increase the system pressure to find the leak

(because of an especially low charge) add

refrigerant. If it is possible to repair the leak without

discharging the refrigerant system, use the

procedure for correcting low refrigerant level.

HANDLING TUBING AND FITTINGS

Kinks in the refrigerant tubing or sharp bends in the

refrigerant hose lines will greatly reduce the capacity

of the entire system. High pressures are produced in

the system when it is operating. Extreme care must

be exercised to make sure that all connections are

pressure tight. Dirt and moisture can enter the

system when it is opened for repair or replacement of

lines or components. The following precautions must

be observed. The system must be completely

discharged before opening any fitting of connection

in the refrigeration system. Open fittings with caution

even after the system has been discharged. If any

pressure is noticed as a fitting is loosened, allow

trapped pressure to bleed off very slowly.

Never attempt to rebend formed lines to fit. Use the

correct line for the installation you are servicing. A

good rule for the flexible hose lines is keep the radius

of all bends at least 10 times the diameter of the

hose.Sharper bends will reduce the flow of refrigerant. The

flexible hose lines should be routed so that they are

at least 80 mm from the exhaust manifold. It is good

practice to inspect all flexible hose lines at least once

a year to make sure they are in good condition and

properly routed.

On standard plumbing fittings with O-rings, these

O-rings are not reusable.

COMPRESSOR NOISE CHECKM1552008700272

You must first know the conditions when the noise

occurs. These conditions are: weather, vehicle

speed, in gear or neutral, engine temperature or any

other special conditions.

Noises that develop during A/C operation can often

be misleading. For example: what sounds like a

failed front bearing or connecting rod, may be

caused by loose bolts, nuts, mounting brackets, or a

loose clutch assembly. Verify accessory drive belt

tension (power steering or alternator).

Improper accessory drive belt tension can cause a

misleading noise when the compressor is engaged

and little or no noise when the compressor is

disengaged.

Drive belts are speed-sensitive. That is, at different

engine speeds, and depending upon belt tension,

belts can develop unusual noises that are often

mistaken for mechanical problems within the

compressor.

ADJUSTMENT

1. Select a quiet area for testing. Duplicate

conditions as much as possible. Switch the

compressor on and off several times to clearly

identify compressor noise. To duplicate high

ambient conditions (high head pressure), restrict

air flow through the condenser. Install a manifold

gauge set to make sure discharge pressure

doesn't exceed 2,070 kPa.

2. Tighten all compressor mounting bolts, clutch

mounting bolt, and compressor drive belt. Check

to assure clutch coil is tight (no rotation or

wobble).

3. Check refrigerant hoses for rubbing or

interference that can cause unusual noises.

4. Check refrigerant charge (Refer to P.55-69).

5. Recheck compressor noise as in Step 1.

6. If noise still exists, loosen compressor mounting

bolts and retighten. Repeat Step 1.

7. If noise continues, replace compressor and repeat

Step 1.

Page 648 of 788

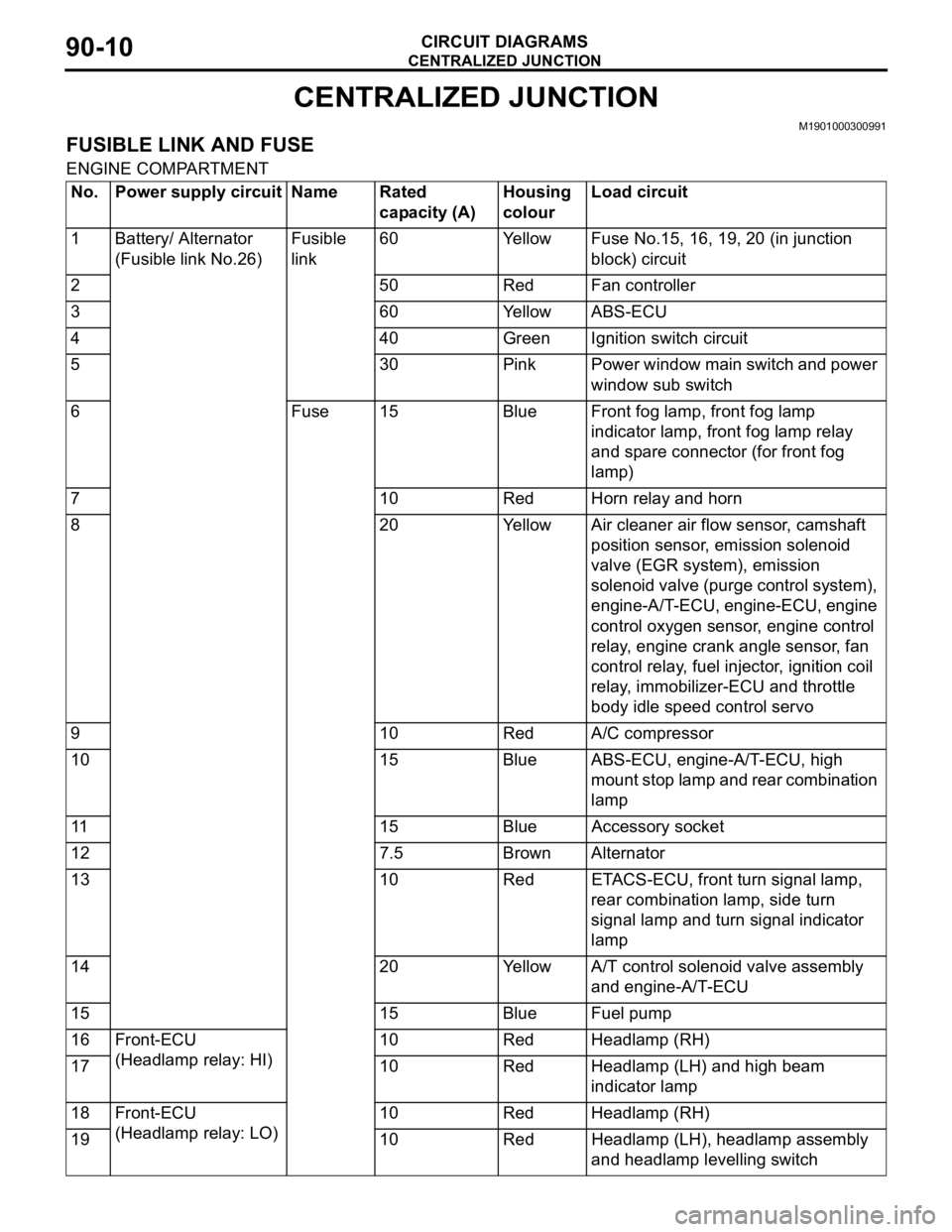

CENTRALIZED JUNCTION

CIRCUIT DIAGRAMS90-10

CENTRALIZED JUNCTION

M1901000300991

FUSIBLE LINK AND FUSE

ENGINE COMPARTMENT

No. Power supply circuit Name Rated

capacity (A)Housing

colourLoad circuit

1 Battery/ Alternator

(Fusible link No.26)Fusible

link60 Yellow Fuse No.15, 16, 19, 20 (in junction

block) circuit

2 50 Red Fan controller

3 60 Yellow ABS-ECU

4 40 Green Ignition switch circuit

5 30 Pink Power window main switch and power

window sub switch

6 Fuse 15 Blue Front fog lamp, front fog lamp

indicator lamp, front fog lamp relay

and spare connector (for front fog

lamp)

7 10 Red Horn relay and horn

8 20 Yellow Air cleaner air flow sensor, camshaft

position sensor, emission solenoid

valve (EGR system), emission

solenoid valve (purge control system),

engine-A/T-ECU, engine-ECU, engine

control oxygen sensor, engine control

relay, engine crank angle sensor, fan

control relay, fuel injector, ignition coil

relay, immobilizer-ECU and throttle

body idle speed control servo

9 10 Red A/C compressor

10 15 Blue ABS-ECU, engine-A/T-ECU, high

mount stop lamp and rear combination

lamp

11 15 Blue Accessory socket

12 7.5 Brown Alternator

13 10 Red ETACS-ECU, front turn signal lamp,

rear combination lamp, side turn

signal lamp and turn signal indicator

lamp

14 20 Yellow A/T control solenoid valve assembly

and engine-A/T-ECU

15 15 Blue Fuel pump

16 Front-ECU

(Headlamp relay: HI)10 Red Headlamp (RH)

17 10 Red Headlamp (LH) and high beam

indicator lamp

18 Front-ECU

(Headlamp relay: LO)10 Red Headlamp (RH)

19 10 Red Headlamp (LH), headlamp assembly

and headlamp levelling switch

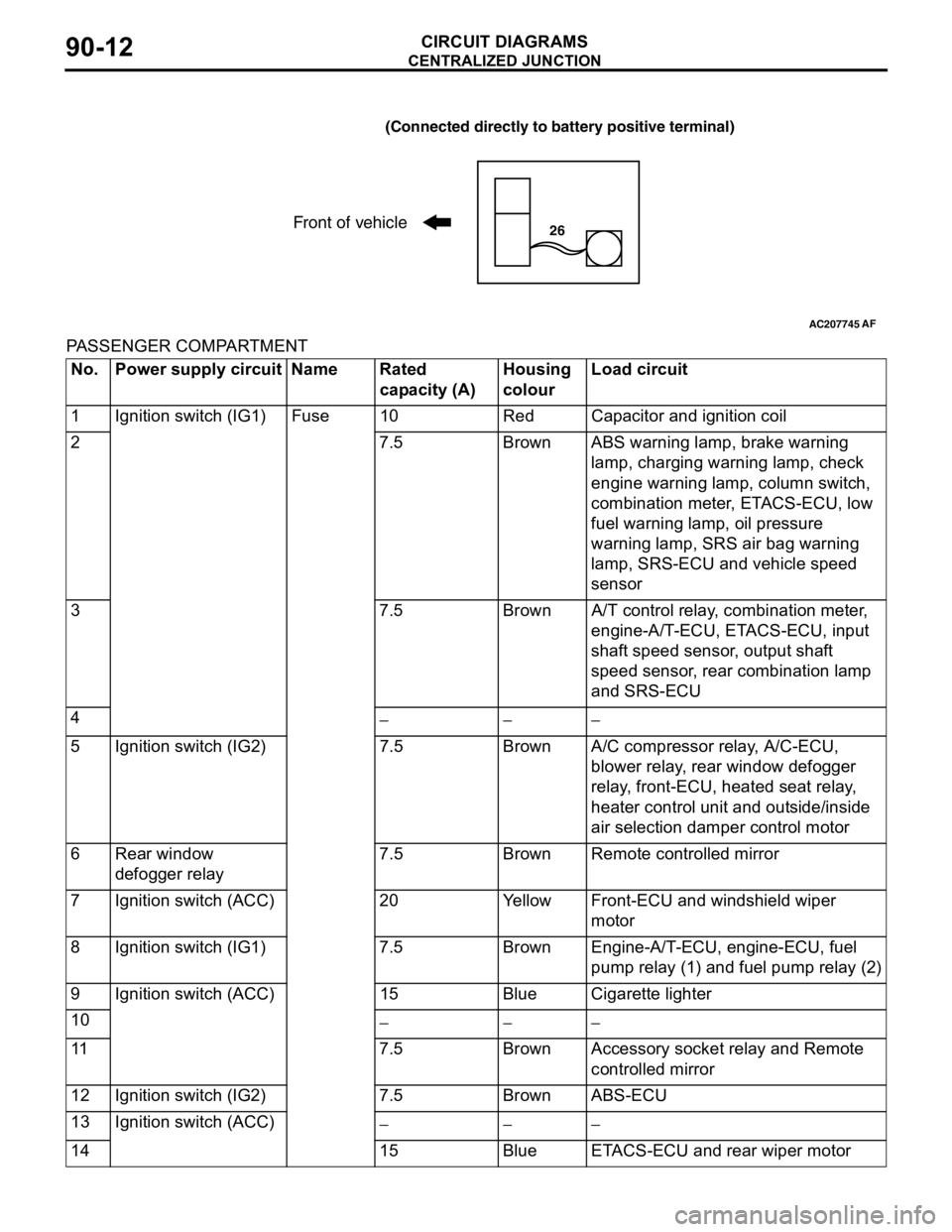

Page 650 of 788

CENTRALIZED JUNCTION

CIRCUIT DIAGRAMS90-12

PASSENGER COMPARTMENT

AC207745

(Connected directly to battery positive terminal)

Front of vehicle26

AF

No. Power supply circuit Name Rated

capacity (A)Housing

colourLoad circuit

1 Ignition switch (IG1) Fuse 10 Red Capacitor and ignition coil

2 7.5 Brown ABS warning lamp, brake warning

lamp, charging warning lamp, check

engine warning lamp, column switch,

combination meter, ETACS-ECU, low

fuel warning lamp, oil pressure

warning lamp, SRS air bag warning

lamp, SRS-ECU and vehicle speed

sensor

3 7.5 Brown A/T control relay, combination meter,

engine-A/T-ECU, ETACS-ECU, input

shaft speed sensor, output shaft

speed sensor, rear combination lamp

and SRS-ECU

4

−−−

5 Ignition switch (IG2) 7.5 Brown A/C compressor relay, A/C-ECU,

blower relay, rear window defogger

relay, front-ECU, heated seat relay,

heater control unit and outside/inside

air selection damper control motor

6 Rear window

defogger relay7.5 Brown Remote controlled mirror

7 Ignition switch (ACC) 20 Yellow Front-ECU and windshield wiper

motor

8 Ignition switch (IG1) 7.5 Brown Engine-A/T-ECU, engine-ECU, fuel

pump relay (1) and fuel pump relay (2)

9 Ignition switch (ACC) 15 Blue Cigarette lighter

10

−−−

11 7.5 Brown Accessory socket relay and Remote

controlled mirror

12 Ignition switch (IG2) 7.5 Brown ABS-ECU

13 Ignition switch (ACC)

−−−

14 15 Blue ETACS-ECU and rear wiper motor