heater MITSUBISHI LANCER 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 1 of 788

GROUP INDEX

00General . . . . . . . . . . . . . . . . . . . . . . . .

11Engine. . . . . . . . . . . . . . . . . . . . . . . . .

12Engine Lubrication . . . . . . . . . . . . . .

13Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . .

14Engine Cooling . . . . . . . . . . . . . . . . .

15Intake and Exhaust . . . . . . . . . . . . . .

16Engine Electrical . . . . . . . . . . . . . . . .

17Engine and Emission Control . . . . .

21Clutch . . . . . . . . . . . . . . . . . . . . . . . . .

22Manual Transmission . . . . . . . . . . . .

23Automatic Transmission. . . . . . . . . .

26Front Axle . . . . . . . . . . . . . . . . . . . . . .

27Rear Axle . . . . . . . . . . . . . . . . . . . . . .

31Wheel and Tyre . . . . . . . . . . . . . . . . .

32Power Plant Mount . . . . . . . . . . . . . .

33Front Suspension . . . . . . . . . . . . . . .

34Rear Suspension . . . . . . . . . . . . . . . .

35Service Brakes . . . . . . . . . . . . . . . . . .

36Parking Brakes . . . . . . . . . . . . . . . . .

37Power Steering . . . . . . . . . . . . . . . . .

42Body . . . . . . . . . . . . . . . . . . . . . . . . . .

51Exterior . . . . . . . . . . . . . . . . . . . . . . . .

52 . . . . . . . . . .

54Chassis Electrical . . . . . . . . . . . . . . .

55 . . . . . . .

70Component Locations. . . . . . . . . . . .

80Configration Diagrams . . . . . . . . . . .

90Circuit Diagrams . . . . . . . . . . . . . . . .

LANCER /

LANCER WAGON

WORKSHOP MANUAL

FOREWORD

This Workshop manual contains procedures for

service mechanics, including removal, disassembly,

inspection, adjustment, reassembly and installation.

Use the following manuals in combination with this

manual as required.

TECHNICAL INFORMATION MANUAL

PYME0302

PYME0302-A

WORKSHOP MANUAL

CHASSIS GROUP PWME0302

BODY REPAIR MANUAL

PBME0302

PBME0302-A

PARTS CATALOGUE

B606K005A_

All information, illustrations and product descriptions

contained in this manual are current as at the time of

publication. We, however, reserve the right to make

changes at any time without prior notice or obligation.

Mitsubishi Motors Corporation May 2004

Heater, Air Conditioner and

Ventilation Interior and Supplemental

Restraint System (SRS)

Page 36 of 788

ON-VEHICLE SERVICE

ENGINE COOLING14-22

ON-VEHICLE SERVICE

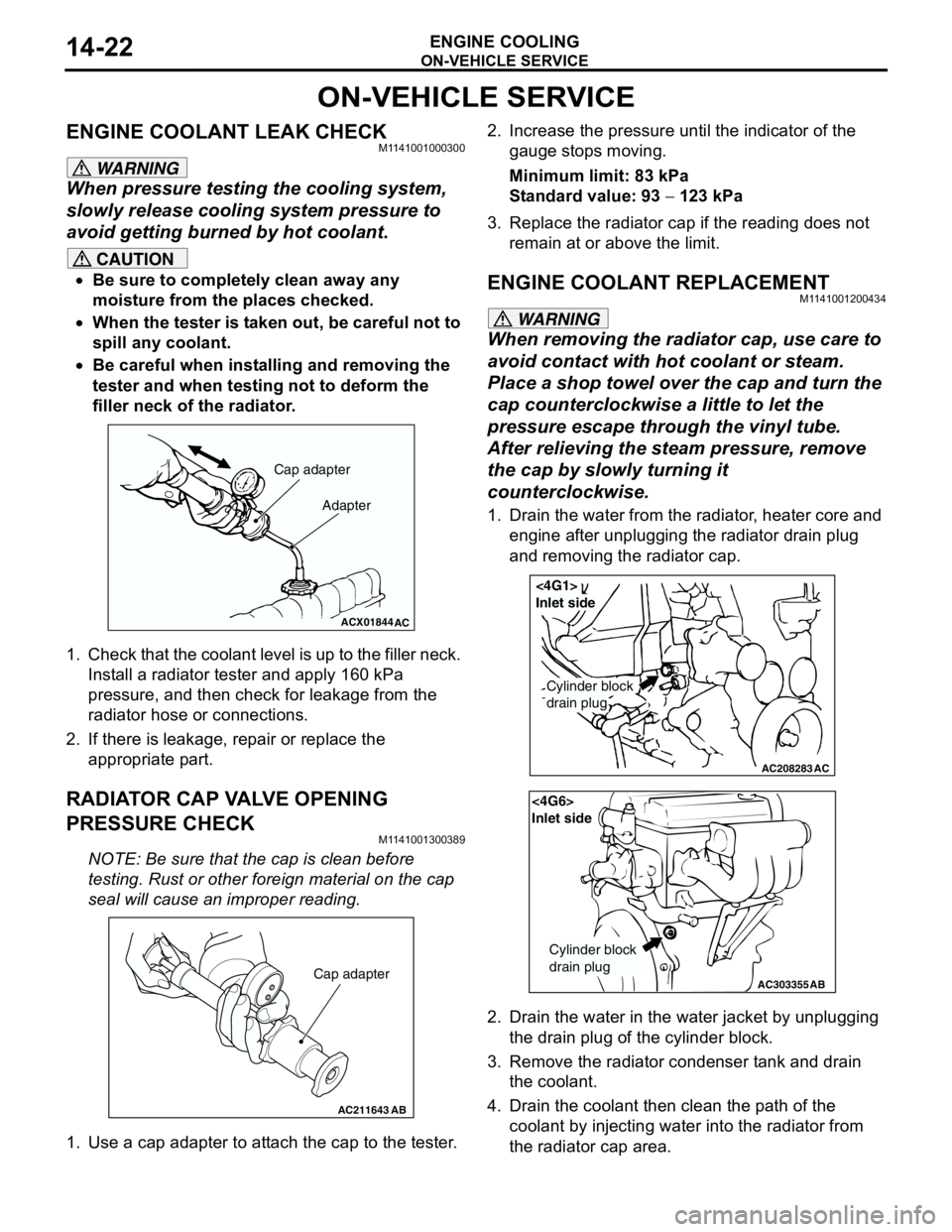

ENGINE COOLANT LEAK CHECKM1141001000300

WARNING

When pressure testing the cooling system,

slowly release cooling system pressure to

avoid getting burned by hot coolant.

CAUTION

•Be sure to completely clean away any

moisture from the places checked.

•When the tester is taken out, be careful not to

spill any coolant.

•Be careful when installing and removing the

tester and when testing not to deform the

filler neck of the radiator.

1. Check that the coolant level is up to the filler neck.

Install a radiator tester and apply 160 kPa

pressure, and then check for leakage from the

radiator hose or connections.

2. If there is leakage, repair or replace the

appropriate part.

RADIATOR CAP VALVE OPENING

PRESSURE CHECK

M1141001300389

NOTE: Be sure that the cap is clean before

testing. Rust or other foreign material on the cap

seal will cause an improper reading.

1. Use a cap adapter to attach the cap to the tester.2. Increase the pressure until the indicator of the

gauge stops moving.

Minimum limit: 83 kPa

Standard value: 93 − 123 kPa

3. Replace the radiator cap if the reading does not

remain at or above the limit.

ENGINE COOLANT REPLACEMENTM1141001200434

WARNING

When removing the radiator cap, use care to

avoid contact with hot coolant or steam.

Place a shop towel over the cap and turn the

cap counterclockwise a little to let the

pressure escape through the vinyl tube.

After relieving the steam pressure, remove

the cap by slowly turning it

counterclockwise.

1. Drain the water from the radiator, heater core and

engine after unplugging the radiator drain plug

and removing the radiator cap.

2. Drain the water in the water jacket by unplugging

the drain plug of the cylinder block.

3. Remove the radiator condenser tank and drain

the coolant.

4. Drain the coolant then clean the path of the

coolant by injecting water into the radiator from

the radiator cap area.

ACX01844

Cap adapter

Adapter

AC

AC211643AB

Cap adapter

AC208283AC

Cylinder block

drain plug

<4G1>

Inlet side

AC303355

<4G6>

Inlet side

Cylinder block

drain plug

AB

Page 45 of 788

WATER HOSE AND WATER PIPE

ENGINE COOLING14-31

WATER HOSE AND WATER PIPE

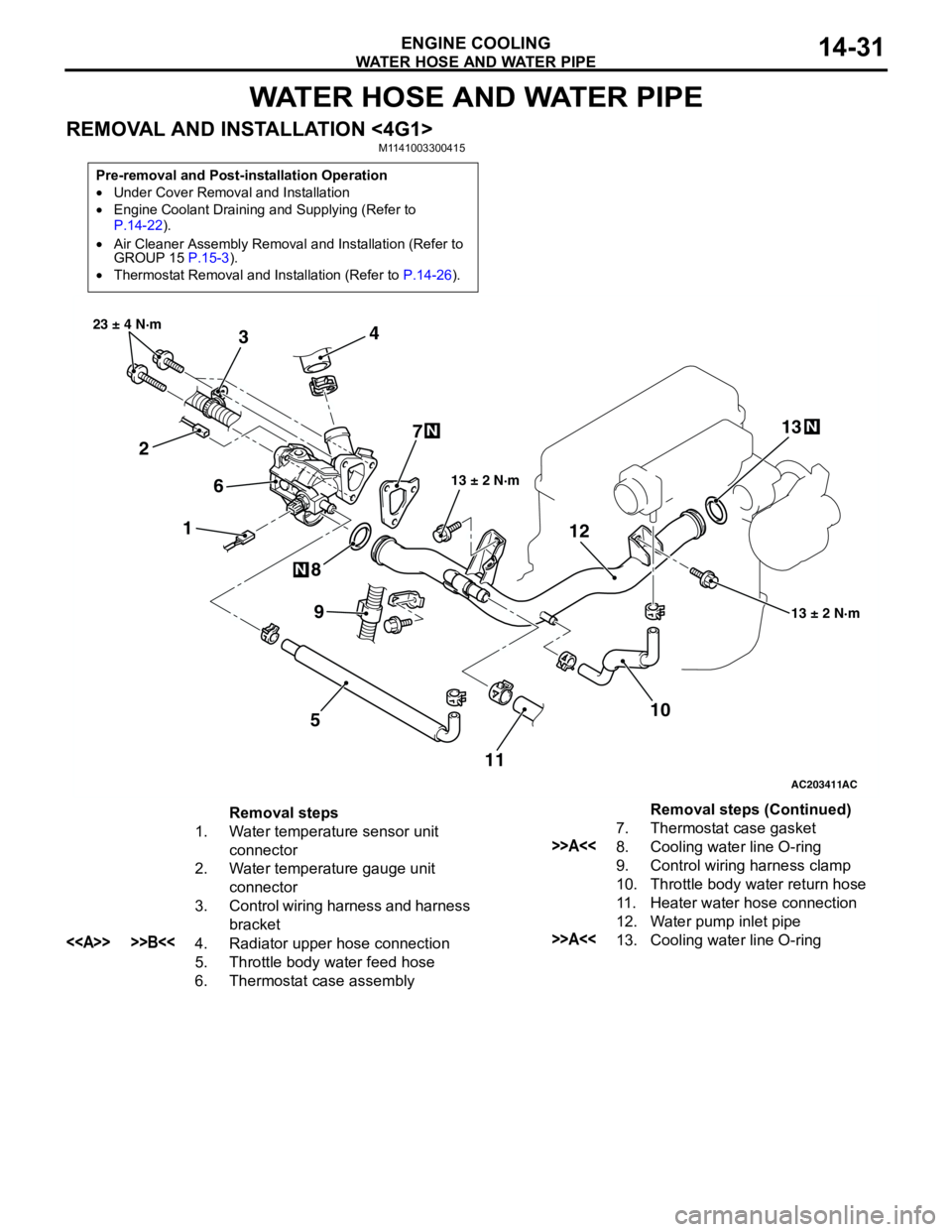

REMOVAL AND INSTALLATION <4G1>M1141003300415

Pre-removal and Post-installation Operation

•Under Cover Removal and Installation

•Engine Coolant Draining and Supplying (Refer to

P.14-22).

•Air Cleaner Assembly Removal and Installation (Refer to

GROUP 15 P.15-3).

•Thermostat Removal and Installation (Refer to P.14-26).

AC203411

1 234

5 67

8

10 9

13 ± 2 N·m 23 ± 4 N·m

13 ± 2 N·m

N

N

AC

111213

N

Removal steps

1. Water temperature sensor unit

connector

2. Water temperature gauge unit

connector

3. Control wiring harness and harness

bracket

<> >>B<<4. Radiator upper hose connection

5. Throttle body water feed hose

6. Thermostat case assembly7. Thermostat case gasket

>>A<<8. Cooling water line O-ring

9. Control wiring harness clamp

10. Throttle body water return hose

11. Heater water hose connection

12. Water pump inlet pipe

>>A<<13. Cooling water line O-ringRemoval steps (Continued)

Page 47 of 788

WATER HOSE AND WATER PIPE

ENGINE COOLING14-33

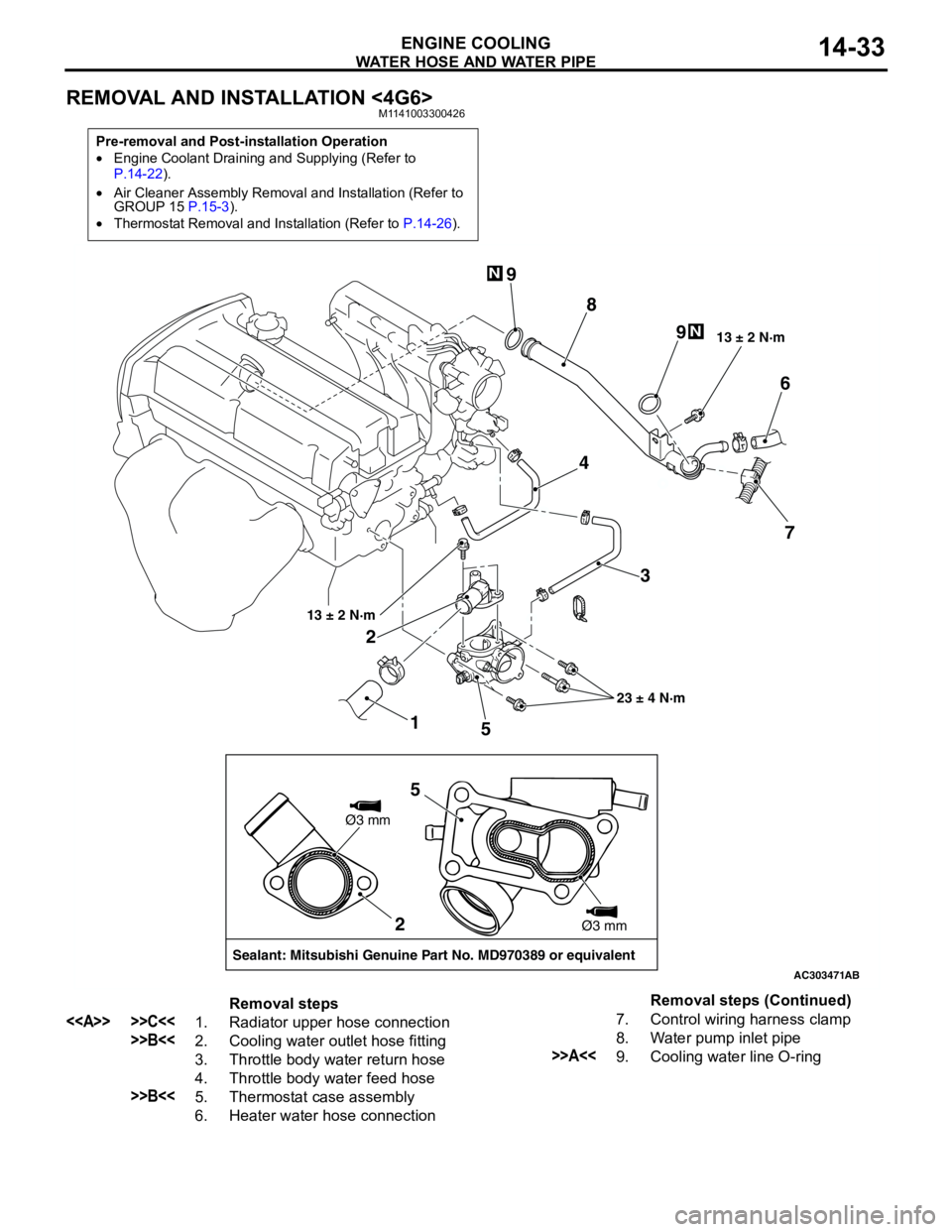

REMOVAL AND INSTALLATION <4G6>M1141003300426

Pre-removal and Post-installation Operation

•Engine Coolant Draining and Supplying (Refer to

P.14-22).

•Air Cleaner Assembly Removal and Installation (Refer to

GROUP 15 P.15-3).

•Thermostat Removal and Installation (Refer to P.14-26).

AC303471

1 23 4

56

7 8 9

9

13 ± 2 N·m

23 ± 4 N·m 13 ± 2 N·m

N

N

AB

2

Sealant: Mitsubishi Genuine Part No. MD970389 or equivalentØ3 mm

Ø3 mm

5

Removal steps

<> >>C<<1. Radiator upper hose connection

>>B<<2. Cooling water outlet hose fitting

3. Throttle body water return hose

4. Throttle body water feed hose

>>B<<5. Thermostat case assembly

6. Heater water hose connection7. Control wiring harness clamp

8. Water pump inlet pipe

>>A<<9. Cooling water line O-ringRemoval steps (Continued)

Page 70 of 788

CHARGING SYSTEM

ENGINE ELECTRICAL16-6

7. Connect a tachometer or the MUT-II/III (Refer to

GROUP 11A − On-vehicle Service − Idle speed

check <4G1> P.11A-11 or GROUP 11C −

On-vehicle Service − Idle speed check <4G6>

P.11C-11).

8. Leave the hood open.

9. Check that the reading on the voltmeter is equal

to the battery voltage.

NOTE: If the voltage is 0 V, the cause is probably

an open circuit in the wire or fusible link between

the alternator "B" terminal and the battery (+)

terminal.

10.Turn the light switch on to turn on headlamps and

then start the engine.

11.Immediately after setting the headlamps to high

beam and turning the heater blower switch to the

high revolution position, increase the engine

speed to 2,500 r/min and read the maximum

current output value displayed on the ammeter.

Limit: 70 % of normal current outputNOTE: .

•For the nominal current output, refer to the

Alternator Specifications.

•Because the current from the battery will soon

drop after the engine is started, the above step

should be carried out as quickly as possible in

order to obtain the maximum current output

value.

•The current output value will depend on the

electrical load and the temperature of the

alternator body.

•If the electrical load is small while testing, the

specified level of current may not be output

even though the alternator is normal. In such

cases, increase the electrical load by leaving

the headlamps turned on for some time to

discharge the battery or by using the lighting

system in another vehicle, and then test again.

•The specified level of current also may not be

output if the temperature of the alternator body

or the ambient temperature is too high. In such

cases, cool the alternator and then test again.

12.The reading on the ammeter should be above the

limit value. If the reading is below the limit value

and the alternator output wire is normal, remove

the alternator from the engine and check the

alternator.

13.Run the engine at idle after the test.

14.Turn the ignition switch to the "LOCK" (OFF)

position.

15.Remove the tachometer or the MUT-II/III.

16.Disconnect the negative battery cable.

17.Disconnect the ammeter and voltmeter.

18.Connect the negative battery cable.

Page 374 of 788

DOOR MIRROR

EXTERIOR51-36

DOOR MIRROR

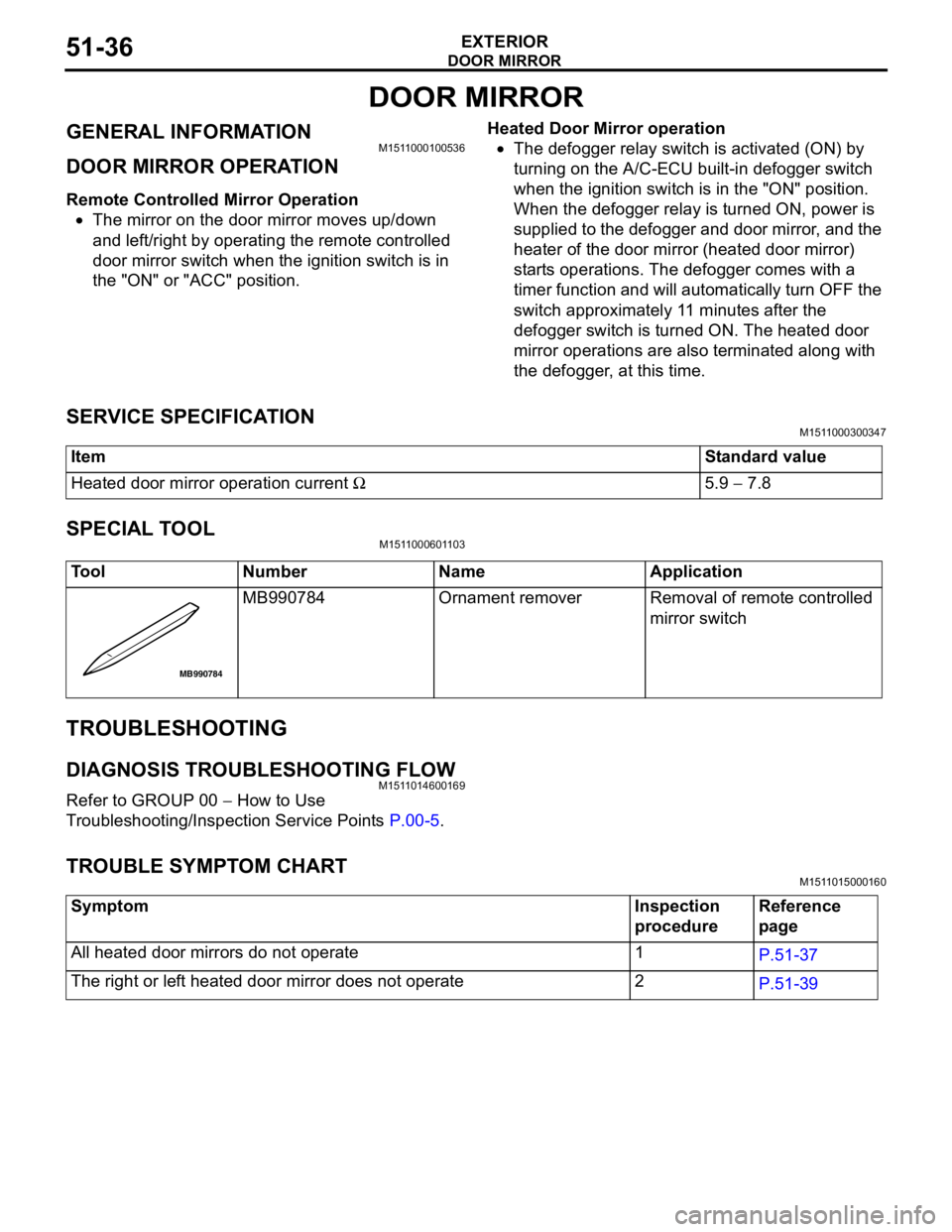

GENERAL INFORMATIONM1511000100536

DOOR MIRROR OPERATION

Remote Controlled Mirror Operation

•The mirror on the door mirror moves up/down

and left/right by operating the remote controlled

door mirror switch when the ignition switch is in

the "ON" or "ACC" position.Heated Door Mirror operation

•The defogger relay switch is activated (ON) by

turning on the A/C-ECU built-in defogger switch

when the ignition switch is in the "ON" position.

When the defogger relay is turned ON, power is

supplied to the defogger and door mirror, and the

heater of the door mirror (heated door mirror)

starts operations. The defogger comes with a

timer function and will automatically turn OFF the

switch approximately 11 minutes after the

defogger switch is turned ON. The heated door

mirror operations are also terminated along with

the defogger, at this time.

SERVICE SPECIFICATIONM1511000300347

SPECIAL TOOLM1511000601103

TROUBLESHOOTING

DIAGNOSIS TROUBLESHOOTING FLOWM1511014600169

Refer to GROUP 00 − How to Use

Troubleshooting/Inspection Service Points P.00-5.

TROUBLE SYMPTOM CHARTM1511015000160

ItemStandard value

Heated door mirror operation current Ω5.9 − 7.8

Tool Number Name Application

MB990784 Ornament remover Removal of remote controlled

mirror switch

MB990784

Symptom Inspection

procedureReference

page

All heated door mirrors do not operate 1

P.51-37

The right or left heated door mirror does not operate 2

P.51-39

Page 375 of 788

DOOR MIRROR

EXTERIOR51-37

SYMPTOM PROCEDURES

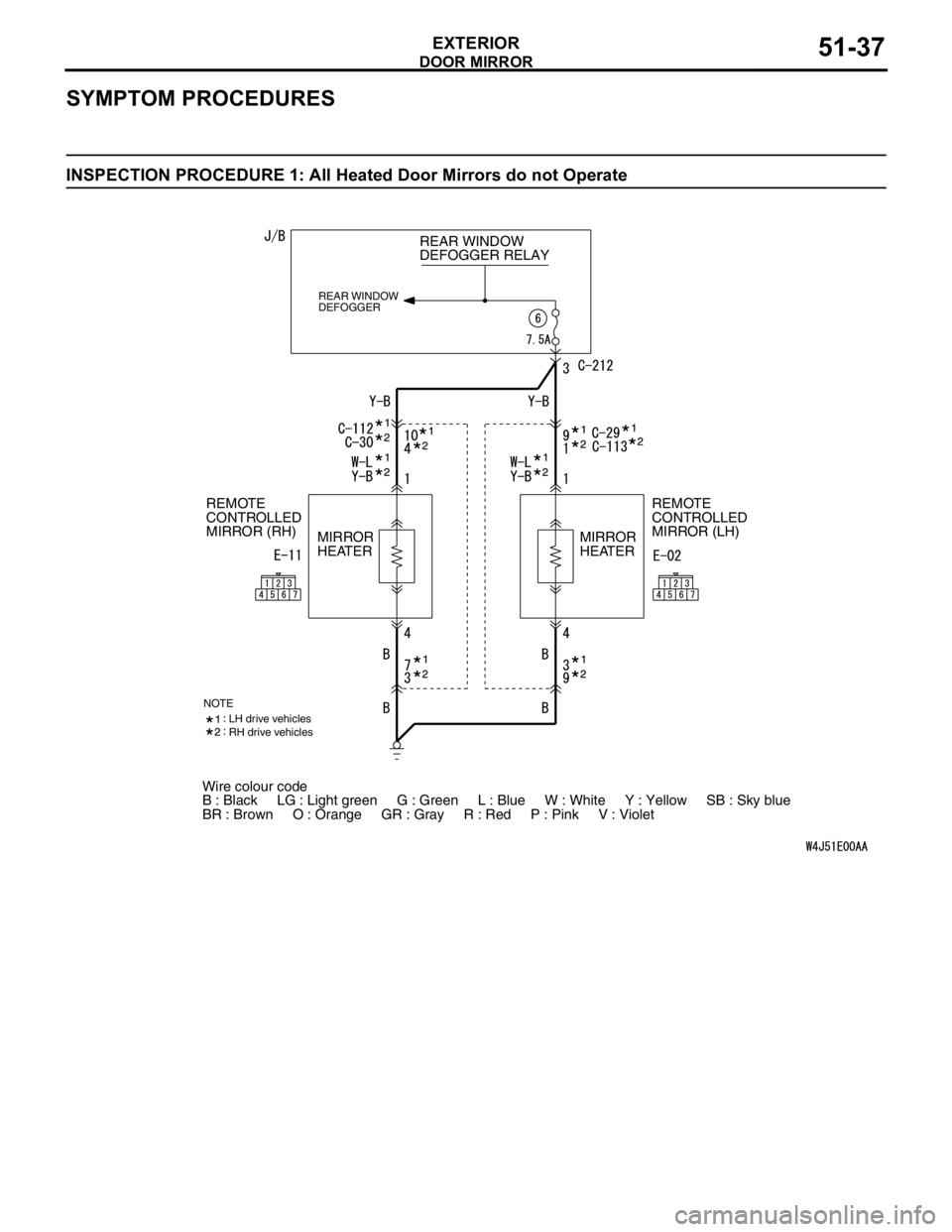

INSPECTION PROCEDURE 1: All Heated Door Mirrors do not Operate

Wire colour code

B : Black LG : Light green G : Green L : Blue W : White Y : Yellow SB : Sky blue

BR : Brown O : Orange GR : Gray R : Red P : Pink V : Violet REAR WINDOW

DEFOGGER RELAY

REAR WINDOW

DEFOGGER

REMOTE

CONTROLLED

MIRROR (LH) REMOTE

CONTROLLED

MIRROR (RH)

MIRROR

HEATERMIRROR

HEATER

NOTELH drive vehicles

RH drive vehicles

Page 376 of 788

DOOR MIRROR

EXTERIOR51-38

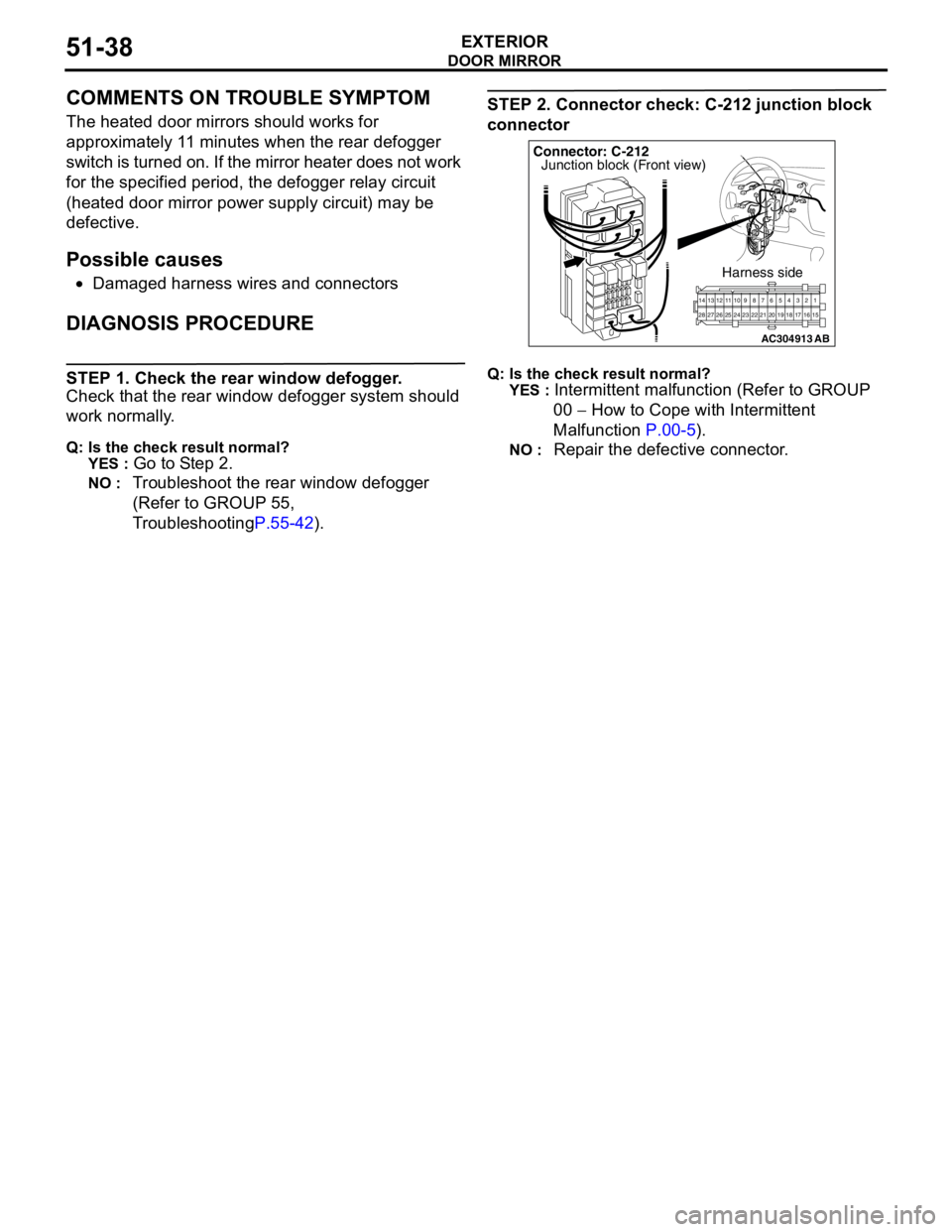

COMMENTS ON TROUBLE SYMPTOM

The heated door mirrors should works for

approximately 11 minutes when the rear defogger

switch is turned on. If the mirror heater does not work

for the specified period, the defogger relay circuit

(heated door mirror power supply circuit) may be

defective.

Possible causes

•Damaged harness wires and connectors

DIAGNOSIS PROCEDURE

STEP 1. Check the rear window defogger.

Check that the rear window defogger system should

work normally.

Q: Is the check result normal?

YES :

Go to Step 2.

NO : Troubleshoot the rear window defogger

(Refer to GROUP 55,

TroubleshootingP.55-42).

STEP 2. Connector check: C-212 junction block

connector

Q: Is the check result normal?

YES :

Intermittent malfunction (Refer to GROUP

00 − How to Cope with Intermittent

Malfunction P.00-5).

NO : Repair the defective connector.

AC304913

21716151718 201912345 623 222425282627981011141213

Connector: C-212

Harness side

AB

Junction block (Front view)

Page 377 of 788

DOOR MIRROR

EXTERIOR51-39

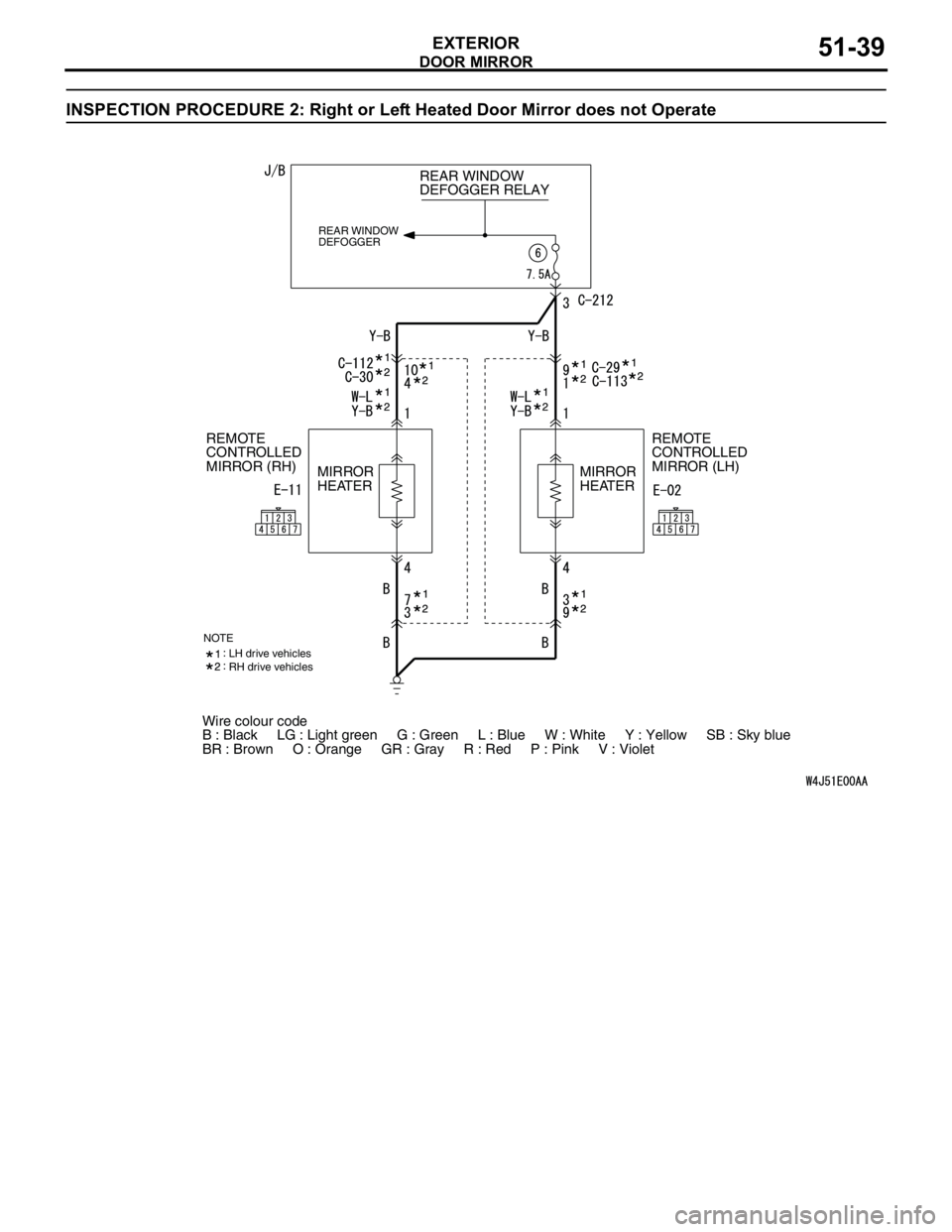

INSPECTION PROCEDURE 2: Right or Left Heated Door Mirror does not Operate

Wire colour code

B : Black LG : Light green G : Green L : Blue W : White Y : Yellow SB : Sky blue

BR : Brown O : Orange GR : Gray R : Red P : Pink V : Violet REAR WINDOW

DEFOGGER RELAY

REAR WINDOW

DEFOGGER

REMOTE

CONTROLLED

MIRROR (LH) REMOTE

CONTROLLED

MIRROR (RH)

MIRROR

HEATERMIRROR

HEATER

NOTELH drive vehicles

RH drive vehicles

Page 378 of 788

DOOR MIRROR

EXTERIOR51-40

COMMENTS ON TROUBLE SYMPTOM

If either of the heated door mirrors does not work, the

door mirror assembly may be defective.

Possible causes

•Malfunction of the door mirror assembly

•Damaged harness wires and connectors

DIAGNOSIS PROCEDURE

Step 1. Verify the operation of each heated door

mirror.

Q: Which door mirror does not heat?

Door mirror (RH) :

Go to Step 2.

Door mirror (LH) : Go to Step 9.

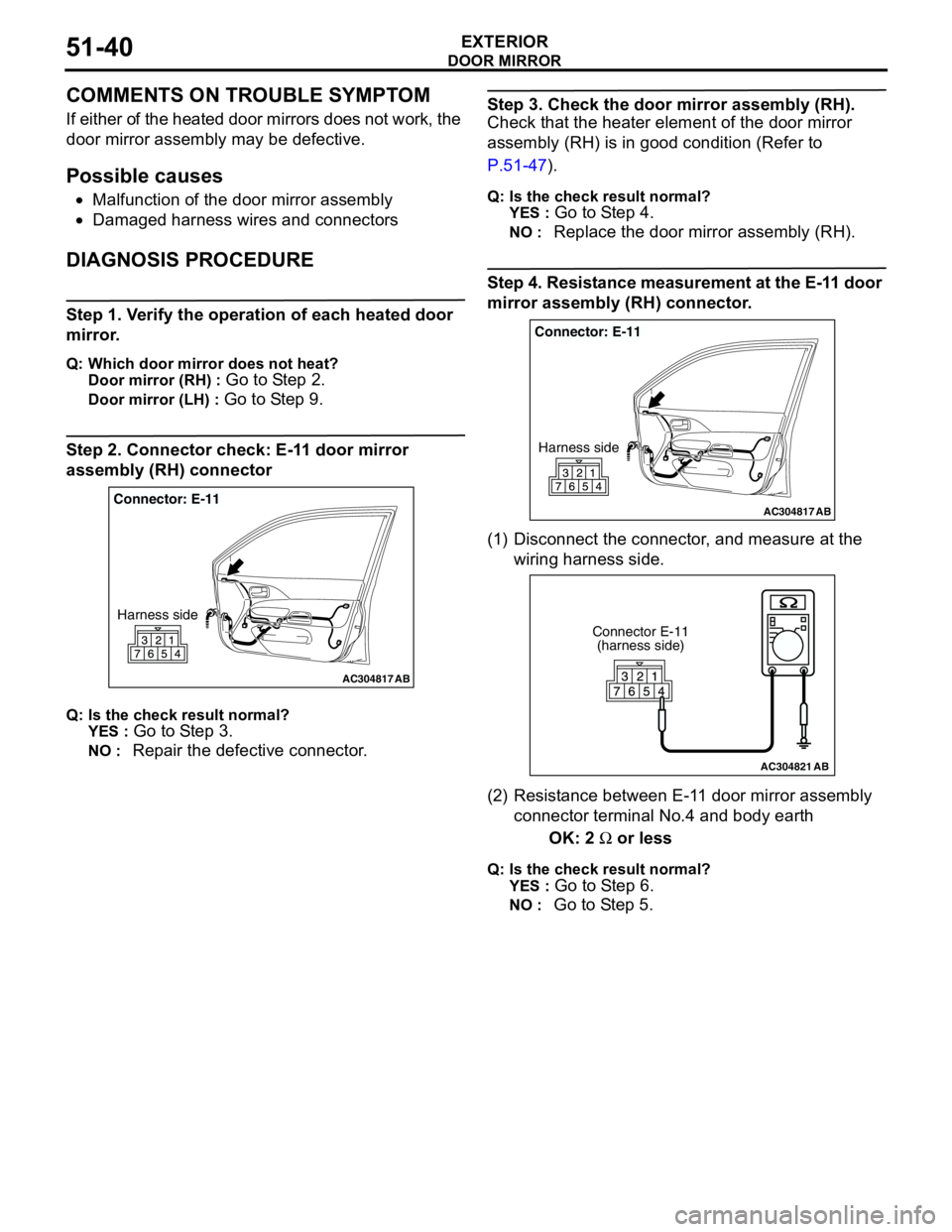

Step 2. Connector check: E-11 door mirror

assembly (RH) connector

Q: Is the check result normal?

YES :

Go to Step 3.

NO : Repair the defective connector.

Step 3. Check the door mirror assembly (RH).

Check that the heater element of the door mirror

assembly (RH) is in good condition (Refer to

P.51-47).

Q: Is the check result normal?

YES :

Go to Step 4.

NO : Replace the door mirror assembly (RH).

Step 4. Resistance measurement at the E-11 door

mirror assembly (RH) connector.

(1) Disconnect the connector, and measure at the

wiring harness side.

(2) Resistance between E-11 door mirror assembly

connector terminal No.4 and body earth

OK: 2 Ω or less

Q: Is the check result normal?

YES :

Go to Step 6.

NO : Go to Step 5.

AC304817

Connector: E-11

Harness side

AB

AC304817

Connector: E-11

Harness side

AB

AC304821

Connector E-11

(harness side)

AB