heater MITSUBISHI LANCER 2005 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 380 of 788

DOOR MIRROR

EXTERIOR51-42

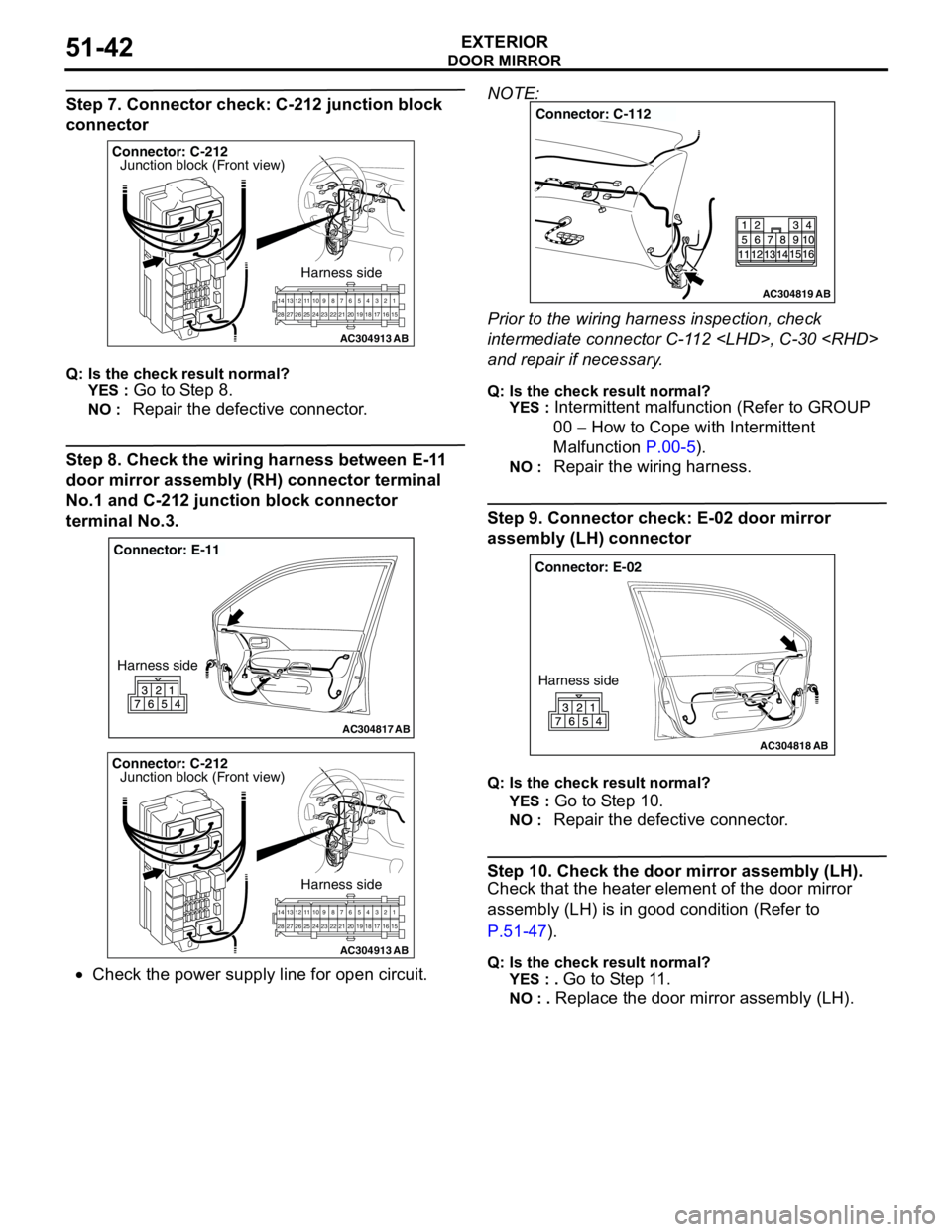

Step 7. Connector check: C-212 junction block

connector

Q: Is the check result normal?

YES :

Go to Step 8.

NO : Repair the defective connector.

Step 8. Check the wiring harness between E-11

door mirror assembly (RH) connector terminal

No.1 and C-212 junction block connector

terminal No.3.

•Check the power supply line for open circuit.NOTE:

Prior to the wiring harness inspection, check

intermediate connector C-112

and repair if necessary.

Q: Is the check result normal?

YES :

Intermittent malfunction (Refer to GROUP

00 − How to Cope with Intermittent

Malfunction P.00-5).

NO : Repair the wiring harness.

Step 9. Connector check: E-02 door mirror

assembly (LH) connector

Q: Is the check result normal?

YES :

Go to Step 10.

NO : Repair the defective connector.

Step 10. Check the door mirror assembly (LH).

Check that the heater element of the door mirror

assembly (LH) is in good condition (Refer to

P.51-47).

Q: Is the check result normal?

YES : .

Go to Step 11.

NO : . Replace the door mirror assembly (LH).

AC304913

21716151718 201912345 623 222425282627981011141213

Connector: C-212

Harness side

AB

Junction block (Front view)

AC304817

Connector: E-11

Harness side

AB

AC304913

21716151718 201912345 623 222425282627981011141213

Connector: C-212

Harness side

AB

Junction block (Front view)

AC304819

Connector: C-112

AB

AC304818

Connector: E-02

Harness side

AB

Page 391 of 788

54A-3

REAR COMBINATION

LAMP . . . . . . . . . . . . . . . . . . . . .

54A-79

TROUBLESHOOTING . . . . . . . . . .

54A-79

SPECIAL TOOL . . . . . . . . . . . . . . .54A-79

REAR COMBINATION LAMP . . . .54A-79

REMOVAL AND INSTALLATION . . . . . 54A-79

HIGH-MOUNTED

STOP LAMP. . . . . . . . . . . . . . . .

54A-80

ON-VEHICLE SERVICE. . . . . . . . .

54A-80

HIGH-MOUNTED STOP LAMP BULB

REPLACEMENT

HIGH-MOUNTED STOP LAMP . . .54A-81

REMOVAL AND INSTALLATION . . . . . 54A-81

LICENCE PLATE LAMP . . . . . .54A-84

REMOVAL AND INSTALLATION .

54A-84

HAZARD WARNING LAMP

SWITCH . . . . . . . . . . . . . . . . . . .

54A-85

TROUBLESHOOTING . . . . . . . . . .

54A-85

SPECIAL TOOL . . . . . . . . . . . . . . .54A-85

HAZARD WARNING LAMP SWITCH54A-86

REMOVAL AND INSTALLATION . . . . . 54A-86

INSPECTION . . . . . . . . . . . . . . . . . . . . . 54A-86

COLUMN SWITCH. . . . . . . . . . .54A-87

SPECIAL TOOL . . . . . . . . . . . . . . .

54A-87

COLUMN SWITCH. . . . . . . . . . . . .54A-87

REMOVAL AND INSTALLATION . . . . . 54A-87

INSPECTION . . . . . . . . . . . . . . . . . . . . . 54A-88

HORN . . . . . . . . . . . . . . . . . . . . 54A-89

REMOVAL AND INSTALLATION . . . . . . 54A-89

HORN RELAY CONTINUITY CHECK . . 54A-89

CLOCK . . . . . . . . . . . . . . . . . . . 54A-90

SPECIAL TOOL . . . . . . . . . . . . . . .

54A-90

CLOCK . . . . . . . . . . . . . . . . . . . . . .54A-90

REMOVAL AND INSTALLATION . . . . . . 54A-90

CIGARETTE LIGHTER . . . . . . 54A-91

INSPECTION . . . . . . . . . . . . . . . . . . . . . 54A-91

RHEOSTAT . . . . . . . . . . . . . . . 54A-91

REMOVAL AND INSTALLATION . . . . . . 54A-91

INSPECTION . . . . . . . . . . . . . . . . . . . . . 54A-92

SPEAKER. . . . . . . . . . . . . . . . . 54A-93

REMOVAL AND INSTALLATION . . . . . . 54A-93

ANTENNA . . . . . . . . . . . . . . . . 54A-94

REMOVAL AND INSTALLATION . . . . . . 54A-94

REAR WINDOW

DEFOGGER . . . . . . . . . . . . . . .

54A-95

GENERAL INFORMATION . . . . . .

54A-95

TROUBLESHOOTING . . . . . . . . . .54A-95

ON-VEHICLE SERVICE . . . . . . . . .54A-96

PRINTED HEATER LINES CHECK . . . . 54A-96

REAR WINDOW DEFOGGER

SWITCH . . . . . . . . . . . . . . . . . . . . .

54A-96

REMOVAL AND INSTALLATION . . . . . . 54A-96

INSPECTION . . . . . . . . . . . . . . . . . . . . . 54A-96

Page 484 of 788

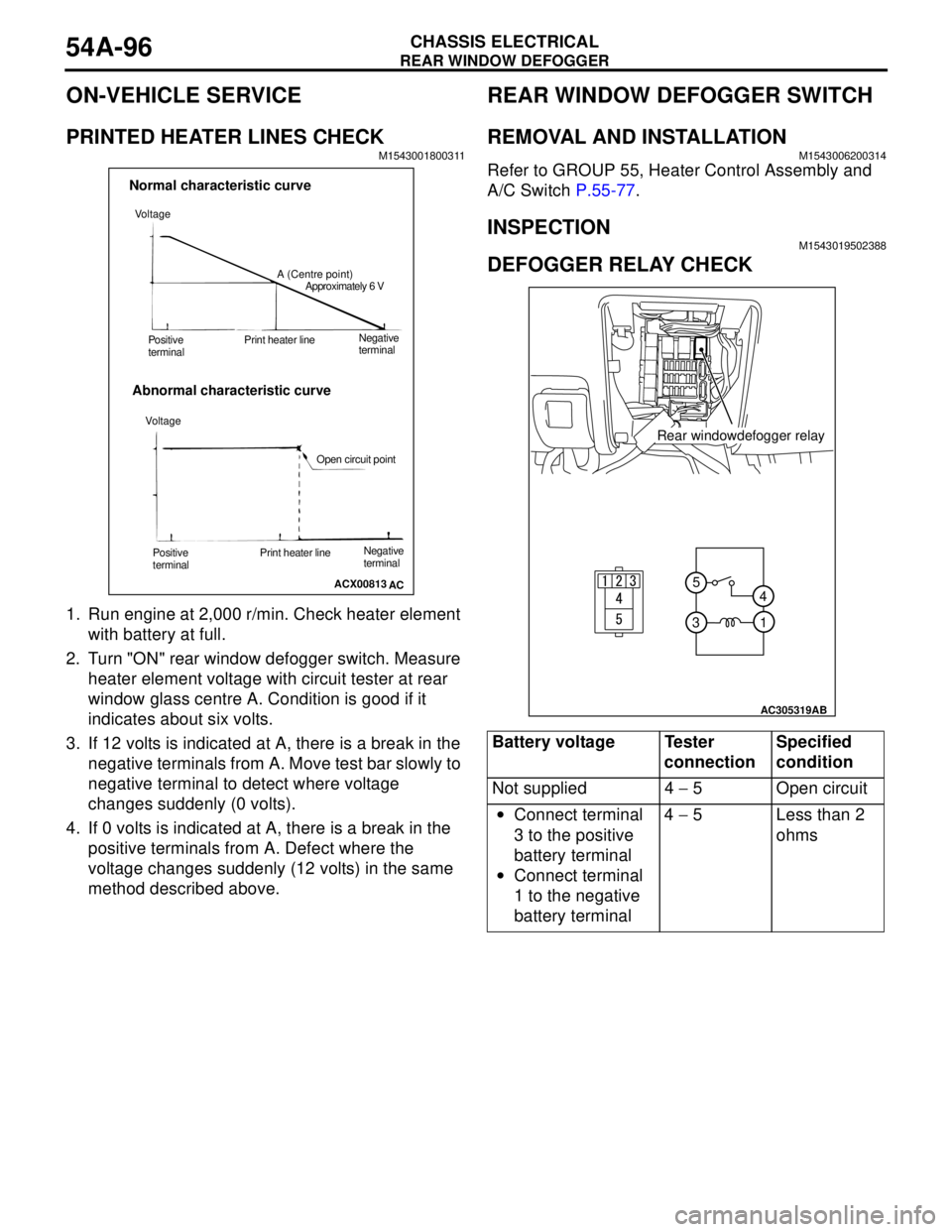

REAR WINDOW DEFOGGER

CHASSIS ELECTRICAL54A-96

ON-VEHICLE SERVICE

PRINTED HEATER LINES CHECKM1543001800311

1. Run engine at 2,000 r/min. Check heater element

with battery at full.

2. Turn "ON" rear window defogger switch. Measure

heater element voltage with circuit tester at rear

window glass centre A. Condition is good if it

indicates about six volts.

3. If 12 volts is indicated at A, there is a break in the

negative terminals from A. Move test bar slowly to

negative terminal to detect where voltage

changes suddenly (0 volts).

4. If 0 volts is indicated at A, there is a break in the

positive terminals from A. Defect where the

voltage changes suddenly (12 volts) in the same

method described above.

REAR WINDOW DEFOGGER SWITCH

REMOVAL AND INSTALLATIONM1543006200314

Refer to GROUP 55, Heater Control Assembly and

A/C Switch P.55-77.

INSPECTIONM1543019502388

DEFOGGER RELAY CHECK

ACX00813

Normal characteristic curve

Abnormal characteristic curve

A (Centre point)

Approximately 6 V

Negative

terminal Print heater line

Positive

terminal

Open circuit point Voltage

AC Voltage

Negative

terminal Print heater line

Positive

terminal

Battery voltage Tester

connectionSpecified

condition

Not supplied 4 − 5 Open circuit

•Connect terminal

3 to the positive

battery terminal

•Connect terminal

1 to the negative

battery terminal4 − 5 Less than 2

ohms

1 5

4

3

AC305319

AB

Rear windowdefogger relay

Page 485 of 788

55-1

GROUP 55

HEATER, AIR

CONDITIONER AND

VENTILATION

CONTENTS

SERVICE SPECIFICATIONS . . . . . . .55-3

LUBRICANTS . . . . . . . . . . . . . . . . . .55-3

SPECIAL TOOLS . . . . . . . . . . . . . . . .55-4

TROUBLESHOOTING . . . . . . . . . . . .55-5DIAGNOSIS TROUBLESHOOTING

FLOW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55-5

SYMPTOM CHART . . . . . . . . . . . . . . . . . . . 55-5

SYMPTOM PROCEDURES . . . . . . . . . . . . 55-5

CHECK AT ECU TERMINAL

CHECK AT ECU TERMINAL

Continued on next page

W ARNING S RE GA RDING S E RV ICIN G O F SUP P LE MEN TAL R ES TRAI NT S Y ST EM (SRS ) E Q UIP PE D VE HICL ES

I mp roper se rvi ce o r m ai nte na nce of a ny c omp onent of the SRS , or an y SRS -re la te d c om pone nt, ca n le a d to

personal injury or death to service personnel (from inadvertent firing of the air bag) or to the driver (from

re nd er ing the S RS inop er ati ve).

S e rvic e or m ai nten anc e of an y SRS com pon ent or SRS -re late d com pone nt m ust be pe rfor me d only a t an

authorized MITSUBISHI dealer.

M ITSUBISHI dealer p erso nnel must thoroughly review th is man ual, and esp ecially its GROU P 52B - Su pplemen tal

Restraint System (SR S) b efore beginn ing an y service o r maintenance of any comp onent of th e SRS or any SRS-

rel ated com ponent.

NOTE

The SRS includes the following components: front impact sens ors , SRS-ECU, SRS warning lamp, air bag module, c lock spring

and interconnecting wiring. Other SRS-related components (that may have to be remov ed/installed in connection with SRS

service or maintenance) are indicated in the table of c ontents by an asterisk (*).

Page 486 of 788

55-2

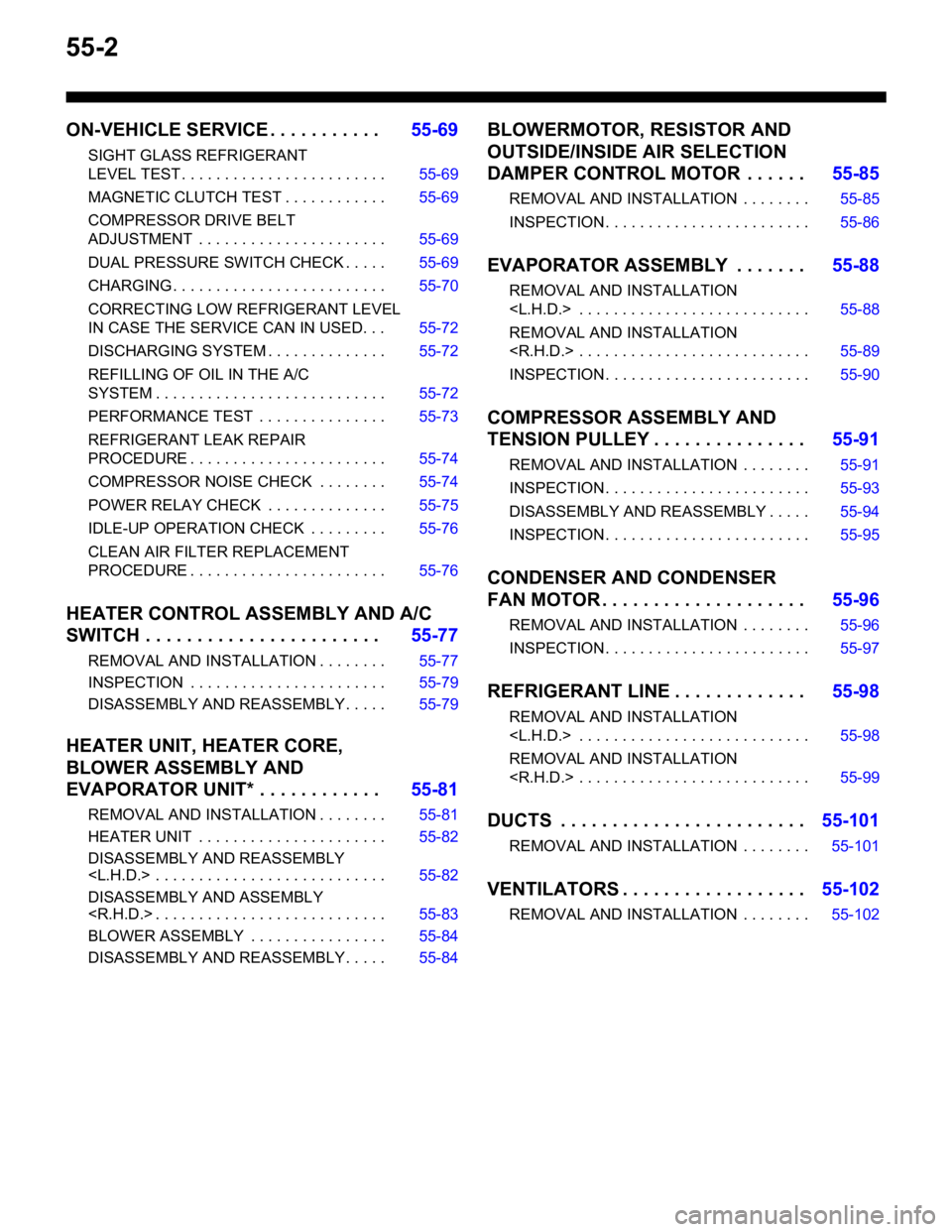

ON-VEHICLE SERVICE . . . . . . . . . . .55-69

SIGHT GLASS REFRIGERANT

LEVEL TEST . . . . . . . . . . . . . . . . . . . . . . . . 55-69

MAGNETIC CLUTCH TEST . . . . . . . . . . . . 55-69

COMPRESSOR DRIVE BELT

ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . 55-69

DUAL PRESSURE SWITCH CHECK . . . . . 55-69

CHARGING . . . . . . . . . . . . . . . . . . . . . . . . . 55-70

CORRECTING LOW REFRIGERANT LEVEL

IN CASE THE SERVICE CAN IN USED. . . 55-72

DISCHARGING SYSTEM . . . . . . . . . . . . . . 55-72

REFILLING OF OIL IN THE A/C

SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . 55-72

PERFORMANCE TEST . . . . . . . . . . . . . . . 55-73

REFRIGERANT LEAK REPAIR

PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . 55-74

COMPRESSOR NOISE CHECK . . . . . . . . 55-74

POWER RELAY CHECK . . . . . . . . . . . . . . 55-75

IDLE-UP OPERATION CHECK . . . . . . . . . 55-76

CLEAN AIR FILTER REPLACEMENT

PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . 55-76

HEATER CONTROL ASSEMBLY AND A/C

SWITCH . . . . . . . . . . . . . . . . . . . . . . .55-77

REMOVAL AND INSTALLATION . . . . . . . . 55-77

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . 55-79

DISASSEMBLY AND REASSEMBLY . . . . . 55-79

HEATER UNIT, HEATER CORE,

BLOWER ASSEMBLY AND

EVAPORATOR UNIT* . . . . . . . . . . . .55-81

REMOVAL AND INSTALLATION . . . . . . . . 55-81

HEATER UNIT . . . . . . . . . . . . . . . . . . . . . . 55-82

DISASSEMBLY AND REASSEMBLY

DISASSEMBLY AND ASSEMBLY

BLOWER ASSEMBLY . . . . . . . . . . . . . . . . 55-84

DISASSEMBLY AND REASSEMBLY . . . . . 55-84

BLOWERMOTOR, RESISTOR AND

OUTSIDE/INSIDE AIR SELECTION

DAMPER CONTROL MOTOR . . . . . .55-85

REMOVAL AND INSTALLATION . . . . . . . . 55-85

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 55-86

EVAPORATOR ASSEMBLY . . . . . . .55-88

REMOVAL AND INSTALLATION

REMOVAL AND INSTALLATION

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 55-90

COMPRESSOR ASSEMBLY AND

TENSION PULLEY . . . . . . . . . . . . . . .55-91

REMOVAL AND INSTALLATION . . . . . . . . 55-91

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 55-93

DISASSEMBLY AND REASSEMBLY . . . . . 55-94

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 55-95

CONDENSER AND CONDENSER

FAN MOTOR . . . . . . . . . . . . . . . . . . . .55-96

REMOVAL AND INSTALLATION . . . . . . . . 55-96

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 55-97

REFRIGERANT LINE . . . . . . . . . . . . .55-98

REMOVAL AND INSTALLATION

REMOVAL AND INSTALLATION

DUCTS . . . . . . . . . . . . . . . . . . . . . . . .55-101

REMOVAL AND INSTALLATION . . . . . . . . 55-101

VENTILATORS . . . . . . . . . . . . . . . . . .55-102

REMOVAL AND INSTALLATION . . . . . . . . 55-102

Page 487 of 788

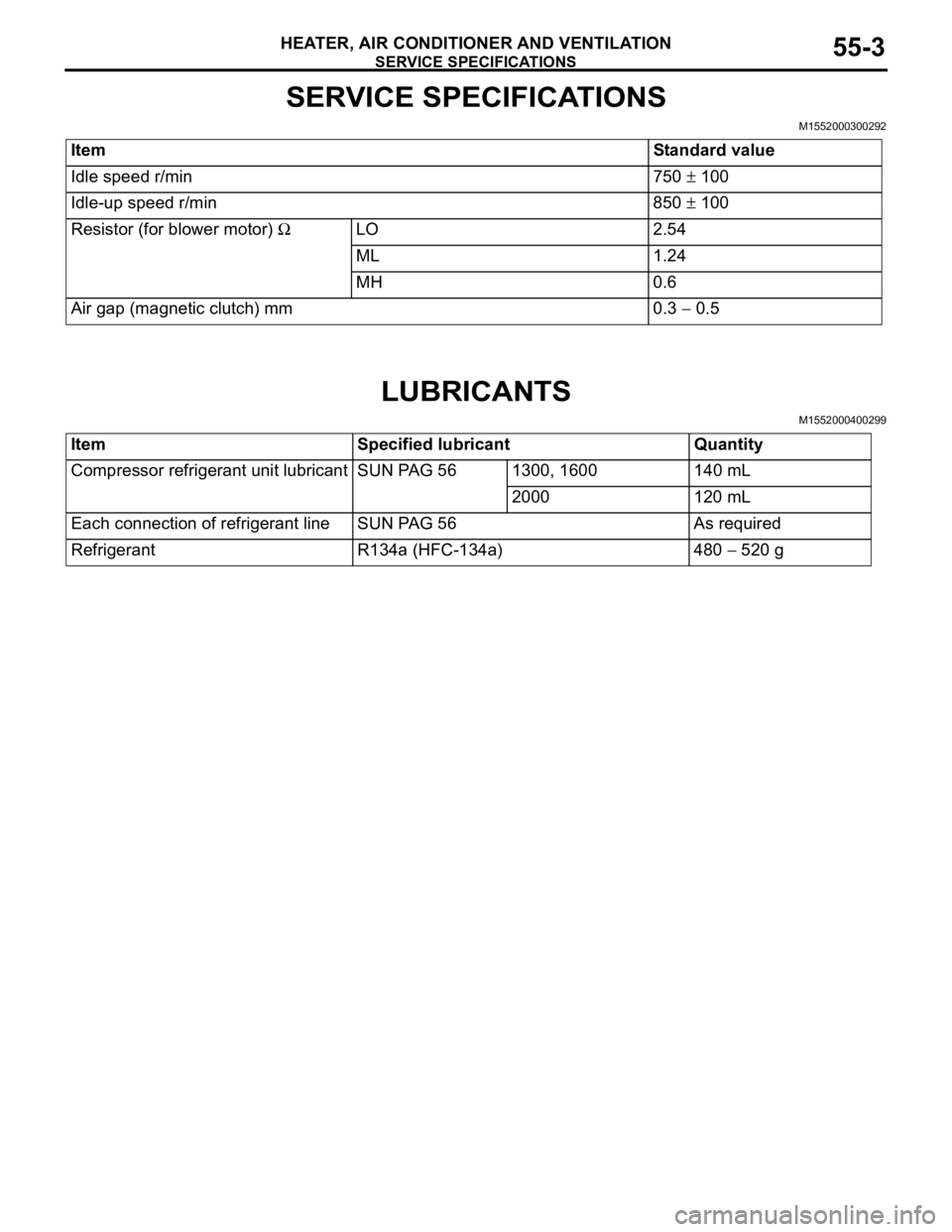

SERVICE SPECIFICATIONS

HEATER, AIR CONDITIONER AND VENTILATION55-3

SERVICE SPECIFICATIONS

M1552000300292

LUBRICANTS

M1552000400299

ItemStandard value

Idle speed r/min 750 ± 100

Idle-up speed r/min 850 ± 100

Resistor (for blower motor) ΩLO 2.54

ML 1.24

MH 0.6

Air gap (magnetic clutch) mm 0.3 − 0.5

Item Specified lubricant Quantity

Compressor refrigerant unit lubricant SUN PAG 56 1300, 1600 140 mL

2000 120 mL

Each connection of refrigerant line SUN PAG 56 As required

Refrigerant R134a (HFC-134a) 480 − 520 g

Page 488 of 788

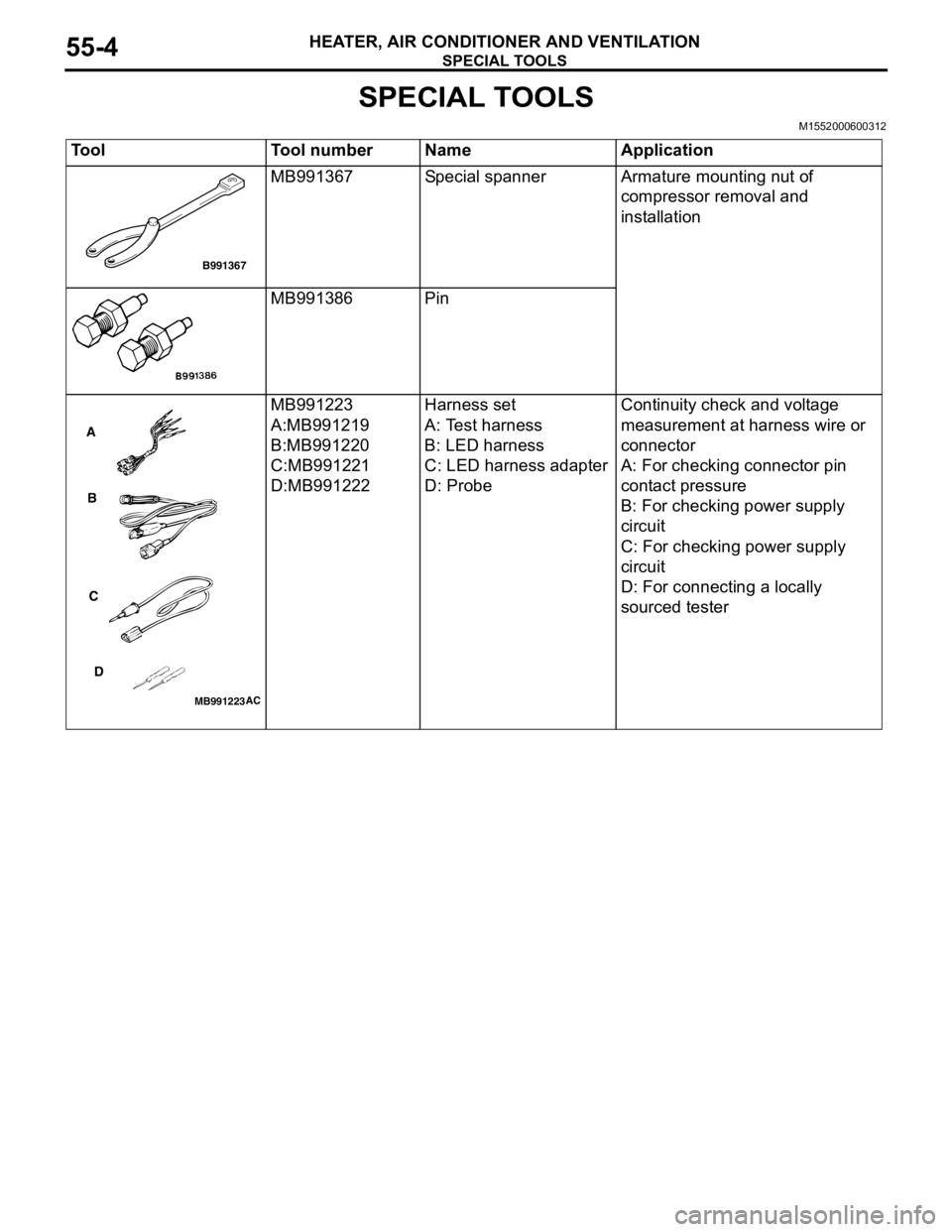

SPECIAL TOOLS

HEATER, AIR CONDITIONER AND VENTILATION55-4

SPECIAL TOOLS

M1552000600312

Tool Tool number Name Application

MB991367 Special spanner Armature mounting nut of

compressor removal and

installation

MB991386 Pin

MB991223

A:MB991219

B:MB991220

C:MB991221

D:MB991222Harness set

A: Test harness

B: LED harness

C: LED harness adapter

D: ProbeContinuity check and voltage

measurement at harness wire or

connector

A: For checking connector pin

contact pressure

B: For checking power supply

circuit

C: For checking power supply

circuit

D: For connecting a locally

sourced tester

B991367

MB991223

A

B

C

D

AC

Page 489 of 788

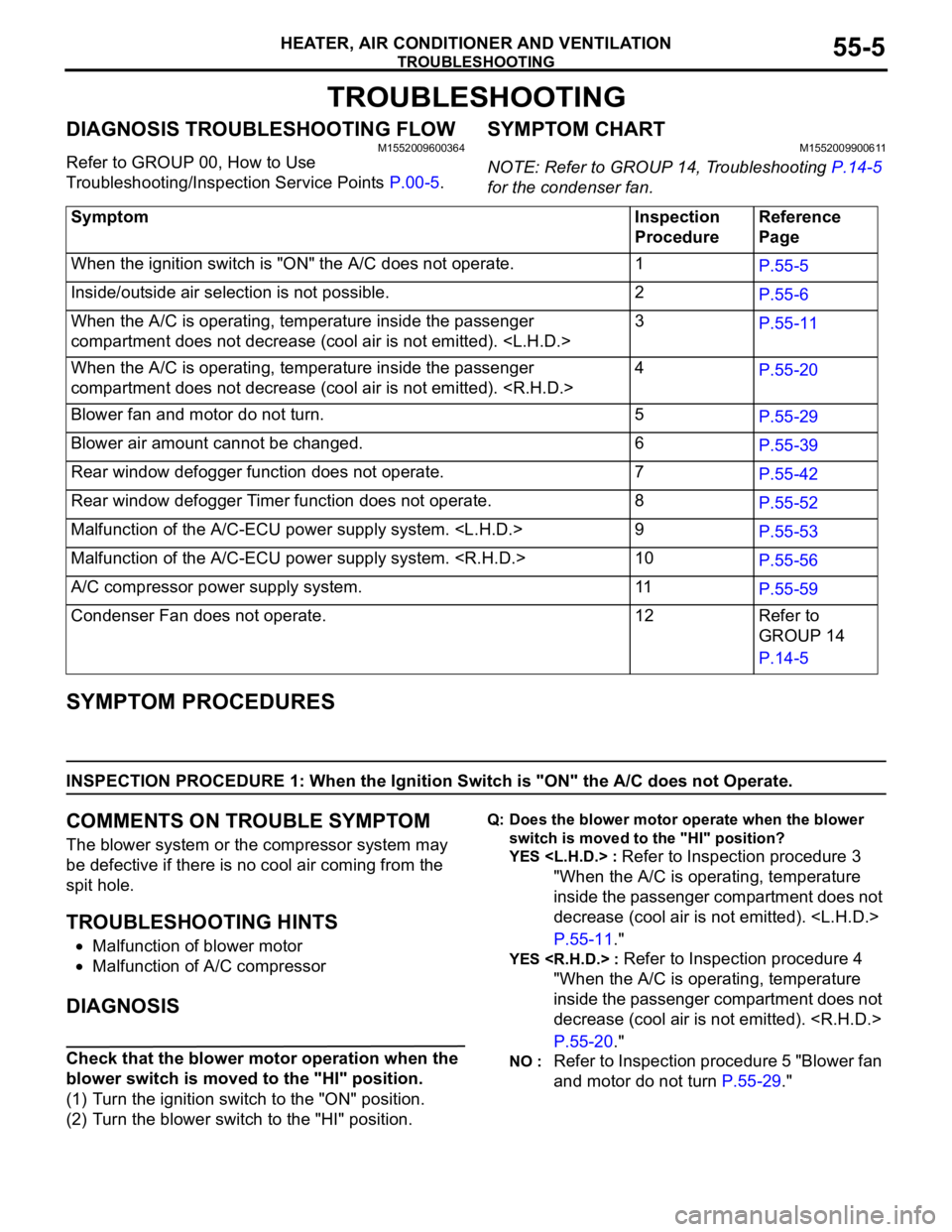

TROUBLESHOOTING

HEATER, AIR CONDITIONER AND VENTILATION55-5

TROUBLESHOOTING

DIAGNOSIS TROUBLESHOOTING FLOWM1552009600364

Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points P.00-5.

SYMPTOM CHARTM1552009900611

NOTE: Refer to GROUP 14, Troubleshooting P.14-5

for the condenser fan.

SYMPTOM PROCEDURES

INSPECTION PROCEDURE 1: When the Ignition Switch is "ON" the A/C does not Operate.

COMMENTS ON TROUBLE SYMPTOM

The blower system or the compressor system may

be defective if there is no cool air coming from the

spit hole.

TROUBLESHOOTING HINTS

•Malfunction of blower motor

•Malfunction of A/C compressor

DIAGNOSIS

Check that the blower motor operation when the

blower switch is moved to the "HI" position.

(1) Turn the ignition switch to the "ON" position.

(2) Turn the blower switch to the "HI" position.

Q: Does the blower motor operate when the blower

switch is moved to the "HI" position?

YES

Refer to Inspection procedure 3

"When the A/C is operating, temperature

inside the passenger compartment does not

decrease (cool air is not emitted).

P.55-11."

YES

"When the A/C is operating, temperature

inside the passenger compartment does not

decrease (cool air is not emitted).

P.55-20."

NO : Refer to Inspection procedure 5 "Blower fan

and motor do not turn P.55-29." Symptom Inspection

ProcedureReference

Page

When the ignition switch is "ON" the A/C does not operate. 1

P.55-5

Inside/outside air selection is not possible. 2

P.55-6

When the A/C is operating, temperature inside the passenger

compartment does not decrease (cool air is not emitted).

P.55-11

When the A/C is operating, temperature inside the passenger

compartment does not decrease (cool air is not emitted).

P.55-20

Blower fan and motor do not turn. 5

P.55-29

Blower air amount cannot be changed. 6

P.55-39

Rear window defogger function does not operate. 7

P.55-42

Rear window defogger Timer function does not operate. 8

P.55-52

Malfunction of the A/C-ECU power supply system.

P.55-53

Malfunction of the A/C-ECU power supply system.

P.55-56

A/C compressor power supply system. 11

P.55-59

Condenser Fan does not operate. 12 Refer to

GROUP 14

P.14-5

Page 490 of 788

TROUBLESHOOTING

HEATER, AIR CONDITIONER AND VENTILATION55-6

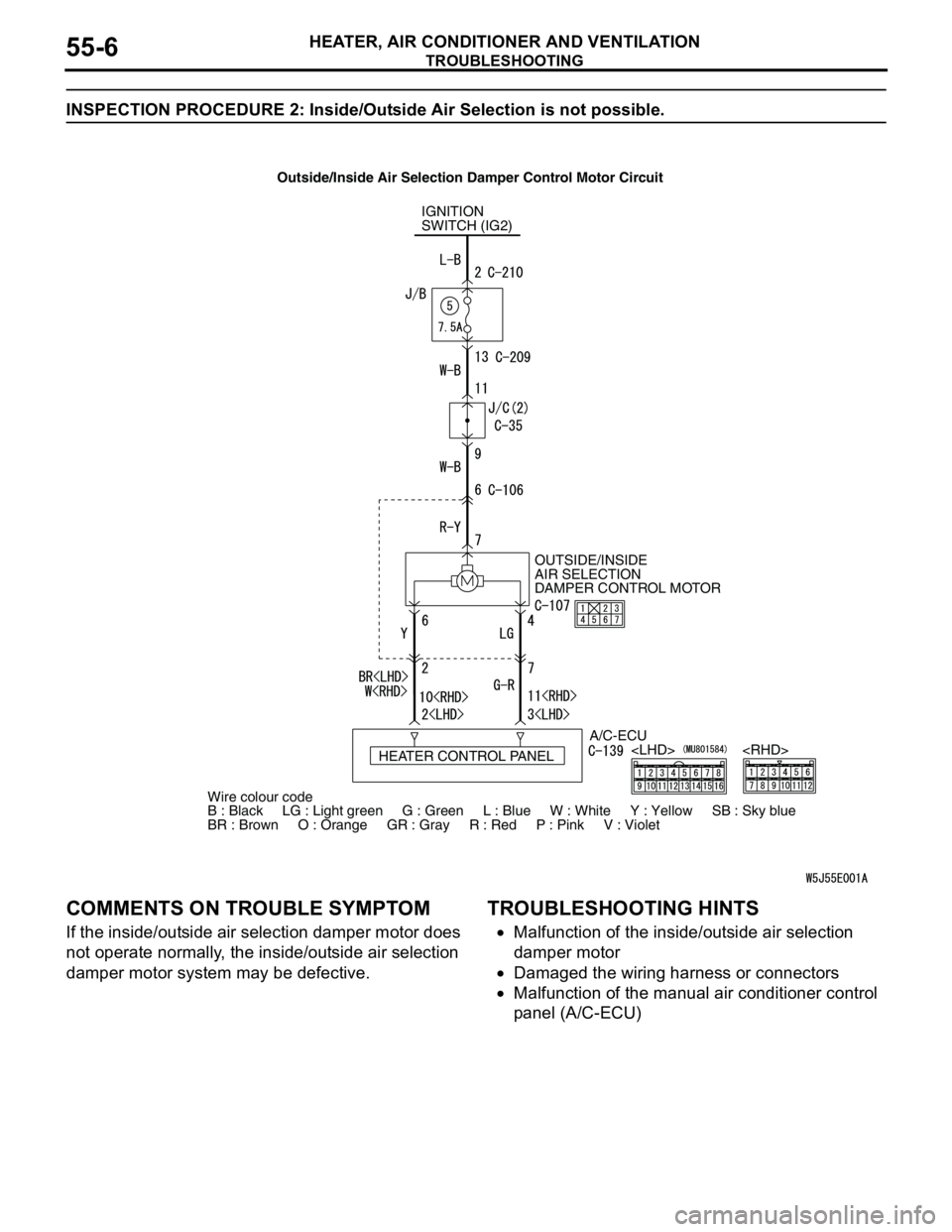

INSPECTION PROCEDURE 2: Inside/Outside Air Selection is not possible.

COMMENTS ON TROUBLE SYMPTOM

If the inside/outside air selection damper motor does

not operate normally, the inside/outside air selection

damper motor system may be defective.

TROUBLESHOOTING HINTS

•Malfunction of the inside/outside air selection

damper motor

•Damaged the wiring harness or connectors

•Malfunction of the manual air conditioner control

panel (A/C-ECU)

IGNITION

SWITCH (IG2)

OUTSIDE/INSIDE

AIR SELECTION

DAMPER CONTROL MOTOR

A/C-ECU

HEATER CONTROL PANEL

Wire colour code

B : Black LG : Light green G : Green L : Blue W : White Y : Yellow SB : Sky blue

BR : Brown O : Orange GR : Gray R : Red P : Pink V : Violet

Outside/Inside Air Selection Damper Control Motor Circuit

Page 491 of 788

TROUBLESHOOTING

HEATER, AIR CONDITIONER AND VENTILATION55-7

DIAGNOSIS

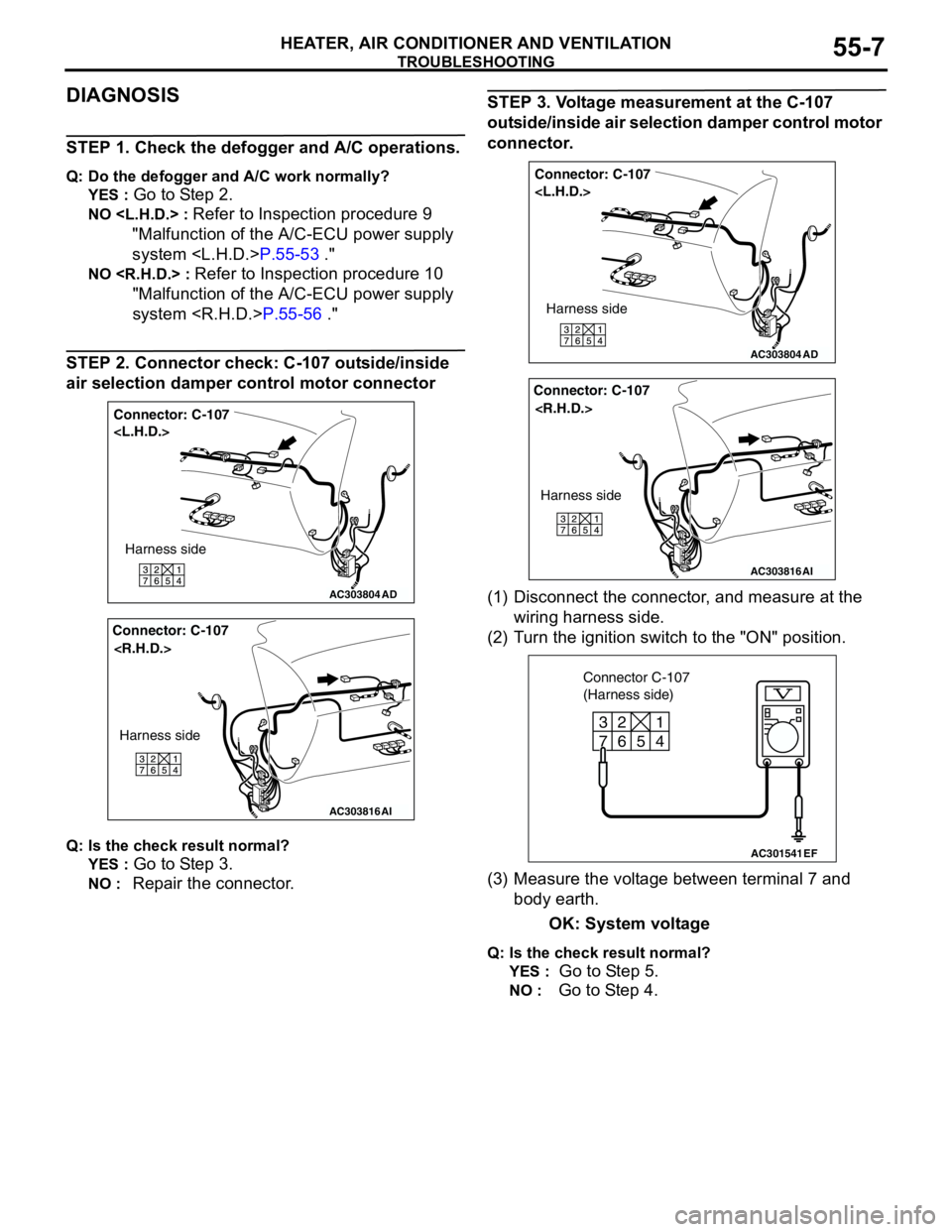

STEP 1. Check the defogger and A/C operations.

Q: Do the defogger and A/C work normally?

YES :

Go to Step 2.

NO

"Malfunction of the A/C-ECU power supply

system

NO

"Malfunction of the A/C-ECU power supply

system

STEP 2. Connector check: C-107 outside/inside

air selection damper control motor connector

Q: Is the check result normal?

YES :

Go to Step 3.

NO : Repair the connector.

STEP 3. Voltage measurement at the C-107

outside/inside air selection damper control motor

connector.

(1) Disconnect the connector, and measure at the

wiring harness side.

(2) Turn the ignition switch to the "ON" position.

(3) Measure the voltage between terminal 7 and

body earth.

OK: System voltage

Q: Is the check result normal?

YES :

Go to Step 5.

NO : Go to Step 4.

AC303804

Connector: C-107

AD

Harness side

AC303816

Connector: C-107

AI

Harness side

AC303804

Connector: C-107

AD

Harness side

AC303816

Connector: C-107

AI

Harness side

AC301541

6 2

7

3

5

4

1

EF

Connector C-107

(Harness side)