ignition switch trouble shooting MITSUBISHI LANCER 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 21 of 788

TROUBLESHOOTING

ENGINE COOLING14-7

CIRCUIT OPERATION

•The cooling fan motor drive control unit is

powered from fusible link (2).

•The engine-ECU

uses input signals from the A/C switch, the

water temperature sensor unit and the vehicle

speed sensor

sensor to control the speed of the cooling

fan motor (L.H.) and the cooling fan motor (R.H.)

<4G1 (Vehicles with A/C)> or A/C condenser fan

motor <4G6>.

•The engine-ECU

controls the cooling fan motor drive control

unit to activate the cooling fan motor (L.H.) and

the cooling fan motor (R.H.) <4G1 (Vehicles with

A/C)> or A/C condenser fan motor <4G6>.

TECHNICAL DESCRIPTION

•The cause could be a malfunction of the cooling

fan motor drive control unit power supply or earth

circuit.

•If the communication line wiring harness between

the cooling fan motor drive control unit and the

engine-ECU

short-circuited to earth, the cooling fan motor

(L.H.) and the cooling fan motor (R.H.) <4G1

(Vehicles with A/C)> or the A/C condenser fan

motor <4G6> will not rotate.

•The cause could also be a malfunction of the

cooling fan motor (L.H.).

•The cause could also be a malfunction of imput

signal from the A/C switch, the water temperature

sensor unit and the vehicle speed sensor

or the output shaft speed sensor to the

engine-ECU

•The cause could also be a malfunction of the

cooling fan motor drive control unit or the

engine-ECU

TROUBLESHOOTING HINTS

•Malfunction of fusible link (2)

•Malfunction of fan control relay

•Malfunction of cooling fan motor (L.H.)

•Malfunction of cooling fan motor drive control unit

•Malfunction of engine-ECU

engine-A/T-ECU

•Damaged wiring harness or connector

DIAGNOSIS

STEP 1. Check the cooling fan motor (L.H.).

Refer to P.14-25.

Q: Is the cooling fan motor (L.H.) in good condition?

YES :

Go to Step 2 .

NO : Replace the cooling fan motor (L.H.) (Refer

to P.14-35). Then go to Step 24 .

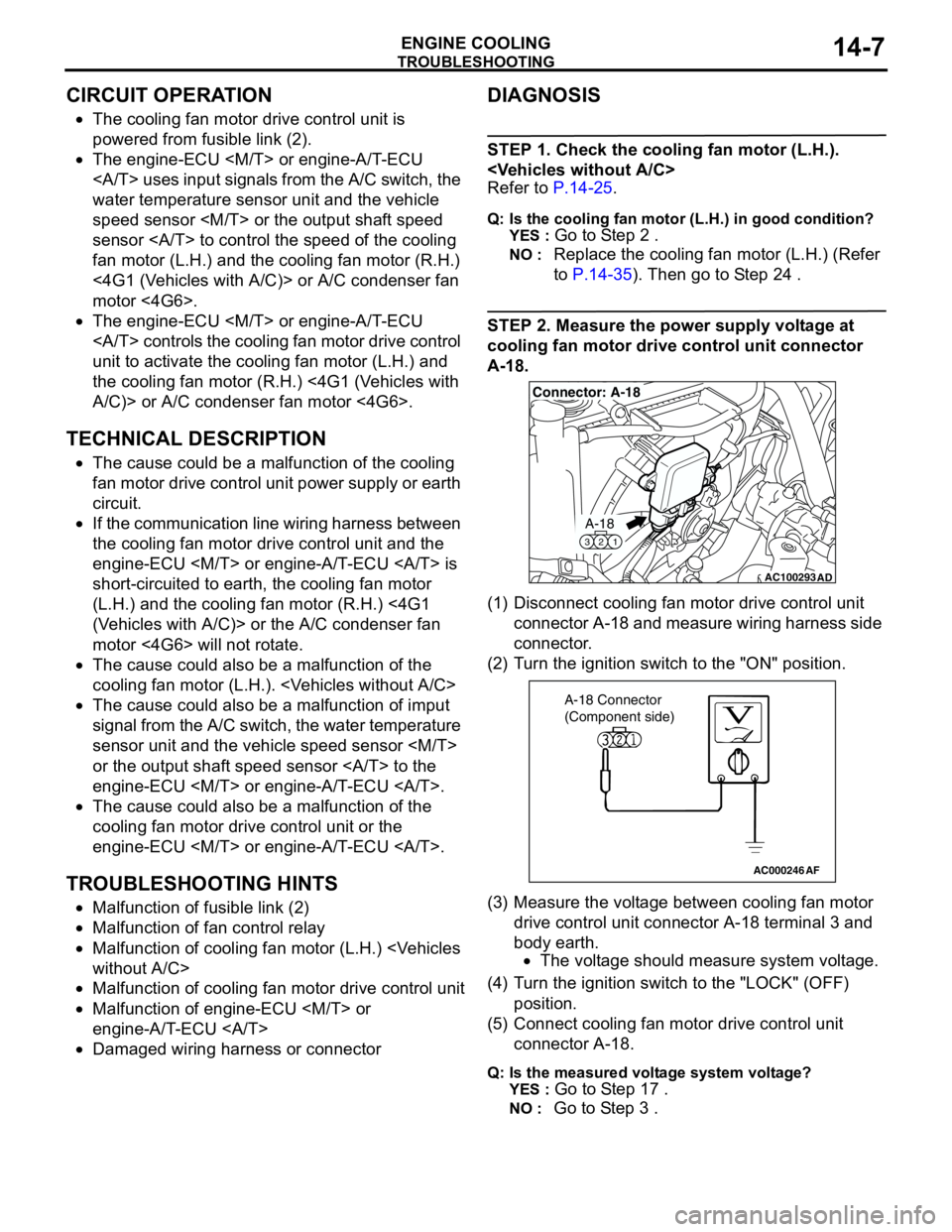

STEP 2. Measure the power supply voltage at

cooling fan motor drive control unit connector

A-18.

(1) Disconnect cooling fan motor drive control unit

connector A-18 and measure wiring harness side

connector.

(2) Turn the ignition switch to the "ON" position.

(3) Measure the voltage between cooling fan motor

drive control unit connector A-18 terminal 3 and

body earth.

•The voltage should measure system voltage.

(4) Turn the ignition switch to the "LOCK" (OFF)

position.

(5) Connect cooling fan motor drive control unit

connector A-18.

Q: Is the measured voltage system voltage?

YES :

Go to Step 17 .

NO : Go to Step 3 .

AC100293

A-18

321

Connector: A-18

AD

AC000246AF

A-18 Connector

(Component side)

Page 22 of 788

TROUBLESHOOTING

ENGINE COOLING14-8

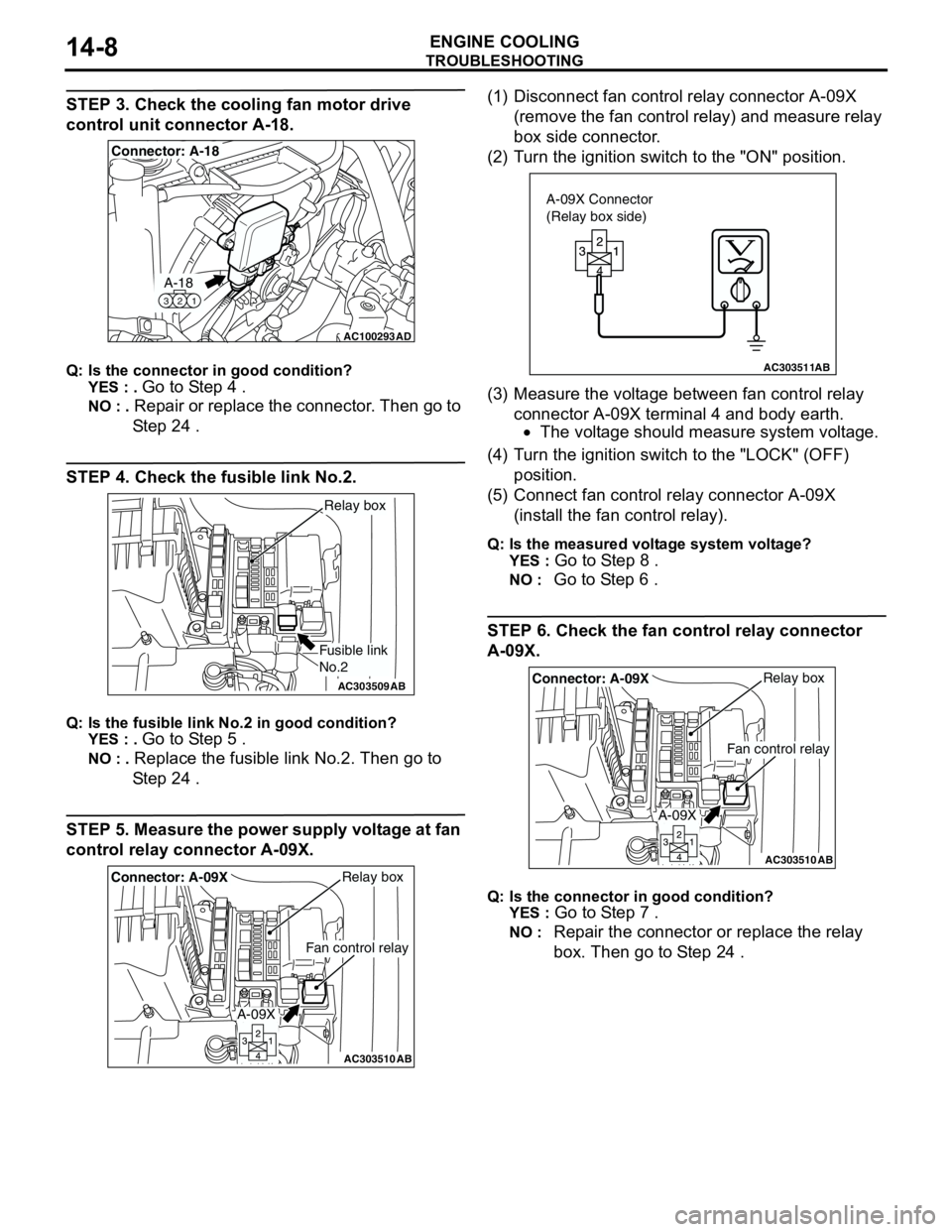

STEP 3. Check the cooling fan motor drive

control unit connector A-18.

Q: Is the connector in good condition?

YES : .

Go to Step 4 .

NO : . Repair or replace the connector. Then go to

Step 24 .

STEP 4. Check the fusible link No.2.

Q: Is the fusible link No.2 in good condition?

YES : .

Go to Step 5 .

NO : . Replace the fusible link No.2. Then go to

Step 24 .

STEP 5. Measure the power supply voltage at fan

control relay connector A-09X.(1) Disconnect fan control relay connector A-09X

(remove the fan control relay) and measure relay

box side connector.

(2) Turn the ignition switch to the "ON" position.

(3) Measure the voltage between fan control relay

connector A-09X terminal 4 and body earth.

•The voltage should measure system voltage.

(4) Turn the ignition switch to the "LOCK" (OFF)

position.

(5) Connect fan control relay connector A-09X

(install the fan control relay).

Q: Is the measured voltage system voltage?

YES :

Go to Step 8 .

NO : Go to Step 6 .

STEP 6. Check the fan control relay connector

A-09X.

Q: Is the connector in good condition?

YES :

Go to Step 7 .

NO : Repair the connector or replace the relay

box. Then go to Step 24 .

AC100293

A-18

321

Connector: A-18

AD

AC303509AB

Fusible link

No.2

Relay box

AC303510AB

Fan control relay

Relay boxConnector: A-09X

A-09X

AC303511AB

A-09X Connector

(Relay box side)

AC303510AB

Fan control relay

Relay boxConnector: A-09X

A-09X

Page 23 of 788

TROUBLESHOOTING

ENGINE COOLING14-9

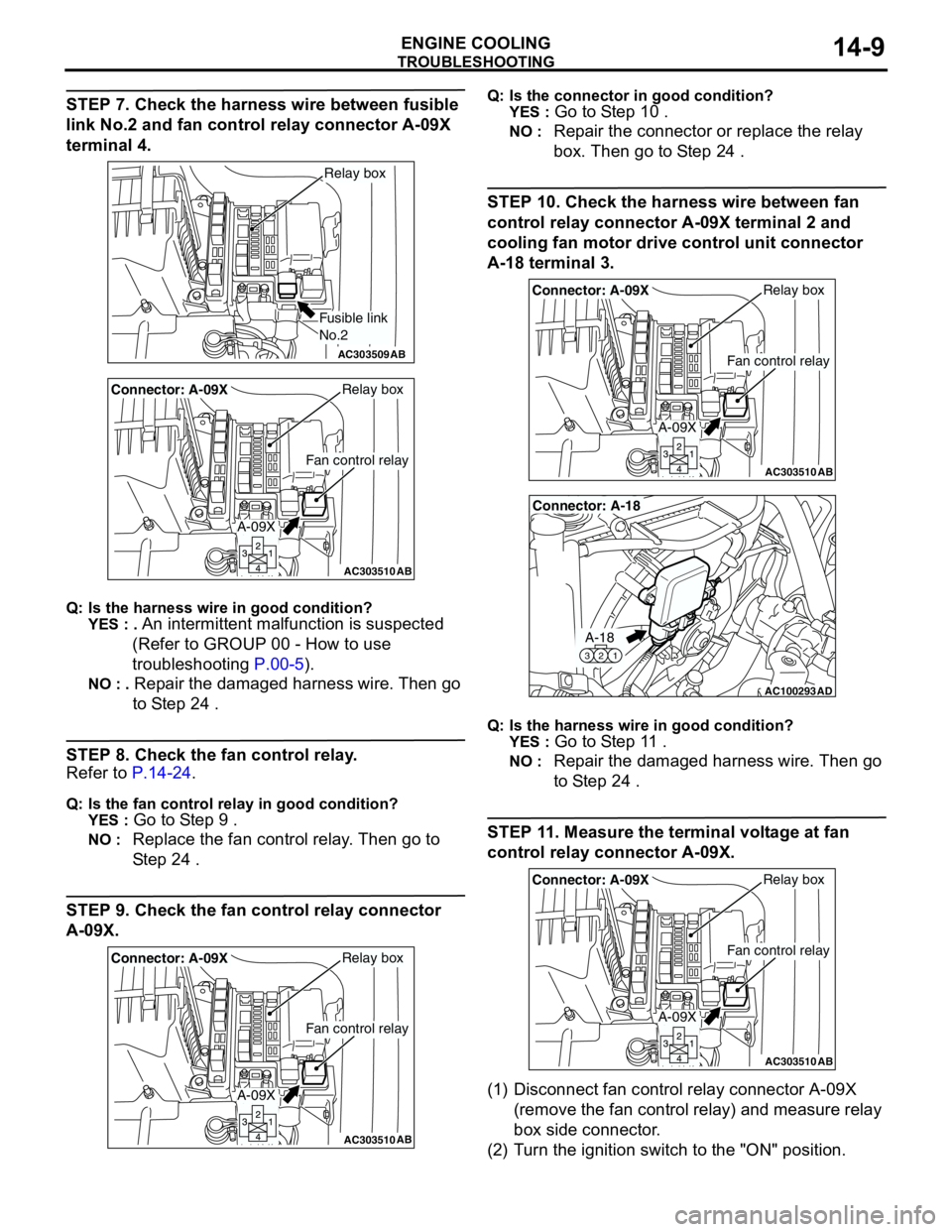

STEP 7. Check the harness wire between fusible

link No.2 and fan control relay connector A-09X

terminal 4.

Q: Is the harness wire in good condition?

YES : .

An intermittent malfunction is suspected

(Refer to GROUP 00 - How to use

troubleshooting P.00-5).

NO : . Repair the damaged harness wire. Then go

to Step 24 .

STEP 8. Check the fan control relay.

Refer to P.14-24.

Q: Is the fan control relay in good condition?

YES :

Go to Step 9 .

NO : Replace the fan control relay. Then go to

Step 24 .

STEP 9. Check the fan control relay connector

A-09X.

Q: Is the connector in good condition?

YES :

Go to Step 10 .

NO : Repair the connector or replace the relay

box. Then go to Step 24 .

STEP 10. Check the harness wire between fan

control relay connector A-09X terminal 2 and

cooling fan motor drive control unit connector

A-18 terminal 3.

Q: Is the harness wire in good condition?

YES :

Go to Step 11 .

NO : Repair the damaged harness wire. Then go

to Step 24 .

STEP 11. Measure the terminal voltage at fan

control relay connector A-09X.

(1) Disconnect fan control relay connector A-09X

(remove the fan control relay) and measure relay

box side connector.

(2) Turn the ignition switch to the "ON" position.

AC303509AB

Fusible link

No.2

Relay box

AC303510AB

Fan control relay

Relay boxConnector: A-09X

A-09X

AC303510AB

Fan control relay

Relay boxConnector: A-09X

A-09X

AC303510AB

Fan control relay

Relay boxConnector: A-09X

A-09X

AC100293

A-18

321

Connector: A-18

AD

AC303510AB

Fan control relay

Relay boxConnector: A-09X

A-09X

Page 24 of 788

TROUBLESHOOTING

ENGINE COOLING14-10

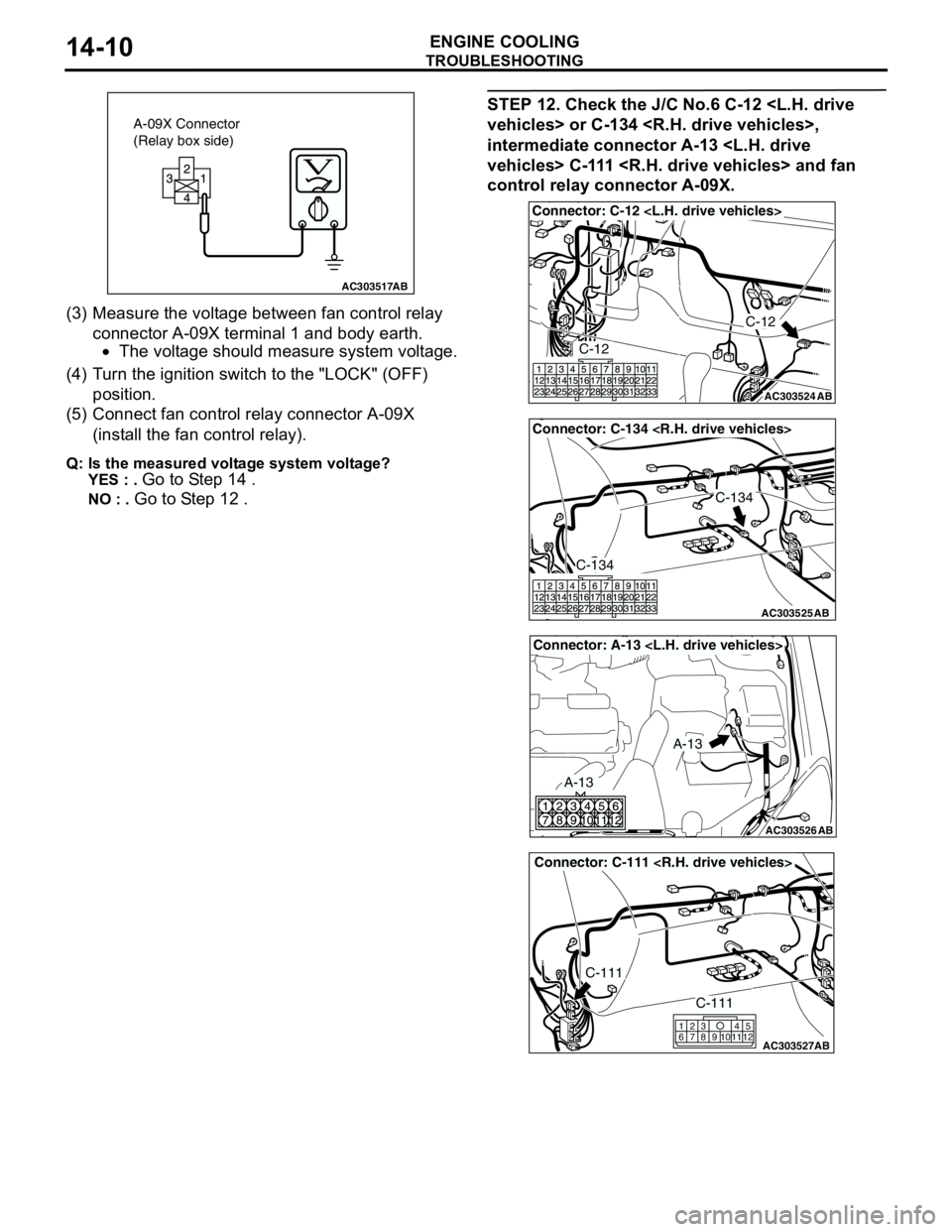

(3) Measure the voltage between fan control relay

connector A-09X terminal 1 and body earth.

•The voltage should measure system voltage.

(4) Turn the ignition switch to the "LOCK" (OFF)

position.

(5) Connect fan control relay connector A-09X

(install the fan control relay).

Q: Is the measured voltage system voltage?

YES : .

Go to Step 14 .

NO : . Go to Step 12 .

STEP 12. Check the J/C No.6 C-12

intermediate connector A-13

control relay connector A-09X.

AC303517AB

A-09X Connector

(Relay box side)

AC303524

Connector: C-12

AB

C-12

C-12

AC303525

Connector: C-134

AB

C-134

C-134

AC303526

Connector: A-13

AB

A-13

A-13

AC303527

Connector: C-111

AB

C-111

C-111

615

121179

810234

Page 29 of 788

TROUBLESHOOTING

ENGINE COOLING14-15

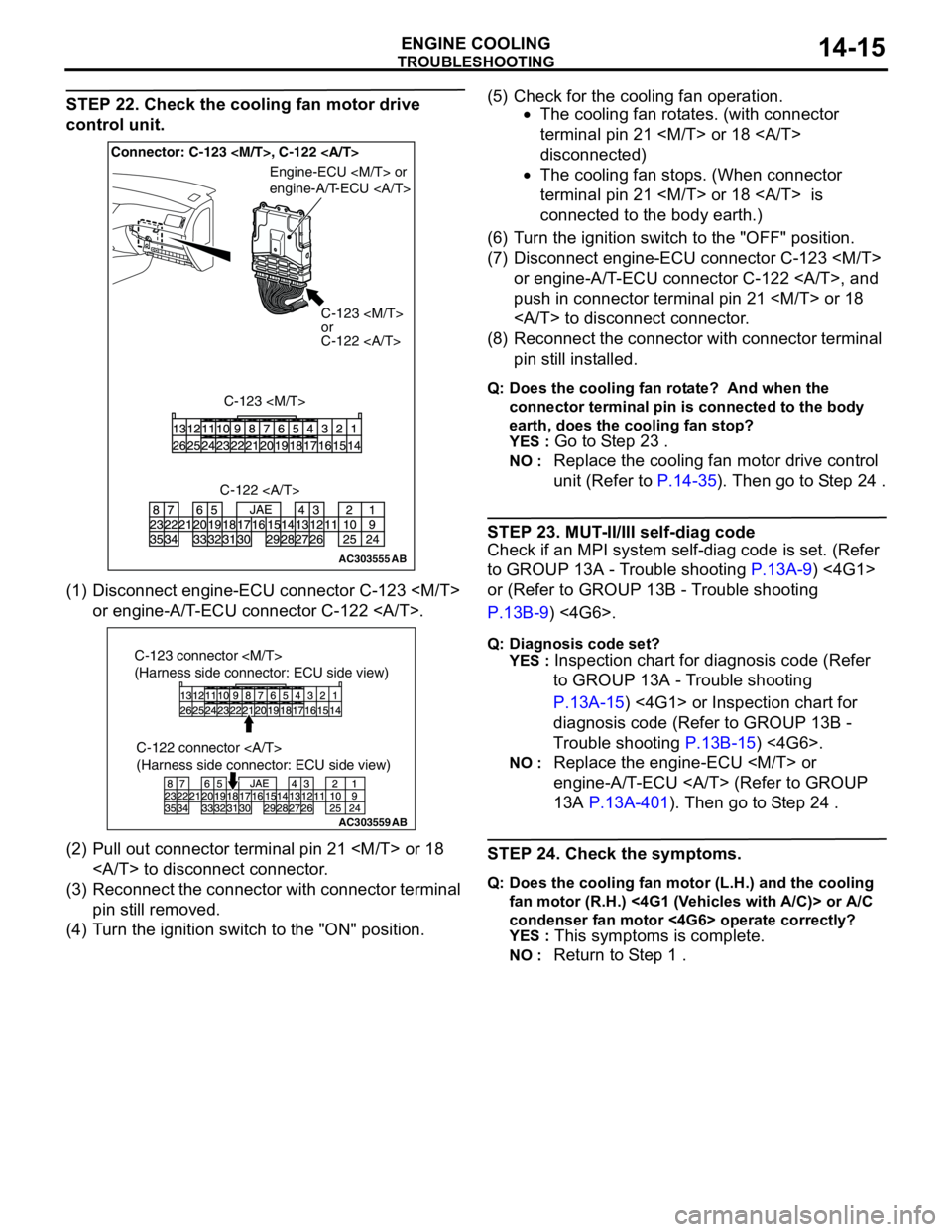

STEP 22. Check the cooling fan motor drive

control unit.

(1) Disconnect engine-ECU connector C-123

or engine-A/T-ECU connector C-122 .

(2) Pull out connector terminal pin 21

to disconnect connector.

(3) Reconnect the connector with connector terminal

pin still removed.

(4) Turn the ignition switch to the "ON" position.(5) Check for the cooling fan operation.

•The cooling fan rotates. (with connector

terminal pin 21

disconnected)

•The cooling fan stops. (When connector

terminal pin 21

connected to the body earth.)

(6) Turn the ignition switch to the "OFF" position.

(7) Disconnect engine-ECU connector C-123

or engine-A/T-ECU connector C-122 , and

push in connector terminal pin 21

to disconnect connector.

(8) Reconnect the connector with connector terminal

pin still installed.

Q: Does the cooling fan rotate? And when the

connector terminal pin is connected to the body

earth, does the cooling fan stop?

YES :

Go to Step 23 .

NO : Replace the cooling fan motor drive control

unit (Refer to P.14-35). Then go to Step 24 .

STEP 23. MUT-II/III self-diag code

Check if an MPI system self-diag code is set. (Refer

to GROUP 13A - Trouble shooting P.13A-9) <4G1>

or (Refer to GROUP 13B - Trouble shooting

P.13B-9) <4G6>.

Q: Diagnosis code set?

YES :

Inspection chart for diagnosis code (Refer

to GROUP 13A - Trouble shooting

P.13A-15) <4G1> or Inspection chart for

diagnosis code (Refer to GROUP 13B -

Trouble shooting P.13B-15) <4G6>.

NO : Replace the engine-ECU

engine-A/T-ECU (Refer to GROUP

13A P.13A-401). Then go to Step 24 .

STEP 24. Check the symptoms.

Q: Does the cooling fan motor (L.H.) and the cooling

fan motor (R.H.) <4G1 (Vehicles with A/C)> or A/C

condenser fan motor <4G6> operate correctly?

YES :

This symptoms is complete.

NO : Return to Step 1 .

AC303555AB

Connector: C-123

C-123

or

C-122

C-123

Engine-ECU

engine-A/T-ECU

C-122

AC303559

C-122 connector

(Harness side connector: ECU side view)

AB

C-123 connector

(Harness side connector: ECU side view)

Page 33 of 788

TROUBLESHOOTING

ENGINE COOLING14-19

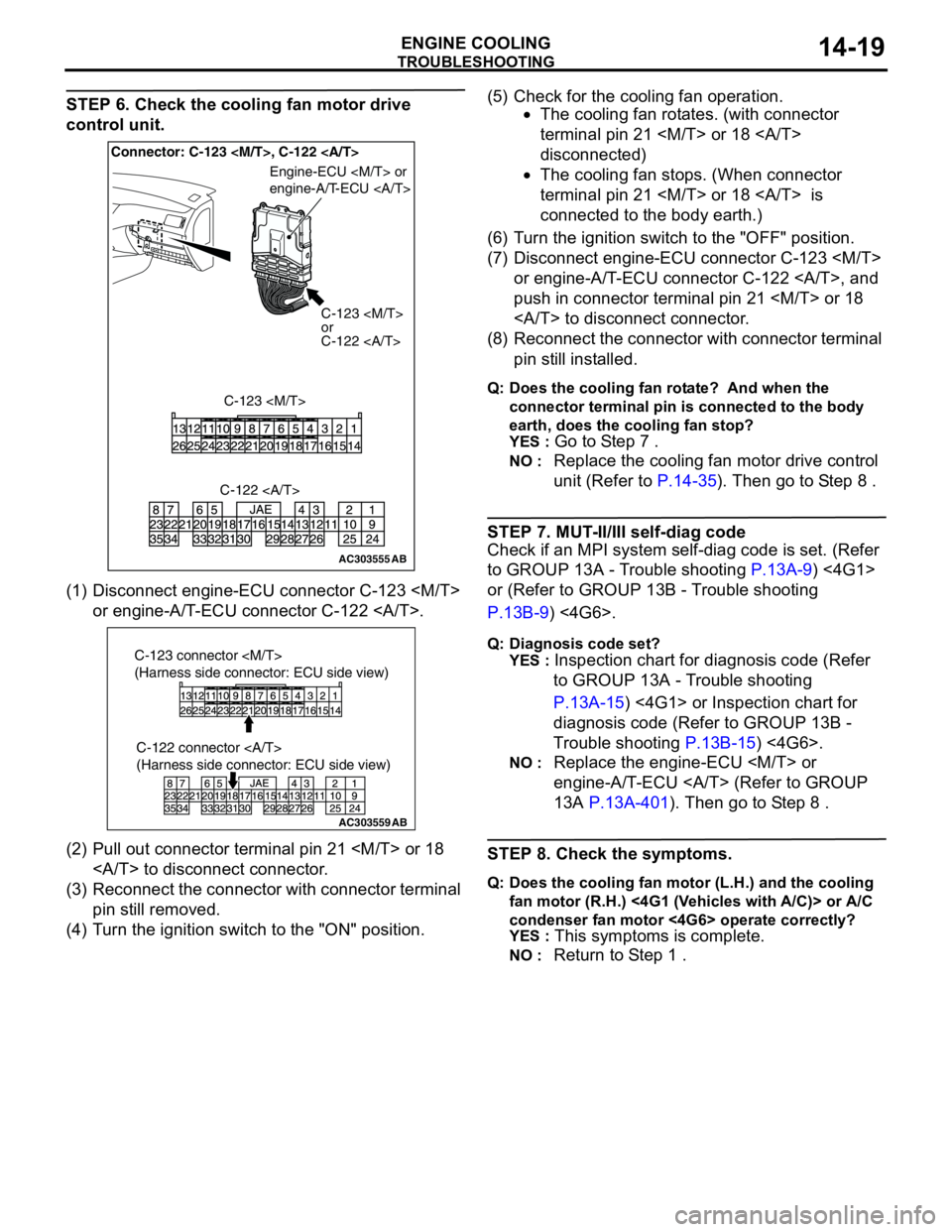

STEP 6. Check the cooling fan motor drive

control unit.

(1) Disconnect engine-ECU connector C-123

or engine-A/T-ECU connector C-122 .

(2) Pull out connector terminal pin 21

to disconnect connector.

(3) Reconnect the connector with connector terminal

pin still removed.

(4) Turn the ignition switch to the "ON" position.(5) Check for the cooling fan operation.

•The cooling fan rotates. (with connector

terminal pin 21

disconnected)

•The cooling fan stops. (When connector

terminal pin 21

connected to the body earth.)

(6) Turn the ignition switch to the "OFF" position.

(7) Disconnect engine-ECU connector C-123

or engine-A/T-ECU connector C-122 , and

push in connector terminal pin 21

to disconnect connector.

(8) Reconnect the connector with connector terminal

pin still installed.

Q: Does the cooling fan rotate? And when the

connector terminal pin is connected to the body

earth, does the cooling fan stop?

YES :

Go to Step 7 .

NO : Replace the cooling fan motor drive control

unit (Refer to P.14-35). Then go to Step 8 .

STEP 7. MUT-II/III self-diag code

Check if an MPI system self-diag code is set. (Refer

to GROUP 13A - Trouble shooting P.13A-9) <4G1>

or (Refer to GROUP 13B - Trouble shooting

P.13B-9) <4G6>.

Q: Diagnosis code set?

YES :

Inspection chart for diagnosis code (Refer

to GROUP 13A - Trouble shooting

P.13A-15) <4G1> or Inspection chart for

diagnosis code (Refer to GROUP 13B -

Trouble shooting P.13B-15) <4G6>.

NO : Replace the engine-ECU

engine-A/T-ECU (Refer to GROUP

13A P.13A-401). Then go to Step 8 .

STEP 8. Check the symptoms.

Q: Does the cooling fan motor (L.H.) and the cooling

fan motor (R.H.) <4G1 (Vehicles with A/C)> or A/C

condenser fan motor <4G6> operate correctly?

YES :

This symptoms is complete.

NO : Return to Step 1 .

AC303555AB

Connector: C-123

C-123

or

C-122

C-123

Engine-ECU

engine-A/T-ECU

C-122

AC303559

C-122 connector

(Harness side connector: ECU side view)

AB

C-123 connector

(Harness side connector: ECU side view)

Page 331 of 788

KEYLESS ENTRY SYSTEM

BODY42-53

TROUBLESHOOTINGM1428000700287

The keyless entry system is controlled by the Smart

Wiring System (SWS). For troubleshooting, refer to

GROUP 54B, Troubleshooting P.54B-17 or GROUP

54C, Troubleshooting P.54C-4.

ON-VEHICLE SERVICE

KEYLESS ENTRY SYSTEM CHECKM1428001400096

Check the system as described below. If the system

does not work, carry out troubleshooting. Refer to

GROUP 54B, Troubleshooting P.54B-17, refer to

GROUP 54C, Troubleshooting P.54C-4.

•Operate the transmitter to check that the doors

and tailgate can be locked and unlocked.

•Operate the transmitter to check that the

answerback function works in response to door

and tailgate

NOTE: The adjustment function allows you to

change the answerback setting as follows. Prior

to that check, confirm which setting is activated.

.

•The hazard warning lamps flash twice when

locked and once when unlocked. The room

lamp flashes twice when locked and

illuminates for 15 seconds when unlocked.

•The hazard warning lamps do not flash when

locked and flash once when unlocked. The

room lamp flashes twice when locked and

illuminates for 15 seconds when unlocked.

•The hazard warning lamps flash twice when

locked and do not flash when unlocked. The

room lamp flashes twice when locked and

illuminates for 15 seconds when unlocked.

•The hazard warning lamps do not flash when

both locked and unlocked. The room lamp

flashes twice when locked and illuminates for

15 seconds when unlocked.

KEYLESS ENTRY SYSTEM TIMER LOCK

FUNCTION INSPECTION

M1428004000138

Push the transmitter unlock button and check to see

that the doors and tailgate

seconds. If it doesn't, then execute troubleshooting

remedies. Refer to GROUP 54B, Troubleshooting

P.54B-17, refer to GROUP 54C, Troubleshooting

P.54C-4.

ENABLING/DISABLING THE

ANSWERBACK FUNCTION

M1428003200214

If the keyless entry system locks or unlocks the

doors, the room lamp flashes or illuminates, the

hazard warning lamp flashes (hazard answerback

function). The hazard answerback function can be

enabled or disabled according to the following

procedure:

ENABLING/DISABLING THE HAZARD

ANSWERBACK FUNCTION

The hazard answerback function can be enabled or

disabled by one of the two following procedures.

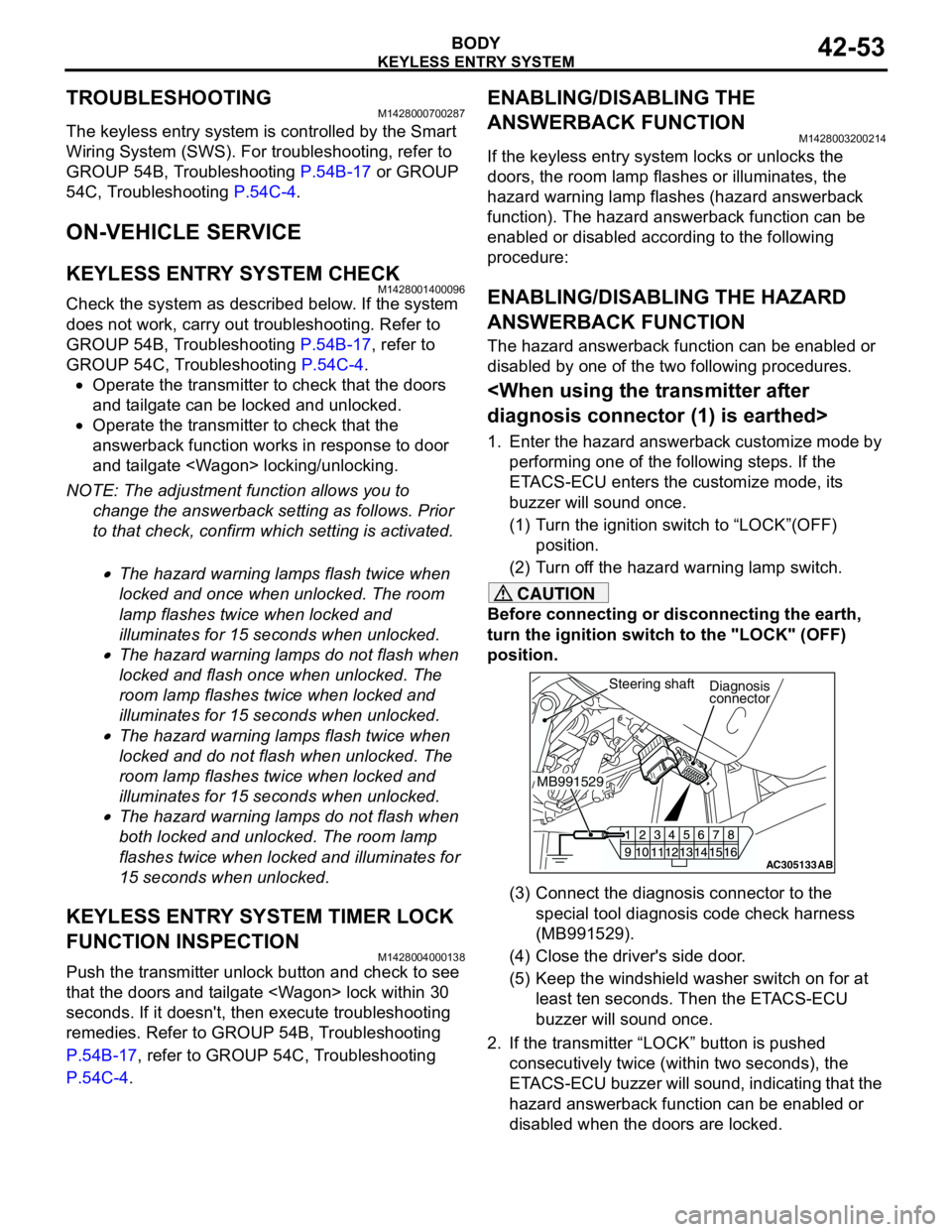

1. Enter the hazard answerback customize mode by

performing one of the following steps. If the

ETACS-ECU enters the customize mode, its

buzzer will sound once.

(1) Turn the ignition switch to “LOCK”(OFF)

position.

(2) Turn off the hazard warning lamp switch.

CAUTION

Before connecting or disconnecting the earth,

turn the ignition switch to the "LOCK" (OFF)

position.

(3) Connect the diagnosis connector to the

special tool diagnosis code check harness

(MB991529).

(4) Close the driver's side door.

(5) Keep the windshield washer switch on for at

least ten seconds. Then the ETACS-ECU

buzzer will sound once.

2. If the transmitter “LOCK” button is pushed

consecutively twice (within two seconds), the

ETACS-ECU buzzer will sound, indicating that the

hazard answerback function can be enabled or

disabled when the doors are locked.

AC305133AB

Diagnosis

connector

MB991529Steering shaft

Page 360 of 788

WINDSHIELD WIPER AND WASHER

EXTERIOR51-22

SERVICE SPECIFICATIONM1511000300325

TROUBLESHOOTINGM1511000700323

The windshield wiper and washer are controlled by

the Smart Wiring System (SWS). For

troubleshooting, refer to GROUP 54B,

Troubleshooting P.54B-17 or GROUP 54C,

Troubleshooting P.54C-4.

NOTE: Even when the ETACS-ECU has failed, the

windshield wiper can work at low speed as fail-safe

mode. (Normally, the windshield wiper operates

when the ignition switch is at the "ACC" position. But,

if it enters the fail-safe mode, the wiper can operate

only when the ignition switch is at the "ON" position.)

ON-VEHICLE SERVICEM1511000800461

WINDSHIELD INTERMITTENT WIPER

INSPECTION

1. If the windshield intermittent wiper interval

adjusting knob is operated, the wiper interval

should change.

2. Holding the windshield intermittent wiper interval

adjusting knob, input the simulated vehicle speed

with MUT-II MB991502 and check that the wiper

interval changes as the vehicle speed changes.

3. If not, carry out the troubleshooting (Refer to

GROUP 54B, Troubleshooting P.54B-17 or

GROUP 54C, Troubleshooting P.54C-4). ItemStandard value

Windshield wiper blade park position mm 34 ± 5

Page 366 of 788

REAR WIPER AND WASHER

EXTERIOR51-28

REAR WIPER AND WASHER

GENERAL INFORMATIONM1511000100525

REAR WIPER AND WASHER OPERATION

Rear Wiper Operation

•If the rear wiper and washer switch is turned to

"INT" position with the ignition switch at "ACC" or

"ON" position, the ETACS-ECU turns ON the rear

wiper drive signal for three seconds

(approximately two cycles), then 7.4 seconds

later the intermittent motion operates every eight

seconds. If the selector lever is moved to the "R"

position when the rear wiper and washer switch is

turned to the "INT" position and the ignition

switch is at the "ACC" or "ON" position, the inhibitor switch "R" turns ON. One second later,

the ETACS-ECU turns ON the rear wiper drive

signal for three seconds (approximately two

cycles). Then, 7.4 seconds later, the intermittent

motion of eight seconds' cycle is restored.

Rear Washer Operation

•If the rear wiper and washer switch is turned to

the ON (washer) position with the ignition switch

at the "ACC" or "ON" position, the rear washer

ON signal is sent to the ETACS-ECU, causing the

rear wiper signal to turn on after 0.3 second. After

the rear washer switch signal turns off, the rear

wiper signal turns off in three seconds. If the rear

washer switch is turned to the ON position while

the rear wiper is in intermittent mode, the rear

washer works for that period when the washer

switch remains on. Then the rear wipers return to

the intermittent mode.

SERVICE SPECIFICATIONM1511000300336

TROUBLESHOOTINGM1511000700334

The rear wiper and washer are controlled by the

Smart Wiring System (SWS). For troubleshooting,

refer to GROUP 54B, Troubleshooting P.54B-17 or

GROUP 54C, Troubleshooting P.54C-4.

ON-VEHICLE SERVICEM1511000800472

CHECK OF REAR WIPER OPERATION

WHEN SELECTOR LEVER IS AT THE "R"

POSITION

1. When the selector lever is moved to the "R"

position with the rear wiper switch at the "INT"

position, the wiper should operate twice or three

times at low speed after approximately one

second.

2. If not, carry out the troubleshooting (Refer to

GROUP 54B, Troubleshooting P.54B-17 or

GROUP 54C, Troubleshooting P.54C-4). ItemStandard value

Rear wiper blade park position mm 42 ± 5

Page 374 of 788

DOOR MIRROR

EXTERIOR51-36

DOOR MIRROR

GENERAL INFORMATIONM1511000100536

DOOR MIRROR OPERATION

Remote Controlled Mirror Operation

•The mirror on the door mirror moves up/down

and left/right by operating the remote controlled

door mirror switch when the ignition switch is in

the "ON" or "ACC" position.Heated Door Mirror operation

•The defogger relay switch is activated (ON) by

turning on the A/C-ECU built-in defogger switch

when the ignition switch is in the "ON" position.

When the defogger relay is turned ON, power is

supplied to the defogger and door mirror, and the

heater of the door mirror (heated door mirror)

starts operations. The defogger comes with a

timer function and will automatically turn OFF the

switch approximately 11 minutes after the

defogger switch is turned ON. The heated door

mirror operations are also terminated along with

the defogger, at this time.

SERVICE SPECIFICATIONM1511000300347

SPECIAL TOOLM1511000601103

TROUBLESHOOTING

DIAGNOSIS TROUBLESHOOTING FLOWM1511014600169

Refer to GROUP 00 − How to Use

Troubleshooting/Inspection Service Points P.00-5.

TROUBLE SYMPTOM CHARTM1511015000160

ItemStandard value

Heated door mirror operation current Ω5.9 − 7.8

Tool Number Name Application

MB990784 Ornament remover Removal of remote controlled

mirror switch

MB990784

Symptom Inspection

procedureReference

page

All heated door mirrors do not operate 1

P.51-37

The right or left heated door mirror does not operate 2

P.51-39