instrument panel MITSUBISHI LANCER 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 255 of 788

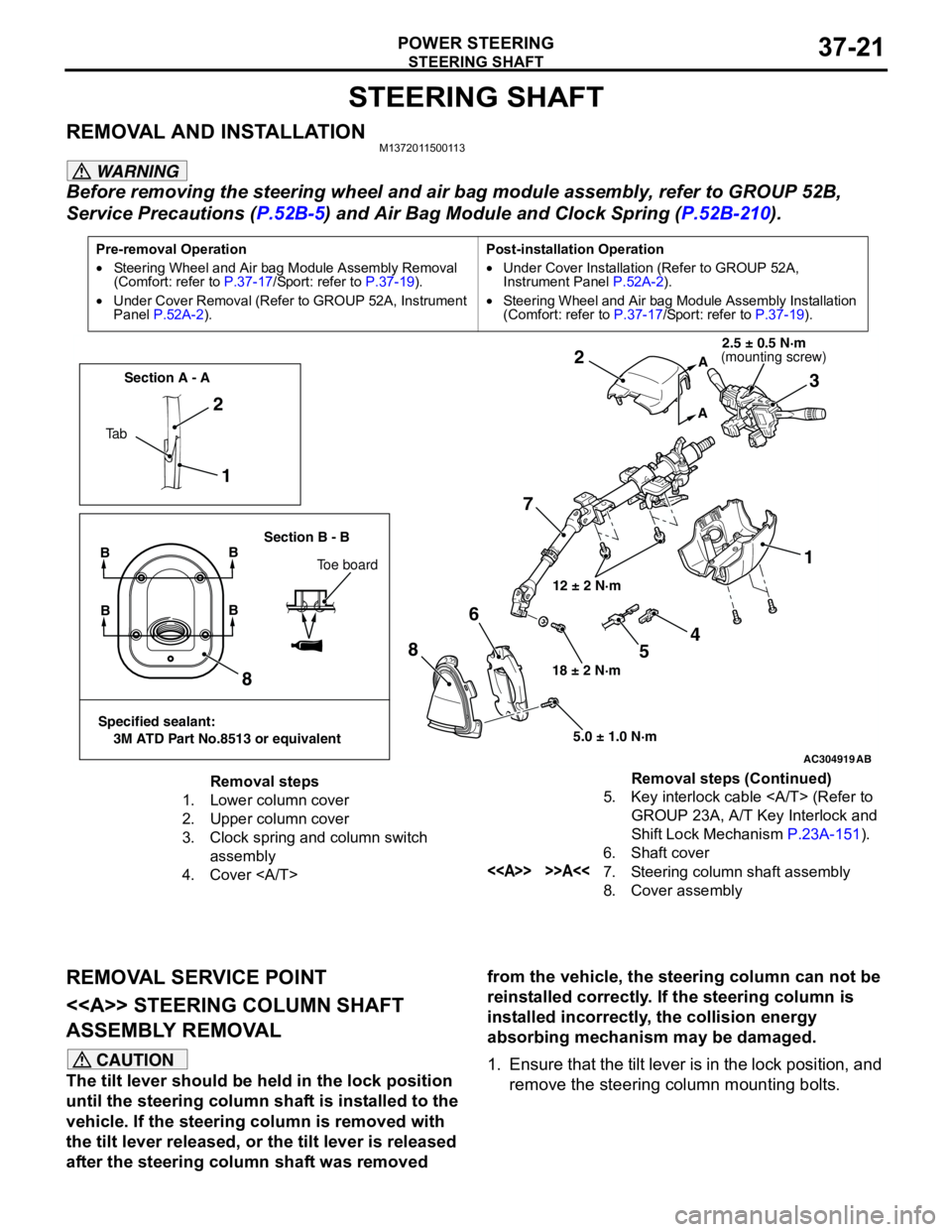

STEERING SHAFT

POWER STEERING37-21

STEERING SHAFT

REMOVAL AND INSTALLATIONM1372011500113

WARNING

Before removing the steering wheel and air bag module assembly, refer to GROUP 52B,

Service Precautions (P.52B-5) and Air Bag Module and Clock Spring (P.52B-210).

REMOVAL SERVICE POINT

<> STEERING COLUMN SHAFT

ASSEMBLY REMOVAL

CAUTION

The tilt lever should be held in the lock position

until the steering column shaft is installed to the

vehicle. If the steering column is removed with

the tilt lever released, or the tilt lever is released

after the steering column shaft was removed from the vehicle, the steering column can not be

reinstalled correctly. If the steering column is

installed incorrectly, the collision energy

absorbing mechanism may be damaged.

1. Ensure that the tilt lever is in the lock position, and

remove the steering column mounting bolts.

Pre-removal Operation

•Steering Wheel and Air bag Module Assembly Removal

(Comfort: refer to P.37-17/Sport: refer to P.37-19).

•Under Cover Removal (Refer to GROUP 52A, Instrument

Panel P.52A-2).Post-installation Operation

•Under Cover Installation (Refer to GROUP 52A,

Instrument Panel P.52A-2).

•Steering Wheel and Air bag Module Assembly Installation

(Comfort: refer to P.37-17/Sport: refer to P.37-19).

AC304919AB

12 ± 2 N·m

18 ± 2 N·m

5.0 ± 1.0 N·m

1 2

73 2

1

8

86

A

A

Ta bSection A - A

Section B - B

BB

Toe board

Specified sealant:

3M ATD Part No.8513 or equivalent

BB

4

5

(mounting screw)2.5 ± 0.5 N·m

Removal steps

1. Lower column cover

2. Upper column cover

3. Clock spring and column switch

assembly

4. Cover 5. Key interlock cable (Refer to

GROUP 23A, A/T Key Interlock and

Shift Lock Mechanism P.23A-151).

6. Shaft cover

<> >>A<<7. Steering column shaft assembly

8. Cover assemblyRemoval steps (Continued)

Page 383 of 788

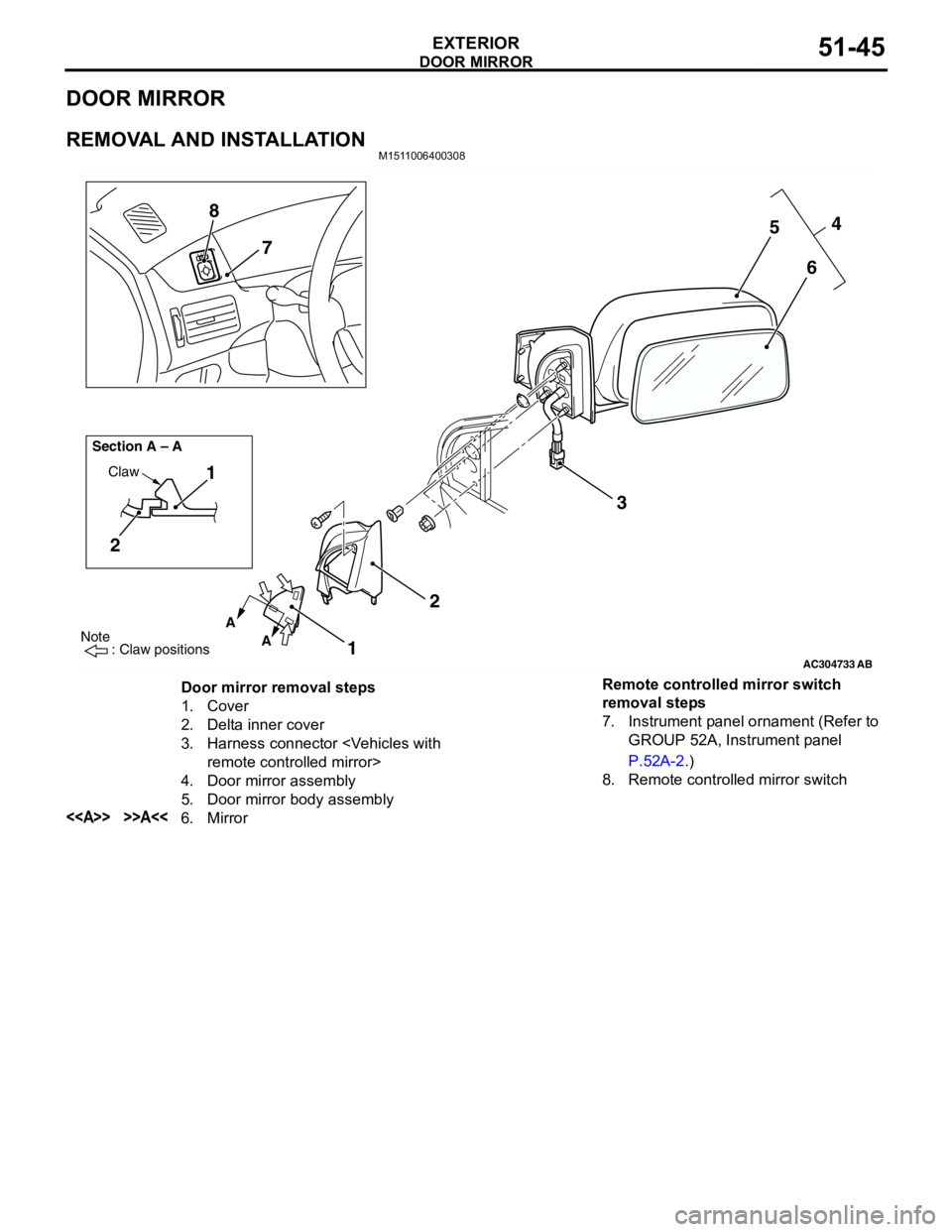

DOOR MIRROR

EXTERIOR51-45

DOOR MIRROR

REMOVAL AND INSTALLATIONM1511006400308

AC304733

Note

: Claw positions

AB

A

A Section A – A

Claw1

2

1234

5

6 7 8

Door mirror removal steps

1. Cover

2. Delta inner cover

3. Harness connector

4. Door mirror assembly

5. Door mirror body assembly

<> >>A<<6. MirrorRemote controlled mirror switch

removal steps

7. Instrument panel ornament (Refer to

GROUP 52A, Instrument panel

P.52A-2.)

8. Remote controlled mirror switch

Page 417 of 788

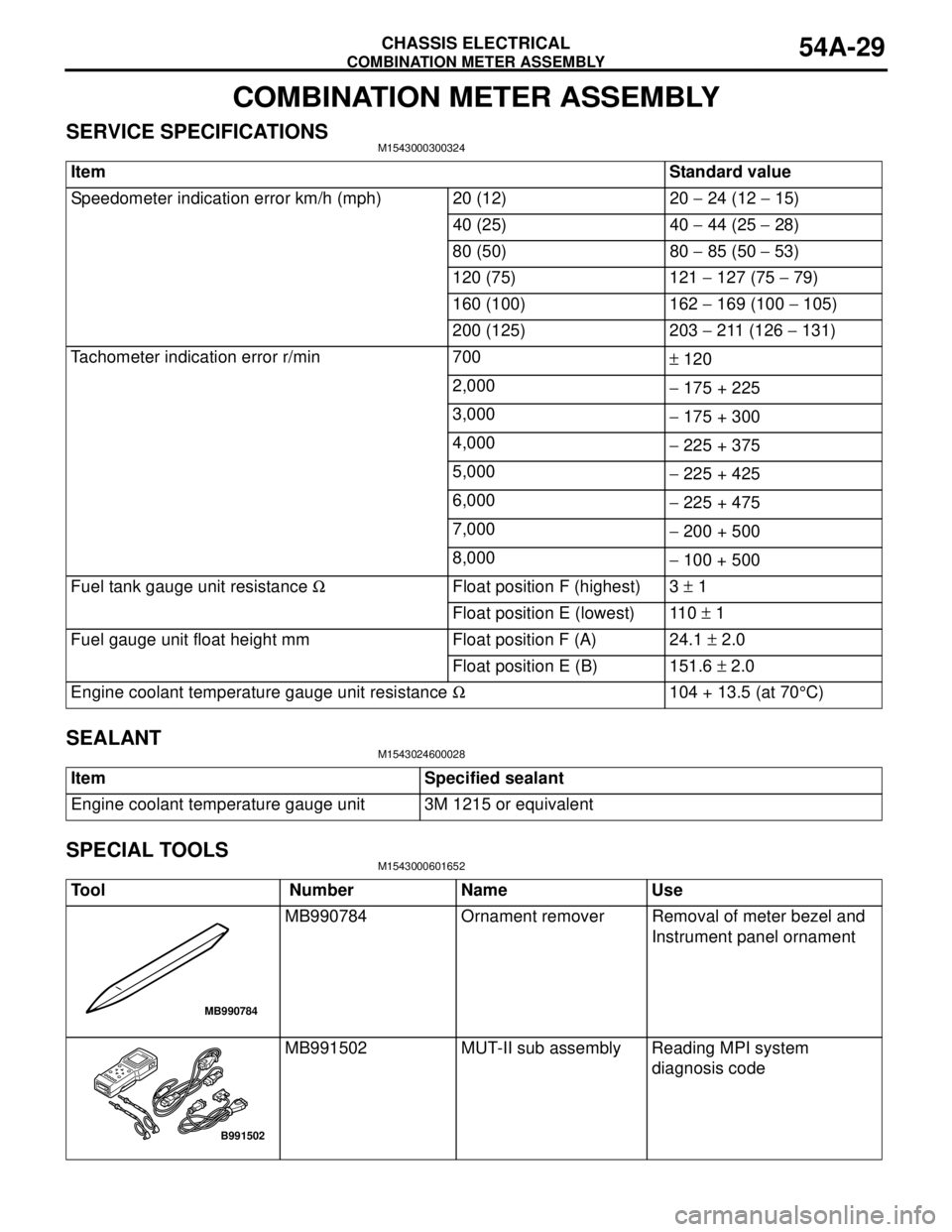

COMBINATION METER ASSEMBLY

CHASSIS ELECTRICAL54A-29

COMBINATION METER ASSEMBLY

SERVICE SPECIFICATIONSM1543000300324

SEALANTM1543024600028

SPECIAL TOOLSM1543000601652

ItemStandard value

Speedometer indication error km/h (mph) 20 (12) 20 − 24 (12 − 15)

40 (25) 40 − 44 (25 − 28)

80 (50) 80 − 85 (50 − 53)

120 (75) 121 − 127 (75 − 79)

160 (100) 162 − 169 (100 − 105)

200 (125) 203 − 211 (126 − 131)

Tachometer indication error r/min 700

± 120

2,000

− 175 + 225

3,000

− 175 + 300

4,000

− 225 + 375

5,000

− 225 + 425

6,000

− 225 + 475

7,000

− 200 + 500

8,000

− 100 + 500

Fuel tank gauge unit resistance ΩFloat position F (highest) 3 ± 1

Float position E (lowest) 110 ± 1

Fuel gauge unit float height mm Float position F (A) 24.1 ± 2.0

Float position E (B) 151.6 ± 2.0

Engine coolant temperature gauge unit resistance Ω104 + 13.5 (at 70°C)

Item Specified sealant

Engine coolant temperature gauge unit 3M 1215 or equivalent

Tool Number Name Use

MB990784 Ornament remover Removal of meter bezel and

Instrument panel ornament

MB991502 MUT-II sub assembly Reading MPI system

diagnosis code

MB990784

B991502

Page 451 of 788

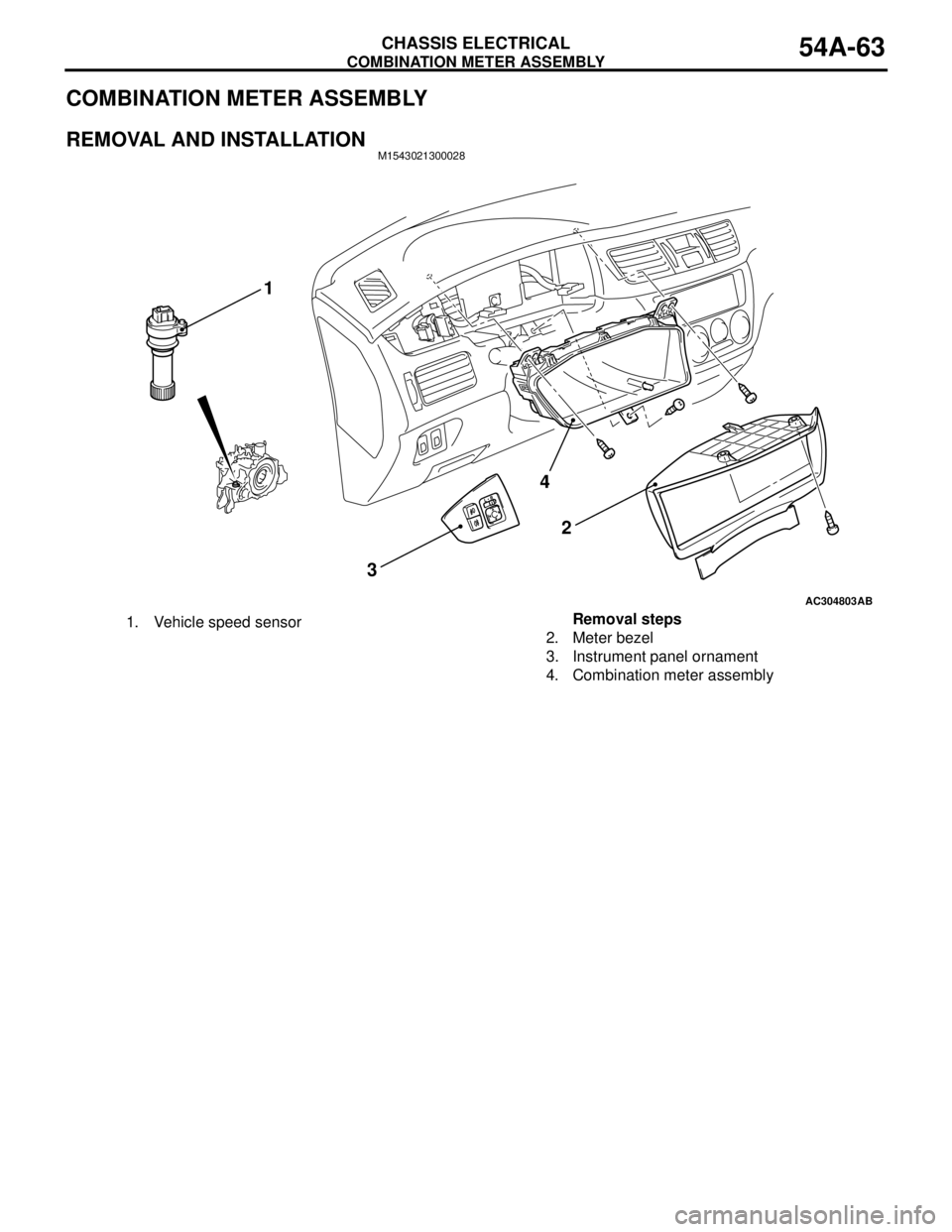

COMBINATION METER ASSEMBLY

CHASSIS ELECTRICAL54A-63

COMBINATION METER ASSEMBLY

REMOVAL AND INSTALLATIONM1543021300028

AC304803

4

32

AB

1

1. Vehicle speed sensorRemoval steps

2. Meter bezel

3. Instrument panel ornament

4. Combination meter assembly

Page 459 of 788

FOG LAMP

CHASSIS ELECTRICAL54A-71

FOG LAMP

SERVICE SPECIFICATIONM1542000300343

SPECIAL TOOLM1542000600894

TROUBLESHOOTINGM1542000701292

When the front fog lamp switch is turned to ON with

the tail lamp or the headlamp on (the tail lamp switch

or the headlamp switch is ON), the fog lamp relay

turns on, and the fog lamps will illuminate.

If the tail lamps or the headlamps are turned off with

the lighting switch OFF while the fog lamps are on,

the front fog lamps turn off at the same time to

prevent unattended operation.

If the tail lamps are turned off by the headlamp

automatic shutdown function, the fog lamps turn off

at the same time. However, if the tail lamps illuminate

again, the fog lamps do not.

The front fog lamps are controlled by the Smart

Wiring System (SWS). For troubleshooting, refer to

respective Groups below.

•Not using SWS monitor: GROUP 54B, SWS

Troubleshooting P.54B-38.

•Using SWS monitor: GROUP 54C, SWS

Troubleshooting P.54C-22.

ON-VEHICLE SERVICE

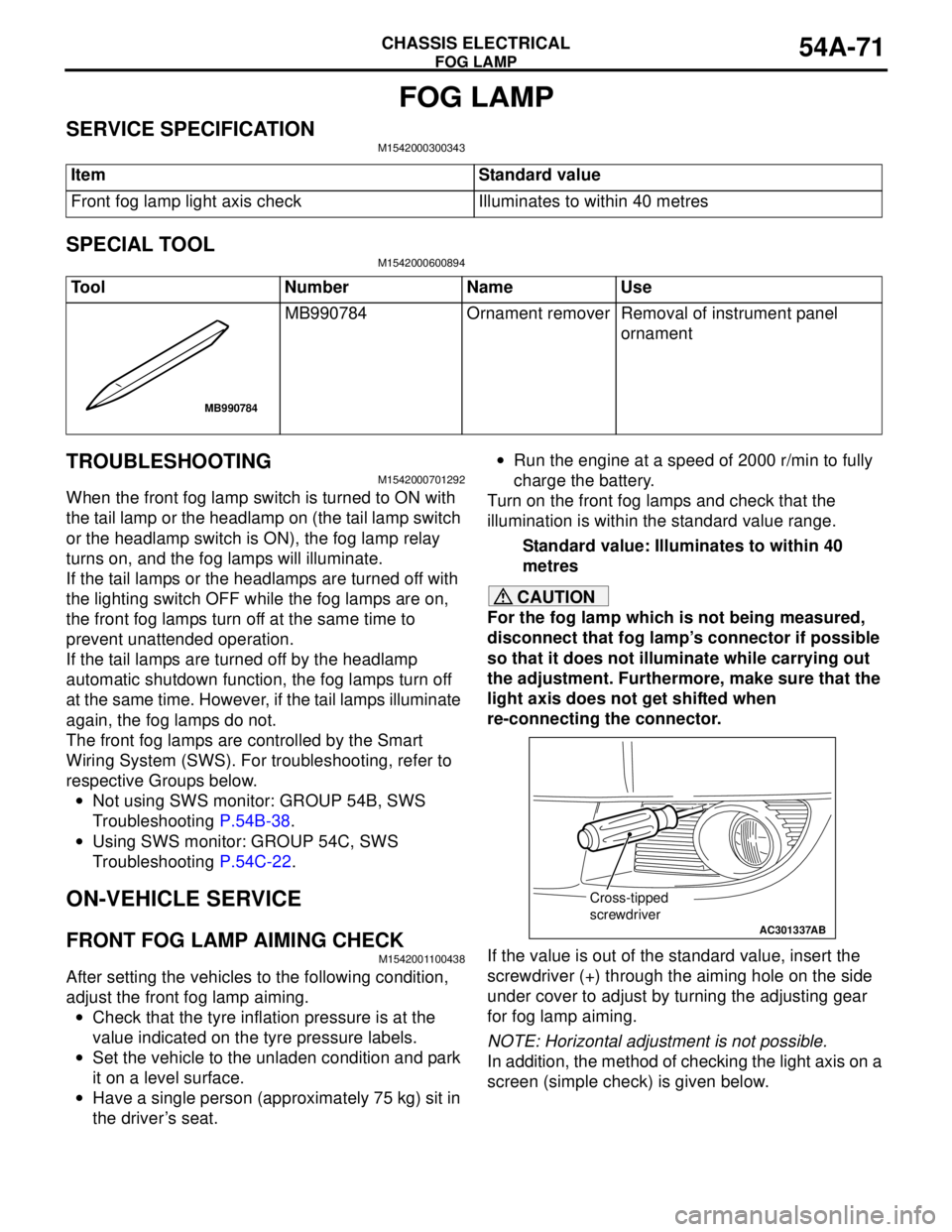

FRONT FOG LAMP AIMING CHECKM1542001100438

After setting the vehicles to the following condition,

adjust the front fog lamp aiming.

•Check that the tyre inflation pressure is at the

value indicated on the tyre pressure labels.

•Set the vehicle to the unladen condition and park

it on a level surface.

•Have a single person (approximately 75 kg) sit in

the driver’s seat.•Run the engine at a speed of 2000 r/min to fully

charge the battery.

Turn on the front fog lamps and check that the

illumination is within the standard value range.

Standard value: Illuminates to within 40

metres

CAUTION

For the fog lamp which is not being measured,

disconnect that fog lamp’s connector if possible

so that it does not illuminate while carrying out

the adjustment. Furthermore, make sure that the

light axis does not get shifted when

re-connecting the connector.

If the value is out of the standard value, insert the

screwdriver (+) through the aiming hole on the side

under cover to adjust by turning the adjusting gear

for fog lamp aiming.

NOTE: Horizontal adjustment is not possible.

In addition, the method of checking the light axis on a

screen (simple check) is given below. Item Standard value

Front fog lamp light axis check Illuminates to within 40 metres

Tool Number Name Use

MB990784 Ornament remover Removal of instrument panel

ornament

MB990784

AC301337

Cross-tipped

screwdriver

AB

Page 462 of 788

FOG LAMP

CHASSIS ELECTRICAL54A-74

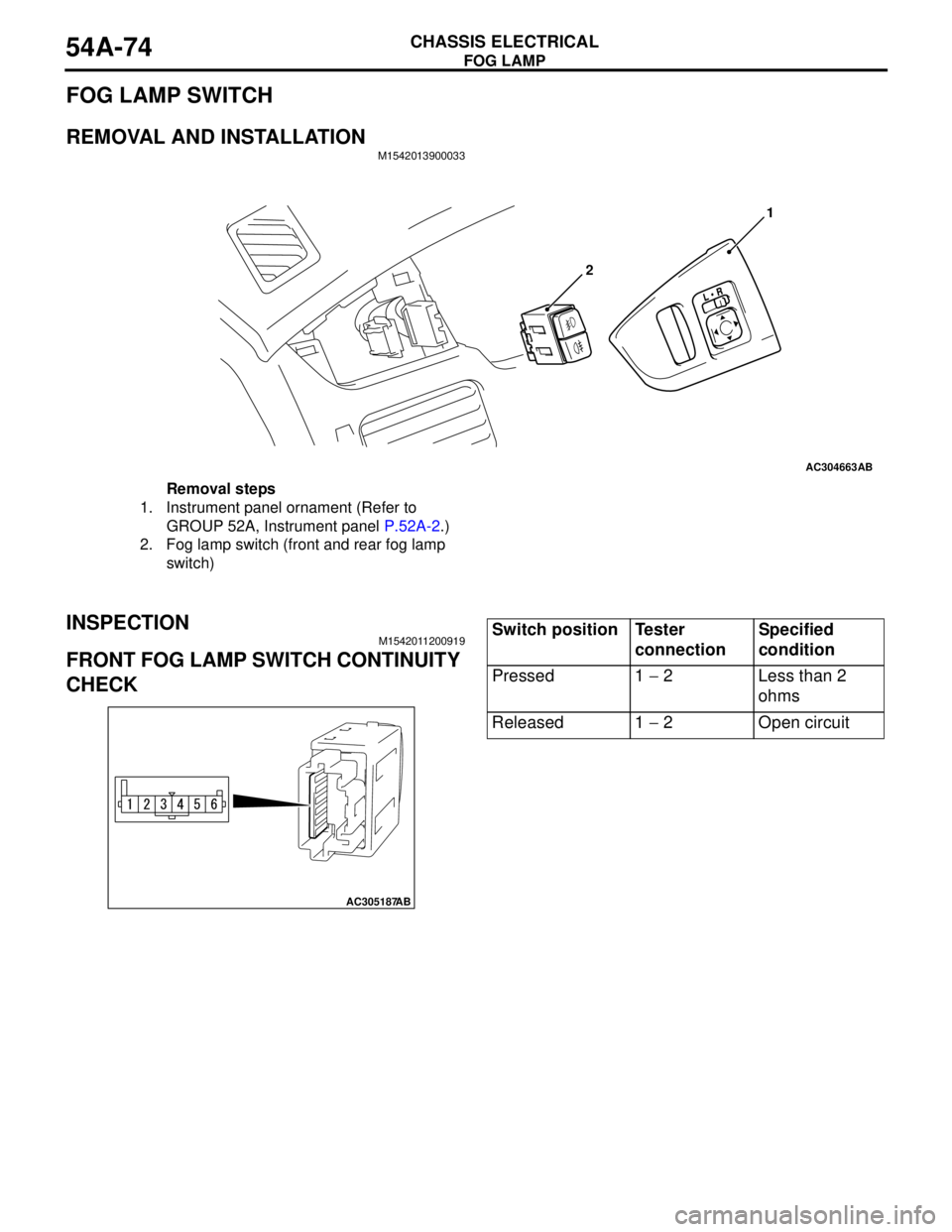

FOG LAMP SWITCH

REMOVAL AND INSTALLATIONM1542013900033

INSPECTIONM1542011200919

FRONT FOG LAMP SWITCH CONTINUITY

CHECK

AC304663AB

21

Removal steps

1. Instrument panel ornament (Refer to

GROUP 52A, Instrument panel P.52A-2.)

2. Fog lamp switch (front and rear fog lamp

switch)

AC305187

AB

Switch position Tester

connectionSpecified

condition

Pressed 1 − 2 Less than 2

ohms

Released 1 − 2 Open circuit

Page 463 of 788

REAR FOG LAMP

CHASSIS ELECTRICAL54A-75

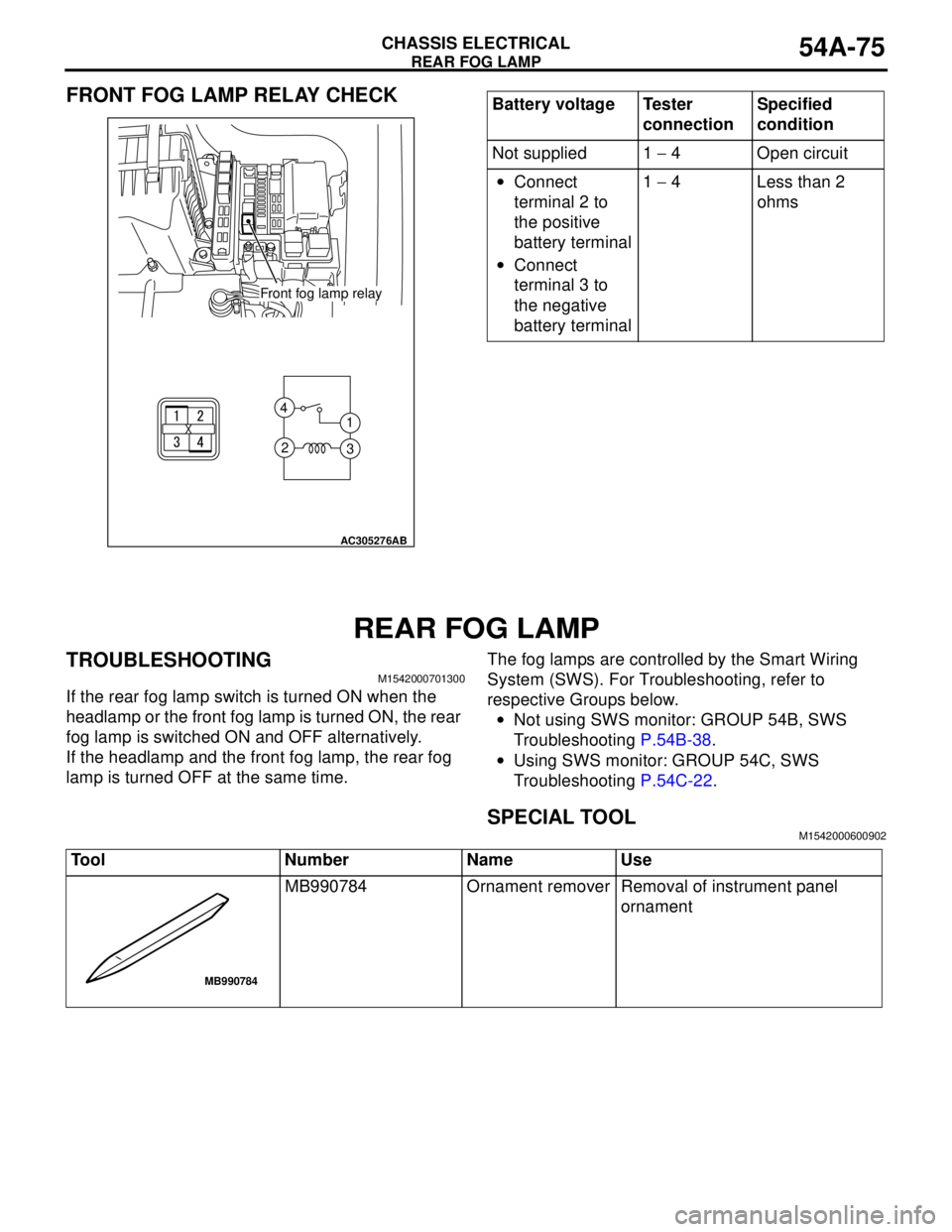

FRONT FOG LAMP RELAY CHECK

REAR FOG LAMP

TROUBLESHOOTINGM1542000701300

If the rear fog lamp switch is turned ON when the

headlamp or the front fog lamp is turned ON, the rear

fog lamp is switched ON and OFF alternatively.

If the headlamp and the front fog lamp, the rear fog

lamp is turned OFF at the same time.The fog lamps are controlled by the Smart Wiring

System (SWS). For Troubleshooting, refer to

respective Groups below.

•Not using SWS monitor: GROUP 54B, SWS

Troubleshooting P.54B-38.

•Using SWS monitor: GROUP 54C, SWS

Troubleshooting P.54C-22.

SPECIAL TOOLM1542000600902

1 4

3 2

AC305276

AB

Front fog lamp relay

Battery voltage Tester

connectionSpecified

condition

Not supplied 1 − 4 Open circuit

•Connect

terminal 2 to

the positive

battery terminal

•Connect

terminal 3 to

the negative

battery terminal1 − 4 Less than 2

ohms

Tool Number Name Use

MB990784 Ornament remover Removal of instrument panel

ornament

MB990784

Page 482 of 788

ANTENNA

CHASSIS ELECTRICAL54A-94

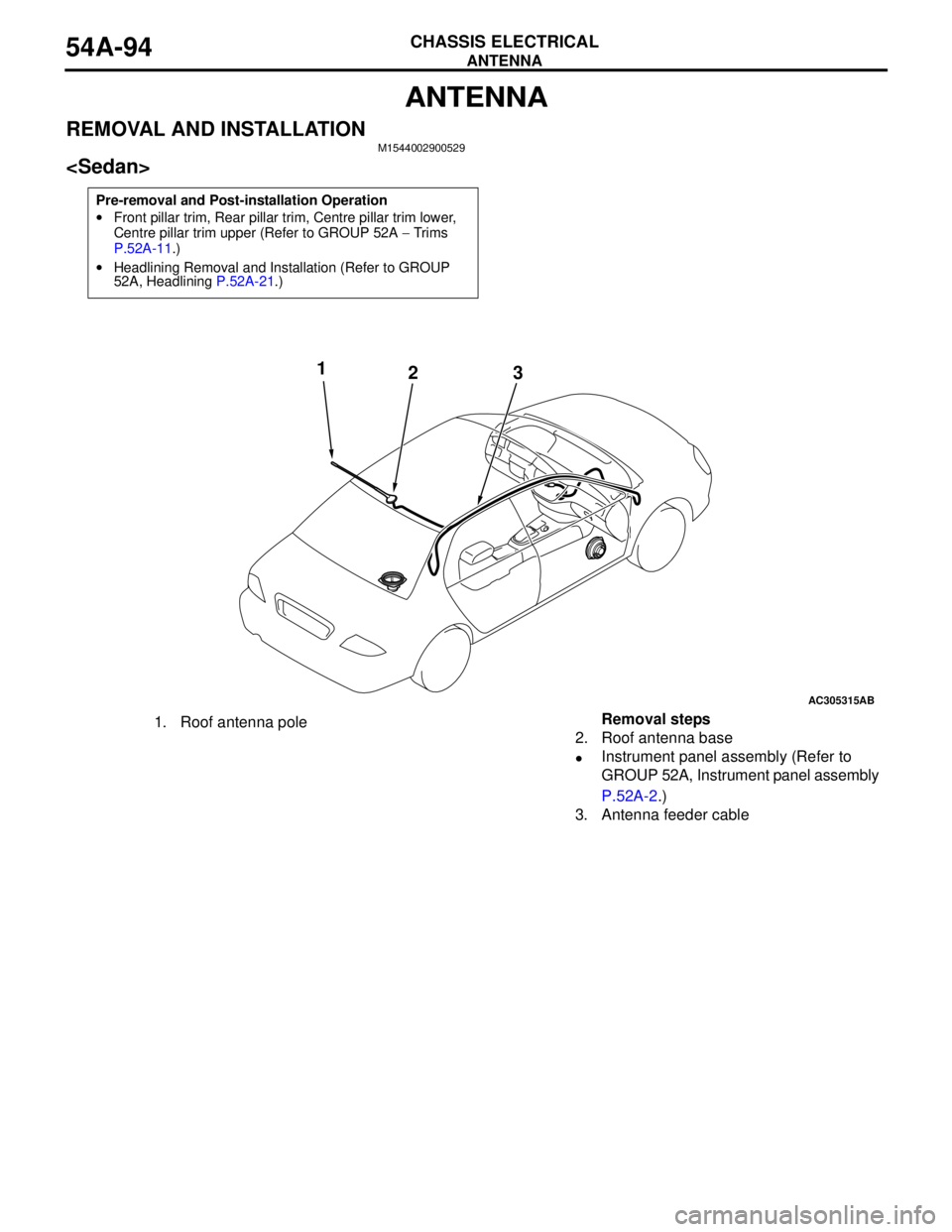

ANTENNA

REMOVAL AND INSTALLATIONM1544002900529

Pre-removal and Post-installation Operation

•Front pillar trim, Rear pillar trim, Centre pillar trim lower,

Centre pillar trim upper (Refer to GROUP 52A − Trims

P.52A-11.)

•Headlining Removal and Installation (Refer to GROUP

52A, Headlining P.52A-21.)

AC305315AB

1

23

1. Roof antenna poleRemoval steps

2. Roof antenna base

•Instrument panel assembly (Refer to

GROUP 52A, Instrument panel assembly

P.52A-2.)

3. Antenna feeder cable

Page 483 of 788

REAR WINDOW DEFOGGER

CHASSIS ELECTRICAL54A-95

REAR WINDOW DEFOGGER

GENERAL INFORMATIONM1543000100319

Rear Defogger operation

The defogger relay turns ON if the defogger switch

built-in the A/C-ECU is turned ON when the ignition

switch is in the "ON" position. When the defogger

relay turns ON, power is supplied to the defogger

and the defogger is activated. The defogger comes

with a timer function that causes the defogger switch

to automatically turn OFF in about 11 minutes after

the defogger switch is turned ON.

TROUBLESHOOTINGM1543000701013

The rear window defogger is controlled by the

A/C-ECU. For troubleshooting, refer to GROUP 55-

Troubleshooting P.55-5.

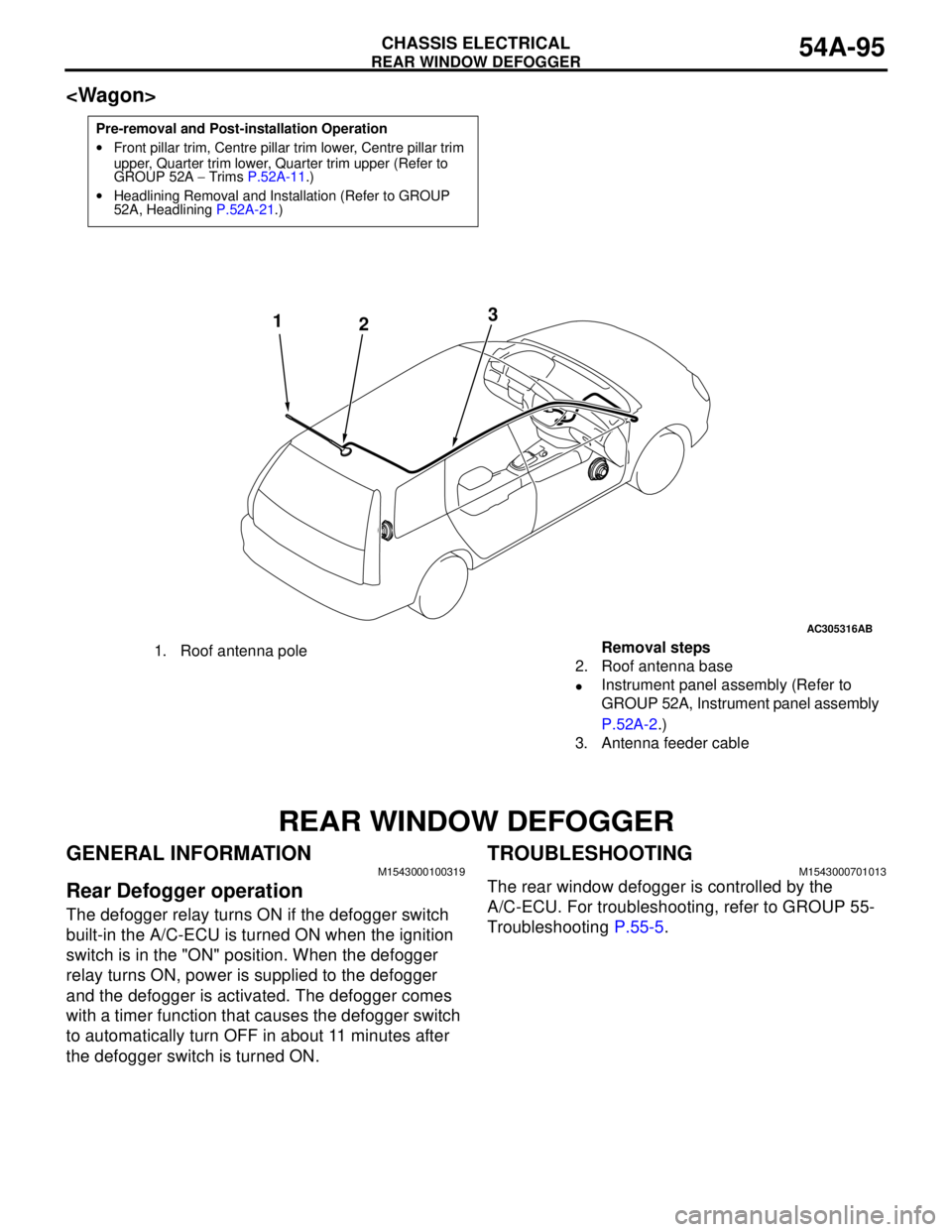

Pre-removal and Post-installation Operation

•Front pillar trim, Centre pillar trim lower, Centre pillar trim

upper, Quarter trim lower, Quarter trim upper (Refer to

GROUP 52A − Trims P.52A-11.)

•Headlining Removal and Installation (Refer to GROUP

52A, Headlining P.52A-21.)

AC305316

AB

1

23

1. Roof antenna poleRemoval steps

2. Roof antenna base

•Instrument panel assembly (Refer to

GROUP 52A, Instrument panel assembly

P.52A-2.)

3. Antenna feeder cable

Page 560 of 788

ON-VEHICLE SERVICE

HEATER, AIR CONDITIONER AND VENTILATION55-76

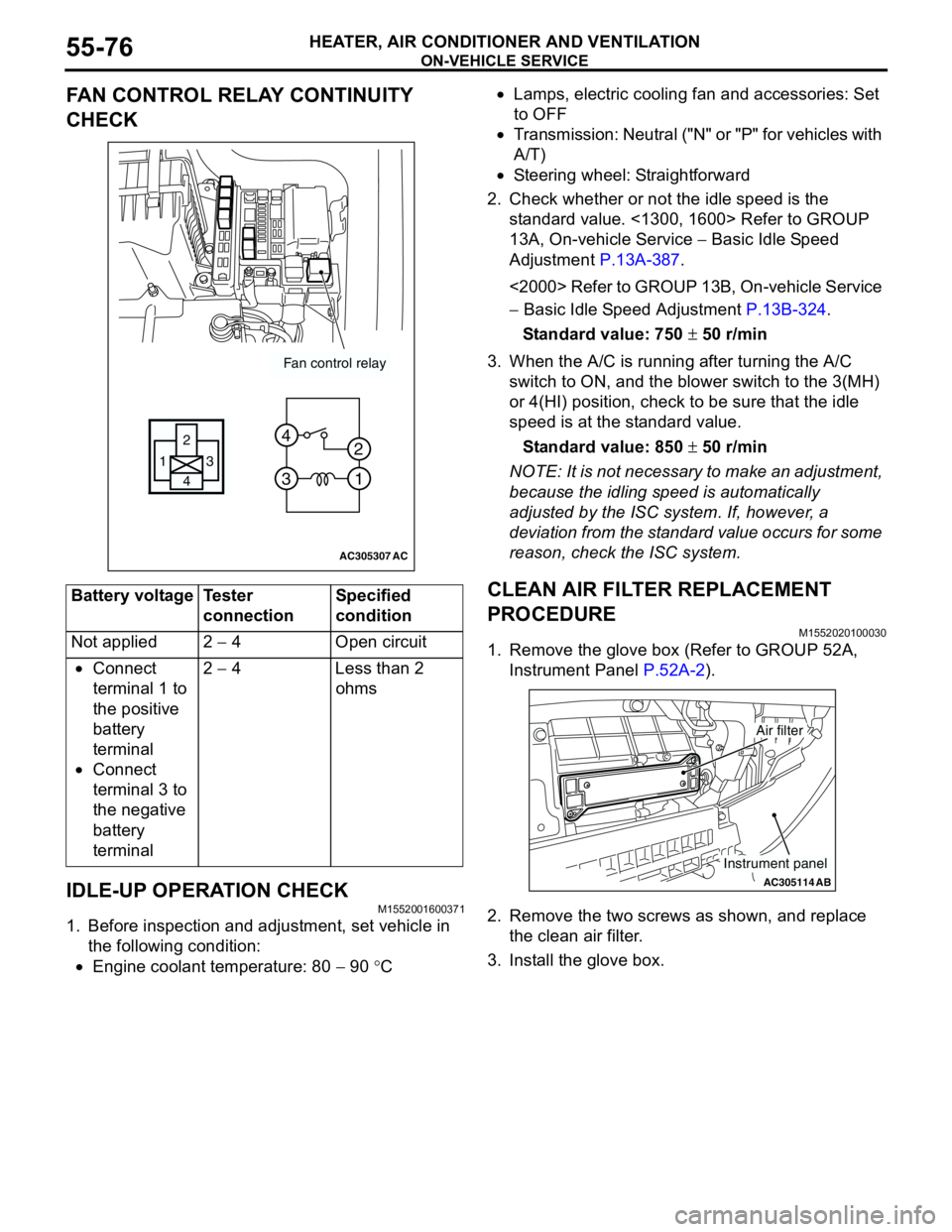

FAN CONTROL RELAY CONTINUITY

CHECK

IDLE-UP OPERATION CHECK

M1552001600371

1. Before inspection and adjustment, set vehicle in

the following condition:

•Engine coolant temperature: 80 − 90 °C•Lamps, electric cooling fan and accessories: Set

to OFF

•Transmission: Neutral ("N" or "P" for vehicles with

A/T)

•Steering wheel: Straightforward

2. Check whether or not the idle speed is the

standard value. <1300, 1600> Refer to GROUP

13A, On-vehicle Service − Basic Idle Speed

Adjustment P.13A-387.

<2000> Refer to GROUP 13B, On-vehicle Service

− Basic Idle Speed Adjustment P.13B-324.

Standard value: 750 ± 50 r/min

3. When the A/C is running after turning the A/C

switch to ON, and the blower switch to the 3(MH)

or 4(HI) position, check to be sure that the idle

speed is at the standard value.

Standard value: 850 ± 50 r/min

NOTE: It is not necessary to make an adjustment,

because the idling speed is automatically

adjusted by the ISC system. If, however, a

deviation from the standard value occurs for some

reason, check the ISC system.

CLEAN AIR FILTER REPLACEMENT

PROCEDURE

M1552020100030

1. Remove the glove box (Refer to GROUP 52A,

Instrument Panel P.52A-2).

2. Remove the two screws as shown, and replace

the clean air filter.

3. Install the glove box. Battery voltage Tester

connectionSpecified

condition

Not applied 2 − 4 Open circuit

•Connect

terminal 1 to

the positive

battery

terminal

•Connect

terminal 3 to

the negative

battery

terminal2 − 4 Less than 2

ohms

AC305307

Fan control relay

13

4 2

3 4

1 2

AC

AC305114AB

Air filter

Instrument panel