length MITSUBISHI LANCER 2006 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 41 of 800

WATE R P U M P

ENGINE COOLING14-27

WAT E R P U M P

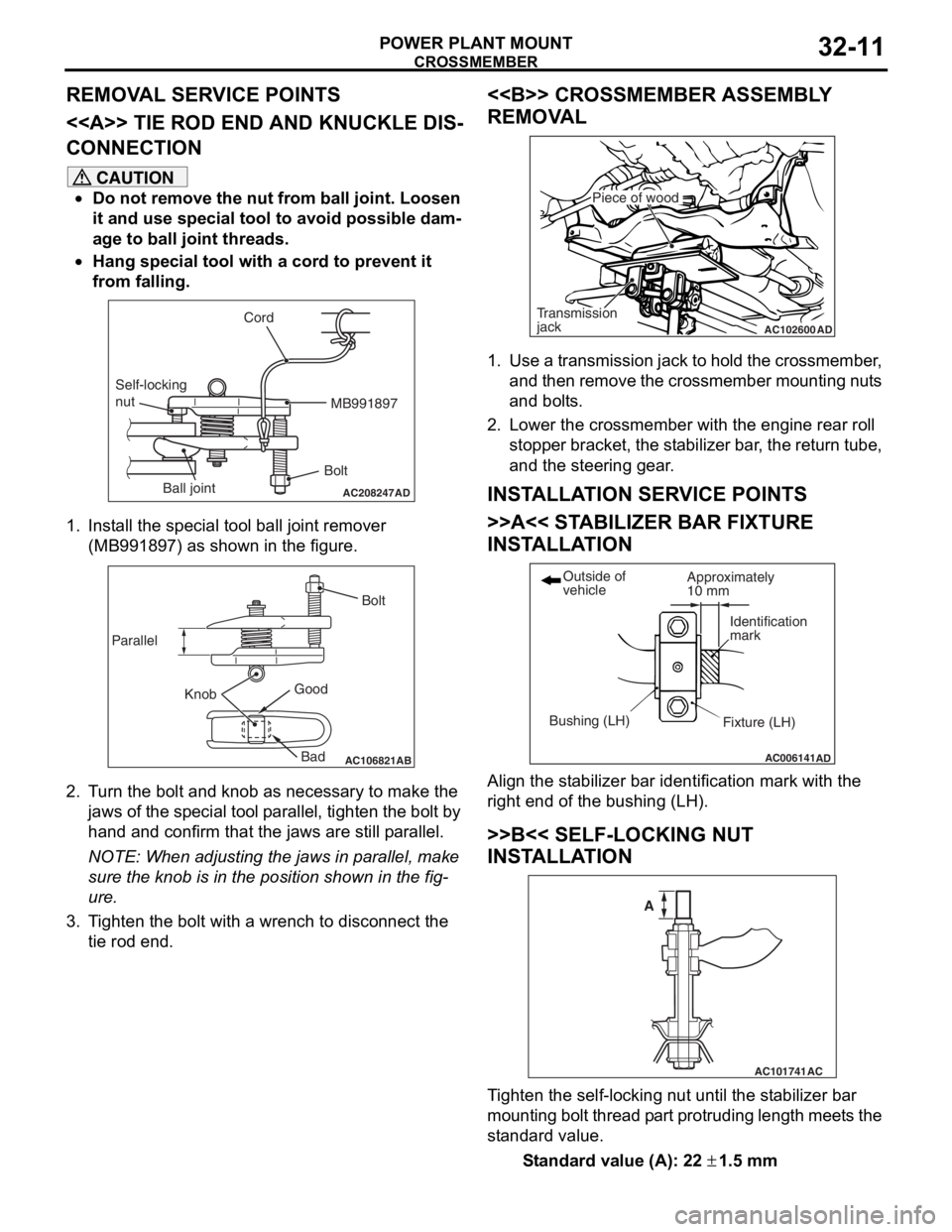

REMOVAL AND INSTALLATION <4G1>M1141002700421

Pre-removal and Post-installation Operation

•Engine Coolant Draining and Refilling (Refer to P.14-21).

•Valve Timing Belt Removal and Installation (Refer to

GROUP 11A P.11A-33).

AC303372

24 ± 3 N·m23 ± 2 N·m

14 ± 1 N·m

1 2

Bolt specifications

Screw diameter × length mm 8 × 50

8 × 308 × 25

AB

2

2

Sealant: Mitsubishi Genuine Part

No. MD970389 or equivalent

Removal steps

1.Alternator adjusting brace

>>A<<2.Water pump assembly

INST ALLA T ION SER VICE POINT

>>A<< WA TER PUMP ASSEMBL Y

INST

ALLA TION

1.Use a gaske t scraper o r wire brush to complet e ly

eliminate all gasket material o n the g a sket

mounting surface.

2. App l y a bead of the specified sealan t.

Specified Sealant: MITSUBISHI GENUINE

P

ART No.MD970 389 or eq uivalen t

3.With the sea l ant still wet (within 1 5 minutes af ter

th e se alant is applied), inst all the wa ter pump

a sse mbly . Do not a pply the sealant in an are a

more th an the required.

Page 42 of 800

WATE R P U M P

ENGINE COOLING14-28

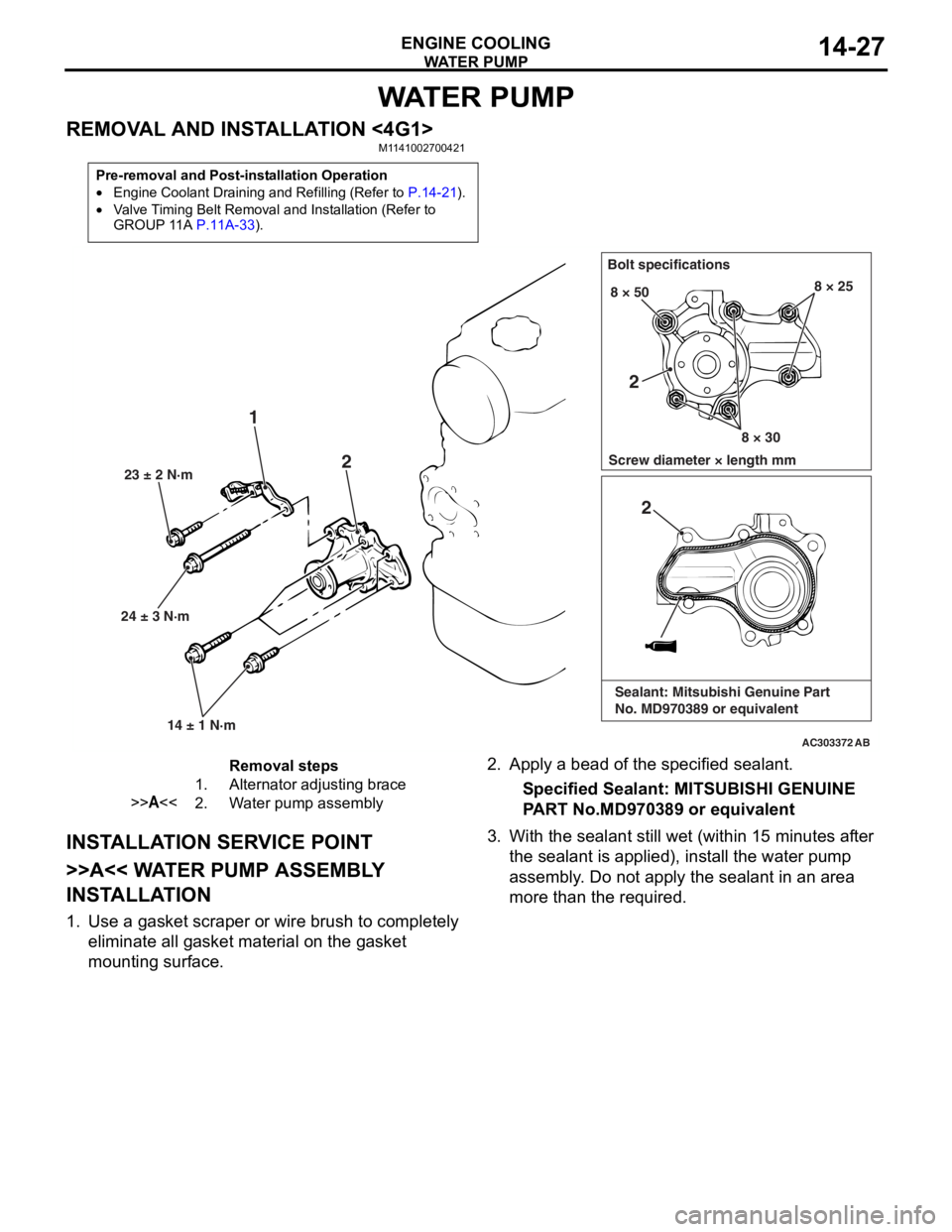

REMOVAL AND INSTALLATION <4G6>

M1141002700432

Pre-removal and Post-installation Operation

•Engine Coolant Draining and Refilling (Refer to P.14-21).

•Valve Timing Belt and Balancer Timing Belt Removal and

Installation (Refer to GROUP 11C

P.11C-35).

AC301467

22 ± 4 N·m23 ± 3 N·m 14 ± 1 N·m

12

3

4

N

N

Bolt specifications

Screw diameter × length mm

8 × 70 8 × 22

8 × 14

8 × 22

8 × 25

2

AB

Removal steps

1.Alternator adjusting brace

2.Water pump assembly

3.Water pump gasket

>>A<<4.Cooling water line O-ring

INST

ALLA T ION SER VICE POINT

>>A<< COOLING WA TER LINE O-RING

INST

ALLA TION

AC103005

Water pump assembly

Cooling water

line O-ring

Water pump inlet pipe

AF

Fit the coo ling water line O-ring to the groove in the

wa

ter pump in let p i pe. T hen lubricate th e co olin g

wa

ter line O-ring and the inside of the wat e r pump

assembly with wa

ter , and then insert the wa ter pu mp

inle

t pip e to the water pu mp asse mbly .

Page 80 of 800

AK202802

CHARGING SYSTEM

ENGINE ELECTRICAL16-18

2.Check t he co ndition of the (−) heat sink by

checkin

g

con

t

inuity b

e

tween th e (

−) he at sink and

ea

ch o

f

the st

a

t

or co

il lead conne

cting termina l s.

If con t inu i ty is p r ese n t in bot h d i re ctio ns, the dio de

is shorted.

Re place the rectifier assembly .

AK202804

3.Check t he co ndition of the diode t r io by testing

continuity of ea ch o f the th ree diodes using a

circuit tester con necte d to both sides of the dio de.

Co nnect in a p o la rity a nd then reverse the polarity

fo r each test.

If continuity exist s or no cont inuity exist s for bo th

po

larities, the d i ode is d e fective . Repla c e th e

rectifier assembly if a

n y o f the d i odes is defe c tive.

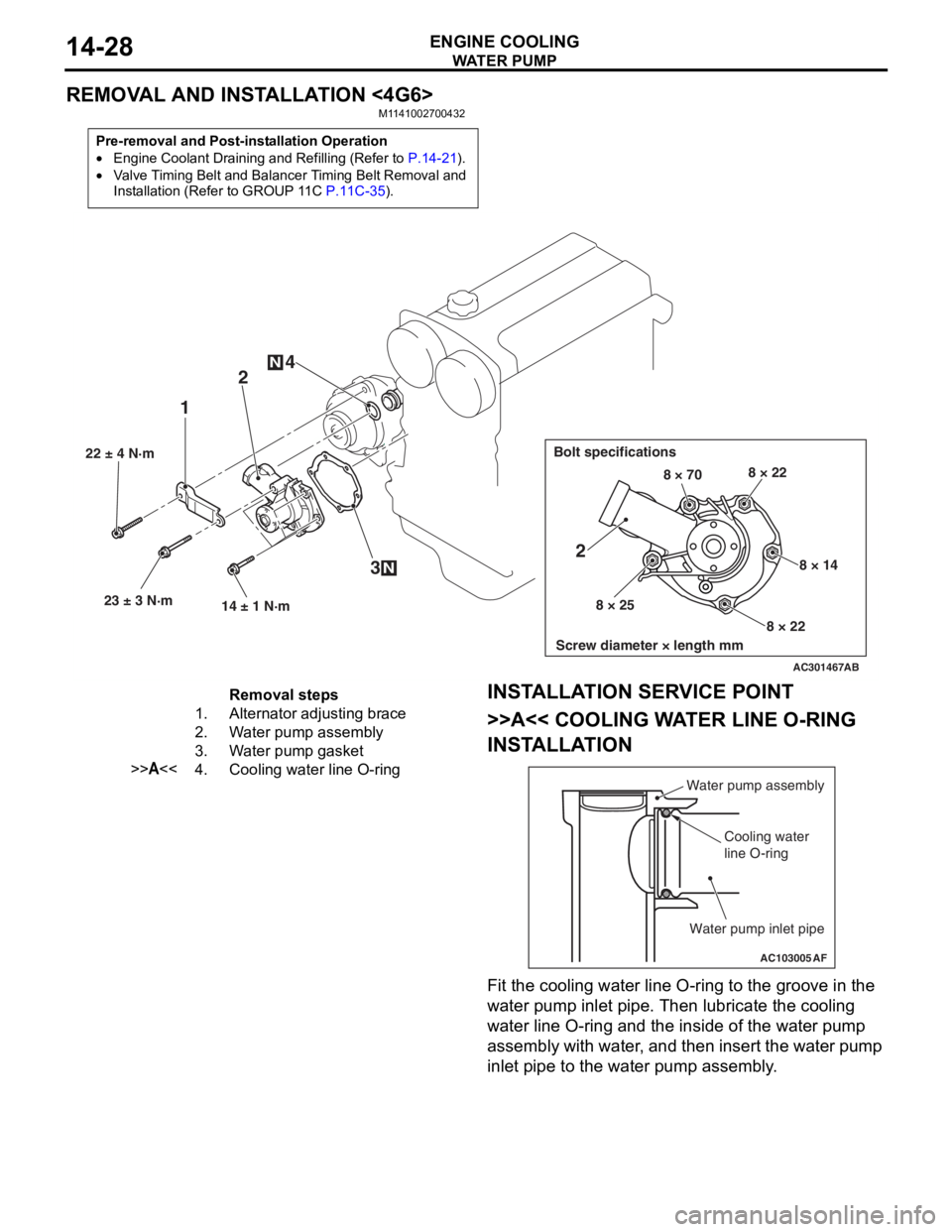

BRUSH

AK202808

Protrusion

length

AB

1.Measure the lengt h of the prot rusion o f the bru s h.

Replace the b r ush if the protrusion lengt h is

shorter than th e limit .

Limit: 2 mm mini mum

2.Unsolde r the lead o f the br ush. The bru s h will

come out, b e coming ready for removal.

AK202834

Solder

AB

3.I n st all a ne w b r ush b y pu sh in g it int o the h o lde r a s

shown in the d r awing a nd soldering th e lea d .

Page 97 of 800

IGNITION SYSTEM

ENGINE ELECTRICAL16-35

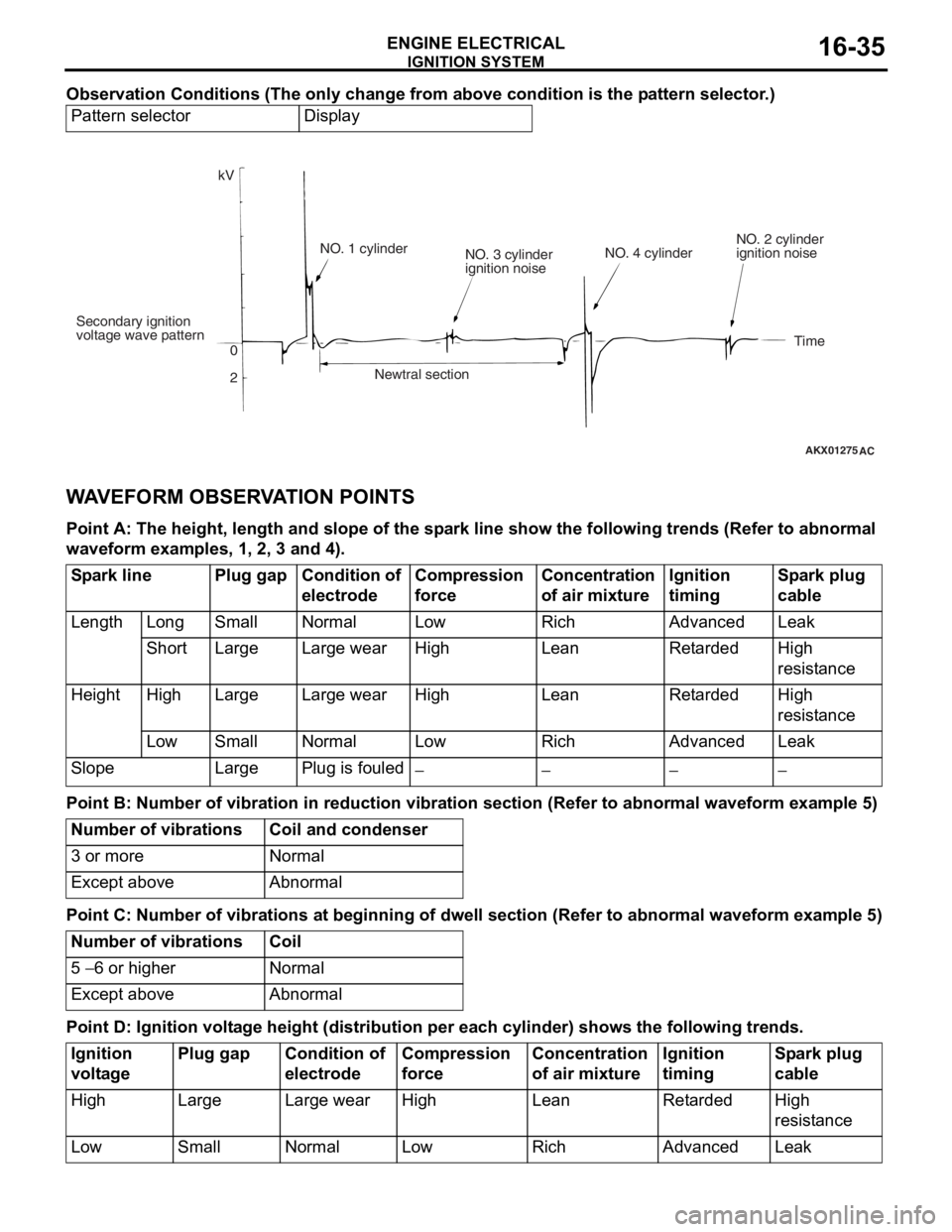

Observation Conditions (The only change from above condition is the pattern selector.)

Pattern selectorDisplay

AKX01275

kV

Secondary ignition

voltage wave pattern 0

2NO. 1 cylinder

NO. 3 cylinder

ignition noise

Newtral section NO. 4 cylinder

NO. 2 cylinder

ignition noise

Time

AC

WA VEFORM OBSER V A T ION POINTS

Point A: The he ight, len g th and s l ope of th e sp a r k line sho w the following trends (Re f er to abnorma l

wave

form exam ples, 1 , 2, 3 a nd 4).

Spark linePlug gapCondition of

electrodeCompression

force Concentration

of air mixtureIgnition

timingSpark plug

cable

LengthLongSmallNormalLowRichAdvancedLeak

ShortLargeLarge wearHigh LeanRetardedHigh

resistance

HeightHighLargeLarge wearHighLeanRetardedHigh

resistance

LowSmallNormalLow RichAdvancedLeak

SlopeLargePlug is fouled−−−−

Point B: Number of v i bra t ion in red uction vi bra t ion sec tion (Refer to a bnormal wavefo r m examp l e 5)

Number of vibrationsCoil and condenser

3 or moreNormal

Except aboveAbnormal

Point C: Number of v i bra t ions a t beginnin g of dwell se ction (Refer to a bnormal wave form exam ple 5)

Number of vibrationsCoil

5 − 6 or higherNormal

Except aboveAbnormal

Point D: Ignition volt a g e height (distribution per each cylinder) s hows the follo wing tren ds.

Ignition

voltagePlug gapCondition of

electrodeCompression

forceConcentration

of air mixtureIgnition

timingSpark plug

cable

HighLargeLarge wearHighLeanRetardedHigh

resistance

LowSmallNormalLowRichAdvancedLeak

Page 134 of 800

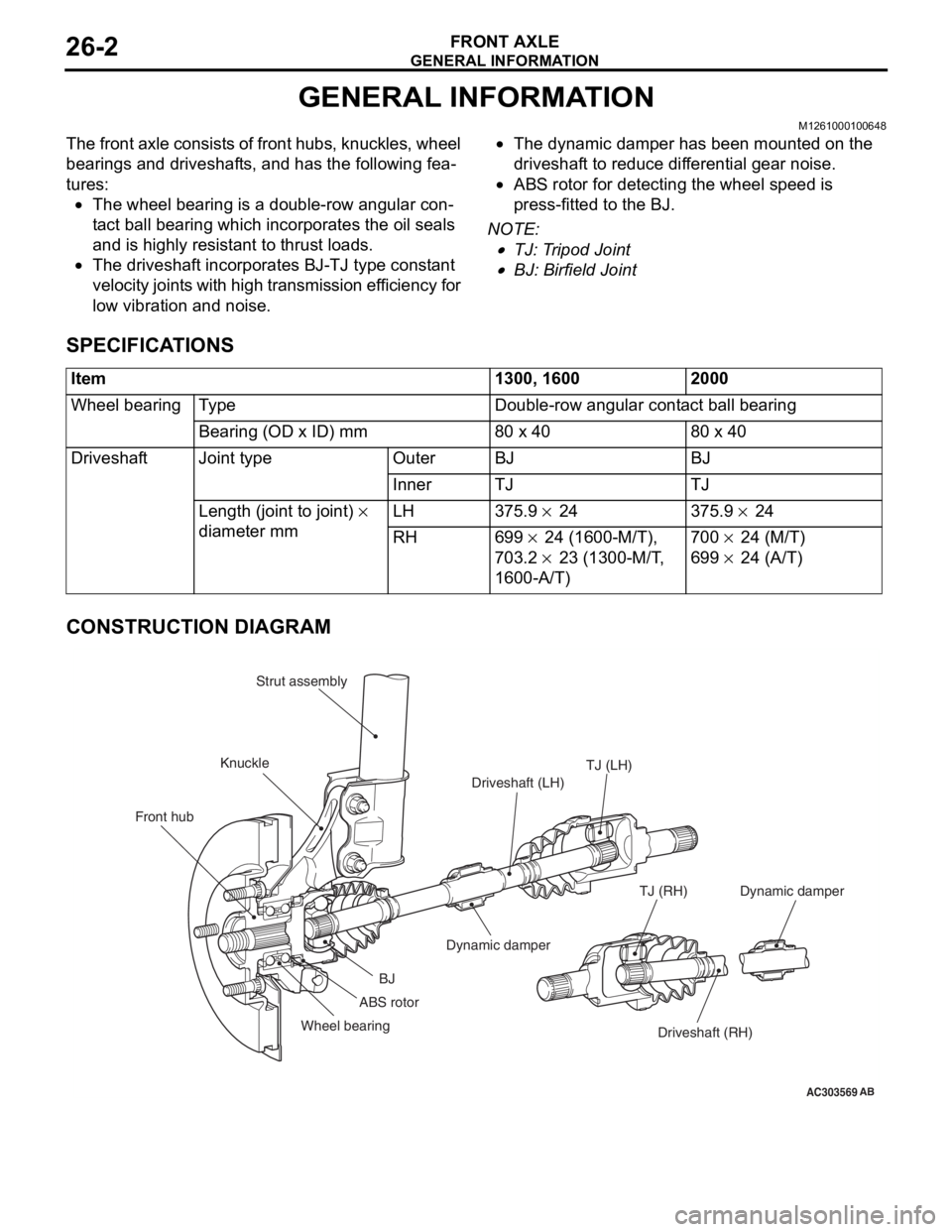

GENERAL INFORMATION

FRONT AXLE26-2

GENERAL INFORMATION

M1261000100648

The front axle consists of front hubs, knuckles, wheel

bearings and driveshafts, and has the following fea

-

tures:

•The wheel bearing is a double-row angular con-

tact ball bearing which incorporates the oil seals

and is highly resistant to thrust loads.

•The driveshaft incorporates BJ-TJ type constant

velocity joints with high transmission efficiency for

low vibration and noise.

•The dynamic damper has been mounted on the

driveshaft to reduce differential gear noise.

•ABS rotor for detecting the wheel speed is

press-fitted to the BJ.

NOTE: .

•TJ: Tripod Joint

•BJ: Birfield Joint

SPECIFICATIONS

Item1300, 16002000

Wheel bearingTy p eDouble-row angular contact ball bearing

Bearing (OD x ID) mm80 x 4080 x 40

DriveshaftJoint typeOuterBJBJ

InnerTJTJ

Length (joint to joint) ×

diameter mm LH 375.9 × 24 375.9 × 24

RH699 × 24 (1600-M/T),

703.2

× 23 (1300-M/T,

1600-A/T)

700 × 24 (M/T)

699 × 24 (A/T)

CONSTRUCTION DIAGRAM

AC303569

Front hub KnuckleStrut assembly

TJ (LH)

Driveshaft (LH)

Dynamic damper

BJ

Wheel bearing Driveshaft (RH)

TJ (RH)

AB

ABS rotor

Dynamic damper

Page 135 of 800

SERVICE SPECIFICATIONS

FRONT AXLE26-3

SERVICE SPECIFICATIONS

M1261000300675

ItemStandard valueLimit

Wheel bearing axial play mm−0.05

Hub starting torque N⋅m−1.8

Protruding length of stabilizer bar mounting bolt mm22 ± 1.5−

Setting of TJ boot length mm1300-RH, 1600-A/T-RH85 ± 3−

1300-LH, 1600-M/T,

1600-A/T-LH, 200090 ± 3−

Opening dimension of the

special tool (MB991561) mmWhen the BJ boot band

(small) is crimped2.9−

When the BJ boot band

(large) is crimped2.9 −

Crimped width of the BJ boot band mm2.4 − 2.8−

LUBRICANTS

M1261000400735

ItemSpecified lubricantQuantity

TJ boot greaseRepair kit grease1300-LH, 1600-LH,

2000-LH120 ± 10 g

1300-RH, 1600-A/T-RH11 0 ± 10 g

1600-M/T-RH, 2000-A/T-RH120 ± 10 g

2000-M/T-RH105 ± 10 g

BJ boot greaseRepair kit grease95 ± 10 g

Page 142 of 800

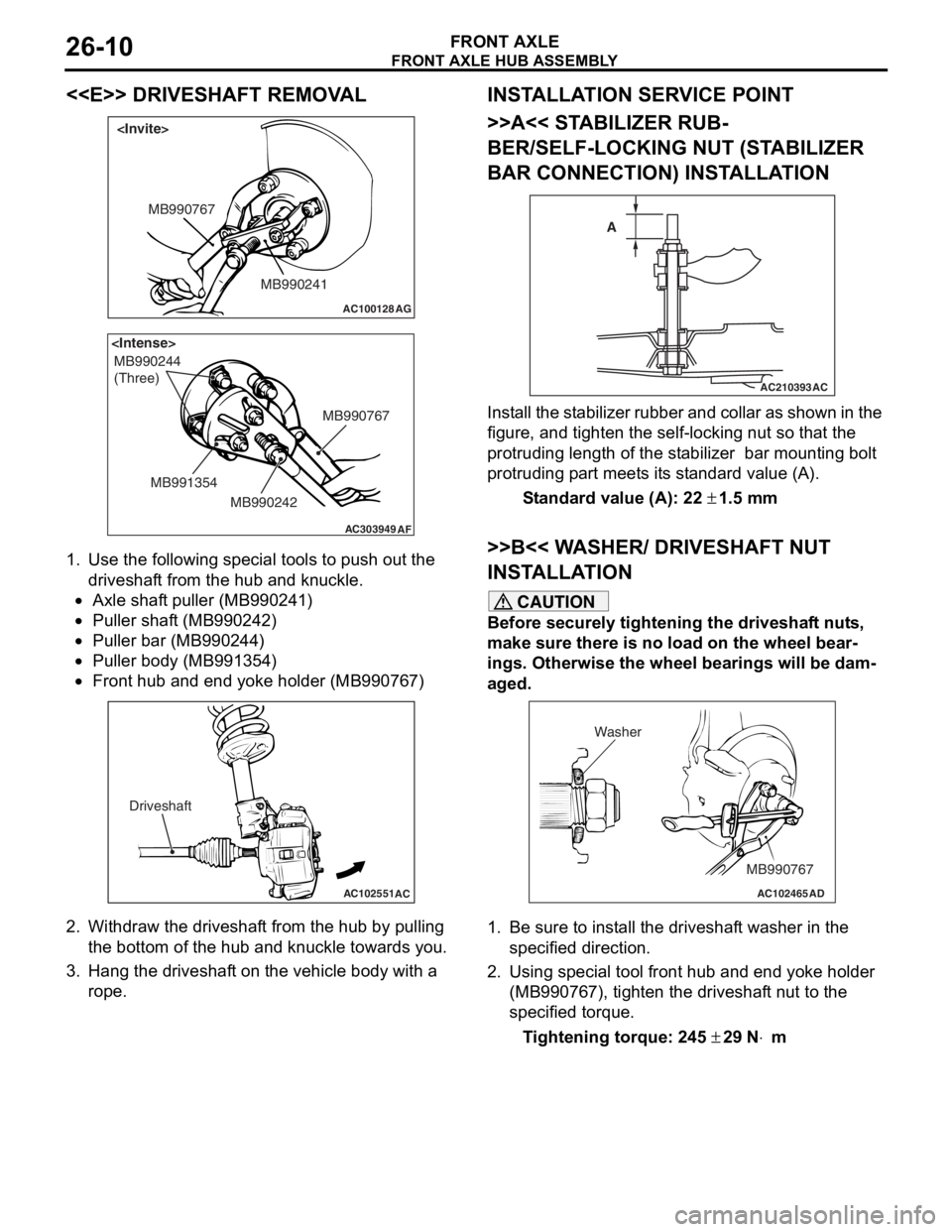

FRONT AXLE HUB ASSEMBLY

FRONT AXLE26-10

<

AC100128

MB990241

MB990767

AG

AC303949

MB990244

(Three)

MB990767

MB990242

MB991354

AF

1.

Use the fo llo wing special to ols to pu sh ou t the

driveshaf t from the hub an d kn uckle.

•Axle shaf t puller (MB9 90241 )

•Puller shaft (MB990 242)

•Puller bar (MB990 244)

•Puller body (MB99135 4)

•

AC102551

AC

Driveshaft

Front hub a nd end yoke holder (MB99076 7)

2.Withdraw th e driveshaf t from the hu b by pulling

th e botto m of the hub and knuckle towards you .

3.Hang the dr ive s haf t on the vehicle b ody with a

rope.

INST ALLA T ION SER VICE POINT

>>A<< STABILIZER RUB-

BER/SELF-LOCKING NUT (ST A BILIZER

BAR CONNECTION) INST

ALLA TION

AC210393AC

A

I

n st a ll the st a b ili zer rubb er an d coll ar as sho w n in t he

figure

, and t i ghte n the self-locking nut so tha t the

protruding length

of the st abilize r bar mount ing b o lt

protruding p

a rt meet s it s st and ard value (A).

St andard va lue (A): 22 ± 1.5 m m

>>B<< W A SHER/ DRIVESHAFT NUT

INST

ALLA TION

CAUTION

Before securely tightening the driveshaft nuts,

make sure there is no load on the wheel bear

-

ings. Otherwise the wheel bearings will be dam-

aged.

AC102465AD

MB990767

Washer

1. Be sure to install the driveshaft washer in the

specified direction.

2. Using special tool front hub and end yoke holder (MB990767), tighten the driveshaft nut to the

specified torque.

Tightening torque: 245 ± 29 N⋅m

Page 148 of 800

AC102551AC

Drive shaft

DRIVESHAFT ASSEMBL Y

FRONT AXLE26-16

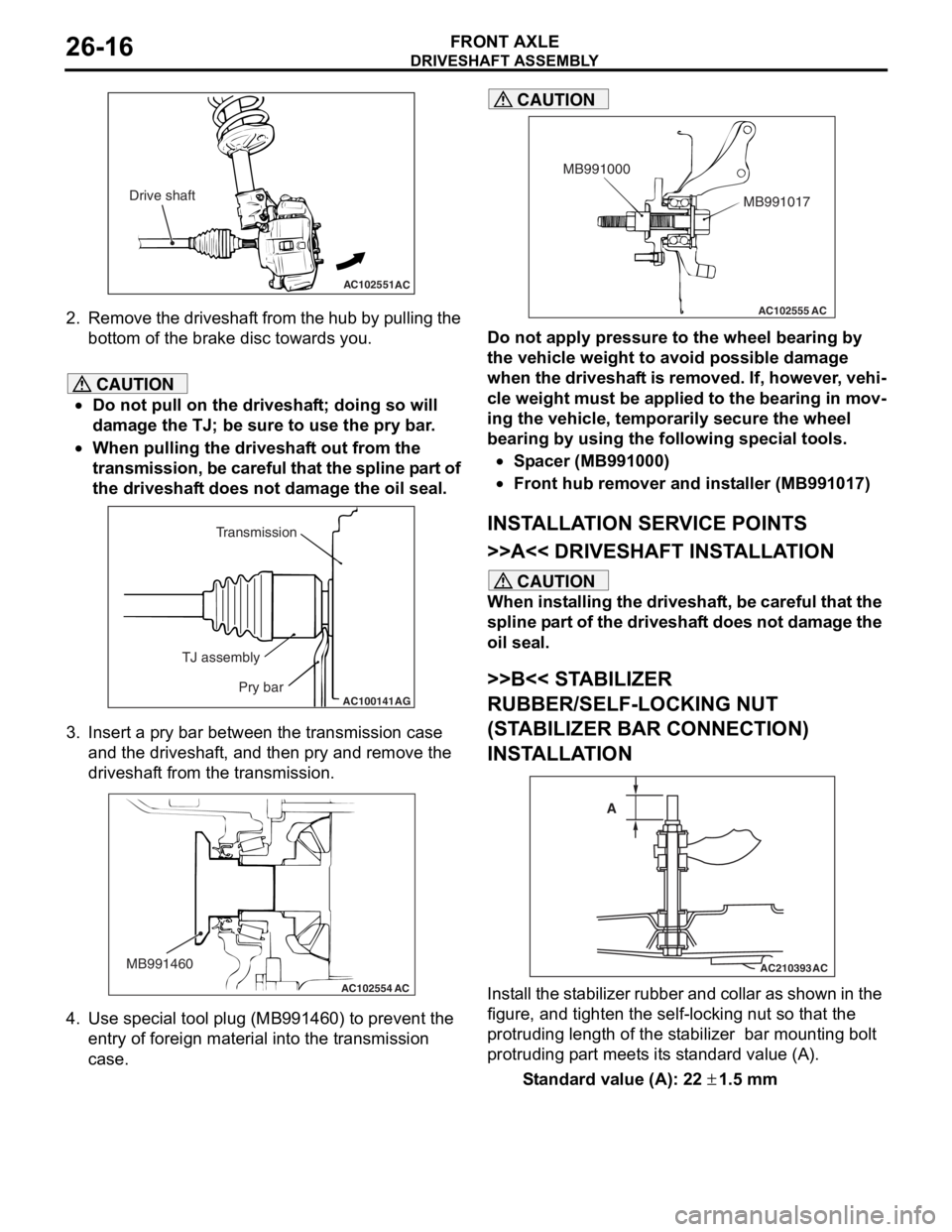

2.Remove th e dr ivesh a f t from th e h ub b y p u lling the

bo ttom of the brake disc toward s you.

CAUTION

•Do not pull on the driveshaft; doing so will

damage the TJ; be sure to use the pry bar.

•

AC100141

Transmission

TJ assembly Pry bar

AG

When pulling the driveshaft out from the

transmission, be careful that the spline part of

the driveshaft does not damage the oil seal.

3. Insert a pry bar between the transmission case and the driveshaft, and then pry and remove the

driveshaft from the transmission.

AC102554

MB991460

AC

4. Use special tool plug (MB991460) to prevent the

entry of foreign material into the transmission

case.

AC102555 AC

MB991017

MB991000

CAUTION

Do not apply pressure to the wheel bearing by

the vehicle weight to avoid possible damage

when the driveshaft is removed. If, however, vehi

-

cle weight must be applied to the bearing in mov-

ing the vehicle, temporarily secure the wheel

bearing by using the following special tools.

•Spacer (MB991000)

•Front hub remover and installer (MB991017)

INSTALLATION SERVICE POINTS

>>A<< DRIVESHAFT INSTALLATION

CAUTION

When installing the driveshaft, be careful that the

spline part of the driveshaft does not damage the

oil seal.

>>B<< STABILIZER

RUBBER/SELF-LOCKING NUT

(STABILIZER BAR CONNECTION)

INSTALLATION

AC210393

AC

A

Install the stabilizer rubber and collar as shown in the

figure, and tighten the self-locking nut so that the

protruding length of the stabilizer bar mounting bolt

protruding part meets its standard value (A).

Standard value (A): 22 ± 1.5 mm

Page 173 of 800

SERVICE SPECIFICATION

POWER PLANT MOUNT32-3

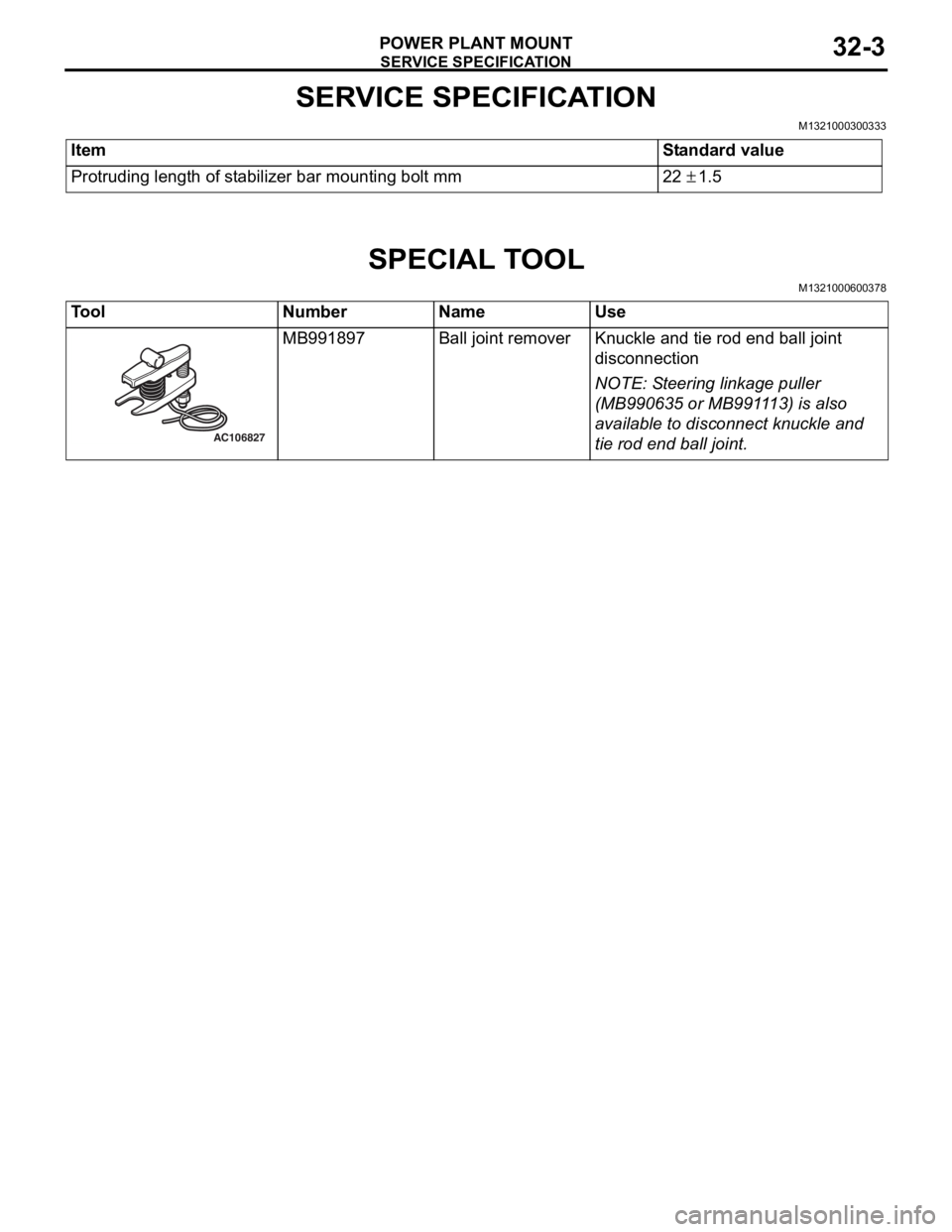

SERVICE SPECIFICATION

M1321000300333

ItemStandard value

Protruding length of stabilizer bar mounting bolt mm22 ± 1.5

SPECIAL TOOL

M1321000600378

ToolNumberNameUse

AC106827

MB991897Ball j o in t remo verKnuckle and tie rod e nd ball joint

discon

nection

NOTE: St eering linkage pu lle r

(MB990 635 o r MB991 1 13) is also

ava

ilab

l e to disconn ect knuckle and

tie ro

d end ball joint.

Page 181 of 800