body MITSUBISHI LANCER 2006 Owners Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 331 of 800

KEYLESS ENTRY SYSTEM

BODY42-59

REASSEMBLY SERVICE POINT

>>A<< BATTERY INSTALLATION

CAUTION

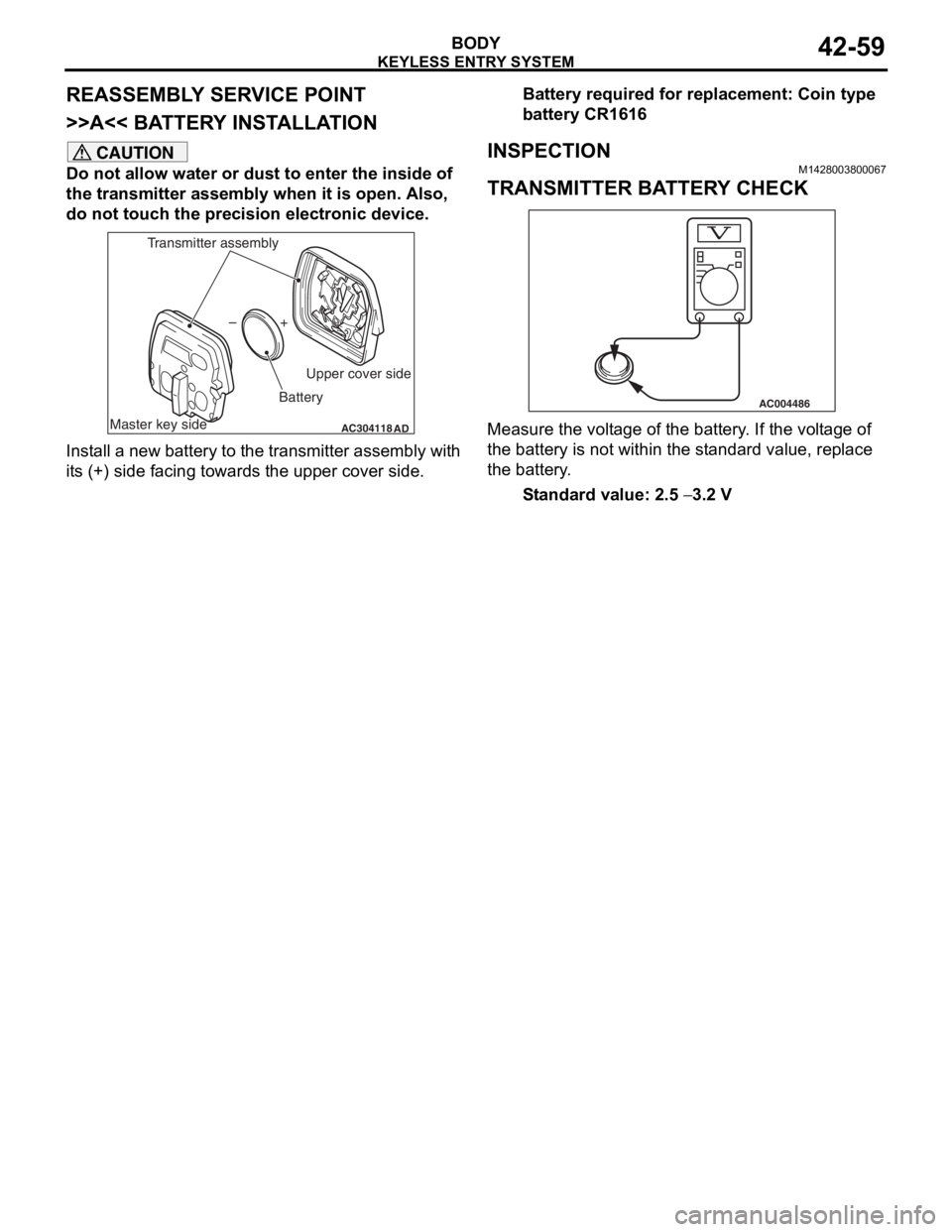

Do not allow water or dust to enter the inside of

the transmitter assembly when it is open. Also,

do not touch the precision electronic device.

AC304118AD

+

–

Master key side Upper cover side

Battery

Transmitter assembly

Install a new battery to the transmitter assembly with

its (+) side facing towards the upper cover side.

Battery required for replacement: Coin type

battery CR1616

INSPECTION

M1428003800067

TRANSMITTER BATTERY CHECK

AC004486

Measure the voltage of the battery. If the voltage of

the battery is not within the standard value, replace

the battery.

Standard value: 2.5 − 3.2 V

Page 343 of 800

MOULDINGS

EXTERIOR51-11

INSTALLATION SERVICE POINTS

>>A<< DRIP MOULDING CLIP C/DRIP

MOULDING CLIP B/DRIP MOULDING

CLIP A INSTALLATION

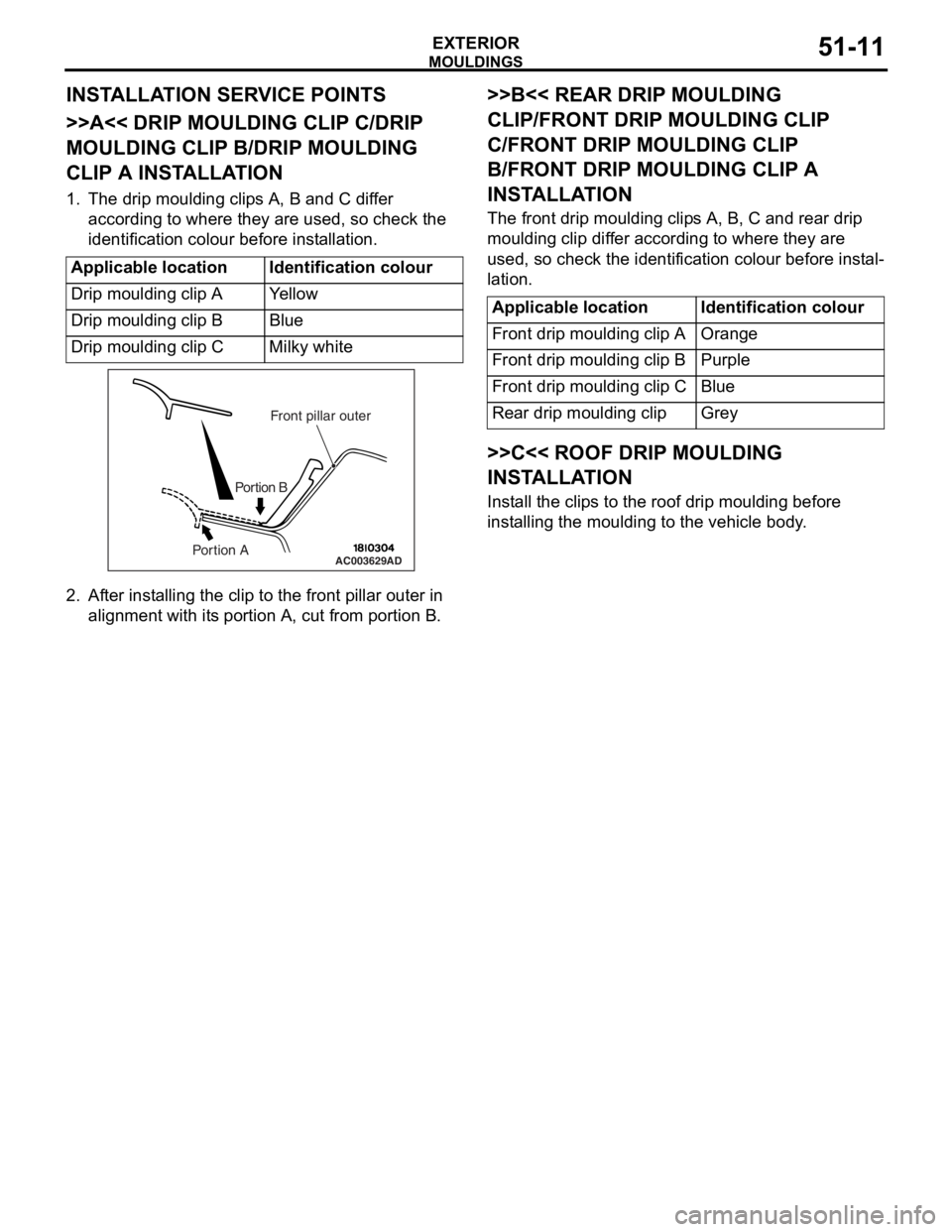

1. The drip moulding clips A, B and C differ according to where they are used, so check the

identification colour before installation.

Applicable locationIdentification colour

Drip moulding clip AYe l l o w

Drip moulding clip BBlue

Drip moulding clip CMilky white

AC003629

Front pillar outer

Portion B

Portion AAD

2. Af ter inst alling the clip to the f r ont pilla r outer in

align m ent with it s portio n A, cu t from portion B.

>>B<< REAR DRIP MOULDING

CLIP/FRONT DRIP MOULDING CLIP

C/FRONT DRIP MOULDING CLIP

B/FRONT DRIP MOULDING CLIP A

INST

ALLA TION

The front drip mou l din g clip s A, B, C an d rear d r ip

moulding

clip dif f er accordin g to where they are

used

, so check th e ide n tification colou r before inst al

-

lation.

Applicable locationIdentification colour

Front drip moulding clip AOrange

Front drip moulding clip BPurple

Front drip moulding clip CBlue

Rear drip moulding clipGrey

>>C<< ROOF DRIP MOULDING

INSTALLA TION

Install the clip s to th e roof d r ip mould i ng before

inst

allin g the moulding to the vehicle body .

Page 345 of 800

AC000420Double-sided tapeProtection tapeAB

MO

UL DI N G S

EXTERIOR51-13

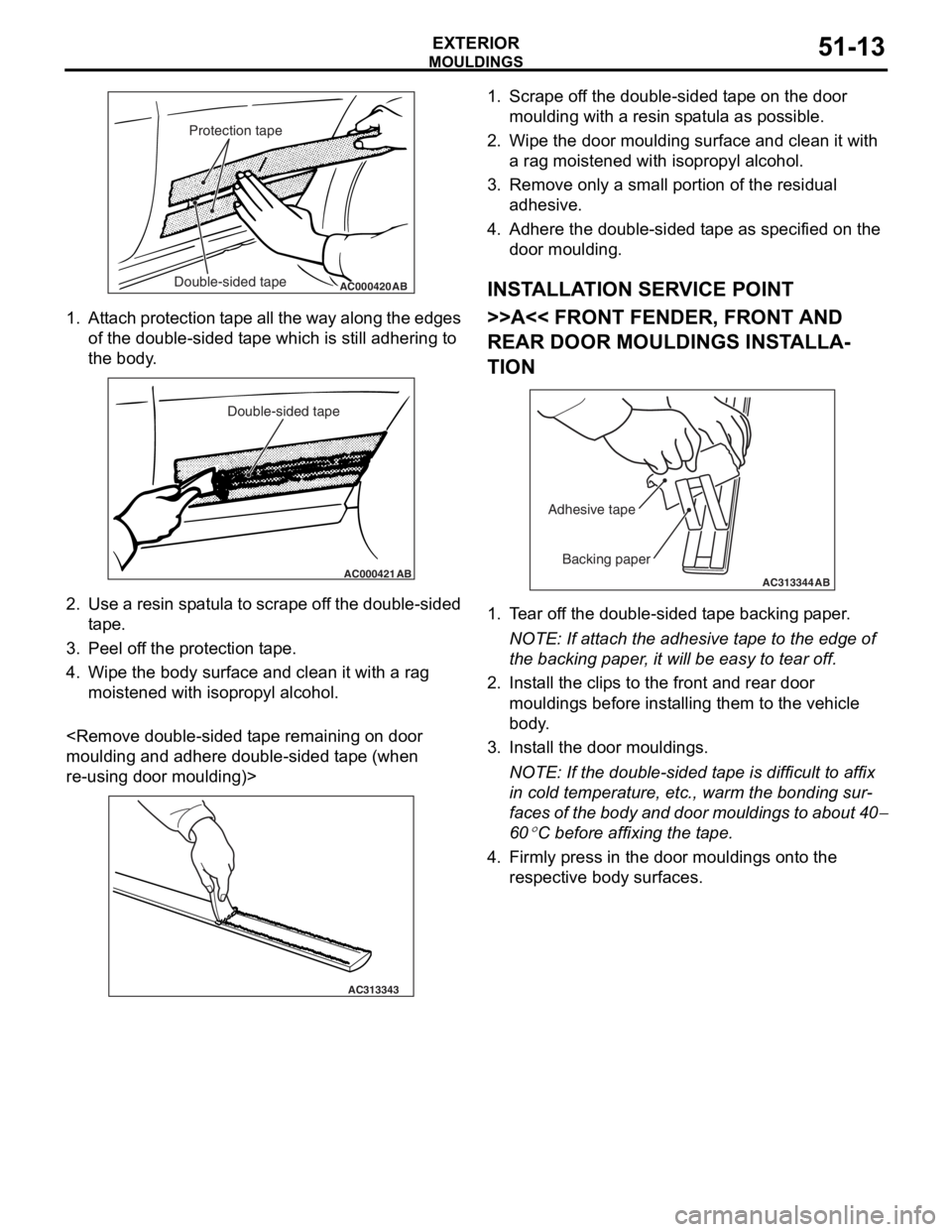

1.At t a ch pro t ection t a pe all th e wa y alon g the e dge s

of the do uble - sid ed t ape which is still adh ering to

th e body .

AC000421

Double-sided tape

AB

2.Use a resin sp atula to scrape of f t he dou ble-sided

t ape .

3.Pee l of f the pr otect i on t ape .

4.Wipe th e body su rface and clean it with a rag

moistened with isopro p yl alcohol.

and a dhere d ouble-sided t ape (wh en

re-using do

or mo ulding)>

AC313343

1.Scrape o f f the double-sided t ape on th e door

moulding with a re sin sp atula as possible.

2.Wipe th e door moulding surfa c e a nd clean it with

a rag moistened with isoprop yl a l co hol.

3.Remove only a small po rtion o f the re sid ual

a dhesive .

4.Adh e re the double-sided t ape as specified on t he

d oor mo ulding.

INSTALLA T ION SER VICE POINT

>>A<< FRONT FENDER, FRONT AND

REAR DOOR MOULDINGS INST

ALLA

-

TION

AC313344

Backing paper

Adhesive tape

AB

1.

T ear of f the double-sided t ape backing p aper .

NOTE: If atta ch the adhesive t a pe to the edg e of

th

e backing p aper , it will be easy to te ar off.

2.In st all the clip s to the front a nd rear door

mouldings befo r e inst alling th em to the vehicle

b ody .

3.In st all the do or mo uldings.

NOTE: If the double-sided t ape is difficult to af fix

in co

ld te mpera t ure, et c., warm the b ondin g su r

-

faces of the bod y and doo r mo uldin g s to ab out 40−

60

°C bef ore affixing the t a p e .

4.Firmly pre ss in the door moulding s ont o the

re spective bod y surface s .

Page 347 of 800

Page 374 of 800

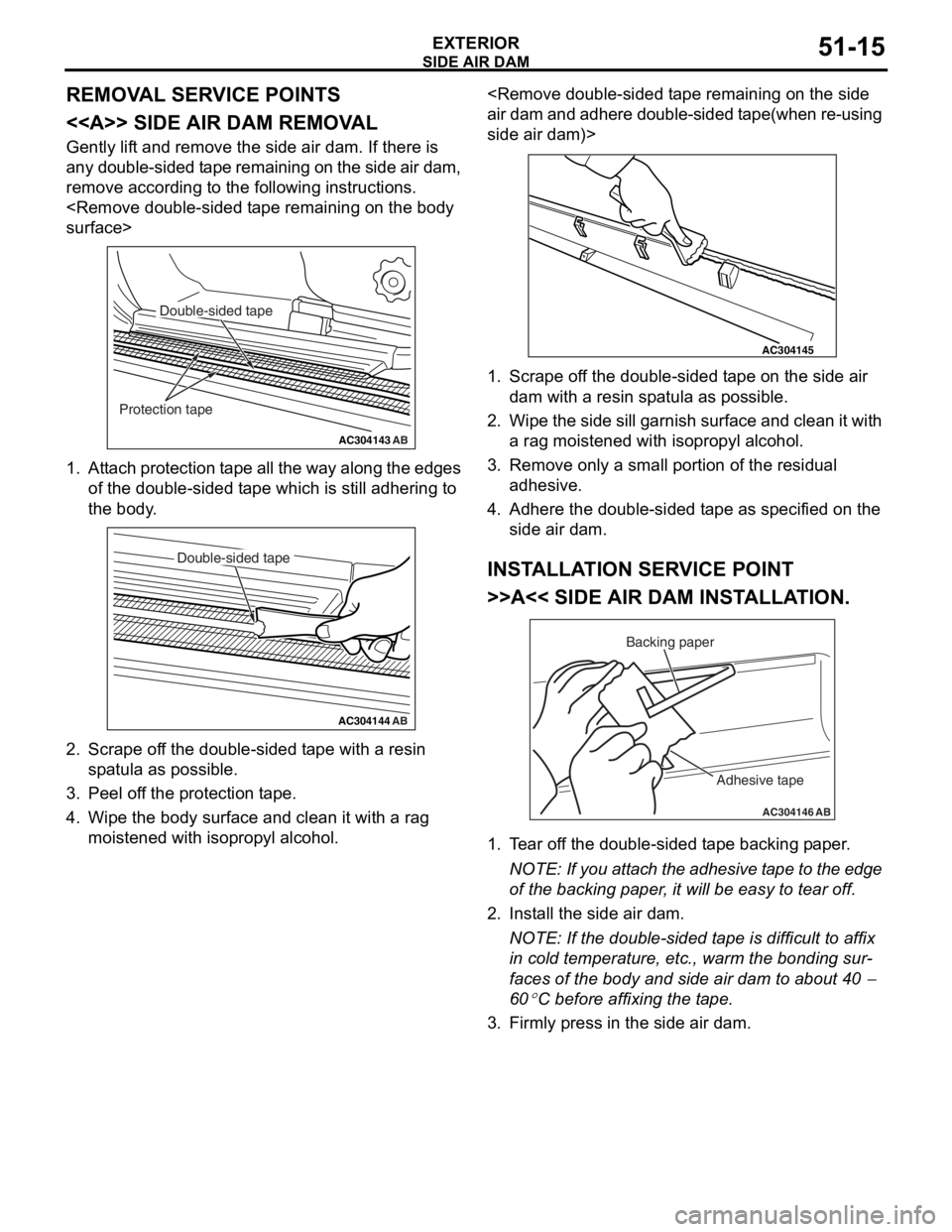

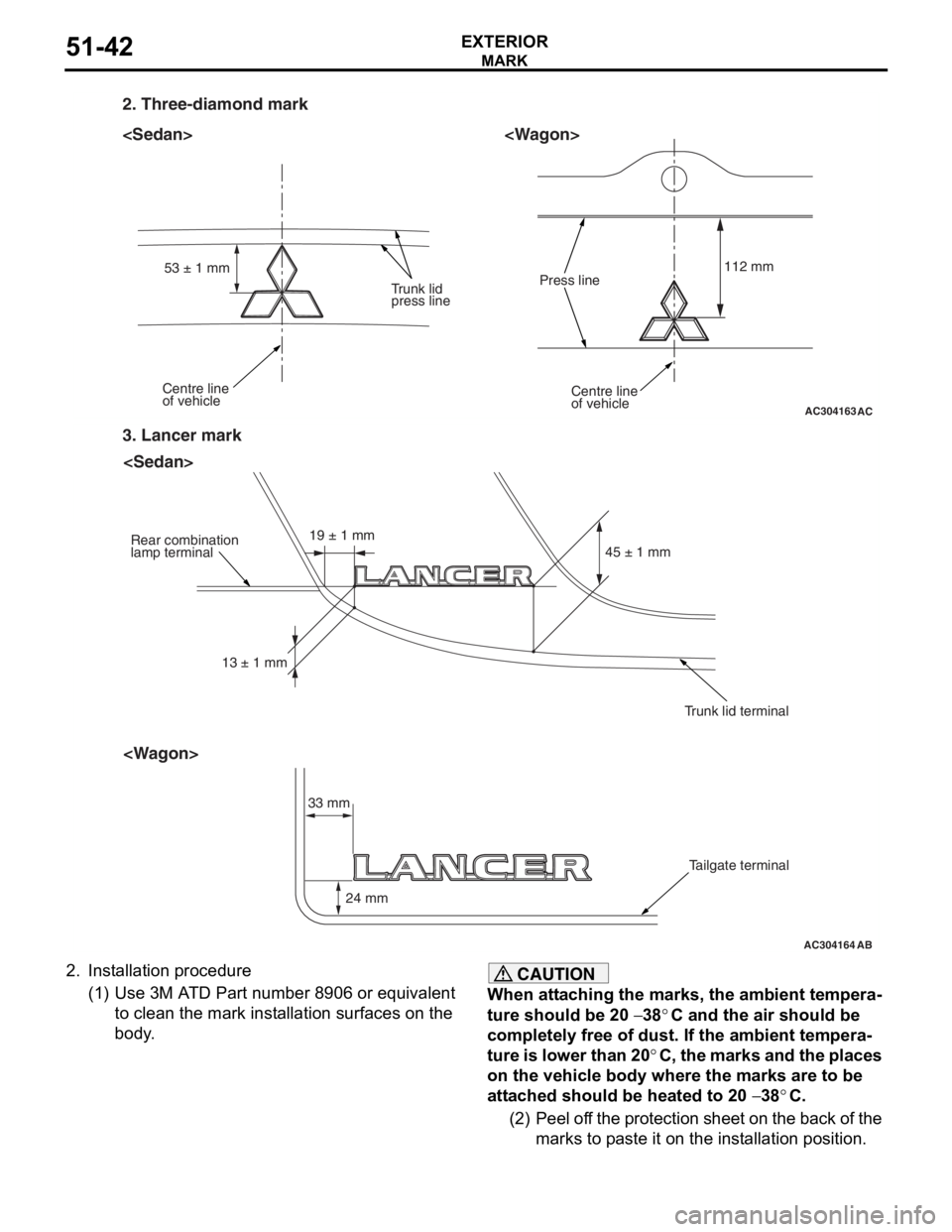

AC304163

2. Three-diamond mark

Centre line

of vehicleCentre line

of vehicle

Trunk lid

press linePress line

112 mm

53 ± 1 mm

AC

AC304164

3. Lancer mark

Rear combination

lamp terminal

Trunk lid terminalTailgate terminal

33 mm 24 mm 45 ± 1 mm

13 ± 1 mm 19 ± 1 mm

AB

MARK

EXTERIOR51-42

2.

In st allation procedure

(1)U se 3 M A T D Pa rt number 890 6 or eq uivalen t

to clean the mark inst allation surface s on the

body .

CAUTION

When attaching the marks, the ambient tempera-

ture should be 20 − 38°C and the air should be

completely free of dust. If the ambient tempera

-

ture is lower than 20°C, the marks and the places

on the vehicle body where the marks are to be

attached should be heated to 20

− 38°C.

(2) Peel off the protection sheet on the back of the marks to paste it on the installation position.

Page 382 of 800

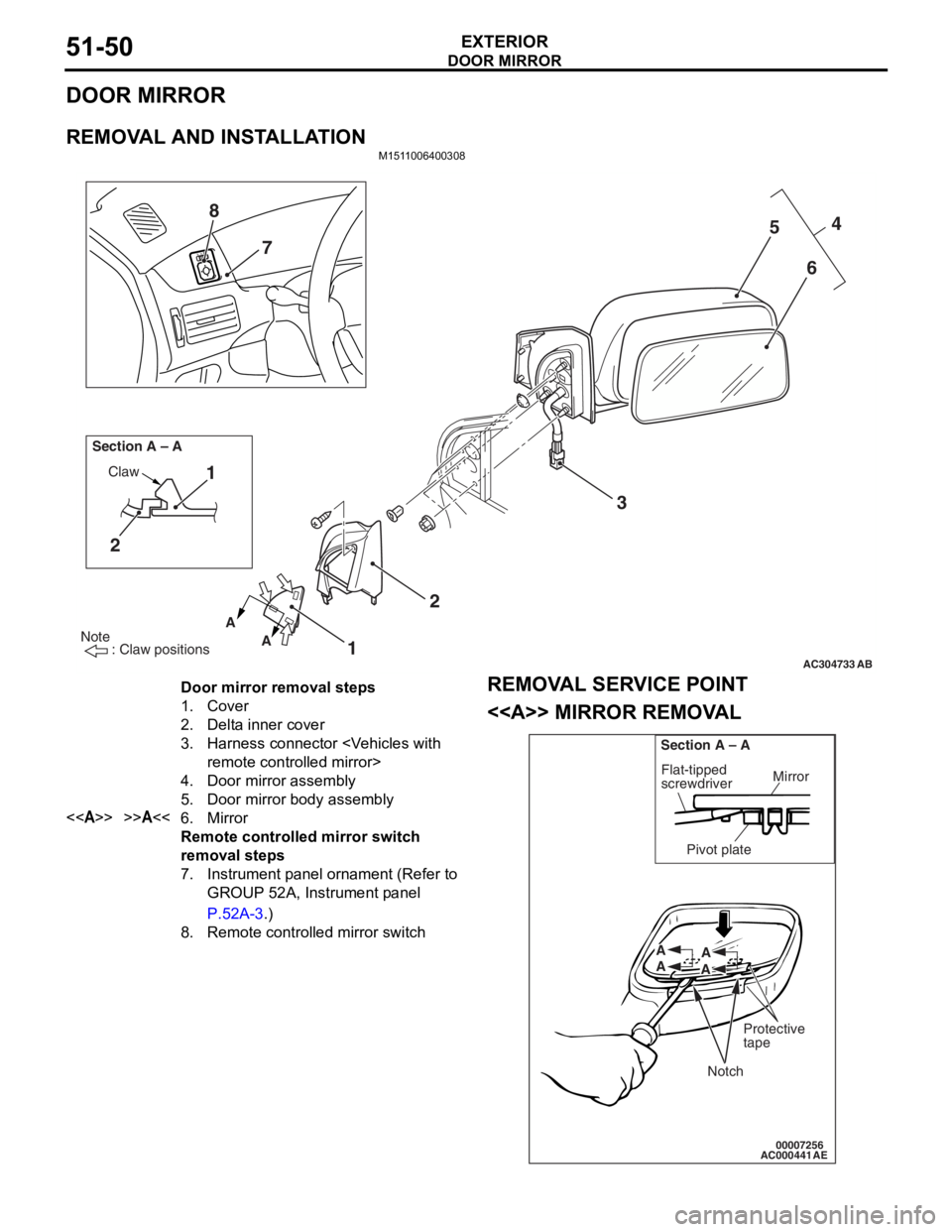

DOOR MIRROR

EXTERIOR51-50

DOOR MIRROR

REMOVAL AND INSTALLATION

M1511006400308

AC304733

Note

: Claw positions

AB

AA

Section A – A

Claw1

2

12 3 4

5

6

7

8

Door mirror removal steps

1.Cover

2.Delta inner cover

3.Harness connector

4.Door mirror assembly

5.Door mirror body assembly

<>>>A<<6.Mirror

Remote controlled mirror switch

removal steps

7.Instrument panel ornament (Refer to

GROUP 52A, Instrument panel

P.52A-3.)

8.Remote controlled mirror switch

REMOV

A L SER VICE POINT

<> MIRROR REMOV A L

AC00044100007256

Mirror

Flat-tipped

screwdriver

Section A – A

Pivot plate

Notch

Protective

tape

A

A A

A

AE

Page 396 of 800

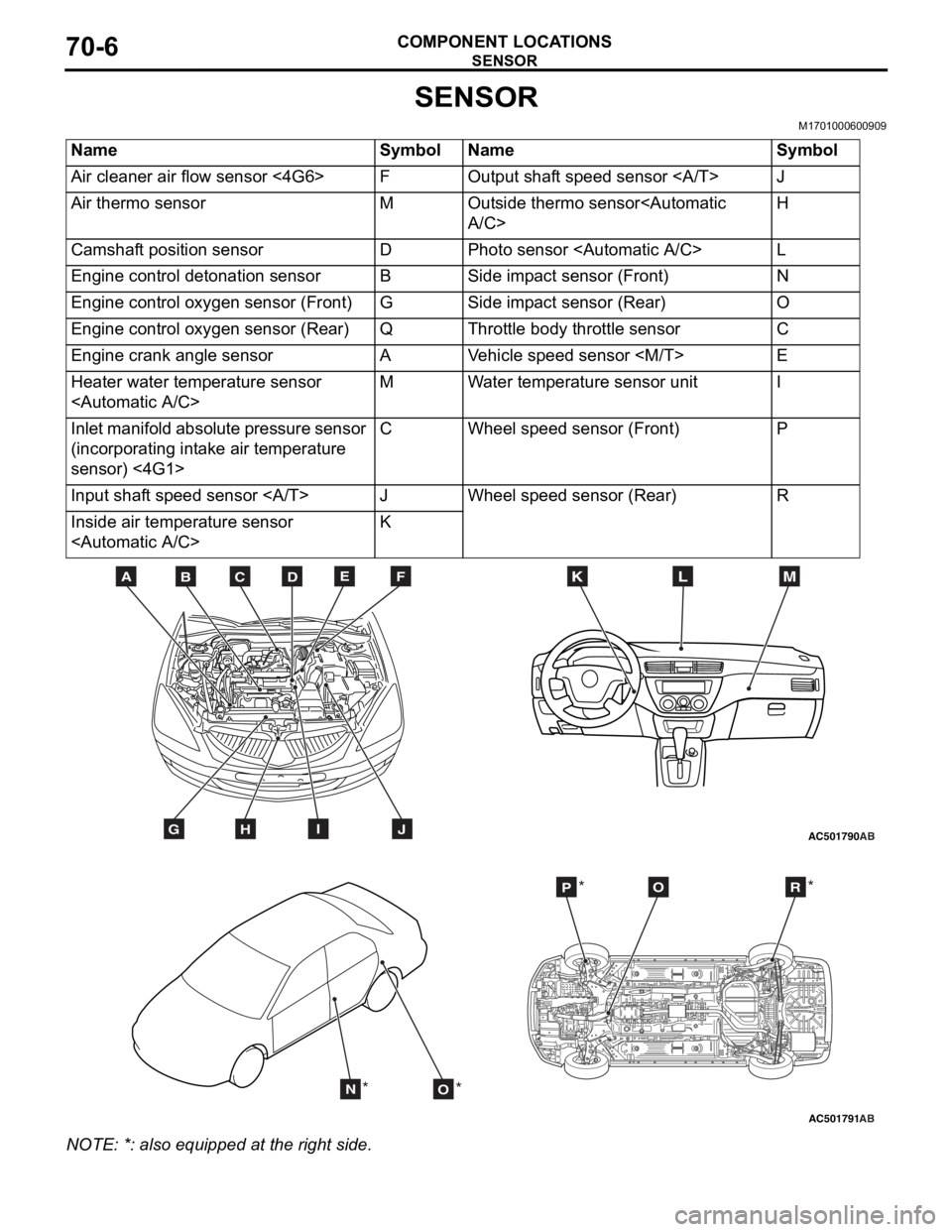

SENSOR

COMPONENT LOCATIONS70-6

SENSOR

M1701000600909

NameSymbolNameSymbol

Air cleaner air flow sensor <4G6>FOutput shaft speed sensor J

Air thermo sensorMOutside thermo sensor

Camshaft position sensorDPhoto sensor

Engine control detonation sensorBSide impact sensor (Front)N

Engine control oxygen sensor (Front)GSide impact sensor (Rear)O

Engine control oxygen sensor (Rear)QThrottle body throttle sensorC

Engine crank angle sensorAVehicle speed sensor

Heater water temperature sensor

Inlet manifold absolute pressure sensor

(incorporating intake air temperature

sensor) <4G1>CWheel speed sensor (Front)P

Input shaft speed sensor JWheel speed sensor (Rear)R

Inside air temperature sensor

AC501790

BDCFEA

GHIJ

MKL

AB

AC501791AB

NO

POR

** *

*

NO

TE: *: also eq uipp ed at t he rig h t side.

Page 397 of 800

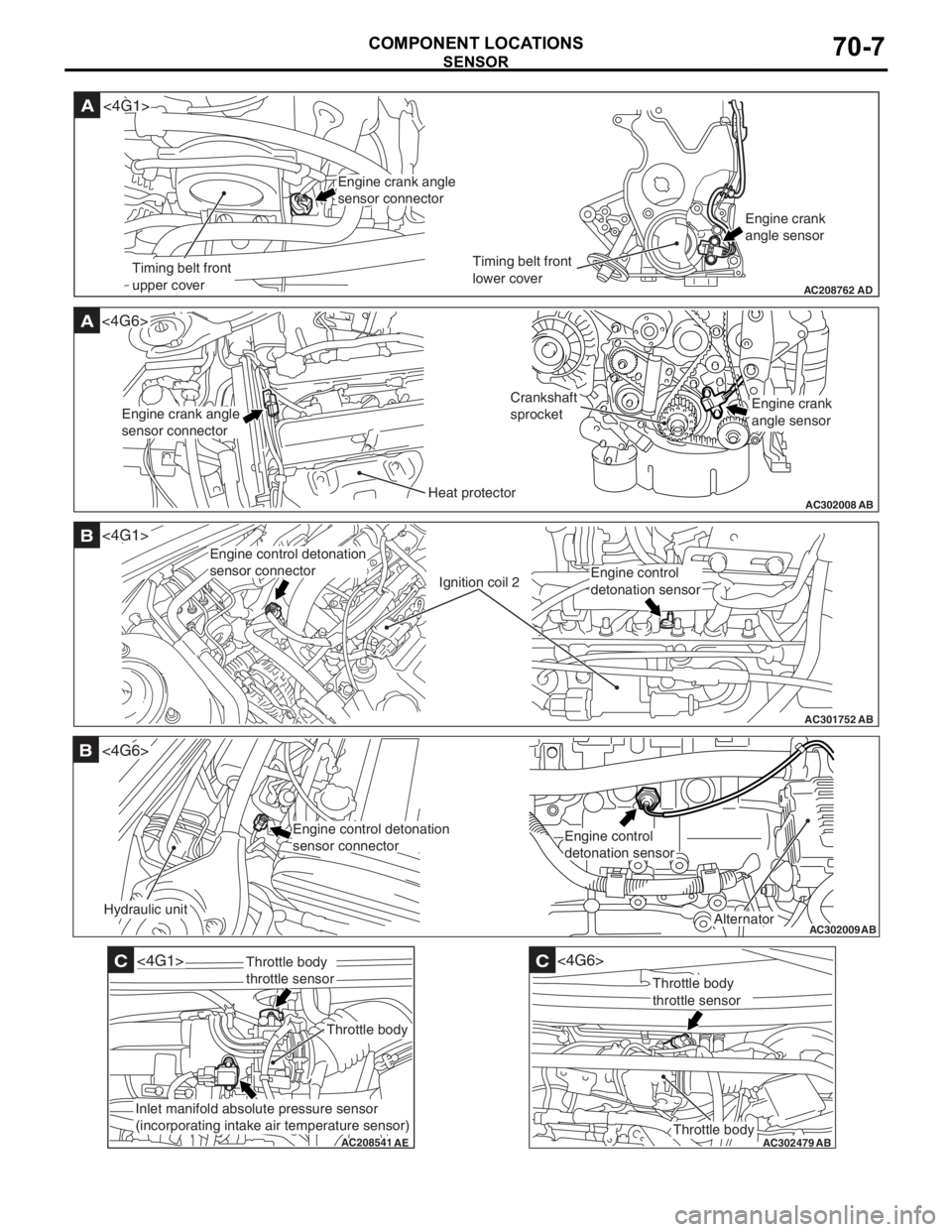

AC208762

A

AD

Timing belt front

upper coverTiming belt front

lower coverEngine crank

angle sensor

<4G1>

Engine crank angle

sensor connector

AC302008

A<4G6>

ABHeat protector

Crankshaft

sprocket

Engine crank angle

sensor connectorEngine crank

angle sensor

AC301752

B

AB

Ignition coil 2

<4G1>

Engine control detonation

sensor connector

Engine control

detonation sensor

AC302009

B

AB

Hydraulic unit

<4G6>

Alternator

Engine control detonation

sensor connectorEngine control

detonation sensor

AC208541

C

AE

<4G1>

Throttle body

Throttle body

throttle sensor

Inlet manifold absolute pressure sensor

(incorporating intake air temperature sensor)

AC302479

AB

C

Throttle body

<4G6>

Throttle body

throttle sensor

SENSOR

COMPONENT LOCA TIONS70-7

Page 402 of 800

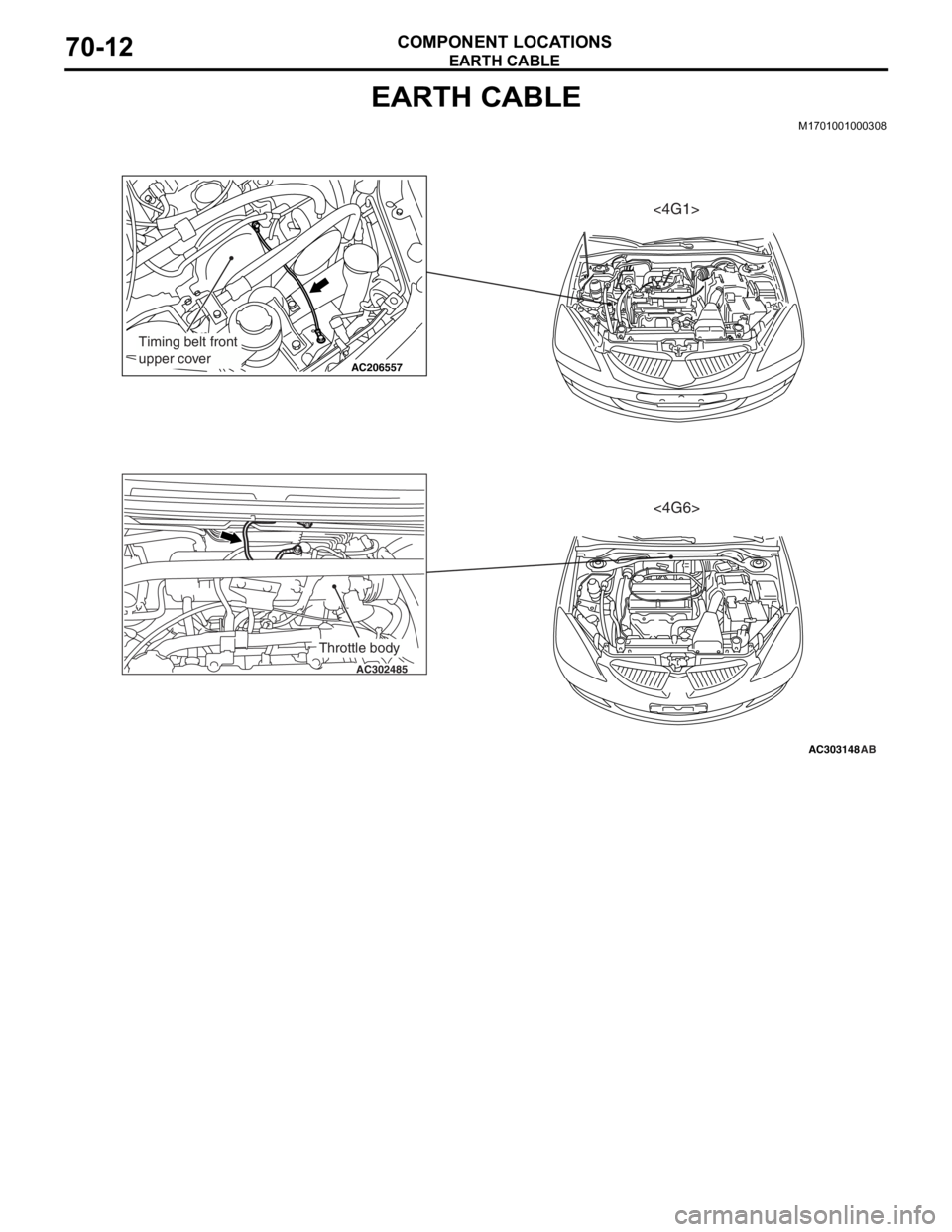

EARTH CABLE

COMPONENT LOCATIONS70-12

EARTH CABLE

M1701001000308

AC303148

AC206557

AC302485

AB

Timing belt front

upper cover

Throttle body

<4G1><4G6>

Page 420 of 800

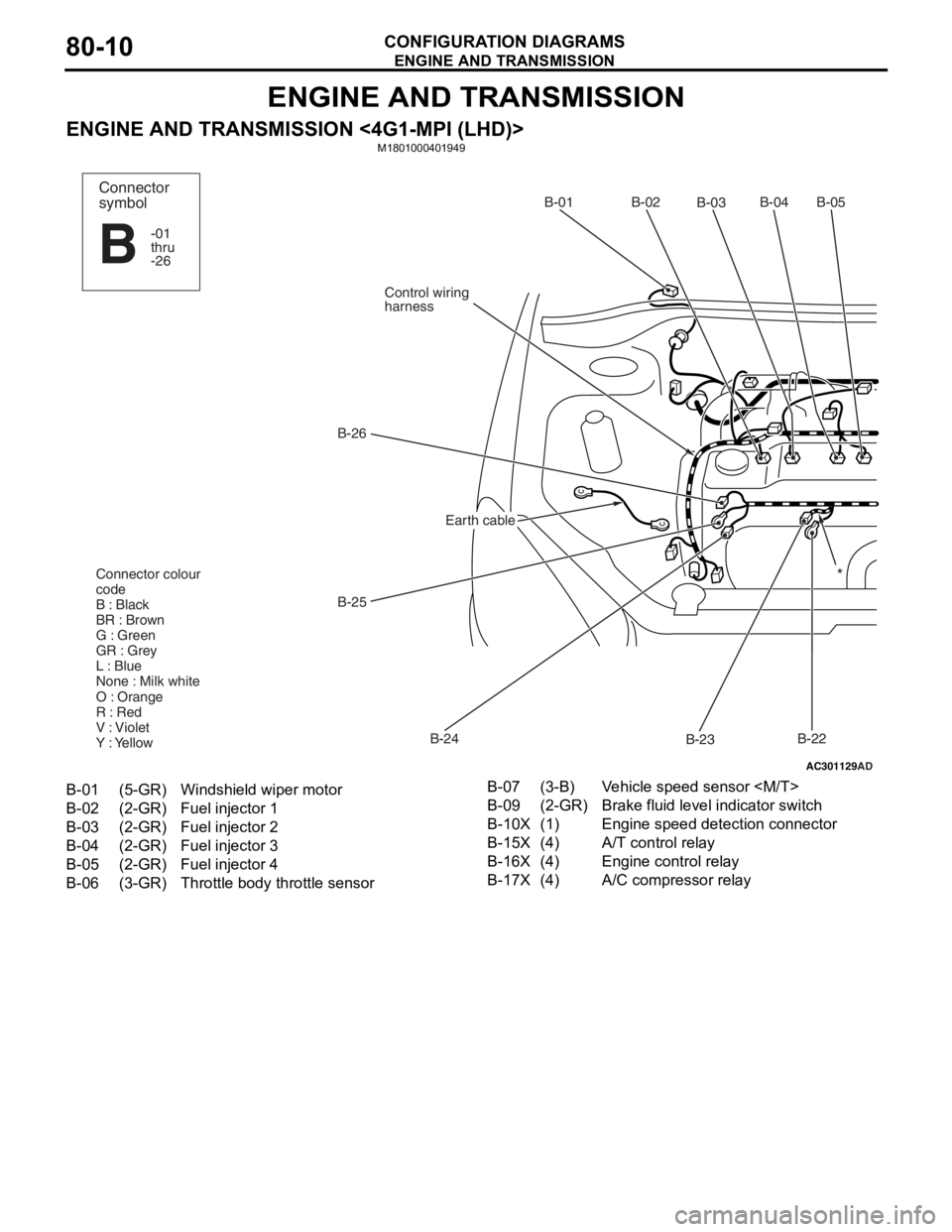

ENGINE AND TRANSMISSION

CONFIGURATION DIAGRAMS80-10

ENGINE AND TRANSMISSION

ENGINE AND TRANSMISSION <4G1-MPI (LHD)>M1801000401949

AC301129

AD

B-02

B-03B-04B-05

B-22

B-23

B-24

B-25

B-26

Control wiring

harnessB-01

Connector colour

code

B : Black

BR : Brown

G : Green

GR : Grey

L : Blue

None : Milk white

O : Orange

R : Red

V : Violet

Y : Yellow*

Connector

symbol

-01

thru

-26

B

Earth cable

B-01(5-GR)Windshield wiper motor

B-02(2-GR)Fuel injector 1

B-03(2-GR)Fuel injector 2

B-04(2-GR)Fuel injector 3

B-05(2-GR)Fuel injector 4

B-06(3-GR)Throttle body throttle sensor

B-07(3-B)Vehicle speed sensor

B-09(2-GR)Brake fluid level indicator switch

B-10X(1)Engine speed detection connector

B-15X(4)A/T control relay

B-16X(4)Engine control relay

B-17X(4)A/C compressor relay