ABS MITSUBISHI LANCER 2006 Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 250 of 800

STEERING COLUMN SHAFT ASSEMBLY

POWER STEERING37-20

STEERING COLUMN SHAFT ASSEMBLY

REMOVAL AND INSTALLATIONM1372003100080

WARNING

Before removing the steering wheel and air bag module assembly, refer to GROUP 52B, Serv-

ice Precautions (P.52B-5) and Air Bag Module and Clock Spring (P.52B-194).

Pre-removal Operation

•Steering Wheel and Air bag Module Assembly Removal

(INVITE: refer to

P.37-17/INTENSE: refer to P.37-18).

•Under Cover Removal (Refer to GROUP 52A, Instrument

Panel

P.52A-3).

Post-installation Operation

•Under Cover Installation (Refer to GROUP 52A, Instru-

ment Panel P.52A-3).

•Steering Wheel and Air bag Module Assembly Installation

(INVITE: refer to

P.37-17/INTENSE: refer to P.37-18).

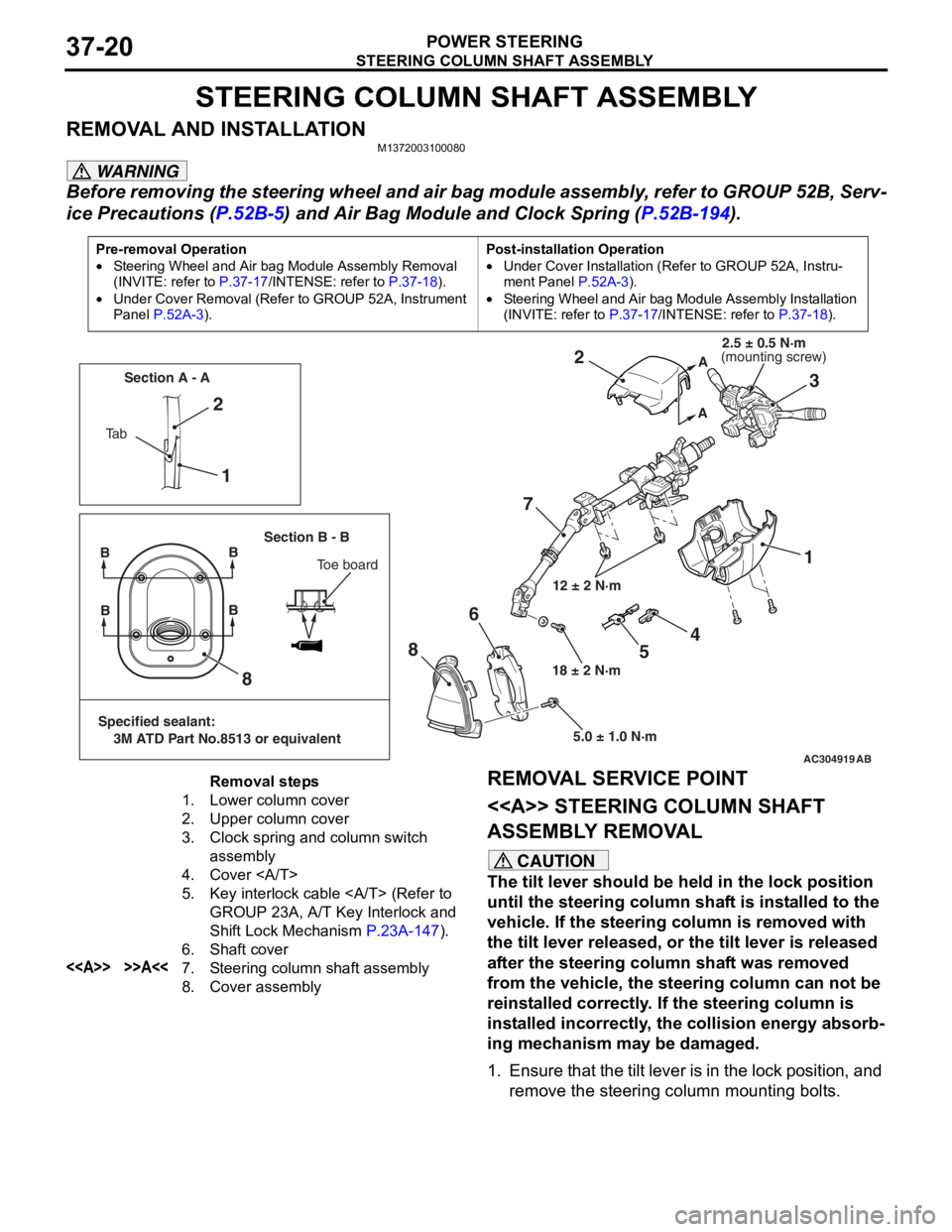

AC304919AB

12 ± 2 N·m

18 ± 2 N·m 5.0 ± 1.0 N·m

1

2

73

2

1

8

8 6

A

A

Ta b Section A - A

Section B - B

BB

Toe board

Specified sealant:

3M ATD Part No.8513 or equivalent

BB

4

5

(mounting screw)2.5 ± 0.5 N·m

Removal steps

1.Lower column cover

2.Upper column cover

3.Clock spring and column switch

assembly

4.Cover

5.Key interlock cable (Refer to

GROUP 23A, A/T Key Interlock and

Shift Lock Mechanism

P.23A-147).

6.Shaft cover

<>>>A<<7.Steering column shaft assembly

8.Cover assembly

REMOVAL SERVICE POINT

<> STEERING

COLUMN SHAFT

ASSEMBLY REMOVAL

CAUTION

The tilt lever should be held in the lock position

until the steering column shaft is installed to the

vehicle. If the steering column is removed with

the tilt lever released, or the tilt lever is released

after the steering column shaft was removed

from the vehicle, the steering column can not be

reinstalled correctly. If the steering column is

installed incorrectly, the collision energy absorb

-

ing mechanism may be damaged.

1. Ensure that the tilt lever is in the lock position, and remove the steering column mounting bolts.

Page 251 of 800

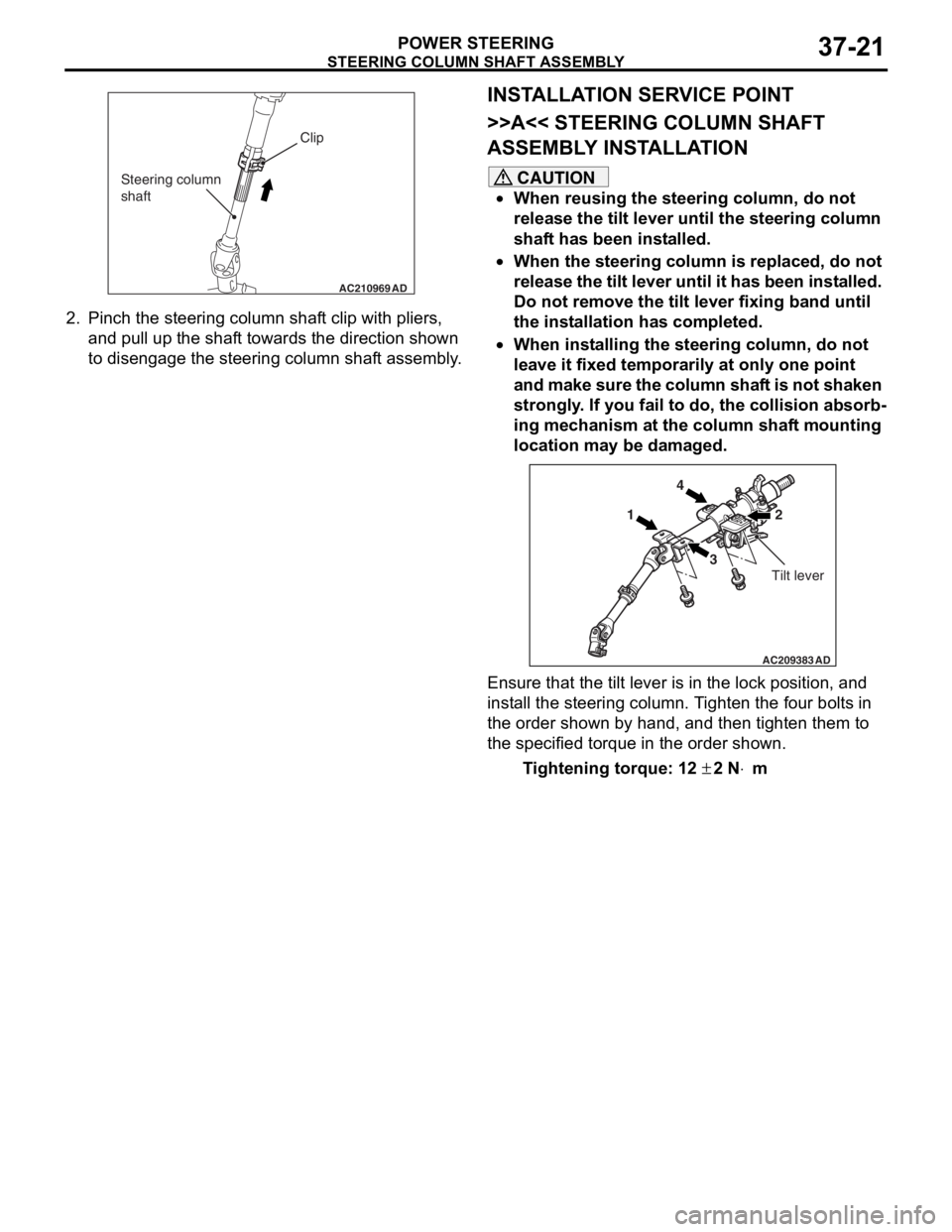

AC210969AD

Clip

Steering column

shaft

STE E RING C O LUMN SHAFT AS SEMBL Y

POWER STEERING37-21

2.Pin c h t he st eering column shaf t clip with pliers,

an d pull up the shaf t towards the d i rection shown

to disengag e the steering column shaf t assembly .

INSTALLA T ION SER VICE POINT

>>A<< STEERING COLUMN SHAFT

ASSEMBL

Y INST ALLA TION

CAUTION

•When reusing the steering column, do not

release the tilt lever until the steering column

shaft has been installed.

•When the steering column is replaced, do not

release the tilt lever until it has been installed.

Do not remove the tilt lever fixing band until

the installation has completed.

•When installing the steering column, do not

leave it fixed temporarily at only one point

and make sure the column shaft is not shaken

strongly. If you fail to do, the collision absorb

-

ing mechanism at the column shaft mounting

location may be damaged.

AC209383AD

14

3 2

Tilt lever

Ensure that the tilt lever is in the lock position, and

install the steering column. Tighten the four bolts in

the order shown by hand, and then tighten them to

the specified torque in the order shown.

Tightening torque: 12 ± 2 N⋅m

Page 288 of 800

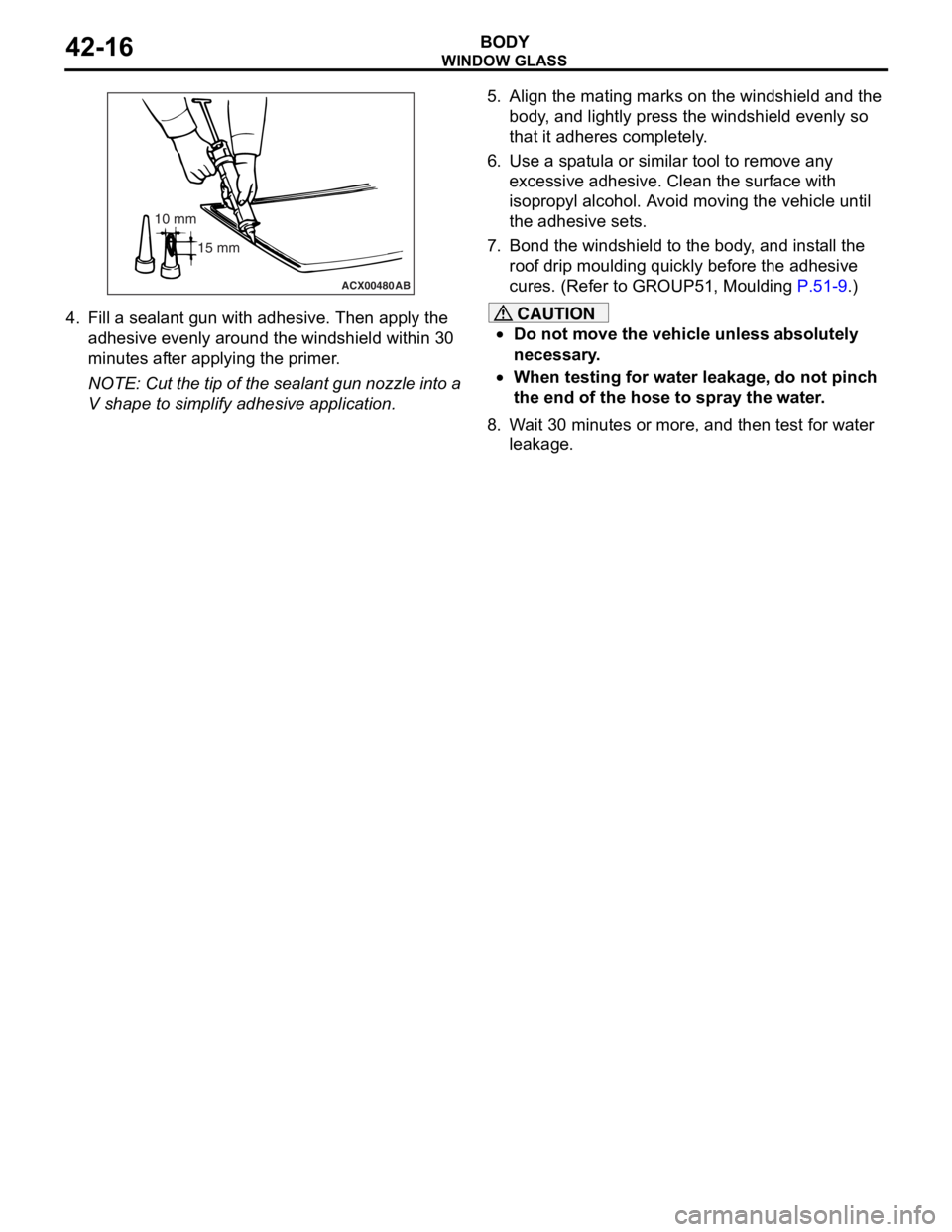

ACX00480

10 mm15 mm

AB

WI ND OW GLAS S

BODY42-16

4.Fill a sea l ant gun with adhe sive. The n apply th e

ad hesive even ly a r ound the wind shield within 3 0

minut es af ter applying the pr ime r .

NOTE: Cut the tip of t he seala n t gu n nozzle into a

V shape to simplify adhesive app licatio n.

5.Align t he mating ma rks on th e windshie l d a nd the

b ody , and lig htly press the windshield evenly so

th at it adheres co mpletely .

6.Use a sp a t ula o r similar tool to re move any

e xce ssive adhesive. Clean the surface with

isopr opyl alcohol. A v o i d moving the veh i cle unt il

th e adhe sive set s .

7.Bon d the windsh i eld to the body , a nd in st all the

ro of drip mou l din g quickly b e fore t he adh esive

cures. (Refer to GROUP51, Mou l din g

P.51-9.)

CAUTION

•Do not move the vehicle unless absolutely

necessary.

•When testing for water leakage, do not pinch

the end of the hose to spray the water.

8. Wait 30 minutes or more, and then test for water leakage.

Page 392 of 800

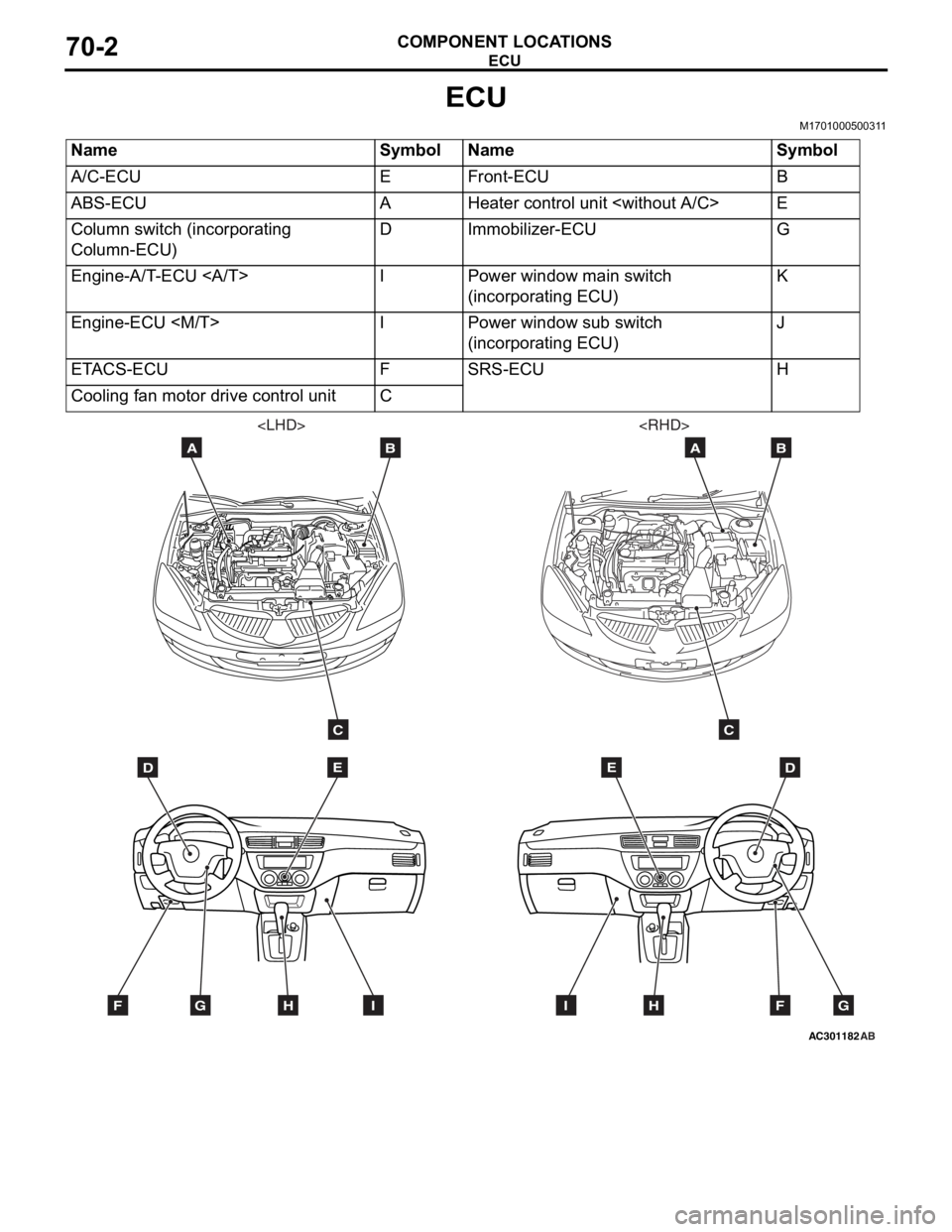

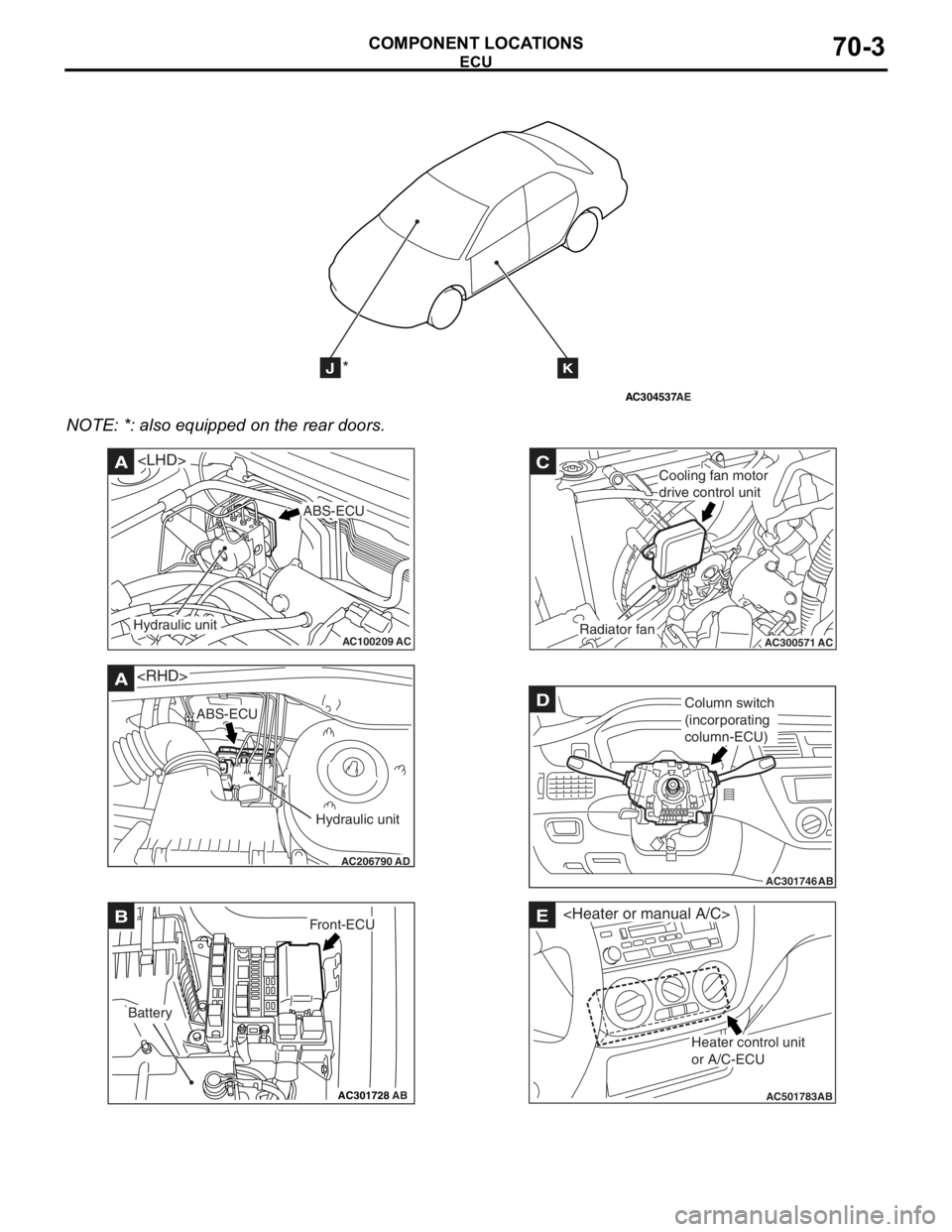

ECU

COMPONENT LOCATIONS70-2

ECU

M1701000500311

NameSymbolNameSymbol

A/C-ECUEFront-ECUB

ABS-ECUAHeater control unit

Column switch (incorporating

Column-ECU)DImmobilizer-ECUG

Engine-A/T-ECU IPower window main switch

(incorporating ECU)K

Engine-ECU

(incorporating ECU)J

ETACS-ECUFSRS-ECUH

Cooling fan motor drive control unitC

AC301182

DE

AB

C

FGHI

AB

DE

AB

C

FGHI

Page 393 of 800

AC304537

JK*

AE

ECU

COMPONENT LOCA TIONS70-3

NOTE: *: also eq uipp ed on the rear doors.

AC100209AC

A

ABS-ECU

Hydraulic unit

AC206790

A

AD

ABS-ECU

Hydraulic unit

AC301728AB

BFront-ECU

Battery

AC300571

C

ACRadiator fan

Cooling fan motor

drive control unit

AC301746

DColumn switch

(incorporating

column-ECU)

AB

AC501783AB

E

Heater control unit

or A/C-ECU

Page 396 of 800

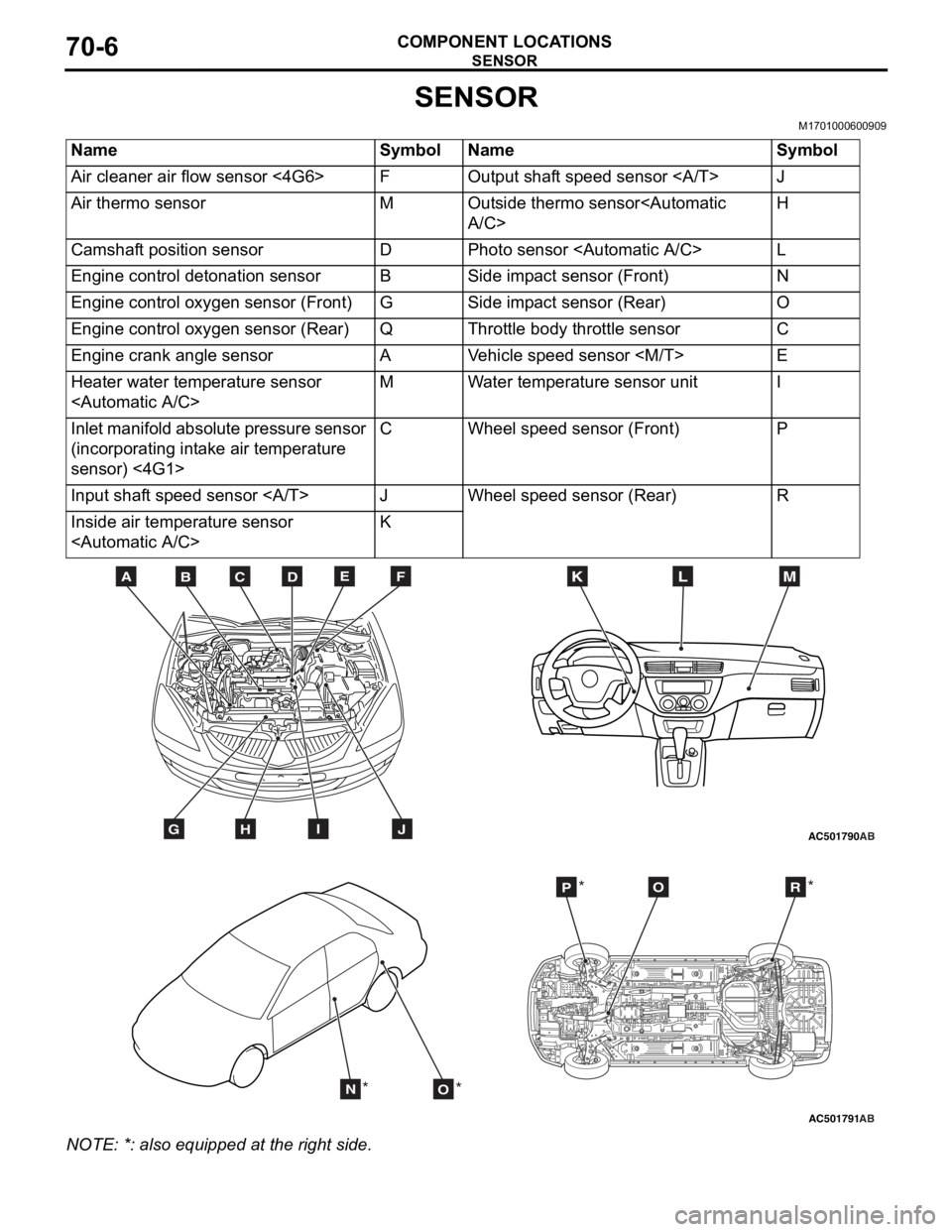

SENSOR

COMPONENT LOCATIONS70-6

SENSOR

M1701000600909

NameSymbolNameSymbol

Air cleaner air flow sensor <4G6>FOutput shaft speed sensor J

Air thermo sensorMOutside thermo sensor

Camshaft position sensorDPhoto sensor

Engine control detonation sensorBSide impact sensor (Front)N

Engine control oxygen sensor (Front)GSide impact sensor (Rear)O

Engine control oxygen sensor (Rear)QThrottle body throttle sensorC

Engine crank angle sensorAVehicle speed sensor

Heater water temperature sensor

Inlet manifold absolute pressure sensor

(incorporating intake air temperature

sensor) <4G1>CWheel speed sensor (Front)P

Input shaft speed sensor JWheel speed sensor (Rear)R

Inside air temperature sensor

AC501790

BDCFEA

GHIJ

MKL

AB

AC501791AB

NO

POR

** *

*

NO

TE: *: also eq uipp ed at t he rig h t side.

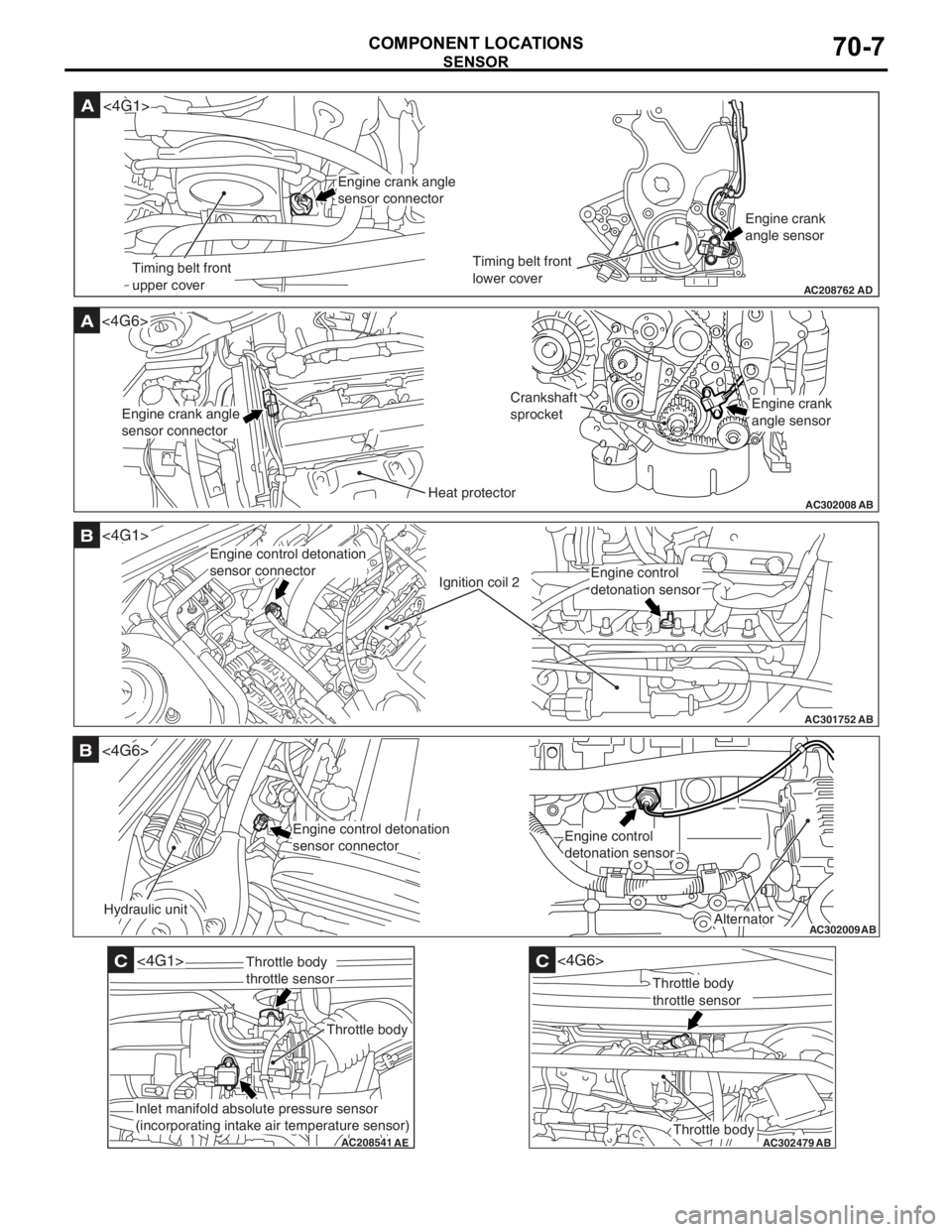

Page 397 of 800

AC208762

A

AD

Timing belt front

upper coverTiming belt front

lower coverEngine crank

angle sensor

<4G1>

Engine crank angle

sensor connector

AC302008

A<4G6>

ABHeat protector

Crankshaft

sprocket

Engine crank angle

sensor connectorEngine crank

angle sensor

AC301752

B

AB

Ignition coil 2

<4G1>

Engine control detonation

sensor connector

Engine control

detonation sensor

AC302009

B

AB

Hydraulic unit

<4G6>

Alternator

Engine control detonation

sensor connectorEngine control

detonation sensor

AC208541

C

AE

<4G1>

Throttle body

Throttle body

throttle sensor

Inlet manifold absolute pressure sensor

(incorporating intake air temperature sensor)

AC302479

AB

C

Throttle body

<4G6>

Throttle body

throttle sensor

SENSOR

COMPONENT LOCA TIONS70-7

Page 422 of 800

ENGINE AND TRANSMISSION

CONFIGURATION DIAGRAMS80-12

ENGINE AND TRANSMISSION <4G1-MPI (LHD)> (CONTINUED)

AC301129AE

B-118B-101 B-102

B-113

B-114

B-115

B-116 B-117

Earth cable

Control wiring

harness

Connector colour

code

B : Black

BR : Brown

G : Green

GR : Grey

L : Blue

None : Milk white

O : Orange

R : Red

V : Violet

Y : Yellow

Connector

symbol

-101

thru

-118

B

*

B-101(2-BR)Emission solenoid valve (EGR system)

B-102(4-GR)Inlet manifold absolu te pressure sensor

B-103(6-B)Throttle body idle speed control servo

B-104(3-GR)Ignition coil 1

B-105(2-B)Emission solenoid va lve (Purge control

system)

B-107(3-B)Camshaft position sensor

B-108(3-GR)Output shaft speed sensor

B-109(3-B)Input shaft speed sensor

B-110(2-B)Back-up lamp switch

B-111(2-B)Water temperature sensor unit

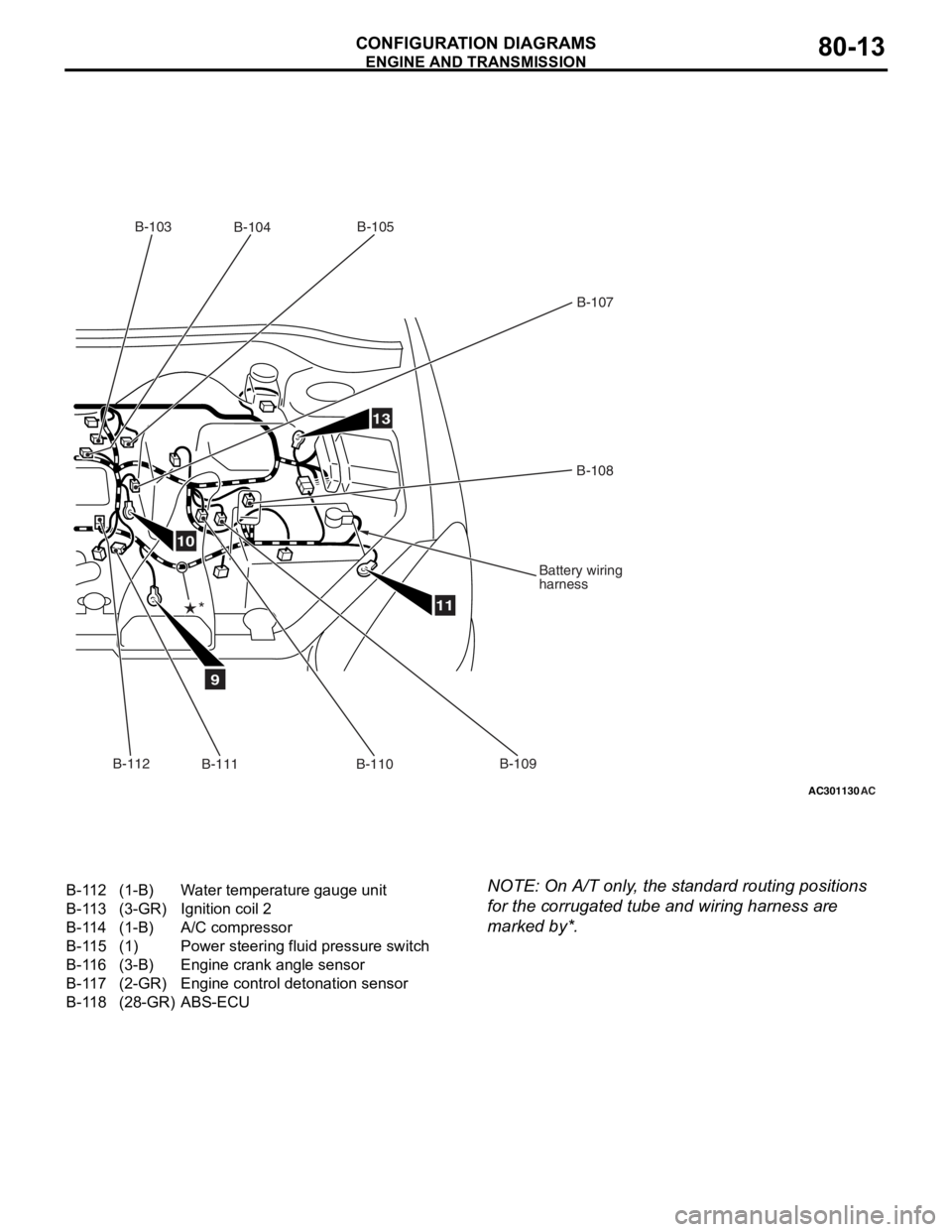

Page 423 of 800

AC301130AC

9

10

11

13

B-103B-104 B-105

B-107

B-108

Battery wiring

harness

B-109

B-110

B-111

*

B-112

B-112(1-B)Water temperature gauge unit

B-113(3-GR)Ignition coil 2

B-114(1-B)A/C compressor

B-115(1)Power steering fluid pressure switch

B-116(3-B)Engine crank angle sensor

B-117(2-GR)Engine control detonation sensor

B-118(28-GR)ABS-ECU

ENGINE AND TRA

N SMISSION

CONF IGURA TION D I A G RA MS80-13

NOTE: On A/T only , the st andard routing positions

for the

corrug a ted tu be and wiring harne ss are

marked by*.

Page 426 of 800

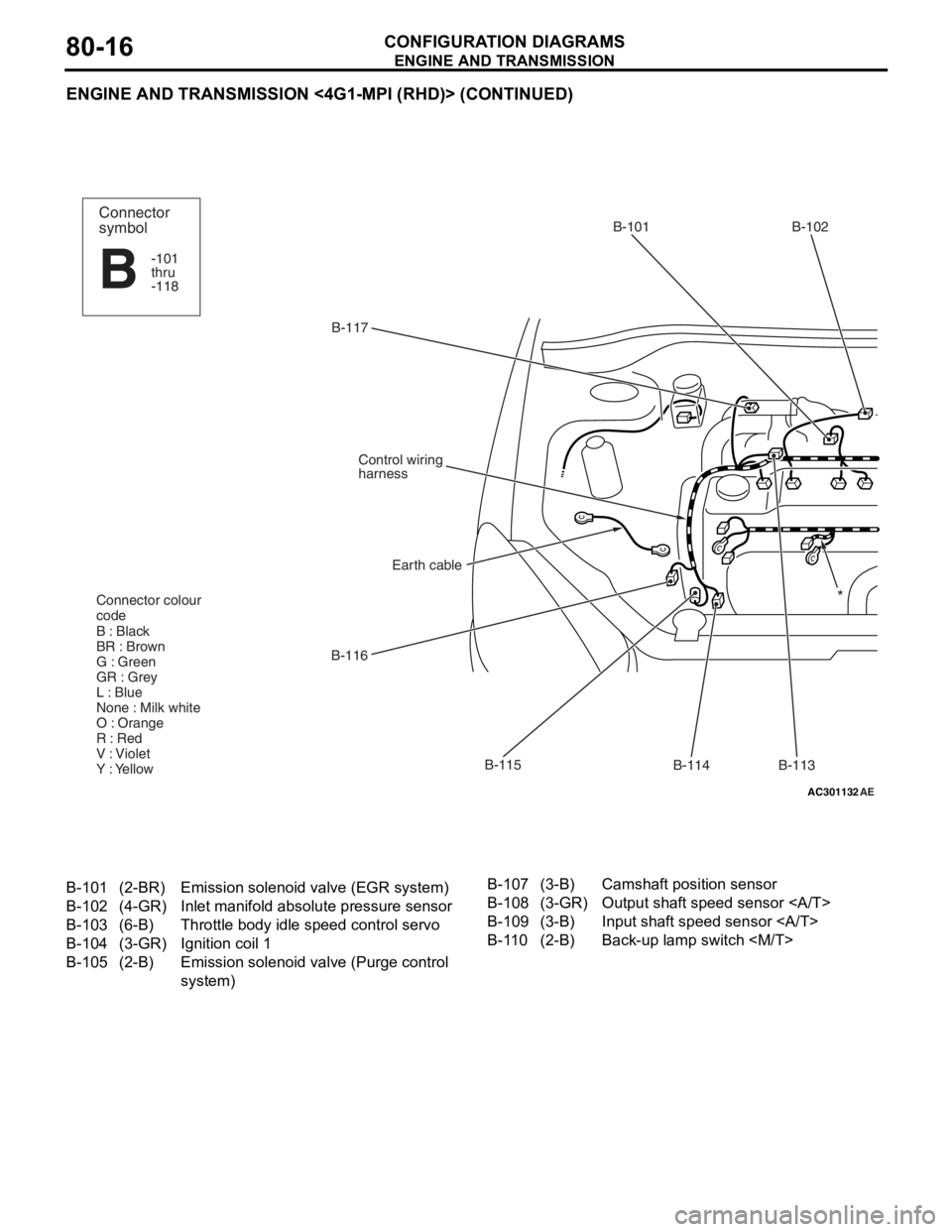

ENGINE AND TRANSMISSION

CONFIGURATION DIAGRAMS80-16

ENGINE AND TRANSMISSION <4G1-MPI (RHD)> (CONTINUED)

AC301132AE

B-117B-101 B-102

B-113

B-114

B-115

B-116

Earth cable

Control wiring

harness

Connector colour

code

B : Black

BR : Brown

G : Green

GR : Grey

L : Blue

None : Milk white

O : Orange

R : Red

V : Violet

Y : Yellow

Connector

symbol

-101

thru

-118

B

*

B-101(2-BR)Emission solenoid valve (EGR system)

B-102(4-GR)Inlet manifold absolu te pressure sensor

B-103(6-B)Throttle body idle speed control servo

B-104(3-GR)Ignition coil 1

B-105(2-B)Emission solenoid va lve (Purge control

system)

B-107(3-B)Camshaft position sensor

B-108(3-GR)Output shaft speed sensor

B-109(3-B)Input shaft speed sensor

B-110(2-B)Back-up lamp switch