check engine MITSUBISHI LANCER 2006 Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 66 of 800

CHARGING SYSTEM

ENGINE ELECTRICAL16-4

2. Turn the ignition switch to the "LOCK" (OFF)

position.

3. Disconnect the negative battery cable.

4. Connect a clamp-type DC test ammeter with a

range of 0

− 120 A to the alternator "B" terminal

output wire.

NOTE: The way of disconnecting the alternator

output wire and of connecting the ammeter is pos

-

sibly not found the problem that the output current

is dropping due to the insufficient connection

between terminal "B" and the output wire.

5. Connect a digital-type voltmeter between the

alternator "B" terminal and the battery (+)

terminal. [Connect the (+) lead of the voltmeter to

the "B" terminal and the connect the (-) lead of the

voltmeter to the battery (+) cable].

6. Reconnect the negative battery cable.

7. Connect a tachometer or the M.U.T.-II/III (Refer to

GROUP 11A

− On-vehicle Service − Idle speed

check <4G1>

P.11A-11 or GROUP 11C −

On-vehicle Service − Idle speed check <4G6>

P.11C-11).

8. Leave the hood open.

9. Start the engine.

10.With the engine running at 2,500 r/min, turn the

headlamps and other lamps on and off to adjust

the alternator load so that the value displayed on

the ammeter is slightly above 30 A.

Adjust the engine speed by gradually decreasing

it until the value displayed on the ammeter is 30

A. Take a reading of the value displayed on the

voltmeter at this time.

Limit: maximum 0.3 V

NOTE: When the alternator output is high and the

value displayed on the ammeter does not

decrease until 30 A, set the value to 40 A. Read

the value displayed on the voltmeter at this time.

When the value range is 40 A, the limit is maxi

-

mum 0.4 V.

11.If the value displayed on the voltmeter is above

the limit value, there is probably a malfunction in

the alternator output wire, so check the wiring

between the alternator "B" terminal and the

battery (+) terminal (including fusible link).

If a terminal is not sufficiently tight or if the

harness has become discolored due to

overheating, repair and then test again.

12.After the test, run the engine at idle.

13.Turn off all lamps and the ignition switch.

14.Remove the tachometer or the M.U.T.-II/III.

15.Disconnect the negative battery cable.

16.Disconnect the ammeter and voltmeter.

17.Connect the negative battery cable.

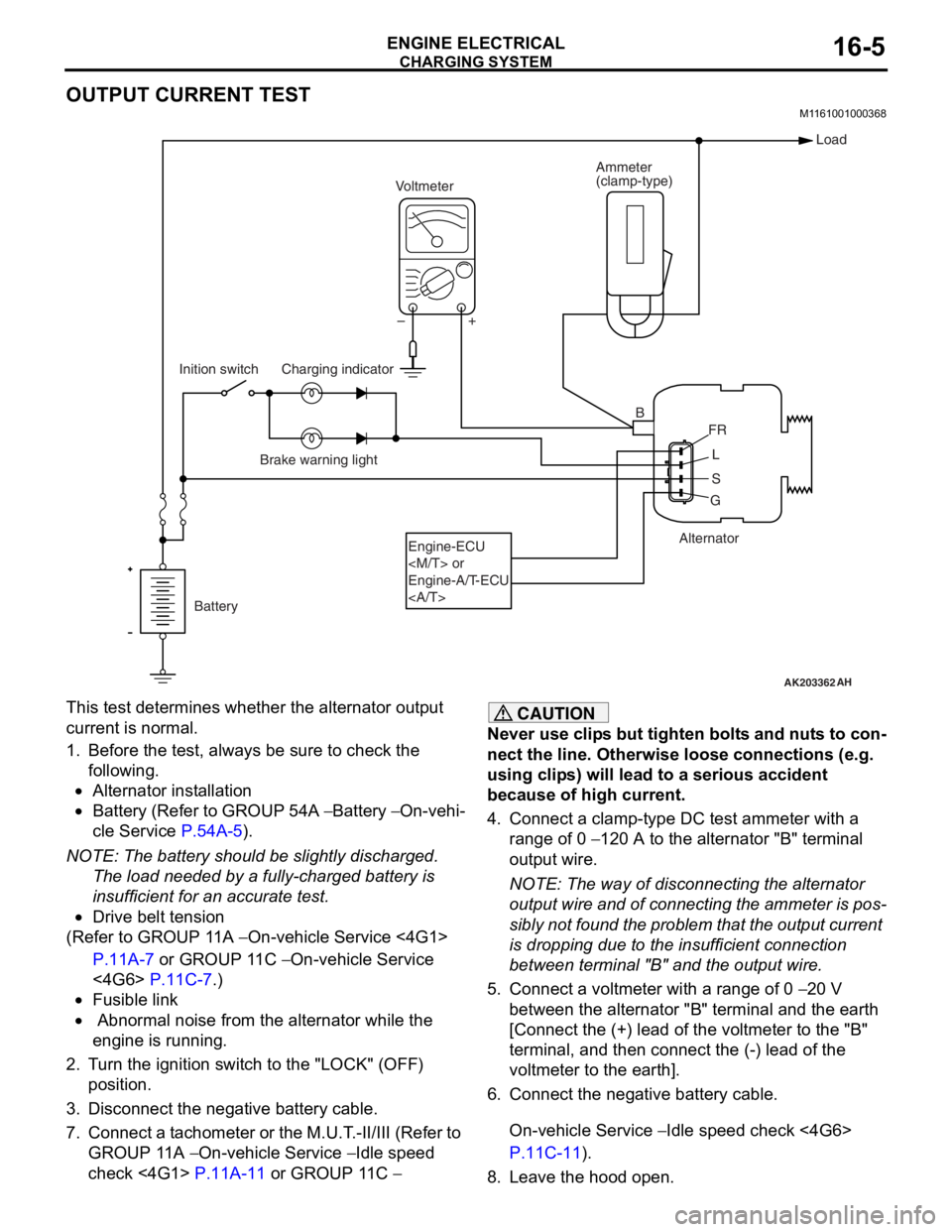

Page 67 of 800

Page 68 of 800

CHARGING SYSTEM

ENGINE ELECTRICAL16-6

9. Check that the reading on the voltmeter is equal

to the battery voltage.

NOTE: If the voltage is 0 V, the cause is probably

an open circuit in the wire or fusible link between

the alternator "B" terminal and the battery (+) ter

-

minal.

10.Turn the light switch on to turn on headlamps and

then start the engine.

11.Immediately after setting the headlamps to high

beam and turning the heater blower switch to the

high revolution position, increase the engine

speed to 2,500 r/min and read the maximum

current output value displayed on the ammeter.

Limit: 70 % of normal current output

NOTE: .

•For the nominal current output, refer to the

Alternator Specifications.

•Because the current from the battery will soon

drop after the engine is started, the above step

should be carried out as quickly as possible in

order to obtain the maximum current output

value.

•The current output value will depend on the

electrical load and the temperature of the

alternator body.

•If the electrical load is small while testing, the

specified level of current may not be output

even though the alternator is normal. In such

cases, increase the electrical load by leaving

the headlamps turned on for some time to dis

-

charge the battery or by using the lighting sys-

tem in another vehicle, and then test again.

•The specified level of current also may not be

output if the temperature of the alternator body

or the ambient temperature is too high. In such

cases, cool the alternator and then test again.

12.The reading on the ammeter should be above the

limit value. If the reading is below the limit value

and the alternator output wire is normal, remove

the alternator from the engine and check the

alternator.

13.Run the engine at idle after the test.

14.Turn the ignition switch to the "LOCK" (OFF)

position.

15.Remove the tachometer or the M.U.T.-II/III.

16.Disconnect the negative battery cable.

17.Disconnect the ammeter and voltmeter.

18.Connect the negative battery cable.

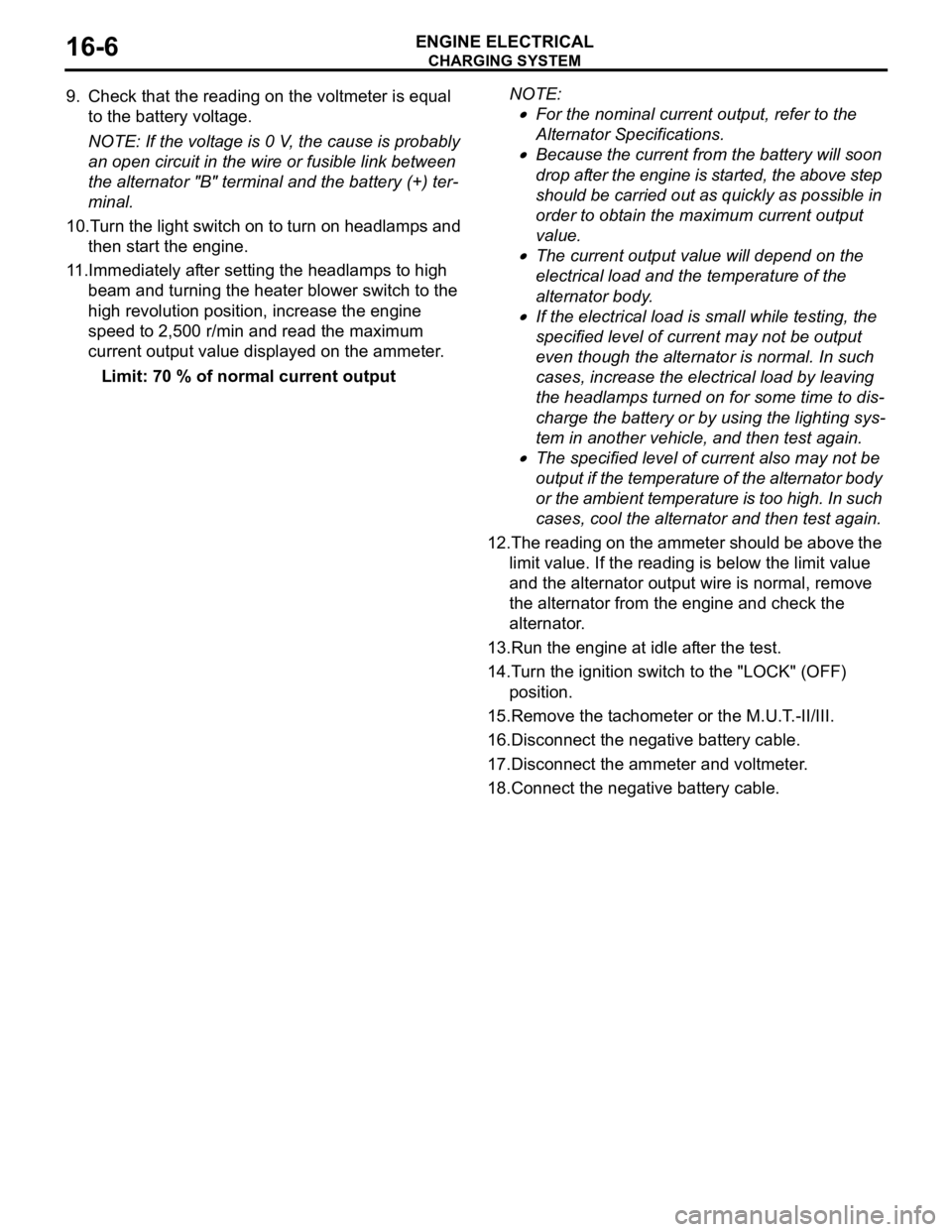

Page 69 of 800

Page 71 of 800

CHARGING SYSTEM

ENGINE ELECTRICAL16-9

WAVEFORM CHECK USING AN OSCILLOSCOPE

M1161001200124

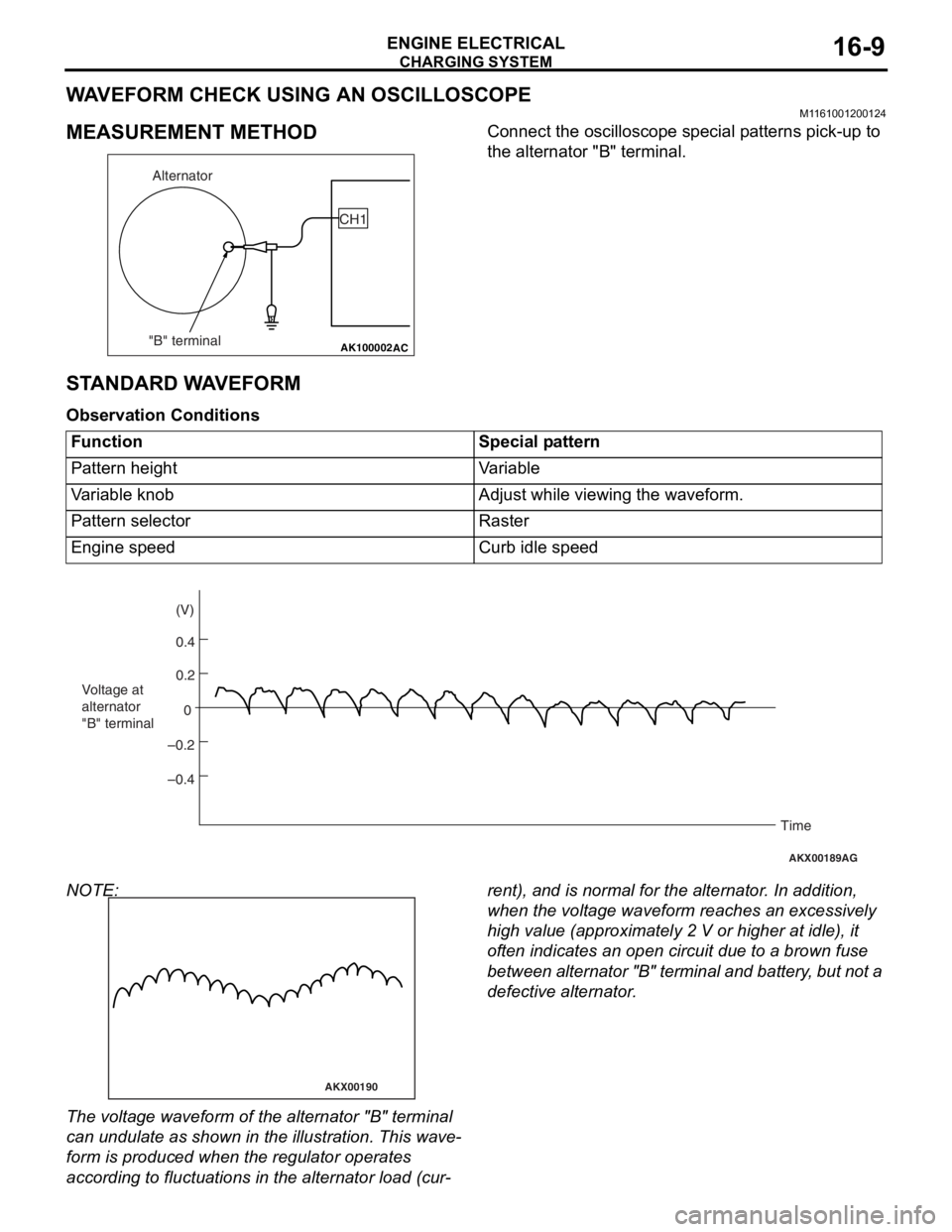

MEASUREMENT METHOD

AK100002

Alternator

"B" terminal CH1

AC

Co

nnect the oscillo scope specia l p a tt erns p i ck-up to

the alternato

r "B" terminal.

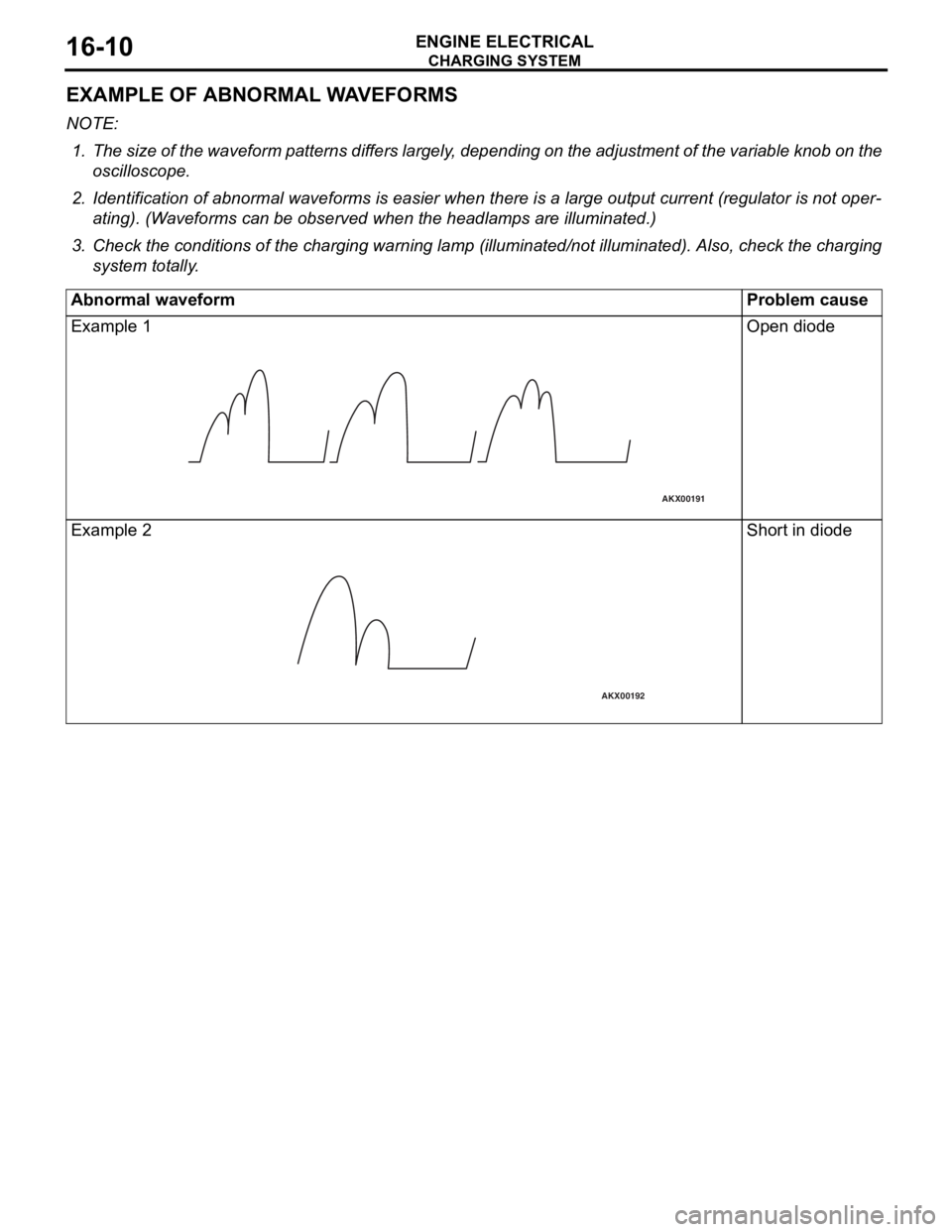

STANDARD W A VEFORM

Observ ation Conditi ons

FunctionSpecial pattern

Pattern heightVariable

Variable knobAdjust while viewing the waveform.

Pattern selectorRaster

Engine speedCurb idle speed

AKX00189

0.4 (V)

0.2

0

–0.2

–0.4

Voltage at

alternator

"B" terminal

Time

AG

NOTE:

AKX00190

The volt age waveform of th e alte rnator "B" t e rminal

can u

ndulate as sho w n in th e illustratio n . This wave

-

form is produce d when t he regu lator operate s

accordin

g to fluctu ation s in the alterna t or loa d (cu r

-

rent), and is normal fo r the alterna t or . In ad dition,

wh

en the volt ag e wavef o rm re ache s an excessively

high

value (app roximate ly 2 V or higher at idle ), it

of

ten indicates an o pen circuit du e to a brown fuse

be

twe e n a l te rn at or "B " t e r m in al an d ba tt er y , b u t n o t a

defective alte

rnator .

Page 72 of 800

CHARGING SYSTEM

ENGINE ELECTRICAL16-10

EXAMPLE OF ABNORMAL WAVEFORMS

NOTE: .

1. The size of the waveform patterns differs largely, depending on the adjustment of the variable knob on the

oscilloscope.

2. Identification of abnormal waveforms is easier when th ere is a large output current (regulator is not oper-

ating). (Waveforms can be observed when the headlamps are illuminated.)

3. Check the conditions of the charging warning lamp (illuminated/not illum inated). Also, check the charging

system totally.

Abnormal waveformProblem cause

Example 1

AKX00191

Open diod e

Exampl e 2

AKX00192

Shor t in diode

Page 79 of 800

CHARGING SYSTEM

ENGINE ELECTRICAL16-17

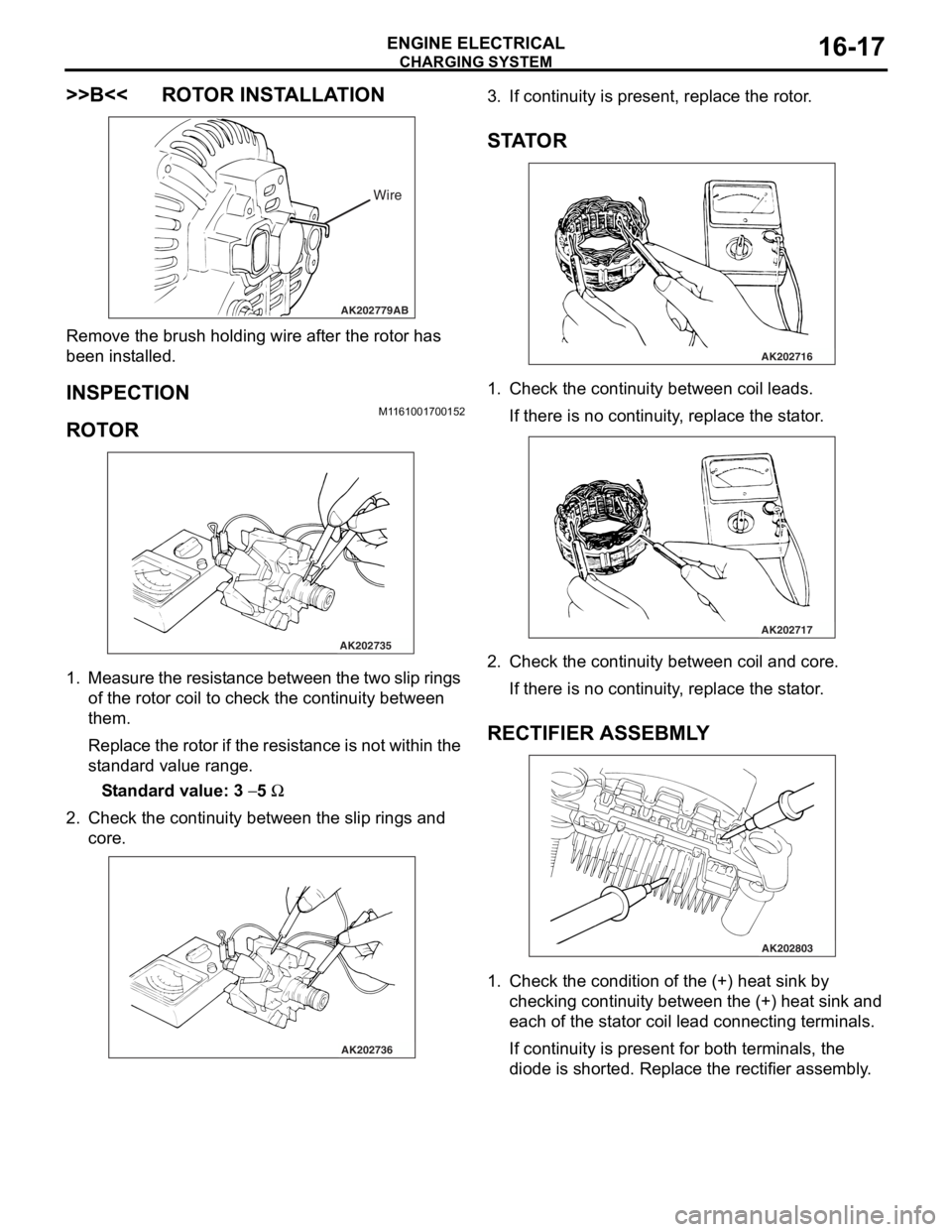

>>B<< ROTOR INSTALLATION

AK202779

Wire

AB

Remove the br ush holding wire af ter the rotor ha s

been inst

alled.

INSPECTION

M1161 0017 0015 2

ROTO R

AK202735

1. Measure th e resist a n ce b e tween the two slip rings

of the rot o r coil to check t he co ntinu i ty between

th em.

Repla c e th e r o to r if th e resist ance is no t within the

st

a ndard valu e range .

St andard va lue: 3 − 5 Ω

2.Check t he co ntinu i ty between the slip rings and

core.

AK202736

3. If cont inuity is pre s ent, repla c e th e rotor .

STA T OR

AK202716

1.Check t he co ntinu i ty between coil le ads.

If there is no con t inuity , replace the st a t or .

AK202717

2.Check t he co ntinu i ty between coil and core .

If there is no con t inuity , replace the st a t or .

RECTIFIER ASSEBMLY

AK202803

1.Check t he co ndition o f the (+) h eat sink by

checkin g contin uity be twe en t he (+) heat sink and

e a ch o f the st a t or coil lead conn ecting termina l s.

If cont inuity is pre s ent for both terminals, the

d

i ode is shorte d. Repla c e th e rectifie r assembly .

Page 80 of 800

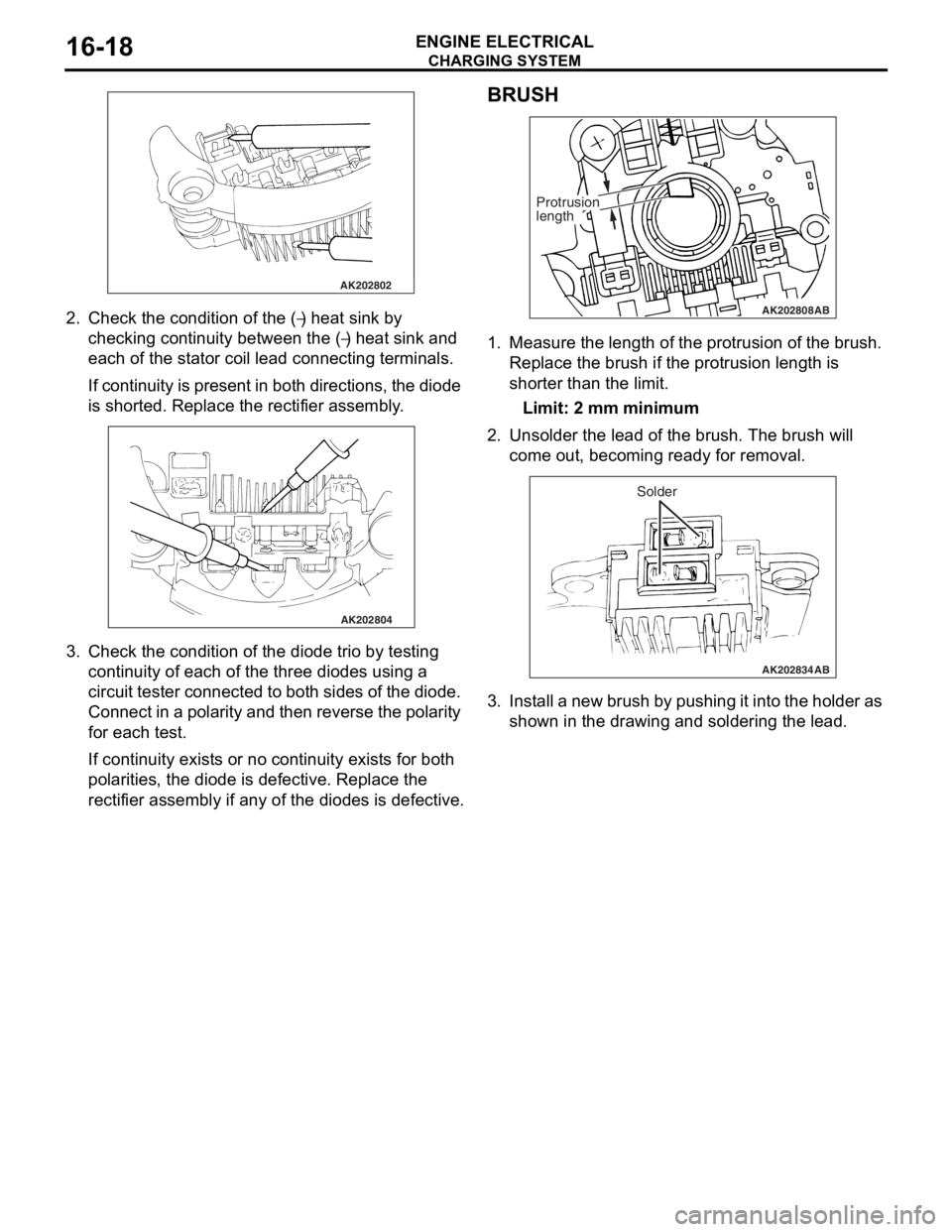

AK202802

CHARGING SYSTEM

ENGINE ELECTRICAL16-18

2.Check t he co ndition of the (−) heat sink by

checkin

g

con

t

inuity b

e

tween th e (

−) he at sink and

ea

ch o

f

the st

a

t

or co

il lead conne

cting termina l s.

If con t inu i ty is p r ese n t in bot h d i re ctio ns, the dio de

is shorted.

Re place the rectifier assembly .

AK202804

3.Check t he co ndition of the diode t r io by testing

continuity of ea ch o f the th ree diodes using a

circuit tester con necte d to both sides of the dio de.

Co nnect in a p o la rity a nd then reverse the polarity

fo r each test.

If continuity exist s or no cont inuity exist s for bo th

po

larities, the d i ode is d e fective . Repla c e th e

rectifier assembly if a

n y o f the d i odes is defe c tive.

BRUSH

AK202808

Protrusion

length

AB

1.Measure the lengt h of the prot rusion o f the bru s h.

Replace the b r ush if the protrusion lengt h is

shorter than th e limit .

Limit: 2 mm mini mum

2.Unsolde r the lead o f the br ush. The bru s h will

come out, b e coming ready for removal.

AK202834

Solder

AB

3.I n st all a ne w b r ush b y pu sh in g it int o the h o lde r a s

shown in the d r awing a nd soldering th e lea d .

Page 85 of 800

STARTING SYSTEM

ENGINE ELECTRICAL16-23

STARTER MOTOR ASSEMBLY INSPECTION

M1162001100205

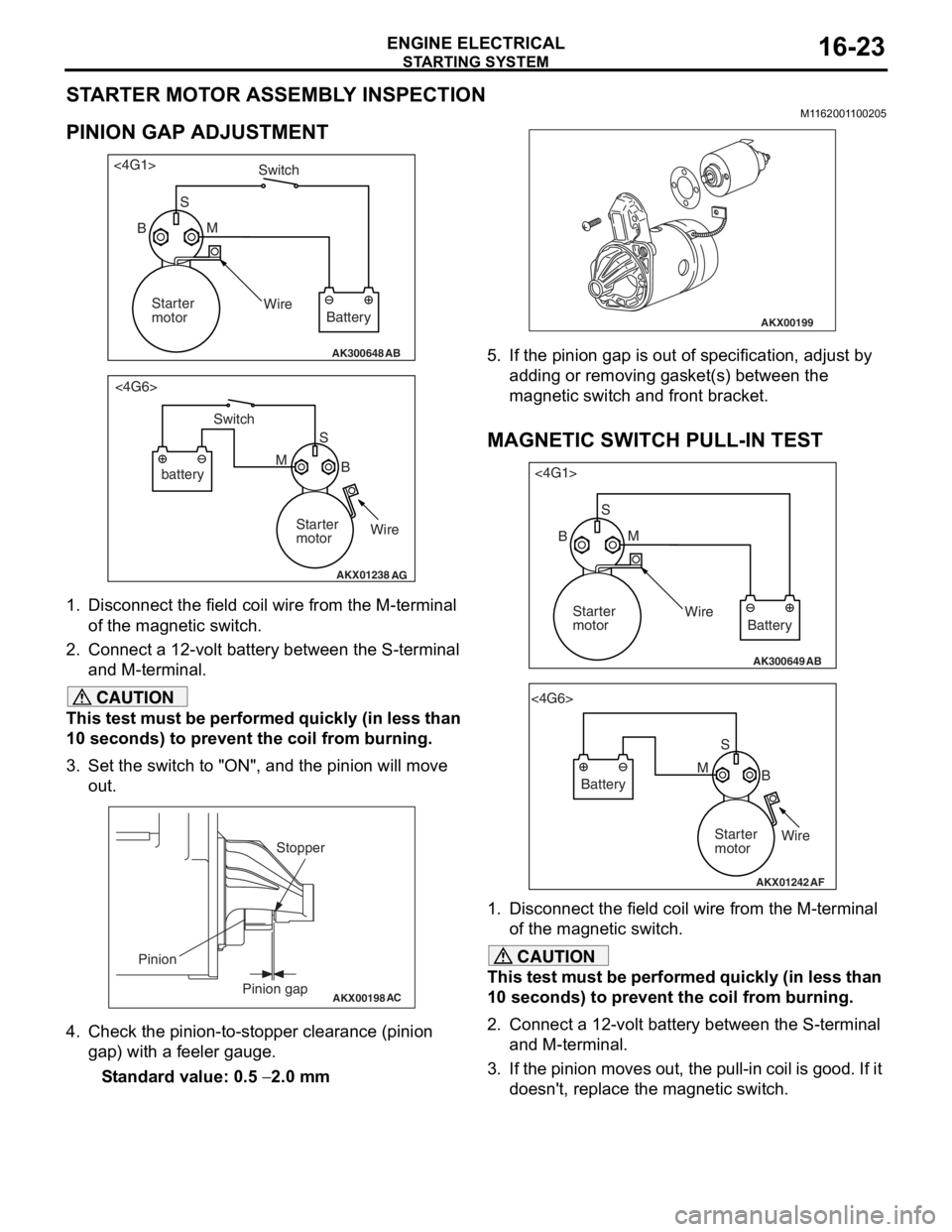

PINION GAP ADJUSTMENT

AK300648AB

<4G1>

Switch

S M

Wire Battery

Starter

motor

B

AKX01238

<4G6>

B

M S

battery Switch

Starter

motorWire

AG

1.

Disco nnect the field coil wire f r om th e M-te rmin al

of the magnet ic switch.

2.Conn ect a 12-volt b a ttery between the S-termina l

an d M-t e rminal.

CAUTION

This test must be performed quickly (in less than

10 seconds) to prevent the coil from burning.

3. Set the switch to "ON", and the pinion will move out.

AKX00198

Stopper

Pinion gap

Pinion

AC

4. Check the pinion-to-stopper clearance (pinion

gap) with a feeler gauge.

Standard value: 0.5 − 2.0 mm

AKX00199

5. If the pinion gap is out of specification, adjust by adding or removing gasket(s) between the

magnetic switch and front bracket.

MAGNETIC SWITCH PULL-IN TEST

AK300649AB

<4G1>

SM

Wire Battery

Starter

motor

B

AKX01242

<4G6>

SB

M

Battery

Starter

motorWire

AF

1. Disconnect the field coil wire from the M-terminal

of the magnetic switch.

CAUTION

This test must be performed quickly (in less than

10 seconds) to prevent the coil from burning.

2. Connect a 12-volt battery between the S-terminal and M-terminal.

3. If the pinion moves out, the pull-in coil is good. If it doesn't, replace the magnetic switch.

Page 90 of 800

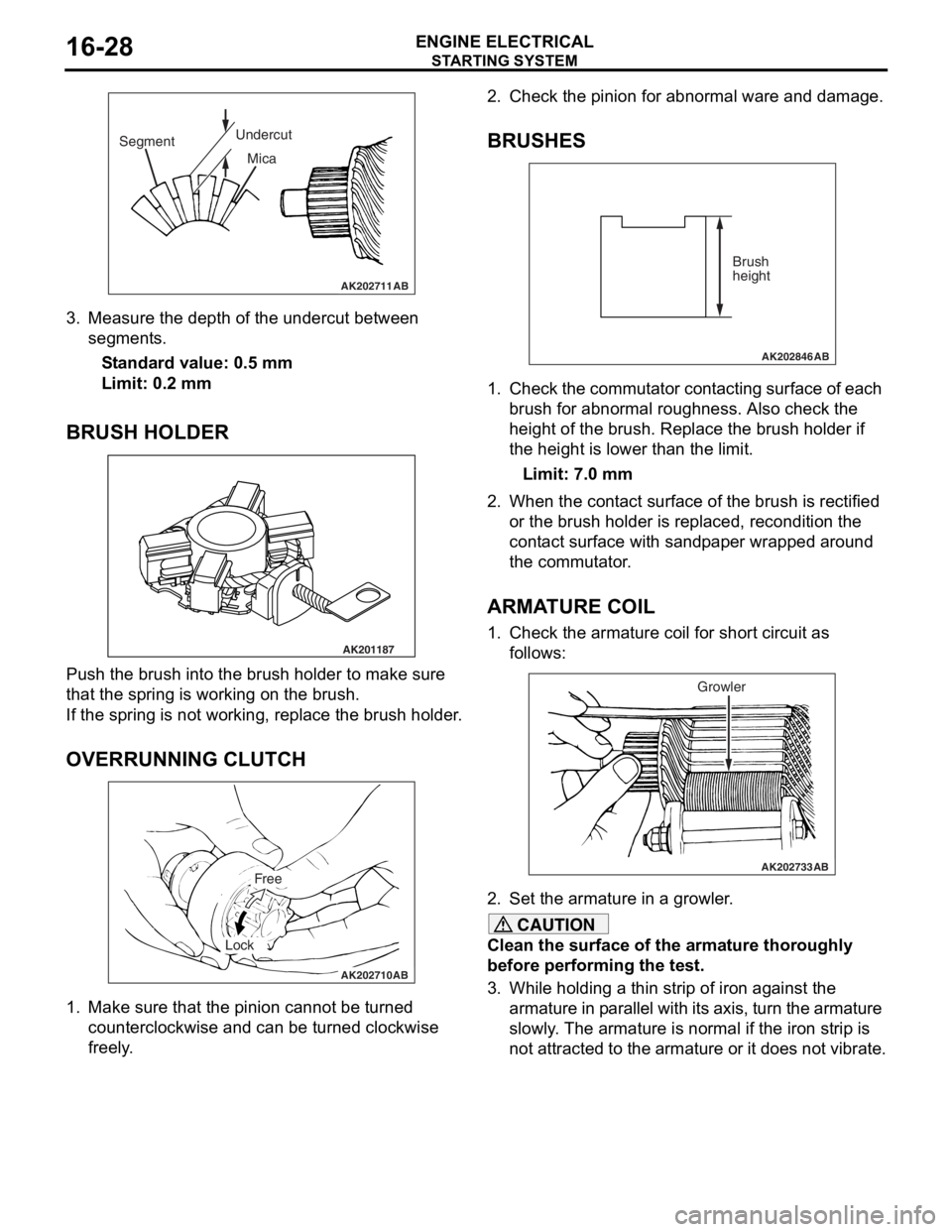

AK202711

SegmentUndercut

Mica

AB

ST ARTING SYS TEM

ENGINE ELECTRICAL16-28

3.Measure the depth of the undercut be twe en

segment s.

St andard va lue: 0.5 mm

Limit: 0.2 mm

BRUSH HOLDER

AK201187

Push th e brush in to the b r ush hold e r to make sure

that the

spring is working o n the b r ush.

If the spring is not working, repla c e th e brush holder .

OVERRUNNING CLUTCH

AK202710

Free

Lock

AB

1.Make sure that th e pin i on canno t be tu rned

counte r clo ckwise a nd ca n be tu rned clockwise

fre e ly .

2.Check t he pinion for abn ormal ware an d damage.

BRUSHES

AK202846

Brush

height

AB

1.Che ck the commut ator con t a c tin g surface of each

b r ush f o r abno rmal rough ness. Also ch eck the

h e ight of the brush . Replace th e brush holder if

th e height is lo we r than t he limit.

Limit: 7.0 mm

2.Wh en the con t act su rface of the brush is rectified

o r the bru s h h o lder is re placed, re cond itio n the

cont act surfa c e wit h san d p a p e r wrapped around

th e co mmu t a t o r .

ARMATURE COIL

1.Check t he armature coil for short circuit a s

fo llows:

AK202733

Growler

AB

2.Set the armature in a growler .

CAUTION

Clean the surface of the armature thoroughly

before performing the test.

3. While holding a thin strip of iron against the

armature in parallel with it s axis, turn the armature

slowly. The armature is normal if the iron strip is

not attracted to the armature or it does not vibrate.