MITSUBISHI LANCER 2006 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 51 of 800

15-1

GROUP 15

INTAKE AND

EXHAUST

CONTENTS

GENERAL INFORMATIO N . . . . . . . .15-2

SERVICE SPECIFICATION . . . . . . . .15-2

SPECIAL TOOL . . . . . . . . . . . . . . . . .15-2

AIR CLEANER . . . . . . . . . . . . . . . . . .15-3

REMOVAL AND INSTALLATION . . . . . . . . 15-3

INLET MANIFOLD . . . . . . . . . . . . . . .15-5

REMOVAL AND INSTALLATION <4G1> . . 15-5

REMOVAL AND INSTALLATION <4G6> . . 15-6

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 15-7

EXHAUST MANIFOLD . . . . . . . . . . . .15-7

REMOVAL AND INSTALLATION <4G1> . . 15-7

REMOVAL AND INSTALLATION <4G6> . . 15-9

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 15-10

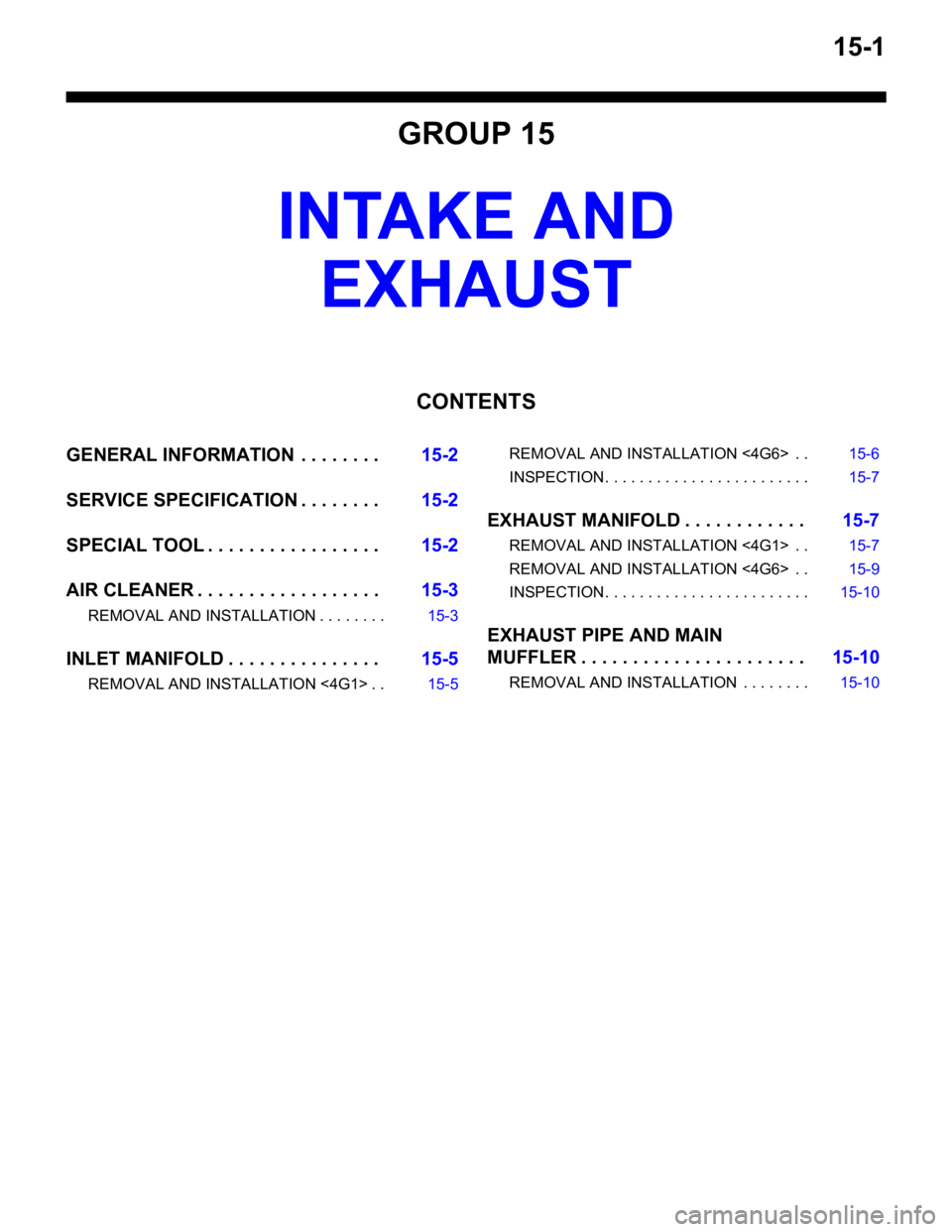

EXHAUST PIPE AND MAIN

MUFFLER . . . . . . . . . . . . . . . . . . . . . .15-10

REMOVAL AND INSTALLATION . . . . . . . . 15-10

Page 52 of 800

GENERAL INFORMATION

INTAKE AND EXHAUST15-2

GENERAL INFORMATION

M1151000100402

The exhaust pipe is divided into three parts.

SERVICE SPECIFICATION

M1151000300428

ItemStandard valueLimit

Manifold distortion of the installation surface mm0.15 or less0.20

SPECIAL TOOL

M1151000600399

ToolNumberNameUse

MD998770Oxygen sensor wrenchRemoval and installation of

engine control oxygen sensor

Page 53 of 800

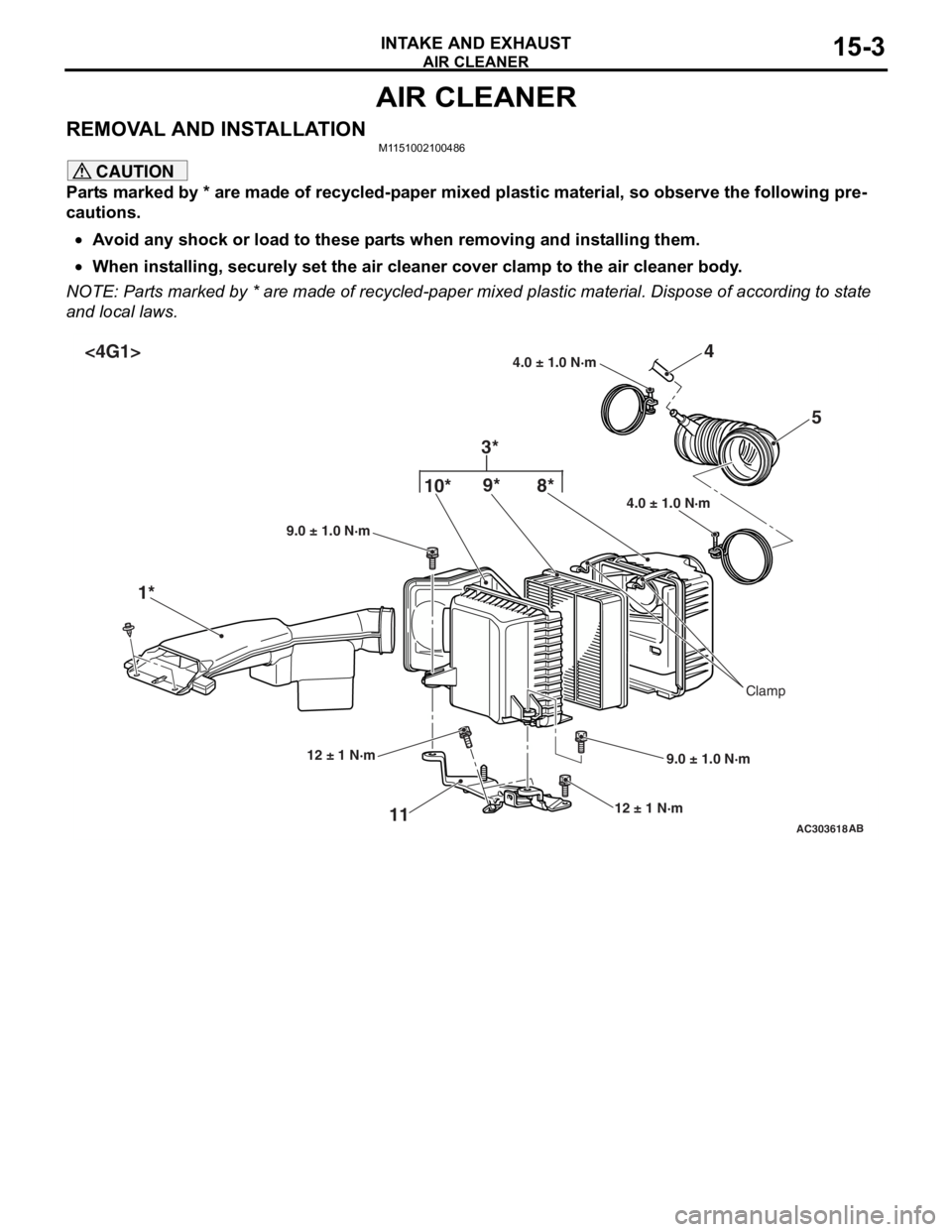

AIR CLEANER

INTAKE AND EXHAUST15-3

AIR CLEANER

REMOVAL AND INSTALLATIONM1151002100486

CAUTION

Parts marked by * are made of recycled-paper mixed plastic material, so observe the following pre-

cautions.

•Avoid any shock or load to these parts when removing and installing them.

•When installing, securely set the air cleaner cover clamp to the air cleaner body.

NOTE: Parts marked by * are made of recycled-paper mixed plastic material. Dispose of according to state

and local laws.

AC303618

4.0 ± 1.0 N·m

4.0 ± 1.0 N·m

10*

9* 4

1* 5

11

12 ± 1 N·m 9.0 ± 1.0 N·m

9.0 ± 1.0 N·m

AB

12 ± 1 N·m

Clamp

8*

3*

<4G1>

Page 54 of 800

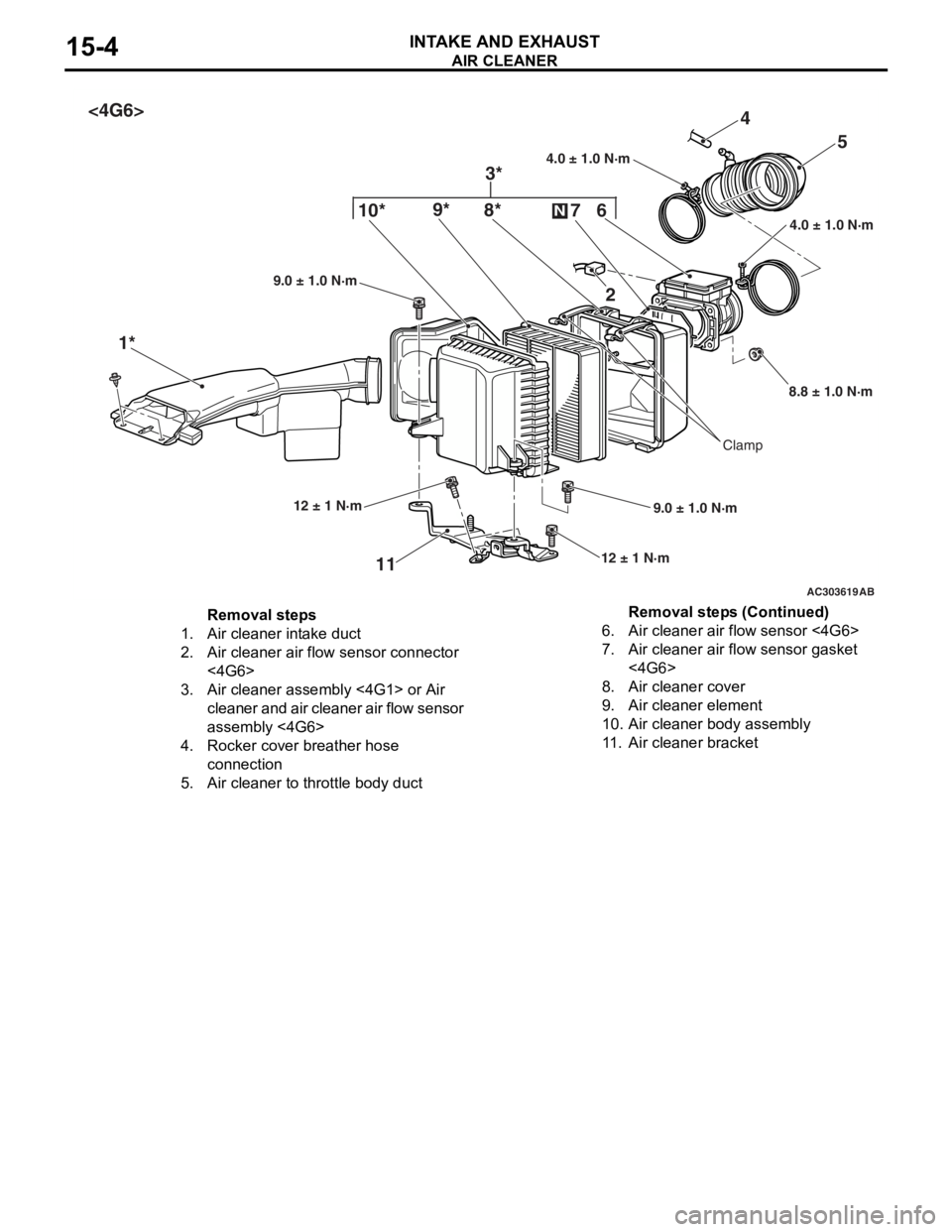

AC303619

4.0 ± 1.0 N·m

4.0 ± 1.0 N·m10*

9* 4

1* 5

11

12 ± 1 N·m 9.0 ± 1.0 N·m

9.0 ± 1.0 N·m

AB

12 ± 1 N·m

Clamp

8*

3*

<4G6>

6

7

N

2

8.8 ± 1.0 N·m

Removal steps

1.Air cleaner intake duct

2.Air cleaner air flow sensor connector

<4G6>

3.Air cleaner assembly <4G1> or Air

cleaner and air cleaner air flow sensor

assembly <4G6>

4.Rocker cover breather hose

connection

5.Air cleaner to throttle body duct

6.Air cleaner air flow sensor <4G6>

7.Air cleaner air flow sensor gasket

<4G6>

8.Air cleaner cover

9.Air cleaner element

10.Air cleaner body assembly

11 .Air cleaner bracket

AIR CLEA NER

INTAKE AN D EXHAU ST15-4

Removal steps (Continued)

Page 55 of 800

INLET MANIFOLD

INTAKE AND EXHAUST15-5

INLET MANIFOLD

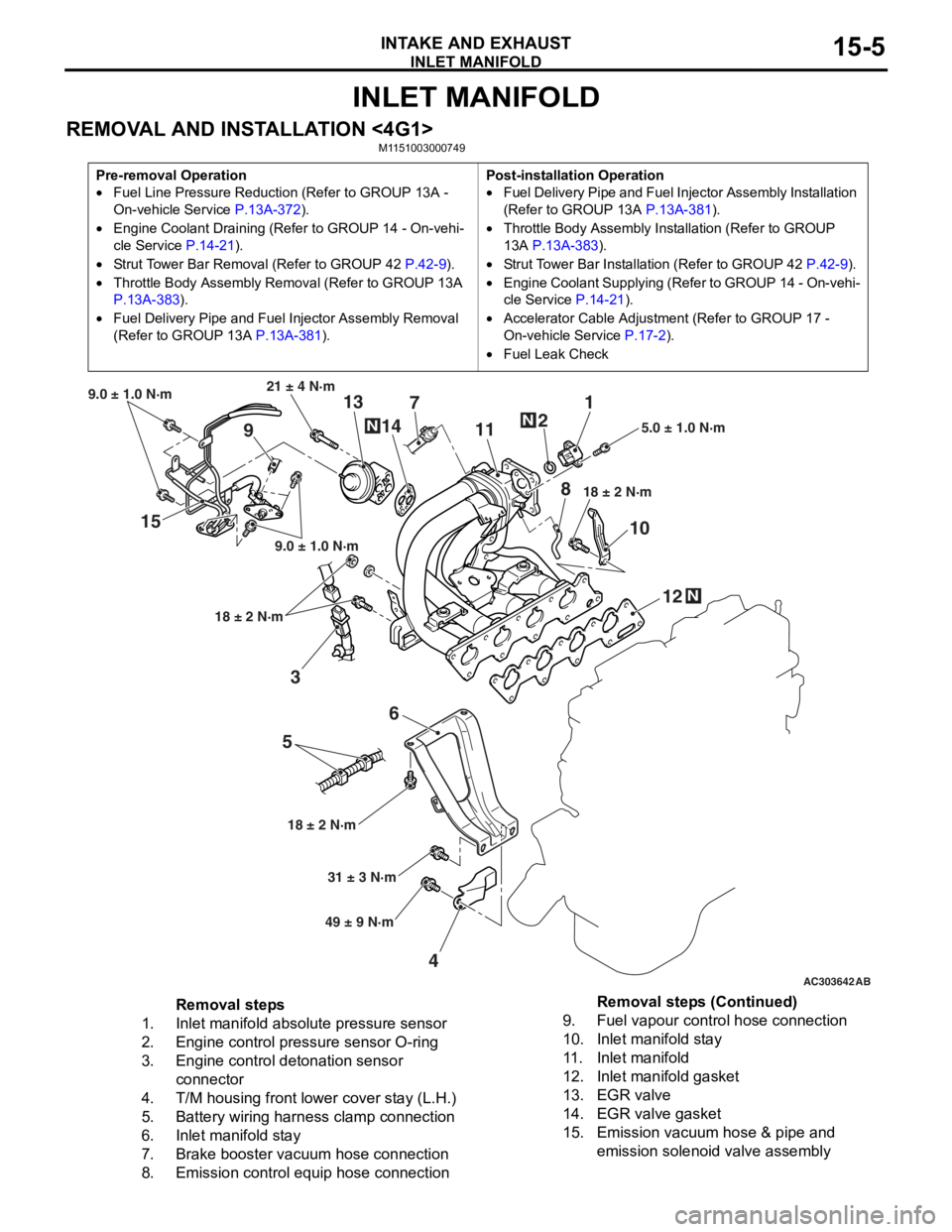

REMOVAL AND INSTALLATION <4G1>M1151003000749

Pre-removal Operation

•Fuel Line Pressure Reduction (Refer to GROUP 13A -

On-vehicle Service

P.13A-372).

•Engine Coolant Draining (Refer to GROUP 14 - On-vehi-

cle Service P.14-21).

•Strut Tower Bar Removal (Refer to GROUP 42 P.42-9).

•Throttle Body Assembly Re moval (Refer to GROUP 13A

P.13A-383).

•Fuel Delivery Pipe and Fuel Injector Assembly Removal

(Refer to GROUP 13A

P.13A-381).

Post-installation Operation

•Fuel Delivery Pipe and Fuel Injector Assembly Installation

(Refer to GROUP 13A

P.13A-381).

•Throttle Body Assembly Inst allation (Refer to GROUP

13A

P.13A-383).

•Strut Tower Bar Installati on (Refer to GROUP 42 P.42-9).

•Engine Coolant Supplying (Refer to GROUP 14 - On-vehi-

cle Service P.14-21).

•Accelerator Cable Adjustment (Refer to GROUP 17 -

On-vehicle Service

P.17-2).

•Fuel Leak Check

AC303642AB

15

36

5

4 12

10

7

1

2

11

9 13

14

21 ± 4 N·m

9.0 ± 1.0 N·m

9.0 ± 1.0 N·m

18 ± 2 N·m

18 ± 2 N·m 18 ± 2 N·m

5.0 ± 1.0 N·m

31 ± 3 N·m

49 ± 9 N·m

N

N

N

8

Removal steps

1.Inlet manifold absolute pressure sensor

2.Engine control pressure sensor O-ring

3.Engine control detonation sensor

connector

4.T/M housing front lower cover stay (L.H.)

5.Battery wiring harness clamp connection

6.Inlet manifold stay

7.Brake booster vacuum hose connection

8.Emission control equip hose connection

9.Fuel vapour control hose connection

10.Inlet manifold stay

11 .Inlet manifold

12.Inlet manifold gasket

13.EGR valve

14.EGR valve gasket

15.Emission vacuum hose & pipe and

emission solenoid valve assembly

Removal steps (Continued)

Page 56 of 800

INLET MANIFOLD

INTAKE AND EXHAUST15-6

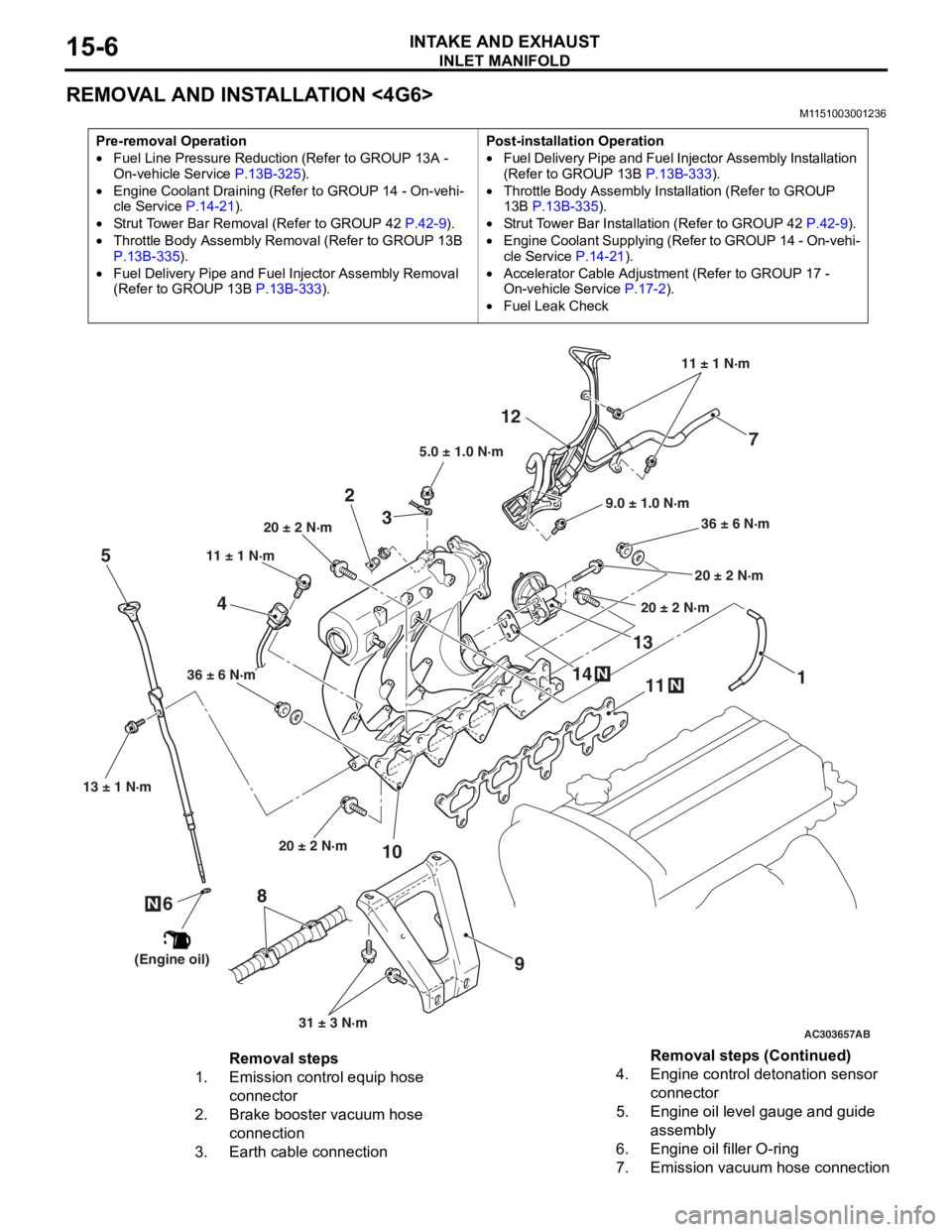

REMOVAL AND INSTALLATION <4G6>

M1151003001236

Pre-removal Operation

•Fuel Line Pressure Reduction (Refer to GROUP 13A -

On-vehicle Service P.13B-325).

•Engine Coolant Draining (Refer to GROUP 14 - On-vehi-cle Service P.14-21).

•Strut Tower Bar Removal (Refer to GROUP 42 P.42-9).

•Throttle Body Assembly Re moval (Refer to GROUP 13B

P.13B-335).

•Fuel Delivery Pipe and Fuel Injector Assembly Removal

(Refer to GROUP 13B

P.13B-333).

Post-installation Operation

•Fuel Delivery Pipe and Fuel Injector Assembly Installation

(Refer to GROUP 13B P.13B-333).

•Throttle Body Assembly Inst allation (Refer to GROUP

13B P.13B-335).

•Strut Tower Bar Installati on (Refer to GROUP 42 P.42-9).

•Engine Coolant Supplying (Refer to GROUP 14 - On-vehi-

cle Service P.14-21).

•Accelerator Cable Adjustment (Refer to GROUP 17 -

On-vehicle Service

P.17-2).

•Fuel Leak Check

AC303657

9.0 ± 1.0 N·m11 ± 1 N·m

20 ± 2 N·m 31 ± 3 N·m

36 ± 6 N·m

20 ± 2 N·m

20 ± 2 N·m

36 ± 6 N·m

20 ± 2 N·m

11

9

10

2

12

N14

13N

AB

5.0 ± 1.0 N·m

3

1

11 ± 1 N·m

4

N

13 ± 1 N·m

5

6

(Engine oil)

7

8

Removal steps

1.Emission control equip hose

connector

2.Brake booster vacuum hose

connection

3.Earth cable connection

4.Engine control detonation sensor

connector

5.Engine oil level gauge and guide

assembly

6.Engine oil filler O-ring

7.Emission vacuum hose connection

Removal steps (Continued)

Page 57 of 800

EXHAUST MANIFOLD

INTAKE AND EXHAUST15-7

INSPECTION

M1151003100616

Check the following points; replace the part if a prob-

lem is found.

Inlet Manifold Check

1. Check for damage or cracking of any part.

2. Clogging of the negative pressure (vacuum) outlet port, or clogging of the exhaust gas recirculation

passages.

3. Using a straight edge and feeler gauge, check for distortion of the cylinder head installation surface.

Standard value: 0.15 mm or less

Limit: 0.20 mm

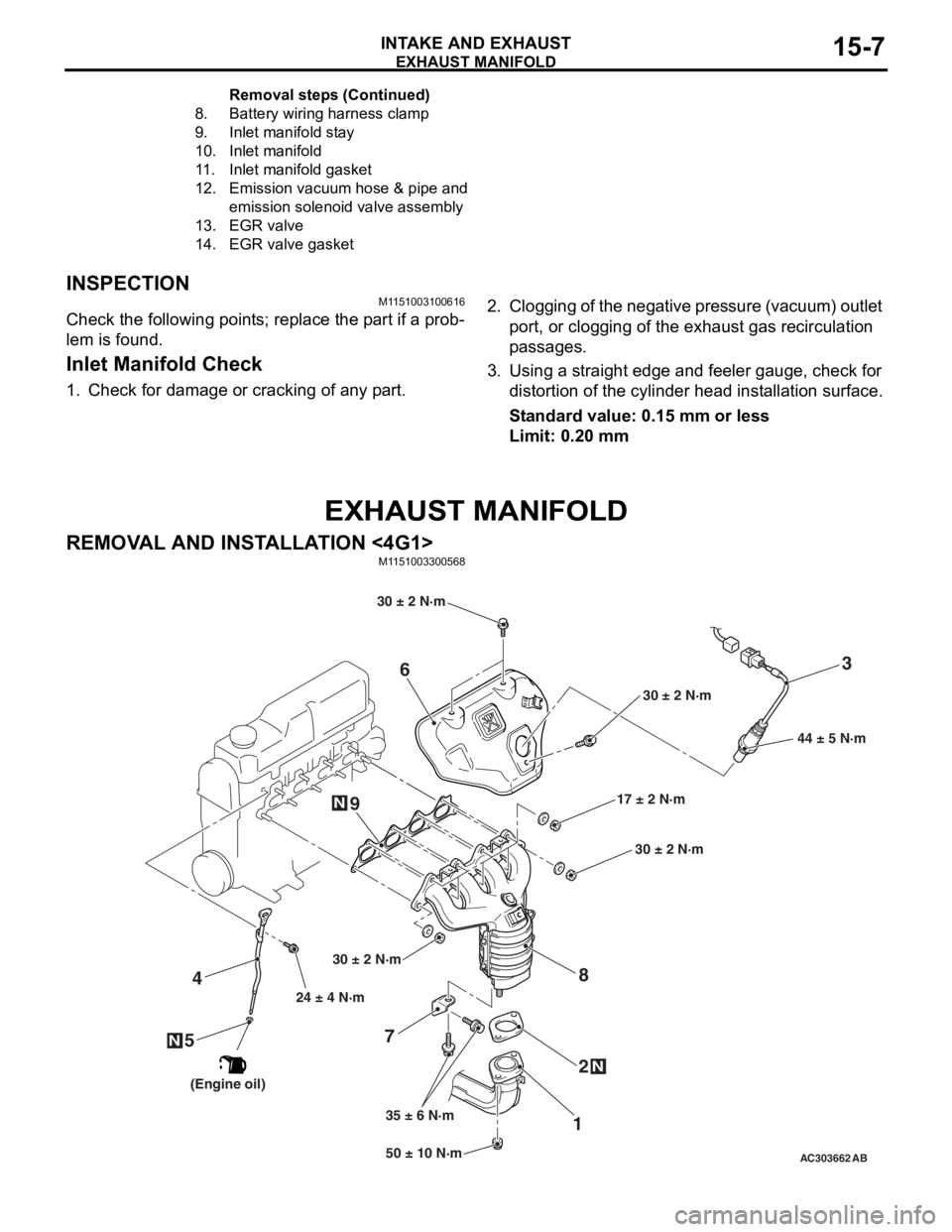

EXHAUST MANIFOLD

REMOVAL AND INSTALLATION <4G1>

M1151003300568

AC30366250 ± 10 N·m

24 ± 4 N·m

35 ± 6 N·m 17 ± 2 N·m

30 ± 2 N·m

N

3

7 12

4

N

6

8

44 ± 5 N·m

AB

9

5N

30 ± 2 N·m

30 ± 2 N·m

30 ± 2 N·m

(Engine oil)

8.Battery wirin g ha rne s s clamp

9.Inlet manifold st ay

10.Inlet manifold

11.Inlet manifold gask et

12.Emission vacuu m hose & pipe and

emis

sion s o lenoid valve assembly

13.EGR v a lve

14.EGR v a lve gasket

Remo va l st ep s ( C o n t in u e d)

Page 58 of 800

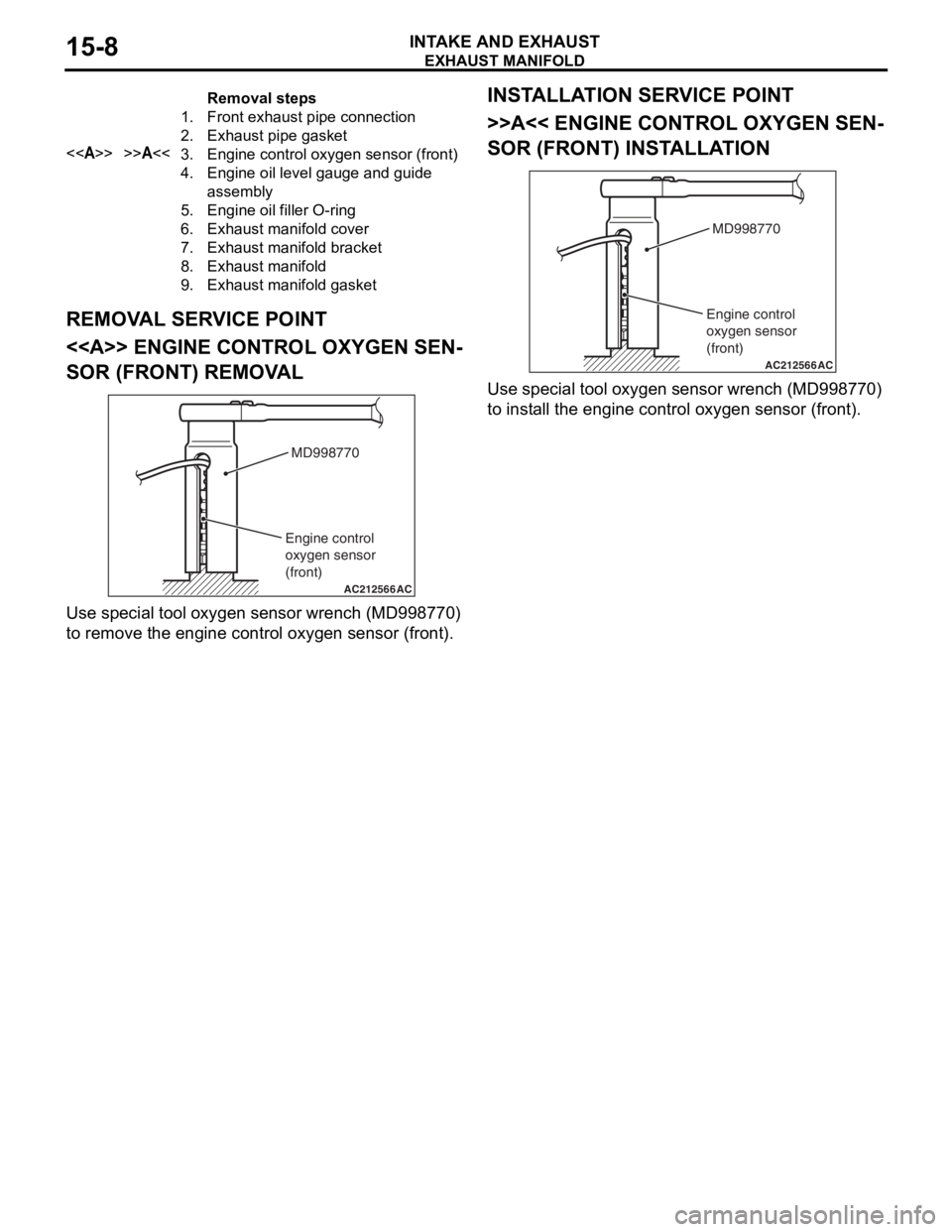

Removal steps

1.Front exhaust pipe connection

2.Exhaust pipe gasket

<>>>A<<3.Engine control oxygen sensor (front)

4.Engine oil level gauge and guide

assembly

5.Engine oil filler O-ring

6.Exhaust manifold cover

7.Exhaust manifold bracket

8.Exhaust manifold

9.Exhaust manifold gasket

EXHAUST MANIFOLD

INTAKE AND EXHAUST15-8

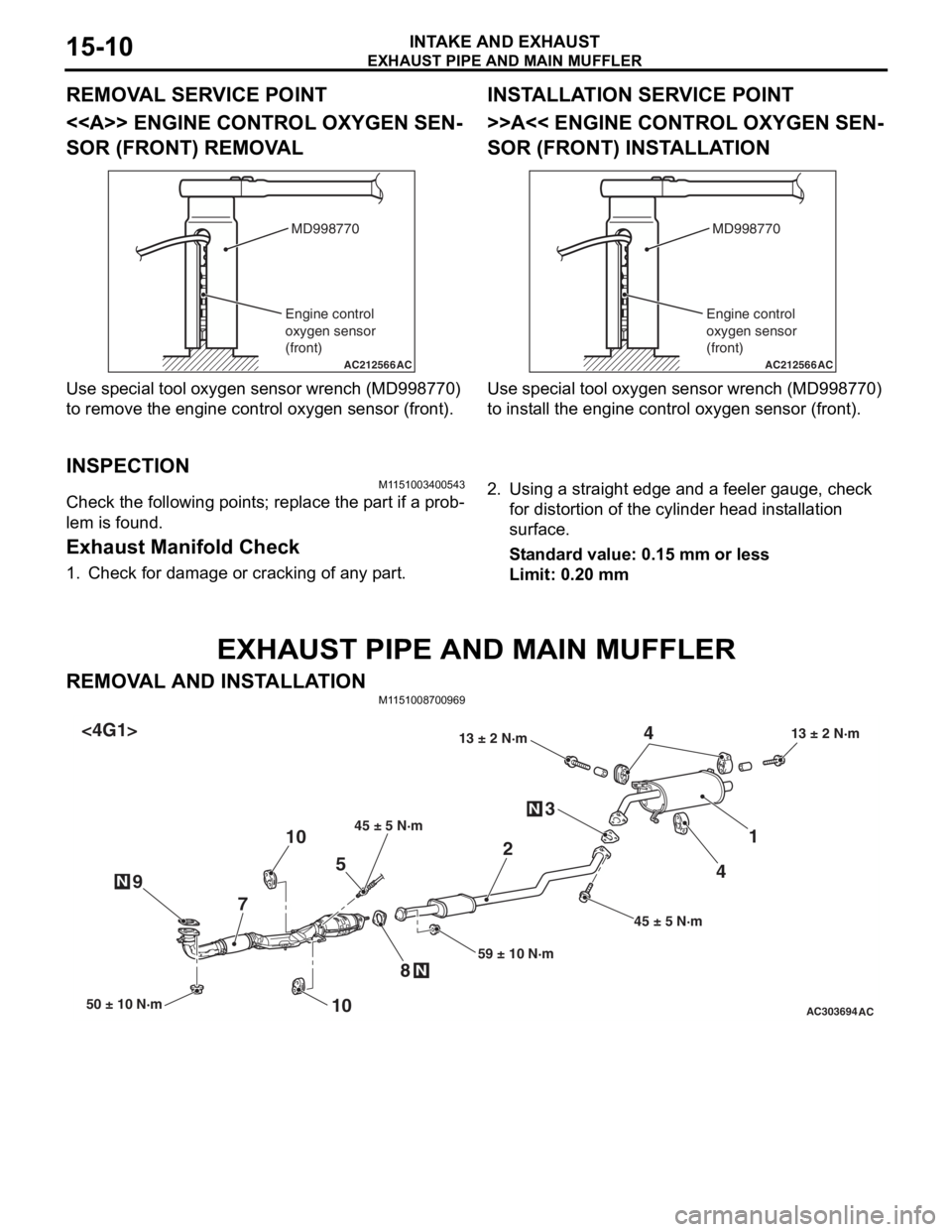

REMOVAL SERVICE POINT

<> ENGINE CONTROL OXYGEN SEN-

SOR (FRONT) REMOVAL

AC212566AC

MD998770

Engine control

oxygen sensor

(front)

Use spe c ia l tool oxyg en sen s or wrench (MD9987 70)

to remove t

he eng ine contro l oxygen sen s or (fro nt).

INSTALLA T ION SER VICE POINT

>>A<< ENGINE CONT ROL OXYGEN SEN-

SOR (FRONT) INSTALLA TION

AC212566AC

MD998770

Engine control

oxygen sensor

(front)

Use spe c ia l tool oxyg en sen s or wrench (MD9987 70)

to inst

all the eng ine contro l oxyge n sen s or (f ront).

Page 59 of 800

EXHAUST MANIFOLD

INTAKE AND EXHAUST15-9

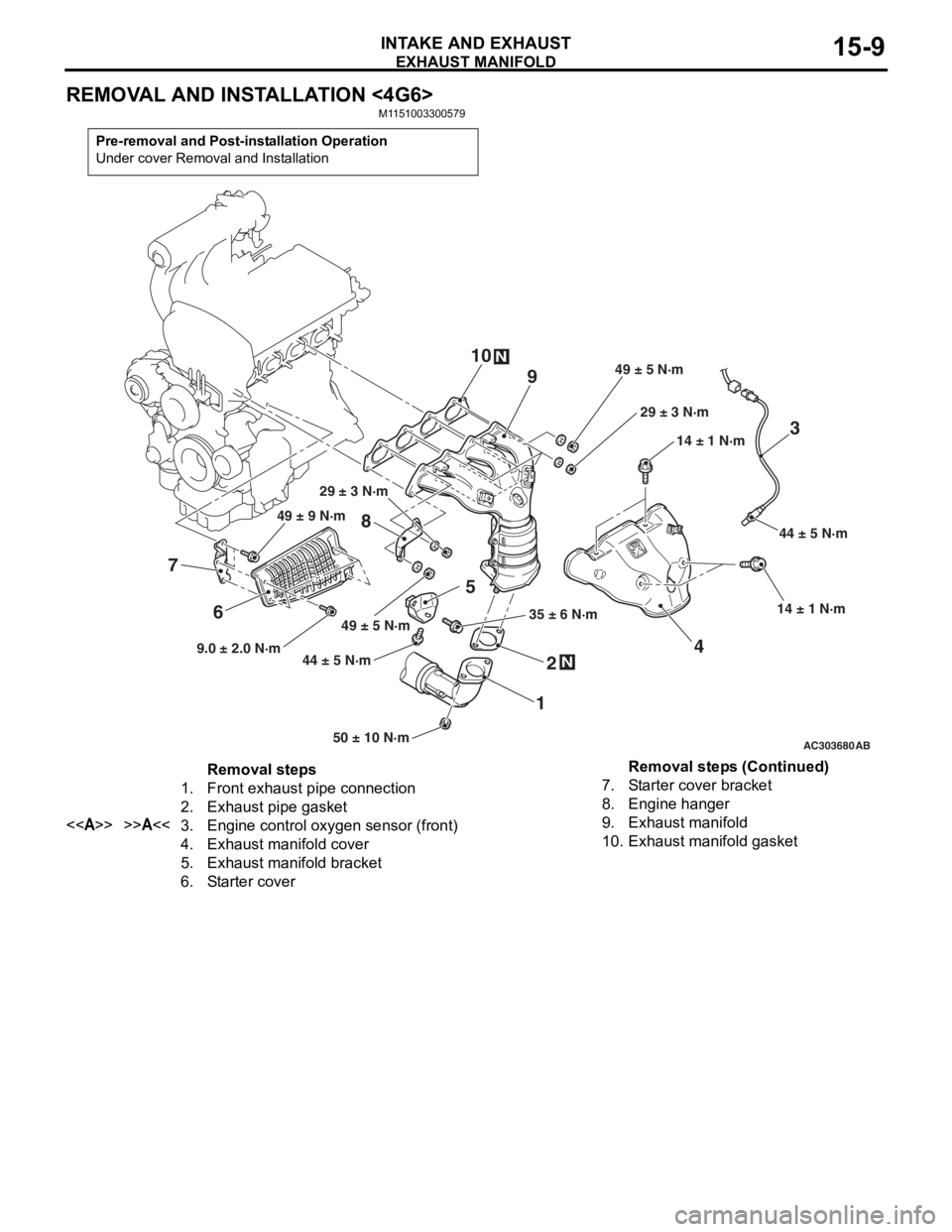

REMOVAL AND INSTALLATION <4G6>

M1151003300579

Pre-removal and Post-installation Operation

Under cover Removal and Installation

AC30368050 ± 10 N·m

44 ± 5 N·m

35 ± 6 N·m14 ± 1 N·m

14 ± 1 N·m

49 ± 5 N·m 29 ± 3 N·m

29 ± 3 N·m

N

3

4

1 2

5

N

8 944 ± 5 N·m

AB

1049 ± 5 N·m

6

7

9.0 ± 2.0 N·m 49 ± 9 N·m

Removal steps

1.Front exhaust pipe connection

2.Exhaust pipe gasket

<>>>A<<3.Engine control oxygen sensor (front)

4.Exhaust manifold cover

5.Exhaust manifold bracket

6.Starter cover

7.Starter cover bracket

8.Engine hanger

9.Exhaust manifold

10.Exhaust manifold gasket

Removal steps (Continued)

Page 60 of 800