ISC MITSUBISHI LANCER 2006 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 242 of 800

ON-VEHICLE SERVICE

POWER STEERING37-12

TIE ROD END BALL JOINT TURNING

TORQUE CHECK

M1372001500554

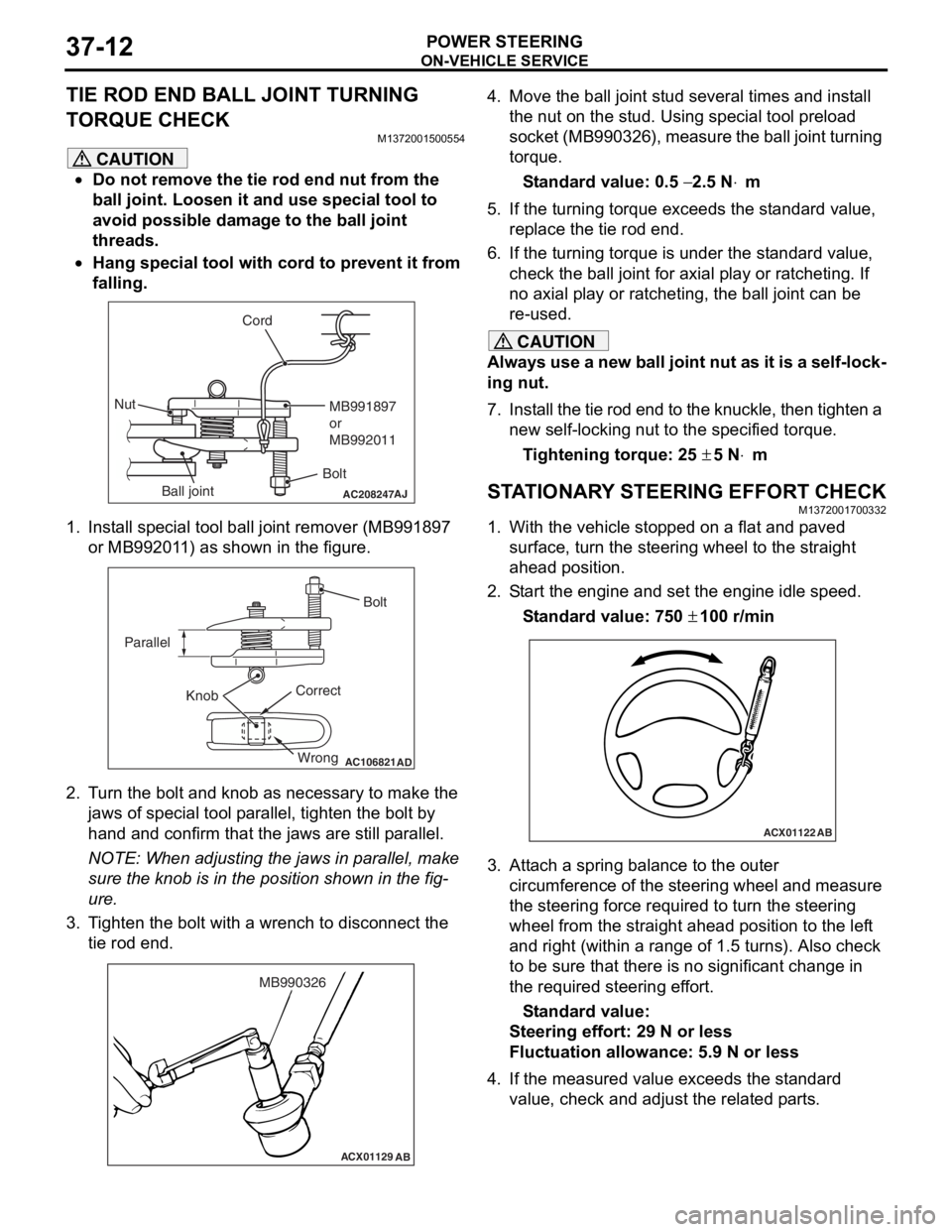

CAUTION

•Do not remove the tie rod end nut from the

ball joint. Loosen it and use special tool to

avoid possible damage to the ball joint

threads.

•

AC208247AJ

CordBoltMB991897

or

MB992011

Nut

Ball joint

Hang special tool with cord to prevent it from

falling.

1. Install special tool ball joint remover (MB991897 or MB992011) as shown in the figure.

AC106821

Knob

Parallel

Bolt

Correct Wrong

AD

2. Turn the bolt and knob as necessary to make the jaws of special tool parallel, tighten the bolt by

hand and confirm that the jaws are still parallel.

NOTE: When adjusting the jaws in parallel, make

sure the knob is in the position shown in the fig

-

ure.

3. Tighten the bolt with a wrench to disconnect the tie rod end.

ACX01129 AB

MB990326

4. Move the ball joint stud several times and install

the nut on the stud. Using special tool preload

socket (MB990326), measure the ball joint turning

torque.

Standard value: 0.5 − 2.5 N⋅m

5. If the turning torque exceeds the standard value, replace the tie rod end.

6. If the turning torque is under the standard value, check the ball joint for axial play or ratcheting. If

no axial play or ratcheting, the ball joint can be

re-used.

CAUTION

Always use a new ball joint nut as it is a self-lock-

ing nut.

7. Install the tie rod end to the knuckle, then tighten a new self-locking nut to the specified torque.

Tightening torque: 25 ± 5 N⋅m

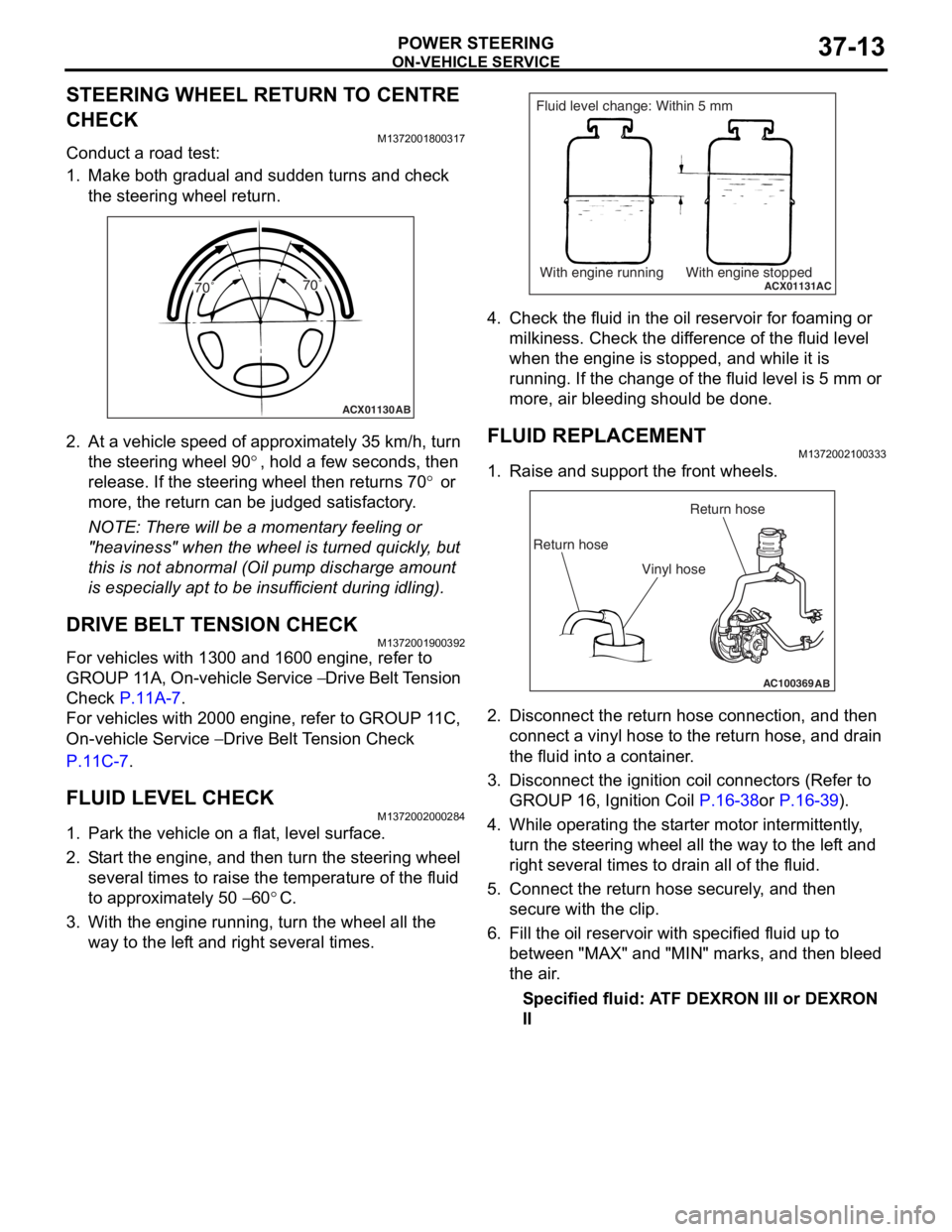

STATIONARY STEERING EFFORT CHECKM1372001700332

1. With the vehicle stopped on a flat and paved

surface, turn the steering wheel to the straight

ahead position.

2. Start the engine and set the engine idle speed.

Standard value: 750 ± 100 r/min

ACX01122 AB

3. Attach a spring balance to the outer

circumference of the steering wheel and measure

the steering force required to turn the steering

wheel from the straight ahead position to the left

and right (within a range of 1.5 turns). Also check

to be sure that there is no significant change in

the required steering effort.

Standard value:

Steering effort: 29 N or less

Fluctuation allowance: 5.9 N or less

4. If the measured value exceeds the standard value, check and adjust the related parts.

Page 243 of 800

ON-VEHICLE SERVICE

POWER STEERING37-13

STEERING WHEEL RETURN TO CENTRE

CHECK

M1372001800317

Conduct a road test:

1. Make both gradual and sudden turns and check the steering wheel return.

ACX01130 AB

70˚ 70˚

2.

At a vehicle sp eed of a pproxima t ely 35 km/h, turn

th e ste e ring wh eel 9 0

°, ho ld a few se cond s, the n

release. If th

e ste

e

ring

wh eel t hen ret u rns 7 0

° or

more, th

e return

can

be ju

dged satisfactory

.

NOTE: There will be a mome nt a r y fee lin g or

"he

a

viness" when t he wheel is turned quickly , but

th

is is n o t abno rmal (Oil pu mp discharge amou nt

is especially a p t to b e insufficie n t during id lin g).

DRIVE BELT TENSION CHECK

M13720019 0039 2

For vehicles with 13 00 and 1600 engin e , refer to

GROUP 1

1 A, On-vehicle Service

− Drive Belt T ension

Che

c

k

P.11A-7.

For veh i cles wit h 2000 e ngin e , refer to GROUP 1 1 C,

On-vehicle Se

rvice

− Drive Belt Te nsion Check

P.1 1 C - 7.

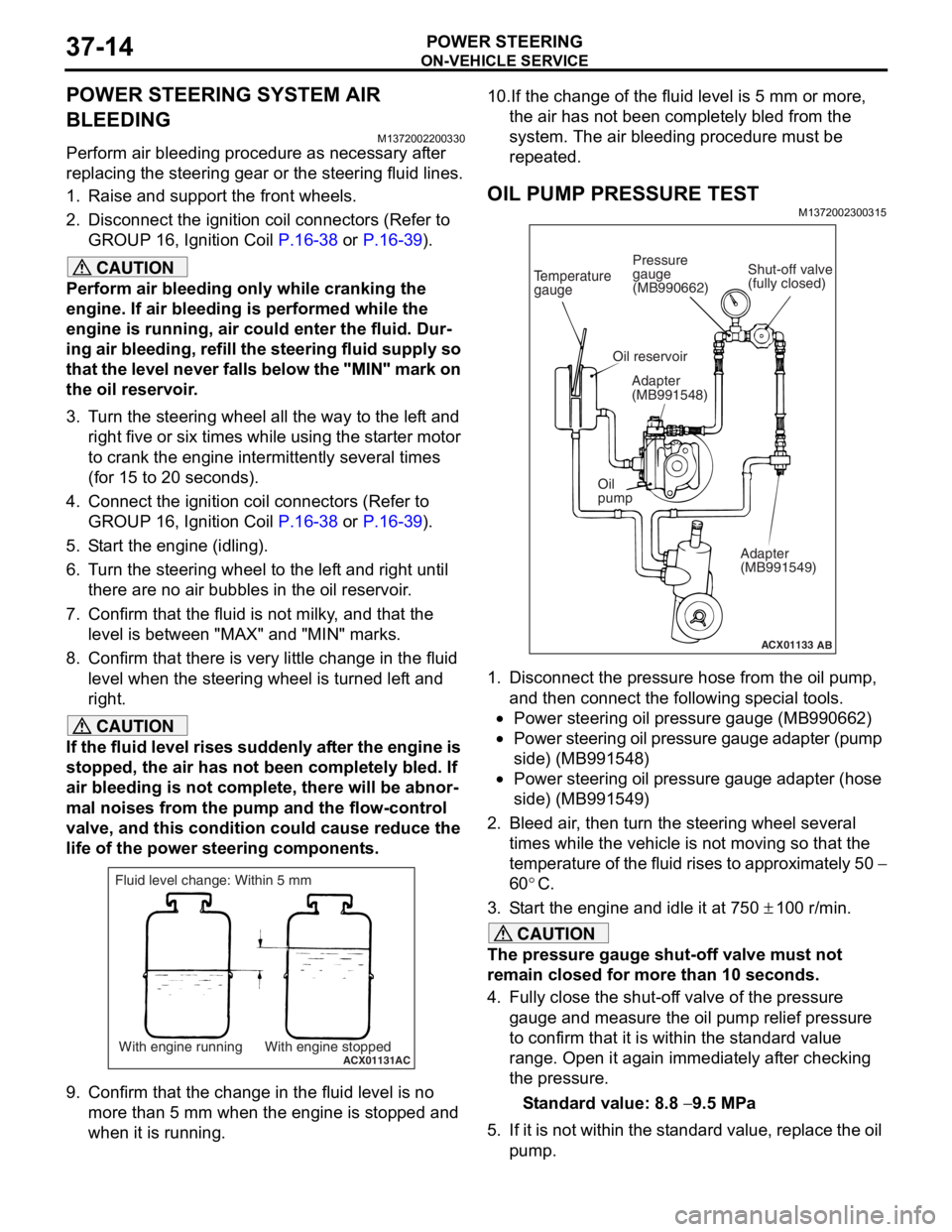

FLUID LEVEL CHECK

M13720020 0028 4

1.Park the vehicle on a f l at, leve l su rface .

2.S t art the engine, and t hen tu rn the ste e ring wheel

seve ral times to raise the temperat ure of th e flu i d

to approximately 50

− 60°C.

3.With the engine run n ing, turn the wheel all the

way to the lef t an d righ t several times.

ACX01131With engine running With engine stoppedAC

Fluid level change: Within 5 mm

4.Check t he flu i d in the oil r e servoir f o r foaming or

milkine s s. Check the d i f f e r ence of the fluid le vel

when the e ngine is stop ped, an d while it is

ru nning . If the chan ge of th e fluid le vel is 5 mm or

more, a i r bleedin g sh ould be don e.

FLUID REPLACEMENT

M13720021 0033 3

1.Raise a nd su pport t he fron t wheels.

AC100369AB

Return hoseReturn hose

Vinyl hose

2. Disco nnect the re turn hose connection , and then

conne ct a vinyl hose to the re turn h o se, and drain

th e flu i d into a cont ain e r .

3.Disco nnect the ignition coil con necto rs (Refe r to

GROUP 16, Ignition Coil

P.16-38or P.16-39).

4.Wh ile operat ing th e st arter moto r inter m itt ently ,

tu rn the steering whee l all the wa y to t he le f t a nd

right seve ral times to dra i n all of the fluid.

5.Conn ect the retu rn hose se curely , and then

secu re with t he clip.

6.Fill the oil reservo i r with specified fluid u p to

b e tween "MAX" and "MIN" marks, and then bleed

th e air .

Specified fluid: A TF DEXRON III or DEXRON

II

Page 244 of 800

ON-VEHICLE SERVICE

POWER STEERING37-14

POWER STEERING SYSTEM AIR

BLEEDING

M1372002200330

Perform air bleeding procedure as necessary after

replacing the steering gear or the steering fluid lines.

1. Raise and support the front wheels.

2. Disconnect the ignition coil connectors (Refer to GROUP 16, Ignition Coil

P.16-38 or P.16-39).

CAUTION

Perform air bleeding only while cranking the

engine. If air bleeding is performed while the

engine is running, air could enter the fluid. Dur

-

ing air bleeding, refill the steering fluid supply so

that the level never falls below the "MIN" mark on

the oil reservoir.

3. Turn the steering wheel all the way to the left and

right five or six times wh ile using the starter motor

to crank the engine intermittently several times

(for 15 to 20 seconds).

4. Connect the ignition coil connectors (Refer to GROUP 16, Ignition Coil

P.16-38 or P.16-39).

5. Start the engine (idling).

6. Turn the steering wheel to the left and right until there are no air bubbles in the oil reservoir.

7. Confirm that the fluid is not milky, and that the level is between "MAX" and "MIN" marks.

8. Confirm that there is very little change in the fluid

level when the steering wheel is turned left and

right.

CAUTION

If the fluid level rises suddenly after the engine is

stopped, the air has not been completely bled. If

air bleeding is not complete, there will be abnor

-

mal noises from the pump and the flow-control

valve, and this condition could cause reduce the

life of the power steering components.

ACX01131With engine running With engine stoppedAC

Fluid level change: Within 5 mm

9. Confirm that the change in the fluid level is no more than 5 mm when the engine is stopped and

when it is running.

10.If the change of the fluid level is 5 mm or more,

the air has not been completely bled from the

system. The air bleeding procedure must be

repeated.

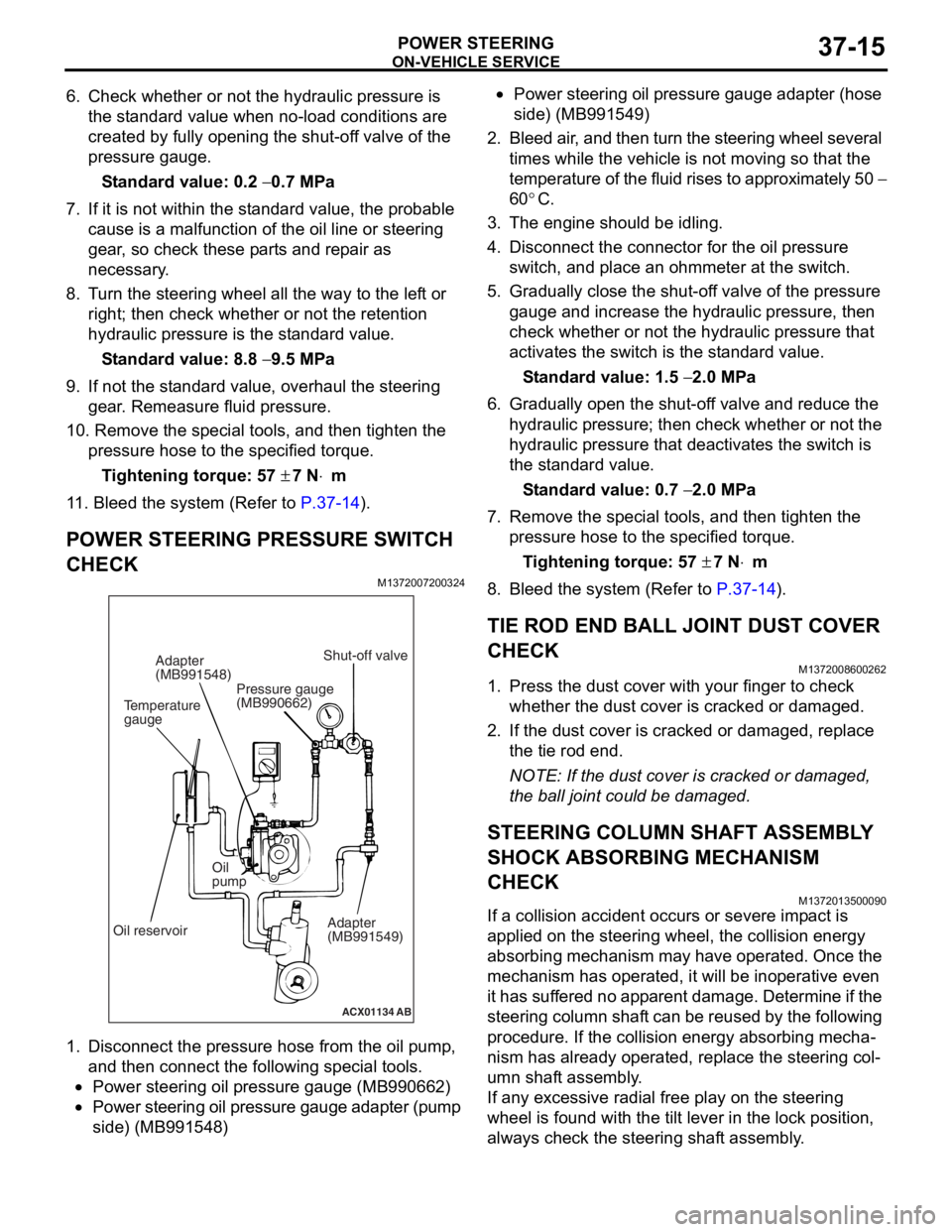

OIL PUMP PRESSURE TEST

M1372002300315

ACX01133

Temperature

gauge

Oil reservoir

Adapter

(MB991548)

Oil

pump Adapter

(MB991549)

AB

Shut-off valve

(fully closed)

Pressure

gauge

(MB990662)

1. Disconnect the pressure hose from the oil pump,

and then connect the following special tools.

•Power steering oil pressure gauge (MB990662)

•Power steering oil pressure gauge adapter (pump

side) (MB991548)

•Power steering oil pressure gauge adapter (hose

side) (MB991549)

2. Bleed air, then turn the steering wheel several times while the vehicle is not moving so that the

temperature of the fluid rises to approximately 50

−

60

°C.

3. Start the engine and idle it at 750 ± 100 r/min.

CAUTION

The pressure gauge shut-off valve must not

remain closed for more than 10 seconds.

4. Fully close the shut-off valve of the pressure gauge and measure the oil pump relief pressure

to confirm that it is within the standard value

range. Open it again immediately after checking

the pressure.

Standard value: 8.8 − 9.5 MPa

5. If it is not within the standard value, replace the oil pump.

Page 245 of 800

ON-VEHICLE SERVICE

POWER STEERING37-15

6. Check whether or not the hydraulic pressure is the standard value when no-load conditions are

created by fully opening the shut-off valve of the

pressure gauge.

Standard value: 0.2 − 0.7 MPa

7. If it is not within the standard value, the probable cause is a malfunction of the oil line or steering

gear, so check these parts and repair as

necessary.

8. Turn the steering wheel all the way to the left or right; then check whether or not the retention

hydraulic pressure is the standard value.

Standard value: 8.8 − 9.5 MPa

9. If not the standard value, overhaul the steering gear. Remeasure fluid pressure.

10. Remove the special tools, and then tighten the

pressure hose to the specified torque.

Tightening torque: 57 ± 7 N⋅m

11. Bleed the system (Refer to P.37-14).

POWER STEERING PRESSURE SWITCH

CHECK

M1372007200324

ACX01134 AB

Temperature

gaugeAdapter

(MB991548)

Oil reservoir Oil

pump

Adapter

(MB991549)

Shut-off valve

Pressure gauge

(MB990662)

1. Disco nnect the pre s sure hose from the oil pump ,

an d then con nect the followin g sp ecial too l s.

•Power steering oil pressure gauge (MB990 662)

•Power steering oil pressure gauge ad apter (pump

side) (MB99154

8)

•Power steering oil pressure gaug e a dapte r (ho s e

side) (MB99154

9)

2. Bleed air , and the n turn t he steering wheel several

times while the vehicle is not moving so that the

tempe r atu r e o f th e flu i d rise s to approximately 50

−

60

°C.

3. Th e engine should be idling.

4.Disco nnect the conne ctor fo r the o il pr essure

switch , and p l ace an o h mmeter a t the switch .

5.Gradua lly close the shut-of f valve of the pressure

g auge a nd in crease the hyd r aulic pre ssu re, the n

check wheth e r or no t the h y drau lic pressure that

a c tivates the switch is the st a ndard valu e.

St andard va lue: 1.5 − 2.0 MPa

6.Gradua lly open the shut-of f va lve and re duce the

h y drau lic p r essure; then check whethe r o r n o t the

h y drau lic pressure that de activate s the switch is

th e st and ard va lue.

St andard va lue: 0.7 − 2.0 MPa

7.Remove the special tools, and then tighten the

p r essure hose to the specified torque .

Ti ghte n ing torque: 57 ± 7 N⋅m

8.Bleed the system (Refer to P.37-14).

TIE ROD END BALL JOINT DUST COVER

CHECK

M13720086 0026 2

1.Press th e dust co ver wit h you r fing er to check

whet her the dust cover is cra cke d or da mage d.

2.If the du st cover is cracked o r damaged, repla c e

th e tie rod end .

NOTE: If the dust cover is cra cke d or da mag ed,

th

e ball jo int could be da mage d.

STEERING COLUMN SHAFT ASSEMBL Y

SHOCK ABSORBING MECHANISM

CHECK

M13720135 0009 0

If a collision accid ent occu rs or seve re imp a ct is

applied on

the steering w heel, the collision energy

abso

r bing mechanism ma y h a ve opera t ed. Once the

mechanism

has o perate d , it will b e ino perative e v en

it has

suf f er ed no app a r en t d a mage . De termin e if the

steering colu

mn shaf t can b e reused b y th e following

proce

dure. If the collision en ergy a b sor b ing mecha

-

nism has already operated, rep l ace the steering col-

umn shaft assembly .

If any excessive radial fre e pla y on the steering

wh

eel is fo und with the tilt lever in the lock po sit i on,

always ch

eck the steering shaf t assembly .

Page 325 of 800

KEYLESS ENTRY SYSTEM

BODY42-53

TROUBLESHOOTING

M1428000700287

The keyless entry system is controlled by the Smart

Wiring System (SWS). For troubleshooting, refer to

GROUP 54B, Troubleshooting

P.54B-15 or GROUP

54C, Troubleshooting P.54C-4.

ON-VEHICLE SERVICE

KEYLESS ENTR Y SYSTEM CHECKM1428001400096

Check the system as described below. If the system

does not work, carry out troubleshooting. Refer to

GROUP 54B, Troubleshooting

P.54B-15, refer to

GROUP 54C, Troubleshooting P.54C-4.

•Operate the transmitter to check that the doors

and tailgate can be locked and unlocked.

•Operate the transmitter to check that the answer-

back function works in response to door and tail-

gate

NOTE: The adjustment function allows you to

change the answerback setting as follows. Prior

to that check, confirm which setting is activated.

.

•The hazard warning lamps flash twice when

locked and once when unlocked. The room

lamp flashes twice when locked and illumi

-

nates for 15 seconds when unlocked.

•The hazard warning lamps do not flash when

locked and flash once when unlocked. The

room lamp flashes twice when locked and illu

-

minates for 15 seconds when unlocked.

•The hazard warning lamps flash twice when

locked and do not flash when unlocked. The

room lamp flashes twice when locked and illu

-

minates for 15 seconds when unlocked.

•The hazard warning lamps do not flash when

both locked and unlocked. The room lamp

flashes twice when locked and illuminates for

15 seconds when unlocked.

KEYLESS ENTRY SYS TEM TIMER LOCK

FUNCTION INSPECTION

M1428004000138

Push the transmitter unlock button and check to see

that the doors and tailgate

seconds. If it doesn't, then execute troubleshooting

remedies. Refer to GROUP 54B, Troubleshooting

P.54B-15, refer to GROUP 54C, Troubleshooting

P.54C-4.

ENABLING/DISABLING THE

ANSWERBACK FUNCTION

M1428003200214

If the keyless entry system locks or unlocks the

doors, the room lamp flashes or illuminates, the haz

-

ard warning lamp flashes (hazard answerback func-

tion). The hazard answerback function can be

enabled or disabled according to the following proce

-

dure:

ENABLING/DISABLING THE HAZARD

ANSWERBACK FUNCTION

The hazard answerback function can be enabled or

disabled by one of the two following procedures.

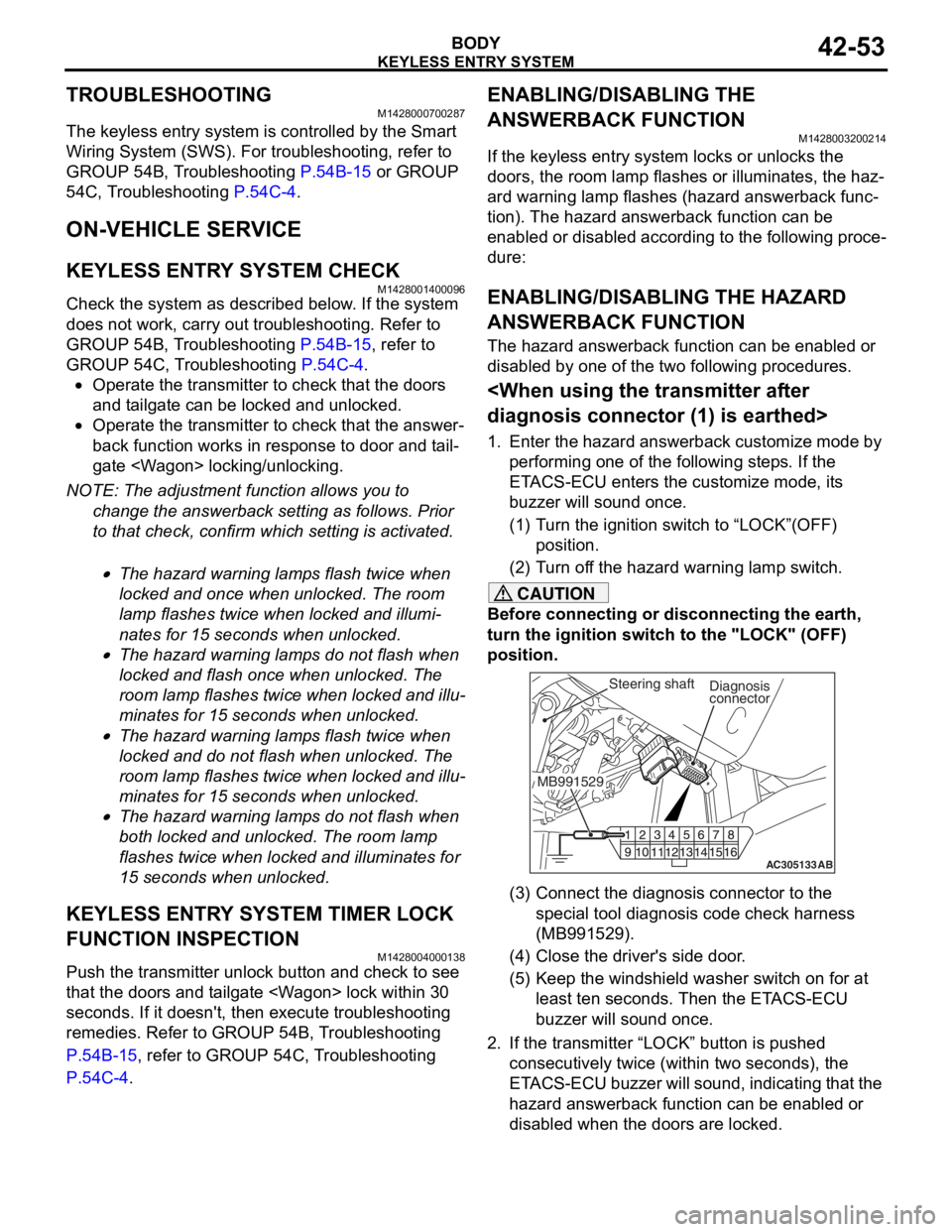

1. Enter the hazard answerback customize mode by performing one of the following steps. If the

ETACS-ECU enters the customize mode, its

buzzer will sound once.

(1) Turn the ignition switch to “LOCK”(OFF) position.

(2) Turn off the hazard warning lamp switch.

CAUTION

Before connecting or disconnecting the earth,

turn the ignition switch to the "LOCK" (OFF)

position.

AC305133AB

Diagnosis

connector

MB991529Steering shaft

(3) Connect the diagnosis connector to the special tool diagnosis code check harness

(MB991529).

(4) Close the driver's side door.

(5) Keep the windshield washer switch on for at least ten seconds. Then the ETACS-ECU

buzzer will sound once.

2. If the transmitter “LOCK” button is pushed consecutively twice (wit hin two seconds), the

ETACS-ECU buzzer will sound, indicating that the

hazard answerback function can be enabled or

disabled when the doors are locked.

Page 326 of 800

KEYLESS ENTRY SYSTEM

BODY42-54

•Enable the hazard answerback function

when the doors are locked: The

ETACS-ECU buzzer will sound once.

•Disable the hazard answerback function

when the doors are locked: The

ETACS-ECU buzzer will sound twice.

3. If the transmitter “UNLOCK” button is pushed consecutively twice (wit hin two seconds), the

ETACS-ECU buzzer will sound, indicating that the

hazard answerback function can be enabled or

disabled when the doors are unlocked.

•Enable the hazard answerback function

when the doors are unlocked: The

ETACS-ECU buzzer will sound once.

•Disable the hazard answerback function

when the doors are unlocked: The

ETACS-ECU buzzer will sound twice.

4. Exit the hazard answer back customize mode by

observing one of the following steps.

(1) Disconnect diagnosis connector terminal (1) form the earth.

(2) Turn the ignition switch to position other then “LOCK”(OFF), or remove the ignition key.

(3) Open the driver's side door.

(4) Any other warning buzzer output occurs.

NOTE: If any operation is not done for at least three

minutes after the ETACS-ECU has entered the cus

-

tomize mode, the hazard answerback customize

mode will be canceled automatically.

connector>

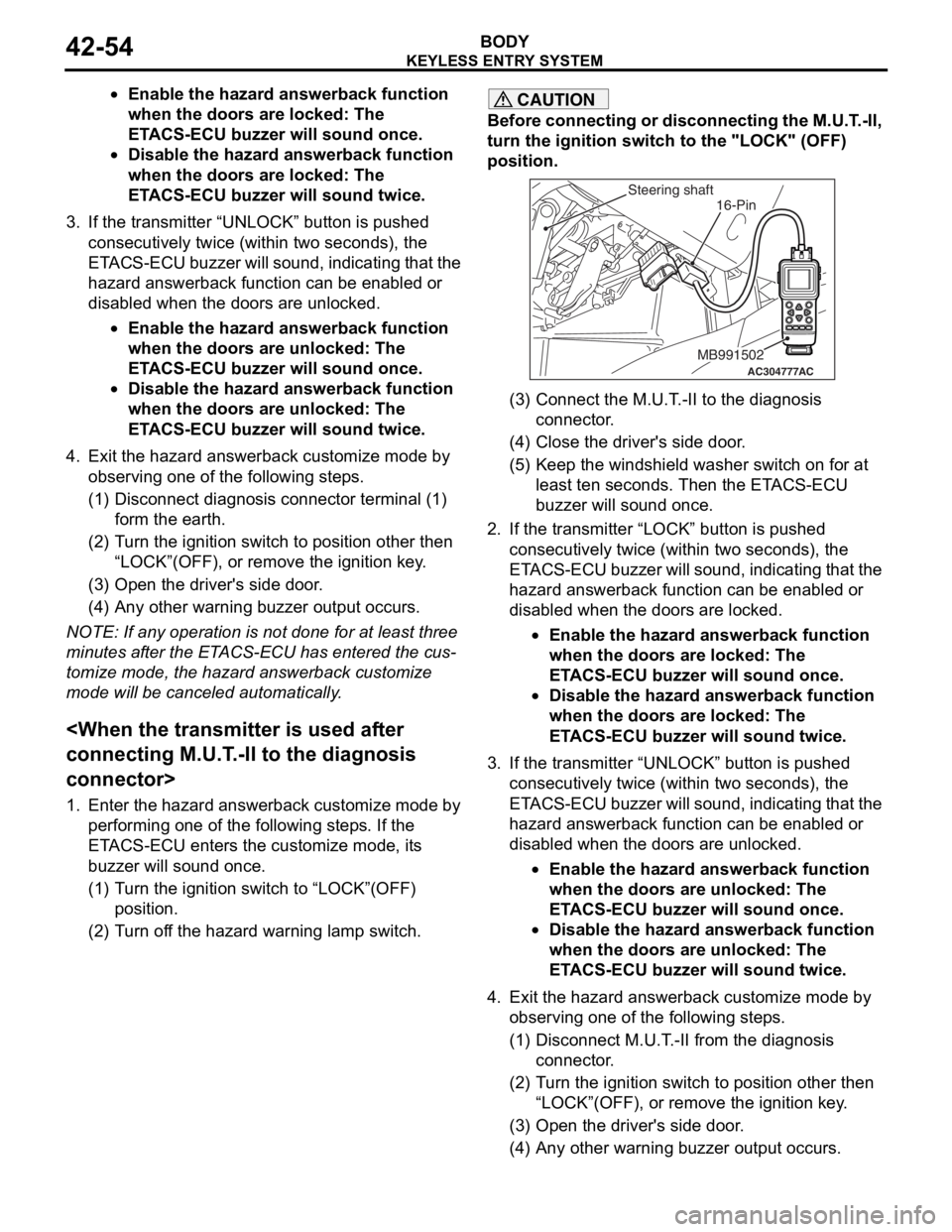

1. Enter the hazard answerback customize mode by performing one of the following steps. If the

ETACS-ECU enters the customize mode, its

buzzer will sound once.

(1) Turn the ignition switch to “LOCK”(OFF) position.

(2) Turn off the hazard warning lamp switch.

CAUTION

Before connecting or disconnecting the M.U.T.-II,

turn the ignition switch to the "LOCK" (OFF)

position.

AC304777

Steering shaft

ACMB991502

16-Pin

(3) Connect the M.U.T.-II to the diagnosis

connector.

(4) Close the driver's side door.

(5) Keep the windshield washer switch on for at least ten seconds. Then the ETACS-ECU

buzzer will sound once.

2. If the transmitter “LOCK” button is pushed consecutively twice (wit hin two seconds), the

ETACS-ECU buzzer will sound, indicating that the

hazard answerback function can be enabled or

disabled when the doors are locked.

•Enable the hazard answerback function

when the doors are locked: The

ETACS-ECU buzzer will sound once.

•Disable the hazard answerback function

when the doors are locked: The

ETACS-ECU buzzer will sound twice.

3. If the transmitter “UNLOCK” button is pushed consecutively twice (wit hin two seconds), the

ETACS-ECU buzzer will sound, indicating that the

hazard answerback function can be enabled or

disabled when the doors are unlocked.

•Enable the hazard answerback function

when the doors are unlocked: The

ETACS-ECU buzzer will sound once.

•Disable the hazard answerback function

when the doors are unlocked: The

ETACS-ECU buzzer will sound twice.

4. Exit the hazard answer back customize mode by

observing one of the following steps.

(1) Disconnect M.U.T.-II from the diagnosis

connector.

(2) Turn the ignition switch to position other then “LOCK”(OFF), or remove the ignition key.

(3) Open the driver's side door.

(4) Any other warning buzzer output occurs.

Page 327 of 800

KEYLESS ENTRY SYSTEM

BODY42-55

NOTE: If any operation is not done for at least three

minutes after the ETACS-ECU has entered the cus

-

tomize mode, the hazard answerback customize

mode will be canceled automatically.

(MB991824) to the diagnosis connector>

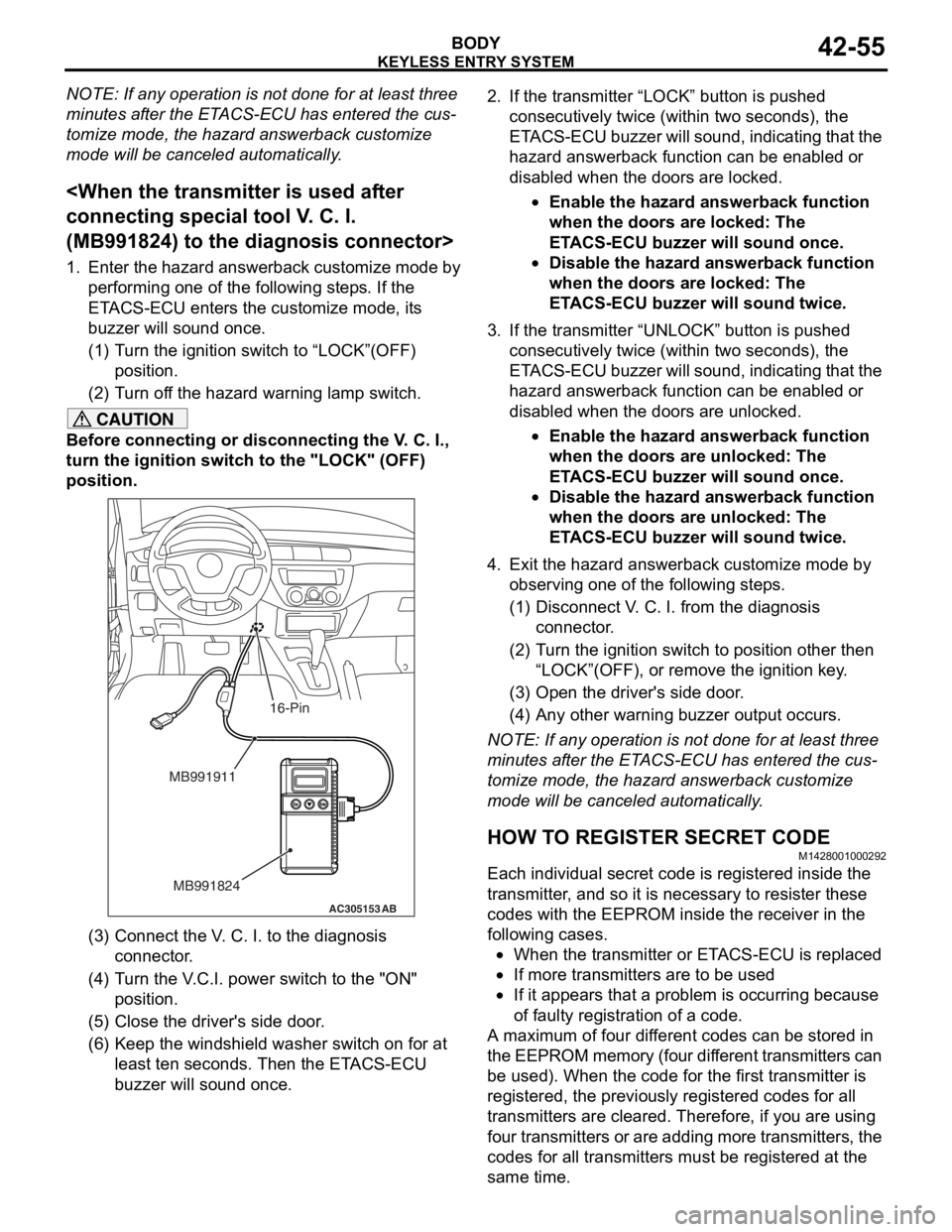

1. Enter the hazard answerback customize mode by

performing one of the following steps. If the

ETACS-ECU enters the customize mode, its

buzzer will sound once.

(1) Turn the ignition switch to “LOCK”(OFF) position.

(2) Turn off the hazard warning lamp switch.

CAUTION

Before connecting or disconnecting the V. C. I.,

turn the ignition switch to the "LOCK" (OFF)

position.

AC305153AB

MB991911

MB991824

16-Pin

(3) Connect the V. C. I. to the diagnosis connector.

(4) Turn the V.C.I. power switch to the "ON" position.

(5) Close the driver's side door.

(6) Keep the windshield washer switch on for at least ten seconds. Then the ETACS-ECU

buzzer will sound once.

2. If the transmitter “LOCK” button is pushed

consecutively twice (wit hin two seconds), the

ETACS-ECU buzzer will sound, indicating that the

hazard answerback function can be enabled or

disabled when the doors are locked.

•Enable the hazard answerback function

when the doors are locked: The

ETACS-ECU buzzer will sound once.

•Disable the hazard answerback function

when the doors are locked: The

ETACS-ECU buzzer will sound twice.

3. If the transmitter “UNLOCK” button is pushed consecutively twice (wit hin two seconds), the

ETACS-ECU buzzer will sound, indicating that the

hazard answerback function can be enabled or

disabled when the doors are unlocked.

•Enable the hazard answerback function

when the doors are unlocked: The

ETACS-ECU buzzer will sound once.

•Disable the hazard answerback function

when the doors are unlocked: The

ETACS-ECU buzzer will sound twice.

4. Exit the hazard answer back customize mode by

observing one of the following steps.

(1) Disconnect V. C. I. from the diagnosis connector.

(2) Turn the ignition switch to position other then

“LOCK”(OFF), or remove the ignition key.

(3) Open the driver's side door.

(4) Any other warning buzzer output occurs.

NOTE: If any operation is not done for at least three

minutes after the ETACS-ECU has entered the cus

-

tomize mode, the hazard answerback customize

mode will be canceled automatically.

HOW TO REGISTER SECRET CODE

M1428001000292

Each individual secret code is registered inside the

transmitter, and so it is necessary to resister these

codes with the EEPROM insi de the receiver in the

following cases.

•When the transmitter or ETACS-ECU is replaced

•If more transmitters are to be used

•If it appears that a probl em is occurring because

of faulty registration of a code.

A maximum of four different codes can be stored in

the EEPROM memory (four different transmitters can

be used). When the code for the first transmitter is

registered, the previously registered codes for all

transmitters are cleared. Therefore, if you are using

four transmitters or are adding more transmitters, the

codes for all transmitters must be registered at the

same time.

Page 328 of 800

KEYLESS ENTRY SYSTEM

BODY42-56

WHEN THE SPECIAL TOOL DIAGNOSIS

CODE CHECK HARNESS (MB991529) IS

USED

1. Check that the doors lock normally when the key is used.

2. Insert the ignition key.

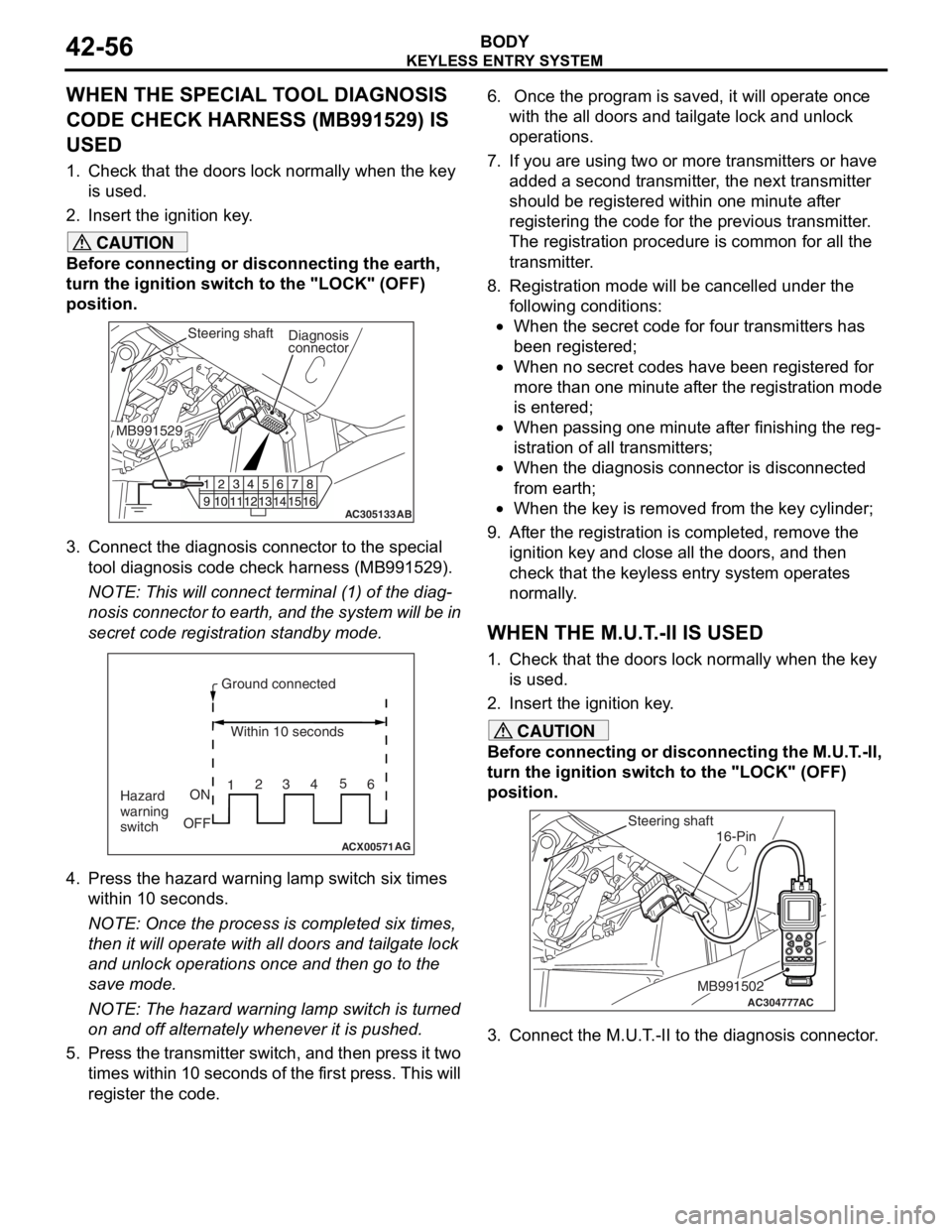

CAUTION

Before connecting or disconnecting the earth,

turn the ignition switch to the "LOCK" (OFF)

position.

AC305133AB

Diagnosis

connector

MB991529Steering shaft

3. Connect the diagnosis connector to the special tool diagnosis code check harness (MB991529).

NOTE: This will connect terminal (1) of the diag-

nosis connector to earth, and the system will be in

secret code registration standby mode.

ACX00571

Ground connected

Within 10 seconds

Hazard

warning

switch ON

OFF 1

23

45

6

AG

4. Press the hazard warning lamp switch six times

within 10 seconds.

NOTE: Once the process is completed six times,

then it will operate with al l doors and tailgate lock

and unlock operations once and then go to the

save mode.

NOTE: The hazard warning lamp switch is turned

on and off alternately whenever it is pushed.

5. Press the transmitter switch, and then press it two times within 10 seconds of the first press. This will

register the code.

6. Once the program is saved, it will operate once

with the all doors and tailgate lock and unlock

operations.

7. If you are using two or more transmitters or have

added a second transmitter, the next transmitter

should be registered within one minute after

registering the code for the previous transmitter.

The registration procedure is common for all the

transmitter.

8. Registration mode will be cancelled under the following conditions:

•When the secret code for four transmitters has

been registered;

•When no secret codes have been registered for

more than one minute after the registration mode

is entered;

•When passing one minute after finishing the reg-

istration of all transmitters;

•When the diagnosis connector is disconnected

from earth;

•When the key is removed from the key cylinder;

9. After the registration is completed, remove the ignition key and close all the doors, and then

check that the keyless entry system operates

normally.

WHEN THE M.U.T.-II IS USED

1. Check that the doors lock normally when the key

is used.

2. Insert the ignition key.

CAUTION

Before connecting or disconnecting the M.U.T.-II,

turn the ignition switch to the "LOCK" (OFF)

position.

AC304777

Steering shaft

ACMB991502

16-Pin

3. Connect the M.U.T.-II to the diagnosis connector.

Page 329 of 800

ACX00571

M.U.T.-II connectedWithin 10 seconds

Hazard

warning

switch ON

OFF 1

23

45

6

AB

KEYLE SS ENTR Y SYSTEM

BOD Y42-57

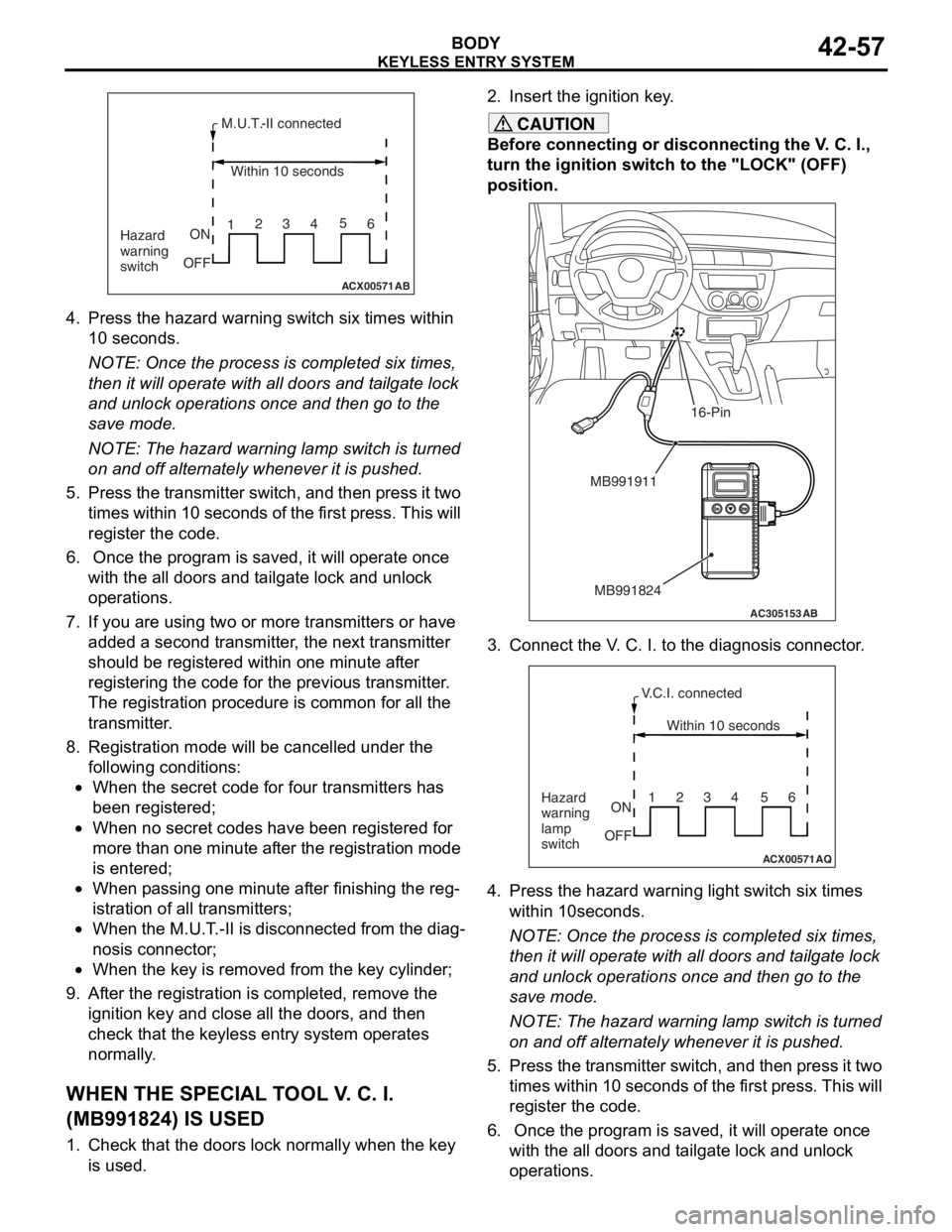

4.Press th e hazard warning switch six times within

10 seconds.

NOTE: Once th e process is comple ted six t i me s,

th

en it

will operate with al l do ors an d t a ilgate lock

an

d unlock opera t ions once and then go to th e

save

mode .

NOTE: The h a zard warnin g lamp switch is turned

on

and o ff alt e rnately when ever it is pushed.

5.Pre s s th e tr ansmitter switch, a nd then pre s s it two

t i mes within 10 second s of th e f i rst pre s s. This will

reg i st er the code.

6. Once the p r ogram is saved, it will opera t e once

wit h the a ll d oors a nd t a ilgate lock and unlo ck

op erations.

7.If you a r e using t w o or mo re transmitters or have

ad ded a second tra n smitter , the n e xt tra n smitter

should be re gistered within o ne minute af ter

reg i st ering the code fo r the pre v io us tra n smitter .

Th e registration pr oced ure is co mmo n for a ll th e

tra n smitter .

8.Registra tion mode will be ca ncelled under the

fo llowing condit i ons:

•When the secr et co de for fo ur transmitters has

bee

n registere d ;

•When no secre t cod e s h a ve b een re gist ered fo r

more tha

n one minute af ter the registration mode

is ente

r ed;

•When p a ssing o ne minute af ter fin i sh ing t he reg-

istration of all t r ansmitte rs;

•When the M.U.T . -II is d i sconne cted from th e dia g-

nosis connecto r;

•When the key is re moved fro m the key cylin der;

9.Af ter the registration is completed, remove the

ignition key a nd close all the d oors, and th en

check tha t the keyless entry syste m op erates

no rmally .

WH EN THE SPECIAL T O OL V . C. I.

(

M B991824) I S USED

1.Check t hat the doors lock n o rmally wh en the key

is used.

2. In sert t he ig nition ke y .

CAUTION

Before connecting or disconnecting the V. C. I.,

turn the ignition switch to the "LOCK" (OFF)

position.

AC305153AB

MB991911

MB991824

16-Pin

3. Connect the V. C. I. to the diagnosis connector.

ACX00571

Within 10 seconds

Hazard

warning

lamp

switch ON

OFF 1234 56

AQ

V.C.I. connected

4. Press the hazard warning

light switch six times

within 10seconds.

NOTE: Once the process is completed six times,

then it will operate with all doors and tailgate lock

and unlock operations once and then go to the

save mode.

NOTE: The hazard warning lamp switch is turned

on and off alternately whenever it is pushed.

5. Press the transmitter switch, and then press it two times within 10 seconds of the first press. This will

register the code.

6. Once the program is saved, it will operate once with the all doors and tailgate lock and unlock

operations.

Page 330 of 800

KEYLESS ENTRY SYSTEM

BODY42-58

7. If you are using two or more transmitters or have added a second transmitter, the next transmitter

should be registered within one minute after

registering the code for the previous transmitter.

The registration procedure is common for all the

transmitter.

8. Registration mode will be cancelled under the following conditions:

•When the secret code for four transmitters has

been registered;

•When no secret codes have been registered for

more than one minute after the registration mode

is entered;

•When passing one minute after finishing the reg-

istration of all transmitters;

•When the V.C.I. is disconnected from the diagno-

sis connector;

•When the key is removed from the key cylinder;

9. After the registration is completed, remove the ignition key and close all the doors, and then

check that the keyless entry system operates

normally.

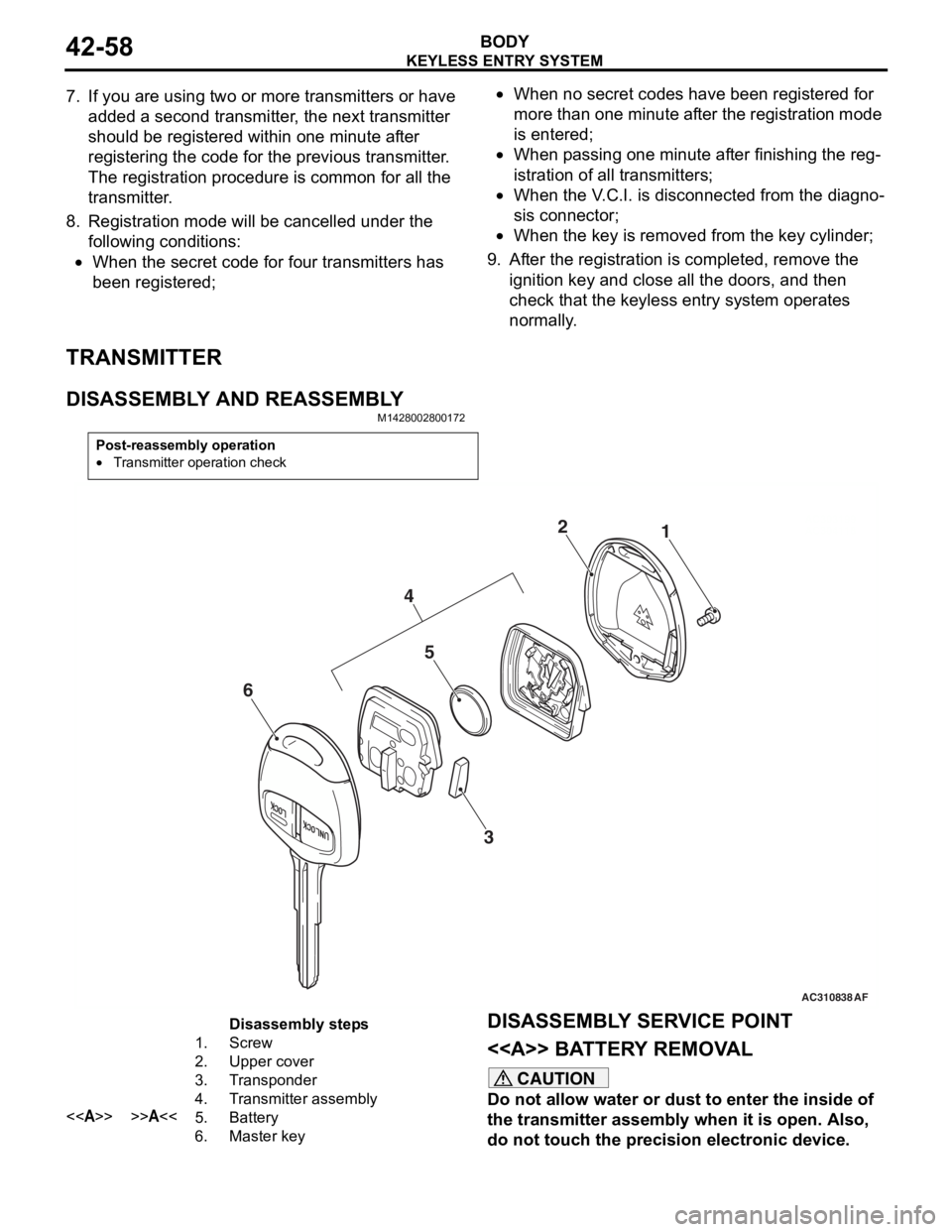

TRANSMITTER

DISASSEMBLY AND REASSEMBLY

M1428002800172

Post-reassembly operation

•Transmitter operation check

AC310838AC303199

AC3041181

2

AF

5

3

4

6

Disassembly steps

1.Screw

2.Upper cover

3.Transponder

4.Transmitter assembly

<>>>A<<5.Battery

6.Master key

DISASSEMBL Y SER V ICE POINT

<> BATTER Y REMOV A L

CAUTION

Do not allow water or dust to enter the inside of

the transmitter assembly when it is open. Also,

do not touch the precision electronic device.