Purge MITSUBISHI LANCER 2006 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 107 of 800

17-1

GROUP 17

ENGINE AND

EMISSION

CONTROL

CONTENTS

ENGINE CONTROL . . . . . . . . . .17-2

GENERAL INFORMATION . . . . . .17-2

SERVICE SPECIFICATIONS. . . . .17-2

ON-VEHICLE SERVICE. . . . . . . . .17-2

ACCEL CABLE CHECK AND

ADJUSTMENT . . . . . . . . . . . . . . . . . . . . 17-2

ACCELERATOR CABLE AND

PEDAL . . . . . . . . . . . . . . . . . . . . . .17-3

REMOVAL AND INSTALLATION . . . . . 17-3

EMISSION CONTROL MPI . . . .17-4

GENERAL INFORMATION . . . . . .17-4

EMISSION CONTROL DEVICE

REFERENCE TABLE . . . . . . . . . .17-4

SERVICE SPECIFICATION(S) . . .17-5

VACUUM HOSE. . . . . . . . . . . . . . .17-5

VACUUM HOSE PIPING DIAGRAM . . . 17-5

VACUUM CIRCUIT DIAGRAM . . . . . . . 17-7

VACUUM HOSE CHECK. . . . . . . . . . . . 17-7

VACUUM HOSE INSTALLATION . . . . . 17-8

CRANKCASE EMISSION CONTROL

SYSTEM . . . . . . . . . . . . . . . . . . . . .17-8

GENERAL INFORMATION (CRANKCASE

EMISSION CONTROL SYSTEM) . . . . . 17-8

COMPONENT LOCATI ON (CRANKCASE

EMISSION CONTROL SYSTEM) . . . . . 17-9

POSITIVE CRANKCASE VENTILATION SYSTEM

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . 17-9

POSITIVE CRANKCASE VENTILATION (PCV)

VALVE CHECK . . . . . . . . . . . . . . . . . . . 17-9

EVAPORATIVE EMISSION CONTROL

SYSTEM . . . . . . . . . . . . . . . . . . . . .17-9

GENERAL INFORMATION (EVAPORATIVE

EMISSION CONTROL SYSTEM) . . . . . 17-9

COMPONENT LOCATION (EVAPORATIVE

EMISSION CONTROL SYSTEM) . . . . . 17-10

PURGE CONTROL SYSTEM CHECK . . 17-10

PURGE PORT VACUUM CHECK . . . . . 17-11

PURGE CONTROL SOLENOID VALVE

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . 17-11

FUEL VAPOUR CANISTER REMOVAL

AND INSTALLATION . . . . . . . . . . . . . . . 17-12

EXHAUST GAS RECIRCULATION

(EGR) SYSTEM . . . . . . . . . . . . . . .17-12

GENERAL INFORMATION

(EGR SYSTEM) . . . . . . . . . . . . . . . . . . . 17-12

COMPONENT LOCATION

(EGR SYSTEM) . . . . . . . . . . . . . . . . . . . 17-14

EGR SYSTEM CHECK . . . . . . . . . . . . . 17-15

EGR VALVE CHECK . . . . . . . . . . . . . . . 17-15

EGR PORT VACUUM CHECK <4G1>. . 17-16

EGR PORT VACUUM CHECK <4G6>. . 17-16

EGR CONTROL SOLENOID VALVE

CHECK <4G1> . . . . . . . . . . . . . . . . . . . . 17-16

EGR CONTROL SOLENOID VALVE

CHECK <4G6> . . . . . . . . . . . . . . . . . . . . 17-17

EXHAUST GAS RECIRCULATION (EGR)

VALVE REMOVAL AND I

NSTALLATION . . . . . . . . . . . . . . . . . . . . 17-18

CATALYTIC CONVERTER . . . . . .17-19

REMOVAL AND INSTALLATION

<4G1, 4G6-M/T> . . . . . . . . . . . . . . . . . . 17-19

REMOVAL AND INSTALLATION

<4G6-A/T> . . . . . . . . . . . . . . . . . . . . . . . 17-19

Page 110 of 800

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-4

INSTALLATION SERVICE POINT

>>A<< ACCEL PEDAL PAD INSTALLA-

TION

CAUTION

To prevent damages to the accelerator pedal pad,

warm the thumb area of the accelerator pedal

pad with a dryer, etc. prior to assembling it.

NOTE: If it is difficult to assemble, apply soapy water

to the thumb area to enhance the assembling proc

-

ess.

EMISSION CONTROL

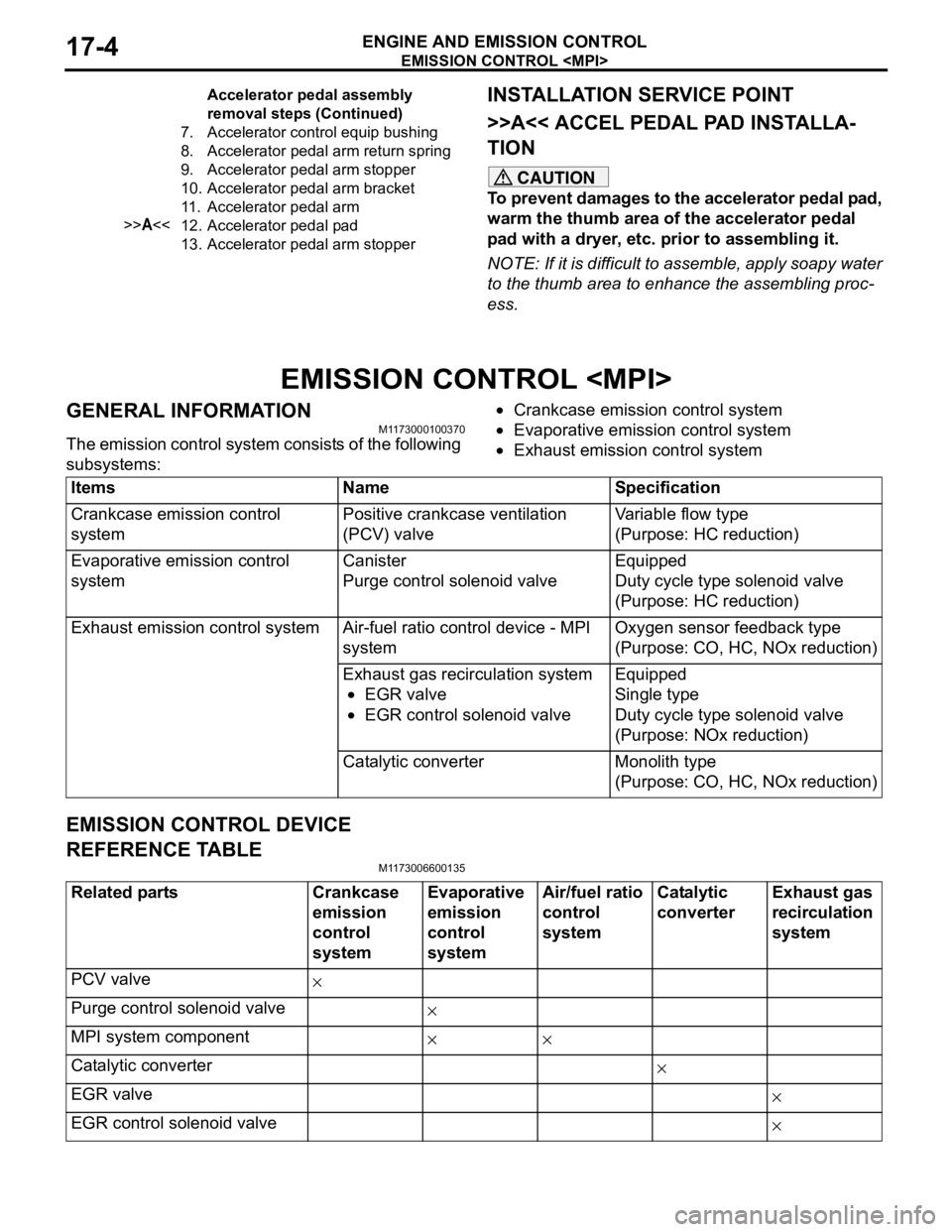

GENERAL INFORMATION

M1173000100370

The emission control system consists of the following

subsystems:

•Crankcase emission control system

•Evaporative emission control system

•

ItemsNameSpecification

Crankcase emission control

systemPositive crankcase ventilation

(PCV) valveVariable flow type

(Purpose: HC reduction)

Evaporative emission control

systemCanister

Purge control solenoid valve

Equipped

Duty cycle type solenoid valve

(Purpose: HC reduction)

Exhaust emission control systemAir-fuel ratio control device - MPI

systemOxygen sensor feedback type

(Purpose: CO, HC, NOx reduction)

Exhaust gas recirculation system

•EGR valve

•EGR control solenoid valve

Equipped

Single type

Duty cycle type solenoid valve

(Purpose: NOx reduction)

Catalytic converterMonolith type

(Purpose: CO, HC, NOx reduction)

Exhaust emission control system

EMISSION CONTROL DEVICE

REFERENCE TABLE

M1173006600135

Related partsCrankcase

emission

control

systemEvaporative

emission

control

systemAir/fuel ratio

control

systemCatalytic

converterExhaust gas

recirculation

system

PCV valve×

Purge control solenoid valve×

MPI system component××

Catalytic converter×

EGR valve×

EGR control solenoid valve×

7.Accelerator control equip bushing

8.Accelerator pedal arm return spring

9.Accelerator pedal arm stopper

10.Accelerator pedal arm bracket

11 .Accelerator pedal arm

>>A<<12.Accelerator pedal pad

13.Accelerator pedal arm stopper

Accelerator pedal assembly

removal steps (Continued)

Page 111 of 800

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-5

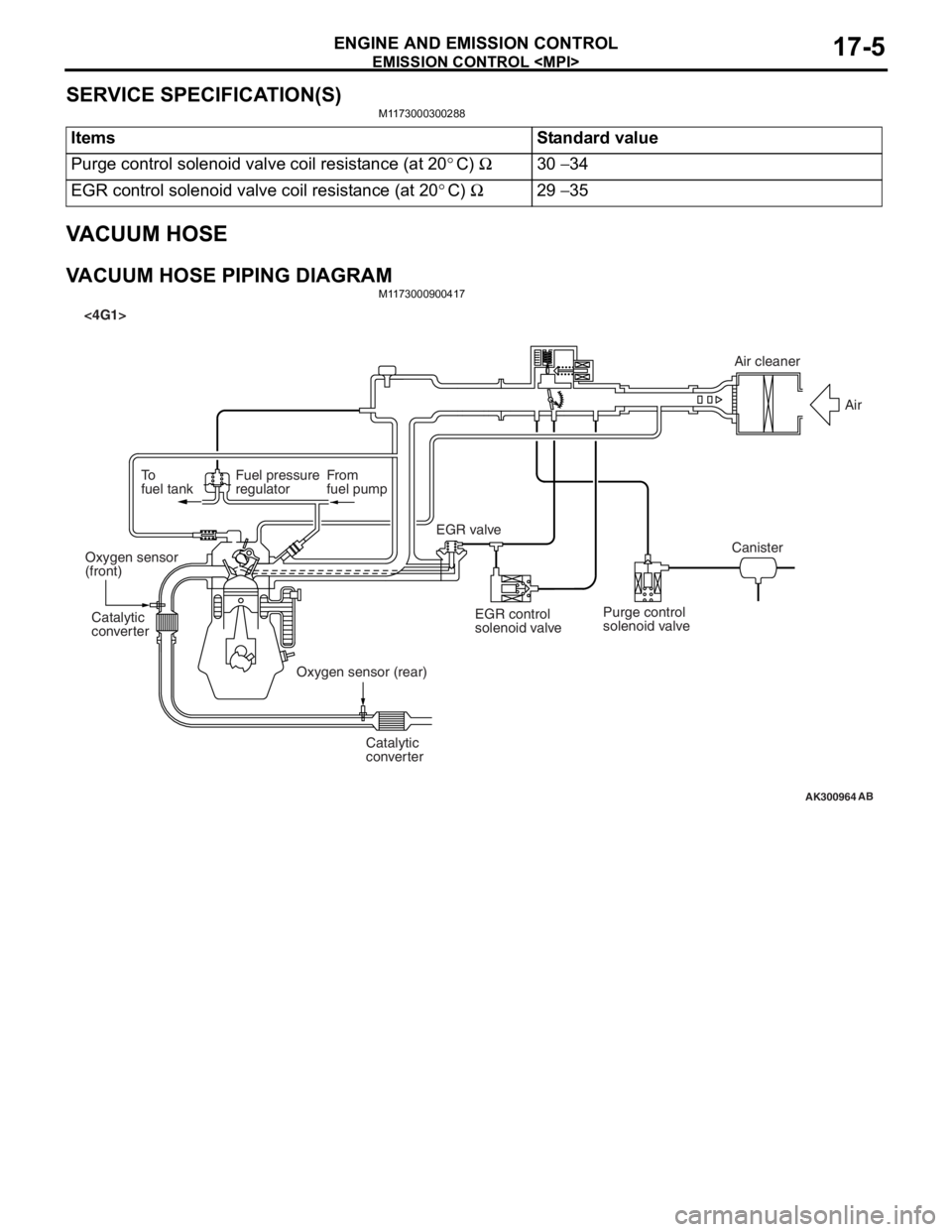

SERVICE SPECIFICATION(S)

M1173000300288

ItemsStandard value

Purge control solenoid valve coil resistance (at 20°C) Ω30 − 34

EGR control solenoid valve coil resistance (at 20°C) Ω29 − 35

VACUUM HOSE

VACUUM HOSE PIPING DIAGRAMM1173000900417

AK300964

To

fuel tankFuel pressure

regulatorFrom

fuel pump

Catalytic

converter Catalytic

converter

Oxygen sensor

(front)

Oxygen sensor (rear)EGR valve

<4G1>

EGR control

solenoid valvePurge control

solenoid valve CanisterAir

AB

Air cleaner

Page 112 of 800

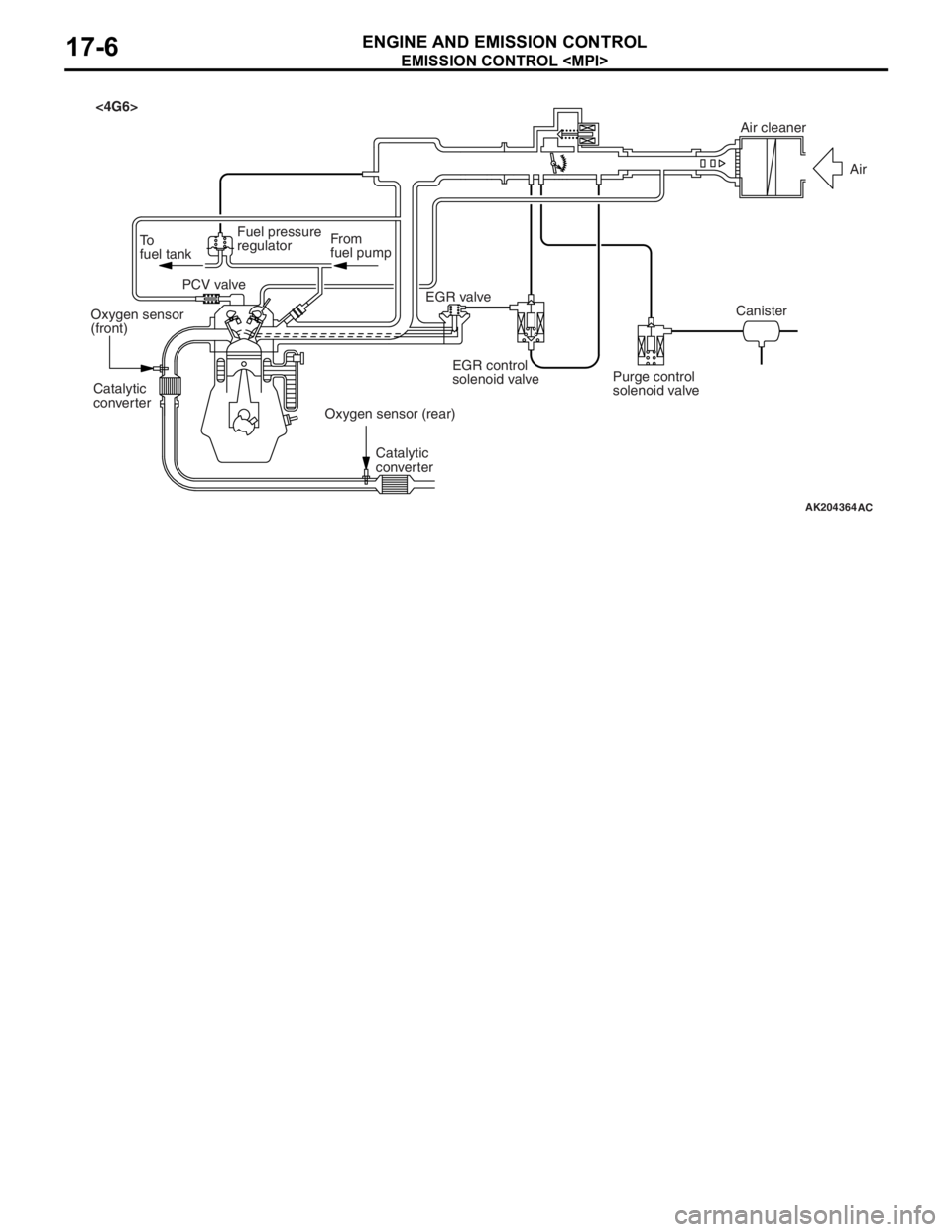

AK204364AC

Air cleaner

Air

Canister

Purge control

solenoid valve

EGR control

solenoid valve

EGR valve

From

fuel pump

To

fuel tank Fuel pressure

regulator

PCV valve

Oxygen sensor

(front)

Oxygen sensor (rear)

Catalytic

converter

Catalytic

converter

<4G6>

EMISSION CONTROL

ENGINE AND E M ISSION CON T ROL17-6

Page 113 of 800

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-7

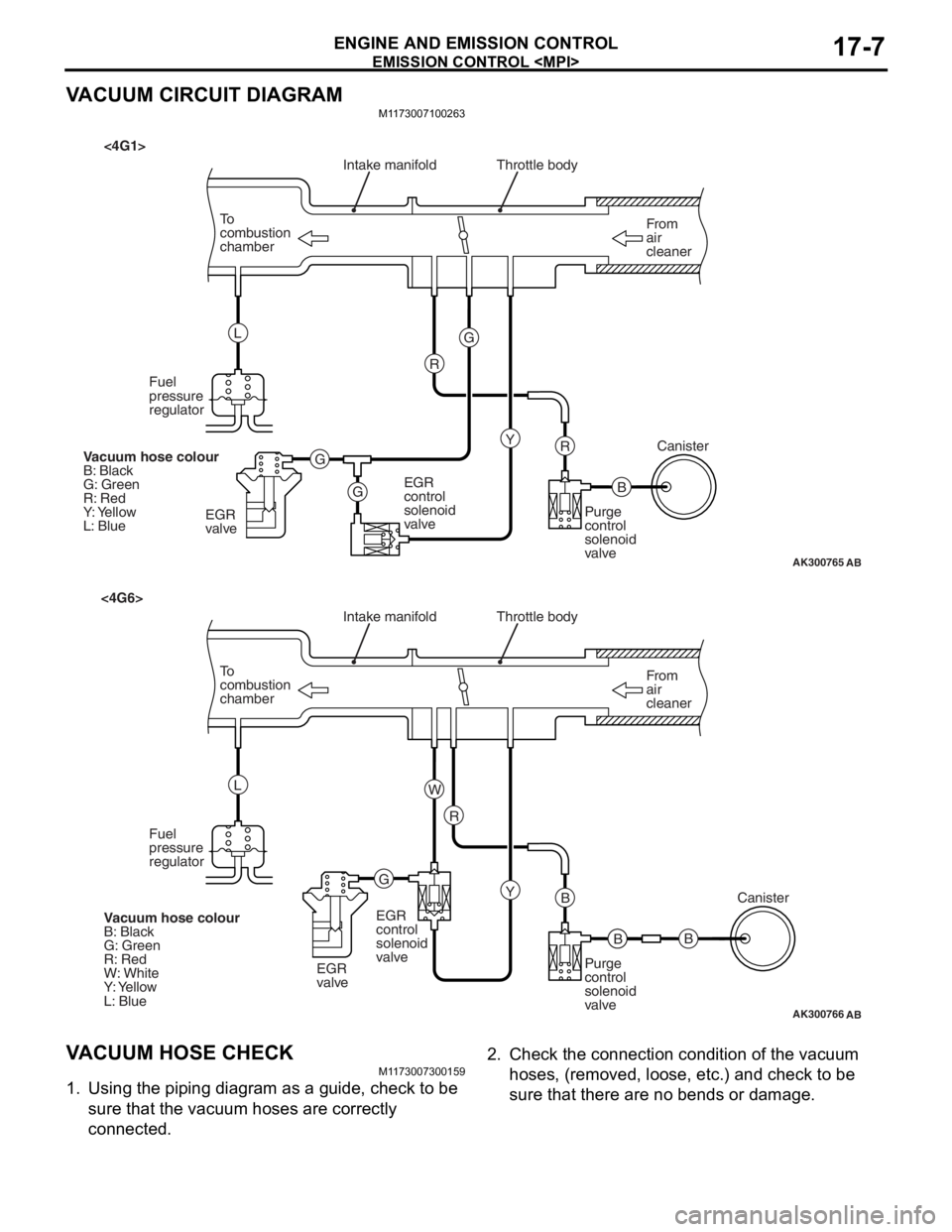

VACUUM CIRCUIT DIAGRAM

M1173007100263

AK300765

From

air

cleaner

To

combustion

chamber Throttle body

B

R

AB

Intake manifold

Y

G

G G R

L

Fuel

pressure

regulator

EGR

valve EGR

control

solenoid

valve

Purge

control

solenoid

valveCanister

Vacuum hose colour

B: Black

G: Green

R: Red

Y: Yellow

L: Blue

<4G1>

AK300766

From

air

cleaner

To

combustion

chamber Throttle body

B

B

AB

Intake manifold

Y

R

G W

L

Fuel

pressure

regulator

EGR

valveEGR

control

solenoid

valve

Purge

control

solenoid

valveCanister

Vacuum hose colour

B: Black

G: Green

R: Red

W: White

Y: Yellow

L: Blue

<4G6>

B

V ACUUM HOSE CHECK

M1 173 0073 0015 9

1.Using th e pip i ng d i agra m as a gu ide, check to be

sure th at the vacuum h o ses are correctly

connected.

2. Check t he co nnection cond itio n of th e vacuum

ho s e s, (re mo v e d, l o os e , et c . ) an d c h e c k t o b e

sure th at there are no bends or da mage .

Page 115 of 800

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-9

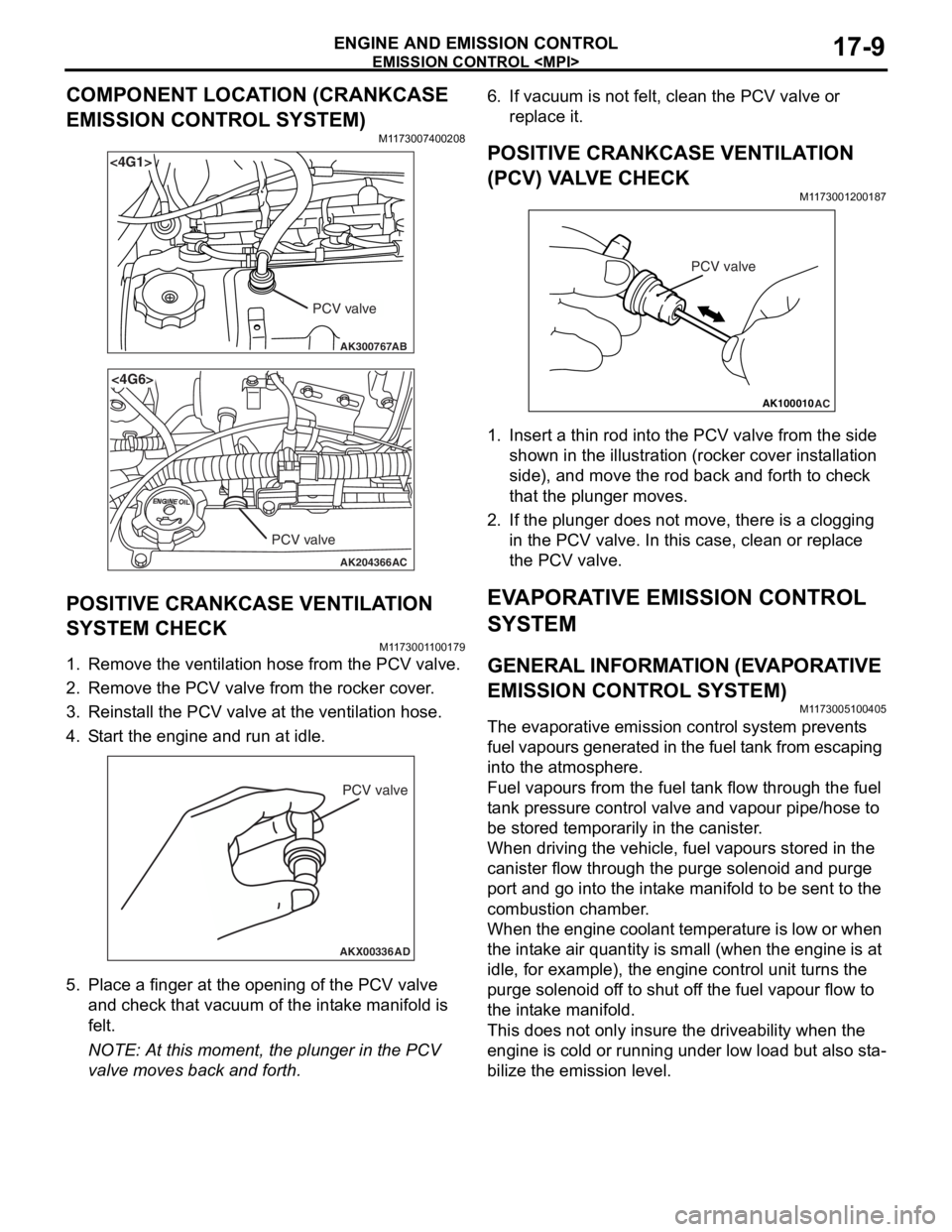

COMPONENT LOCATION (CRANKCASE

EMISSION CONTROL SYSTEM)

M1173007400208

AK300767

<4G1>

AB

PCV valve

AK204366

<4G6>

AC

PCV valve

POSITIVE CRANKCASE VENTILATION

SYSTEM CHECK

M11 7300 1 1 0017 9

1.Remove the ventilatio n hose from the PCV valve.

2.Remove the PCV valve from t he rocker cove r .

3.Reinst all the PCV valve at the ven t ila tion h o se.

4.S t art the engin e and run at idle .

AKX00336

PCV valve

AD

5.Pla c e a fing er at the open ing o f the PCV va lve

an d ch eck that vacu um o f the int a ke manifold is

fe lt.

NOTE: At this mo men t, the p l unge r in t he PCV

valve mo ves back an d forth.

6.If vacuum is not felt, clean t he PCV valve o r

re place it.

POSITIVE CRANKCASE VENTILA TION

(

P CV) V A L VE CHECK

M1173 0012 0018 7

AK100010

PCV valve

AC

1.In sert a thin rod in to the PCV valve from the side

shown in the illu strat i on (ro cke r cover in st allation

side) , and move the ro d back an d forth to ch eck

th at the plung er mo ves.

2.If the plunger does not move , there is a clo ggin g

in the PCV valve. In th is case, clean o r repla c e

th e PCV valve.

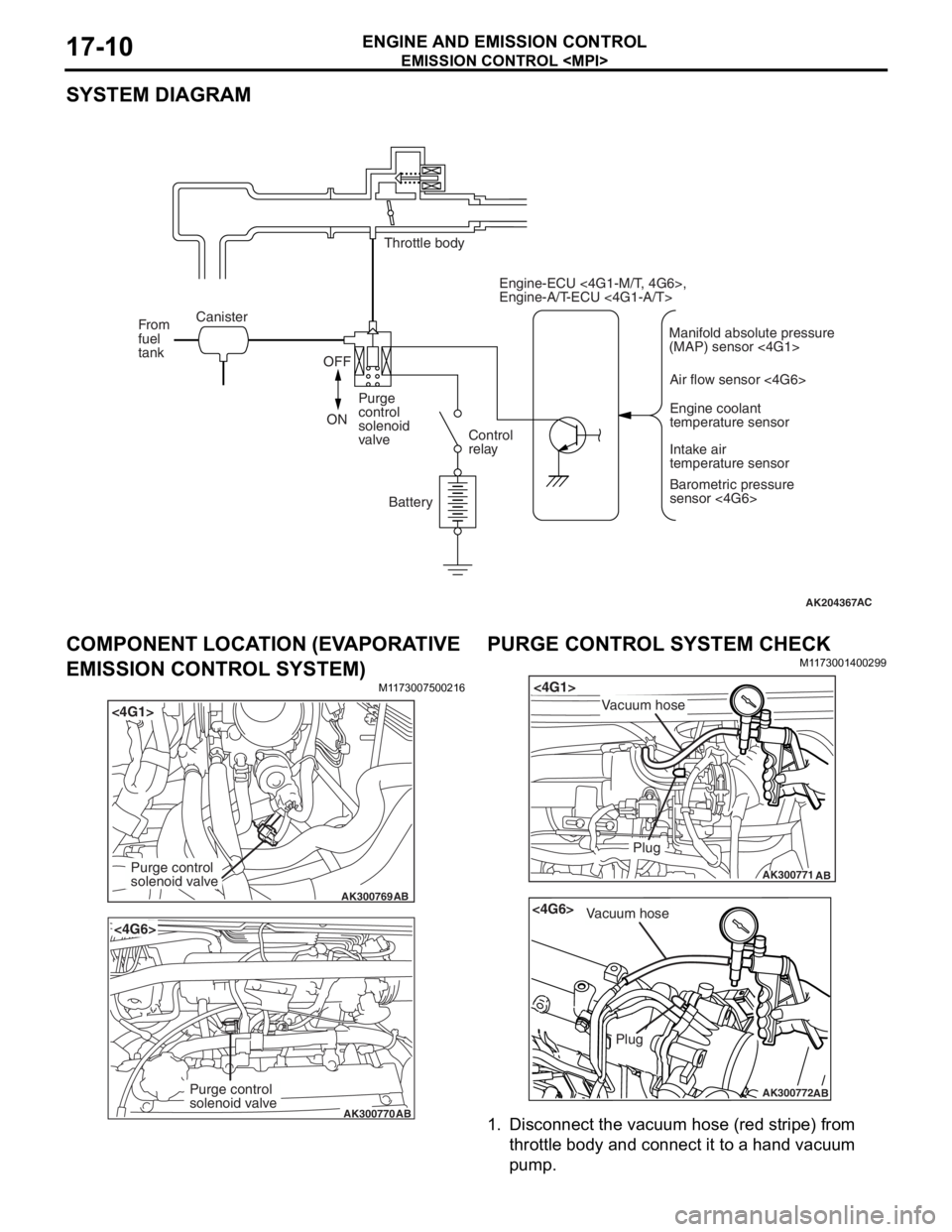

EVAPORA T IVE EMISSION CONTROL

SYSTEM

GENERAL INFORMA T ION (EV A PORA TIVE

EMISSION CONTROL SYSTEM)

M1173 0051 0040 5

The evaporat ive emission contro l syste m pre v ent s

f

uel vapours generat ed in t he fuel t ank from escaping

into t

he atmosp here.

Fuel vapours fro m the fuel t a n k flow throug h the f uel

t

a n k pre ssu re co ntrol valve an d vap our pipe/ho se to

be st

ored te mpora r ily in t he ca nister .

When dr iving the veh i cle, fue l va pours stor ed in the

canister

flow thro ugh th e purge solenoid and purge

port an

d go into the int a ke ma nifold to b e sen t to th e

combust

i on chamber .

When the eng ine co ola n t te mp eratu r e is low o r when

the int

a ke air q uantity is small (wh en the engine is at

idle

, for example), t he eng ine contro l unit turns the

purge sole

noid of f to shu t of f the fue l va pour flow to

the in

t a ke manif o ld.

This does not on ly insure the driveability when t he

engin

e is cold or runn ing und er low load b u t also st a

-

bilize the emissio n level.

Page 116 of 800

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-10

SYSTEM DIAGRAM

AK204367AC

Throttle body

Canister

From

fuel

tank

OFF

ON Purge

control

solenoid

valve

Control

relay

Battery Engine-ECU <4G1-M/T, 4G6>,

Engine-A/T-ECU <4G1-A/T>

Air flow sensor <4G6>Engine coolant

temperature sensor

Intake air

temperature sensor

Barometric pressure

sensor <4G6>

Manifold absolute pressure

(MAP) sensor <4G1>

COMPONENT LOCA

TION (EV A PORA TIVE

EMISSION CONTROL SYSTEM)

M1173 0075 0021 6

AK300769

<4G1>

AB

Purge control

solenoid valve

AK300770

<4G6>

AB

Purge control

solenoid valve

PURGE CONTROL SYSTEM CHECK

M1173 0014 0029 9

AK300771

<4G1>

AB

Plug

Vacuum hose

AK300772

<4G6>

AB

Plug

Vacuum hose

1.Disco nnect the vacu um h o se (re d str i pe) fro m

th rottle body and conne ct it to a h and vacu um

pu m p .

Page 117 of 800

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-11

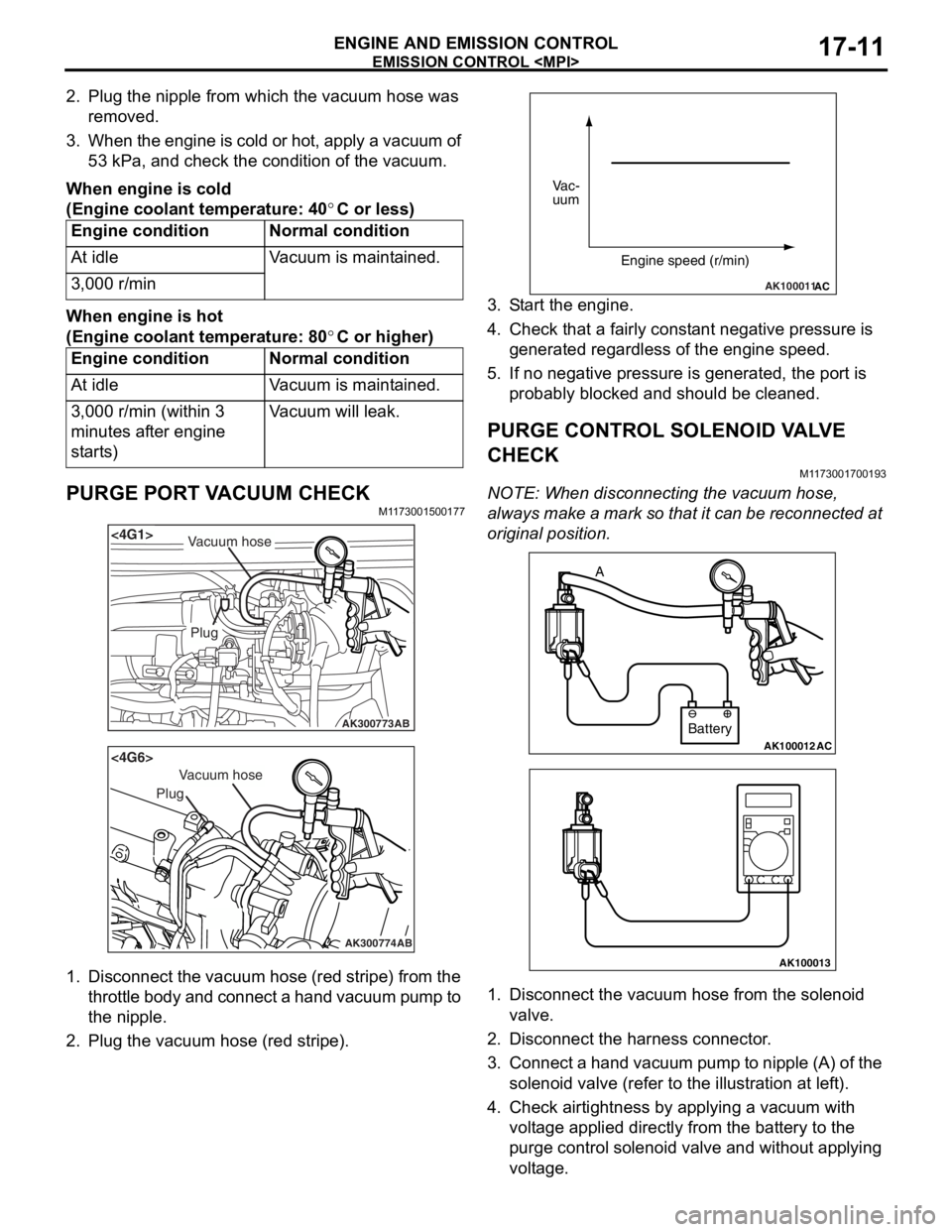

2. Plug the nipple from which the vacuum hose was removed.

3. When the engine is cold or hot, apply a vacuum of 53 kPa, and check the condition of the vacuum.

When engine is cold

(Engine coolant temperature: 40°C or less)

Engine conditionNormal condition

At idleVacuum is maintained.

3,000 r/min

When engine is hot

(Engine coolant temperature: 80°C or higher)

Engine conditionNormal condition

At idleVacuum is maintained.

3,000 r/min (within 3

minutes after engine

starts)Vacuum will leak.

PURGE PORT VACUUM CHECKM1173001500177

AK300773

<4G1>

AB

Plug

Vacuum hose

AK300774

<4G6>

AB

Plug

Vacuum hose

1.Disco nnect th e vacuum ho se (red st ripe) from the

throttle body and connect a hand vacuum pump to

th e nip p le.

2.Plu g the vacuum hose (red stripe).

AK100011AC

Vac-

uum

Engine speed (r/min)

3.S t art the engine.

4.Check t hat a f a irly co nst ant n egative p r essure is

g enerate d regard l ess of the en gine spee d.

5.If no neg ative pressur e is genera t ed, th e port is

p r obably blocked an d sh ould be cleane d.

PURGE CONTROL SOLENOID VA L V E

CHECK

M1173 0017 0019 3

NOTE: Whe n discon nect i ng th e va cuum hose,

always make a mark so th at it can be reconnected at

original p o sition.

AK100012AC

Battery

A

AK100013

1.

Disco nnect the vacu um h o se f r om th e solenoid

valve.

2.Disco nnect the ha rness connector .

3.Con nect a ha nd vacu um pump to nipp le (A) of the

solen o id valve (ref e r to th e ill ust r ation at le f t ).

4.Check a i rtig htness b y app lying a vacuum with

volt age applied d i rectly from t he batt e ry to the

p u rge con t rol so leno id valve an d without app lying

volt age .

Page 403 of 800

SOLENOID VALVE

COMPONENT LOCATIONS70-13

SOLENOID VALVE

M1701000800516

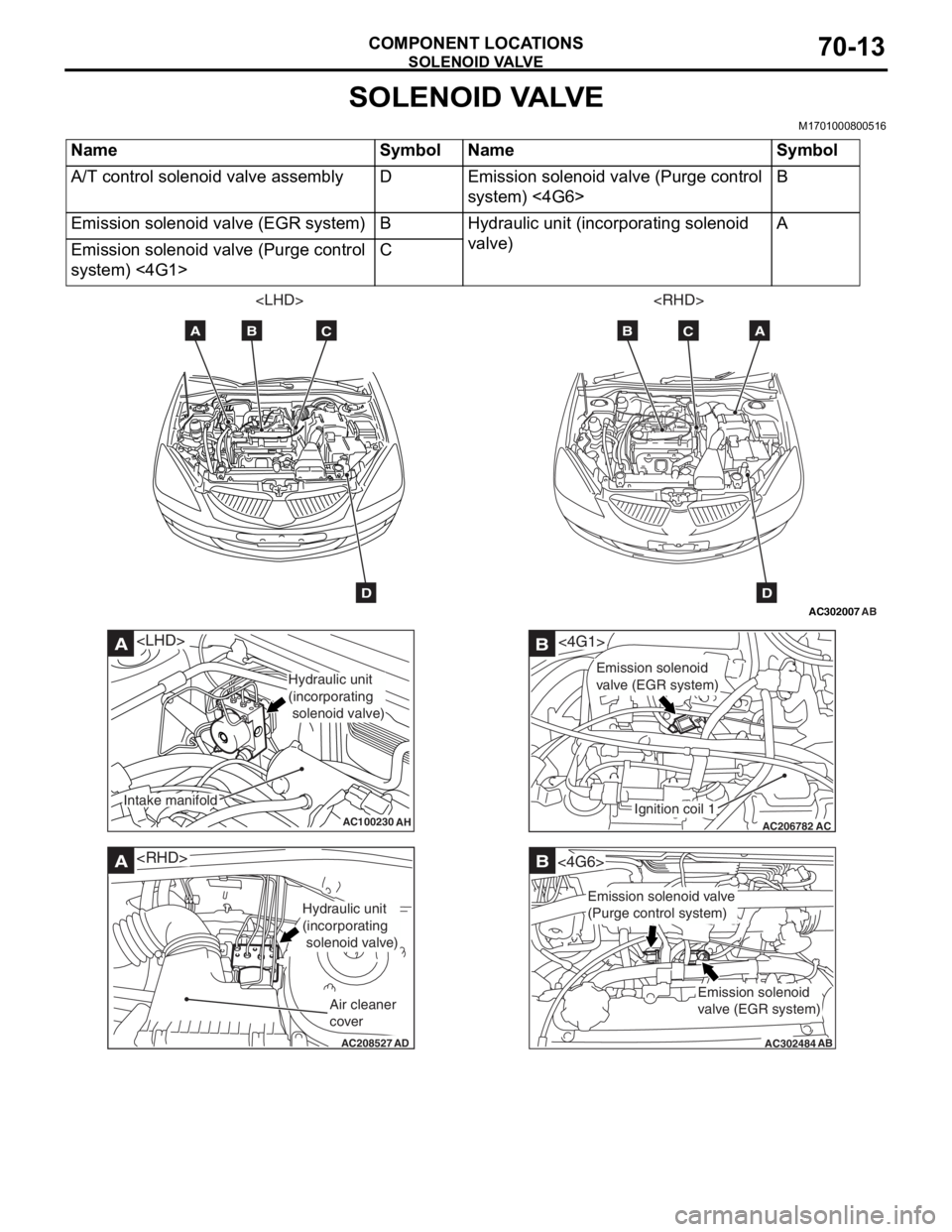

NameSymbolNameSymbol

A/T control solenoid valve assemblyDEmission solenoid valve (Purge control

system) <4G6>B

Emission solenoid valve (EGR system)BHydraulic unit (incorporating solenoid

valve)A

Emission solenoid valve (Purge control

system) <4G1>C

AC302007

AB

AB

ABC

D

C

D

AC100230

A

AH

Hydraulic unit

(incorporating

solenoid valve)

Intake manifold

AC208527

A

AD

Hydraulic unit

(incorporating

solenoid valve)

Air cleaner

cover

AC206782

<4G1>B

AC

Ignition coil 1

Emission solenoid

valve (EGR system)

AC302484

B

AB

<4G6>

Emission solenoid

valve (EGR system)

Emission solenoid valve

(Purge control system)

Page 404 of 800

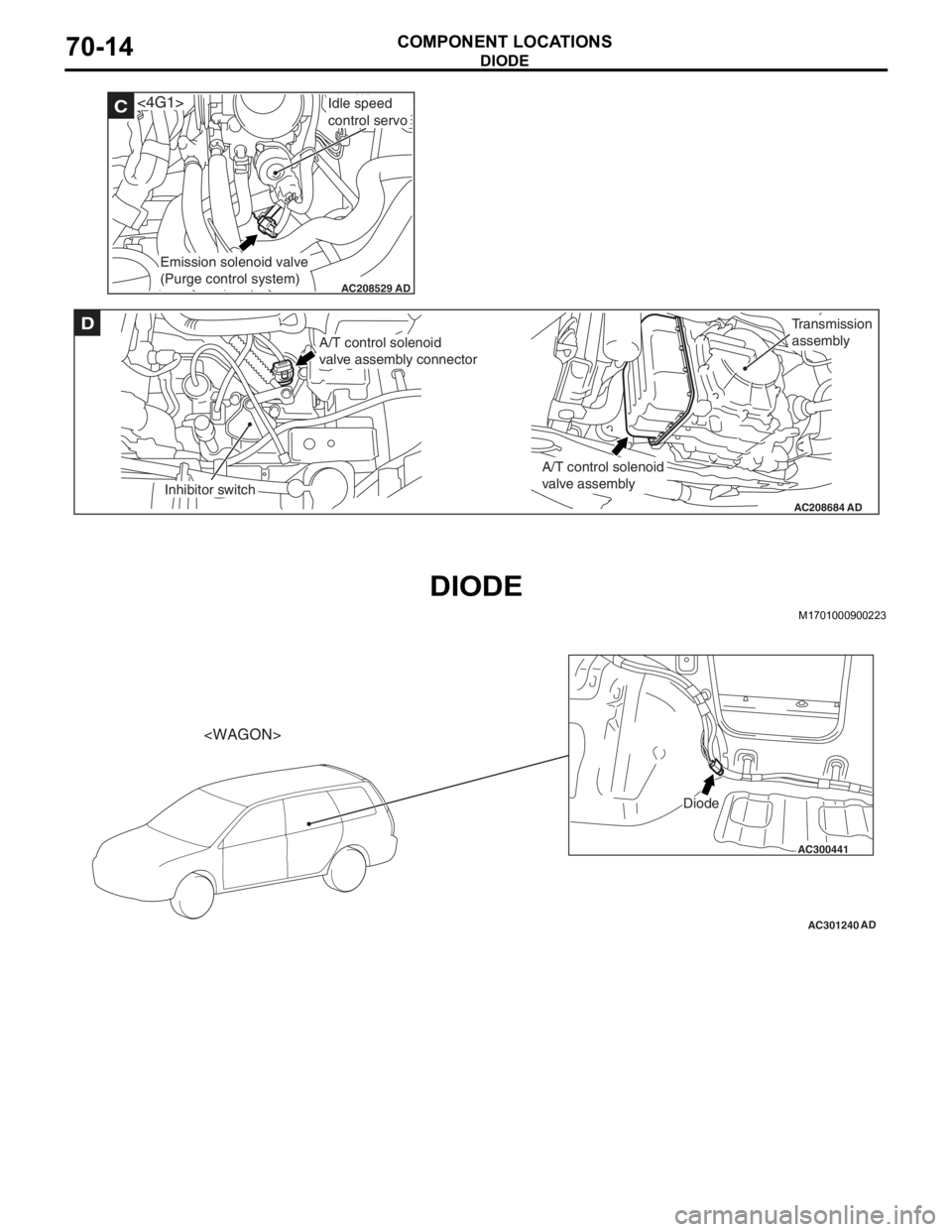

AC208529AD

C<4G1>Idle speed

control servo

Emission solenoid valve

(Purge control system)

AC208684

D

AD

A/T control solenoid

valve assembly connector

Inhibitor switch

A/T control solenoid

valve assembly

Transmission

assembly

DIOD E

COMPONENT LOCA TIONS70-14

DIODE

M1701 0009 0022 3

AC300441

AC301240

Diode

AD