Starting MITSUBISHI LANCER 2006 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 63 of 800

16-1

GROUP 16

ENGINE

ELECTRICAL

CONTENTS

CHARGING SYSTEM . . . . . . . .16-2

GENERAL INFORMATION . . . . . .16-2

SERVICE SPECIFICATIONS. . . . .16-3

SPECIAL TOOL . . . . . . . . . . . . . . .16-3

ON-VEHICLE SERVICE. . . . . . . . .16-3

ALTERNATOR OUTPUT LINE VOLTAGE

DROP TEST . . . . . . . . . . . . . . . . . . . . . 16-3

OUTPUT CURRENT TEST . . . . . . . . . . 16-5

REGULATED VOLTAGE TEST . . . . . . . 16-7

WAVEFORM CHECK USING AN

OSCILLOSCOPE . . . . . . . . . . . . . . . . . . 16-9

ALTERNATOR ASSEMB LY . . . . .16-12

REMOVAL AND INSTALLATION

<4G1> . . . . . . . . . . . . . . . . . . . . . . . . . . 16-12

REMOVAL AND INSTALLATION

<4G6> . . . . . . . . . . . . . . . . . . . . . . . . . . 16-13

DISASSEMBLY AND REASSEMBLY . . 16-15

INSPECTION . . . . . . . . . . . . . . . . . . . . . 16-17

STARTING SYSTEM . . . . . . . . .16-19

GENERAL INFORMATION . . . . . .16-19

SERVICE SPECIFICATIONS. . . . .16-20

STARTER MOTOR ASSEMBLY . .16-21

REMOVAL AND INSTALLATION

<4G1> . . . . . . . . . . . . . . . . . . . . . . . . . . 16-21

REMOVAL AND INSTALLATION

<4G6> . . . . . . . . . . . . . . . . . . . . . . . . . . 16-22

STARTER MOTOR ASSEMBLY

INSPECTION . . . . . . . . . . . . . . . . . . . . . 16-23

DISASSEMBLY AND REASSEMBLY . . 16-26

INSPECTION . . . . . . . . . . . . . . . . . . . . . 16-27

IGNITION SYSTEM . . . . . . . . . 16-30

GENERAL INFORMATION . . . . . .16-30

SERVICE SPECIFICATIONS . . . . .16-31

SPECIAL TOOL . . . . . . . . . . . . . . .16-31

ON-VEHICLE SERVICE . . . . . . . . .16-32

IGNITION COIL (WITH BUILT-IN

POWER TRANSISTOR) CHECK . . . . . . 16-32

RESISTIVE CORD CHECK . . . . . . . . . . 16-32

SPARK PLUG CHECK AND CLEANING

<4G1>. . . . . . . . . . . . . . . . . . . . . . . . . . . 16-32

SPARK PLUG CHECK AND CLEANING

<4G6>. . . . . . . . . . . . . . . . . . . . . . . . . . . 16-33

CAMSHAFT POSITION SENSOR

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . 16-33

CRANK ANGLE SENSOR CHECK . . . . 16-33

DETONATION SENSOR CHECK . . . . . 16-33

IGNITION SECONDARY VOLTAGE

WAVEFORM CHECK USING AN

OSCILLOSCOPE . . . . . . . . . . . . . . . . . . 16-33

IGNITION COIL RELAY CHECK . . . . . . 16-37

IGNITION COIL . . . . . . . . . . . . . . . .16-38

REMOVAL AND INSTALLATION

<4G1>. . . . . . . . . . . . . . . . . . . . . . . . . . . 16-38

REMOVAL AND INSTALLATION

<4G6>. . . . . . . . . . . . . . . . . . . . . . . . . . . 16-39

CAMSHAFT POSITION SENSOR .16-40

REMOVAL AND INSTALLATION . . . . . . 16-40

CRANKSHAFT POSITION SENSOR16-41

REMOVAL AND INSTALLATION

<4G1>. . . . . . . . . . . . . . . . . . . . . . . . . . . 16-41

REMOVAL AND INSTALLATION

<4G6>. . . . . . . . . . . . . . . . . . . . . . . . . . . 16-42

DETONATION SENSOR . . . . . . . .16-43

REMOVAL AND INSTALLATION . . . . . . 16-43

Page 81 of 800

STARTING SYSTEM

ENGINE ELECTRICAL16-19

STARTING SYSTEM

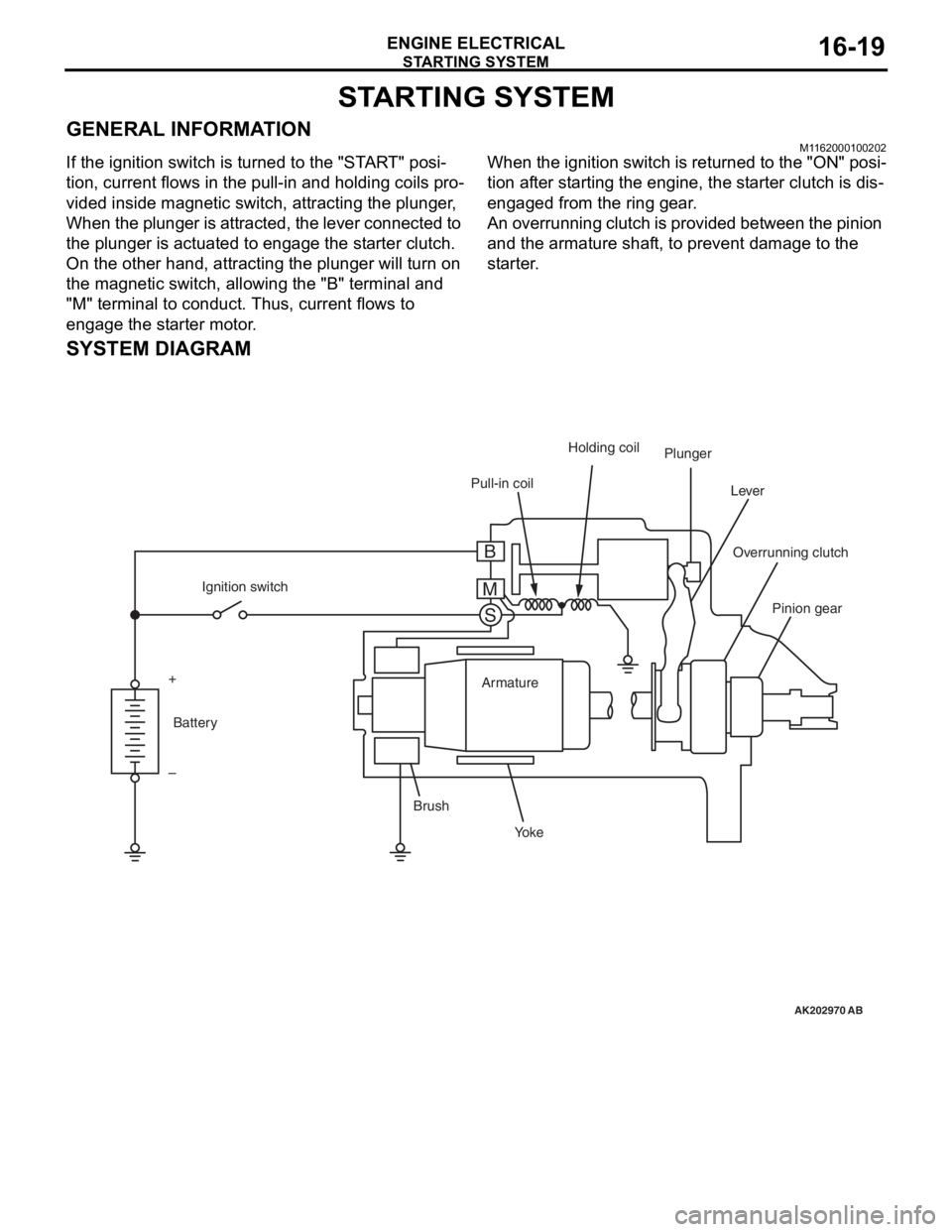

GENERAL INFORMATIONM1162000100202

If the ignition switch is turned to the "START" posi-

tion, current flows in the pull-in and holding coils pro-

vided inside magnetic switch, attracting the plunger,

When the plunger is attracted, the lever connected to

the plunger is actuated to engage the starter clutch.

On the other hand, attracting the plunger will turn on

the magnetic switch, allowing the "B" terminal and

"M" terminal to conduct. Thus, current flows to

engage the starter motor.

When the ignition switch is returned to the "ON" posi-

tion after starting the engine, the starter clutch is dis-

engaged from the ring gear.

An overrunning clutch is provided between the pinion

and the armature shaft, to prevent damage to the

starter.

SYSTEM DIAGRAM

AK202970

Pull-in coilHolding coil

Plunger

Lever

Pinion gear

Overrunning clutch

Yo k e

Brush Armature

Ignition switch

Battery

+

–

AB

B

M S

Page 82 of 800

STARTING SYSTEM

ENGINE ELECTRICAL16-20

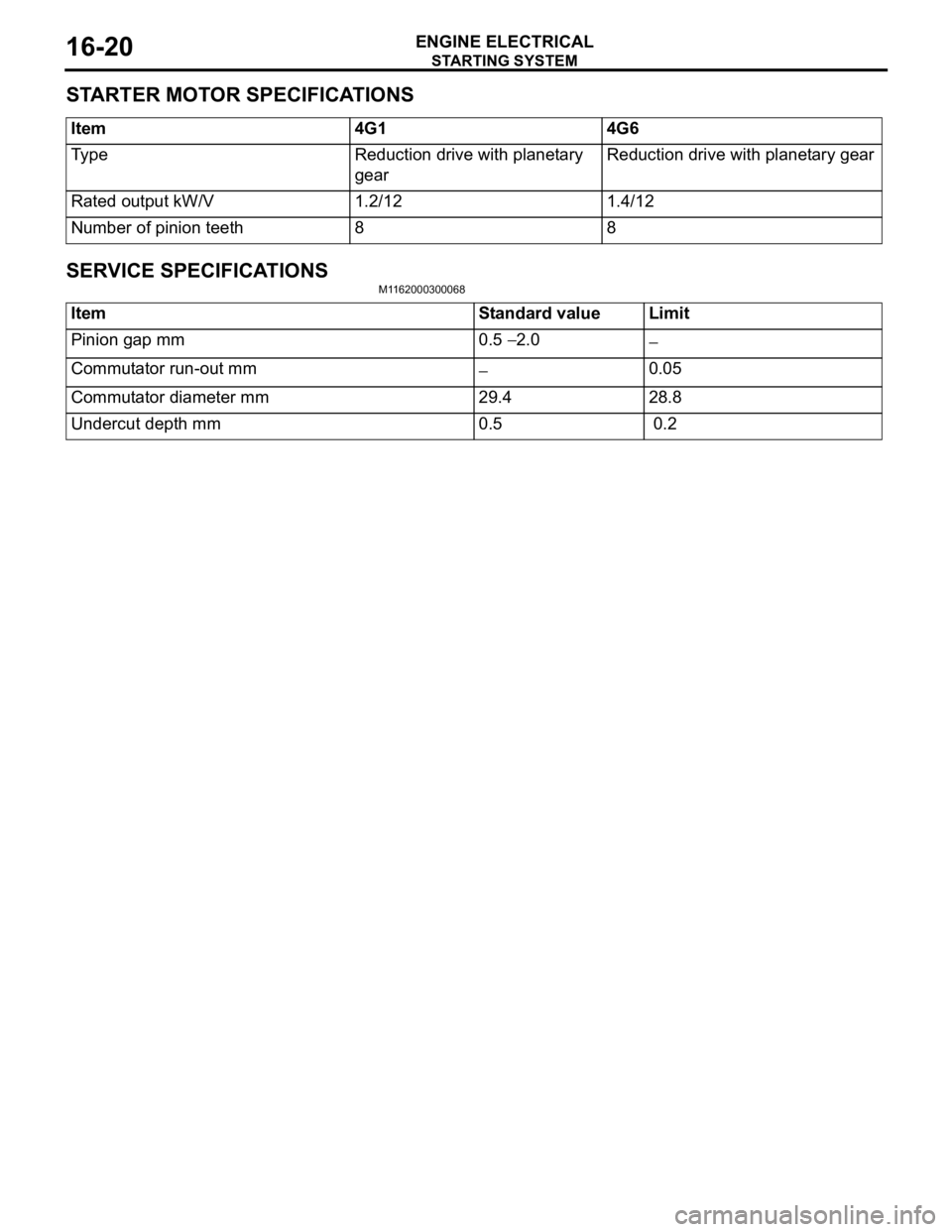

STARTER MOTOR SPECIFICATIONS

Item4G14G6

Ty p eReduction drive with planetary

gearReduction drive with planetary gear

Rated output kW/V1.2/121.4/12

Number of pinion teeth88

SERVICE SPECIFICATIONSM1162000300068

ItemStandard valueLimit

Pinion gap mm0.5 − 2.0−

Commutator run-out mm−0.05

Commutator diameter mm29.428.8

Undercut depth mm0.5 0.2

Page 83 of 800

STARTING SYSTEM

ENGINE ELECTRICAL16-21

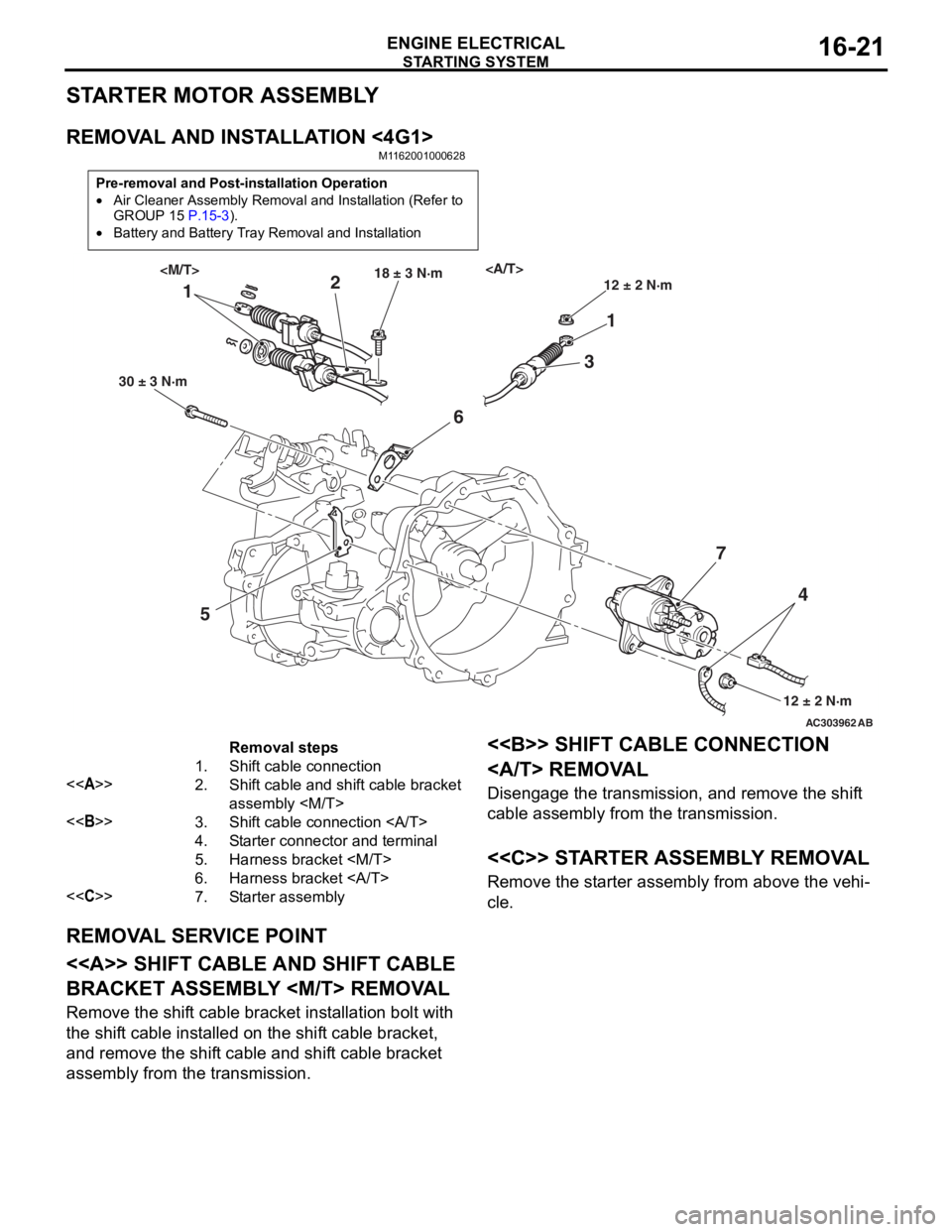

STARTER MOTOR ASSEMBLY

REMOVAL AND INSTALLATION <4G1>

M1162001000628

Pre-removal and Post-installation Operation

•Air Cleaner Assembly Removal and Installation (Refer to

GROUP 15 P.15-3).

•Battery and Battery Tray Removal and Installation

AC303962AB

11

2

3

5 6

74

30 ± 3 N·m 18 ± 3 N·m

12 ± 2 N·m

12 ± 2 N·m

Removal steps

1.Shift cable connection

<>2.Shift cable and shift cable bracket

assembly

<>3.Shift cable connection

4.Starter connector and terminal

5.Harness bracket

6.Harness bracket

<

REMOVA L SER V ICE POINT

<> SHIFT CABLE AND SHIFT CABLE

BRACKET ASSEMBL

Y

Remove the shift cable bracket inst allation bolt with

the shif

t ca ble inst alled o n the shif t cable bracket,

and remove

the shif t cable and shif t cable bracket

assembly fro

m the transmission.

<> SHIFT CABLE CONNECTION

REMOVA L

Disengage th e transmission, a nd remove the shif t

cable assembly from the tra

n smission .

<

Remove the st arter assembly from above the veh i-

cle.

Page 84 of 800

STARTING SYSTEM

ENGINE ELECTRICAL16-22

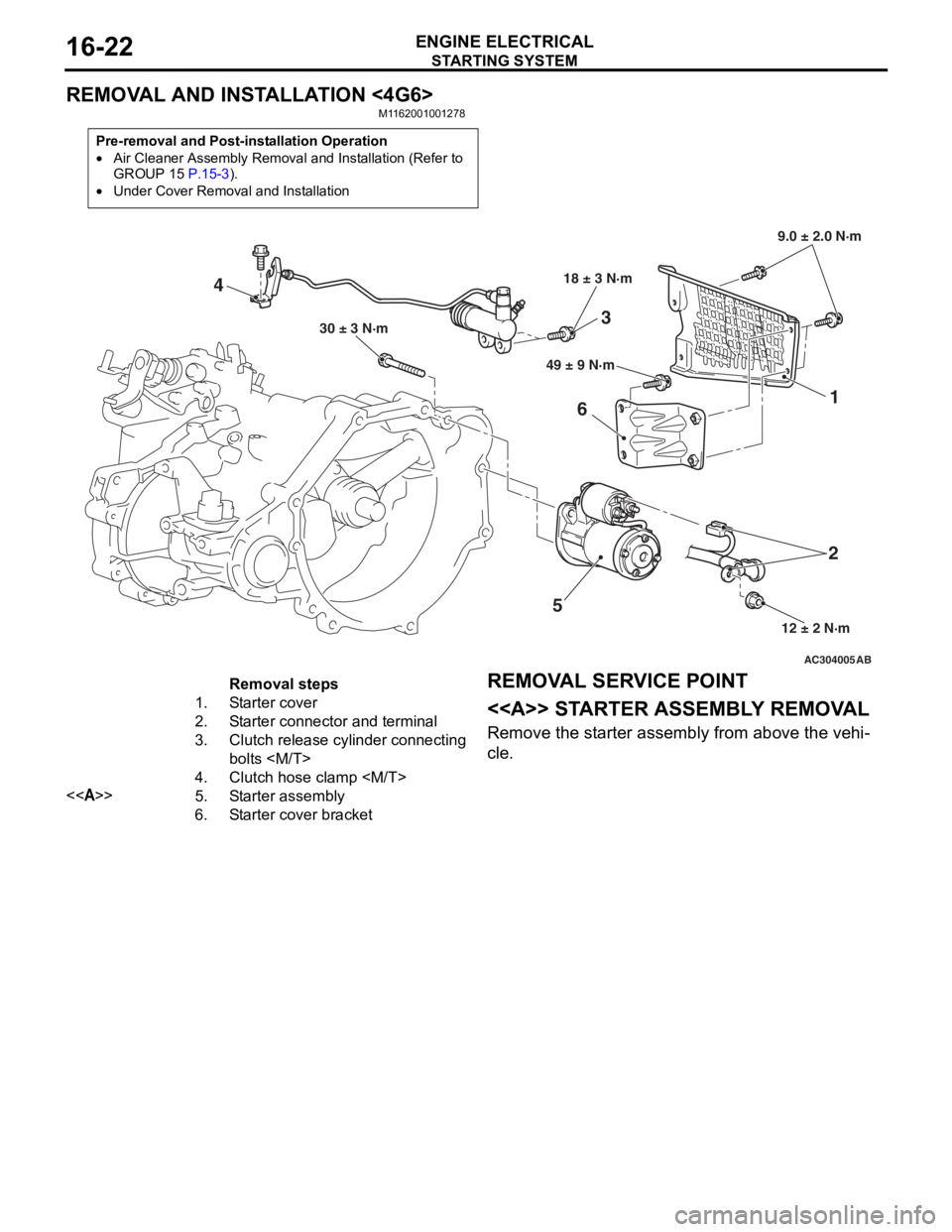

REMOVAL AND INSTALLATION <4G6>

M1162001001278

Pre-removal and Post-installation Operation

•Air Cleaner Assembly Removal and Installation (Refer to

GROUP 15 P.15-3).

•Under Cover Removal and Installation

AC304005

521

6

49 ± 9 N·m 18 ± 3 N·m

9.0 ± 2.0 N·m

30 ± 3 N·m

AB

4 3

12 ± 2 N·m

Removal steps

1.Starter cover

2.Starter connector and terminal

3.Clutch release cylinder connecting

bolts

4.Clutch hose clamp

<>5.Sta rte r as se mb ly

6.Starter cover bracket

REMOVA L SER VICE POINT

<> STARTER ASSEMBL Y REMOV A L

Remove the st arter assembly from above the veh i-

cle.

Page 85 of 800

STARTING SYSTEM

ENGINE ELECTRICAL16-23

STARTER MOTOR ASSEMBLY INSPECTION

M1162001100205

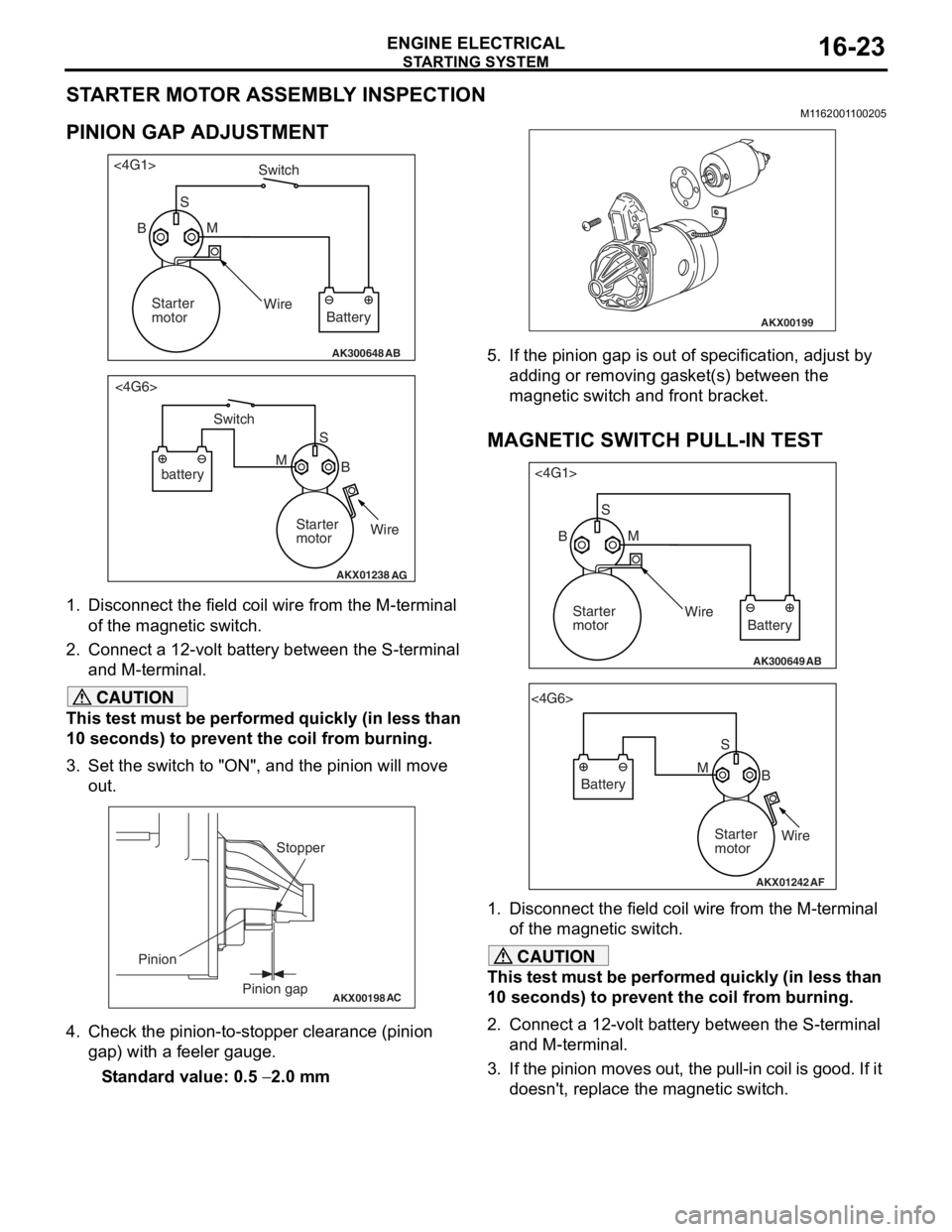

PINION GAP ADJUSTMENT

AK300648AB

<4G1>

Switch

S M

Wire Battery

Starter

motor

B

AKX01238

<4G6>

B

M S

battery Switch

Starter

motorWire

AG

1.

Disco nnect the field coil wire f r om th e M-te rmin al

of the magnet ic switch.

2.Conn ect a 12-volt b a ttery between the S-termina l

an d M-t e rminal.

CAUTION

This test must be performed quickly (in less than

10 seconds) to prevent the coil from burning.

3. Set the switch to "ON", and the pinion will move out.

AKX00198

Stopper

Pinion gap

Pinion

AC

4. Check the pinion-to-stopper clearance (pinion

gap) with a feeler gauge.

Standard value: 0.5 − 2.0 mm

AKX00199

5. If the pinion gap is out of specification, adjust by adding or removing gasket(s) between the

magnetic switch and front bracket.

MAGNETIC SWITCH PULL-IN TEST

AK300649AB

<4G1>

SM

Wire Battery

Starter

motor

B

AKX01242

<4G6>

SB

M

Battery

Starter

motorWire

AF

1. Disconnect the field coil wire from the M-terminal

of the magnetic switch.

CAUTION

This test must be performed quickly (in less than

10 seconds) to prevent the coil from burning.

2. Connect a 12-volt battery between the S-terminal and M-terminal.

3. If the pinion moves out, the pull-in coil is good. If it doesn't, replace the magnetic switch.

Page 86 of 800

STARTING SYSTEM

ENGINE ELECTRICAL16-24

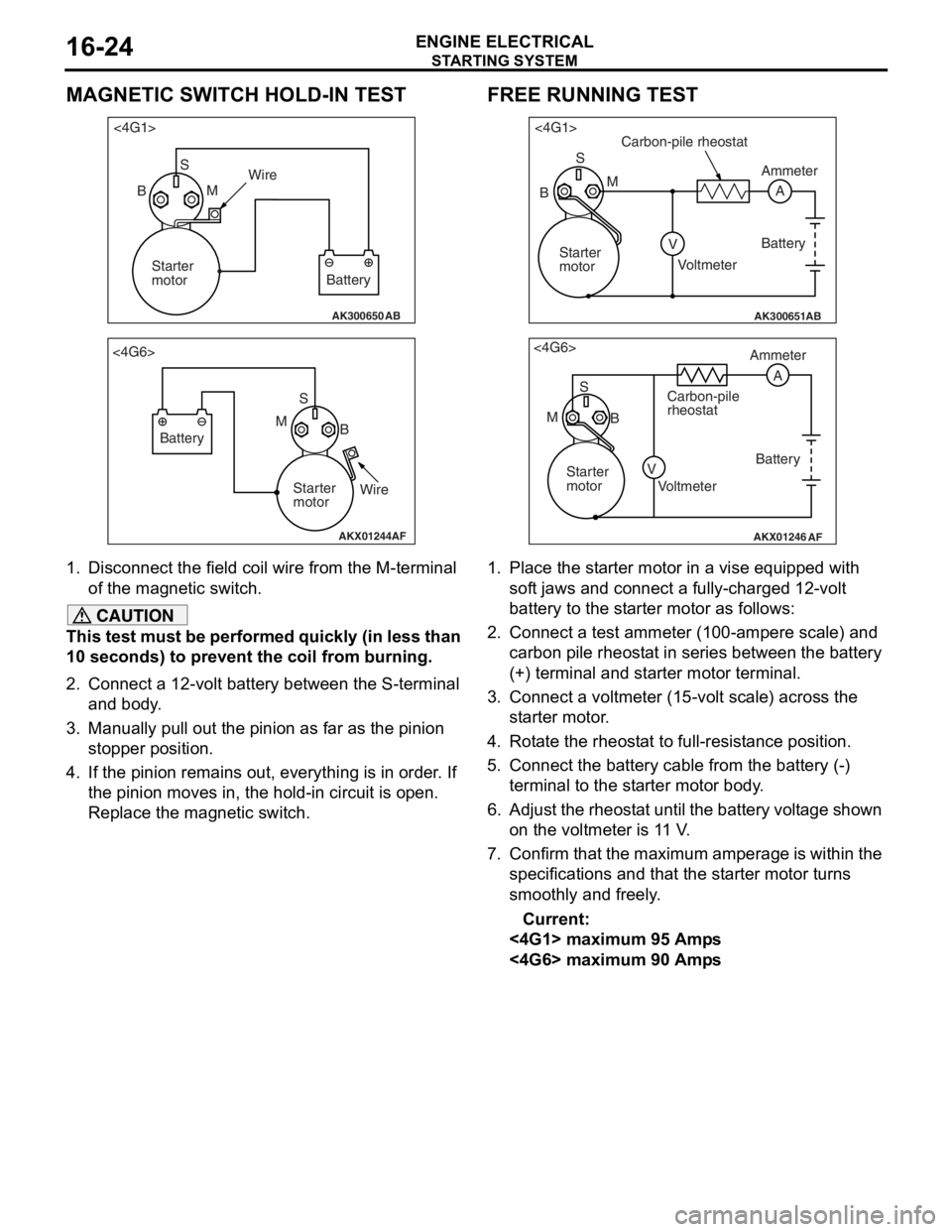

MAGNETIC SWITCH HOLD-IN TEST

AK300650AB

<4G1>S

B MWire

Battery

Starter

motor

AKX01244

<4G6>

SB

M

Battery

Starter

motorWire

AF

1.

Disco nnect the field coil wire f r om th e M-te rmin al

of the magnet ic switch.

CAUTION

This test must be performed quickly (in less than

10 seconds) to prevent the coil from burning.

2. Connect a 12-volt battery between the S-terminal and body.

3. Manually pull out the pinion as far as the pinion stopper position.

4. If the pinion remains out, everything is in order. If

the pinion moves in, the hold-in circuit is open.

Replace the magnetic switch.

FREE RUNNING TEST

AK300651AB

<4G1>

S

A

M

V

B

Carbon-pile rheostat

Battery

Voltmeter Ammeter

Starter

motor

AKX01246

<4G6> S

M B Ammeter

Carbon-pile

rheostat

Battery

Starter

motor Voltmeter

AF

A

V

1. Place the starter motor in a vise equipped with soft jaws and connect a fully-charged 12-volt

battery to the starter motor as follows:

2. Connect a test ammeter (100-ampere scale) and carbon pile rheostat in series between the battery

(+) terminal and starter motor terminal.

3. Connect a voltmeter (15-volt scale) across the starter motor.

4. Rotate the rheostat to full-resistance position.

5. Connect the battery c able from the battery (-)

terminal to the starter motor body.

6. Adjust the rheostat until the battery voltage shown

on the voltmeter is 11 V.

7. Confirm that the maximum amperage is within the specifications and that the starter motor turns

smoothly and freely.

Current:

<4G1> maximum 95 Amps

<4G6> maximum 90 Amps

Page 87 of 800

STARTING SYSTEM

ENGINE ELECTRICAL16-25

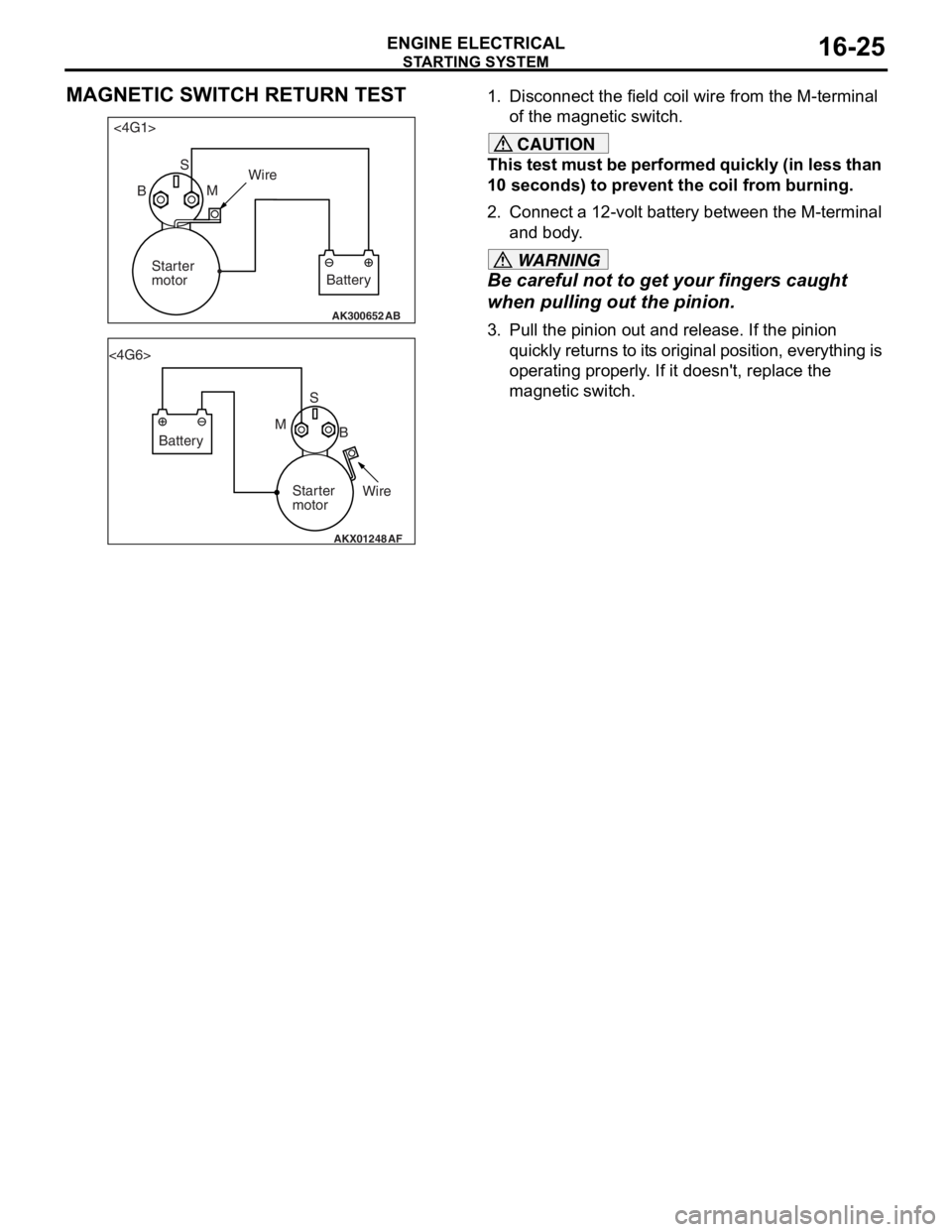

MAGNETIC SWITCH RETURN TEST

AK300652AB

<4G1>S

B MWire

Battery

Starter

motor

AKX01248

<4G6>

SB

M

Battery

Starter

motorWire

AF

1.

Disco nnect the field coil wire f r om th e M-te rmin al

o f the magnet ic switch.

CAUTION

This test must be performed quickly (in less than

10 seconds) to prevent the coil from burning.

2. Connect a 12-volt battery between the M-terminal and body.

WARNING

Be careful not to ge t your fingers caught

when pulling out the pinion.

3. Pull the pinion out and release. If the pinion

quickly returns to its original position, everything is

operating properly. If it doesn't, replace the

magnetic switch.

Page 88 of 800

STARTING SYSTEM

ENGINE ELECTRICAL16-26

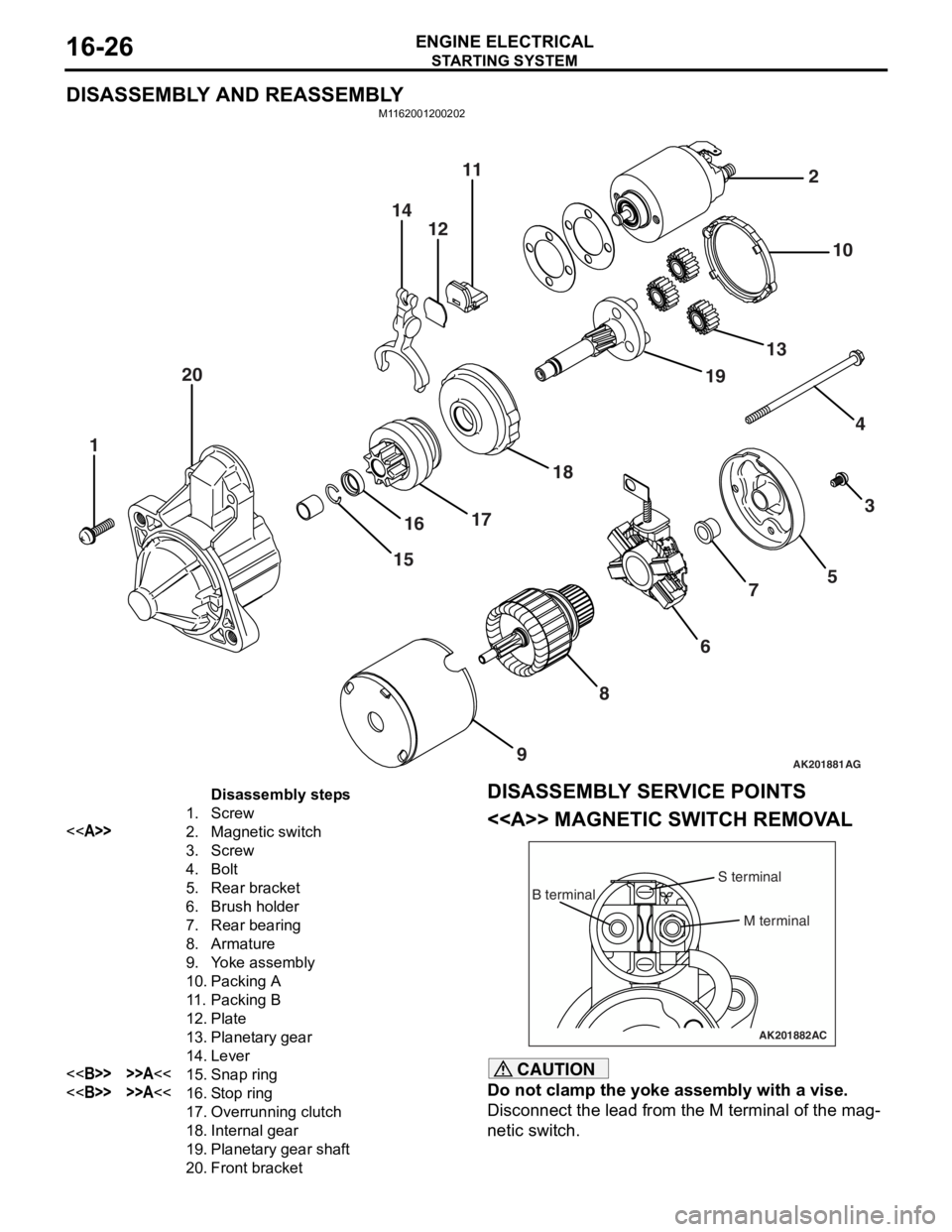

DISASSEMBLY AND REASSEMBLY

M1162001200202

AK201881

141211

20

1

1516

17 18 19

13 10

2

43

5

7

6

8

9

AG

Disassembly steps

1.Screw

<>2.Magnetic switch

3.Screw

4.Bolt

5.Rear bracket

6.Brush holder

7.Rear bearing

8.Armature

9.Yoke assembly

10.Packing A

11 .Packing B

12.Plate

13.Planetary gear

14.Lever

<>>>A<<15.Snap ring

<>>>A<<16.Stop ring

17.Overrunning clutch

18.Internal gear

19.Planetary gear shaft

20.Front bracket

DISASSEMBL Y SER V ICE POINTS

<> MA GNETIC SW ITCH REM O V A L

AK201882

B terminal

M terminal

S terminal

AC

CAUTION

Do not clamp the yoke assembly with a vise.

Disconnect the lead from the M terminal of the mag-

netic switch.

Page 89 of 800

STARTING SYSTEM

ENGINE ELECTRICAL16-27

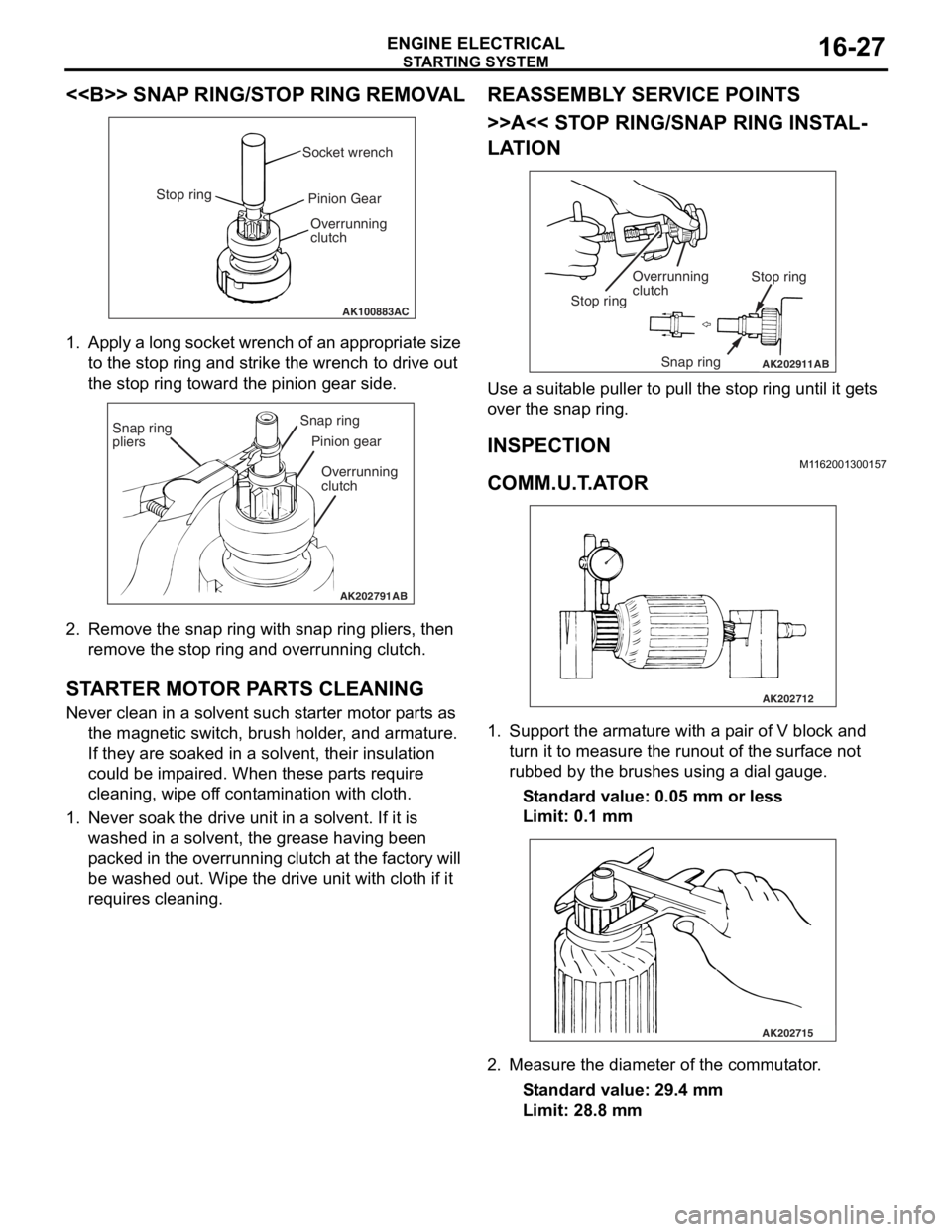

<> SNAP RING/STOP RING REMOVAL

AK100883AC

Socket wrench

Stop ring Pinion Gear

Overrunning

clutch

1. Ap ply a lo ng socket wr ench o f a n ap pro p ria t e size

to the stop ring and strike th e wrench to drive out

th e sto p ring toward th e pin i on g ear side.

AK202791

Snap ring

pliersSnap ring

Pinion gear

Overrunning

clutch

AB

2. Remove the snap ring with sna p ring pliers, th en

remove the stop ring an d overrunning clutch.

STARTER MOT O R P ARTS CLEANING

Never clean in a solvent such st arte r moto r p a rt s as

th e ma gnetic switch, brush hold e r , and arma ture.

If they are soake d in a solven t, their insulat i on

could be imp a ire d . When these p a rt s requ ire

clean ing, wipe of f co nt a m in ation with cloth .

1.Never so ak th e drive un it in a solve n t. If it is

washed in a solvent, th e grea se ha vin g been

p a cke d in th e over run n ing clutch at t he fa ct or y will

be washe d out. Wipe t he drive u n it with cloth if it

req u ires cleaning.

REASSEM BL Y SER V ICE POINT S

>>A<< STOP RING/SNAP RING INST AL-

LATION

AK202911

Overrunning

clutch Stop ring

Snap ring

Stop ring

AB

Use a suit

able puller to pull the stop ring u n til it ge t s

over t

he snap ring.

INSPECTION

M1162 0013 0015 7

COMM.U.T .A T O R

AK202712

1.Sup port the arma ture with a p a ir o f V block a nd

tu rn it t o mea s ure the run out of the surface not

ru bbed b y the brushes u s in g a dial g auge.

St andard va lue: 0.0 5 mm o r l ess

Limit: 0.1 mm

AK202715

2.Measure the diameter o f the commut ator .

St andard va lue: 29 .4 mm

Limit: 28.8 mm