service MITSUBISHI LANCER 2006 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 7 of 800

12-1

GROUP 12

ENGINE

LUBRIC ATION

CONTENTS

GENERAL INFORMATIO N . . . . . . . .12-2

SERVICE SPECIFICATION . . . . . . . .12-2

LUBRICANT . . . . . . . . . . . . . . . . . . . .12-2

SEALANT . . . . . . . . . . . . . . . . . . . . . .12-3

SPECIAL TOOLS . . . . . . . . . . . . . . . .12-3

ON-VEHICLE SERVICE . . . . . . . . . . .12-4

ENGINE OIL CHECK . . . . . . . . . . . . . . . . . 12-4

ENGINE OIL REPLACEMENT . . . . . . . . . . 12-4

ENGINE OIL FILTER REPLACEMENT . . . . 12-4

OIL PRESSURE CHECK . . . . . . . . . . . . . . 12-5

Page 8 of 800

GENERAL INFORMATION

ENGINE LUBRICATION12-2

GENERAL INFORMATION

M1121000100357

The lubrication method is a fully force-fed, full-flow fil-

tration type. The engine oil pump is a trochoid type

which is driven by the crankshaft <4G1>.The engine

oil pump is a gear type which is driven by the crank

-

shaft via the balancer timing belt <4G6>.

ENGINE OILS

Health Warning

Prolonged and repeated contact with mineral oil will

result in the removal of natural fats from the skin,

leading to dryness, irritation and dermatitis. In addi

-

tion, used engine oil contains potentially harmful con-

taminants which may cause skin cancer. Adequate

means of skin protection and washing facilities must

be provided.

Recommended Precautions

The most effective precaution is to adapt working

practices which prevent, as far as practicable, the

risk of skin contact with mineral oils, for example by

using enclosed systems for handling used engine oil

and by degreasing components, where practicable,

before handling them. Other precautions:

•Avoid prolonged and repeated contact with oils,

particularly used engine oils.

•Wear protective clothing, including impervious

gloves where practicable.

•Avoid contaminating clothes, particularly under-

pants, with oil.

•Do not put oily rags in pockets, the use of overalls

without pockets will avoid this.

•Do not wear heavily soiled clothing and

oil-impregnated foot-wear. Overalls must be

cleaned regularly and kept separate from per

-

sonal clothing.

•Where there is a risk of eye contact, eye protec-

tion should be worn, for example, chemical gog-

gles or face shields; in addition an eye wash

facility should be provided.

•Obtain first aid treatment immediately for open

cuts and wounds.

•Wash regularly with soap and water to ensure all

oil is removed, especially before meals (skin

cleansers and nail brushes will help). After clean

-

ing, the application of preparations containing

lanolin to replace the natur al skin oils is advised.

•Do not use petrol, kerosine, diesel fuel, gas oil,

thinners or solvents for cleaning skin.

•Use barrier creams, applying them before each

work period, to help the removal of oil from the

skin after work.

•If skin disorders develop, obtain medical advice

without delay.

SERVICE SPECIFICATION

M1121000300232

ItemStandard value

Oil pressure kPaat idle29 or more

at 3,500 r/min294 − 686

LUBRICANT

M1121000400433

ItemSpecification

Engine oil ACEA classificationA1, A2 or A3

Engine oil API classificationSG or higher

Engine oil quantity L4G1Oil filter0.3

To t a l3.3

4G6Oil filter0.3

To t a l4.3

Page 10 of 800

ON-VEHICLE SERVICE

ENGINE LUBRICATION12-4

ON-VEHICLE SERVICE

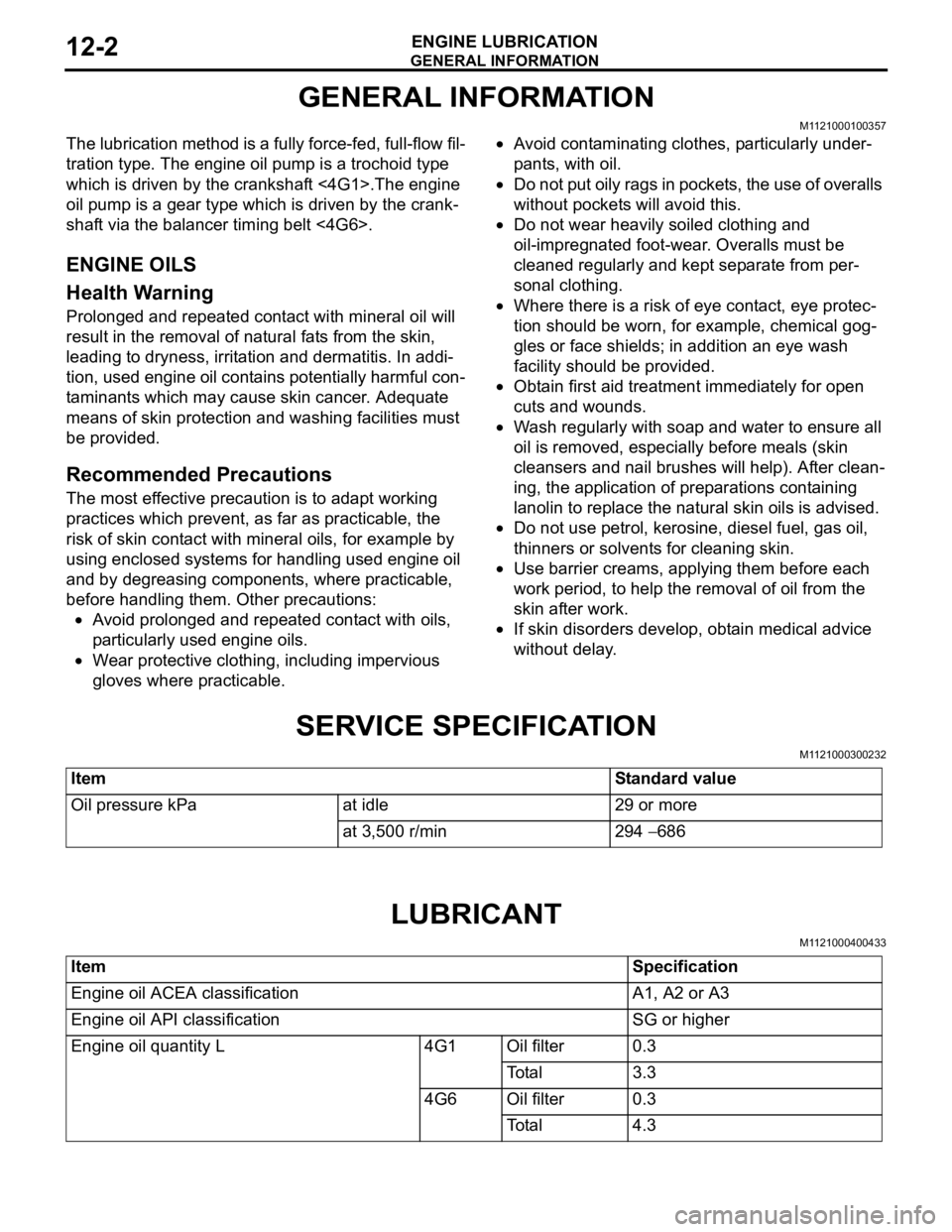

ENGINE OIL CHECKM1121000900342

ACX00892 AC

Good

Maximum Minimum

<4G1>

AC205268

Maximum MinimumGood

AC

<4G6>

1.

Pull ou t the en gine oil level ga uge slowly and

check tha t the o il level is in t he illustrated range.

2.Check t hat the oil is not excessively dirty , that

th ere is no coolant or p e trol mixed in, and that it

ha s s u f f i c ie nt vi sc osi t y .

ENGINE OIL REPLACEMENT

M1121 0010 0041 6

1.S t art the engin e and allow it to war m up until the

te mpera t ure of the coola n t reaches 80

°C to 90

°C.

2.Remove the en gine oil filler ca p.

CAUTION

Use care as engine oil could be hot.

3. Remove the engine oil pan drain plug to drain

engine oil.

AC208299

Engine oil pan

AC

Engine oip pan

drain plug

Engine oip pan

drain plug

Engine oil

pan side

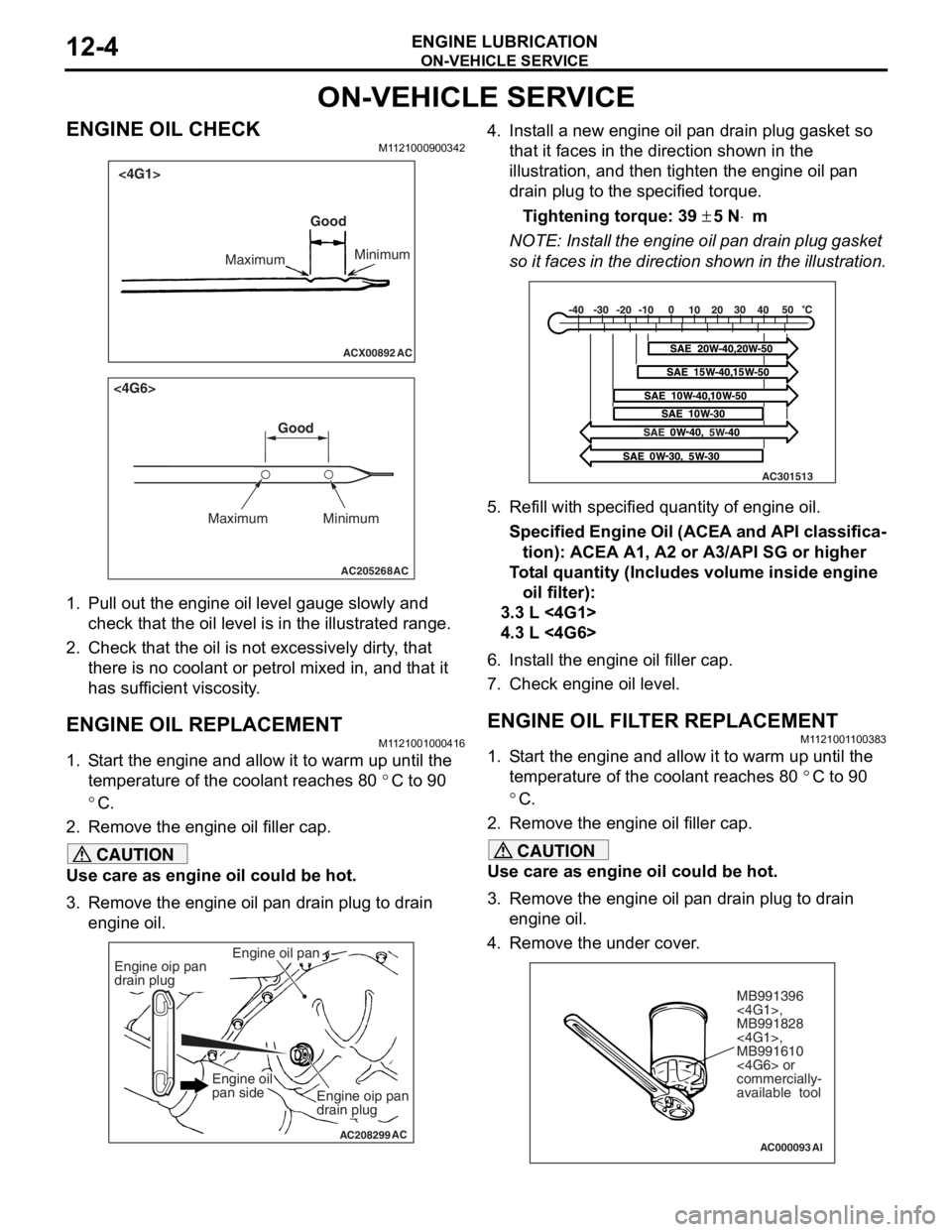

4. Install a new engine oil pan drain plug gasket so

that it faces in the direction shown in the

illustration, and then tighten the engine oil pan

drain plug to the specified torque.

Tightening torque: 39 ± 5 N⋅m

NOTE: Install the engine oil pan drain plug gasket

so it faces in the direction shown in the illustration.

AC301513

5. Refill with specifi ed quantity of engine oil.

Specified Engine Oil (ACEA and API classifica-

tion): ACEA A1, A2 or A3/API SG or higher

Total quantity (Includes volume inside engine

oil filter):

3.3 L <4G1>

4.3 L <4G6>

6. Install the engine oil filler cap.

7. Check engine oil level.

ENGINE OIL FILTER REPLACEMENTM1121001100383

1. Start the engine and allow it to warm up until the temperature of the coolant reaches 80

°C to 90

°C.

2. Remove the engine oil filler cap.

CAUTION

Use care as engine oil could be hot.

3. Remove the engine oil pan drain plug to drain engine oil.

4. Remove the under cover.

AC000093

MB991396

<4G1>,

MB991828

<4G1>,

MB991610

<4G6> or

commercially-

available tool

AI

Page 11 of 800

ON-VEHICLE SERVICE

ENGINE LUBRICATION12-5

5. Use the respective tool in the following table to remove the engine oil filter.

NumberSpecial tool

MD348631 <4G1>Oil filter wrench (MB991828) or

equivalent

MD365876 <4G1>

MD360935 <4G1>Oil filter wrench (MB991396) or

equivalent

MD136466 <4G6>Commercially- available tool

MD322508 <4G6>

MD356000 <4G6>Oil filter wrench (MB991610) or

equivalent

6. Cle an the filt er bracket side mou n ting surfa c e.

AC103250AD

O-ring

7.Ap ply a small a m ou nt o f en gine o i l to th e O-rin g of

th e new eng ine oil f ilte r .

8.Once the O-ring of the engine oil filter is tou c hing

th e flange, use the resp ective tool in the following

t able to tighten to the specified tor que.

NumberSpecial toolTightening torque

MD348631

<4G1>Oil filter wrench

(MB991828) or

equivalentApproximately 3/4

turn (16

± 4 N⋅m)

MD365876

<4G1>

MD360935

<4G1>Oil filter wrench

(MB991396) or

equivalentApproximately 1 turn

(14

± 2 N⋅m)

MD136466

<4G6>Commercially-

available toolApproximately 3/4

turn (17

± 3 N⋅m)

MD322508

<4G6>

MD356000

<4G6>Oil filter wrench

(MB991610) or

equivalentApproximately 3/4

turn (14

± 2 N⋅m)

9.In st all the en gine oil p a n drain plu g and refill the

en gine oil (Re f er to

P.12-4).

10.Race the en gine 2−3 times, and che ck to be sure

th

at n

o

en

gin

e

oil leaks fr om in st allation sectio n of

th

e engine oil filter

.

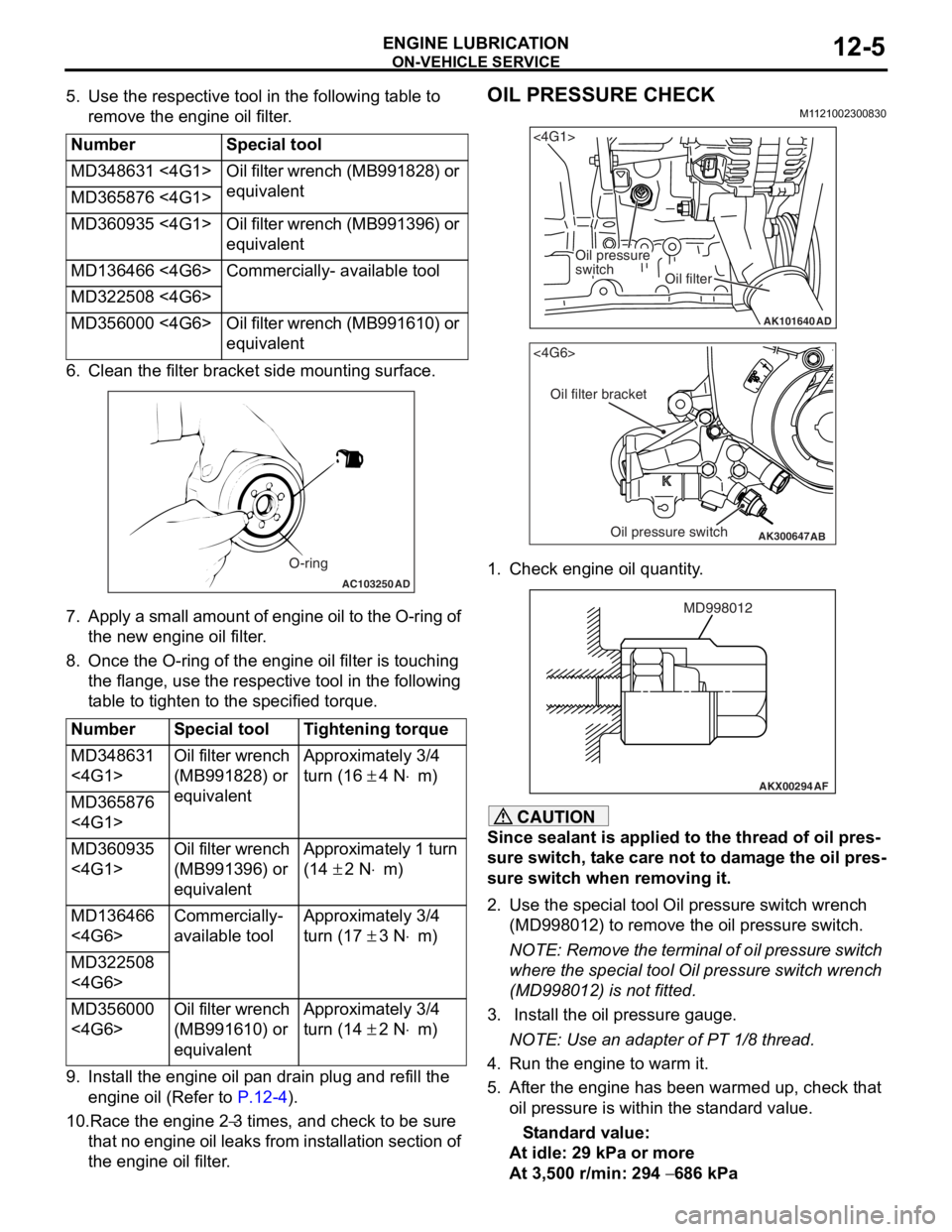

OIL PRESSURE CHECK

M1 121 0023 0083 0

AK101640

<4G1>

Oil pressure

switch

Oil filter

AD

AK300647

AB

<4G6>

Oil filter bracket

Oil pressure switch

1.Check e ngin e oil quan tity .

AKX00294

MD998012

AF

CAUTION

Since sealant is applied to the thread of oil pres-

sure switch, take care not to damage the oil pres-

sure switch when removing it.

2. Use the special tool Oil pressure switch wrench

(MD998012) to remove the oil pressure switch.

NOTE: Remove the terminal of oil pressure switch

where the special tool Oil pressure switch wrench

(MD998012) is not fitted.

3. Install the oil pressure gauge.

NOTE: Use an adapter of PT 1/8 thread.

4. Run the engine to warm it.

5. After the engine has been warmed up, check that oil pressure is within the standard value.

Standard value:

At idle: 29 kPa or more

At 3,500 r/min: 294 − 686 kPa

Page 12 of 800

ON-VEHICLE SERVICE

ENGINE LUBRICATION12-6

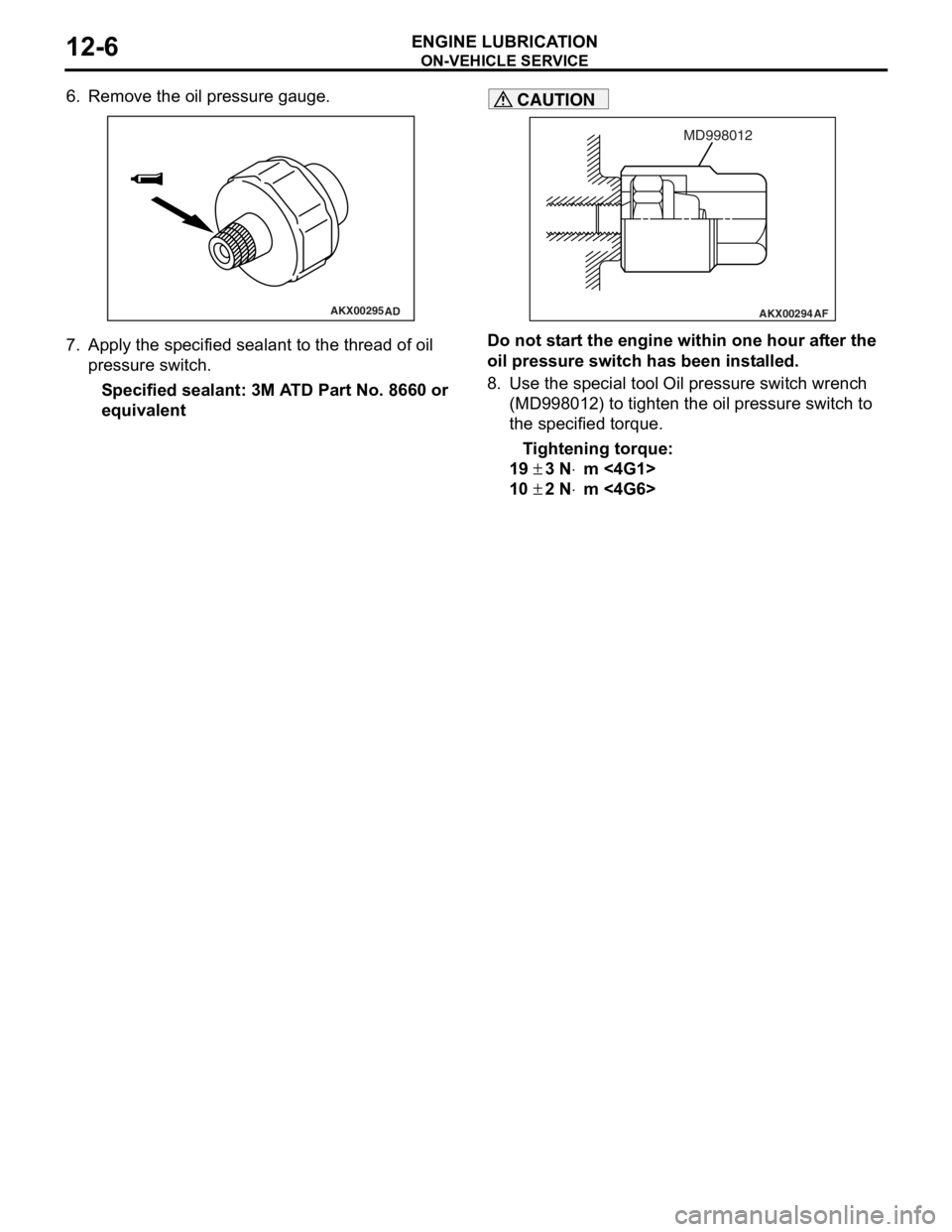

6. Remove the oil pressure gauge.

AKX00295AD

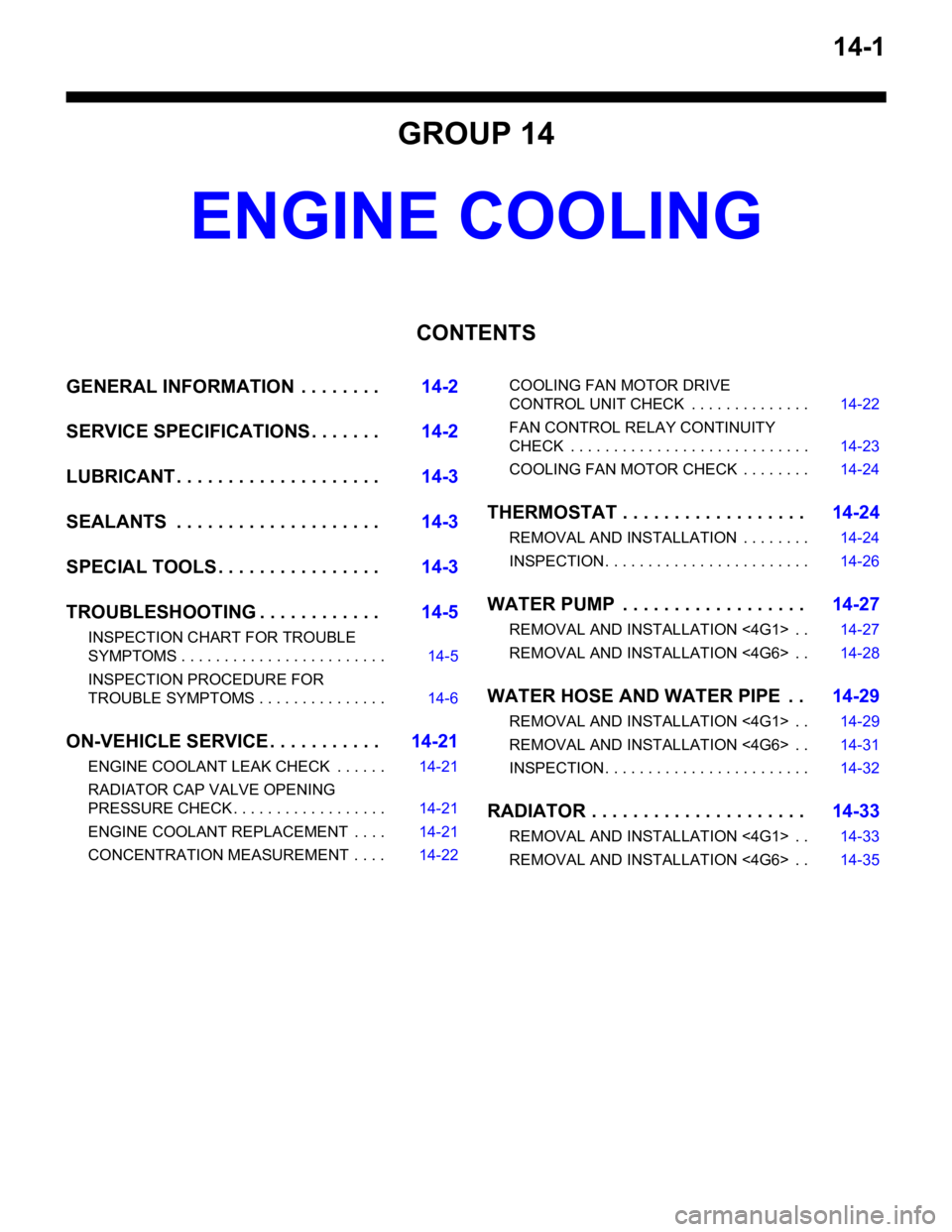

7.App l y t he sp ecified sealant to the thr ead of oil

pres sure sw itc h .

Specified sealan t: 3M A T D Part No. 8660 or

equival

ent

AKX00294

MD998012

AF

CAUTION

Do not start the engine within one hour after the

oil pressure switch has been installed.

8. Use the special tool Oil pressure switch wrench (MD998012) to tighten the oil pressure switch to

the specified torque.

Tightening torque:

19 ± 3 N⋅m <4G1>

10 ± 2 N⋅m <4G6>

Page 15 of 800

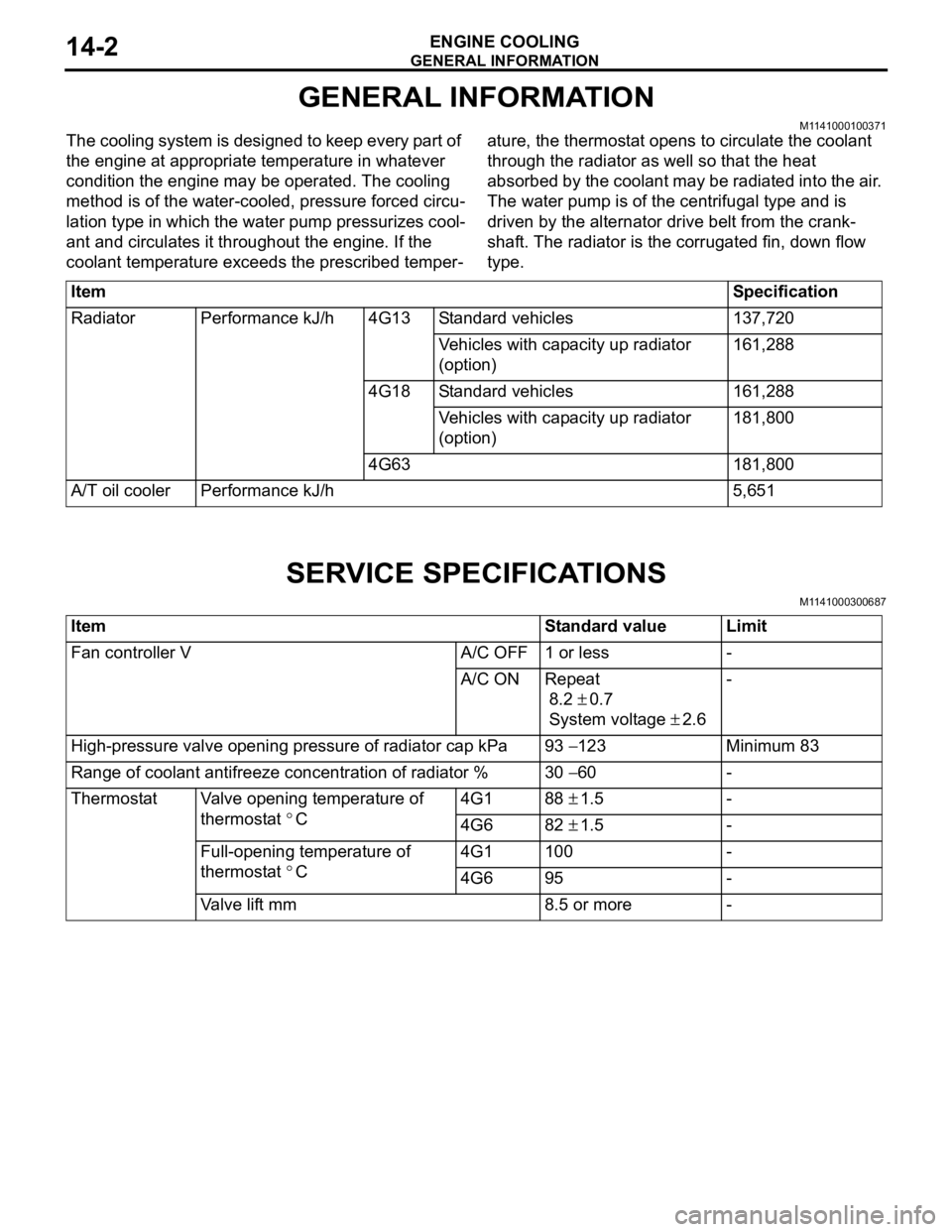

14-1

GROUP 14

ENGINE COOLING

CONTENTS

GENERAL INFORMATION . . . . . . . .14-2

SERVICE SPECIFICATIONS . . . . . . .14-2

LUBRICANT . . . . . . . . . . . . . . . . . . . .14-3

SEALANTS . . . . . . . . . . . . . . . . . . . .14-3

SPECIAL TOOLS . . . . . . . . . . . . . . . .14-3

TROUBLESHOOTING . . . . . . . . . . . .14-5

INSPECTION CHART FOR TROUBLE

SYMPTOMS . . . . . . . . . . . . . . . . . . . . . . . . 14-5

INSPECTION PROCEDURE FOR

TROUBLE SYMPTOMS . . . . . . . . . . . . . . . 14-6

ON-VEHICLE SERVICE . . . . . . . . . . .14-21

ENGINE COOLANT LEAK CHECK . . . . . . 14-21

RADIATOR CAP VALVE OPENING

PRESSURE CHECK . . . . . . . . . . . . . . . . . . 14-21

ENGINE COOLANT REPLACEMENT . . . . 14-21

CONCENTRATION MEASUREMENT . . . . 14-22

COOLING FAN MOTOR DRIVE

CONTROL UNIT CHECK . . . . . . . . . . . . . . 14-22

FAN CONTROL RELAY CONTINUITY

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-23

COOLING FAN MOTOR CHECK . . . . . . . . 14-24

THERMOSTAT . . . . . . . . . . . . . . . . . .14-24

REMOVAL AND INSTALLATION . . . . . . . . 14-24

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 14-26

WATER PUMP . . . . . . . . . . . . . . . . . .14-27

REMOVAL AND INSTALLATION <4G1> . . 14-27

REMOVAL AND INSTALLATION <4G6> . . 14-28

WATER HOSE AND WATER PIPE . .14-29

REMOVAL AND INSTALLATION <4G1> . . 14-29

REMOVAL AND INSTALLATION <4G6> . . 14-31

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 14-32

RADIATOR . . . . . . . . . . . . . . . . . . . . .14-33

REMOVAL AND INSTALLATION <4G1> . . 14-33

REMOVAL AND INSTALLATION <4G6> . . 14-35

Page 16 of 800

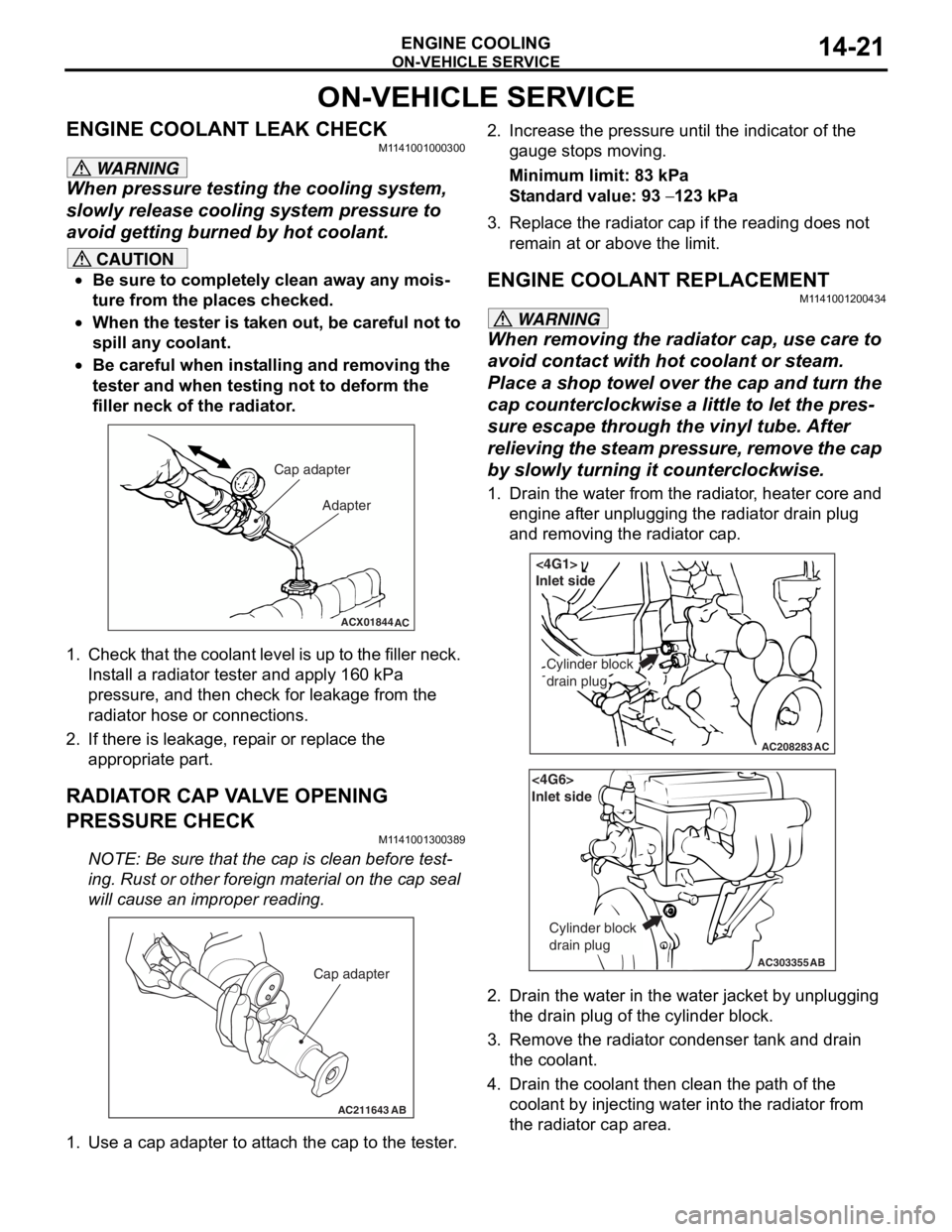

GENERAL INFORMATION

ENGINE COOLING14-2

GENERAL INFORMATION

M1141000100371

The cooling system is designed to keep every part of

the engine at appropriate temperature in whatever

condition the engine may be operated. The cooling

method is of the water-cooled, pressure forced circu

-

lation type in which the water pump pressurizes cool-

ant and circulates it throughout the engine. If the

coolant temperature exceeds the prescribed temper

-

ature, the thermostat opens to circulate the coolant

through the radiator as well so that the heat

absorbed by the coolant may be radiated into the air.

The water pump is of the centrifugal type and is

driven by the alternator drive belt from the crank

-

shaft. The radiator is the corrugated fin, down flow

type.

ItemSpecification

RadiatorPerformance kJ/h4G13Standard vehicles137,720

Vehicles with capacity up radiator

(option)161,288

4G18Standard vehicles161,288

Vehicles with capacity up radiator

(option)181,800

4G63181,800

A/T oil coolerPerformance kJ/h5,651

SERVICE SPECIFICATIONS

M1141000300687

ItemStandard valueLimit

Fan controller VA/C OFF1 or less-

A/C ONRepeat

8.2 ± 0.7

System voltage ± 2.6

-

High-pressure valve opening pressure of radiator cap kPa93 − 123Minimum 83

Range of coolant antifreeze concentration of radiator %30 − 60-

ThermostatValve opening temperature of

thermostat

°C

4G188 ± 1.5-

4G682 ± 1.5-

Full-opening temperature of

thermostat

°C

4G1100-

4G695-

Valve lift mm8.5 or more-

Page 35 of 800

ON-VEHICLE SERVICE

ENGINE COOLING14-21

ON-VEHICLE SERVICE

ENGINE COOLANT LEAK CHECKM1141001000300

WARNING

When pressure testing the cooling system,

slowly release cooling system pressure to

avoid getting burned by hot coolant.

CAUTION

•Be sure to completely clean away any mois-

ture from the places checked.

•When the tester is taken out, be careful not to

spill any coolant.

•

ACX01844

Cap adapter

Adapter

AC

Be careful when installing and removing the

tester and when testing not to deform the

filler neck of the radiator.

1. Check that the coolant leve l is up to the filler neck.

Install a radiator tester and apply 160 kPa

pressure, and then check for leakage from the

radiator hose or connections.

2. If there is leakage, repair or replace the

appropriate part.

RADIATOR CAP VALVE OPENING

PRESSURE CHECK

M1141001300389

NOTE: Be sure that the cap is clean before test-

ing. Rust or other foreign material on the cap seal

will cause an improper reading.

AC211643AB

Cap adapter

1. Use a cap adapter to attach the cap to the tester.

2. Increase the pressure until the indicator of the gauge stops moving.

Minimum limit: 83 kPa

Standard value: 93 − 123 kPa

3. Replace the radiator cap if the reading does not remain at or above the limit.

ENGINE COOLANT REPLACEMENT

M1141001200434

WARNING

When removing the radiator cap, use care to

avoid contact with hot coolant or steam.

Place a shop towel over the cap and turn the

cap counterclockwise a little to let the pres

-

sure escape through the vinyl tube. After

relieving the steam pres sure, remove the cap

by slowly turning it counterclockwise.

1. Drain the water from the radiator, heater core and

engine after unplugging the radiator drain plug

and removing the radiator cap.

AC208283AC

Cylinder block

drain plug

<4G1>

Inlet side

AC303355

<4G6>

Inlet side

Cylinder block

drain plug

AB

2. Drain the water in the water jacket by unplugging the drain plug of the cylinder block.

3. Remove the radiator condenser tank and drain

the coolant.

4. Drain the coolant then clean the path of the coolant by injecting water into the radiator from

the radiator cap area.

Page 37 of 800

ON-VEHICLE SERVICE

ENGINE COOLING14-23

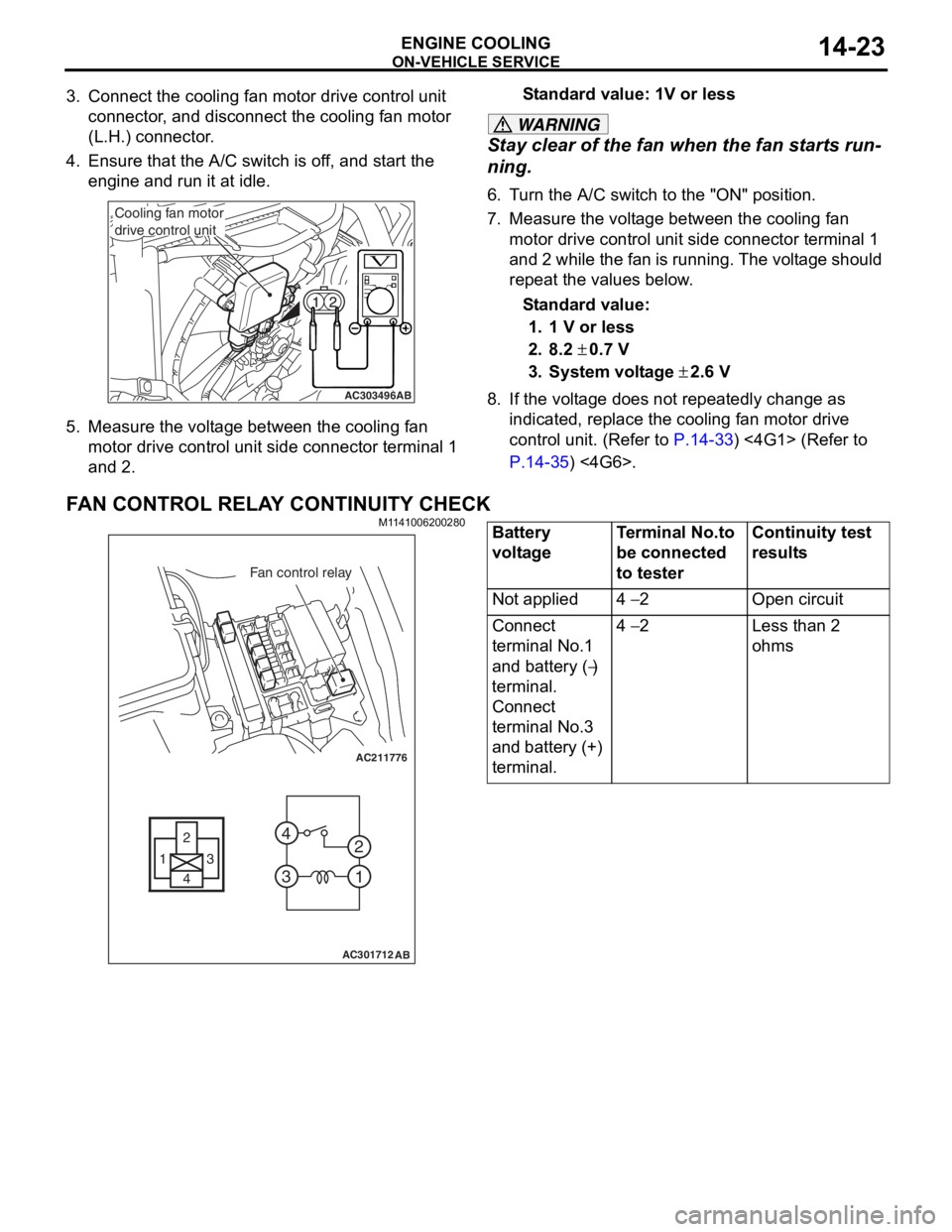

3. Connect the cooling fan motor drive control unit connector, and disconnect the cooling fan motor

(L.H.) connector.

4. Ensure that the A/C switch is off, and start the engine and run it at idle.

AC303496AB

Cooling fan motor

drive control unit

5.Measure the volt ag e betwee n the cooling f an

motor d r ive cont rol un it side conne ctor t e rminal 1

an d 2.

St andard va lue: 1V or le ss

WARNING

Stay clear of the fan when the fan starts run-

ning.

6. Turn the A/C switch to the "ON" position.

7. Measure the voltage between the cooling fan

motor drive control unit side connector terminal 1

and 2 while the fan is running. The voltage should

repeat the values below.

Standard value:

1. 1 V or less

2. 8.2 ± 0.7 V

3. System voltage ± 2.6 V

8. If the voltage does not repeatedly change as indicated, replace the cooling fan motor drive

control unit. (Refer to

P.14-33) <4G1> (Refer to

P.14-35) <4G6>.

FAN CONTROL RELAY CONTINUITY CHECK

M1141006200280

AC211776

13

4 2

3 4

1

2

AC301712

Fan control relay

AB

Battery

voltageTerminal No.to

be connected

to testerContinuity test

results

Not applied4 − 2Open circuit

Connect

terminal No.1

and battery (

−)

terminal.

Connect

terminal No.3

and battery (+)

terminal.

4 − 2Less than 2

ohms

Page 44 of 800

WATER HOSE AND WATER PIPE

ENGINE COOLING14-30

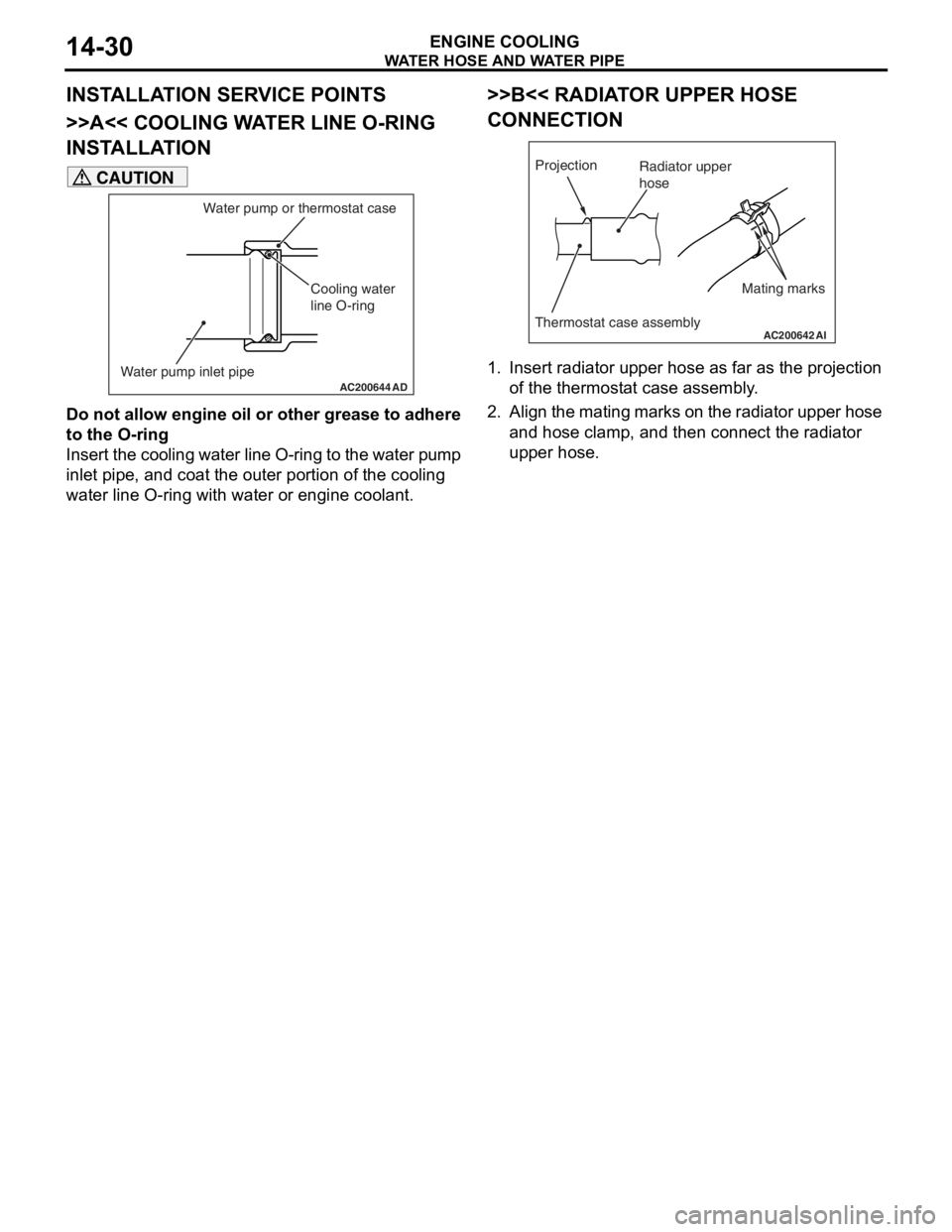

INSTALLATION SERVICE POINTS

>>A<< COOLING WATER LINE O-RING

INSTALLATION

AC200644 AD

Cooling water

line O-ring

Water pump inlet pipe Water pump or thermostat case

CAUTION

Do not allow engine oil or other grease to adhere

to the O-ring

Insert the cooling water line O-ring to the water pump

inlet pipe, and coat the outer portion of the cooling

water line O-ring with water or engine coolant.

>>B<< RADIATOR UPPER HOSE

CONNECTION

AC200642

Mating marks

Projection

Thermostat case assemblyAI

Radiator upper

hose

1. Insert radiator upper hose as far as the projection

of the thermostat case assembly.

2. Align the mating marks on the radiator upper hose and hose clamp, and then connect the radiator

upper hose.