MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 1411 of 1449

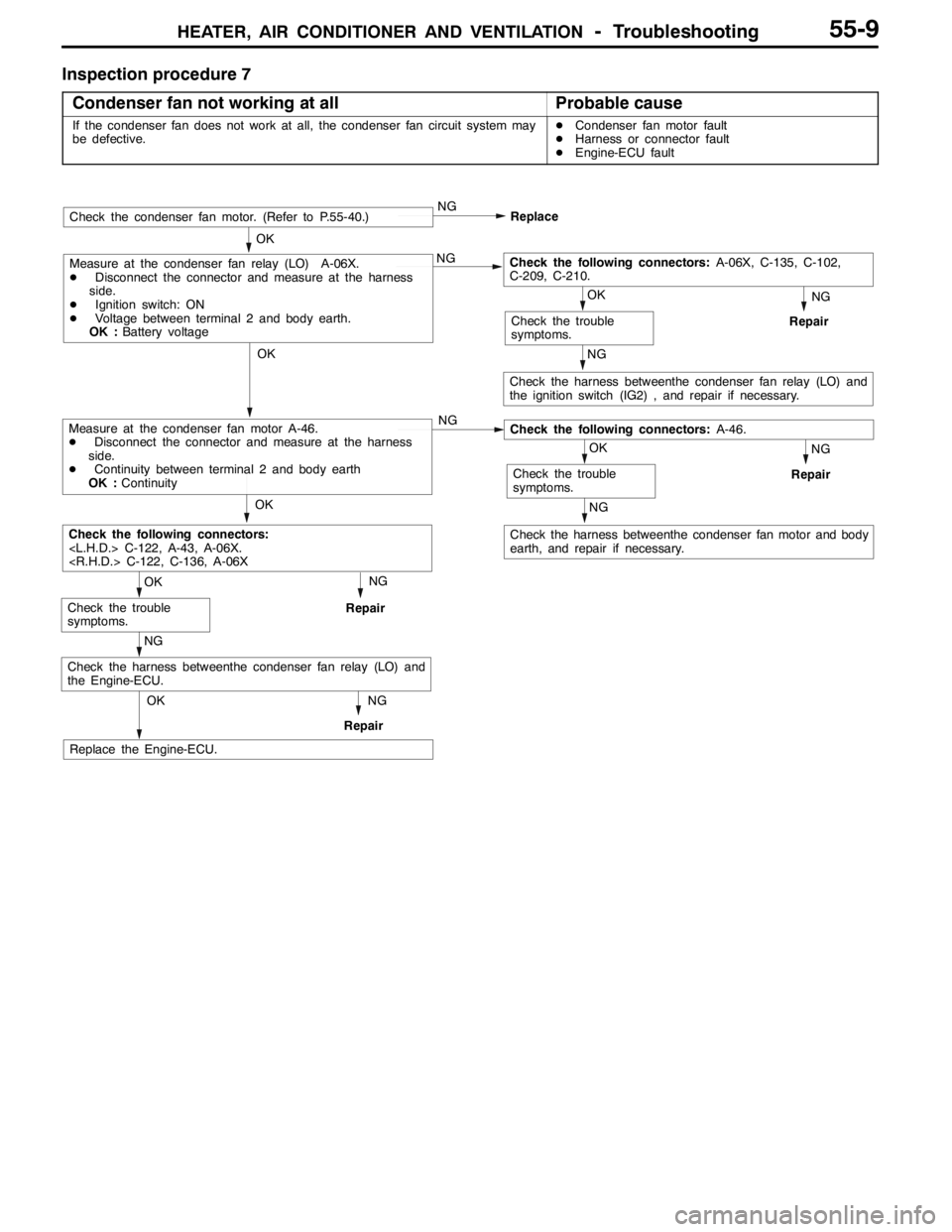

HEATER, AIR CONDITIONER AND VENTILATION-Troubleshooting55-9

Inspection procedure 7

Condenser fan not working at all

Probable cause

If the condenser fan does not work at all, the condenser fan circuit system may

be defective.DCondenser fan motor fault

DHarness or connector fault

DEngine-ECU fault

NG

Check the harness betweenthe condenser fan relay (LO) and

the ignition switch (IG2) , and repair if necessary.

OK

Check the trouble

symptoms.

NG

Repair

NG

Replace

OK

Check the condenser fan motor. (Refer to P.55-40.)

NGCheck the following connectors:A-06X, C-135, C-102,

C-209, C-210.

OK

Measure at the condenser fan relay (LO) A-06X.

DDisconnect the connector and measure at the harness

side.

DIgnition switch: ON

DVoltage between terminal 2 and body earth.

OK :Battery voltage

NG

Check the harness betweenthe condenser fan motor and body

earth, and repair if necessary.

OK

Check the trouble

symptoms.Repair

NGCheck the following connectors:A-46.

NG

OK

Measure at the condenser fan motor A-46.

DDisconnect the connector and measure at the harness

side.

DContinuity between terminal 2 and body earth

OK :Continuity

NG

OK

Check the trouble

symptoms.RepairNG

Check the following connectors:

Replace the Engine-ECU.

OK

RepairNG

Check the harness betweenthe condenser fan relay (LO) and

the Engine-ECU.

Page 1412 of 1449

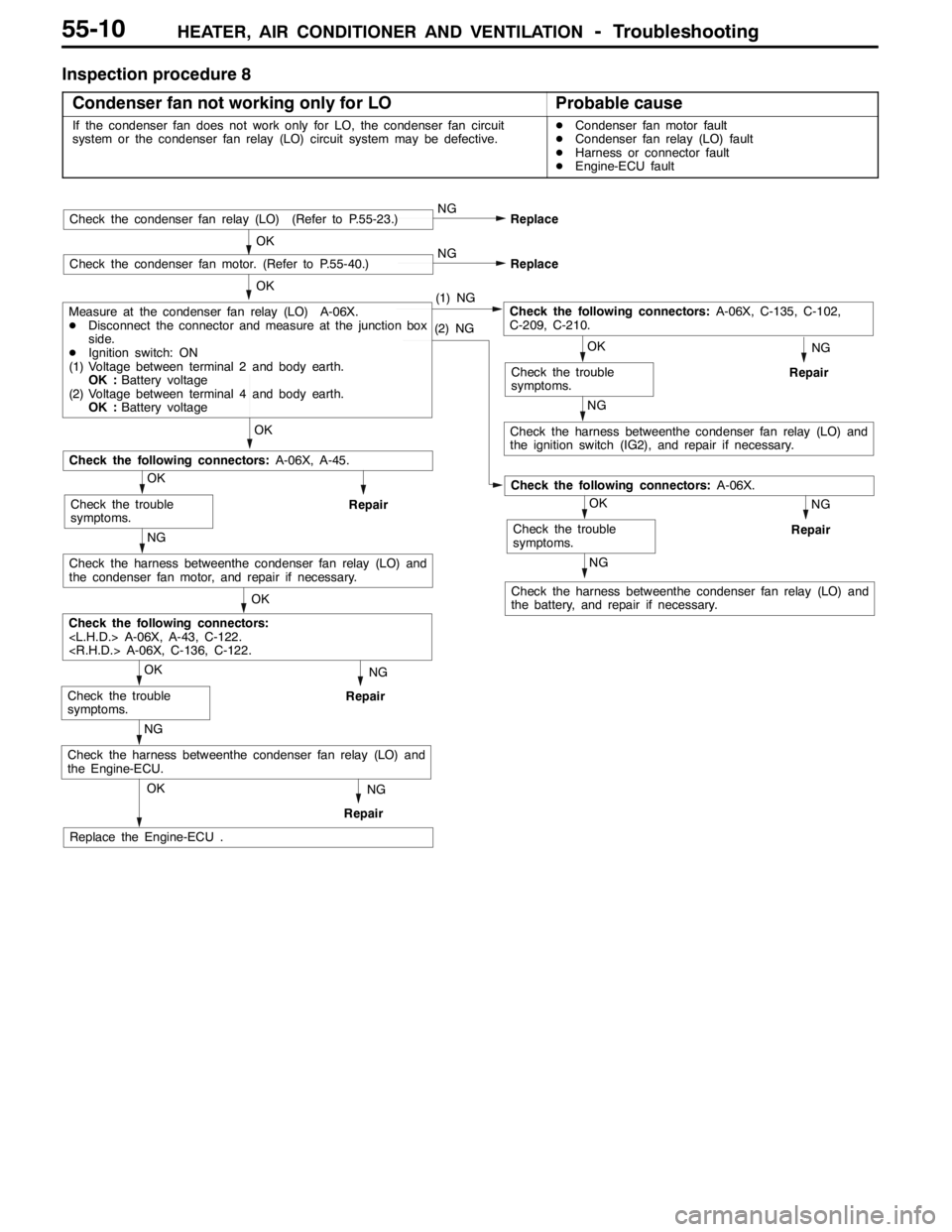

HEATER, AIR CONDITIONER AND VENTILATION-Troubleshooting55-10

Inspection procedure 8

Condenser fan not working only for LO

Probable cause

If the condenser fan does not work only for LO, the condenser fan circuit

system or the condenser fan relay (LO) circuit system may be defective.DCondenser fan motor fault

DCondenser fan relay (LO) fault

DHarness or connector fault

DEngine-ECU fault

NG

Check the harness betweenthe condenser fan relay (LO) and

the ignition switch (IG2), and repair if necessary.

OK

Check the trouble

symptoms.

NG

Repair

NG

Replace

OK

Check the condenser fan motor. (Refer to P.55-40.)

Check the following connectors:A-06X, C-135, C-102,

C-209, C-210.

OK

NG

OK

Check the trouble

symptoms.Repair

Check the following connectors:A-06X.

NG

NG

OK

Check the trouble

symptoms.RepairNG

Check the following connectors:

Replace the Engine-ECU .

OK

RepairNG

Check the harness betweenthe condenser fan relay (LO) and

the Engine-ECU.

(2) NG

Measure at the condenser fan relay (LO) A-06X.

DDisconnect the connector and measure at the junction box

side.

DIgnition switch: ON

(1) Voltage between terminal 2 and body earth.

OK :Battery voltage

(2) Voltage between terminal 4 and body earth.

OK :Battery voltage(1) NG

NG

Replace

OK

Check the condenser fan relay (LO) (Refer to P.55-23.)

NG

OK

Check the trouble

symptoms.Repair

Check the following connectors:A-06X, A-45.

OK

Check the harness betweenthe condenser fan relay (LO) and

the condenser fan motor, and repair if necessary.

Check the harness betweenthe condenser fan relay (LO) and

the battery, and repair if necessary.

Page 1413 of 1449

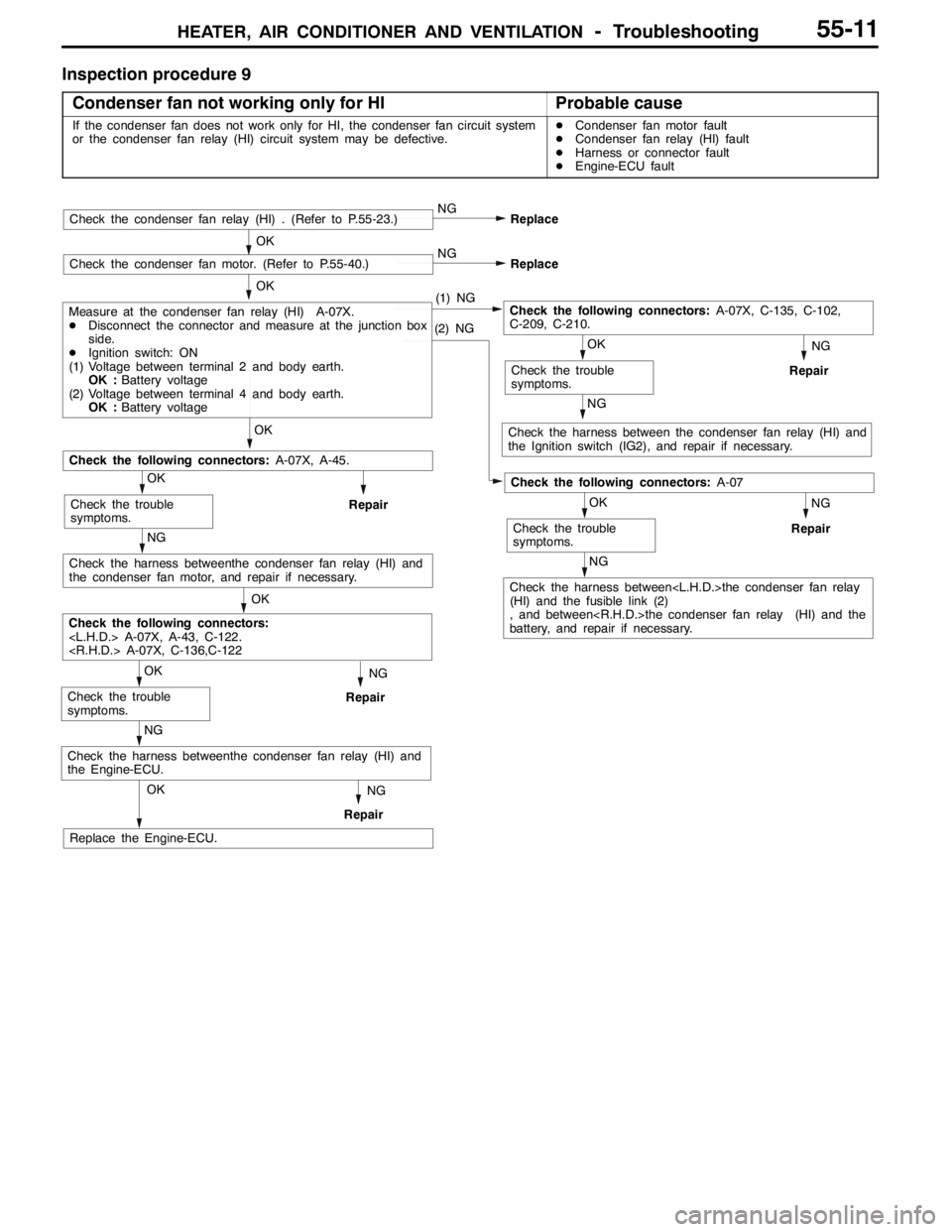

HEATER, AIR CONDITIONER AND VENTILATION-Troubleshooting55-11

Inspection procedure 9

Condenser fan not working only for HI

Probable cause

If the condenser fan does not work only for HI, the condenser fan circuit system

or the condenser fan relay (HI) circuit system may be defective.DCondenser fan motor fault

DCondenser fan relay (HI) fault

DHarness or connector fault

DEngine-ECU fault

NG

Check the harness between the condenser fan relay (HI) and

the Ignition switch (IG2), and repair if necessary.

OK

Check the trouble

symptoms.

NG

Repair

NG

Replace

OK

Check the condenser fan motor. (Refer to P.55-40.)

Check the following connectors:A-07X, C-135, C-102,

C-209, C-210.

OK

NG

Check the harness between

(HI) and the fusible link (2)

, and between

battery, and repair if necessary.

OK

Check the trouble

symptoms.Repair

Check the following connectors:A-07

NG

NG

OK

Check the trouble

symptoms.RepairNG

Check the following connectors:

Replace the Engine-ECU.

OK

RepairNG

Check the harness betweenthe condenser fan relay (HI) and

the Engine-ECU.

(2) NG

Measure at the condenser fan relay (HI) A-07X.

DDisconnect the connector and measure at the junction box

side.

DIgnition switch: ON

(1) Voltage between terminal 2 and body earth.

OK :Battery voltage

(2) Voltage between terminal 4 and body earth.

OK :Battery voltage(1) NG

NG

Replace

OK

Check the condenser fan relay (HI) . (Refer to P.55-23.)

NG

Check the harness betweenthe condenser fan relay (HI) and

the condenser fan motor, and repair if necessary.

OK

Check the trouble

symptoms.Repair

Check the following connectors:A-07X, A-45.

OK

Page 1414 of 1449

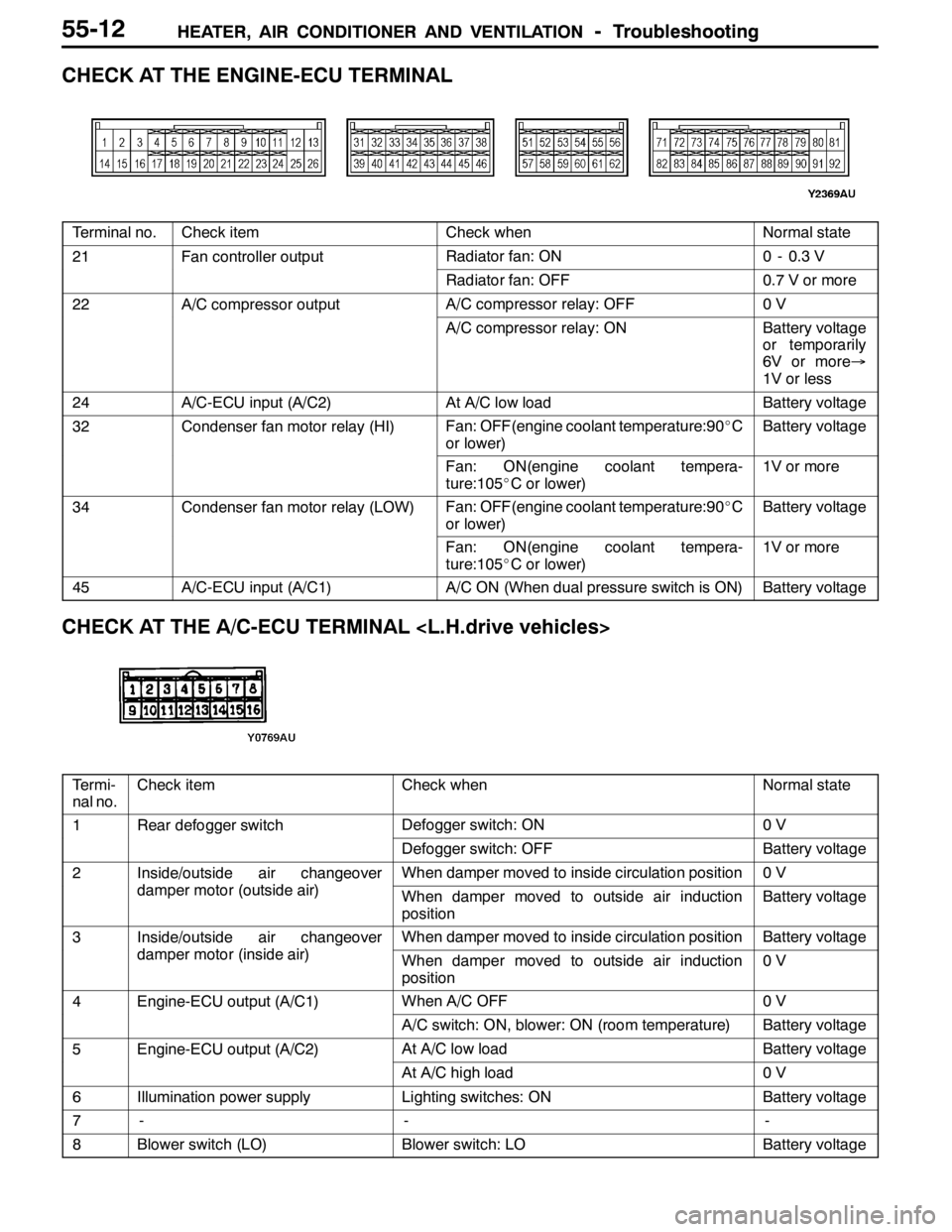

HEATER, AIR CONDITIONER AND VENTILATION-TroubleshootingHEATER, AIR CONDITIONER AND VENTILATION-Troubleshooting55-12

CHECK AT THE ENGINE-ECU TERMINAL

Terminal no.Check itemCheck whenNormal state

21Fan controller outputRadiator fan: ON0 - 0.3 Vp

Radiator fan: OFF0.7 V or more

22A/C compressor outputA/C compressor relay: OFF0Vpp

A/C compressor relay: ONBattery voltage

or temporarily

6V or more→

1V or less

24A/C-ECU input (A/C2)At A/C low loadBattery voltage

32Condenser fan motor relay (HI)Fan: OFF(engine coolant temperature:90_C

or lower)Battery voltage

Fan: ON(engine coolant tempera-

ture:105_C or lower)1V or more

34Condenser fan motor relay (LOW)Fan: OFF(engine coolant temperature:90_C

or lower)Battery voltage

Fan: ON(engine coolant tempera-

ture:105_C or lower)1V or more

45A/C-ECU input (A/C1)A/C ON (When dual pressure switch is ON)Battery voltage

CHECK AT THE A/C-ECU TERMINAL

Termi-

nal no.Check itemCheck whenNormal state

1Rear defogger switchDefogger switch: ON0Vgg

Defogger switch: OFFBattery voltage

2Inside/outside air changeover

dt(tidi)

When damper moved to inside circulation position0Vg

damper motor (outside air)When damper moved to outside air induction

positionBattery voltage

3Inside/outside air changeover

dt(i idi)

When damper moved to inside circulation positionBattery voltageg

damper motor (inside air)When damper moved to outside air induction

position0V

4Engine-ECU output (A/C1)When A/C OFF0Vgp()

A/C switch: ON, blower: ON (room temperature)Battery voltage

5Engine-ECU output (A/C2)At A/C low loadBattery voltagegp()

At A/C high load0V

6Illumination power supplyLighting switches: ONBattery voltage

7---

8Blower switch (LO)Blower switch: LOBattery voltage

Page 1415 of 1449

HEATER, AIR CONDITIONER AND VENTILATION-Troubleshooting55-13

Termi-

nal no.Normal state Check when Check item

9---

10Ignition switch (IG2) power supplyIgnition switch: ONBattery voltage

11Illumination earthAny time0V

12EarthAny time0V

13Air thermo sensorWhen temperature around sensor 25_C (1.5kΩ)2.2 V

14---

15---

16Air thermo sensor earthAny time0V

CHECK AT THE A/C-ECU TERMINAL

Termi-

nal no.Check itemCheck whenNormal state

1Engine-ECU output (A/C1)When A/C OFF0Vgp()

A/C switch: ON, blower: ON (room temperature)Battery voltage

2Engine-ECU output (A/C2)At A/C low loadBattery voltagegp()

At A/C high load0V

3EarthAny time0V

4Air thermo sensor earthAny time0V

5Illumination power supplyLighting switches: ONBattery voltage

6Air thermo sensorWhen temperature around sensor 25_C (1.5kΩ)2.2 V

7Ignition switch (IG2) power supplyIgnition switch: ONBattery voltage

8Blower switch (LO)Blower switch: LOBattery voltage

9Rear defogger switchDefogger switch: ON0Vgg

Defogger switch: OFFBattery voltage

10Inside/outside air changeover

dt(tidi)

When damper moved to inside circulation position0Vg

damper motor (outside air)When damper moved to outside air induction

positionBattery voltage

11Inside/outside air changeover

dt(i idi)

When damper moved to inside circulation positionBattery voltageg

damper motor (inside air)When damper moved to outside air induction

position0V

12Illumination earthAny time0V

Page 1416 of 1449

HEATER, AIR CONDITIONER AND VENTILATION–On-vehicle Service55-14

ON-VEHICLE SERVICE

REFRIGERANT LEVEL TEST THROUGH

PERFORMANCE TEST

1. Start the engine.

2. Turn on the A/C switch, and set the A/C control to MAX.

COOL.

3. Adjust the engine speed to 1,500 r/min.

4. Check the refrigerant level (bubble state) through the

sight glass.

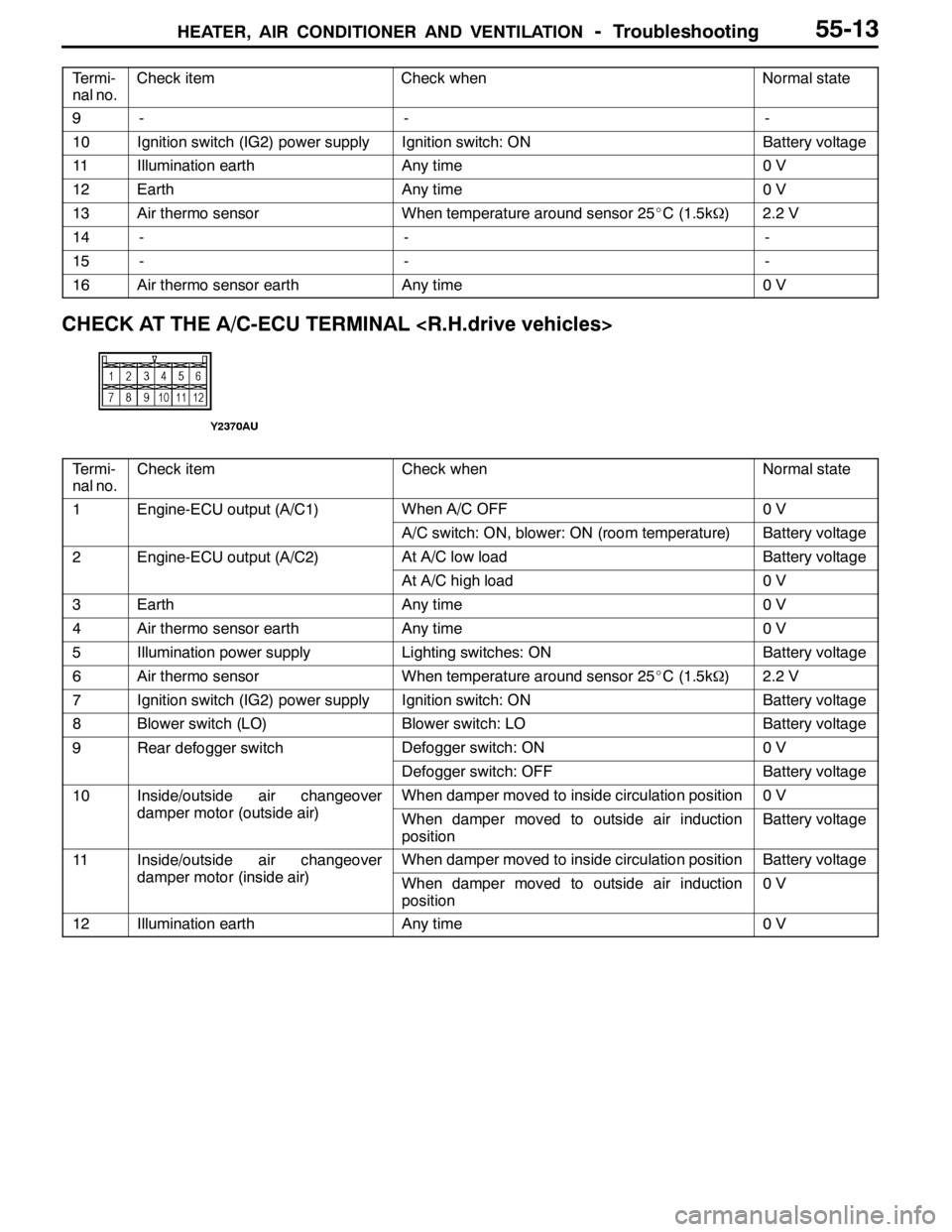

ItemState

Insufficient refriger-

antMany bubbles are seen. If refrigerant

is extremely low, it appears white.

Sufficient or excess

refrigerantNo bubbles are seen

NOTE

1. If insufficient, replenish the refrigerant as follows.

a) Replenish until bubbles disappear from the sight

glass.

b) After the bubbles disappear from the sight glass,

replenish 100g of refrigerant.

2. If excessive, replenish the refrigerant as follows.

a) Drain the refrigerant until bubbles can be seen

through the sight glass.

b) Replenish until bubbles disappear from the sight

glass.

c) After the bubbles disappear from the sight glass,

replenish 100g of refrigerant.

MAGNETIC CLUTCH TEST

1. Disconnect the connector to the magnetic clutch.

2. Connect battery (+) voltage directly to the connector for

the magnetic clutch.

3. If the magnetic clutch is normal, there will be ”click”. If

the pulley and armature do not make contact (’click’),

there is a malfunction.

RECEIVER DRIER TEST

Operate the unit and check the piping temperature by touching

the receiver drier outlet and inlet.

If there is a difference in the temperatures, the receiver drier

is restricted.

Replace the receiver drier.

Insufficient

refrigerantSufficient or excess

refrigerant

Bubbles

Page 1417 of 1449

HEATER, AIR CONDITIONER AND VENTILATION–On-vehicle Service55-15

COMPRESSOR DRIVE BELT ADJUSTMENT

Refer to GROUP 11 - On-vehicle Service.

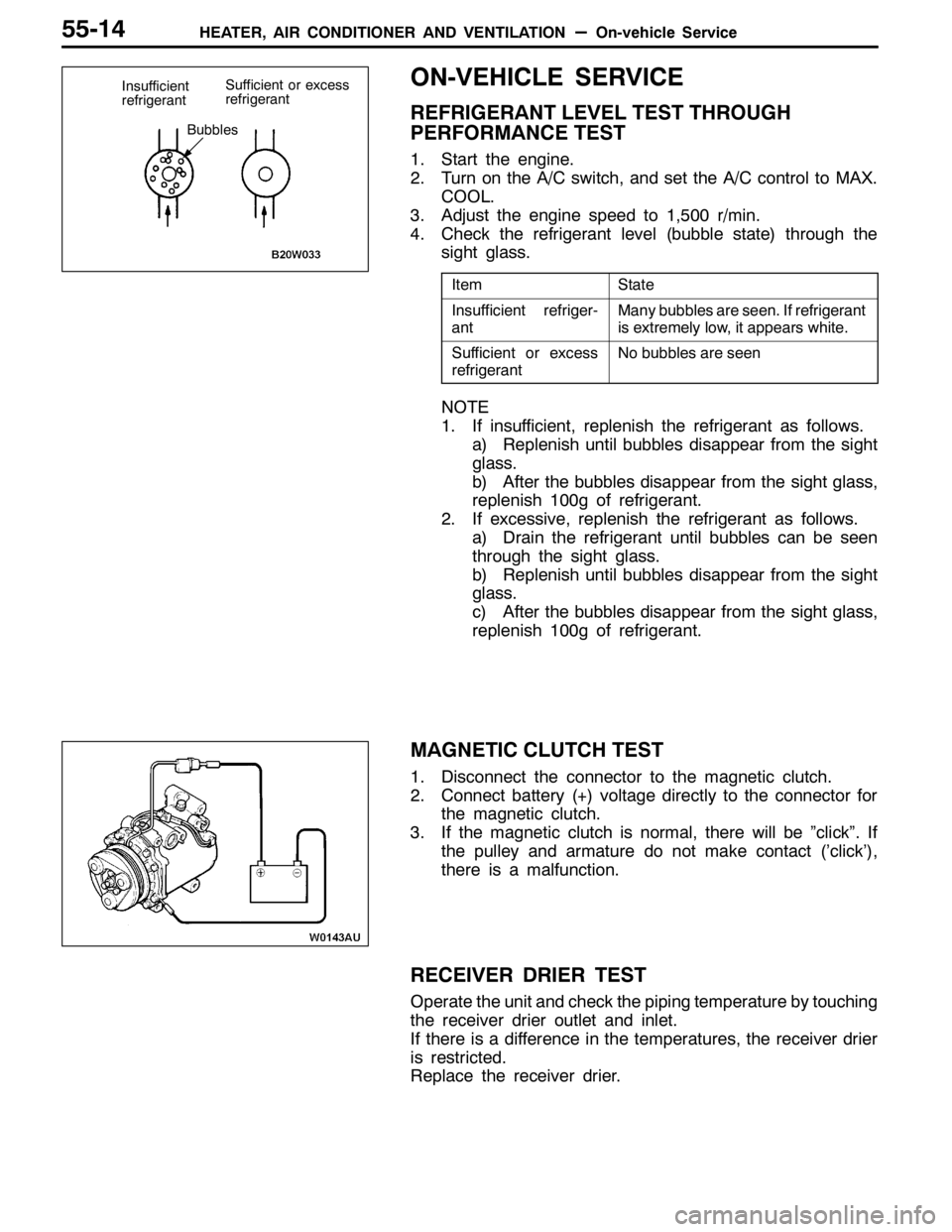

DUAL PRESSURE SWITCH CHECK

1. Remove the dual pressure switch connector and connect

the high/low pressure side terminals located on the

harness side as shown in the illustration.

2. Install a gauge manifold to the high

-pressure side service

valve of the refrigerant line. (Refer to 55-42.)

3. When the high/low pressure sides of the dual pressure

switch are at operation pressure (ON) and there is

continuity between the respective terminals, then the

condition is normal. If there is no continuity, replace the

switch.

Dual pressure switch

ON

OFF

19620

kPa

2202023523722940176

Hood support rod

Page 1418 of 1449

HEATER, AIR CONDITIONER AND VENTILATION–On-vehicle Service55-16

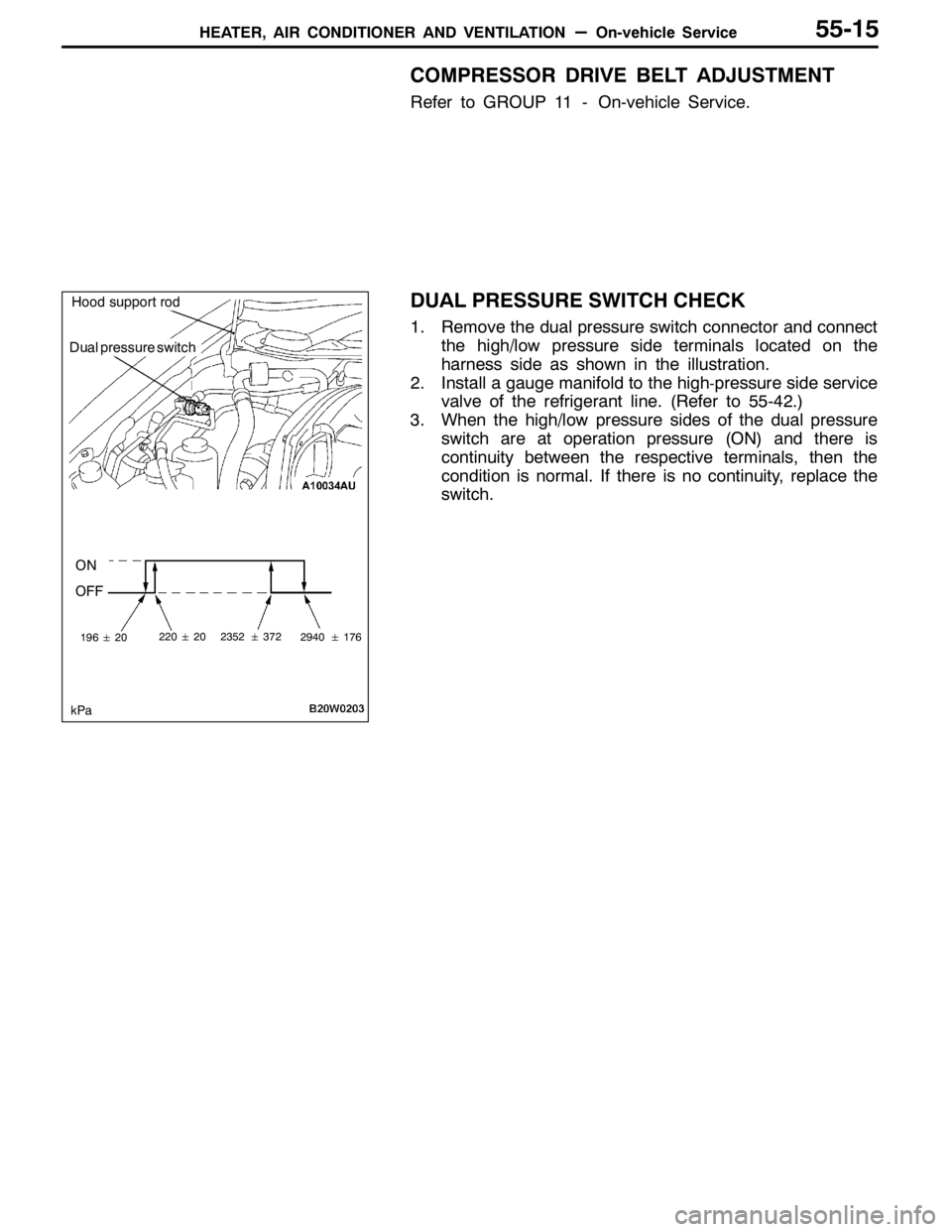

CHARGING

1. With the handles turned back all the way (valve closed),

install the adaptor valve to the low-pressure side of the

gauge manifold.

2. Connect the charging hose (blue) to the adaptor valve.

3. Connect the quick joint (for low

-pressure) to the charging

hose (blue).

4. Connect the quick joint (for low

-pressure) to the low-

pressure service valve.

NOTE

The low-pressure service valve should be connected to

the suction hose.

Caution

(1) Use tools that are suited to R134a.

(2) To install the quick joint, press section “A” firmly

against the service valve until a click is heard.

When connecting, run your hand along the hose

while pressing to ensure that there are no bends

in the hose.

5. Close the high and low

-pressure valves of the gauge

manifold.

6. Install the vacuum pump adaptor to the vacuum pump.

7. Connect the vacuum pump plug to the vacuum pump

adaptor.

8. Connect the charging hose (yellow) to the R-134a

connection port of the vacuum pump adaptor.

9. Tighten the adaptor valve handle (valve open).

10. Open the low

-pressure valve of the gauge manifold.

11. Turn the power switch of the vacuum pump to the ON

position.

NOTE

Even if the vacuum pump power switch is turned ON,

the vacuum pump will not operate because of the power

supply connection in step (7).

Low-pressure

valveHigh-pressure

valve

Gauge manifold

Adapter

valveCharging hose

(yellow)

Charging hose

(blue)

R-12

connection

portSwitch

R-134a

connection

port

Vacuum

pump

adaptor

Vacuum

pump

Power supply

plug

Switch Quick

joint (for

low pres-

sure)

Low-pressure

service valve

SleeveA

Page 1419 of 1449

HEATER, AIR CONDITIONER AND VENTILATION–On-vehicle Service55-17

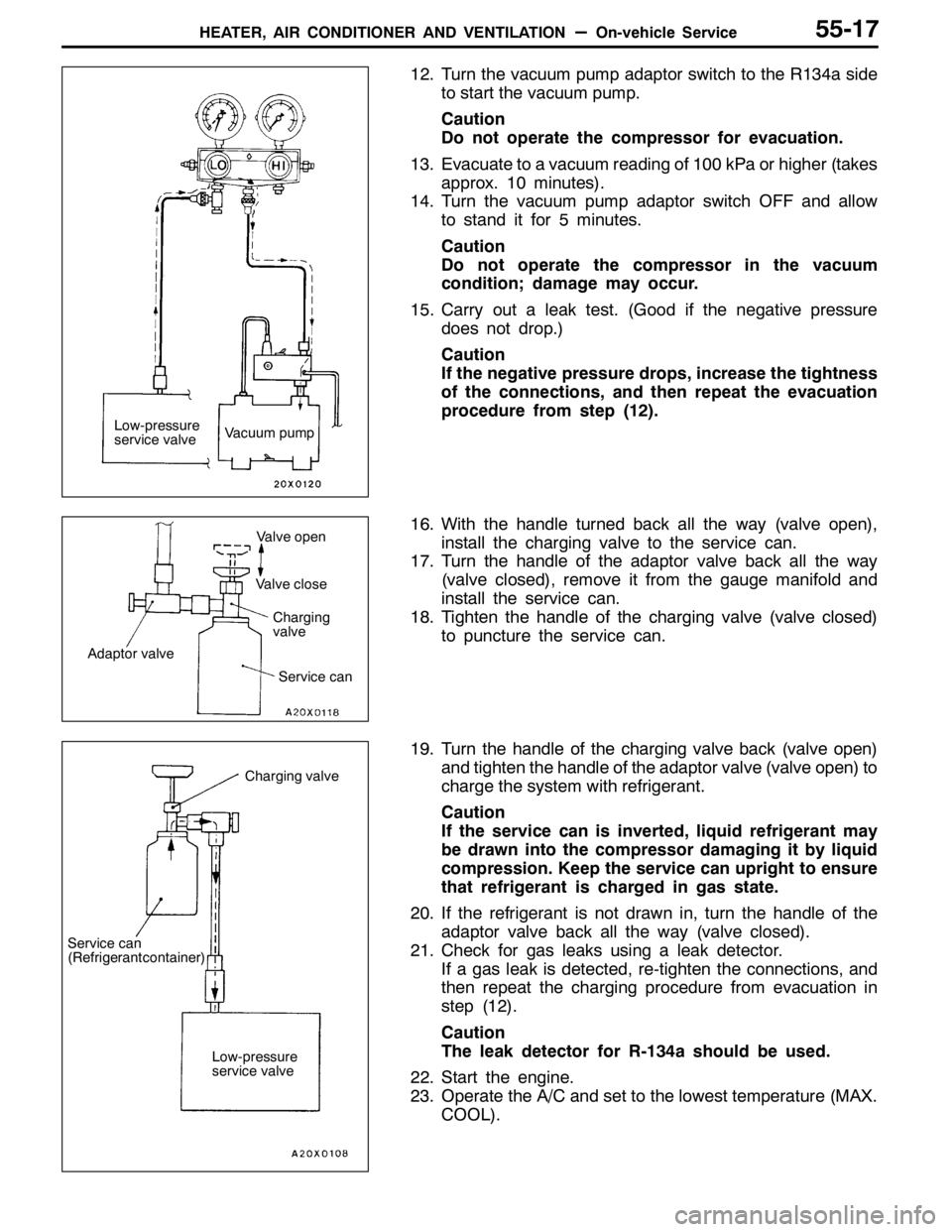

12. Turn the vacuum pump adaptor switch to the R134a side

to start the vacuum pump.

Caution

Do not operate the compressor for evacuation.

13. Evacuate to a vacuum reading of 100 kPa or higher (takes

approx. 10 minutes).

14. Turn the vacuum pump adaptor switch OFF and allow

to stand it for 5 minutes.

Caution

Do not operate the compressor in the vacuum

condition; damage may occur.

15. Carry out a leak test. (Good if the negative pressure

does not drop.)

Caution

If the negative pressure drops, increase the tightness

of the connections, and then repeat the evacuation

procedure from step (12).

16. With the handle turned back all the way (valve open),

install the charging valve to the service can.

17. Turn the handle of the adaptor valve back all the way

(valve closed), remove it from the gauge manifold and

install the service can.

18. Tighten the handle of the charging valve (valve closed)

to puncture the service can.

19. Turn the handle of the charging valve back (valve open)

and tighten the handle of the adaptor valve (valve open) to

charge the system with refrigerant.

Caution

If the service can is inverted, liquid refrigerant may

be drawn into the compressor damaging it by liquid

compression. Keep the service can upright to ensure

that refrigerant is charged in gas state.

20. If the refrigerant is not drawn in, turn the handle of the

adaptor valve back all the way (valve closed).

21. Check for gas leaks using a leak detector.

If a gas leak is detected, re-tighten the connections, and

then repeat the charging procedure from evacuation in

step (12).

Caution

The leak detector for R-134a should be used.

22. Start the engine.

23. Operate the A/C and set to the lowest temperature (MAX.

COOL).

Low-pressure

service valveVacuum pump

Adaptor valveValve open

Valve close

Charging

valve

Service can

Charging valve

Service can

(Refrigerant container)

Low-pressure

service valve

Page 1420 of 1449

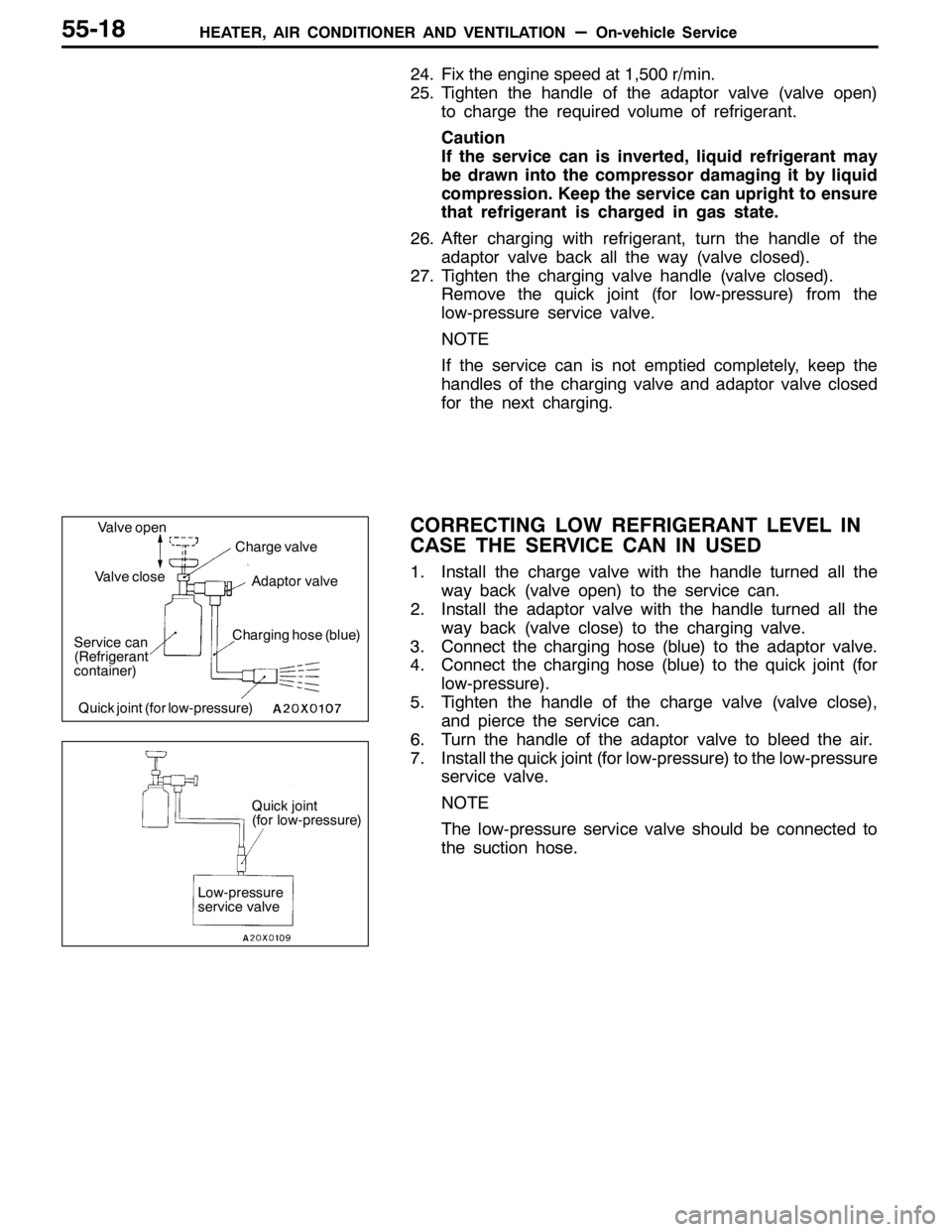

HEATER, AIR CONDITIONER AND VENTILATION–On-vehicle Service55-18

24. Fix the engine speed at 1,500 r/min.

25. Tighten the handle of the adaptor valve (valve open)

to charge the required volume of refrigerant.

Caution

If the service can is inverted, liquid refrigerant may

be drawn into the compressor damaging it by liquid

compression. Keep the service can upright to ensure

that refrigerant is charged in gas state.

26. After charging with refrigerant, turn the handle of the

adaptor valve back all the way (valve closed).

27. Tighten the charging valve handle (valve closed).

Remove the quick joint (for low-pressure) from the

low-pressure service valve.

NOTE

If the service can is not emptied completely, keep the

handles of the charging valve and adaptor valve closed

for the next charging.

CORRECTING LOW REFRIGERANT LEVEL IN

CASE THE SERVICE CAN IN USED

1. Install the charge valve with the handle turned all the

way back (valve open) to the service can.

2. Install the adaptor valve with the handle turned all the

way back (valve close) to the charging valve.

3. Connect the charging hose (blue) to the adaptor valve.

4. Connect the charging hose (blue) to the quick joint (for

low-pressure).

5. Tighten the handle of the charge valve (valve close),

and pierce the service can.

6. Turn the handle of the adaptor valve to bleed the air.

7. Install the quick joint (for low-pressure) to the low-pressure

service valve.

NOTE

The low-pressure service valve should be connected to

the suction hose.

Valve open

Valve close

Service can

(Refrigerant

container)Charge valve

Adaptor valve

Charging hose (blue)

Quick joint (for low-pressure)

Quick joint

(for low-pressure)

Low-pressure

service valve