radiator MITSUBISHI LANCER EVOLUTION 2007 Service User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 434 of 1449

ENGINE -Cylinder Head Gasket11A-28

CYLINDER HEAD GASKET

REMOVAL AND INSTALLATION

Caution

If the vehicle is equipped with the Brembo disc brake, during maintenance, take care not to contact

the parts or tools to the caliper because the paint of caliper will be scratched.

Pre-removal and Post-installation Operation

DFuel Outflow Preventive Operation (Refer to GROUP 13A - On-vehicle Service.)

DFuel Leak Check

DStrut Tower Bar Removal and Installation (Refer to GROUP 42.)

DUnder Cover Removal and Installation (Refer to GROUP 51 - Front Bumper.)

DDrive Belt Tension Check (Refer to P.11A-7.)

DAccelerator Cable Adjustment (Refer to GROUP 17 - On-vehicle Service.)

DDrainage and Refilling Engine Oil (Refer to GROUP 12 - On-vehicle Service.)

DDrainage and Refilling of Engine Coolant (Refer to GROUP 14 - On-vehicle Service.)

DAir Cleaner Assembly Removal and Installation (Refer to GROUP 15.)

DAir Hose E, Air Pipe C, Air hose D Removal and Installation (Refer to GROUP 15 - Intercooler.)

DBattery Removal and Installation

DCenter Cover Removal and Installation (Refer to P.11A-17.)

DAccelerator Cable Removal and Installation (Refer to GROUP 17.)

DRadiator Removal and Installation (Refer to GROUP 14.)

DSecondary Air Control Valve Bracket Removal and Installation (Refer to GROUP 15 - Secondary Air Supply System.)

DCrossmember Bar Removal and Installation (Refer to GROUP32 - Engine Roll Stopper, Centermember.)

DFront Exhaust Pipe Removal and Installation (Refer to GROUP 15.)

DStarter Removal and Installation (Refer to GROUP 16.)

DTiming Belt Removal and Installation (Refer to P.11A-34.)

Page 449 of 1449

ENGINE -Engine Assembly11A-43

ENGINE ASSEMBLY

REMOVAL AND INSTALLATION

Caution

1. If the vehicle is equipped with the Brembo disc brake, during maintenance, take care not to

contact the parts or tools to the caliper because the paint of caliper will be scratched.

2. Tightening sections indicated in the mark (*) should be finally tightened with engine weight

applied on the body after lightly tightening.

Pre-removal and Post-installation Operation

DFuel Outflow Preventive Operation (Refer to GROUP 13A - On-vehicle Service.)

DFuel Leak Check

DRemoval and Installation of Hood (Refer to GROUP 42.)

DRemoval and Installation of Strut Tower Bar (Refer to GROUP 42.)

DRemoval and Installation of Under Cover (Refer to GROUP 51 - Front Bumper.)

DRemoval and Installation of Side Cover.

DDrive Belt Tension Check (Refer to P.11A - 7.)

DAccelerator Cable Adjustment (Refer to GROUP 17 - On-vehicle Service.)

DDrainage and Refilling Engine Oil(Refer to GROUP 12 - On-vehicle Service.)

DDrainage and Refilling of Engine Coolant (Refer to GROUP 14 - On-vehicle Service.)

DAir Cleaner Removal and Installation (Refer to GROUP 15)

DRemoval and Installation of Air Pipe C, Air Pipe B and Air Hose A (Refer to GROUP 15 - Intercooler.)

DBattery and Battery Tray Removal and Installation

DRemoval and Installation of Center Cover (Refer to P.11A - 17.)

DRemoval and Installation of Accelerator Cable (Refer to GROUP 17.)

DRemoval and Installation of Radiator (Refer to GROUP 14.)

DRemoval and Installation of Crossmember Bar (Refer to GROUP 32 - Engine Roll Stopper, Centermember.)

DRemoval and Installation of Front Exhaust Pipe (Refer to GROUP 15.)

DRemoval and Installation of Air Outlet Fitting (Refer to GROUP 15 - Exhaust manifold.)

Page 536 of 1449

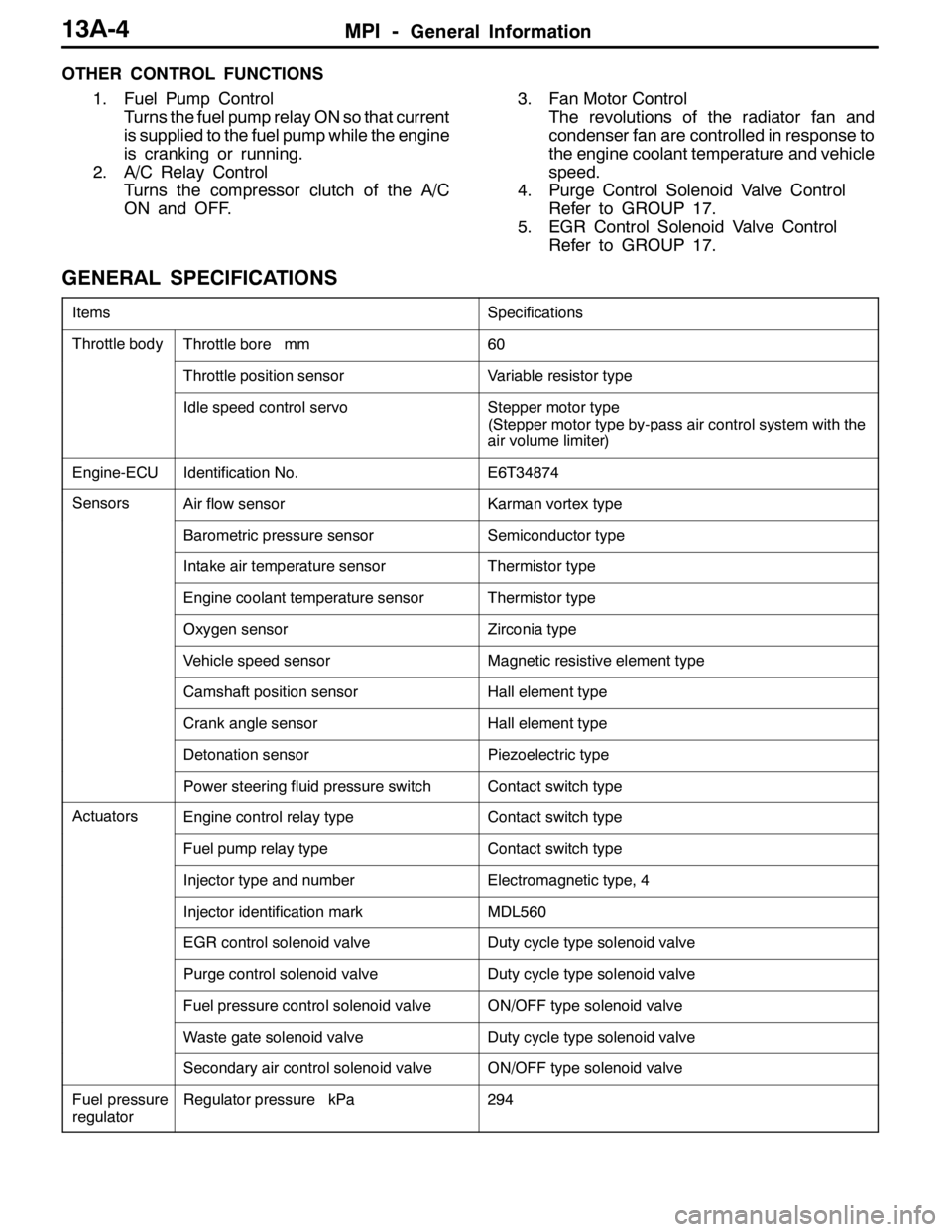

MPI -General Information13A-4

OTHER CONTROL FUNCTIONS

1. Fuel Pump Control

Turns the fuel pump relay ON so that current

is supplied to the fuel pump while the engine

is cranking or running.

2. A/C Relay Control

Turns the compressor clutch of the A/C

ON and OFF.3. Fan Motor Control

The revolutions of the radiator fan and

condenser fan are controlled in response to

the engine coolant temperature and vehicle

speed.

4. Purge Control Solenoid Valve Control

Refer to GROUP 17.

5. EGR Control Solenoid Valve Control

Refer to GROUP 17.

GENERAL SPECIFICATIONS

ItemsSpecifications

Throttle bodyThrottle bore mm60

Throttle position sensorVariable resistor type

Idle speed control servoStepper motor type

(Stepper motor type by-pass air control system with the

air volume limiter)

Engine-ECUIdentification No.E6T34874

SensorsAir flow sensorKarman vortex type

Barometric pressure sensorSemiconductor type

Intake air temperature sensorThermistor type

Engine coolant temperature sensorThermistor type

Oxygen sensorZirconia type

Vehicle speed sensorMagnetic resistive element type

Camshaft position sensorHall element type

Crank angle sensorHall element type

Detonation sensorPiezoelectric type

Power steering fluid pressure switchContact switch type

ActuatorsEngine control relay typeContact switch type

Fuel pump relay typeContact switch type

Injector type and numberElectromagnetic type, 4

Injector identification markMDL560

EGR control solenoid valveDuty cycle type solenoid valve

Purge control solenoid valveDuty cycle type solenoid valve

Fuel pressure control solenoid valveON/OFF type solenoid valve

Waste gate solenoid valveDuty cycle type solenoid valve

Secondary air control solenoid valveON/OFF type solenoid valve

Fuel pressure

regulatorRegulator pressure kPa294

Page 543 of 1449

MPI -TroubleshootingMPI -Troubleshooting13A-11

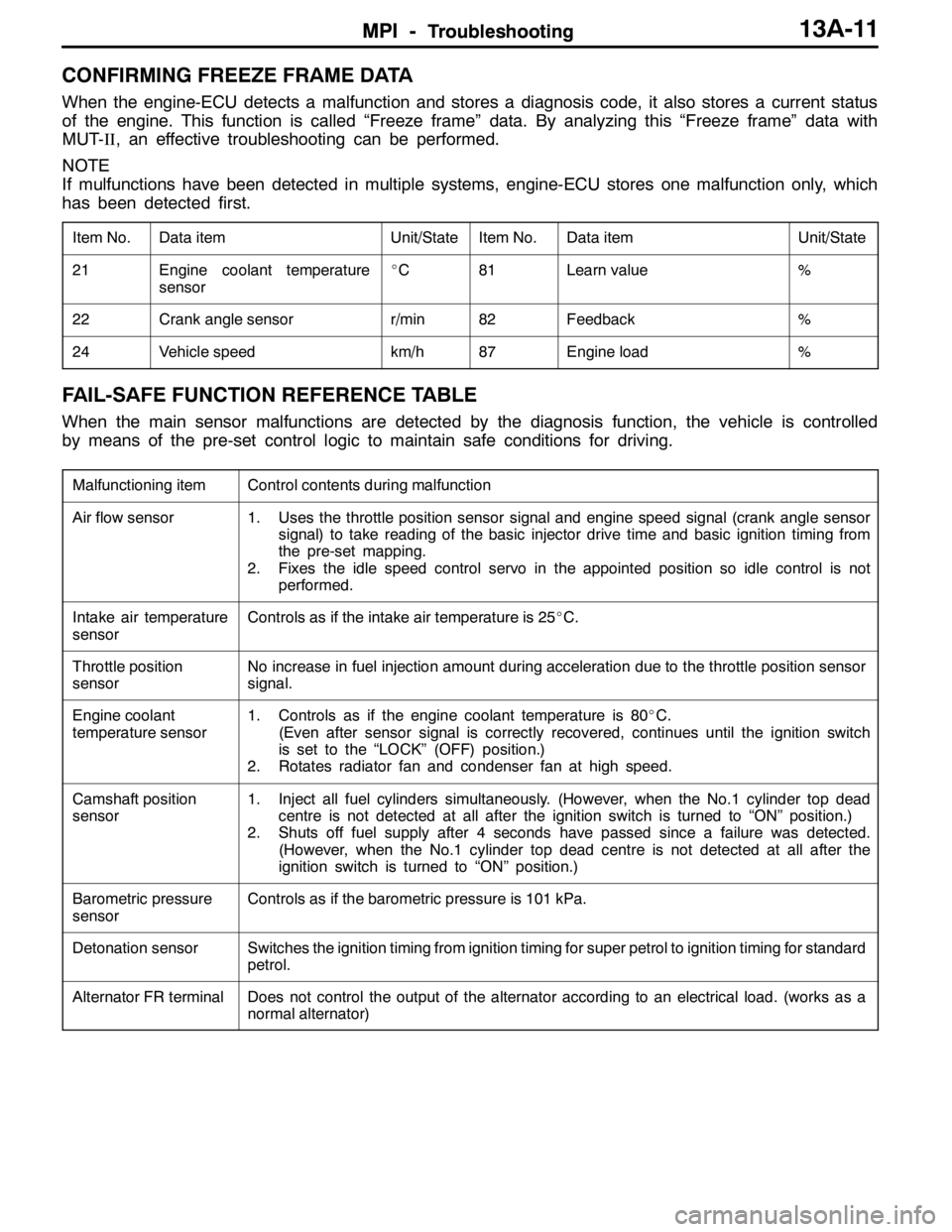

CONFIRMING FREEZE FRAME DATA

When the engine-ECU detects a malfunction and stores a diagnosis code, it also stores a current status

of the engine. This function is called “Freeze frame” data. By analyzing this “Freeze frame” data with

MUT-II, an effective troubleshooting can be performed.

NOTE

If mulfunctions have been detected in multiple systems, engine-ECU stores one malfunction only, which

has been detected first.

Item No.Data itemUnit/StateItem No.Data itemUnit/State

21Engine coolant temperature

sensor_C81Learn value%

22Crank angle sensorr/min82Feedback%

24Vehicle speedkm/h87Engine load%

FAIL-SAFE FUNCTION REFERENCE TABLE

When the main sensor malfunctions are detected by the diagnosis function, the vehicle is controlled

by means of the pre-set control logic to maintain safe conditions for driving.

Malfunctioning itemControl contents during malfunction

Air flow sensor1. Uses the throttle position sensor signal and engine speed signal (crank angle sensor

signal) to take reading of the basic injector drive time and basic ignition timing from

the pre-set mapping.

2. Fixes the idle speed control servo in the appointed position so idle control is not

performed.

Intake air temperature

sensorControls as if the intake air temperature is 25_C.

Throttle position

sensorNo increase in fuel injection amount during acceleration due to the throttle position sensor

signal.

Engine coolant

temperature sensor1. Controls as if the engine coolant temperature is 80_C.

(Even after sensor signal is correctly recovered, continues until the ignition switch

is set to the “LOCK” (OFF) position.)

2. Rotates radiator fan and condenser fan at high speed.

Camshaft position

sensor1. Inject all fuel cylinders simultaneously. (However, when the No.1 cylinder top dead

centre is not detected at all after the ignition switch is turned to “ON” position.)

2. Shuts off fuel supply after 4 seconds have passed since a failure was detected.

(However, when the No.1 cylinder top dead centre is not detected at all after the

ignition switch is turned to “ON” position.)

Barometric pressure

sensorControls as if the barometric pressure is 101 kPa.

Detonation sensorSwitches the ignition timing from ignition timing for super petrol to ignition timing for standard

petrol.

Alternator FR terminalDoes not control the output of the alternator according to an electrical load. (works as a

normal alternator)

Page 558 of 1449

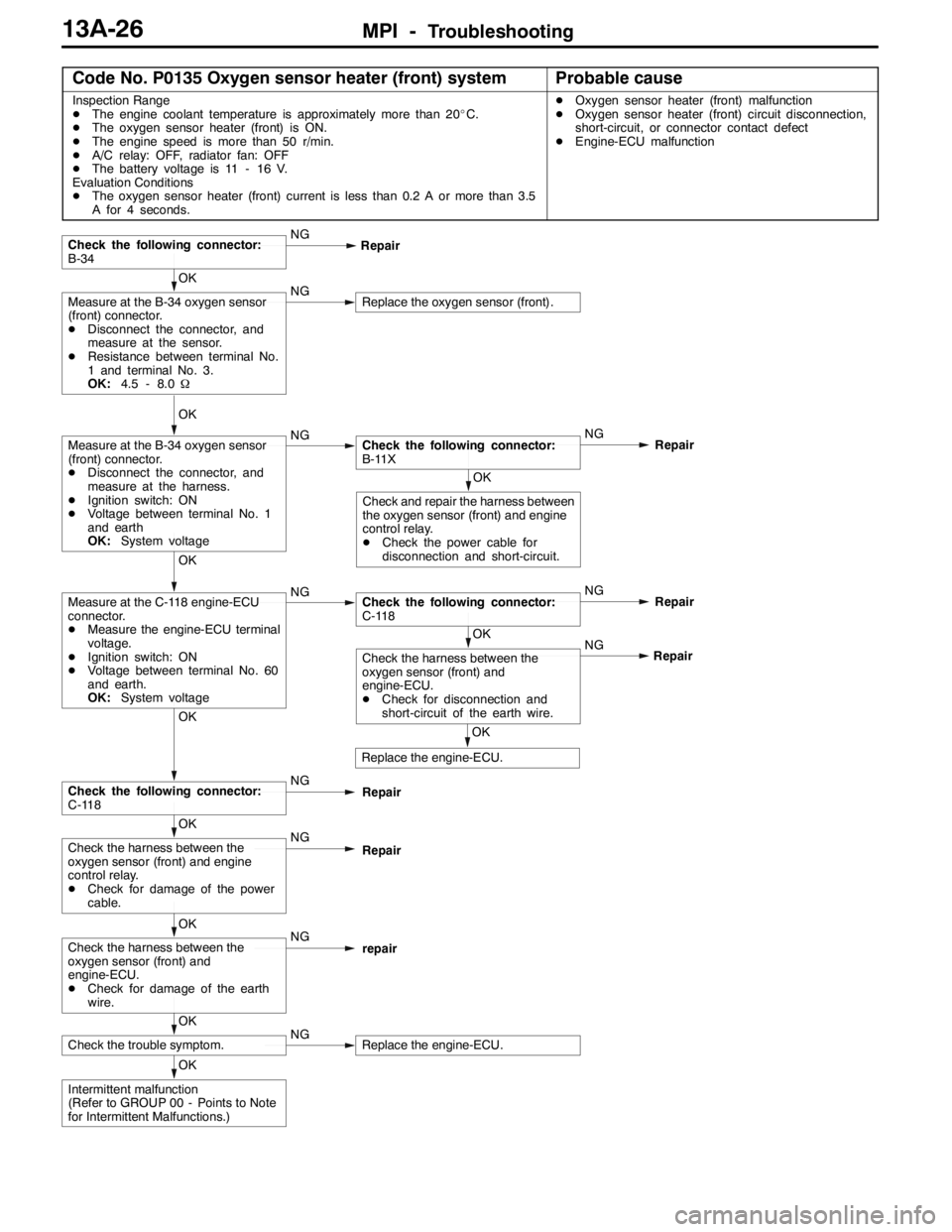

MPI -Troubleshooting13A-26

Code No. P0135 Oxygen sensor heater (front) systemProbable cause

Inspection Range

DThe engine coolant temperature is approximately more than 20_C.

DThe oxygen sensor heater (front) is ON.

DThe engine speed is more than 50 r/min.

DA/C relay: OFF, radiator fan: OFF

DThe battery voltage is 11 - 16 V.

Evaluation Conditions

DThe oxygen sensor heater (front) current is less than 0.2 A or more than 3.5

A for 4 seconds.DOxygen sensor heater (front) malfunction

DOxygen sensor heater (front) circuit disconnection,

short-circuit, or connector contact defect

DEngine-ECU malfunction

OK

Intermittent malfunction

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunctions.)

OK

Check the trouble symptom.NGReplace the engine-ECU.

OK

Check the harness between the

oxygen sensor (front) and

engine-ECU.

DCheck for damage of the earth

wire.NG

repair

OK

Check the harness between the

oxygen sensor (front) and engine

control relay.

DCheck for damage of the power

cable.NG

Repair

OK

Check the following connector:

C-118NG

Repair

OK

Replace the engine-ECU.NG

OK

Check the harness between the

oxygen sensor (front) and

engine-ECU.

DCheck for disconnection and

short-circuit of the earth wire.Repair

OK

Measure at the C-118 engine-ECU

connector.

DMeasure the engine-ECU terminal

voltage.

DIgnition switch: ON

DVoltage between terminal No. 60

and earth.

OK:System voltageNGCheck the following connector:

C-118NG

Repair

OK

Check and repair the harness between

the oxygen sensor (front) and engine

control relay.

DCheck the power cable for

disconnection and short-circuit.

OK

Measure at the B-34 oxygen sensor

(front) connector.

DDisconnect the connector, and

measure at the harness.

DIgnition switch: ON

DVoltage between terminal No. 1

and earth

OK:System voltageNGCheck the following connector:

B-11XNG

Repair

OK

Measure at the B-34 oxygen sensor

(front) connector.

DDisconnect the connector, and

measure at the sensor.

DResistance between terminal No.

1 and terminal No. 3.

OK:4.5 - 8.0ΩNGReplace the oxygen sensor (front).

Check the following connector:

B-34NG

Repair

Page 561 of 1449

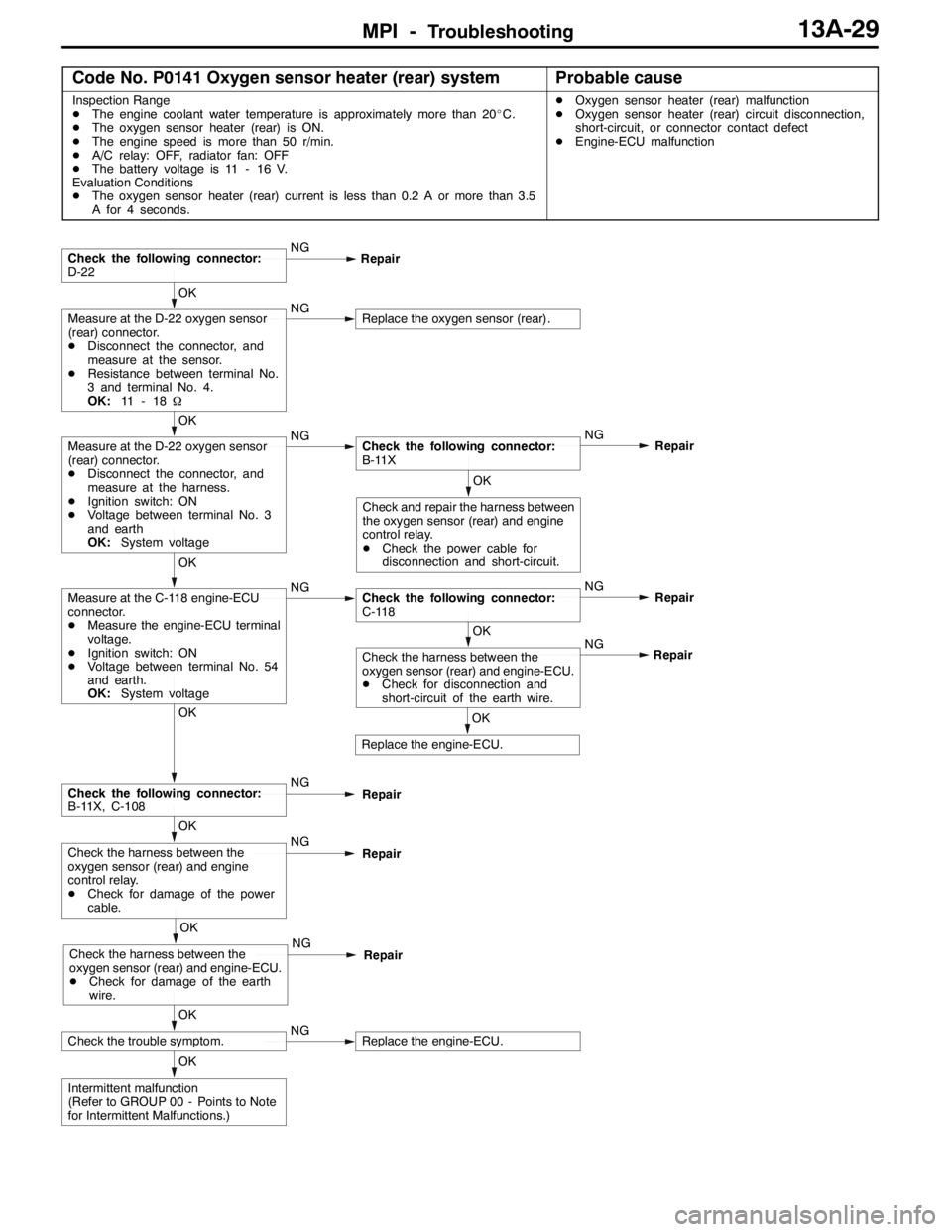

MPI -Troubleshooting13A-29

Code No. P0141 Oxygen sensor heater (rear) systemProbable cause

Inspection Range

DThe engine coolant water temperature is approximately more than 20_C.

DThe oxygen sensor heater (rear) is ON.

DThe engine speed is more than 50 r/min.

DA/C relay: OFF, radiator fan: OFF

DThe battery voltage is 11 - 16 V.

Evaluation Conditions

DThe oxygen sensor heater (rear) current is less than 0.2 A or more than 3.5

A for 4 seconds.DOxygen sensor heater (rear) malfunction

DOxygen sensor heater (rear) circuit disconnection,

short-circuit, or connector contact defect

DEngine-ECU malfunction

OK

Intermittent malfunction

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunctions.)

OK

Check the trouble symptom.NGReplace the engine-ECU.

OK

Check the harness between the

oxygen sensor (rear) and engine-ECU.

DCheck for damage of the earth

wire.NG

Repair

OK

Check the harness between the

oxygen sensor (rear) and engine

control relay.

DCheck for damage of the power

cable.NG

Repair

OK

Check the following connector:

B-11X, C-108NG

Repair

OK

Replace the engine-ECU.NG

OK

Check the harness between the

oxygen sensor (rear) and engine-ECU.

DCheck for disconnection and

short-circuit of the earth wire.Repair

OK

Measure at the C-118 engine-ECU

connector.

DMeasure the engine-ECU terminal

voltage.

DIgnition switch: ON

DVoltage between terminal No. 54

and earth.

OK:System voltageNGCheck the following connector:

C-118NG

Repair

OK

Check and repair the harness between

the oxygen sensor (rear) and engine

control relay.

DCheck the power cable for

disconnection and short-circuit.

OK

Measure at the D-22 oxygen sensor

(rear) connector.

DDisconnect the connector, and

measure at the harness.

DIgnition switch: ON

DVoltage between terminal No. 3

and earth

OK:System voltageNGCheck the following connector:

B-11XNG

Repair

OK

Measure at the D-22 oxygen sensor

(rear) connector.

DDisconnect the connector, and

measure at the sensor.

DResistance between terminal No.

3 and terminal No. 4.

OK:11 - 1 8ΩNGReplace the oxygen sensor (rear).

Check the following connector:

D-22NG

Repair

Page 581 of 1449

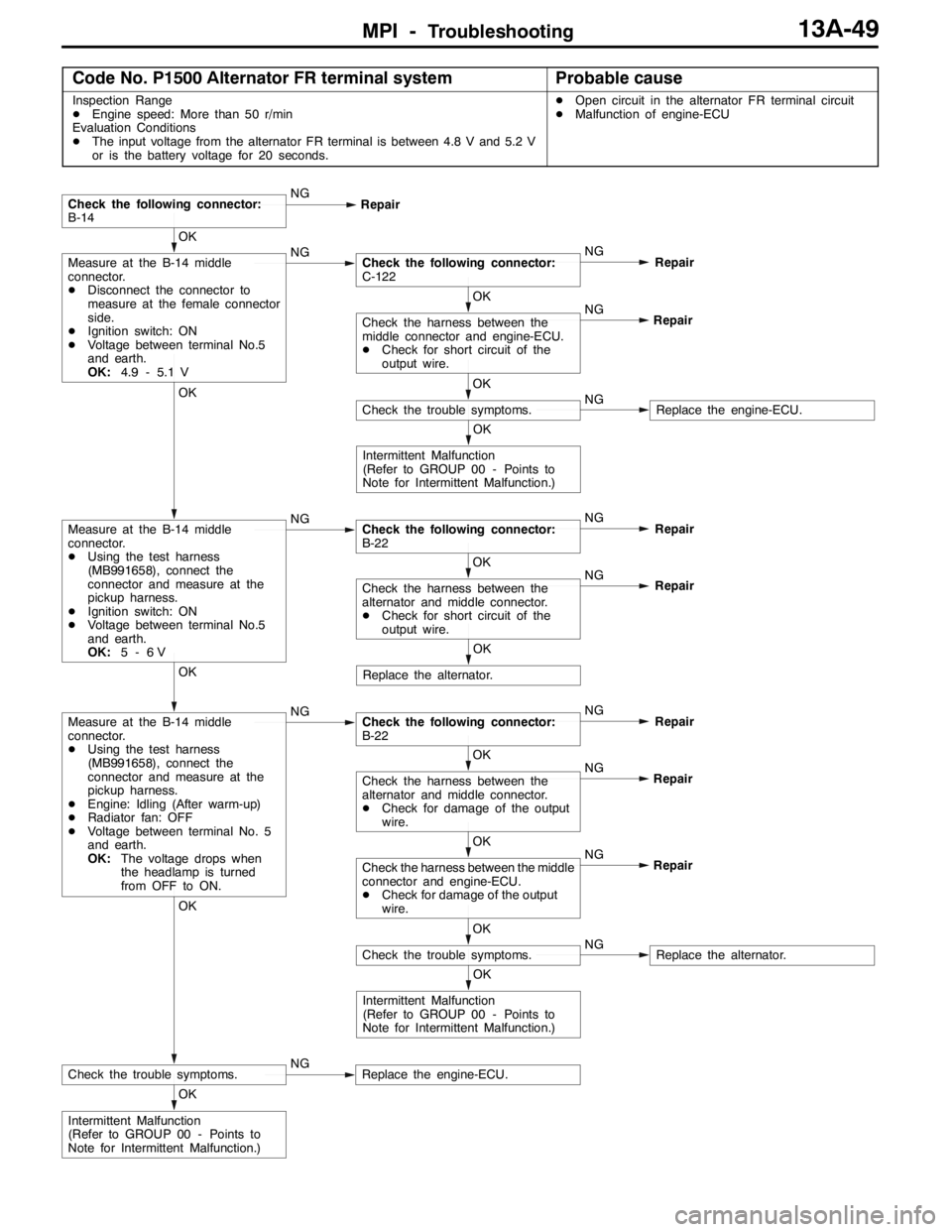

MPI -Troubleshooting13A-49

Code No. P1500 Alternator FR terminal systemProbable cause

Inspection Range

DEngine speed: More than 50 r/min

Evaluation Conditions

DThe input voltage from the alternator FR terminal is between 4.8 V and 5.2 V

or is the battery voltage for 20 seconds.DOpen circuit in the alternator FR terminal circuit

DMalfunction of engine-ECU

OK

Intermittent Malfunction

(Refer to GROUP 00 - Points to

Note for Intermittent Malfunction.)

OK

Check the trouble symptoms.NGReplace the engine-ECU.

OK

Intermittent Malfunction

(Refer to GROUP 00 - Points to

Note for Intermittent Malfunction.)

OK

Check the trouble symptoms.NGReplace the alternator. NG

OK

Check the harness between the middle

connector and engine-ECU.

DCheck for damage of the output

wire.Repair NG

OK

Check the harness between the

alternator and middle connector.

DCheck for damage of the output

wire.Repair

OK

Measure at the B-14 middle

connector.

DUsing the test harness

(MB991658), connect the

connector and measure at the

pickup harness.

DEngine: Idling (After warm-up)

DRadiator fan: OFF

DVoltage between terminal No. 5

and earth.

OK:The voltage drops when

the headlamp is turned

from OFF to ON.NGCheck the following connector:

B-22NG

Repair

OK

Replace the alternator.NG

OK

Check the harness between the

alternator and middle connector.

DCheck for short circuit of the

output wire.Repair

OK

Measure at the B-14 middle

connector.

DUsing the test harness

(MB991658), connect the

connector and measure at the

pickup harness.

DIgnition switch: ON

DVoltage between terminal No.5

and earth.

OK:5-6VNGCheck the following connector:

B-22NG

Repair

OK

Intermittent Malfunction

(Refer to GROUP 00 - Points to

Note for Intermittent Malfunction.)

OK

Check the trouble symptoms.NGReplace the engine-ECU. NG

OK

Check the harness between the

middle connector and engine-ECU.

DCheck for short circuit of the

output wire.Repair

OK

Measure at the B-14 middle

connector.

DDisconnect the connector to

measure at the female connector

side.

DIgnition switch: ON

DVoltage between terminal No.5

and earth.

OK:4.9 - 5.1 VNGCheck the following connector:

C-122NG

Repair

Check the following connector:

B-14NG

Repair

Page 584 of 1449

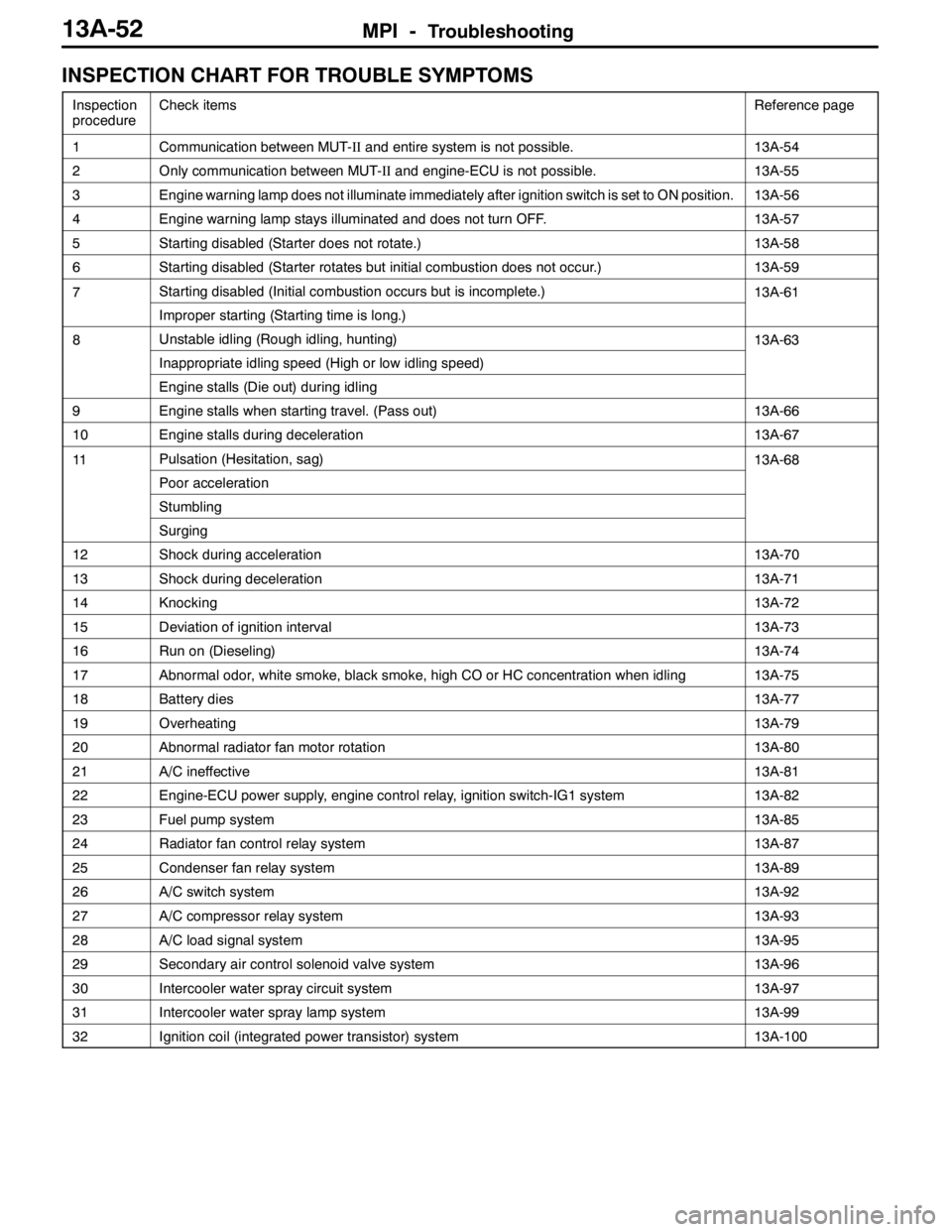

MPI -Troubleshooting13A-52

INSPECTION CHART FOR TROUBLE SYMPTOMS

Inspection

procedureCheck itemsReference page

1Communication between MUT-IIand entire system is not possible.13A-54

2Only communication between MUT-IIand engine-ECU is not possible.13A-55

3Engine warning lamp does not illuminate immediately after ignition switch is set to ON position.13A-56

4Engine warning lamp stays illuminated and does not turn OFF.13A-57

5Starting disabled (Starter does not rotate.)13A-58

6Starting disabled (Starter rotates but initial combustion does not occur.)13A-59

7Starting disabled (Initial combustion occurs but is incomplete.)13A-61

Improper starting (Starting time is long.)

8Unstable idling (Rough idling, hunting)13A-63

Inappropriate idling speed (High or low idling speed)

Engine stalls (Die out) during idling

9Engine stalls when starting travel. (Pass out)13A-66

10Engine stalls during deceleration13A-67

11Pulsation (Hesitation, sag)13A-68

Poor acceleration

Stumbling

Surging

12Shock during acceleration13A-70

13Shock during deceleration13A-71

14Knocking13A-72

15Deviation of ignition interval13A-73

16Run on (Dieseling)13A-74

17Abnormal odor, white smoke, black smoke, high CO or HC concentration when idling13A-75

18Battery dies13A-77

19Overheating13A-79

20Abnormal radiator fan motor rotation13A-80

21A/C ineffective13A-81

22Engine-ECU power supply, engine control relay, ignition switch-IG1 system13A-82

23Fuel pump system13A-85

24Radiator fan control relay system13A-87

25Condenser fan relay system13A-89

26A/C switch system13A-92

27A/C compressor relay system13A-93

28A/C load signal system13A-95

29Secondary air control solenoid valve system13A-96

30Intercooler water spray circuit system13A-97

31Intercooler water spray lamp system13A-99

32Ignition coil (integrated power transistor) system13A-100

Page 596 of 1449

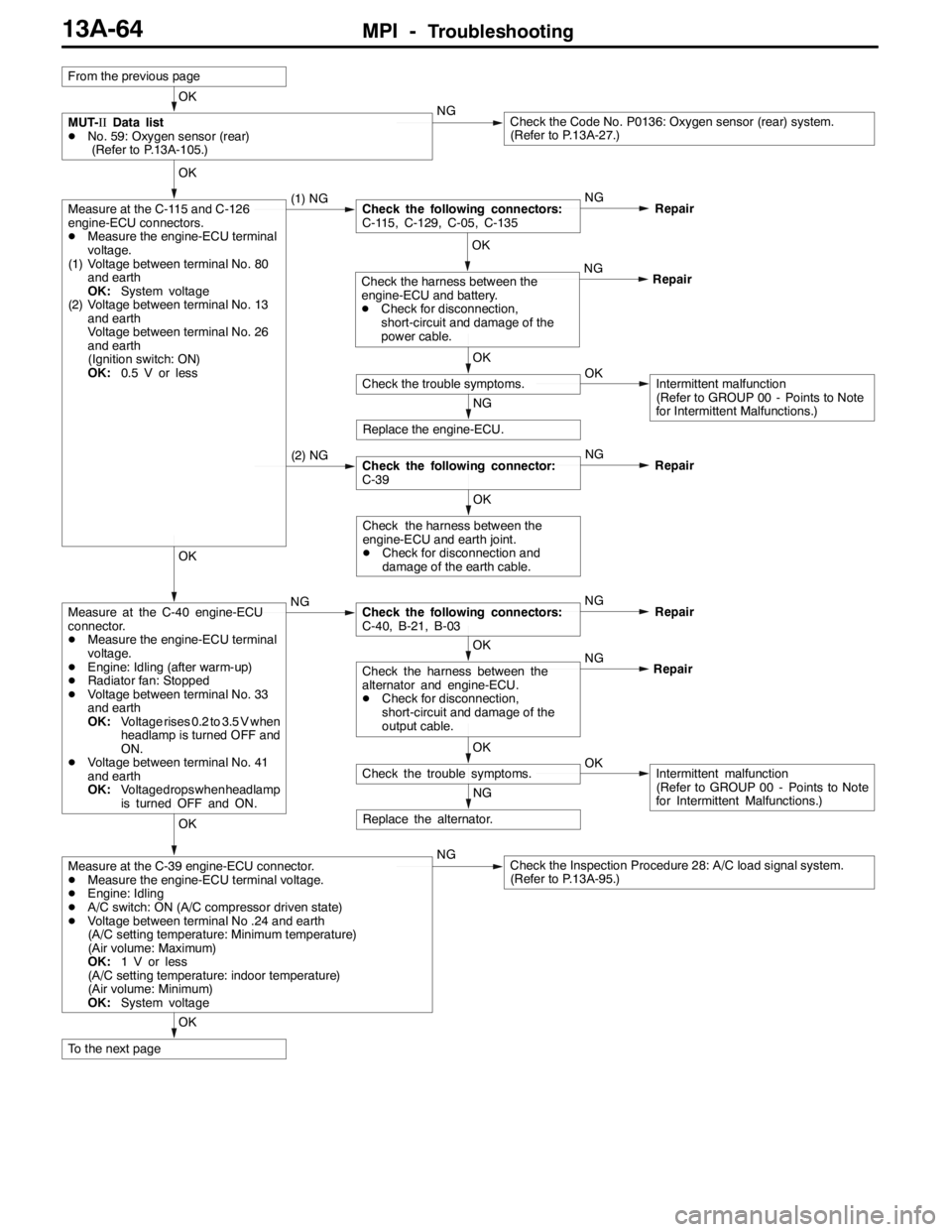

MPI -Troubleshooting13A-64

OK

To the next page

OK

Measure at the C-39 engine-ECU connector.

DMeasure the engine-ECU terminal voltage.

DEngine: Idling

DA/C switch: ON (A/C compressor driven state)

DVoltage between terminal No .24 and earth

(A/C setting temperature: Minimum temperature)

(Air volume: Maximum)

OK:1 V or less

(A/C setting temperature: indoor temperature)

(Air volume: Minimum)

OK:System voltageNGCheck the Inspection Procedure 28: A/C load signal system.

(Refer to P.13A-95.)

NG

Replace the alternator.

OK

Check the trouble symptoms.OKIntermittent malfunction

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunctions.) NG

OK

Check the harness between the

alternator and engine-ECU.

DCheck for disconnection,

short-circuit and damage of the

output cable.Repair

OK

Measure at the C-40 engine-ECU

connector.

DMeasure the engine-ECU terminal

voltage.

DEngine: Idling (after warm-up)

DRadiator fan: Stopped

DVoltage between terminal No. 33

and earth

OK:Voltage rises 0.2 to 3.5 V when

headlamp is turned OFF and

ON.

DVoltage between terminal No. 41

and earth

OK:Voltage drops whenheadlamp

is turned OFF and ON.NGCheck the following connectors:

C-40, B-21, B-03NG

Repair

OK

Check the harness between the

engine-ECU and earth joint.

DCheck for disconnection and

damage of the earth cable.

(2) NGCheck the following connector:

C-39NG

Repair

NG

Replace the engine-ECU.

OK

Check the trouble symptoms.OKIntermittent malfunction

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunctions.) NG

OK

Check the harness between the

engine-ECU and battery.

DCheck for disconnection,

short-circuit and damage of the

power cable.Repair

OK

Measure at the C-115 and C-126

engine-ECU connectors.

DMeasure the engine-ECU terminal

voltage.

(1) Voltage between terminal No. 80

and earth

OK:System voltage

(2) Voltage between terminal No. 13

and earth

Voltage between terminal No. 26

and earth

(Ignition switch: ON)

OK:0.5 V or less(1) NGCheck the following connectors:

C-115, C-129, C-05, C-135NG

Repair

OK

MUT-IIData list

DNo. 59: Oxygen sensor (rear)

(Refer to P.13A-105.)NGCheck the Code No. P0136: Oxygen sensor (rear) system.

(Refer to P.13A-27.)

From the previous page

Page 610 of 1449

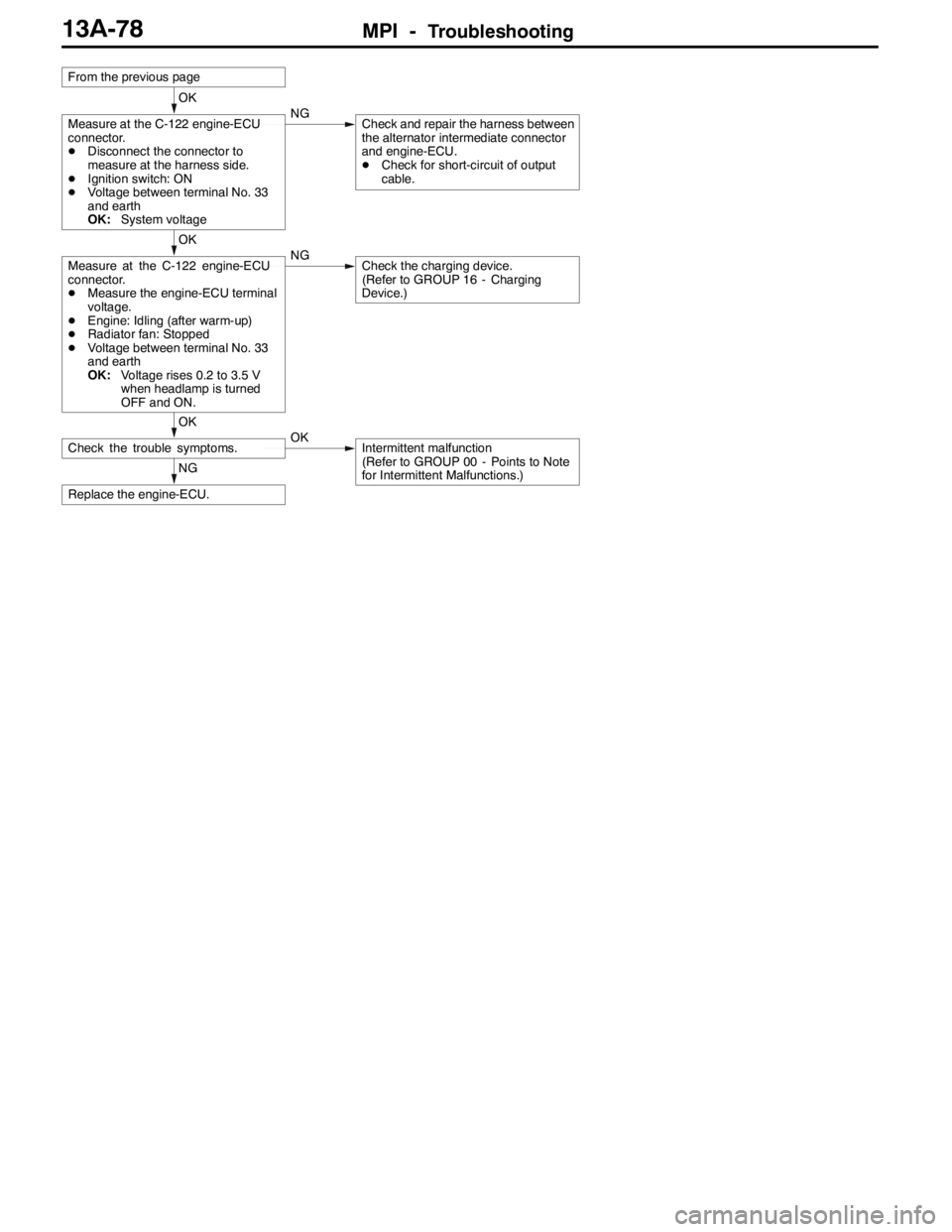

MPI -Troubleshooting13A-78

NG

Replace the engine-ECU.

OK

Check the trouble symptoms.OKIntermittent malfunction

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunctions.)

OK

Measure at the C-122 engine-ECU

connector.

DMeasure the engine-ECU terminal

voltage.

DEngine: Idling (after warm-up)

DRadiator fan: Stopped

DVoltage between terminal No. 33

and earth

OK:Voltage rises 0.2 to 3.5 V

when headlamp is turned

OFF and ON.NGCheck the charging device.

(Refer to GROUP 16 - Charging

Device.)

OK

Measure at the C-122 engine-ECU

connector.

DDisconnect the connector to

measure at the harness side.

DIgnition switch: ON

DVoltage between terminal No. 33

and earth

OK:System voltageNGCheck and repair the harness between

the alternator intermediate connector

and engine-ECU.

DCheck for short-circuit of output

cable.

From the previous page