radiator MITSUBISHI LANCER EVOLUTION 2007 Service Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 611 of 1449

MPI -Troubleshooting13A-79

Inspection Procedure 19

Overheating

Probable cause

Causes shown on right are suspected.DEngine coolant insufficient or deteriorated

DFan controller malfunction

DEngine coolant temperature sensor malfunction

DThermostat malfunction

DWater pump malfunction

DCondenser fan relay malfunction

DRadiator core malfunction

DEngine-ECU malfunction

NO

NG

Replace or replenish the engine coolant.

OK

Replace the radiator core.

OK

Check the water pump. (Refer to GROUP 14 - Water pump.)NGReplace the water pump.

OK

Check the thermostat. (Refer to GROUP 14 - Thermostat.)NGReplace the thermostat.

OK

MUT-IIData list

DNo. 21: Engine coolant temperaure sensor

OK:Approximately the same as the ambient temperature

when cooled.

Between 80 - 120_C when hot.NGCheck the Code No. P0115: Engine coolant temperature

sensor system. (Refer to P.13A-19.)

MUT-IIData list

21 Engine coolant temperature sensor (Refer to P.13A-102.)

OK

MUT-IIActuator Test

DNo. 37: Condenser fan (HI)

DNo. 38: Condenser fan (LOW)

DIgnition switch: ON

OK:Condenser fan rotates (low speed).

OK:Condenser fan rotates (high speed).NGCheck the Inspection Procedure 25: Condenser fan control

relay system. (Refer to P.13A-89.)

MUT-IIActuator Test

DNo. 21: Fan controller

DIgnition switch: ON

OK:Radiator fan rotates.NGCheck the Inspection Procedure 24: Radiator fan control relay

system. (Refer to P.13A-87.)

OK

Check the engine coolant.

(Refer to GROUP 14 - On-vehicle Service.)

If the engine coolant level is low, check whether the engine

coolant has leaked, and repair if required.

MUT-IISelf-Diag Code

Is a diagnosis code output?YESINSPECTION CHART FOR DIAGNOSIS CODE (Refer to

P.13A-12.)

Page 612 of 1449

MPI -Troubleshooting13A-80

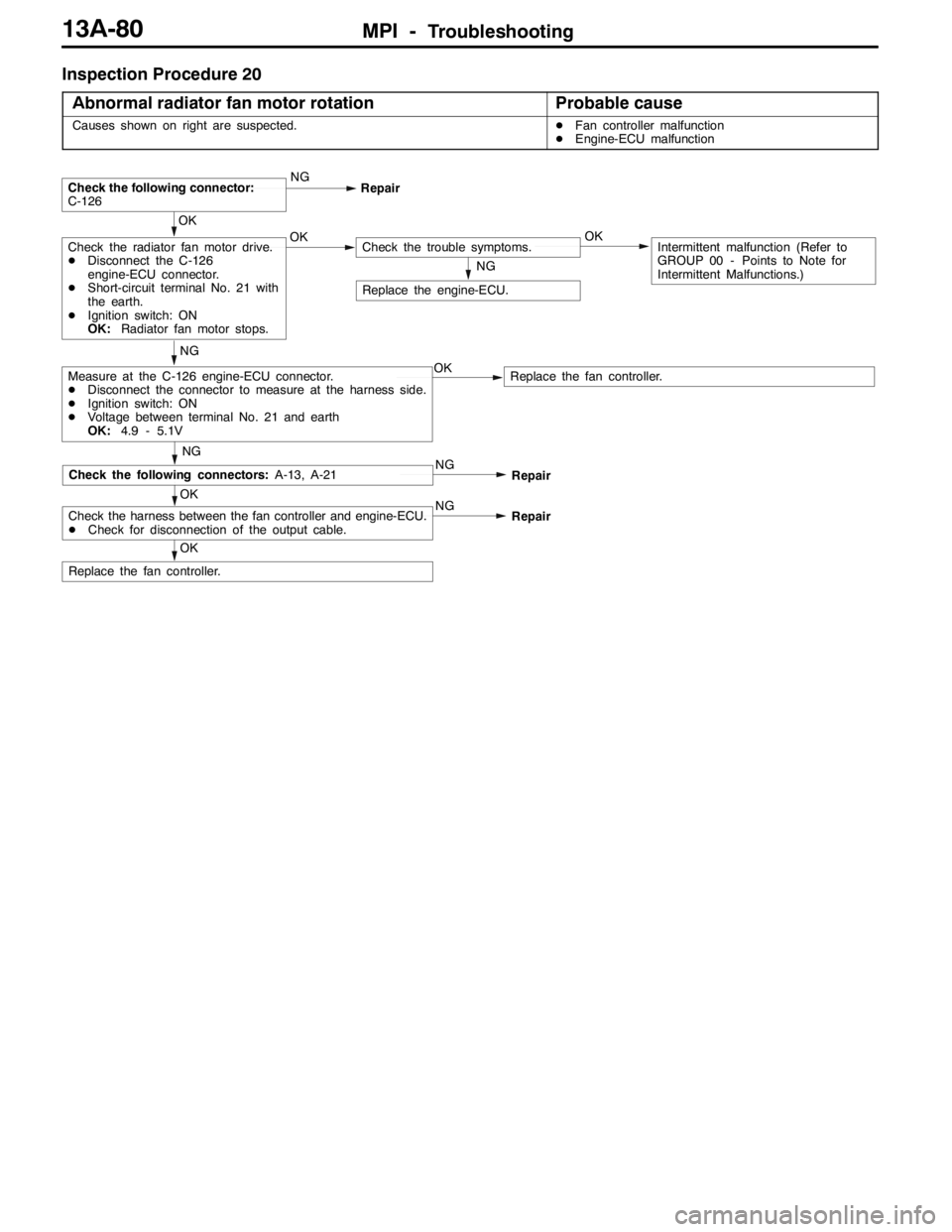

Inspection Procedure 20

Abnormal radiator fan motor rotation

Probable cause

Causes shown on right are suspected.DFan controller malfunction

DEngine-ECU malfunction

Intermittent malfunction (Refer to

GROUP 00 - Points to Note for

Intermittent Malfunctions.)OK

Replace the engine-ECU.

OK

Check the radiator fan motor drive.

DDisconnect the C-126

engine-ECU connector.

DShort-circuit terminal No. 21 with

the earth.

DIgnition switch: ON

OK:Radiator fan motor stops.NGCheck the trouble symptoms.

Check the following connector:

C-126NG

Repair

OK

NG

Measure at the C-126 engine-ECU connector.

DDisconnect the connector to measure at the harness side.

DIgnition switch: ON

DVoltage between terminal No. 21 and earth

OK:4.9 - 5.1VReplace the fan controller. NG

OK

NG

Repair

NGRepair

Replace the fan controller.

Check the following connectors:A-13, A-21

Check the harness between the fan controller and engine-ECU.

DCheck for disconnection of the output cable.OK

OK

Page 619 of 1449

MPI -Troubleshooting13A-87

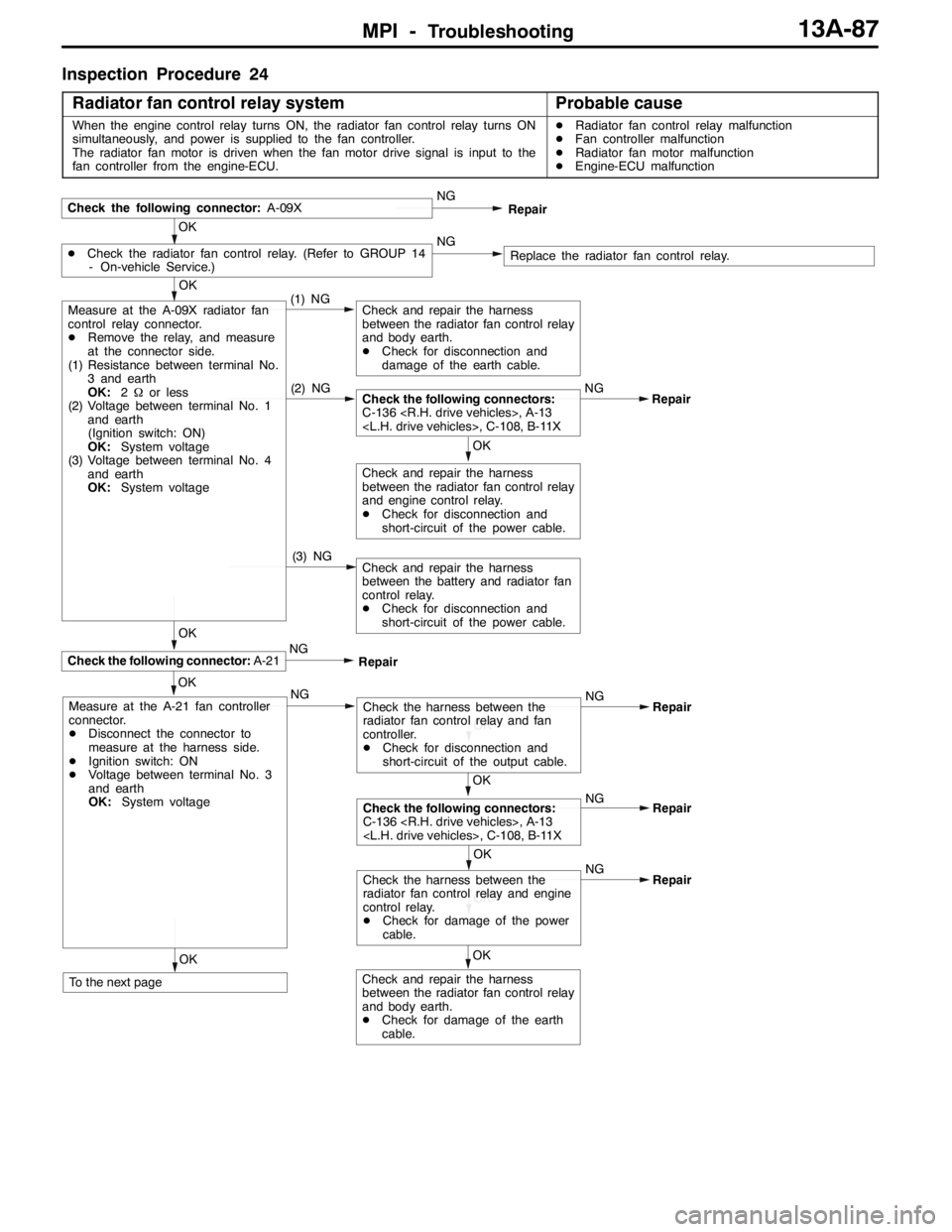

Inspection Procedure 24

Radiator fan control relay system

Probable cause

When the engine control relay turns ON, the radiator fan control relay turns ON

simultaneously, and power is supplied to the fan controller.

The radiator fan motor is driven when the fan motor drive signal is input to the

fan controller from the engine-ECU.DRadiator fan control relay malfunction

DFan controller malfunction

DRadiator fan motor malfunction

DEngine-ECU malfunction

OK

(1) NG

OK

DCheck the radiator fan control relay. (Refer to GROUP 14

- On-vehicle Service.)NGReplace the radiator fan control relay.

Check the following connector:A-09XNG

Repair

OK

OK

(2) NGCheck the following connectors:

C-136

OK

Check and repair the harness

between the radiator fan control relay

and body earth.

DCheck for disconnection and

damage of the earth cable.

Repair

OK

Check the following connector:A-21

Check and repair the harness

between the radiator fan control relay

and engine control relay.

DCheck for disconnection and

short-circuit of the power cable.

(3) NGCheck and repair the harness

between the battery and radiator fan

control relay.

DCheck for disconnection and

short-circuit of the power cable.

Measure at the A-09X radiator fan

control relay connector.

DRemove the relay, and measure

at the connector side.

(1) Resistance between terminal No.

3 and earth

OK:2Ωor less

(2) Voltage between terminal No. 1

and earth

(Ignition switch: ON)

OK:System voltage

(3) Voltage between terminal No. 4

and earth

OK:System voltage

NG

Repair

OK

Measure at the A-21 fan controller

connector.

DDisconnect the connector to

measure at the harness side.

DIgnition switch: ON

DVoltage between terminal No. 3

and earth

OK:System voltage

To the next pageNG

OK

Check the harness between the

radiator fan control relay and fan

controller.

DCheck for disconnection and

short-circuit of the output cable.NG

Repair

OK

Check the following connectors:

C-136

Repair

OK

OK

Check the harness between the

radiator fan control relay and engine

control relay.

DCheck for damage of the power

cable.NG

Repair

Check and repair the harness

between the radiator fan control relay

and body earth.

DCheck for damage of the earth

cable.

Page 620 of 1449

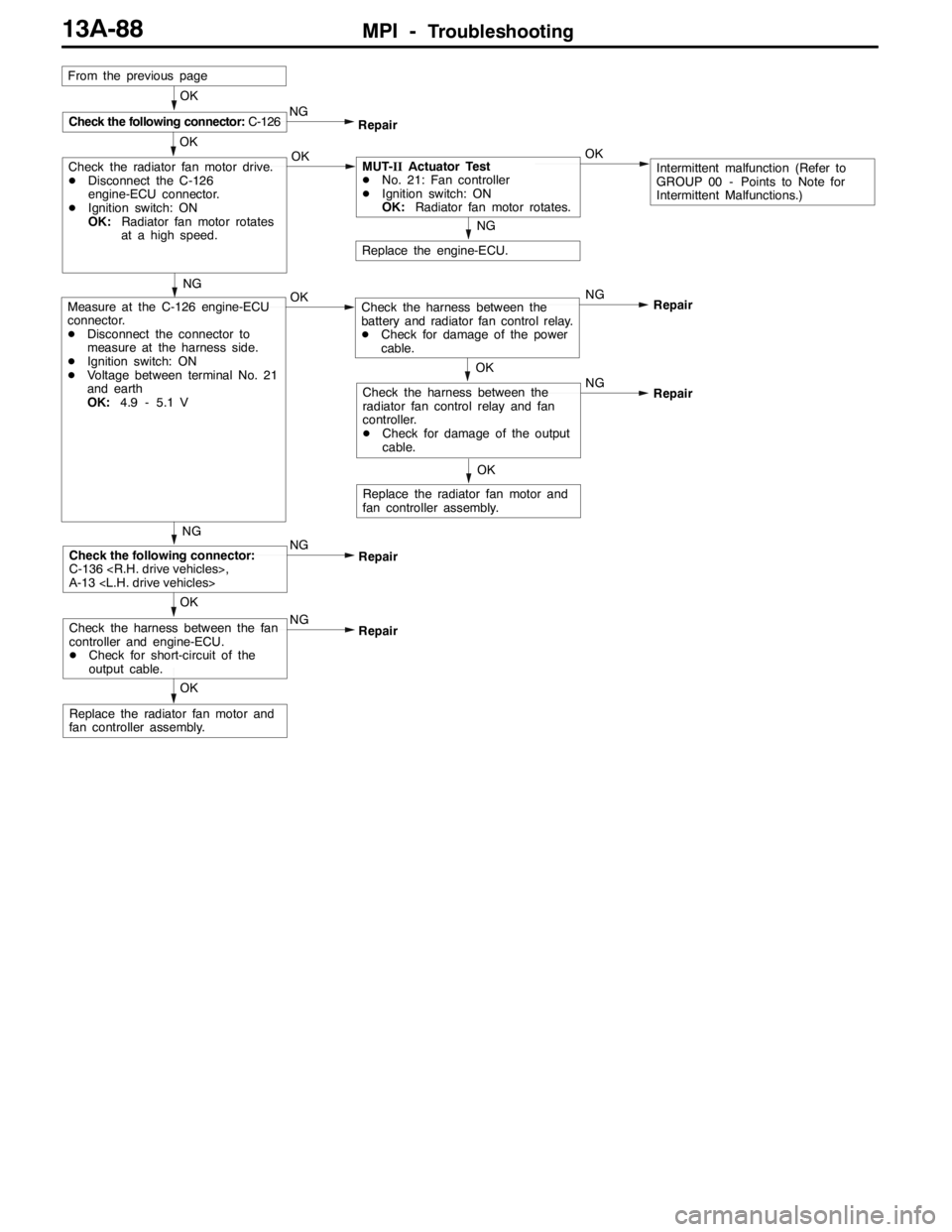

MPI -Troubleshooting13A-88

NGRepair

NG

Repair NG

From the previous page

OK

OK

Replace the engine-ECU.

NG

MUT-IIActuator Test

DNo. 21: Fan controller

DIgnition switch: ON

OK:Radiator fan motor rotates.

NG

Check the radiator fan motor drive.

DDisconnect the C-126

engine-ECU connector.

DIgnition switch: ON

OK:Radiator fan motor rotates

at a high speed.OK

OK

Check the harness between the

battery and radiator fan control relay.

DCheck for damage of the power

cable.RepairMeasure at the C-126 engine-ECU

connector.

DDisconnect the connector to

measure at the harness side.

DIgnition switch: ON

DVoltage between terminal No. 21

and earth

OK:4.9 - 5.1 VOK

OK

Check the harness between the

radiator fan control relay and fan

controller.

DCheck for damage of the output

cable.

Replace the radiator fan motor and

fan controller assembly.NG

NG

OK

Check the following connector:

C-136

A-13

OK

Replace the radiator fan motor and

fan controller assembly.

Check the harness between the fan

controller and engine-ECU.

DCheck for short-circuit of the

output cable.Repair NG

OK

Check the following connector:C-126

Repair

Intermittent malfunction (Refer to

GROUP 00 - Points to Note for

Intermittent Malfunctions.)

Page 640 of 1449

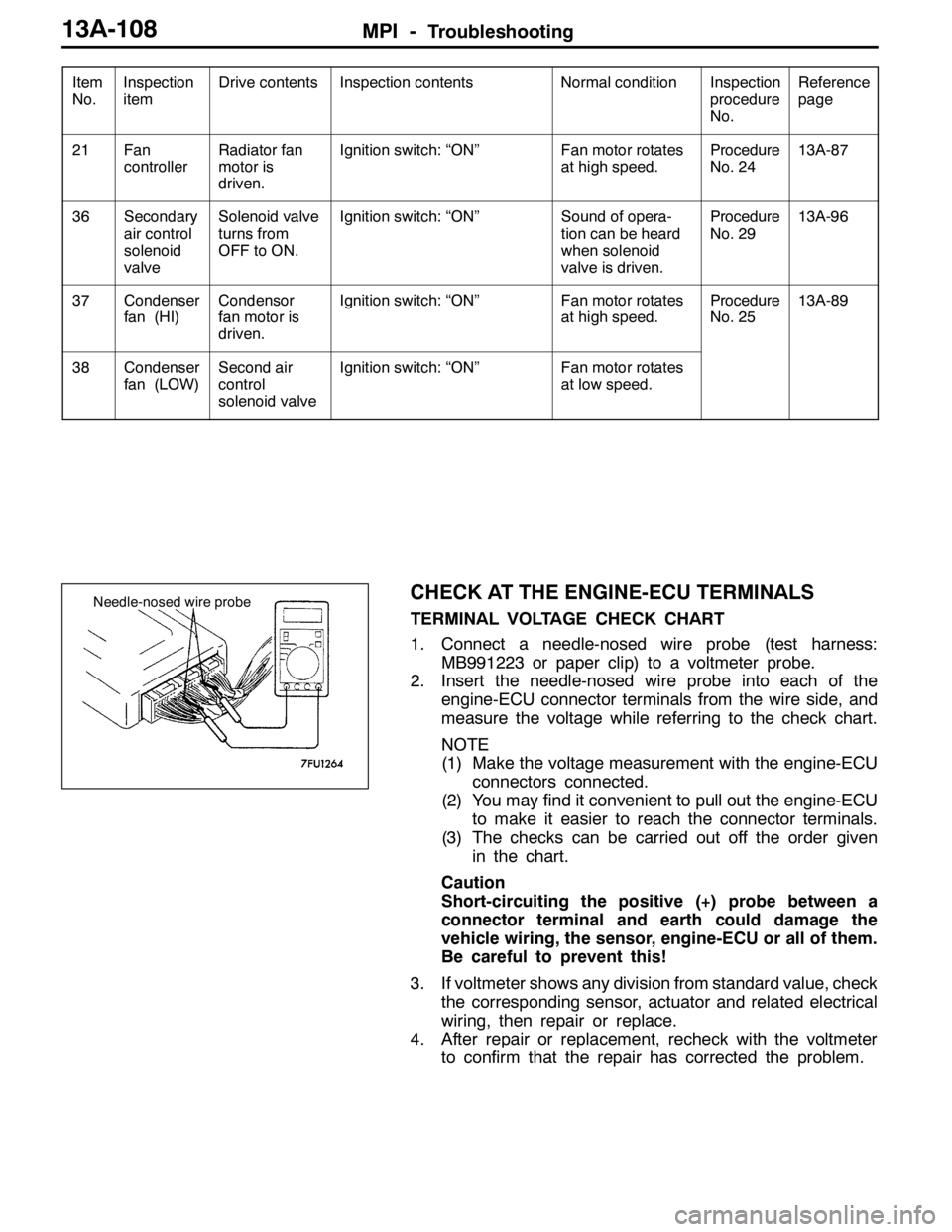

MPI -Troubleshooting13A-108

Item

No.Reference

page Inspection

procedure

No. Normal condition Inspection contents Drive contents Inspection

item

21Fan

controllerRadiator fan

motor is

driven.Ignition switch: “ON”Fan motor rotates

at high speed.Procedure

No. 2413A-87

36Secondary

air control

solenoid

valveSolenoid valve

turns from

OFF to ON.Ignition switch: “ON”Sound of opera-

tion can be heard

when solenoid

valve is driven.Procedure

No. 2913A-96

37Condenser

fan (HI)Condensor

fan motor is

driven.Ignition switch: “ON”Fan motor rotates

at high speed.Procedure

No. 2513A-89

38Condenser

fan (LOW)Second air

control

solenoid valveIgnition switch: “ON”Fan motor rotates

at low speed.

CHECK AT THE ENGINE-ECU TERMINALS

TERMINAL VOLTAGE CHECK CHART

1. Connect a needle-nosed wire probe (test harness:

MB991223 or paper clip) to a voltmeter probe.

2. Insert the needle-nosed wire probe into each of the

engine-ECU connector terminals from the wire side, and

measure the voltage while referring to the check chart.

NOTE

(1) Make the voltage measurement with the engine-ECU

connectors connected.

(2) You may find it convenient to pull out the engine-ECU

to make it easier to reach the connector terminals.

(3) The checks can be carried out off the order given

in the chart.

Caution

Short-circuiting the positive (+) probe between a

connector terminal and earth could damage the

vehicle wiring, the sensor, engine-ECU or all of them.

Be careful to prevent this!

3. If voltmeter shows any division from standard value, check

the corresponding sensor, actuator and related electrical

wiring, then repair or replace.

4. After repair or replacement, recheck with the voltmeter

to confirm that the repair has corrected the problem.

Needle-nosed wire probe

Page 642 of 1449

MPI -Troubleshooting13A-110

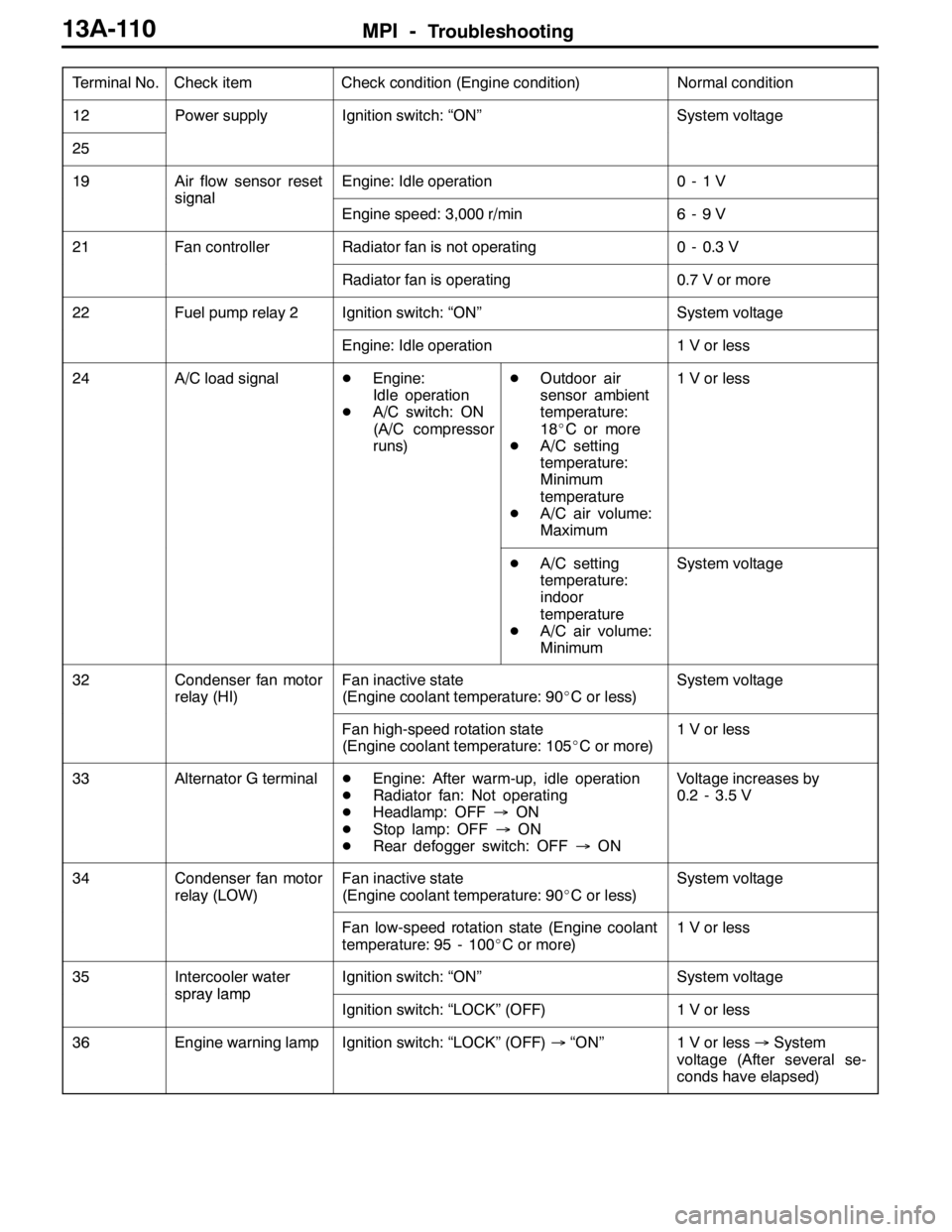

Terminal No.Normal condition Check condition (Engine condition) Check item

12Power supplyIgnition switch: “ON”System voltage

25

19Air flow sensor reset

signal

Engine: Idle operation0-1V

signal

Engine speed: 3,000 r/min6-9V

21Fan controllerRadiator fan is not operating0 - 0.3 V

Radiator fan is operating0.7 V or more

22Fuel pump relay 2Ignition switch: “ON”System voltage

Engine: Idle operation1 V or less

24A/C load signalDEngine:

Idle operation

DA/C switch: ON

(A/C compressor

runs)DOutdoor air

sensor ambient

temperature:

18_C or more

DA/C setting

temperature:

Minimum

temperature

DA/C air volume:

Maximum1 V or less

DA/C setting

temperature:

indoor

temperature

DA/C air volume:

MinimumSystem voltage

32Condenser fan motor

relay (HI)Fan inactive state

(Engine coolant temperature: 90_C or less)System voltage

Fan high-speed rotation state

(Engine coolant temperature: 105_C or more)1 V or less

33Alternator G terminalDEngine: After warm-up, idle operation

DRadiator fan: Not operating

DHeadlamp: OFF→ON

DStop lamp: OFF→ON

DRear defogger switch: OFF→ONVoltage increases by

0.2 - 3.5 V

34Condenser fan motor

relay (LOW)Fan inactive state

(Engine coolant temperature: 90_C or less)System voltage

Fan low-speed rotation state (Engine coolant

temperature: 95 - 100_C or more)1 V or less

35Intercooler water

spraylamp

Ignition switch: “ON”System voltage

spraylamp

Ignition switch: “LOCK” (OFF)1 V or less

36Engine warning lampIgnition switch: “LOCK” (OFF)→“ON”1 V or less→System

voltage (After several se-

conds have elapsed)

Page 643 of 1449

MPI -Troubleshooting13A-111

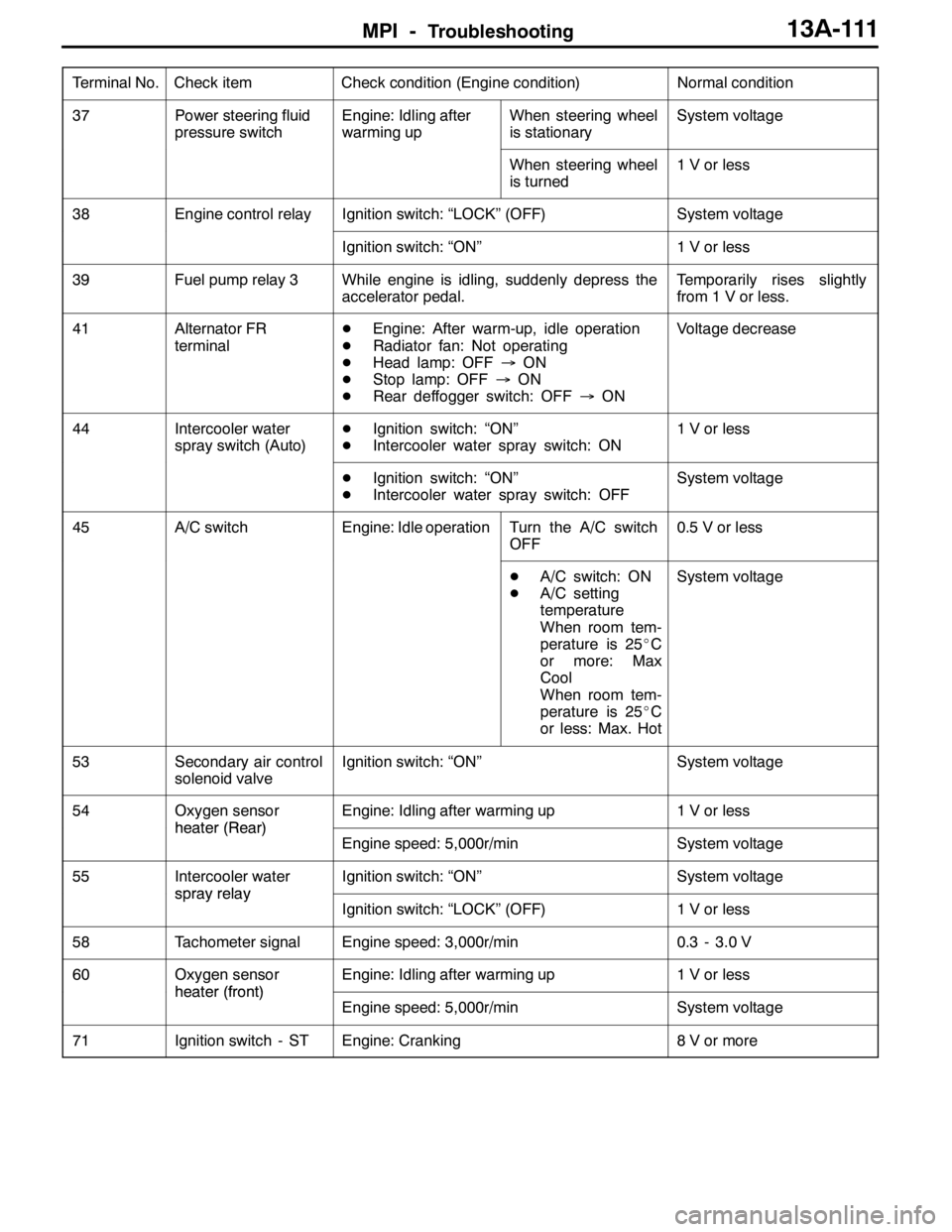

Terminal No.Normal condition Check condition (Engine condition) Check item

37Power steering fluid

pressure switchEngine: Idling after

warming upWhen steering wheel

is stationarySystem voltage

When steering wheel

is turned1 V or less

38Engine control relayIgnition switch: “LOCK” (OFF)System voltage

Ignition switch: “ON”1 V or less

39Fuel pump relay 3While engine is idling, suddenly depress the

accelerator pedal.Temporarily rises slightly

from 1 V or less.

41Alternator FR

terminalDEngine: After warm-up, idle operation

DRadiator fan: Not operating

DHead lamp: OFF→ON

DStop lamp: OFF→ON

DRear deffogger switch: OFF→ONVoltage decrease

44Intercooler water

spray switch (Auto)DIgnition switch: “ON”

DIntercooler water spray switch: ON1 V or less

DIgnition switch: “ON”

DIntercooler water spray switch: OFFSystem voltage

45A/C switchEngine: Idle operationTurn the A/C switch

OFF0.5 V or less

DA/C switch: ON

DA/C setting

temperature

When room tem-

perature is 25_C

or more: Max

Cool

When room tem-

perature is 25_C

or less: Max. HotSystem voltage

53Secondary air control

solenoid valveIgnition switch: “ON”System voltage

54Oxygen sensor

heater(Rear)

Engine: Idling after warming up1 V or less

heater(Rear)

Engine speed: 5,000r/minSystem voltage

55Intercooler water

sprayrelay

Ignition switch: “ON”System voltage

spray relay

Ignition switch: “LOCK” (OFF)1 V or less

58Tachometer signalEngine speed: 3,000r/min0.3 - 3.0 V

60Oxygen sensor

heater(front)

Engine: Idling after warming up1 V or less

heater(front)

Engine speed: 5,000r/minSystem voltage

71Ignition switch - STEngine: Cranking8 V or more

Page 689 of 1449

14-1

ENGINE COOLING

CONTENTS

GENERAL INFORMATION 2..................

SERVICE SPECIFICATIONS 2.................

LUBRICANT 2...............................

SEALANT 2..................................

SPECIAL TOOLS 3...........................

TROUBLESHOOTING 3.......................

ON-VEHICLE SERVICE 6.....................

Engine Coolant Leak Checking 6................

Radiator Cap Opening Pressure Check 6........Engine Coolant Replacement 6..................

Concentration Measurement 7...................

Radiator Fan Relay Continuity Check 8..........

Radiator Fan Controller Check 8................

Radiator Fan Motor Check 10...................

THERMOSTAT 11............................

WATER PUMP 13............................

WATER HOSE AND WATER PIPE 14..........

RADIATOR 15................................

Page 690 of 1449

ENGINE COOLING -GeneralInformation/

Service Specifications/Lubricant/Sealant14-2

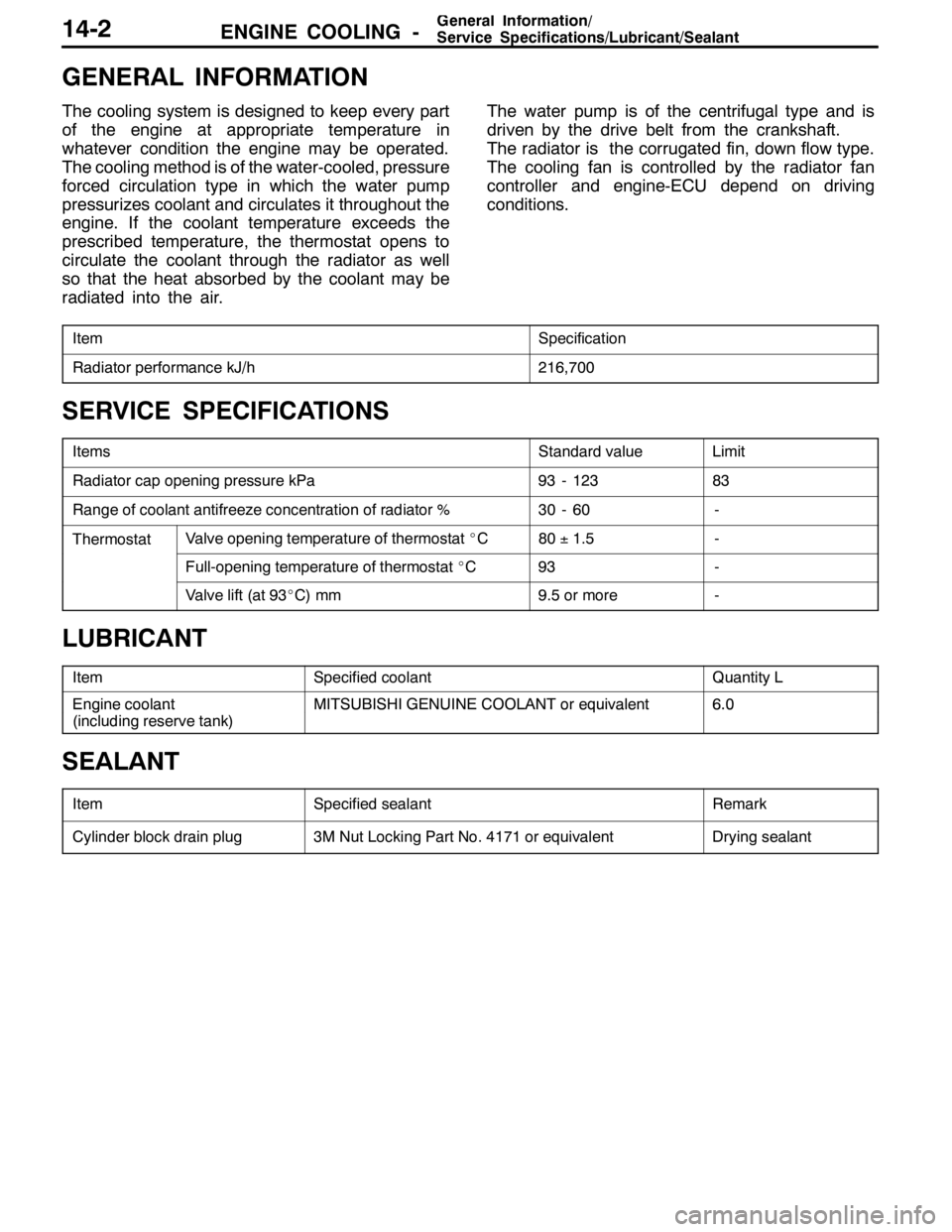

GENERAL INFORMATION

The cooling system is designed to keep every part

of the engine at appropriate temperature in

whatever condition the engine may be operated.

The cooling method is of the water-cooled, pressure

forced circulation type in which the water pump

pressurizes coolant and circulates it throughout the

engine. If the coolant temperature exceeds the

prescribed temperature, the thermostat opens to

circulate the coolant through the radiator as well

so that the heat absorbed by the coolant may be

radiated into the air.The water pump is of the centrifugal type and is

driven by the drive belt from the crankshaft.

The radiator is the corrugated fin, down flow type.

The cooling fan is controlled by the radiator fan

controller and engine-ECU depend on driving

conditions.

ItemSpecification

Radiator performance kJ/h216,700

SERVICE SPECIFICATIONS

ItemsStandard valueLimit

Radiator cap opening pressure kPa93 - 12383

Range of coolant antifreeze concentration of radiator %30 - 60-

ThermostatValve opening temperature of thermostat_C80±1.5-

Full-opening temperature of thermostat_C93-

Valve lift (at 93_C) mm9.5 or more-

LUBRICANT

ItemSpecified coolantQuantity L

Engine coolantMITSUBISHI GENUINE COOLANT or equivalent6.0Enginecoolant

(including reserve tank)

MITSUBISHIGENUINECOOLANTorequivalent6.0

SEALANT

ItemSpecified sealantRemark

Cylinder block drain plug3M Nut Locking Part No. 4171 or equivalentDrying sealant

Page 691 of 1449

ENGINE COOLING -Special Tools/Troubleshooting14-3

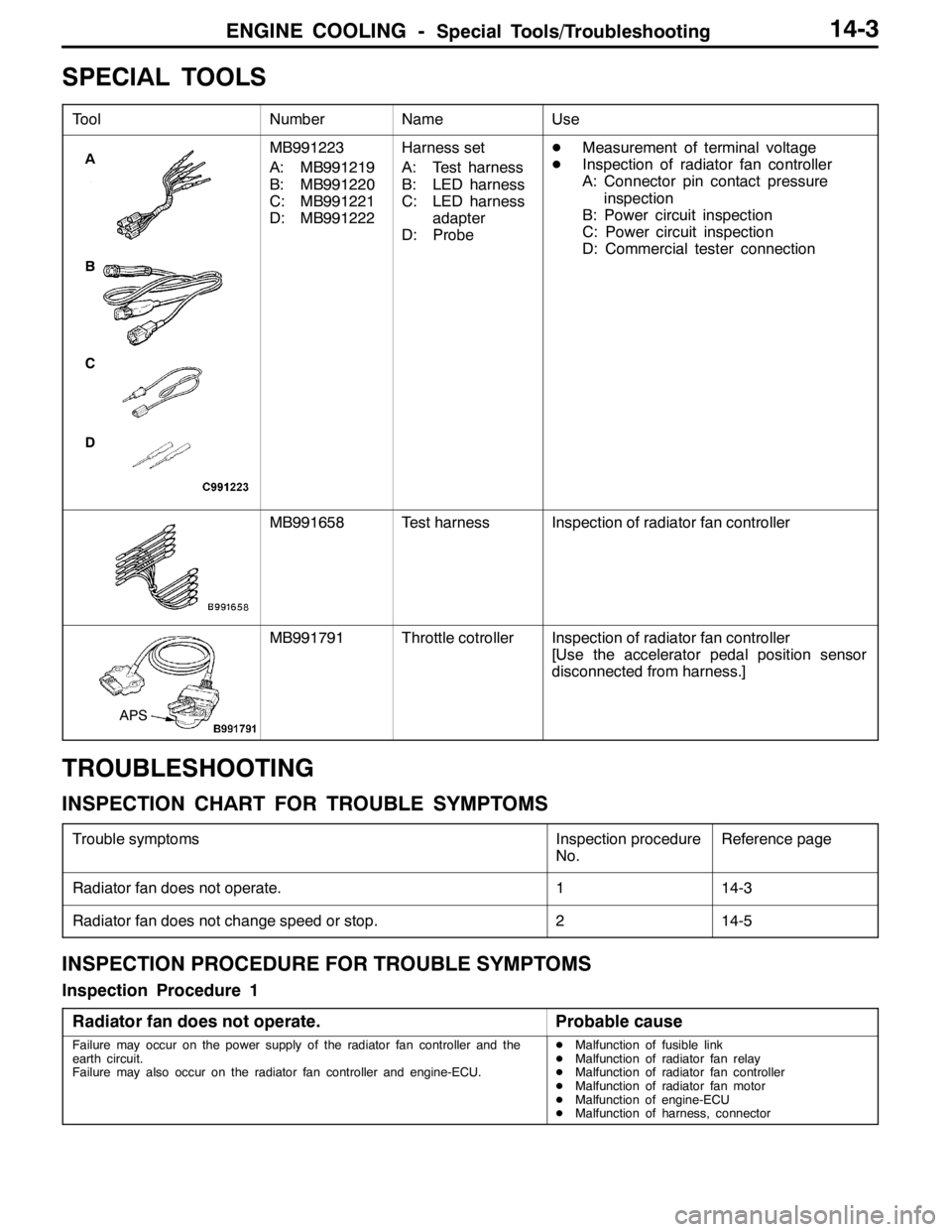

SPECIAL TOOLS

ToolNumberNameUse

A

B

C

DMB991223

A: MB991219

B: MB991220

C: MB991221

D: MB991222Harness set

A: Test harness

B: LED harness

C: LED harness

adapter

D: ProbeDMeasurement of terminal voltage

DInspection of radiator fan controller

A: Connector pin contact pressure

inspection

B: Power circuit inspection

C: Power circuit inspection

D: Commercial tester connection

MB991658Test harnessInspection of radiator fan controller

APS

MB991791Throttle cotrollerInspection of radiator fan controller

[Use the accelerator pedal position sensor

disconnected from harness.]

TROUBLESHOOTING

INSPECTION CHART FOR TROUBLE SYMPTOMS

Trouble symptomsInspection procedure

No.Reference page

Radiator fan does not operate.114-3

Radiator fan does not change speed or stop.214-5

INSPECTION PROCEDURE FOR TROUBLE SYMPTOMS

Inspection Procedure 1

Radiator fan does not operate.

Probable cause

Failure may occur on the power supply of the radiator fan controller and the

earth circuit.

Failure may also occur on the radiator fan controller and engine-ECU.DMalfunction of fusible link

DMalfunction of radiator fan relay

DMalfunction of radiator fan controller

DMalfunction of radiator fan motor

DMalfunction of engine-ECU

DMalfunction of harness, connector