service indicator MITSUBISHI LANCER EVOLUTION 2007 Service User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 1054 of 1449

BASIC BRAKE SYSTEM -On-vehicle Service35A-12

Caution

Take care not to contact the parts or tools to the caliper

because the paint of caliper will be scratched. And if

there is brake fluid on the caliper, wipe out quickly.

NOTE

The wear indicator contacts the brake disc when the brake

pad thickness reaches approximately 2 mm and emit a

squealing sound to warn the driver.

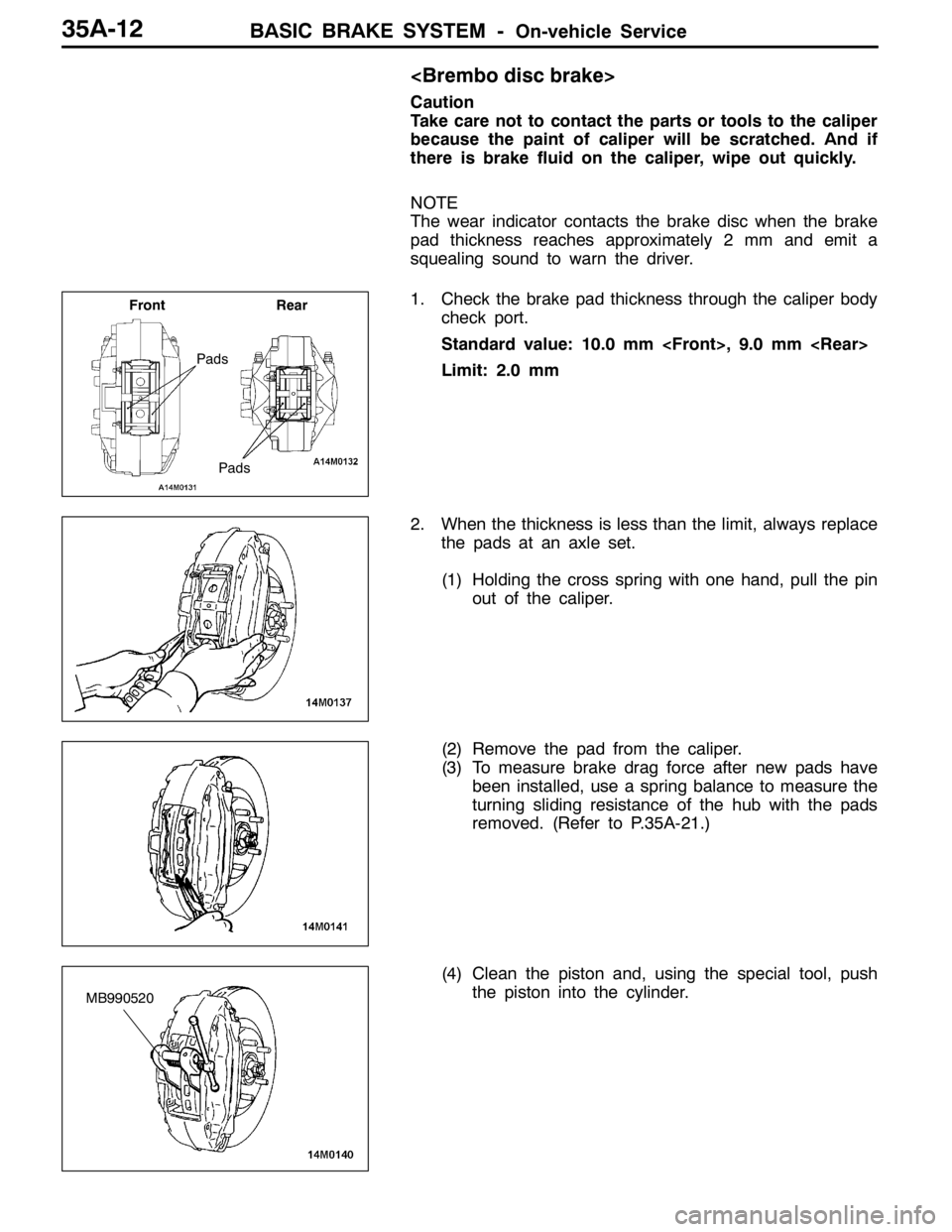

1. Check the brake pad thickness through the caliper body

check port.

Standard value: 10.0 mm

Limit: 2.0 mm

2. When the thickness is less than the limit, always replace

the pads at an axle set.

(1) Holding the cross spring with one hand, pull the pin

out of the caliper.

(2) Remove the pad from the caliper.

(3) To measure brake drag force after new pads have

been installed, use a spring balance to measure the

turning sliding resistance of the hub with the pads

removed. (Refer to P.35A-21.)

(4) Clean the piston and, using the special tool, push

the piston into the cylinder.

Pads

Front Rear

Pads

MB990520

Page 1055 of 1449

BASIC BRAKE SYSTEM -On-vehicle Service35A-13

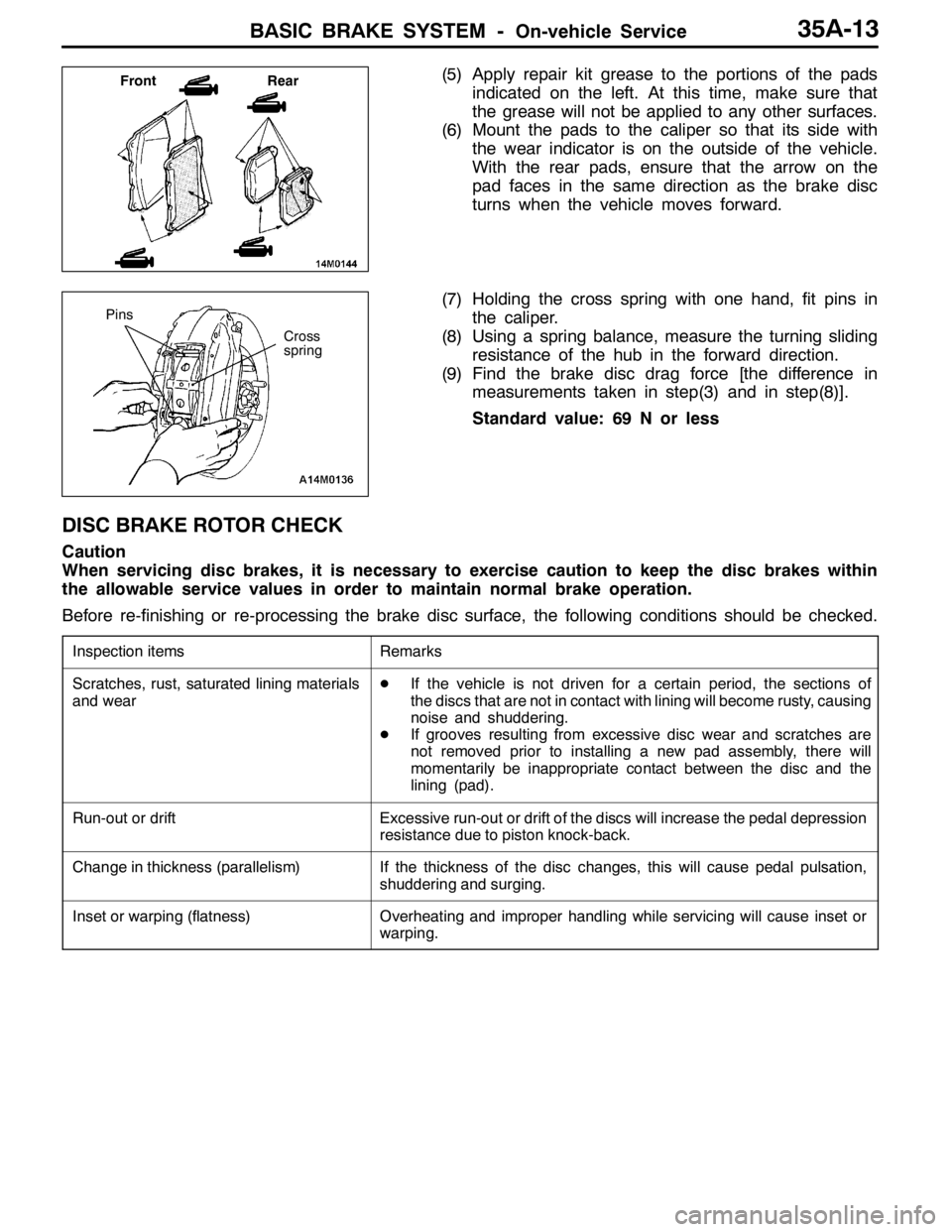

(5) Apply repair kit grease to the portions of the pads

indicated on the left. At this time, make sure that

the grease will not be applied to any other surfaces.

(6) Mount the pads to the caliper so that its side with

the wear indicator is on the outside of the vehicle.

With the rear pads, ensure that the arrow on the

pad faces in the same direction as the brake disc

turns when the vehicle moves forward.

(7) Holding the cross spring with one hand, fit pins in

the caliper.

(8) Using a spring balance, measure the turning sliding

resistance of the hub in the forward direction.

(9) Find the brake disc drag force [the difference in

measurements taken in step(3) and in step(8)].

Standard value: 69 N or less

DISC BRAKE ROTOR CHECK

Caution

When servicing disc brakes, it is necessary to exercise caution to keep the disc brakes within

the allowable service values in order to maintain normal brake operation.

Before re-finishing or re-processing the brake disc surface, the following conditions should be checked.

Inspection itemsRemarks

Scratches, rust, saturated lining materials

and wearDIf the vehicle is not driven for a certain period, the sections of

the discs that are not in contact with lining will become rusty, causing

noise and shuddering.

DIf grooves resulting from excessive disc wear and scratches are

not removed prior to installing a new pad assembly, there will

momentarily be inappropriate contact between the disc and the

lining (pad).

Run-out or driftExcessive run-out or drift of the discs will increase the pedal depression

resistance due to piston knock-back.

Change in thickness (parallelism)If the thickness of the disc changes, this will cause pedal pulsation,

shuddering and surging.

Inset or warping (flatness)Overheating and improper handling while servicing will cause inset or

warping.

Front Rear

Cross

spring

Pins

Page 1339 of 1449

CHASSIS ELECTRICAL -Combination MeterCHASSIS ELECTRICAL -Combination Meter54A-19

Inspection procedure 5All meters inoperative

Probable cause

When individual indicators and warning lamps are properly operated, harness

from power source (IG1) to combination meter is normal.D Meter assembly fault

D Harness or connector fault

NG Repair

NG

OK

Check trouble symptom. Repair

OK

Check the following connectors:

NG

Check harness from ignition switch (IG1) to combination meter.

Replace meter assembly. Repair

NG

OK

Check the following connectors:

C-01

NG

RepairCheck harness from combination meter to body earth.

ON-VEHICLE SERVICE

SPEEDOMETER CHECK

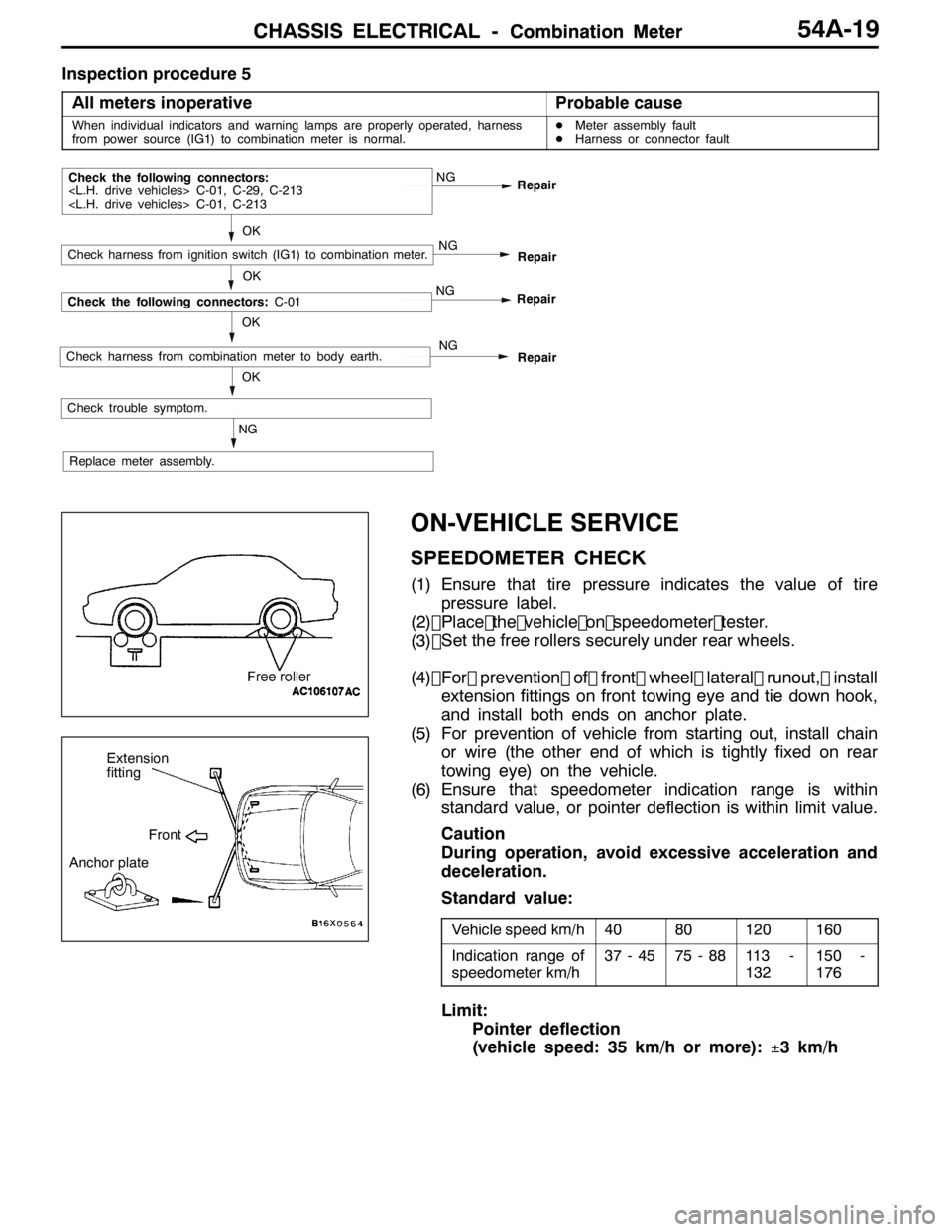

(1) Ensure that tire pressure indicates the value of tirepressure label.

(2) Place the vehicle on speedometer teste r.

(3)

(4) For prevention of front wheel lateral runout, install

extension fittings on front towing eye and tie down hook,

and install both ends on anchor plate.

(5) For prevention of vehicle from starting out, install chain or wire (the other end of which is tightly fixed on rear

towing eye) on the vehicle.

(6) Ensure that speedometer indication range is within standard value, or pointer deflection is within limit value.

Caution

During operation, avoid excessive acceleration and

deceleration.

Standard value:

Vehicle speed km/h4080120160

Indication range of

speedometer km/h37 - 4575 - 8811 3 -

132150 -

176

Limit:

Pointer deflection

(vehicle speed: 35 km/h or more): ±3 km/h

Extension

fitting

Front

Anchor plate

OK

Set the free rollers securely under rear wheels.