charging MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 96 of 1449

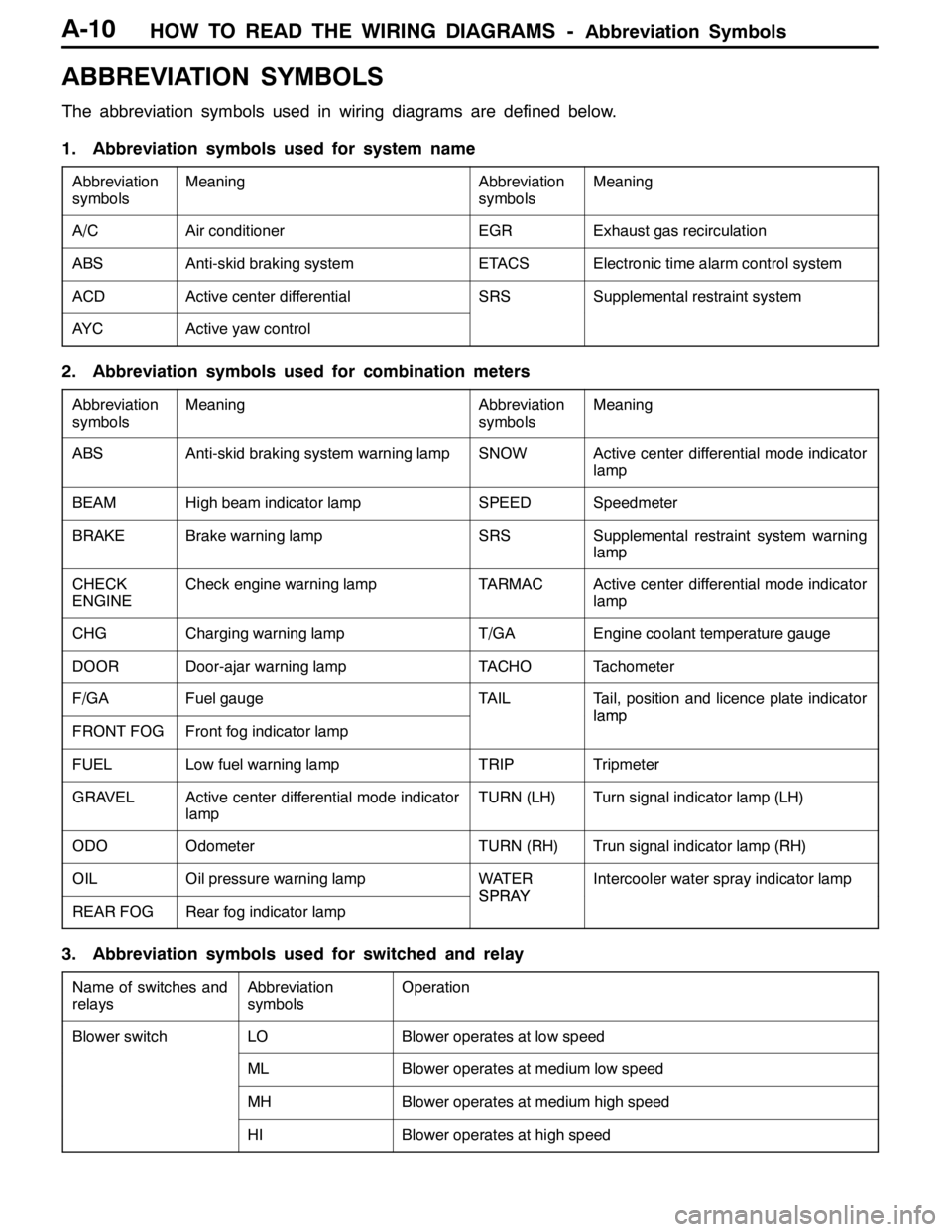

HOW TO READ THE WIRING DIAGRAMS -Abbreviation SymbolsA-10

ABBREVIATION SYMBOLS

The abbreviation symbols used in wiring diagrams are defined below.

1. Abbreviation symbols used for system name

Abbreviation

symbolsMeaningAbbreviation

symbolsMeaning

A/CAir conditionerEGRExhaust gas recirculation

ABSAnti-skid braking systemETACSElectronic time alarm control system

ACDActive center differentialSRSSupplemental restraint system

AY CActive yaw control

2. Abbreviation symbols used for combination meters

Abbreviation

symbolsMeaningAbbreviation

symbolsMeaning

ABSAnti-skid braking system warning lampSNOWActive center differential mode indicator

lamp

BEAMHigh beam indicator lampSPEEDSpeedmeter

BRAKEBrake warning lampSRSSupplemental restraint system warning

lamp

CHECK

ENGINECheck engine warning lampTARMACActive center differential mode indicator

lamp

CHGCharging warning lampT/GAEngine coolant temperature gauge

DOORDoor-ajar warning lampTACHOTachometer

F/GAFuel gaugeTAILTail, position and licence plate indicator

lamp

FRONT FOGFront fog indicator lamp

lamp

FUELLow fuel warning lampTRIPTripmeter

GRAVELActive center differential mode indicator

lampTURN (LH)Turn signal indicator lamp (LH)

ODOOdometerTURN (RH)Trun signal indicator lamp (RH)

OILOil pressure warning lampWATER

SPRAY

Intercooler water spray indicator lamp

REAR FOGRear fog indicator lamp

SPRAY

3. Abbreviation symbols used for switched and relay

Name of switches and

relaysAbbreviation

symbolsOperation

Blower switchLOBlower operates at low speed

MLBlower operates at medium low speed

MHBlower operates at medium high speed

HIBlower operates at high speed

Page 100 of 1449

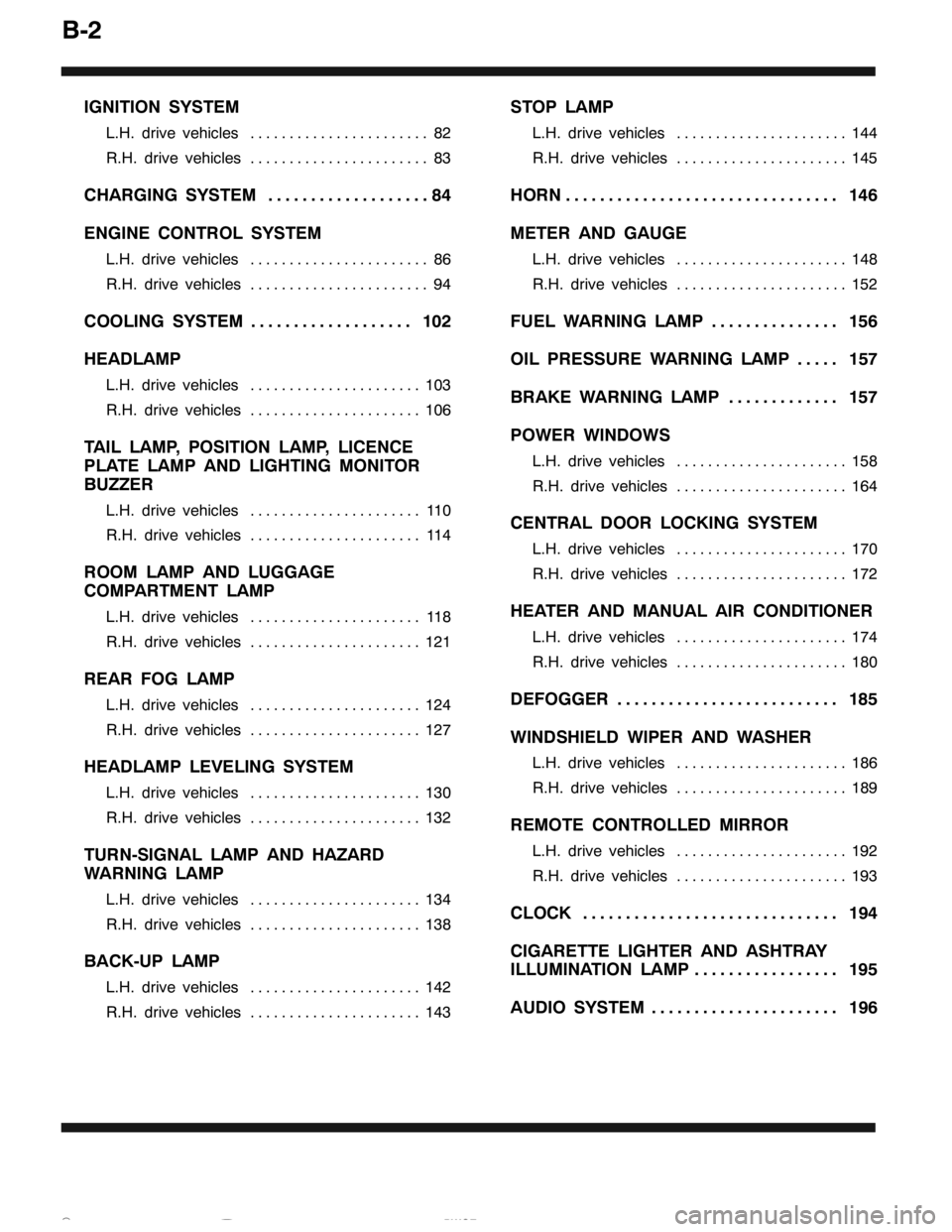

B-2

S

PWGEE

IGNITION SYSTEM

L.H. drive vehicles 82.......................

R.H. drive vehicles 83.......................

CHARGING SYSTEM 84...................

ENGINE CONTROL SYSTEM

L.H. drive vehicles 86.......................

R.H. drive vehicles 94.......................

COOLING SYSTEM 102...................

HEADLAMP

L.H. drive vehicles 103......................

R.H. drive vehicles 106......................

TAIL LAMP, POSITION LAMP, LICENCE

PLATE LAMP AND LIGHTING MONITOR

BUZZER

L.H. drive vehicles 110......................

R.H. drive vehicles 114......................

ROOM LAMP AND LUGGAGE

COMPARTMENT LAMP

L.H. drive vehicles 118......................

R.H. drive vehicles 121......................

REAR FOG LAMP

L.H. drive vehicles 124......................

R.H. drive vehicles 127......................

HEADLAMP LEVELING SYSTEM

L.H. drive vehicles 130......................

R.H. drive vehicles 132......................

TURN-SIGNAL LAMP AND HAZARD

WARNING LAMP

L.H. drive vehicles 134......................

R.H. drive vehicles 138......................

BACK-UP LAMP

L.H. drive vehicles 142......................

R.H. drive vehicles 143......................

STOP LAMP

L.H. drive vehicles 144......................

R.H. drive vehicles 145......................

HORN 146................................

METER AND GAUGE

L.H. drive vehicles 148......................

R.H. drive vehicles 152......................

FUEL WARNING LAMP 156...............

OIL PRESSURE WARNING LAMP 157.....

BRAKE WARNING LAMP 157.............

POWER WINDOWS

L.H. drive vehicles 158......................

R.H. drive vehicles 164......................

CENTRAL DOOR LOCKING SYSTEM

L.H. drive vehicles 170......................

R.H. drive vehicles 172......................

HEATER AND MANUAL AIR CONDITIONER

L.H. drive vehicles 174......................

R.H. drive vehicles 180......................

DEFOGGER 185..........................

WINDSHIELD WIPER AND WASHER

L.H. drive vehicles 186......................

R.H. drive vehicles 189......................

REMOTE CONTROLLED MIRROR

L.H. drive vehicles 192......................

R.H. drive vehicles 193......................

CLOCK 194..............................

CIGARETTE LIGHTER AND ASHTRAY

ILLUMINATION LAMP 195.................

AUDIO SYSTEM 196......................

Page 182 of 1449

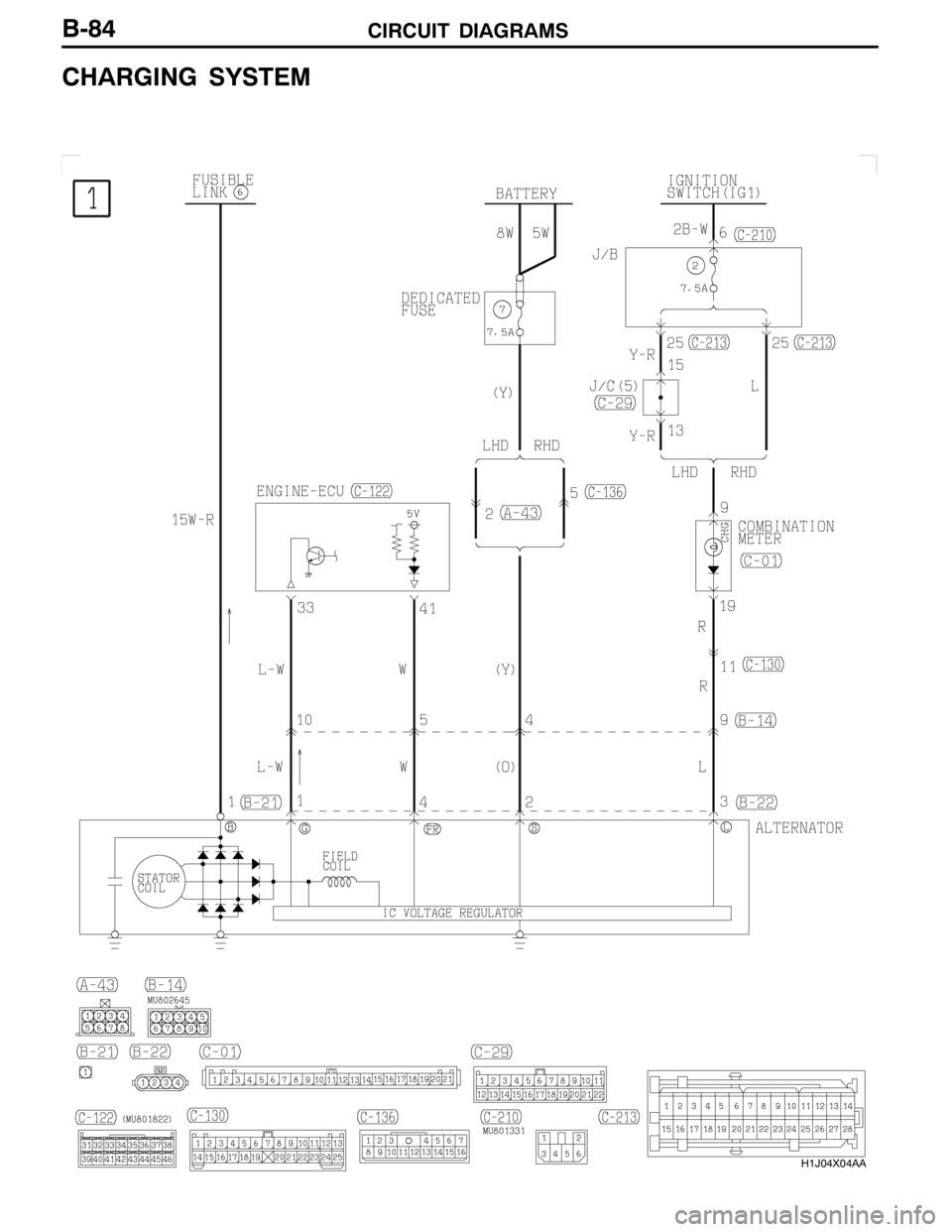

CIRCUIT DIAGRAMS

H1J04X04AA

B-84

CHARGING SYSTEM

Page 183 of 1449

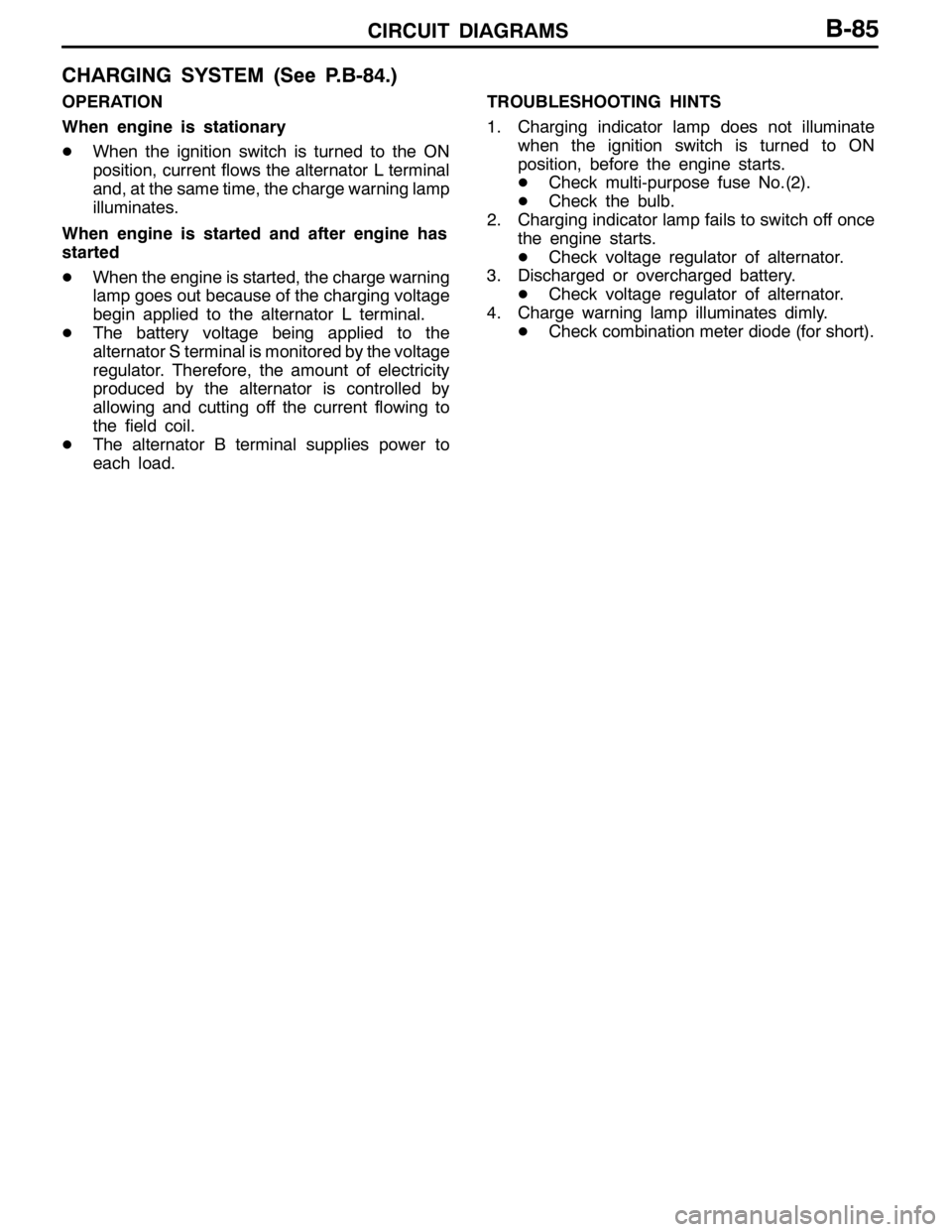

CIRCUIT DIAGRAMSB-85

CHARGING SYSTEM (See P.B-84.)

OPERATION

When engine is stationary

DWhen the ignition switch is turned to the ON

position, current flows the alternator L terminal

and, at the same time, the charge warning lamp

illuminates.

When engine is started and after engine has

started

DWhen the engine is started, the charge warning

lamp goes out because of the charging voltage

begin applied to the alternator L terminal.

DThe battery voltage being applied to the

alternator S terminal is monitored by the voltage

regulator. Therefore, the amount of electricity

produced by the alternator is controlled by

allowing and cutting off the current flowing to

the field coil.

DThe alternator B terminal supplies power to

each load.TROUBLESHOOTING HINTS

1. Charging indicator lamp does not illuminate

when the ignition switch is turned to ON

position, before the engine starts.

DCheck multi-purpose fuse No.(2).

DCheck the bulb.

2. Charging indicator lamp fails to switch off once

the engine starts.

DCheck voltage regulator of alternator.

3. Discharged or overcharged battery.

DCheck voltage regulator of alternator.

4. Charge warning lamp illuminates dimly.

DCheck combination meter diode (for short).

Page 601 of 1449

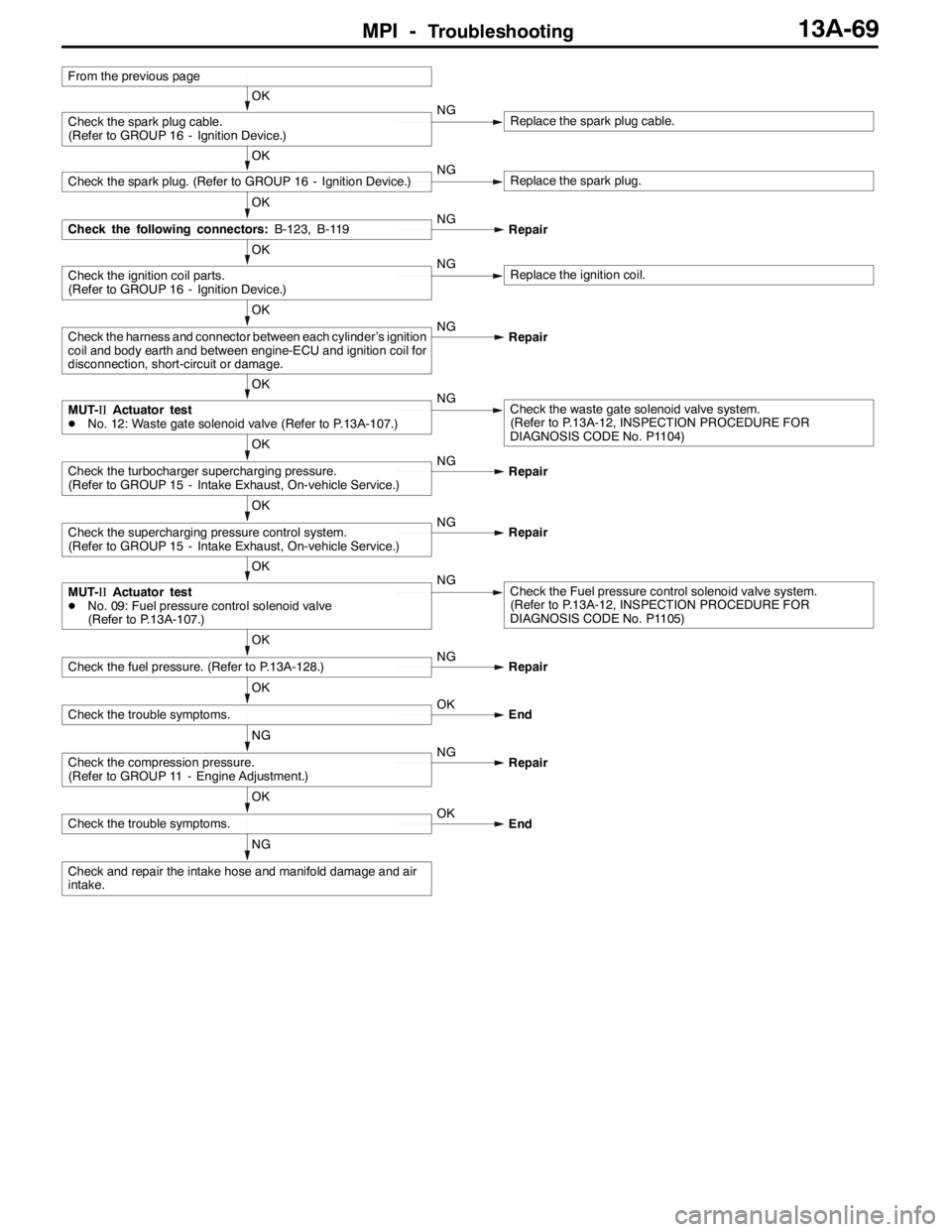

MPI -Troubleshooting13A-69

NG

Check and repair the intake hose and manifold damage and air

intake.

OK

Check the trouble symptoms.OK

End

NG

Check the compression pressure.

(Refer to GROUP 11 - Engine Adjustment.)NG

Repair

OK

Check the trouble symptoms.OK

End

OK

Check the fuel pressure. (Refer to P.13A-128.)NG

Repair

OK

MUT-IIActuator test

DNo. 09: Fuel pressure control solenoid valve

(Refer to P.13A-107.)NGCheck the Fuel pressure control solenoid valve system.

(Refer to P.13A-12, INSPECTION PROCEDURE FOR

DIAGNOSIS CODE No. P1105)

OK

Check the supercharging pressure control system.

(Refer to GROUP 15 - Intake Exhaust, On-vehicle Service.)NG

Repair

OK

Check the turbocharger supercharging pressure.

(Refer to GROUP 15 - Intake Exhaust, On-vehicle Service.)NG

Repair

OK

MUT-IIActuator test

DNo. 12: Waste gate solenoid valve (Refer to P.13A-107.)NGCheck the waste gate solenoid valve system.

(Refer to P.13A-12, INSPECTION PROCEDURE FOR

DIAGNOSIS CODE No. P1104)

OK

Check the harness and connector between each cylinder’s ignition

coil and body earth and between engine-ECU and ignition coil for

disconnection, short-circuit or damage.NG

Repair

OK

Check the ignition coil parts.

(Refer to GROUP 16 - Ignition Device.)NGReplace the ignition coil.

OK

Check the following connectors:B-123, B-119NG

Repair

OK

Check the spark plug. (Refer to GROUP 16 - Ignition Device.)NGReplace the spark plug.

OK

Check the spark plug cable.

(Refer to GROUP 16 - Ignition Device.)NGReplace the spark plug cable.

From the previous page

Page 610 of 1449

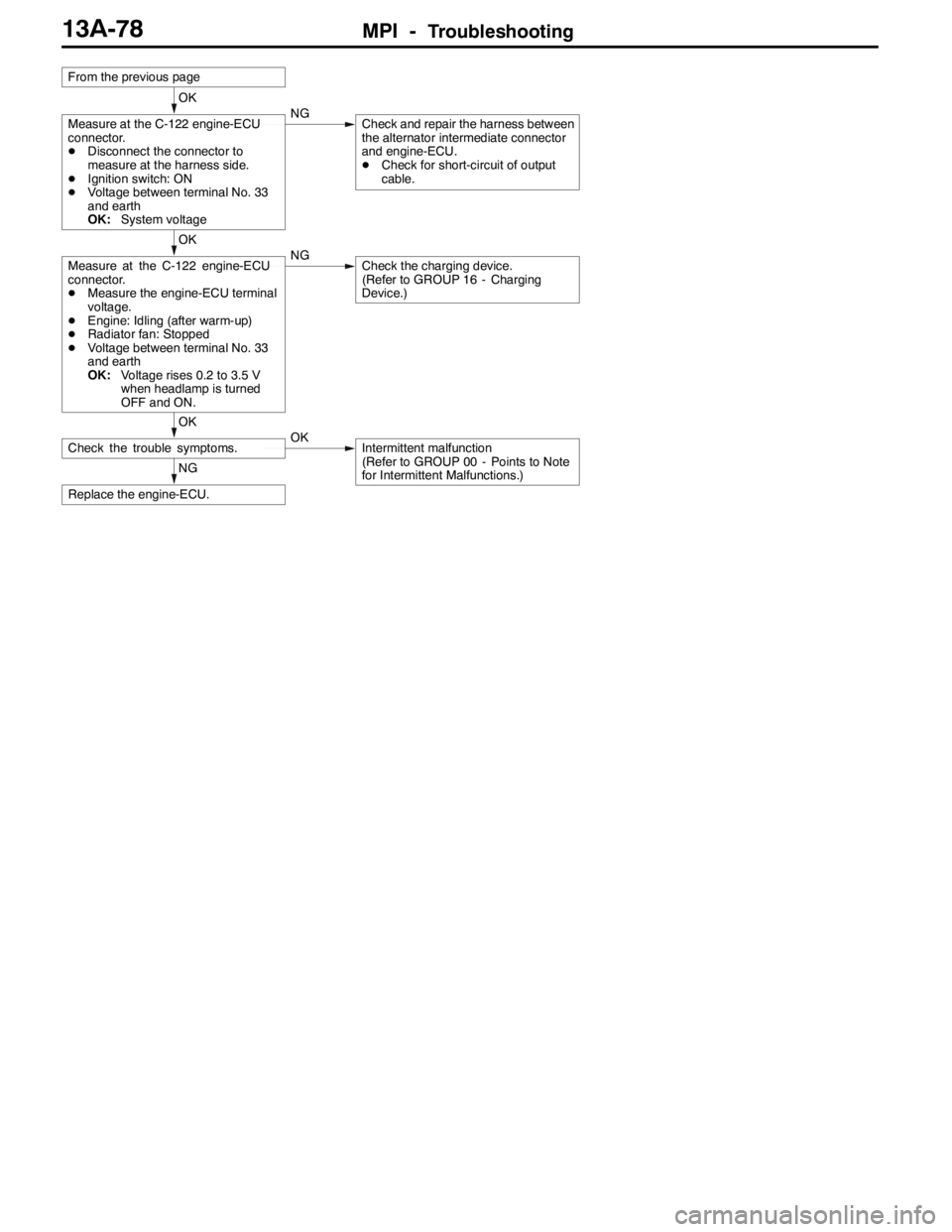

MPI -Troubleshooting13A-78

NG

Replace the engine-ECU.

OK

Check the trouble symptoms.OKIntermittent malfunction

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunctions.)

OK

Measure at the C-122 engine-ECU

connector.

DMeasure the engine-ECU terminal

voltage.

DEngine: Idling (after warm-up)

DRadiator fan: Stopped

DVoltage between terminal No. 33

and earth

OK:Voltage rises 0.2 to 3.5 V

when headlamp is turned

OFF and ON.NGCheck the charging device.

(Refer to GROUP 16 - Charging

Device.)

OK

Measure at the C-122 engine-ECU

connector.

DDisconnect the connector to

measure at the harness side.

DIgnition switch: ON

DVoltage between terminal No. 33

and earth

OK:System voltageNGCheck and repair the harness between

the alternator intermediate connector

and engine-ECU.

DCheck for short-circuit of output

cable.

From the previous page

Page 707 of 1449

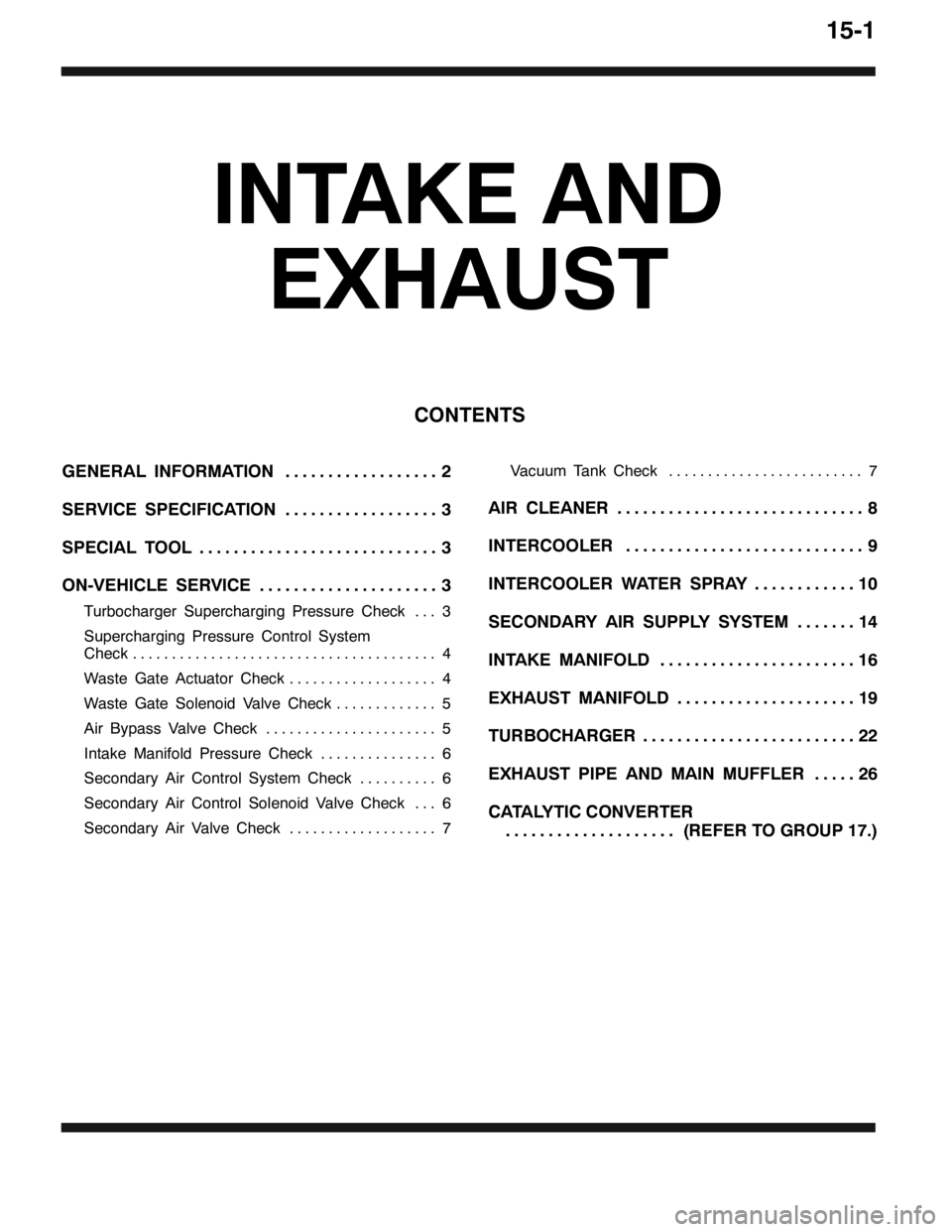

15-1

INTAKE AND

EXHAUST

CONTENTS

GENERAL INFORMATION 2..................

SERVICE SPECIFICATION 3..................

SPECIAL TOOL 3............................

ON-VEHICLE SERVICE 3.....................

Turbocharger Supercharging Pressure Check 3...

Supercharging Pressure Control System

Check 4.......................................

Waste Gate Actuator Check 4...................

Waste Gate Solenoid Valve Check 5.............

Air Bypass Valve Check 5......................

Intake Manifold Pressure Check 6...............

Secondary Air Control System Check 6..........

Secondary Air Control Solenoid Valve Check 6...

Secondary Air Valve Check 7...................Vacuum Tank Check 7.........................

AIR CLEANER 8.............................

INTERCOOLER 9............................

INTERCOOLER WATER SPRAY 10............

SECONDARY AIR SUPPLY SYSTEM 14.......

INTAKE MANIFOLD 16.......................

EXHAUST MANIFOLD 19.....................

TURBOCHARGER 22.........................

EXHAUST PIPE AND MAIN MUFFLER 26.....

CATALYTIC CONVERTER

(REFER TO GROUP 17.) ....................

Page 708 of 1449

INTAKE AND EXHAUST -General Information15-2

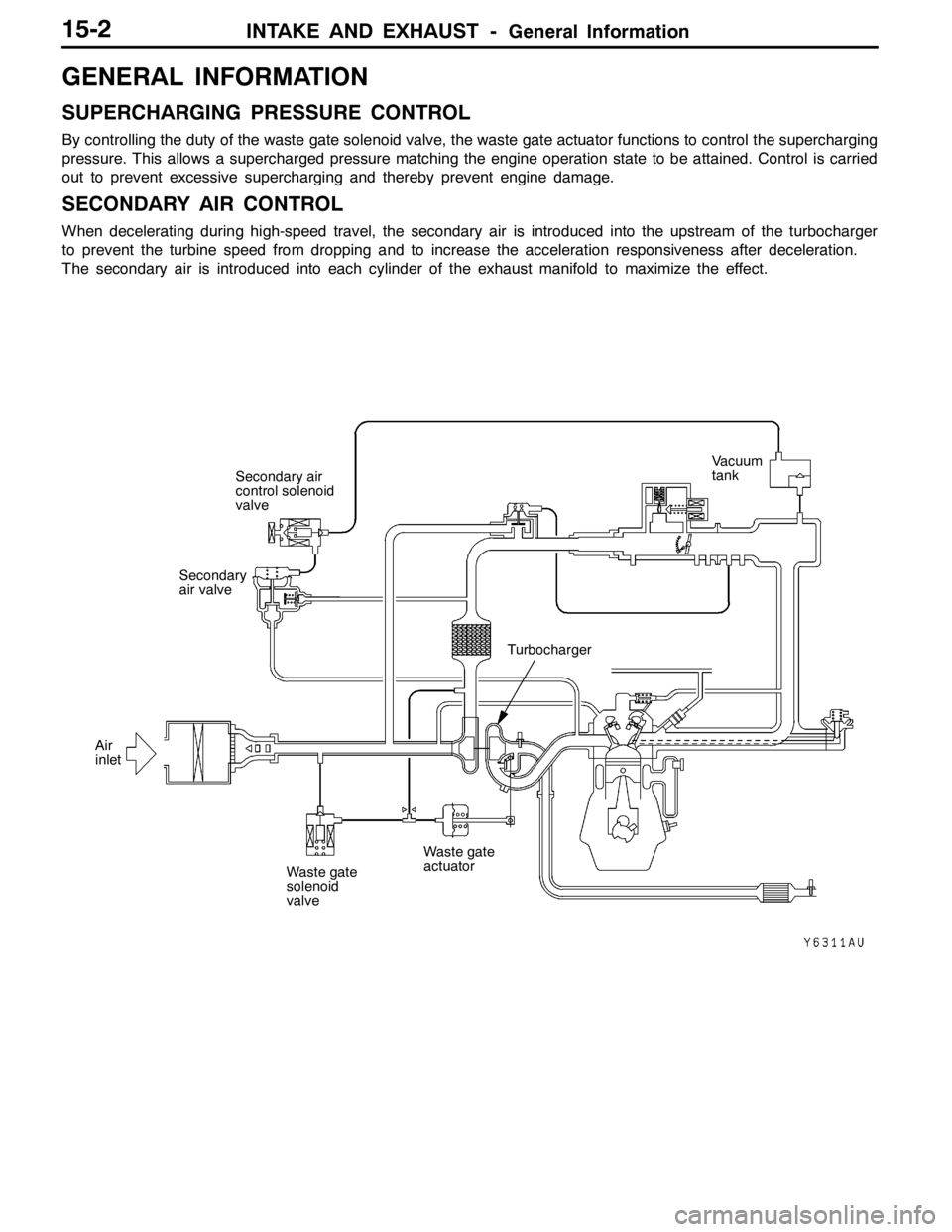

GENERAL INFORMATION

SUPERCHARGING PRESSURE CONTROL

By controlling the duty of the waste gate solenoid valve, the waste gate actuator functions to control the supercharging

pressure. This allows a supercharged pressure matching the engine operation state to be attained. Control is carried

out to prevent excessive supercharging and thereby prevent engine damage.

SECONDARY AIR CONTROL

When decelerating during high-speed travel, the secondary air is introduced into the upstream of the turbocharger

to prevent the turbine speed from dropping and to increase the acceleration responsiveness after deceleration.

The secondary air is introduced into each cylinder of the exhaust manifold to maximize the effect.

Secondary air

control solenoid

valve

Air

inletSecondary

air valve

Waste gate

solenoid

valve

Waste gate

actuator

TurbochargerVacuum

tank

Page 709 of 1449

INTAKE AND EXHAUST -Service Specifications/Special Tool/On-vehicle Service15-3

SERVICE SPECIFICATIONS

ItemStandard valueLimit

Turbocharger supercharging pressure (waste gate solenoid

valve not operating) kPa59 - 84-

Initial activation pressure of waste gate actuator (at the stroke

of approximately 1 mm) kPaApproximately 100-

Waste gate solenoid valve coil resistance (at 20_C)Ω29 - 35-

Initial activation pressure of air bypass valve kPaApproximately 53-

Secondary air control solenoid valve coil resistance

(at 20_C)Ω29 - 35-

Manifold distortion of the installation surface mm0.15 or less0.20

SPECIAL TOOL

ToolNumberNameUse

MD998770Oxygen sensor wrenchRemoval and installation of oxygen sensor

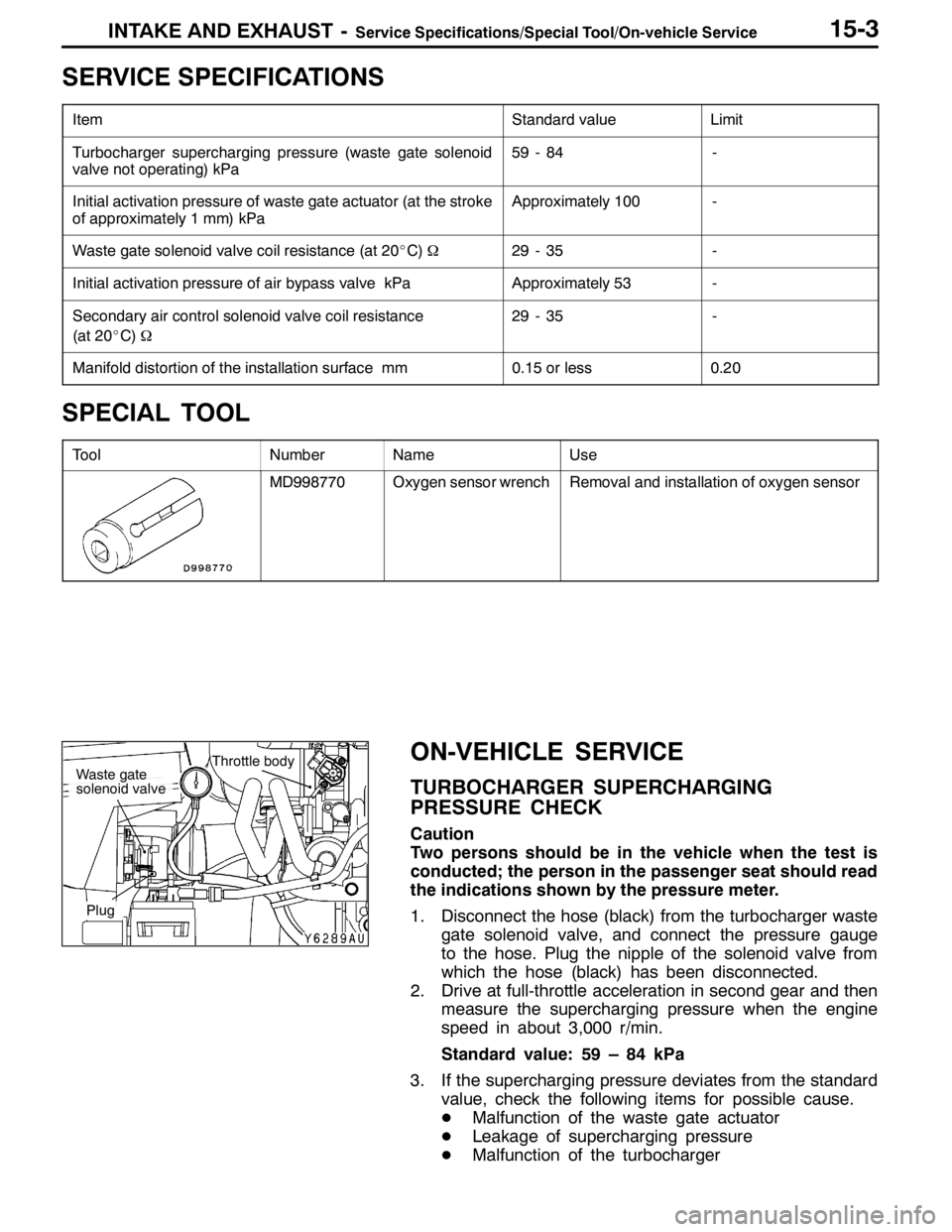

ON-VEHICLE SERVICE

TURBOCHARGER SUPERCHARGING

PRESSURE CHECK

Caution

Two persons should be in the vehicle when the test is

conducted; the person in the passenger seat should read

the indications shown by the pressure meter.

1. Disconnect the hose (black) from the turbocharger waste

gate solenoid valve, and connect the pressure gauge

to the hose. Plug the nipple of the solenoid valve from

which the hose (black) has been disconnected.

2. Drive at full-throttle acceleration in second gear and then

measure the supercharging pressure when the engine

speed in about 3,000 r/min.

Standard value: 59 – 84 kPa

3. If the supercharging pressure deviates from the standard

value, check the following items for possible cause.

DMalfunction of the waste gate actuator

DLeakage of supercharging pressure

DMalfunction of the turbocharger

Throttle bodyWaste gate

solenoid valve

Plug

Page 710 of 1449

INTAKE AND EXHAUST -On-vehicle Service15-4

4. When the indicated supercharging is more than standard

value, supercharging control may be faulty, therefore

check the followings.

DMalfunction of the waste gate actuator

DMalfunction of waste gate valve

DDisconnection or cracks of the waste gate actuator

rubber hose

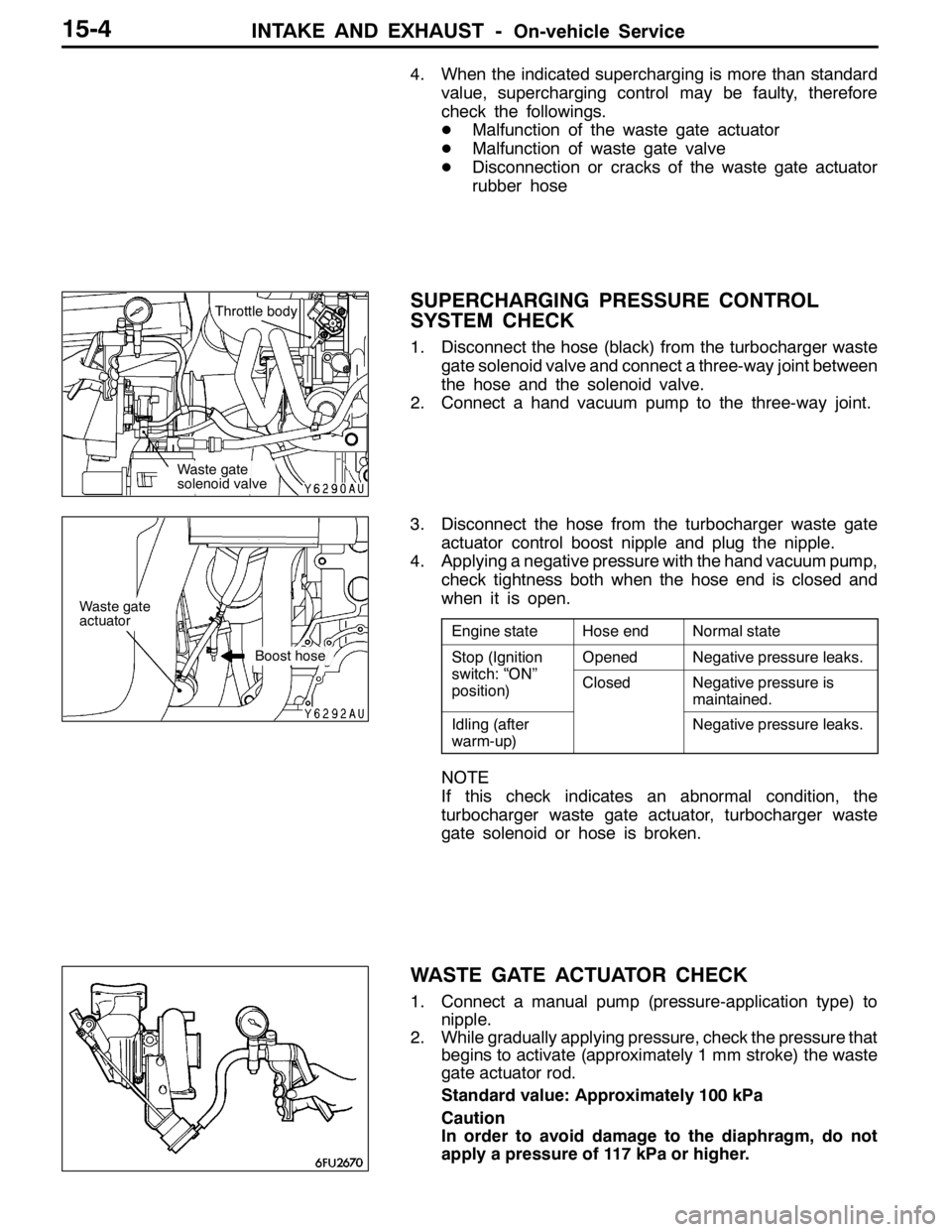

SUPERCHARGING PRESSURE CONTROL

SYSTEM CHECK

1. Disconnect the hose (black) from the turbocharger waste

gate solenoid valve and connect a three-way joint between

the hose and the solenoid valve.

2. Connect a hand vacuum pump to the three-way joint.

3. Disconnect the hose from the turbocharger waste gate

actuator control boost nipple and plug the nipple.

4. Applying a negative pressure with the hand vacuum pump,

check tightness both when the hose end is closed and

when it is open.

Engine stateHose endNormal state

Stop (Ignition

it h“ON”

OpenedNegative pressure leaks.p(g

switch: “ON”

position)ClosedNegative pressure is

maintained.

Idling (after

warm-up)Negative pressure leaks.

NOTE

If this check indicates an abnormal condition, the

turbocharger waste gate actuator, turbocharger waste

gate solenoid or hose is broken.

WASTE GATE ACTUATOR CHECK

1. Connect a manual pump (pressure-application type) to

nipple.

2. While gradually applying pressure, check the pressure that

begins to activate (approximately 1 mm stroke) the waste

gate actuator rod.

Standard value: Approximately 100 kPa

Caution

In order to avoid damage to the diaphragm, do not

apply a pressure of 117 kPa or higher.

Waste gate

solenoid valveThrottle body

Waste gate

actuator

Boost hose