wiper MITSUBISHI LANCER EVOLUTION 2007 Service User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 358 of 1449

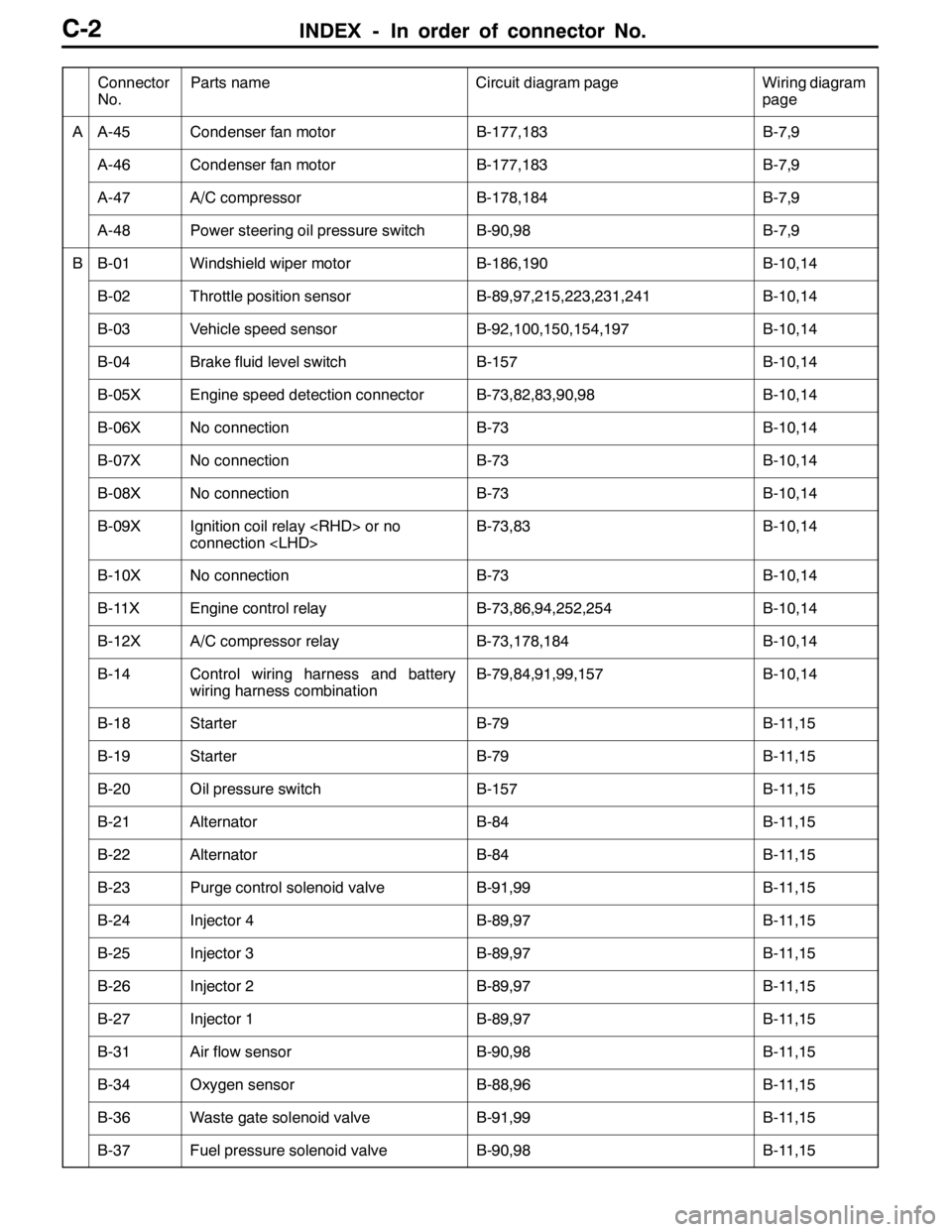

INDEX - In order of connector No.C-2

Wiring diagram

page Circuit diagram page Parts name Connector

No.

AA-45Condenser fan motorB-177,183B-7,9

A-46Condenser fan motorB-177,183B-7,9

A-47A/C compressorB-178,184B-7,9

A-48Power steering oil pressure switchB-90,98B-7,9

BB-01Windshield wiper motorB-186,190B-10,14

B-02Throttle position sensorB-89,97,215,223,231,241B-10,14

B-03Vehicle speed sensorB-92,100,150,154,197B-10,14

B-04Brake fluid level switchB-157B-10,14

B-05XEngine speed detection connectorB-73,82,83,90,98B-10,14

B-06XNo connectionB-73B-10,14

B-07XNo connectionB-73B-10,14

B-08XNo connectionB-73B-10,14

B-09XIgnition coil relay

connection

B-10XNo connectionB-73B-10,14

B-11XEngine control relayB-73,86,94,252,254B-10,14

B-12XA/C compressor relayB-73,178,184B-10,14

B-14Control wiring harness and battery

wiring harness combinationB-79,84,91,99,157B-10,14

B-18StarterB-79B-11,15

B-19StarterB-79B-11,15

B-20Oil pressure switchB-157B-11,15

B-21AlternatorB-84B-11,15

B-22AlternatorB-84B-11,15

B-23Purge control solenoid valveB-91,99B-11,15

B-24Injector 4B-89,97B-11,15

B-25Injector 3B-89,97B-11,15

B-26Injector 2B-89,97B-11,15

B-27Injector 1B-89,97B-11,15

B-31Air flow sensorB-90,98B-11,15

B-34Oxygen sensorB-88,96B-11,15

B-36Waste gate solenoid valveB-91,99B-11,15

B-37Fuel pressure solenoid valveB-90,98B-11,15

Page 376 of 1449

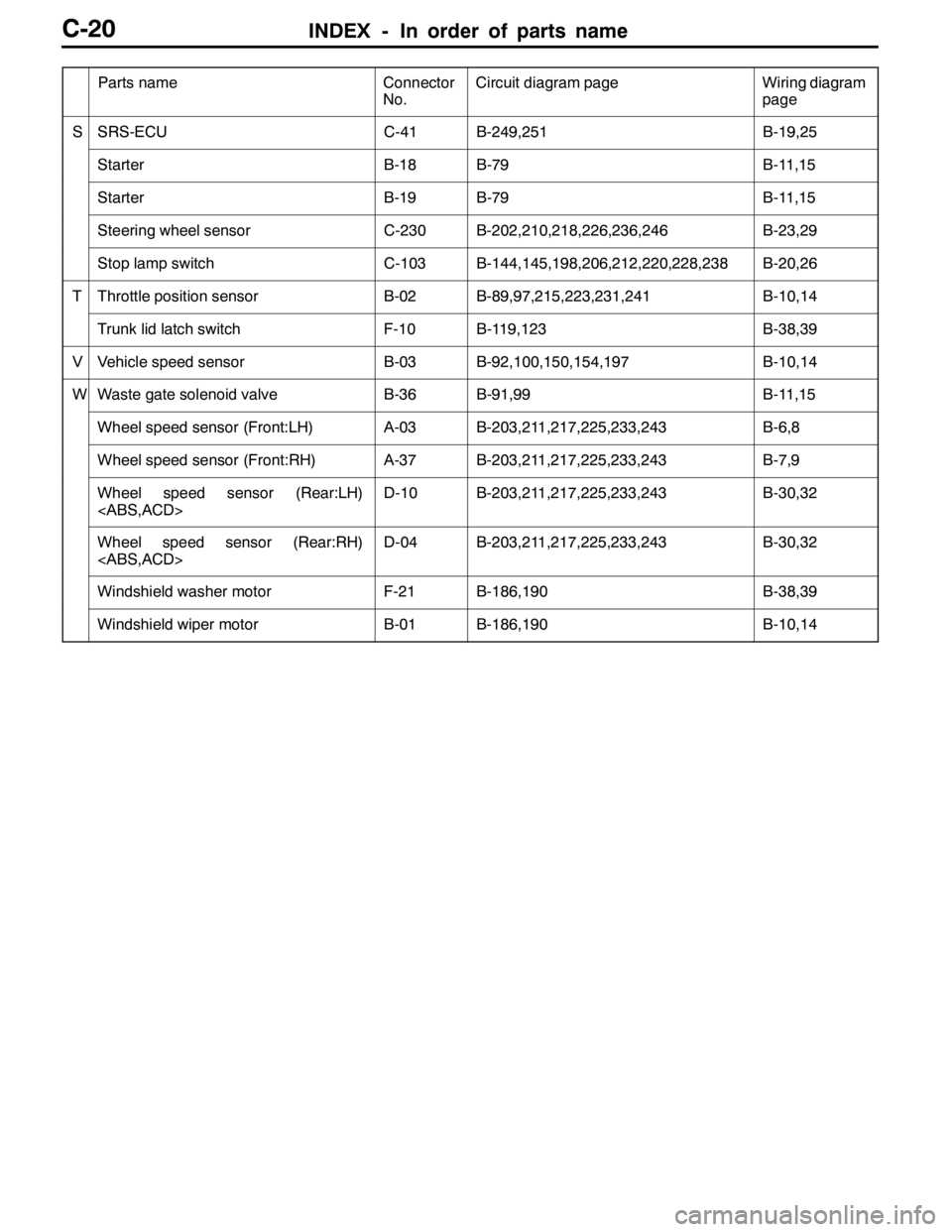

INDEX - In order of parts nameC-20

Wiring diagram

page Circuit diagram page Connector

No. Parts name

SSRS-ECUC-41B-249,251B-19,25

StarterB-18B-79B-11,15

StarterB-19B-79B-11,15

Steering wheel sensorC-230B-202,210,218,226,236,246B-23,29

Stop lamp switchC-103B-144,145,198,206,212,220,228,238B-20,26

TThrottle position sensorB-02B-89,97,215,223,231,241B-10,14

Trunk lid latch switchF-10B-119,123B-38,39

VVehicle speed sensorB-03B-92,100,150,154,197B-10,14

WWaste gate solenoid valveB-36B-91,99B-11,15

Wheel speed sensor (Front:LH)A-03B-203,211,217,225,233,243B-6,8

Wheel speed sensor (Front:RH)A-37B-203,211,217,225,233,243B-7,9

Wheel speed sensor (Rear:LH)

Wheel speed sensor (Rear:RH)

Windshield washer motorF-21B-186,190B-38,39

Windshield wiper motorB-01B-186,190B-10,14

Page 1153 of 1449

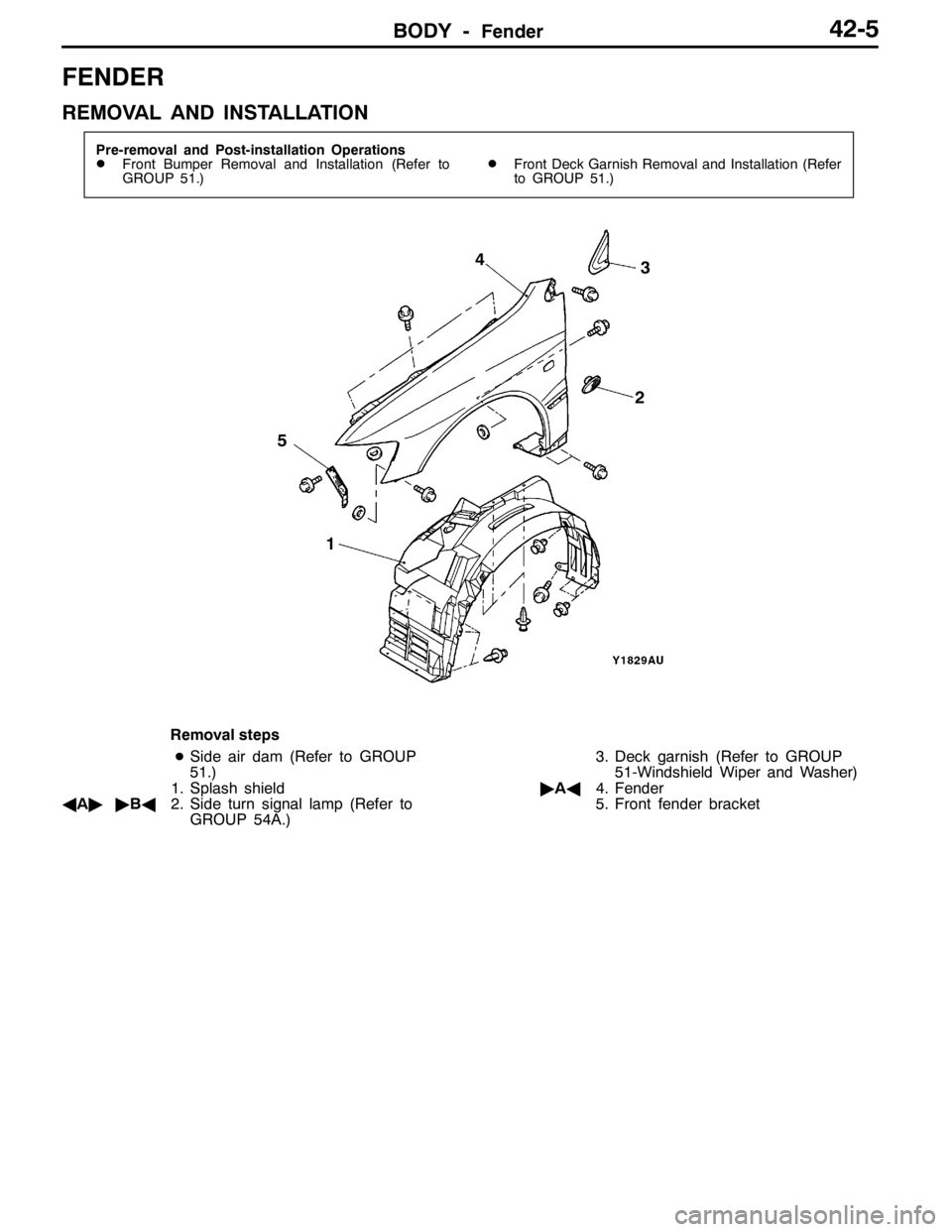

BODY -Fender42-5

FENDER

REMOVAL AND INSTALLATION

Pre-removal and Post-installation OperationsDFront Bumper Removal and Installation (Refer to

GROUP 51.)DFront Deck Garnish Removal and Installation (Refer

to GROUP 51.)

13

2 4

5

Removal steps

DSide air dam (Refer to GROUP

51.)

1. Splash shield

AA""BA2. Side turn signal lamp (Refer to

GROUP 54A.)3. Deck garnish (Refer to GROUP

51-Windshield Wiper and Washer)

"AA4. Fender

5. Front fender bracket

Page 1159 of 1449

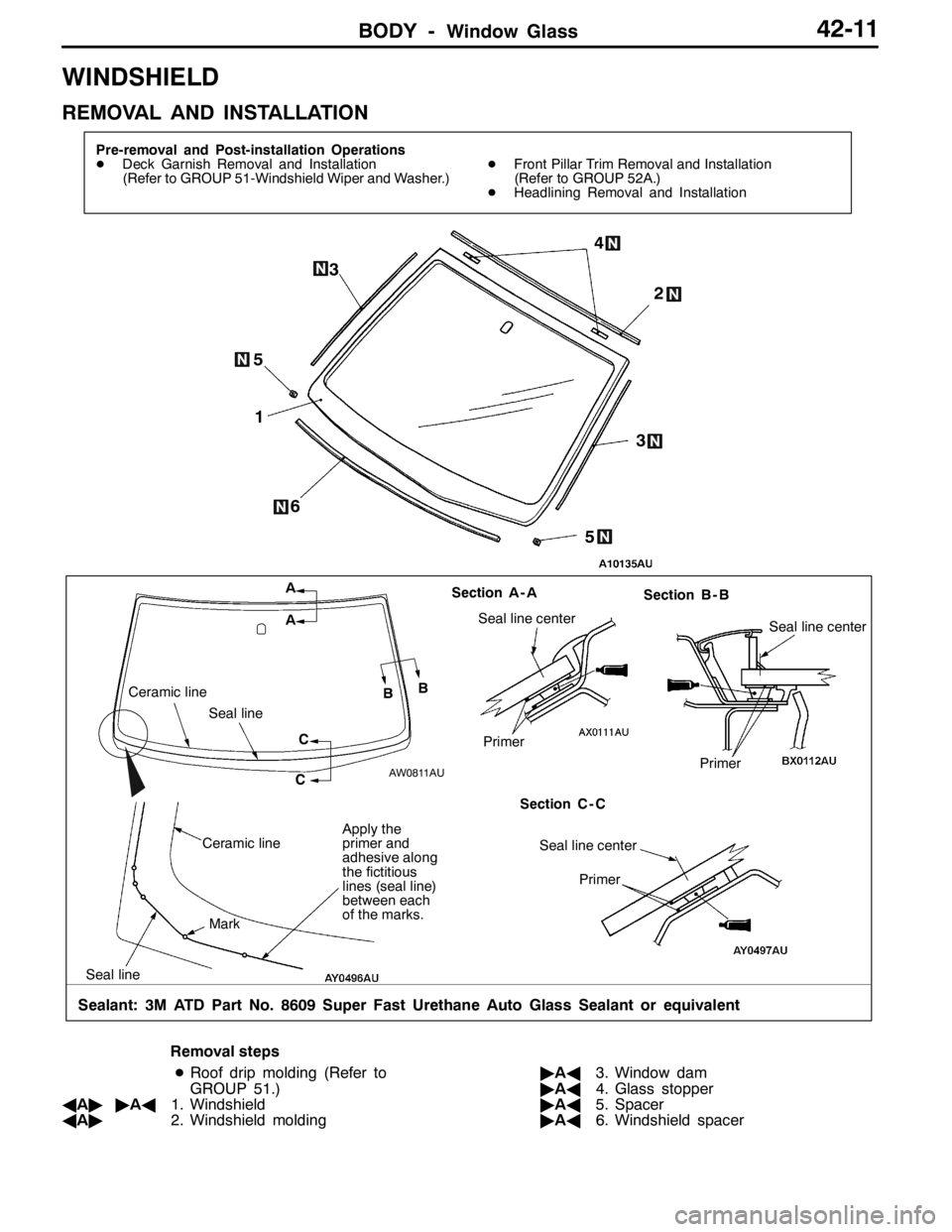

BODY -Window Glass42-11

WINDSHIELD

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operations

DDeck Garnish Removal and Installation

(Refer to GROUP 51-Windshield Wiper and Washer.)DFront Pillar Trim Removal and Installation

(Refer to GROUP 52A.)

DHeadlining Removal and Installation

Section A - A

Section B - B

Section C - C

Sealant: 3M ATD Part No. 8609 Super Fast Urethane Auto Glass Sealant or equivalent

1

BB A

A

C

CPrimer

Primer Primer

54

2

3

3

Ceramic line

Seal line

AW0811AU

Apply the

primer and

adhesive along

the fictitious

lines (seal line)

between each

of the marks.Ceramic line

Seal line

Seal line center

Seal line center

Seal line center

Mark

5

6

Removal steps

DRoof drip molding (Refer to

GROUP 51.)

AA""AA1. Windshield

AA"2. Windshield molding"AA3. Window dam

"AA4. Glass stopper

"AA5. Spacer

"AA6. Windshield spacer

Page 1193 of 1449

51-1

EXTERIOR

CONTENTS

FRONT BUMPER 2....................

ADHESIVE 2..............................

FRONT BUMPER 2........................

REAR BUMPER 6.....................

SIDE AIR DAM, MOLDING AND

GARNISH 8...........................

SPECIAL TOOL 8.........................

ADHESIVE 8..............................

SIDE AIR DAM MOLDING GARNISH 9.....

REAR SPOILER 11....................

ADHESIVE 11.............................REAR SPOILER 12........................

WINDSHIELD WIPER AND WASHER 13.

SERVICE SPECIFICATIONS 13.............

TROUBLESHOOTING 13...................

ON - VEHICLE SERVICE 13.................

WINDSHIELD WIPER AND WASHER 14......

MARKS 20............................

OUTSIDE MIRROR 23.................

SPECIAL TOOL 23........................

OUTSIDE MIRROR 23......................

Page 1205 of 1449

EXTERIOR -Windshield Wiper and Washer51-13

WINDSHIELD WIPER AND WASHER

SERVICE SPECIFICATIONS

ItemStandard value

Stopposition of the windshield wiper arm/blade assembly(distance between the edgeof34±5Stoppositionofthewindshieldwiperarm/bladeassembly(distancebetweentheedgeof

the wiper blade and the end of the deck garnish) mm

34±5

TROUBLESHOOTING

The windshield wiper-washer is controlled by the smart wiring system (SWS). Refer to Group 54B for

troubleshooting.

NOTE

If ETACS-ECU is faulty, the windshield wiper can be operable in LO mode only as the fail - safe function.

(Normally the windshield wiper is operable when the ignition switch is turned to the ACC position. When

the fail - safe function is enabled, it is operable only when the ignition switch is turned to the ON position.)

ON-VEHICLE SERVICE

WINDSHIELD INTERMITTENT WIPER

INSPECTIONS

(1) Check the change in the intermittent time of the wiper

operation by using the windshield intermittent wiper

volume.

(2) Carry out troubleshooting if any of them is faulty.

(Refer to Group 54B.)

Page 1206 of 1449

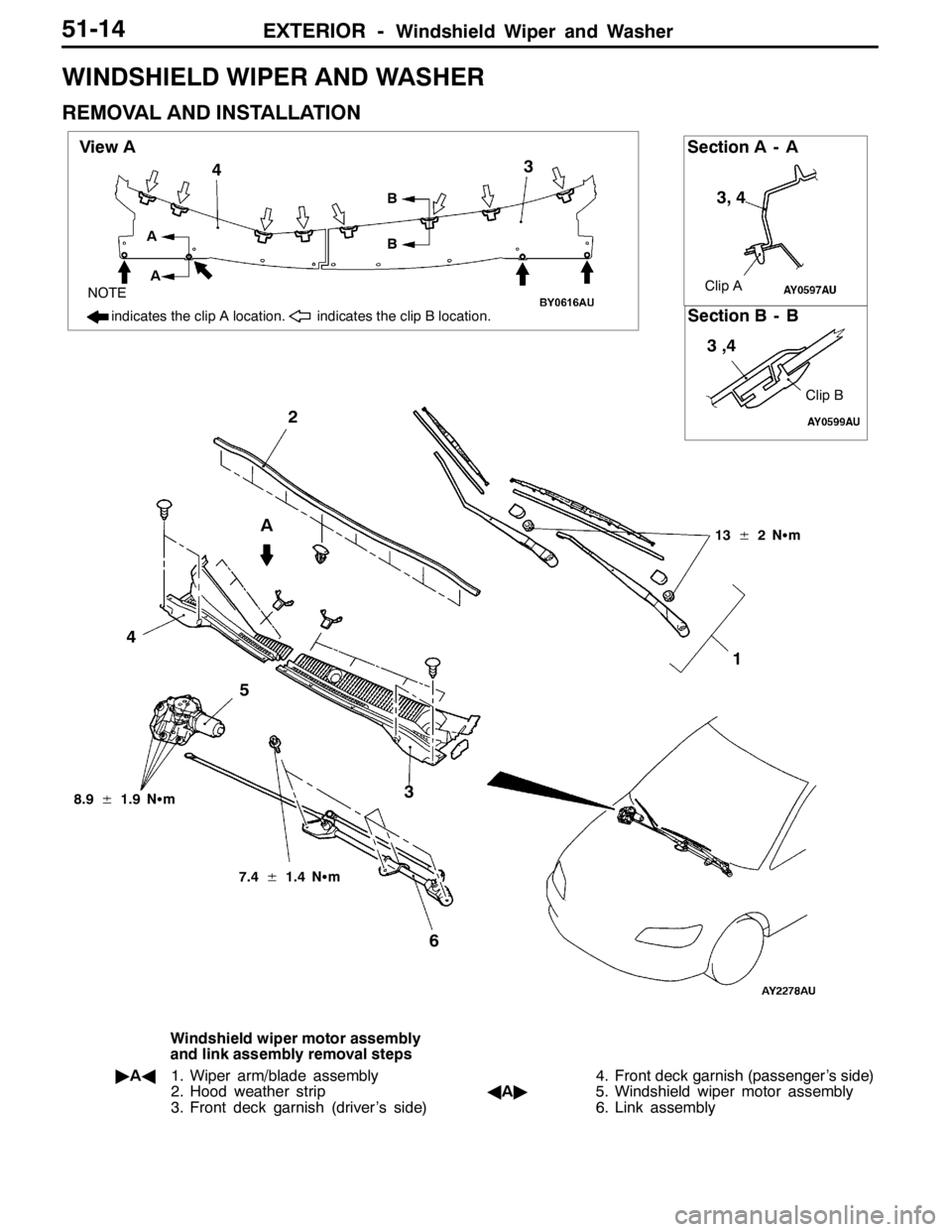

EXTERIOR -Windshield Wiper and Washer51-14

WINDSHIELD WIPER AND WASHER

REMOVAL AND INSTALLATION

NOTE

indicates the clip A location. indicates the clip B location.

Section A - A

Section B - B View A

3,4

Clip A

13±2NSmA

5 4

8.9±1.9 NSm

1

3

Clip B

3, 4

7.4±1.4 NSm

6 43

A

AB B

2

Windshield wiper motor assembly

and link assembly removal steps

"AA1. Wiper arm/blade assembly

2. Hood weather strip

3. Front deck garnish (driver’s side)4. Front deck garnish (passenger’s side)

AA"5. Windshield wiper motor assembly

6. Link assembly

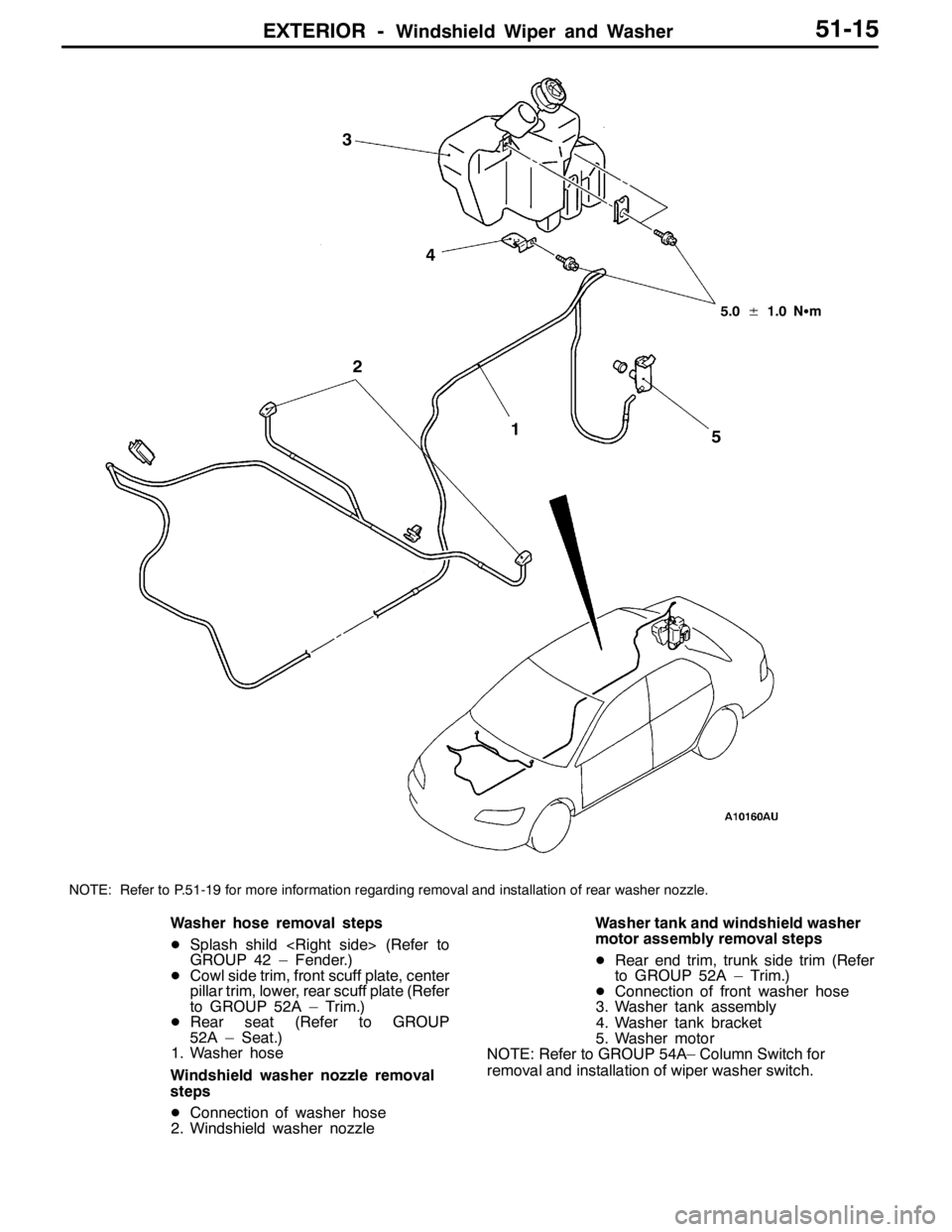

Page 1207 of 1449

EXTERIOR -Windshield Wiper and Washer51-15

5.0±1.0 NSm

4

1 3

2

NOTE: Refer to P.51-19 for more information regarding removal and installation of rear washer nozzle.

5

Washer hose removal steps

DSplash shild

GROUP 42 – Fender.)

DCowl side trim, front scuff plate, center

pillar trim, lower, rear scuff plate (Refer

to GROUP 52A – Trim.)

DRear seat (Refer to GROUP

52A – Seat.)

1. Washer hose

Windshield washer nozzle removal

steps

DConnection of washer hose

2. Windshield washer nozzleWasher tank and windshield washer

motor assembly removal steps

DRear end trim, trunk side trim (Refer

to GROUP 52A – Trim.)

DConnection of front washer hose

3. Washer tank assembly

4. Washer tank bracket

5. Washer motor

NOTE: Refer to GROUP 54A– Column Switch for

removal and installation of wiper washer switch.

Page 1208 of 1449

EXTERIOR -Windshield Wiper and Washer51-16

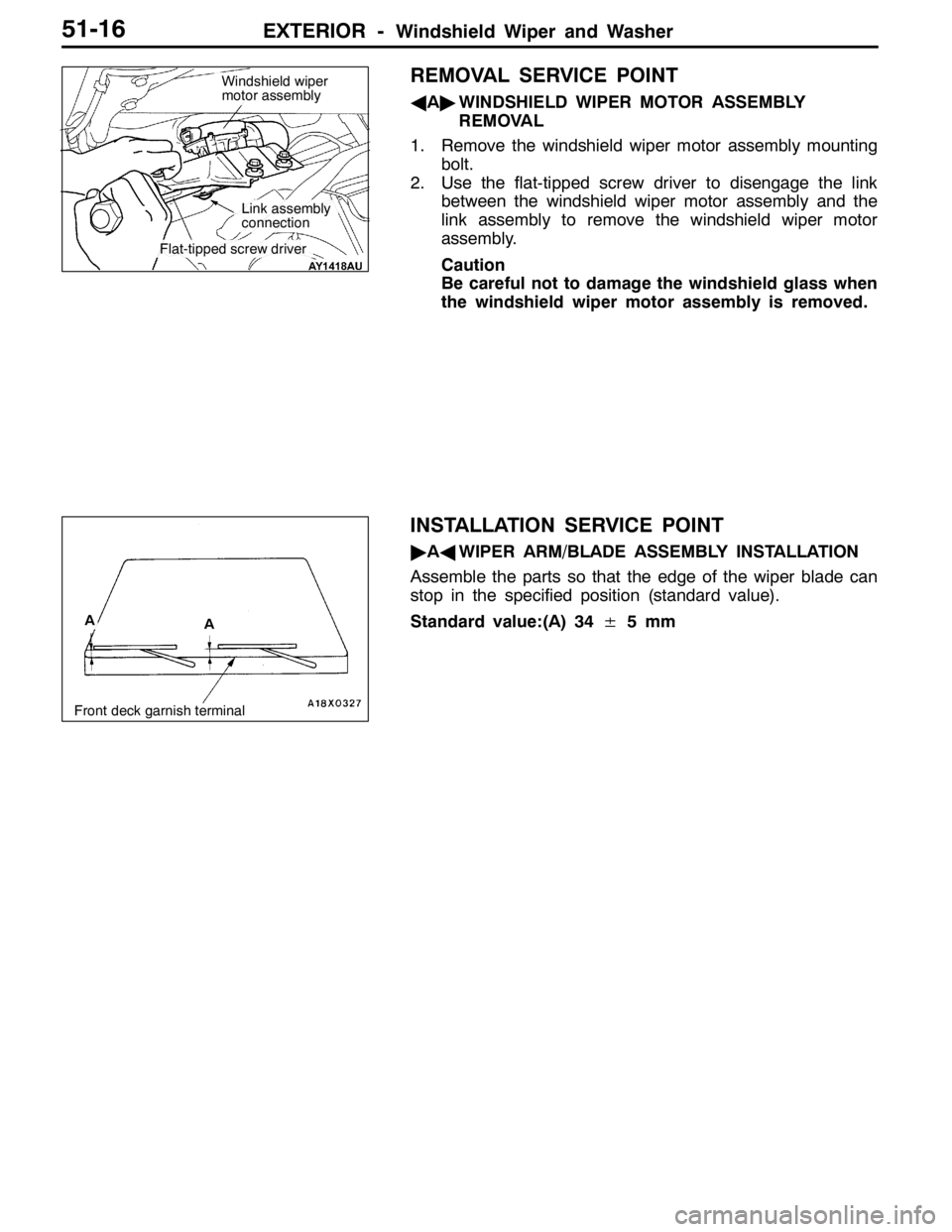

REMOVAL SERVICE POINT

AA"WINDSHIELD WIPER MOTOR ASSEMBLY

REMOVAL

1. Remove the windshield wiper motor assembly mounting

bolt.

2. Use the flat-tipped screw driver to disengage the link

between the windshield wiper motor assembly and the

link assembly to remove the windshield wiper motor

assembly.

Caution

Be careful not to damage the windshield glass when

the windshield wiper motor assembly is removed.

INSTALLATION SERVICE POINT

"AAWIPER ARM/BLADE ASSEMBLY INSTALLATION

Assemble the parts so that the edge of the wiper blade can

stop in the specified position (standard value).

Standard value:(A) 34±5mm

Windshield wiper

motor assembly

Flat-tipped screw driver

Link assembly

connection

Front deck garnish terminal

AA

Page 1209 of 1449

EXTERIOR -Windshield Wiper and Washer51-17

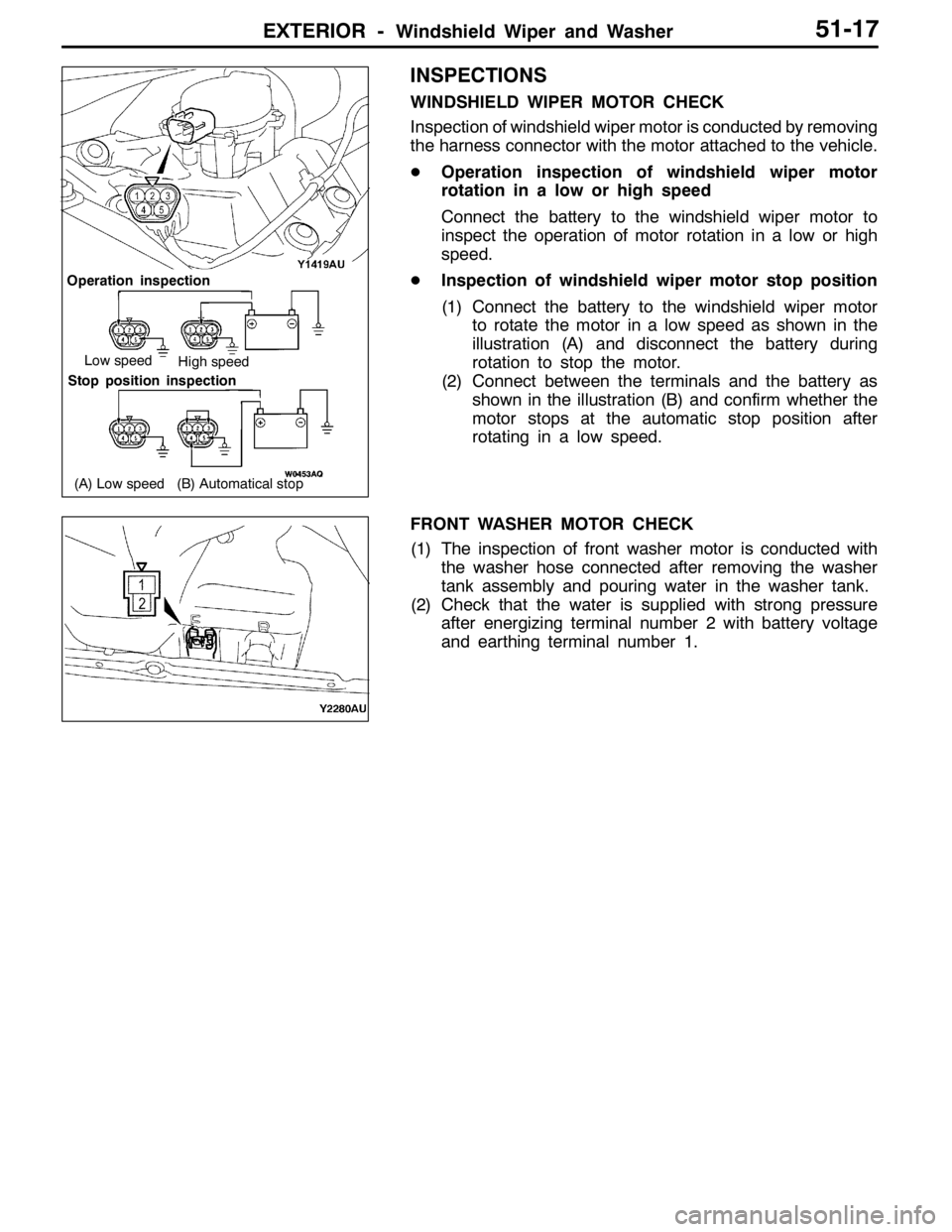

INSPECTIONS

WINDSHIELD WIPER MOTOR CHECK

Inspection of windshield wiper motor is conducted by removing

the harness connector with the motor attached to the vehicle.

DOperation inspection of windshield wiper motor

rotation in a low or high speed

Connect the battery to the windshield wiper motor to

inspect the operation of motor rotation in a low or high

speed.

DInspection of windshield wiper motor stop position

(1) Connect the battery to the windshield wiper motor

to rotate the motor in a low speed as shown in the

illustration (A) and disconnect the battery during

rotation to stop the motor.

(2) Connect between the terminals and the battery as

shown in the illustration (B) and confirm whether the

motor stops at the automatic stop position after

rotating in a low speed.

FRONT WASHER MOTOR CHECK

(1) The inspection of front washer motor is conducted with

the washer hose connected after removing the washer

tank assembly and pouring water in the washer tank.

(2) Check that the water is supplied with strong pressure

after energizing terminal number 2 with battery voltage

and earthing terminal number 1.

(B) Automatical stop

Operation inspection

Low speedHigh speed

Stop position inspection

(A) Low speed