ignition MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 1336 of 1449

CHASSIS ELECTRICAL -Combination Meter54A-16

INSPECTION PROCEDURE FOR TROUBLE SYMPTOMS

Inspection procedure 1

Speedometer inoperative (other meters are operated)

Probable cause

Failure may occur on engine-ECU system, harnesses, connectors, meter

assembly.DEngine-ECU fault

DHarness or connector fault

DMeter assembly fault

NO

MUT-IISelf-Diag. Code

Is diagnostic code P0500 for MPI output?YESPerform troubleshooting for MPI (Refer to GROUP 13A -

Troubleshooting)

OK

NG

Check the following connectors:

Repair

OK

Check trouble symptom.

NG

NG

RepairCheck harnesses:

DCombination meter to engine-ECU.

Check trouble symptom.

NG

Replace meter assembly.

OK

Check for input signal from ETACS-ECU with MUT-II

DVehicle speed signal (engine-ECU)NGReplace engine-ECU

NOTE

When vehicle speed signal is checked with MUT-IIin the ETACS-ECU input signal test, drive the vehicle

with MUT-IIconnected to diagnostic connector. When the buzzer sounds, this test is evaluated OK.

Inspection procedure 2

Tachometer inoperative (other meters are operated)

Probable cause

No input of ignition signal from engine, or failure may occur on power and earth

circuits of meter.DHarness or connector fault

DMeter assembly fault

OK

NO

MUT-IISelf-Diag. Code

Is DTC P0300 for MPI output?YESPerform troubleshooting for MPI (Refer to GROUP 13A -

Troubleshooting.)

NG

NG

RepairRepair

Check trouble symptom.

OK

Check the following connectors:

Replace meter assembly.Check harnesses:

DCombination meter to engine-ECU

Page 1337 of 1449

CHASSIS ELECTRICAL -Combination Meter54A-17

Inspection procedure 3

Fuel gauge inoperative (other meters are operated)

Probable cause

When speedometer and tachometer are properly operated, harness from power

source to combination meter is normal.DFuel gauge unit fault

DHarness or connector fault

DMeter assembly fault

OKReplace main fuel gauge unit.

NG

Check harness from main fuel gauge unit to combination

meter.Repair

Check trouble symptom.

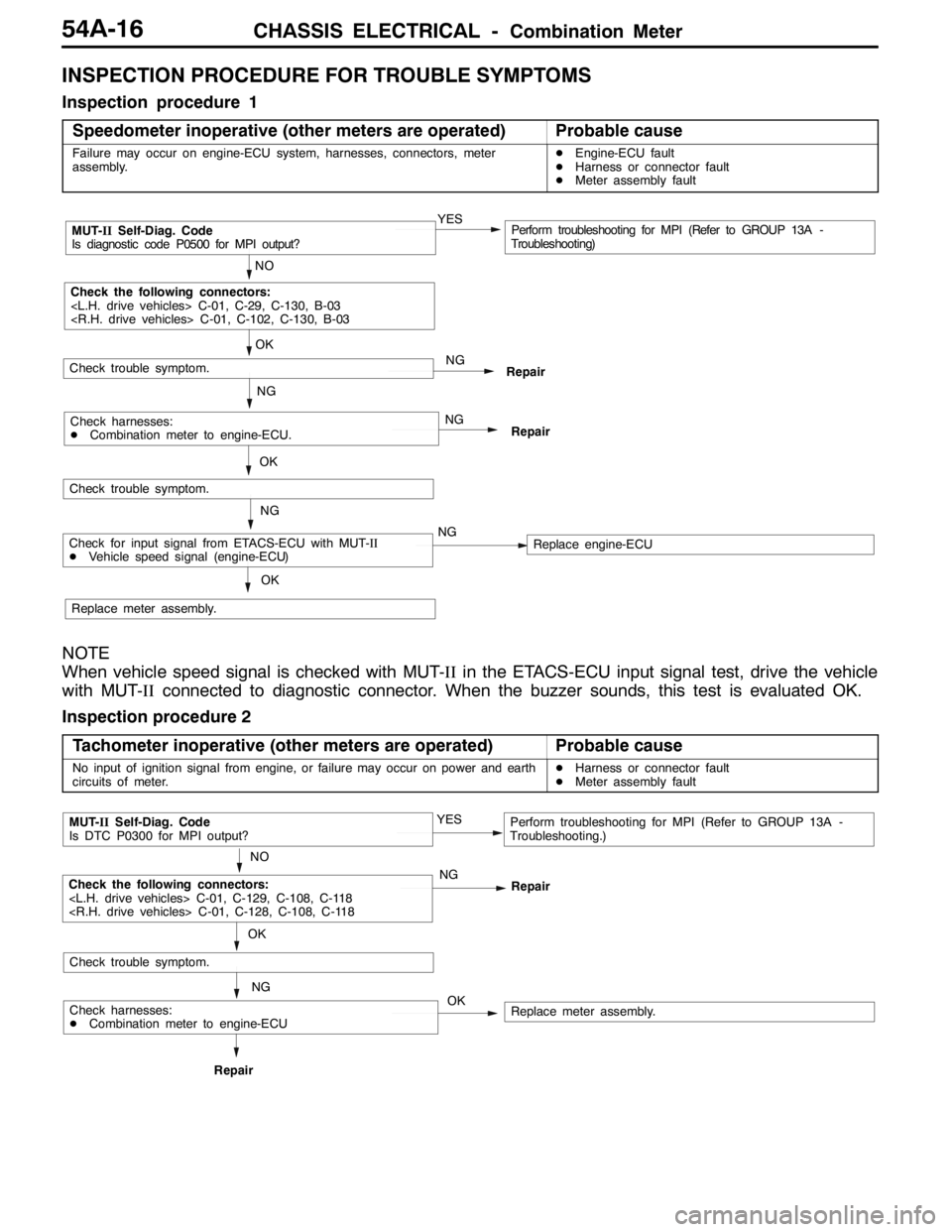

Main fuel gauge circuit check

DDisconnect main fuel gauge unit connector D-09.

DUse special tool on connector at the harness side to

connect test lamp (12V – 3.4W). (Refer to Fig. 1)

DIgnition switch: ON

(1) Is test lamp ON?

OK:Illuminated

(2) Is fuel gauge pointer swinging to the haft range.

OK:Swinging

(1) NG

Fig. 1MB991219

Earth

Fuel gauge

Test lamp

(12V - 3.4W)

Repair

Check trouble symptom.

Check the following connectors:

C-02, D-26, C-146, D-30, D-27, D-09

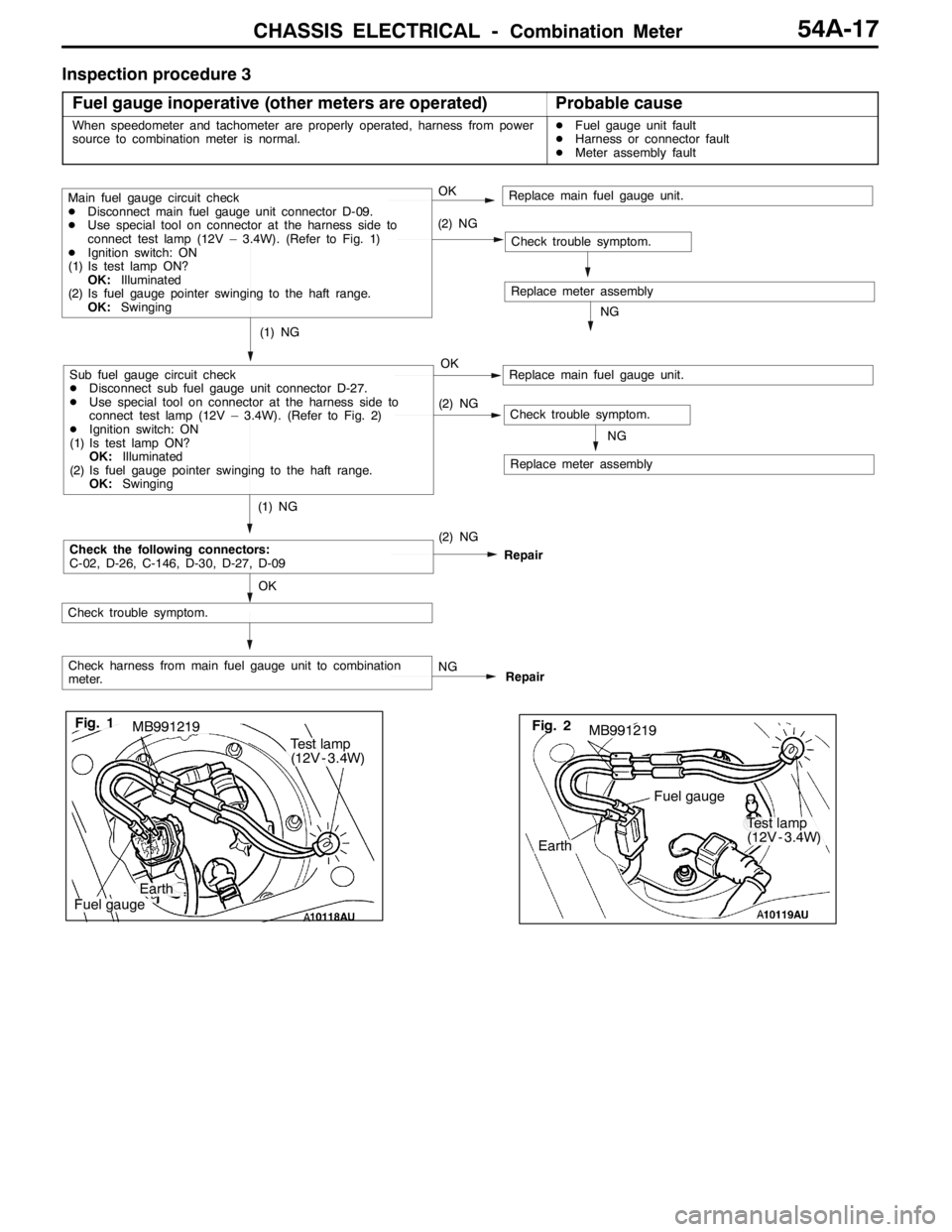

Earth

Test lamp

(12V - 3.4W)

Fuel gauge

MB991219Fig. 2

Sub fuel gauge circuit check

DDisconnect sub fuel gauge unit connector D-27.

DUse special tool on connector at the harness side to

connect test lamp (12V – 3.4W). (Refer to Fig. 2)

DIgnition switch: ON

(1) Is test lamp ON?

OK:Illuminated

(2) Is fuel gauge pointer swinging to the haft range.

OK:Swinging

Replace meter assembly

OK (2) NG

(2) NG

Check trouble symptom.

Replace meter assemblyNG

Replace main fuel gauge unit.

(1) NG

OK

NG (2) NG

Page 1338 of 1449

CHASSIS ELECTRICAL -Combination Meter54A-18

Inspection procedure 4

Water temperature gauge inoperative (other meters are

operated)

Probable cause

When speedometer and tachometer are properly operated, harness from power

source to combination meter is normal.DWater temperature gauge unit fault

DHarness or connector fault

DMeter assembly fault

OKReplace water temperature gauge unit.

NG

RepairNG

OK

Check trouble symptom.

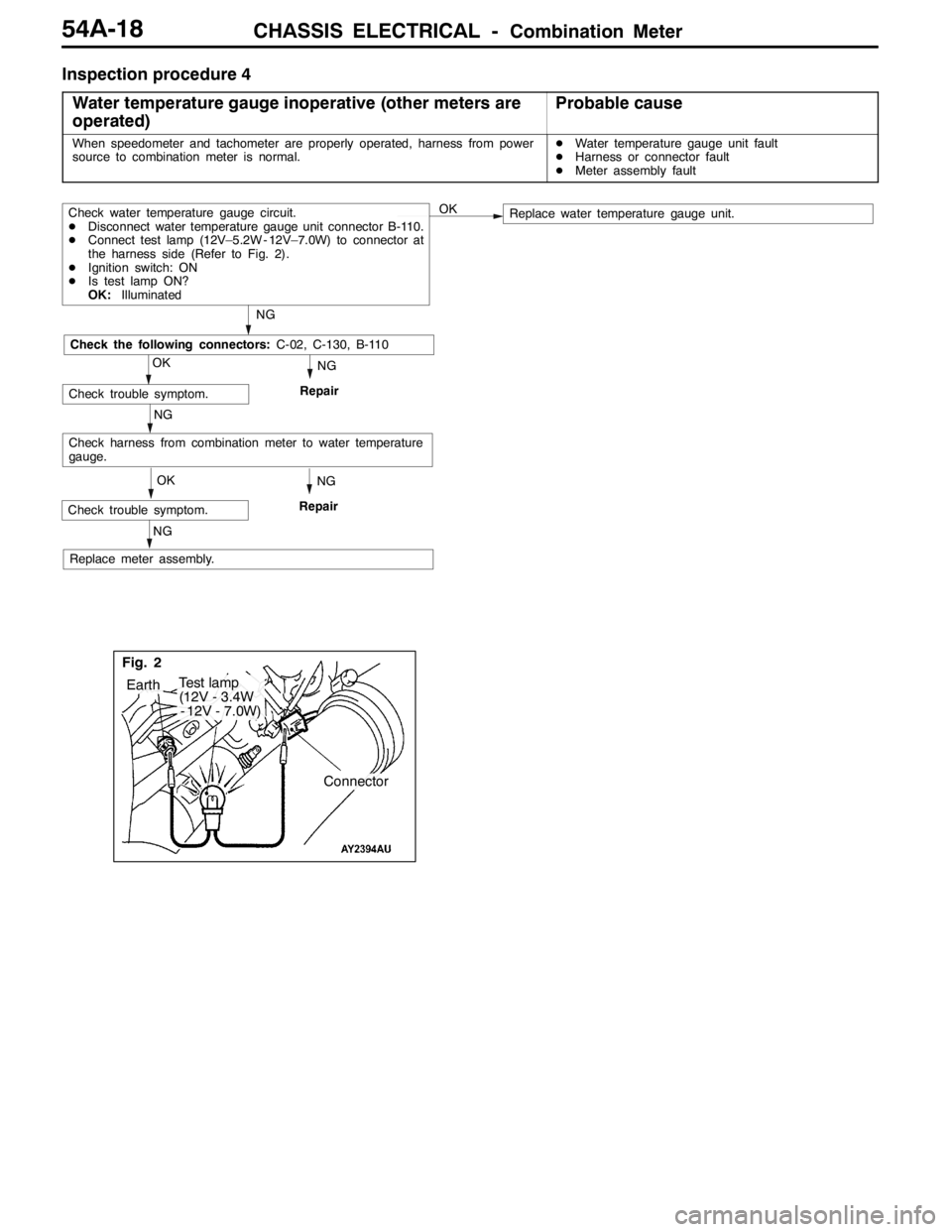

Check water temperature gauge circuit.

DDisconnect water temperature gauge unit connector B-110.

DConnect test lamp (12V–5.2W - 12V–7.0W) to connector at

the harness side (Refer to Fig. 2).

DIgnition switch: ON

DIs test lamp ON?

OK:Illuminated

Check the following connectors:C-02, C-130, B-110

NG

RepairNG

OK

Check trouble symptom.

NG

Replace meter assembly.

Check harness from combination meter to water temperature

gauge.

Connector

EarthTest lamp

(12V - 3.4W

- 12V - 7.0W)

Fig. 2

Page 1339 of 1449

CHASSIS ELECTRICAL -Combination MeterCHASSIS ELECTRICAL -Combination Meter54A-19

Inspection procedure 5All meters inoperative

Probable cause

When individual indicators and warning lamps are properly operated, harness

from power source (IG1) to combination meter is normal.D Meter assembly fault

D Harness or connector fault

NG Repair

NG

OK

Check trouble symptom. Repair

OK

Check the following connectors:

NG

Check harness from ignition switch (IG1) to combination meter.

Replace meter assembly. Repair

NG

OK

Check the following connectors:

C-01

NG

RepairCheck harness from combination meter to body earth.

ON-VEHICLE SERVICE

SPEEDOMETER CHECK

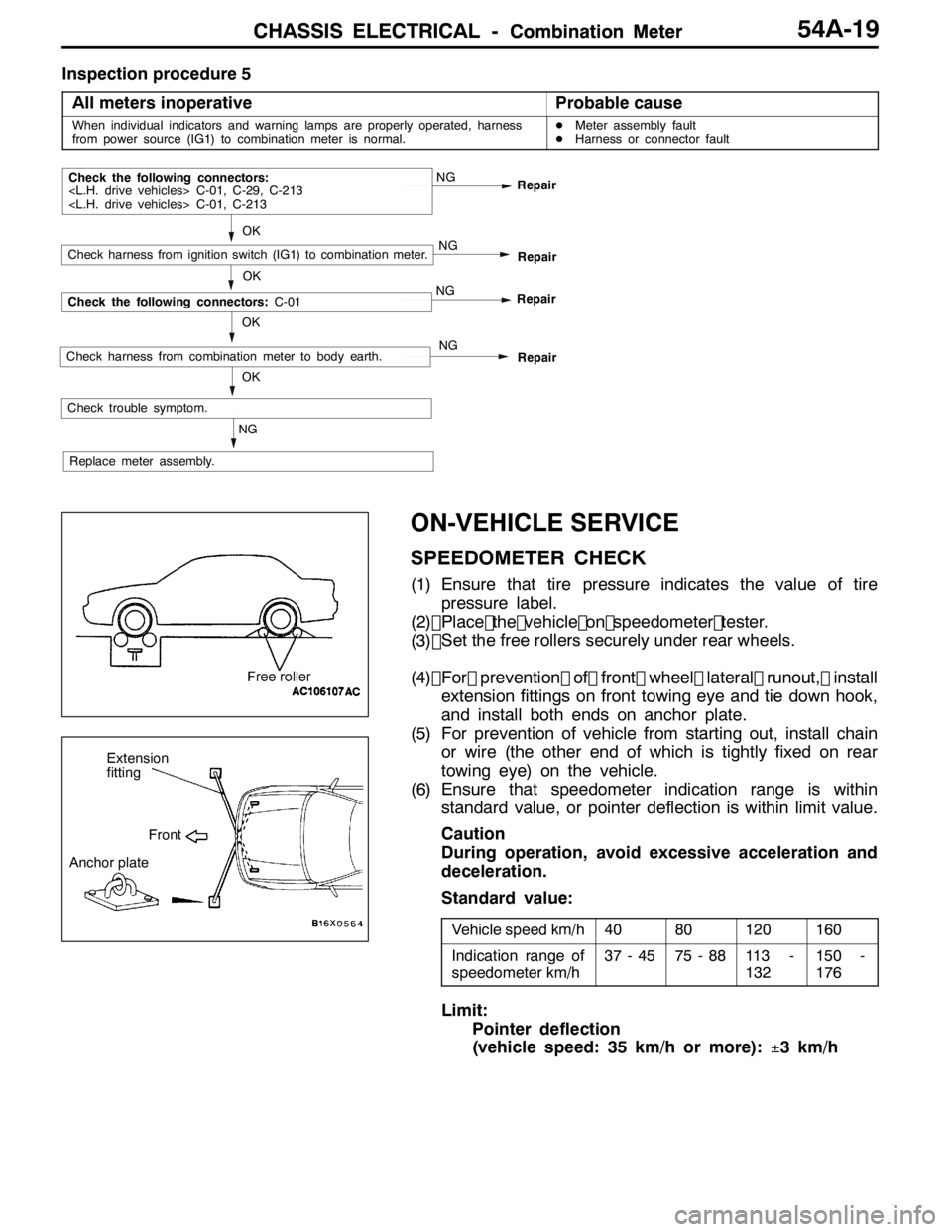

(1) Ensure that tire pressure indicates the value of tirepressure label.

(2) Place the vehicle on speedometer teste r.

(3)

(4) For prevention of front wheel lateral runout, install

extension fittings on front towing eye and tie down hook,

and install both ends on anchor plate.

(5) For prevention of vehicle from starting out, install chain or wire (the other end of which is tightly fixed on rear

towing eye) on the vehicle.

(6) Ensure that speedometer indication range is within standard value, or pointer deflection is within limit value.

Caution

During operation, avoid excessive acceleration and

deceleration.

Standard value:

Vehicle speed km/h4080120160

Indication range of

speedometer km/h37 - 4575 - 8811 3 -

132150 -

176

Limit:

Pointer deflection

(vehicle speed: 35 km/h or more): ±3 km/h

Extension

fitting

Front

Anchor plate

OK

Set the free rollers securely under rear wheels.

Page 1349 of 1449

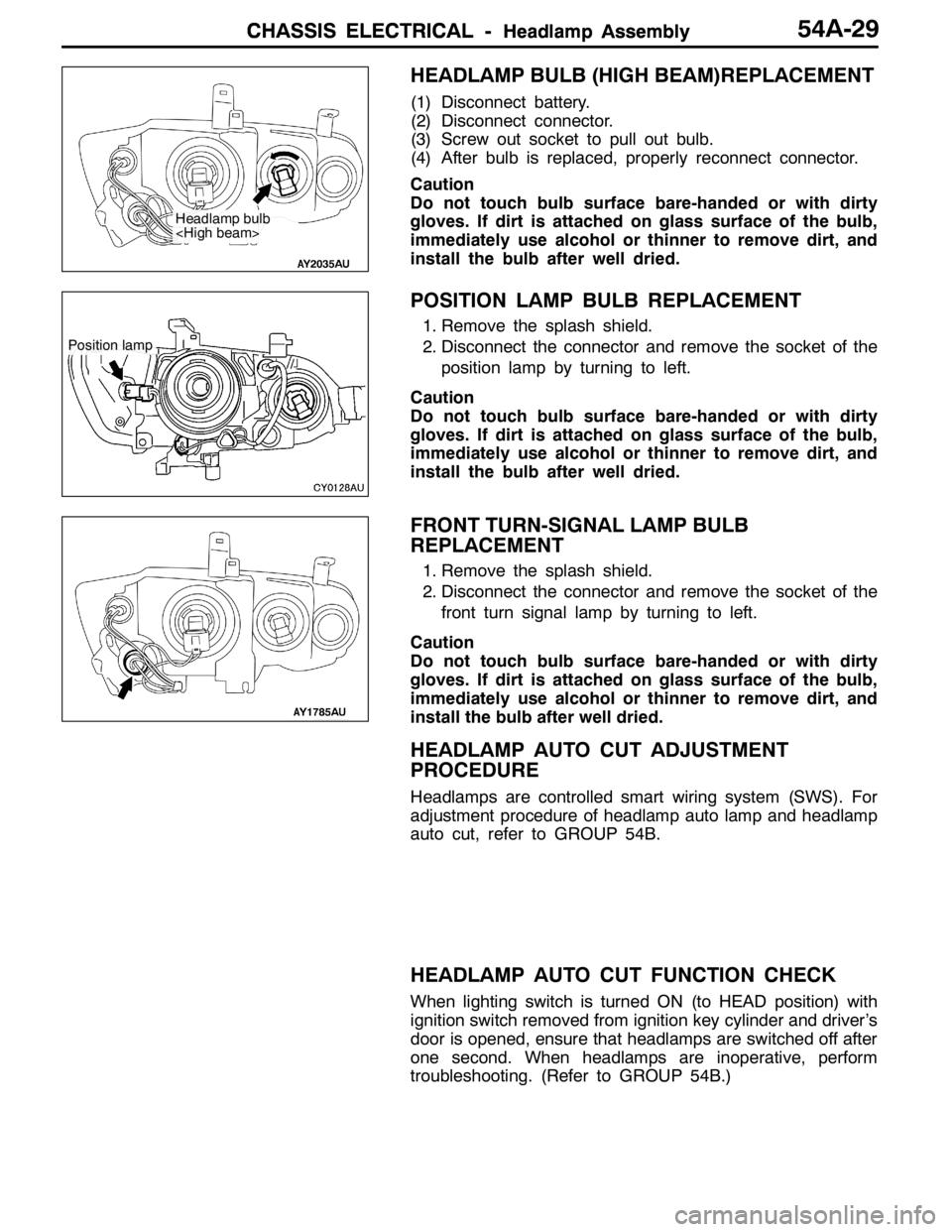

CHASSIS ELECTRICAL -Headlamp AssemblyCHASSIS ELECTRICAL -Headlamp AssemblyCHASSIS ELECTRICAL -Headlamp Assembly54A-29

HEADLAMP BULB (HIGH BEAM)REPLACEMENT

(1) Disconnect battery.

(2) Disconnect connector.

(3) Screw out socket to pull out bulb.

(4) After bulb is replaced, properly reconnect connector.

Caution

Do not touch bulb surface bare-handed or with dirty

gloves. If dirt is attached on glass surface of the bulb,

immediately use alcohol or thinner to remove dirt, and

install the bulb after well dried.

POSITION LAMP BULB REPLACEMENT

1. Remove the splash shield.

2. Disconnect the connector and remove the socket of the

position lamp by turning to left.

Caution

Do not touch bulb surface bare-handed or with dirty

gloves. If dirt is attached on glass surface of the bulb,

immediately use alcohol or thinner to remove dirt, and

install the bulb after well dried.

FRONT TURN-SIGNAL LAMP BULB

REPLACEMENT

1. Remove the splash shield.

2. Disconnect the connector and remove the socket of the

front turn signal lamp by turning to left.

Caution

Do not touch bulb surface bare-handed or with dirty

gloves. If dirt is attached on glass surface of the bulb,

immediately use alcohol or thinner to remove dirt, and

install the bulb after well dried.

HEADLAMP AUTO CUT ADJUSTMENT

PROCEDURE

Headlamps are controlled smart wiring system (SWS). For

adjustment procedure of headlamp auto lamp and headlamp

auto cut, refer to GROUP 54B.

HEADLAMP AUTO CUT FUNCTION CHECK

When lighting switch is turned ON (to HEAD position) with

ignition switch removed from ignition key cylinder and driver’s

door is opened, ensure that headlamps are switched off after

one second. When headlamps are inoperative, perform

troubleshooting. (Refer to GROUP 54B.)

Headlamp bulb

Position lamp

Page 1367 of 1449

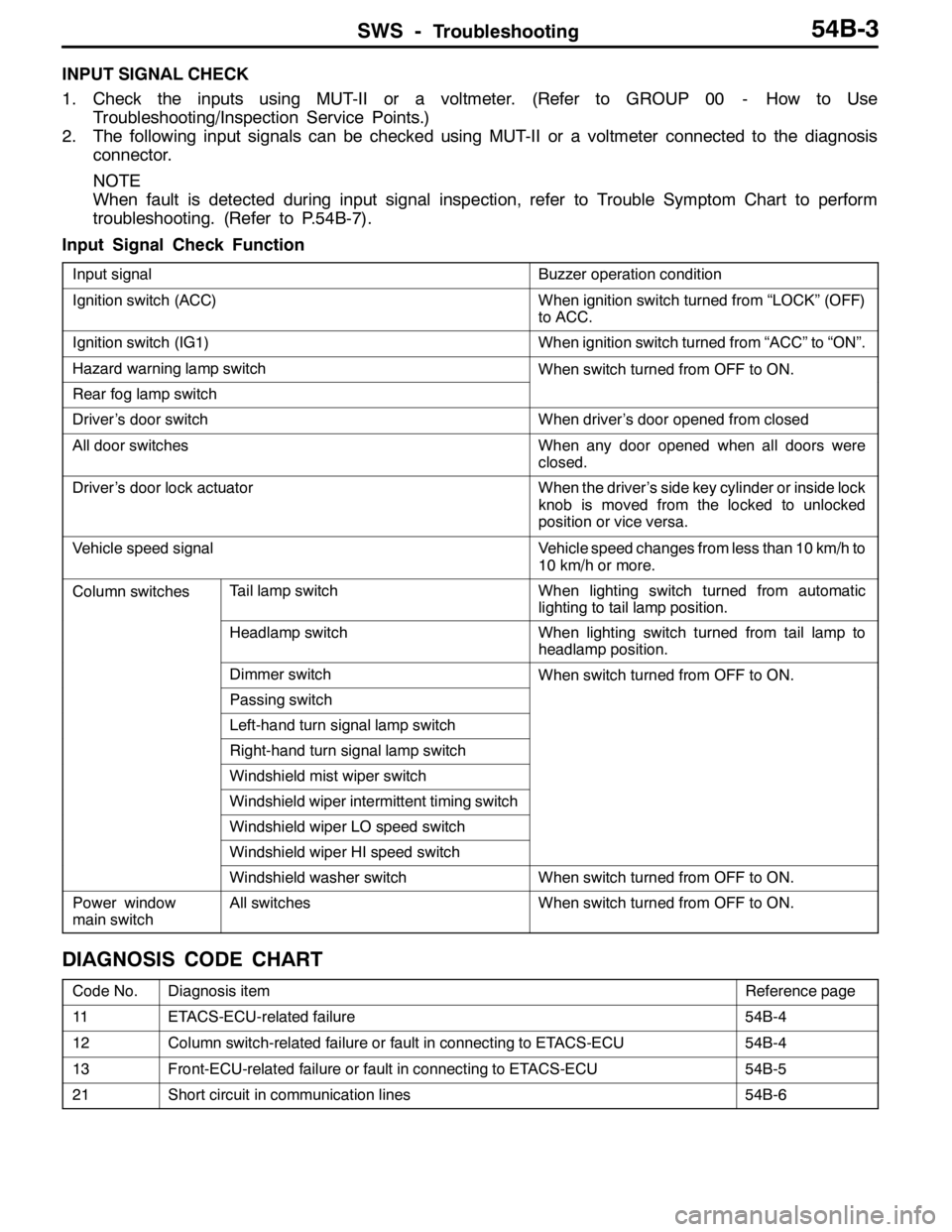

SWS -Troubleshooting54B-3

INPUT SIGNAL CHECK

1. Check the inputs using MUT-II or a voltmeter. (Refer to GROUP 00 - How to Use

Troubleshooting/Inspection Service Points.)

2. The following input signals can be checked using MUT-II or a voltmeter connected to the diagnosis

connector.

NOTE

When fault is detected during input signal inspection, refer to Trouble Symptom Chart to perform

troubleshooting. (Refer to P.54B-7).

Input Signal Check Function

Input signalBuzzer operation condition

Ignition switch (ACC)When ignition switch turned from “LOCK” (OFF)

to ACC.

Ignition switch (IG1)When ignition switch turned from “ACC” to “ON”.

Hazard warning lamp switchWhen switch turned from OFF to ON.

Rear fog lamp switch

Driver’s door switchWhen driver’s door opened from closed

All door switchesWhen any door opened when all doors were

closed.

Driver’s door lock actuatorWhen the driver’s side key cylinder or inside lock

knob is moved from the locked to unlocked

position or vice versa.

Vehicle speed signalVehicle speed changes from less than 10 km/h to

10 km/h or more.

Column switchesTail lamp switchWhen lighting switch turned from automatic

lighting to tail lamp position.

Headlamp switchWhen lighting switch turned from tail lamp to

headlamp position.

Dimmer switchWhen switch turned from OFF to ON.

Passing switch

Left-hand turn signal lamp switch

Right-hand turn signal lamp switch

Windshield mist wiper switch

Windshield wiper intermittent timing switch

Windshield wiper LO speed switch

Windshield wiper HI speed switch

Windshield washer switchWhen switch turned from OFF to ON.

Power window

main switchAll switchesWhen switch turned from OFF to ON.

DIAGNOSIS CODE CHART

Code No.Diagnosis itemReference page

11ETACS-ECU-related failure54B-4

12Column switch-related failure or fault in connecting to ETACS-ECU54B-4

13Front-ECU-related failure or fault in connecting to ETACS-ECU54B-5

21Short circuit in communication lines54B-6

Page 1368 of 1449

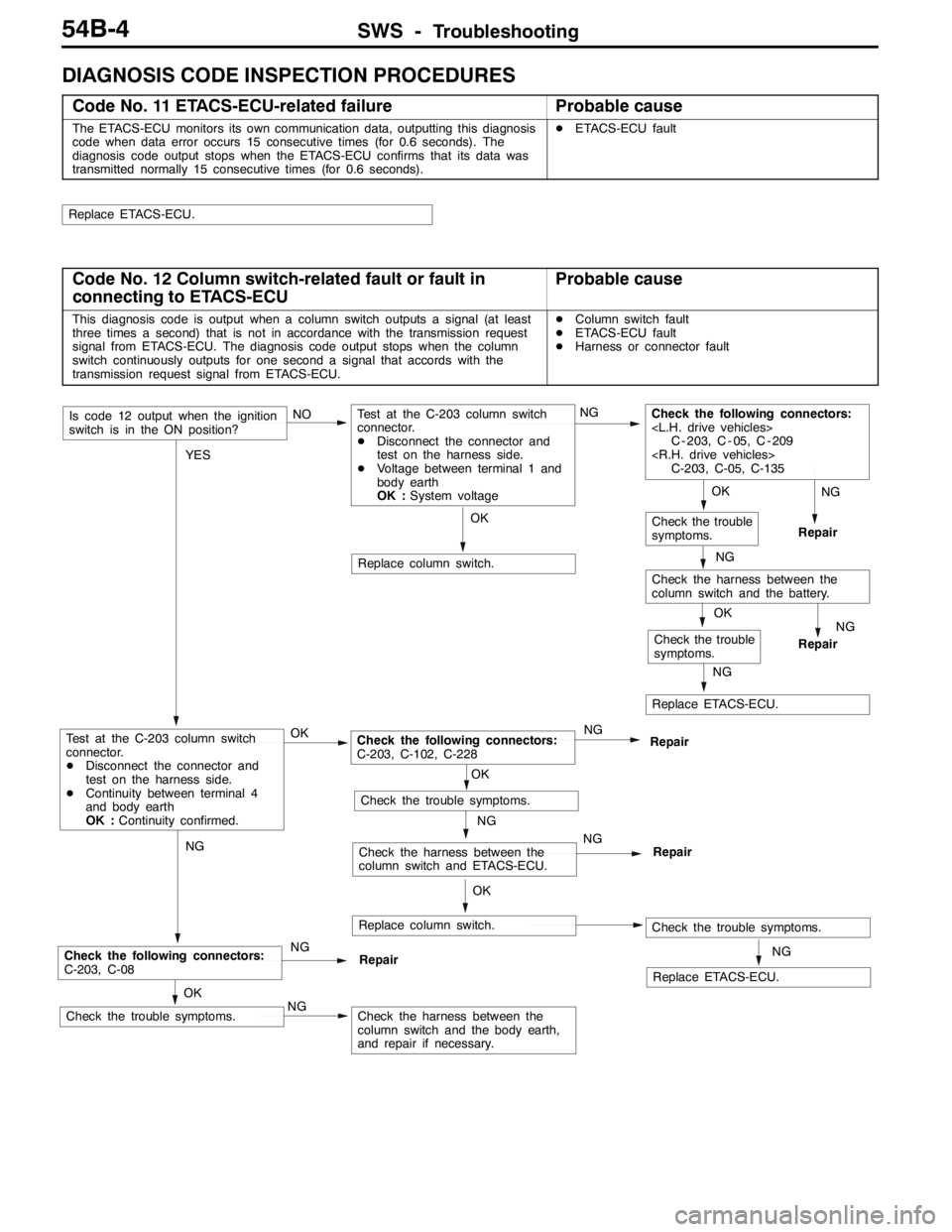

SWS -Troubleshooting54B-4

DIAGNOSIS CODE INSPECTION PROCEDURES

Code No. 11 ETACS-ECU-related failureProbable cause

The ETACS-ECU monitors its own communication data, outputting this diagnosis

code when data error occurs 15 consecutive times (for 0.6 seconds). The

diagnosis code output stops when the ETACS-ECU confirms that its data was

transmitted normally 15 consecutive times (for 0.6 seconds).DETACS-ECU fault

Replace ETACS-ECU.

Code No. 12 Column switch-related fault or fault in

connecting to ETACS-ECUProbable cause

This diagnosis code is output when a column switch outputs a signal (at least

three times a second) that is not in accordance with the transmission request

signal from ETACS-ECU. The diagnosis code output stops when the column

switch continuously outputs for one second a signal that accords with the

transmission request signal from ETACS-ECU.DColumn switch fault

DETACS-ECU fault

DHarness or connector fault

OK

Replace column switch.

NG

Replace ETACS-ECU.

OK

Check the trouble

symptoms.

OK

Check the trouble symptoms.NGCheck the harness between the

column switch and the body earth,

and repair if necessary.

NG

Check the following connectors:

C-203, C-08NG

Repair

NG

Repair

NG

Check the harness between the

column switch and the battery.

OK

Check the trouble

symptoms.

NG

Replace ETACS-ECU.

OK

Replace column switch.Check the trouble symptoms.

NG

Check the harness between the

column switch and ETACS-ECU.NG

Repair

OK

Check the trouble symptoms.

YES

Test at the C-203 column switch

connector.

DDisconnect the connector and

test on the harness side.

DContinuity between terminal 4

and body earth

OK :Continuity confirmed.OKCheck the following connectors:

C-203, C-102, C-228NG

Repair

Is code 12 output when the ignition

switch is in the ON position?NOTest at the C-203 column switch

connector.

DDisconnect the connector and

test on the harness side.

DVoltage between terminal 1 and

body earth

OK :System voltageNGCheck the following connectors:

C - 203, C - 05, C - 209

C-203, C-05, C-135

NG

Repair

Page 1369 of 1449

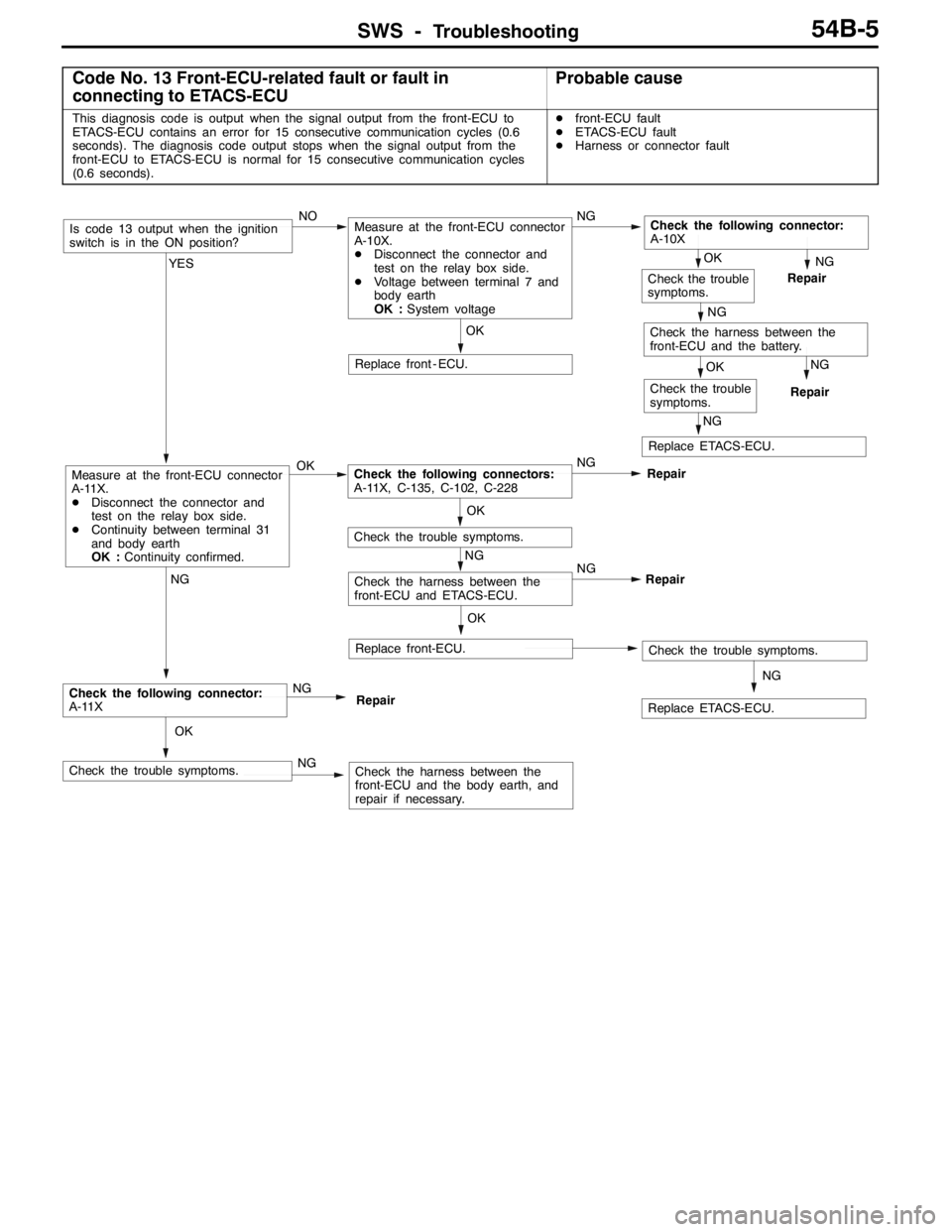

SWS -Troubleshooting54B-5

Code No. 13 Front-ECU-related fault or fault in

connecting to ETACS-ECUProbable cause

This diagnosis code is output when the signal output from the front-ECU to

ETACS-ECU contains an error for 15 consecutive communication cycles (0.6

seconds). The diagnosis code output stops when the signal output from the

front-ECU to ETACS-ECU is normal for 15 consecutive communication cycles

(0.6 seconds).Dfront-ECU fault

DETACS-ECU fault

DHarness or connector fault

NG

Repair

NG

Replace ETACS-ECU.

OK

Check the trouble

symptoms.

NG

Repair

NG

Check the harness between the

front-ECU and the battery.

OK

Check the trouble

symptoms.

NG

Replace ETACS-ECU.

OK

Replace front-ECU.Check the trouble symptoms.

NG

Check the harness between the

front-ECU and ETACS-ECU.NG

Repair

OK

Check the trouble symptoms.

OK

Replace front - ECU.

OK

Check the trouble symptoms.NGCheck the harness between the

front-ECU and the body earth, and

repair if necessary.

NG

Check the following connector:

A-11XNG

Repair

YES

Measure at the front-ECU connector

A-11X.

DDisconnect the connector and

test on the relay box side.

DContinuity between terminal 31

and body earth

OK :Continuity confirmed.OKCheck the following connectors:

A-11X, C-135, C-102, C-228NG

Repair

Is code 13 output when the ignition

switch is in the ON position?NOMeasure at the front-ECU connector

A-10X.

DDisconnect the connector and

test on the relay box side.

DVoltage between terminal 7 and

body earth

OK :System voltageNGCheck the following connector:

A-10X

Page 1372 of 1449

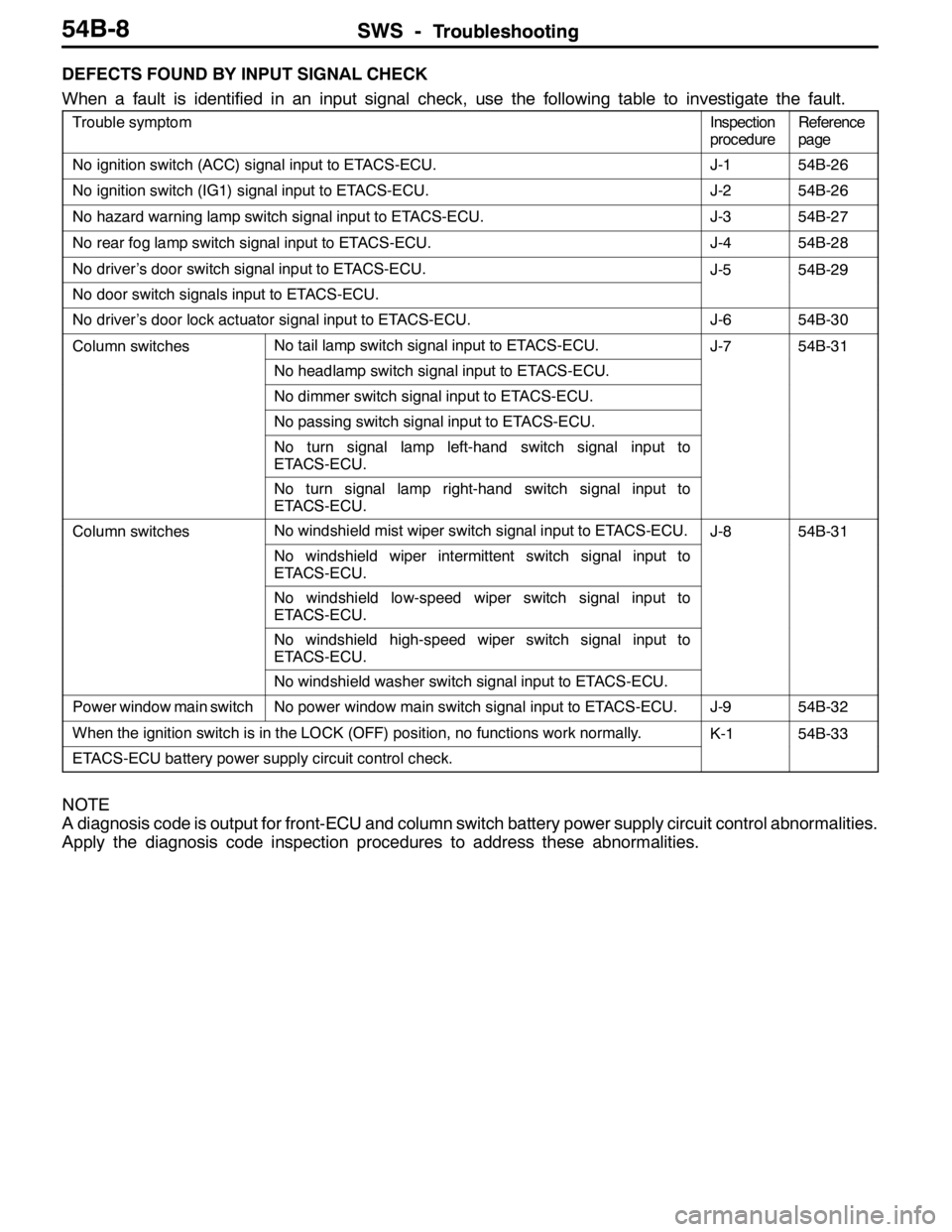

SWS -TroubleshootingSWS -Troubleshooting54B-8

DEFECTS FOUND BY INPUT SIGNAL CHECK

When a fault is identified in an input signal check, use the following table to investigate the fault.

Trouble symptomInspection

procedureReference

page

No ignition switch (ACC) signal input to ETACS-ECU.J-154B-26

No ignition switch (IG1) signal input to ETACS-ECU.J-254B-26

No hazard warning lamp switch signal input to ETACS-ECU.J-354B-27

No rear fog lamp switch signal input to ETACS-ECU.J-454B-28

No driver’s door switch signal input to ETACS-ECU.J-554B-29

No door switch signals input to ETACS-ECU.

No driver’s door lock actuator signal input to ETACS-ECU.J-654B-30

Column switchesNo tail lamp switch signal input to ETACS-ECU.J-754B-31

No headlamp switch signal input to ETACS-ECU.

No dimmer switch signal input to ETACS-ECU.

No passing switch signal input to ETACS-ECU.

No turn signal lamp left-hand switch signal input to

ETACS-ECU.

No turn signal lamp right-hand switch signal input to

ETACS-ECU.

Column switchesNo windshield mist wiper switch signal input to ETACS-ECU.J-854B-31

No windshield wiper intermittent switch signal input to

ETACS-ECU.

No windshield low-speed wiper switch signal input to

ETACS-ECU.

No windshield high-speed wiper switch signal input to

ETACS-ECU.

No windshield washer switch signal input to ETACS-ECU.

Power window main switchNo power window main switch signal input to ETACS-ECU.J-954B-32

When the ignition switch is in the LOCK (OFF) position, no functions work normally.K-154B-33

ETACS-ECU battery power supply circuit control check.

NOTE

A diagnosis code is output for front-ECU and column switch battery power supply circuit control abnormalities.

Apply the diagnosis code inspection procedures to address these abnormalities.

Page 1374 of 1449

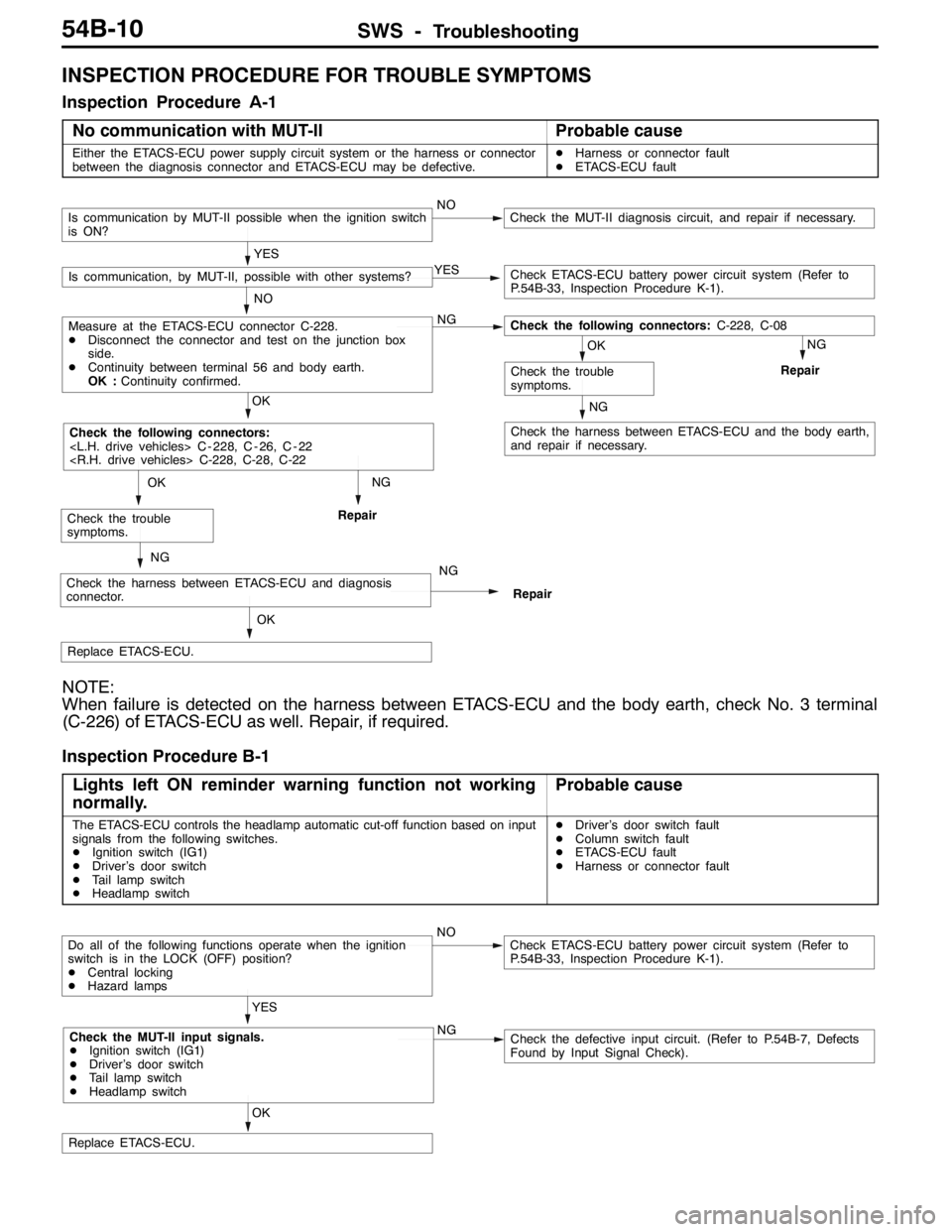

SWS -Troubleshooting54B-10

INSPECTION PROCEDURE FOR TROUBLE SYMPTOMS

Inspection Procedure A-1

No communication with MUT-II

Probable cause

Either the ETACS-ECU power supply circuit system or the harness or connector

between the diagnosis connector and ETACS-ECU may be defective.DHarness or connector fault

DETACS-ECU fault

NG

Check the harness between ETACS-ECU and the body earth,

and repair if necessary.

NG

Repair

NG

Repair

OK

Replace ETACS-ECU.

NG

Check the harness between ETACS-ECU and diagnosis

connector.NG

Repair

OK

Check the trouble

symptoms.

OK

Check the following connectors:

OK

Check the trouble

symptoms.

NO

Measure at the ETACS-ECU connector C-228.

DDisconnect the connector and test on the junction box

side.

DContinuity between terminal 56 and body earth.

OK :Continuity confirmed.NGCheck the following connectors:C-228, C-08

YES

Is communication, by MUT-II, possible with other systems?YESCheck ETACS-ECU battery power circuit system (Refer to

P.54B-33, Inspection Procedure K-1).

Is communication by MUT-II possible when the ignition switch

is ON?NOCheck the MUT-II diagnosis circuit, and repair if necessary.

NOTE:

When failure is detected on the harness between ETACS-ECU and the body earth, check No. 3 terminal

(C-226) of ETACS-ECU as well. Repair, if required.

Inspection Procedure B-1

Lights left ON reminder warning function not working

normally.

Probable cause

The ETACS-ECU controls the headlamp automatic cut-off function based on input

signals from the following switches.

DIgnition switch (IG1)

DDriver’s door switch

DTail lamp switch

DHeadlamp switchDDriver’s door switch fault

DColumn switch fault

DETACS-ECU fault

DHarness or connector fault

OK

Replace ETACS-ECU.

YES

Check the MUT-II input signals.

DIgnition switch (IG1)

DDriver’s door switch

DTail lamp switch

DHeadlamp switchNGCheck the defective input circuit. (Refer to P.54B-7, Defects

Found by Input Signal Check).

Do all of the following functions operate when the ignition

switch is in the LOCK (OFF) position?

DCentral locking

DHazard lampsNOCheck ETACS-ECU battery power circuit system (Refer to

P.54B-33, Inspection Procedure K-1).