brake MITSUBISHI LANCER EVOLUTION 2007 Service Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 440 of 1449

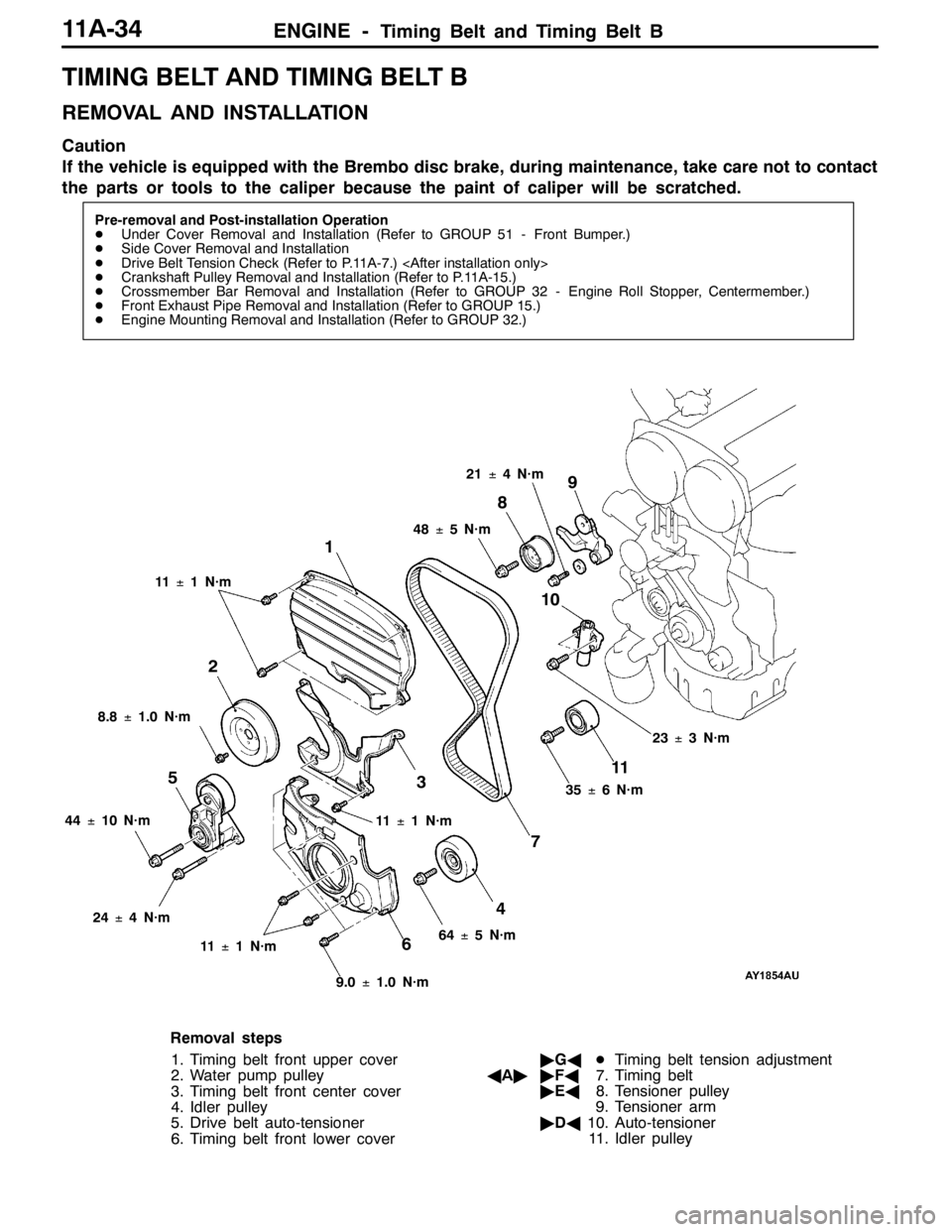

ENGINE -Timing Belt and Timing Belt B11A-34

TIMING BELT AND TIMING BELT B

REMOVAL AND INSTALLATION

Caution

If the vehicle is equipped with the Brembo disc brake, during maintenance, take care not to contact

the parts or tools to the caliper because the paint of caliper will be scratched.

Pre-removal and Post-installation Operation

DUnder Cover Removal and Installation (Refer to GROUP 51 - Front Bumper.)

DSide Cover Removal and Installation

DDrive Belt Tension Check (Refer to P.11A-7.)

DCrankshaft Pulley Removal and Installation (Refer to P.11A-15.)

DCrossmember Bar Removal and Installation (Refer to GROUP 32 - Engine Roll Stopper, Centermember.)

DFront Exhaust Pipe Removal and Installation (Refer to GROUP 15.)

DEngine Mounting Removal and Installation (Refer to GROUP 32.)

1

2

3

4 5

67 89

10

11±1 N·m

8.8±1.0 N·m

44±10 N·m

24±4 N·m

11±1 N·m

9.0±1.0 N·m64±5 N·m 11±1 N·m48±5 N·m21±4 N·m

23±3 N·m

11

35±6 N·m

Removal steps

1. Timing belt front upper cover

2. Water pump pulley

3. Timing belt front center cover

4. Idler pulley

5. Drive belt auto-tensioner

6. Timing belt front lower cover"GADTiming belt tension adjustment

AA""FA7. Timing belt

"EA8. Tensioner pulley

9. Tensioner arm

"DA10. Auto-tensioner

11. Idler pulley

Page 449 of 1449

ENGINE -Engine Assembly11A-43

ENGINE ASSEMBLY

REMOVAL AND INSTALLATION

Caution

1. If the vehicle is equipped with the Brembo disc brake, during maintenance, take care not to

contact the parts or tools to the caliper because the paint of caliper will be scratched.

2. Tightening sections indicated in the mark (*) should be finally tightened with engine weight

applied on the body after lightly tightening.

Pre-removal and Post-installation Operation

DFuel Outflow Preventive Operation (Refer to GROUP 13A - On-vehicle Service.)

DFuel Leak Check

DRemoval and Installation of Hood (Refer to GROUP 42.)

DRemoval and Installation of Strut Tower Bar (Refer to GROUP 42.)

DRemoval and Installation of Under Cover (Refer to GROUP 51 - Front Bumper.)

DRemoval and Installation of Side Cover.

DDrive Belt Tension Check (Refer to P.11A - 7.)

DAccelerator Cable Adjustment (Refer to GROUP 17 - On-vehicle Service.)

DDrainage and Refilling Engine Oil(Refer to GROUP 12 - On-vehicle Service.)

DDrainage and Refilling of Engine Coolant (Refer to GROUP 14 - On-vehicle Service.)

DAir Cleaner Removal and Installation (Refer to GROUP 15)

DRemoval and Installation of Air Pipe C, Air Pipe B and Air Hose A (Refer to GROUP 15 - Intercooler.)

DBattery and Battery Tray Removal and Installation

DRemoval and Installation of Center Cover (Refer to P.11A - 17.)

DRemoval and Installation of Accelerator Cable (Refer to GROUP 17.)

DRemoval and Installation of Radiator (Refer to GROUP 14.)

DRemoval and Installation of Crossmember Bar (Refer to GROUP 32 - Engine Roll Stopper, Centermember.)

DRemoval and Installation of Front Exhaust Pipe (Refer to GROUP 15.)

DRemoval and Installation of Air Outlet Fitting (Refer to GROUP 15 - Exhaust manifold.)

Page 451 of 1449

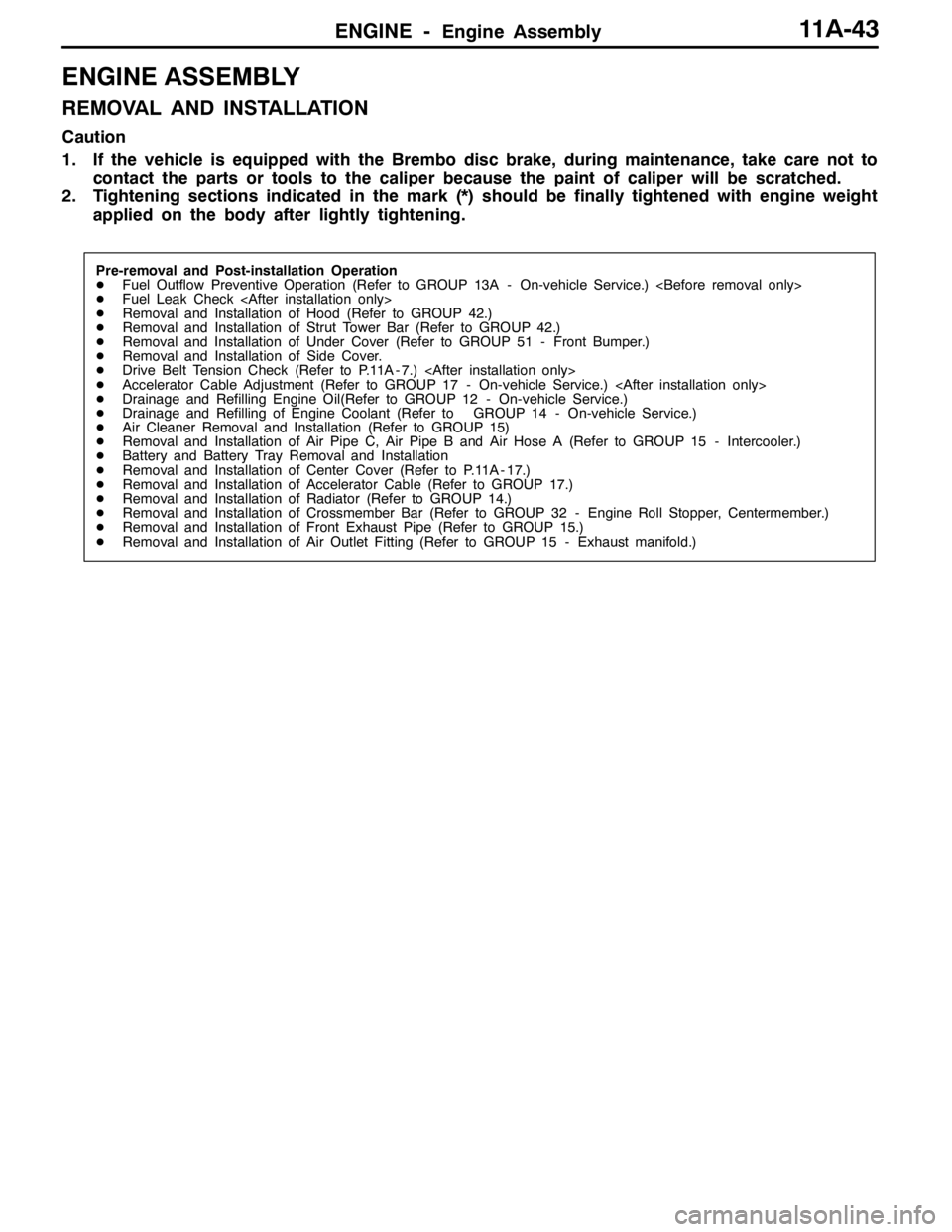

ENGINE -Engine Assembly11A-45

67±7 N·m*

23 33

24 29

3031

32

2722

98±10 N·m*5.0±1.0 N·m

(Engine oil)

20

21 19

25

42±2 N·m22±4 N·m

40±5 N·m

42±2 N·m

26

26

2834

22±4 N·m12±2 N·m

19. Brake booster vacuum hose

connection

20. Purge hose connection

21. Power steering oil pressure switch

connector

22. Heat protector

AB"23. Power steering oil pump, bracket and

oil reservoir assembly

24. A/C compressor connector

AB"25. A/C compressor

26. Engine oil cooler tube gasket

27. Engine oil cooler feed hose connection28. Engine oil cooler return hose

connection

29. Heater hose connection

30. Fuel return hose connection

"CA31. Fuel high pressure hose connection

"CA32. O-ring

DTransfer assembly

(Refer to Group 22.)

DTransmission assembly

(Refer to Group 22.)

AC""BA33. Engine mounting bracket and stopper

assembly

AD""AA34. Engine assembly

Page 531 of 1449

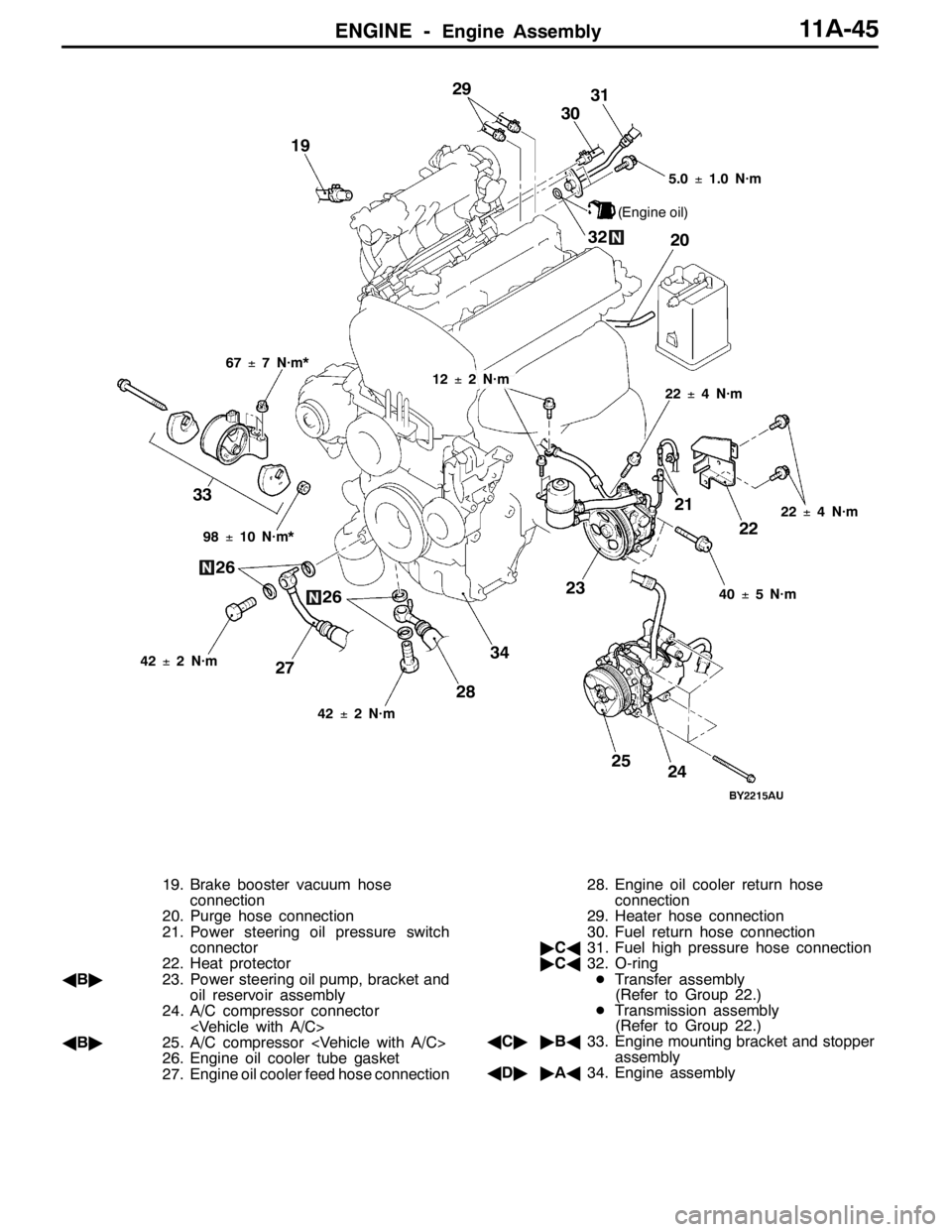

ENGINE LUBLICATION -Engine Oli Cooler12-7

ENGINE OIL COOLER

REMOVAL AND INSTALLATION

Caution

If the vehicle is equipped with the Brembo disc brake, during maintenance, take care not to contact

the parts or tools to the caliper because the paint of caliper will be scratched.

Pre-removal and Post-installation Operation

DEngine Oil Draining and Supplying (Refer to P.12-4.)

DUnder Cover Removal and Installation (Refer to GROUP 51 - Front Bumper.)

DSide Cover Removal and Installation

3

4

5 67

12±2 N·m

42±2 N·m

1 2

1 3

42±2 N·m 12±2 N·m

12±2 N·m

8

Removal steps

1. Engine oil cooler tube gasket

2. Engine oil cooler, braket and hose

assembly

3. Engine oil cooler braket

4. Engine oil cooler tube gasket5. Engine oil cooler feed hose

6. Engine oil cooler tube gasket

7. Engine oil cooler return hose

8. Engine oil cooler

Page 684 of 1449

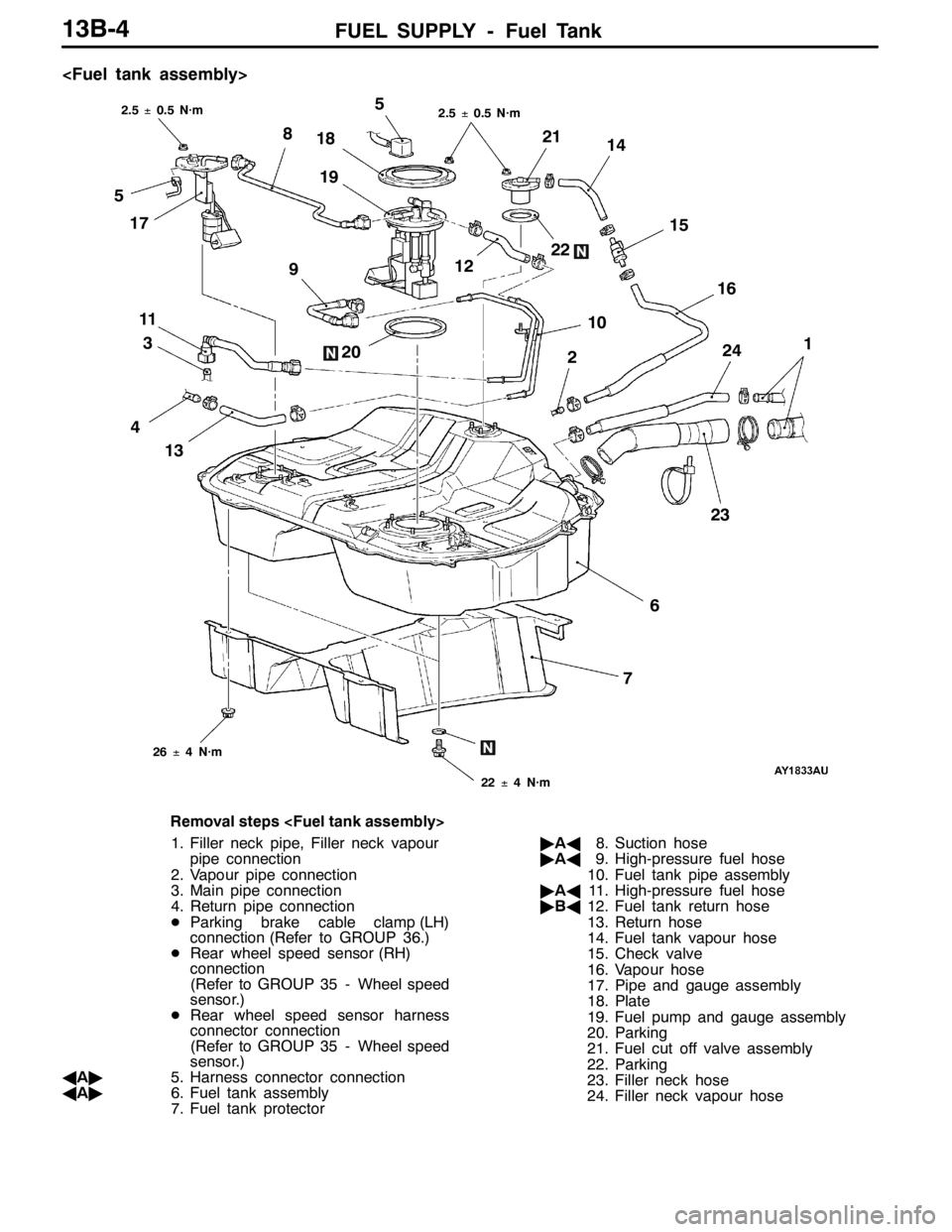

FUEL SUPPLY - Fuel Tank13B-4

12

10

6 21

1

2

4

7 8

915 18

23 20

13 314

22

24 1119

5

16 175

2.5±0.5 N·m

2.5±0.5 N·m

26±4 N·m

22±4 N·m

Removal steps

1. Filler neck pipe, Filler neck vapour

pipe connection

2. Vapour pipe connection

3. Main pipe connection

4. Return pipe connection

DParking brake cable clamp (LH)

connection (Refer to GROUP 36.)

DRear wheel speed sensor (RH)

connection

(Refer to GROUP 35 - Wheel speed

sensor.)

DRear wheel speed sensor harness

connector connection

(Refer to GROUP 35 - Wheel speed

sensor.)

AA"5. Harness connector connection

AA"6. Fuel tank assembly

7. Fuel tank protector"AA8. Suction hose

"AA9. High-pressure fuel hose

10. Fuel tank pipe assembly

"AA11. High-pressure fuel hose

"BA12. Fuel tank return hose

13. Return hose

14. Fuel tank vapour hose

15. Check valve

16. Vapour hose

17. Pipe and gauge assembly

18. Plate

19. Fuel pump and gauge assembly

20. Parking

21. Fuel cut off valve assembly

22. Parking

23. Filler neck hose

24. Filler neck vapour hose

Page 701 of 1449

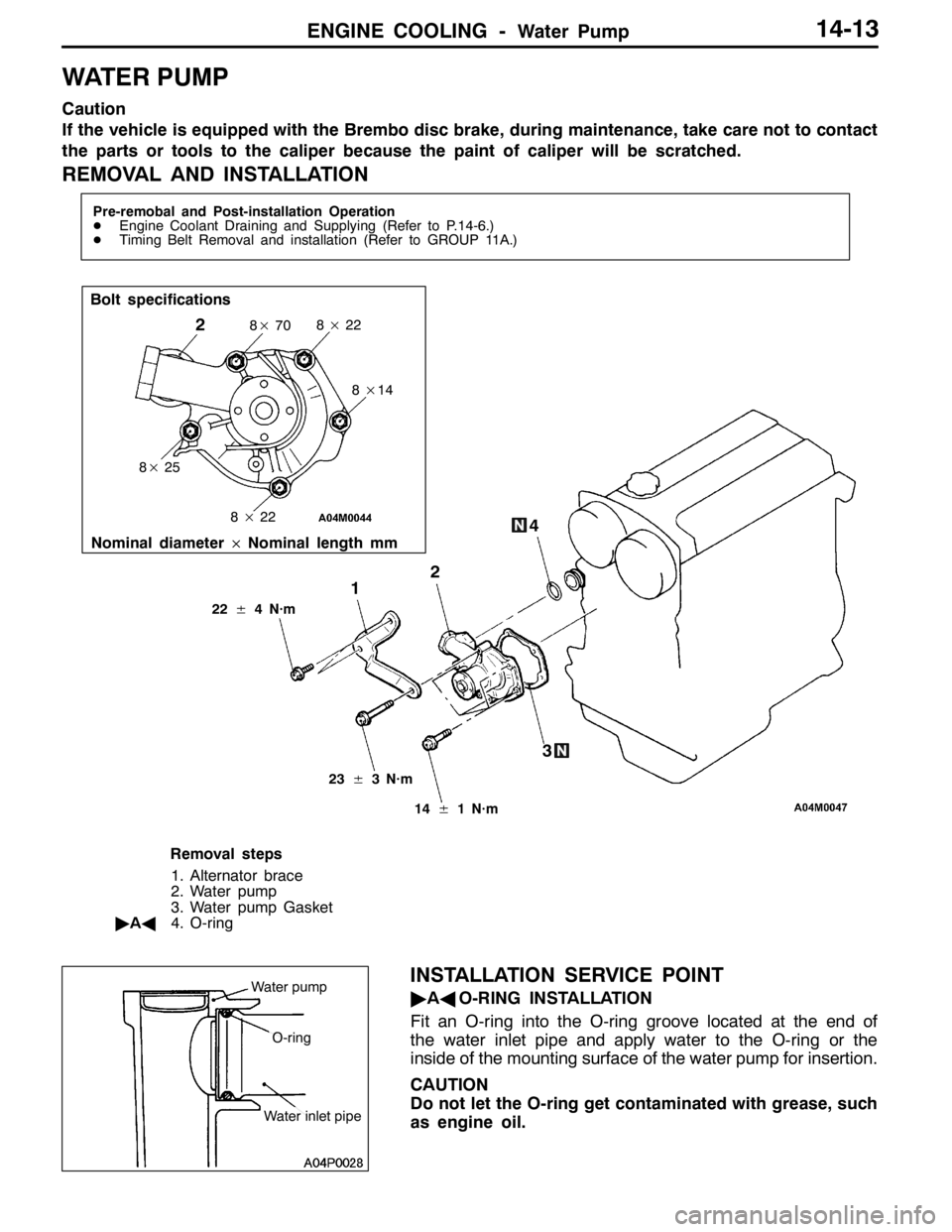

ENGINE COOLING -Water Pump14-13

WATER PUMP

Caution

If the vehicle is equipped with the Brembo disc brake, during maintenance, take care not to contact

the parts or tools to the caliper because the paint of caliper will be scratched.

REMOVAL AND INSTALLATION

Pre-remobal and Post-installation Operation

DEngine Coolant Draining and Supplying (Refer to P.14-6.)

DTiming Belt Removal and installation (Refer to GROUP 11A.)

1

Bolt specifications

28×22

2

23±3 N·m

14±1 N·m

Nominal diameter×Nominal length mm

8×70

8×14

8×22 8×25

3 4

22±4 N·m

Removal steps

1. Alternator brace

2. Water pump

3. Water pump Gasket

"AA4. O-ring

INSTALLATION SERVICE POINT

"AAO-RING INSTALLATION

Fit an O-ring into the O-ring groove located at the end of

the water inlet pipe and apply water to the O-ring or the

inside of the mounting surface of the water pump for insertion.

CAUTION

Do not let the O-ring get contaminated with grease, such

as engine oil.Water pump

O-ring

Water inlet pipe

Page 722 of 1449

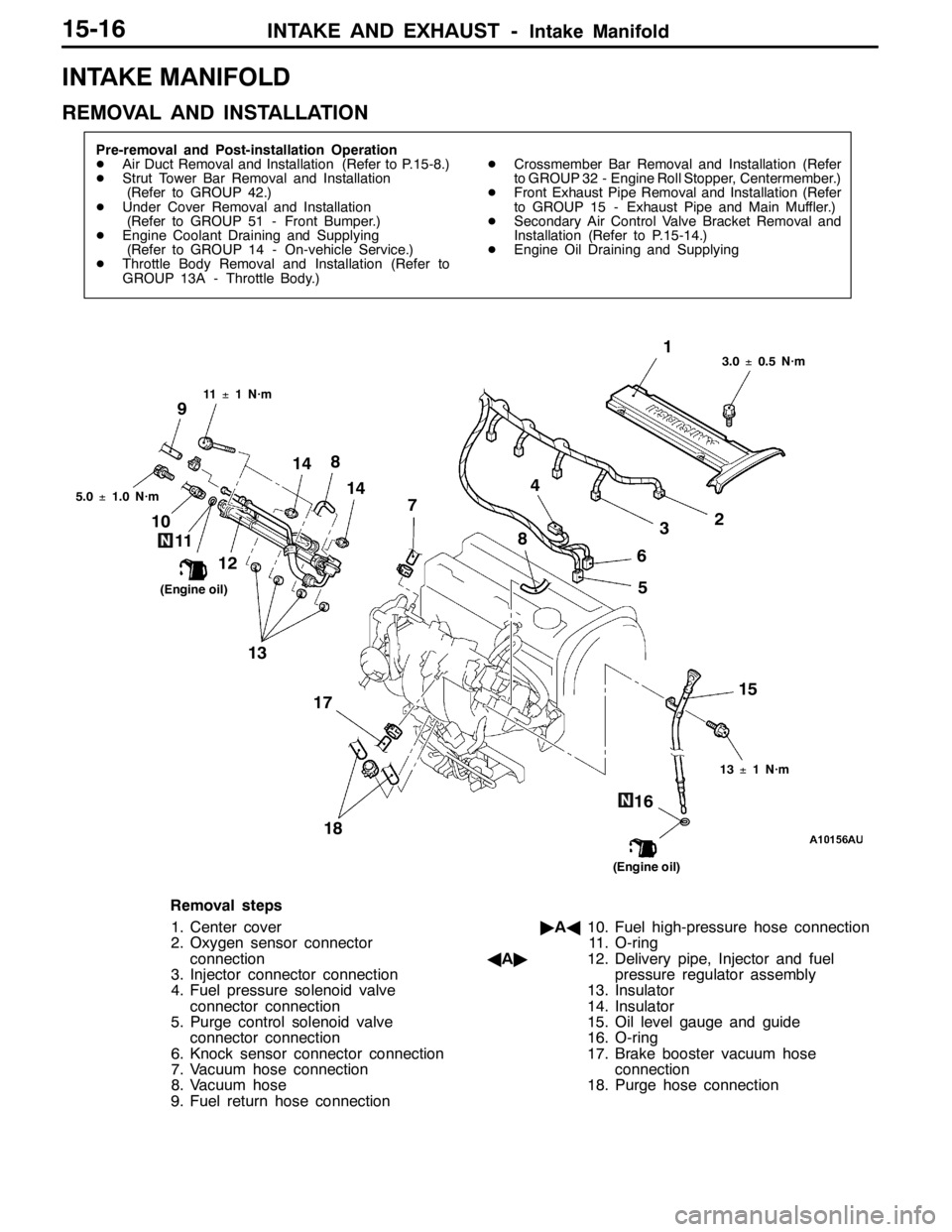

INTAKE AND EXHAUST -Intake Manifold15-16

INTAKE MANIFOLD

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

DAir Duct Removal and Installation (Refer to P.15-8.)

DStrut Tower Bar Removal and Installation

(Refer to GROUP 42.)

DUnder Cover Removal and Installation

(Refer to GROUP 51 - Front Bumper.)

DEngine Coolant Draining and Supplying

(Refer to GROUP 14 - On-vehicle Service.)

DThrottle Body Removal and Installation (Refer to

GROUP 13A - Throttle Body.)DCrossmember Bar Removal and Installation (Refer

to GROUP 32 - Engine Roll Stopper, Centermember.)

DFront Exhaust Pipe Removal and Installation (Refer

to GROUP 15 - Exhaust Pipe and Main Muffler.)

DSecondary Air Control Valve Bracket Removal and

Installation (Refer to P.15-14.)

DEngine Oil Draining and Supplying

1

2

3 4

5 6 7

8 10

11

1214

13

15

16 17

18

9

11±1 N·m3.0±0.5 N·m

13±1 N·m

(Engine oil)

(Engine oil) 5.0±1.0 N·m

14 8

Removal steps

1. Center cover

2. Oxygen sensor connector

connection

3. Injector connector connection

4. Fuel pressure solenoid valve

connector connection

5. Purge control solenoid valve

connector connection

6. Knock sensor connector connection

7. Vacuum hose connection

8. Vacuum hose

9. Fuel return hose connection"AA10. Fuel high-pressure hose connection

11. O-ring

AA"12. Delivery pipe, Injector and fuel

pressure regulator assembly

13. Insulator

14. Insulator

15. Oil level gauge and guide

16. O-ring

17. Brake booster vacuum hose

connection

18. Purge hose connection

Page 742 of 1449

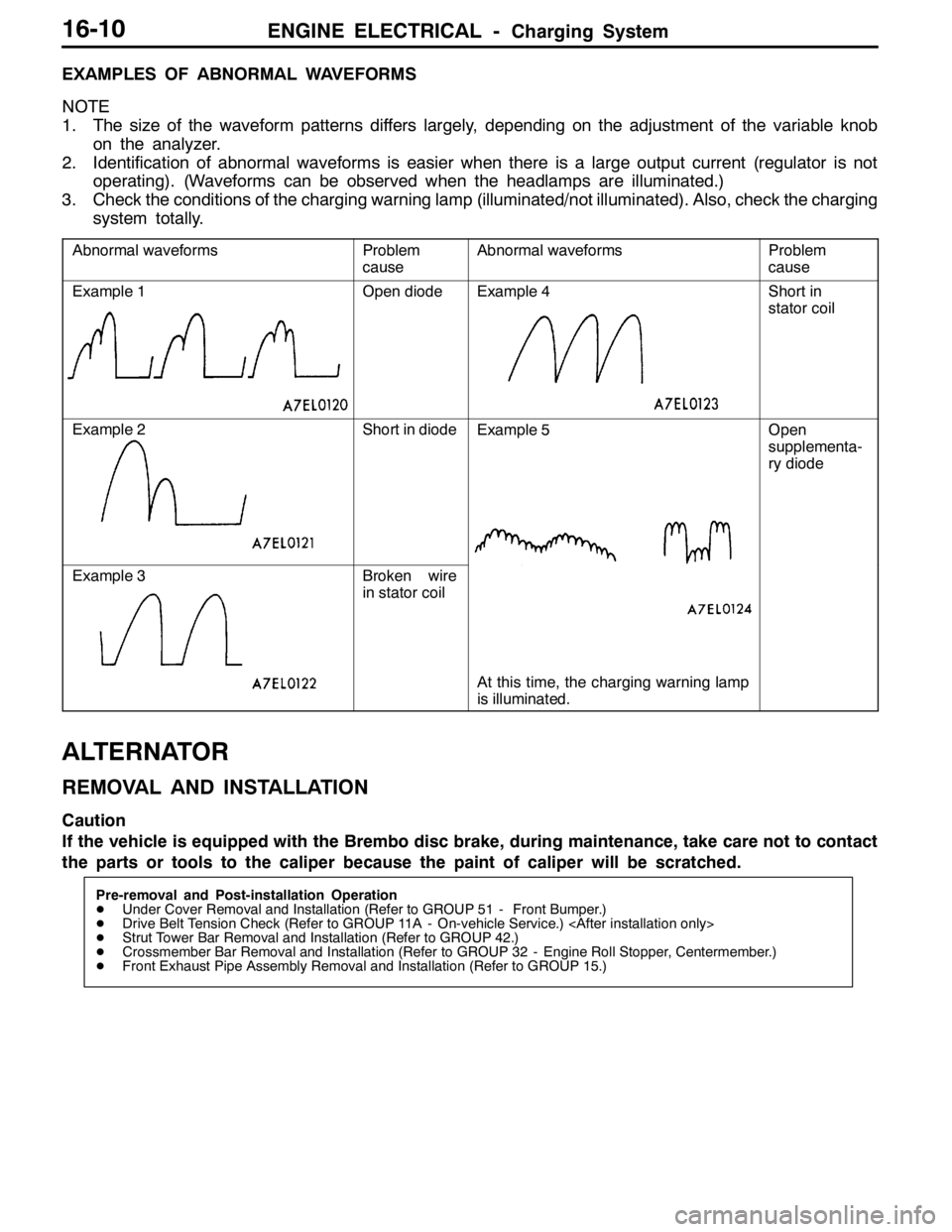

ENGINE ELECTRICAL -Charging System16-10

EXAMPLES OF ABNORMAL WAVEFORMS

NOTE

1. The size of the waveform patterns differs largely, depending on the adjustment of the variable knob

on the analyzer.

2. Identification of abnormal waveforms is easier when there is a large output current (regulator is not

operating). (Waveforms can be observed when the headlamps are illuminated.)

3. Check the conditions of the charging warning lamp (illuminated/not illuminated). Also, check the charging

system totally.

Abnormal waveformsProblem

causeAbnormal waveformsProblem

cause

Example 1Open diodeExample 4Short in

stator coil

Example 2Short in diodeExample 5Open

supplementa-

ry diode

Example 3Broken wire

in stator coil

At this time, the charging warning lamp

is illuminated.

ALTERNATOR

REMOVAL AND INSTALLATION

Caution

If the vehicle is equipped with the Brembo disc brake, during maintenance, take care not to contact

the parts or tools to the caliper because the paint of caliper will be scratched.

Pre-removal and Post-installation Operation

DUnder Cover Removal and Installation (Refer to GROUP 51 - Front Bumper.)

DDrive Belt Tension Check (Refer to GROUP 11A - On-vehicle Service.)

DStrut Tower Bar Removal and Installation (Refer to GROUP 42.)

DCrossmember Bar Removal and Installation (Refer to GROUP 32 - Engine Roll Stopper, Centermember.)

DFront Exhaust Pipe Assembly Removal and Installation (Refer to GROUP 15.)

Page 767 of 1449

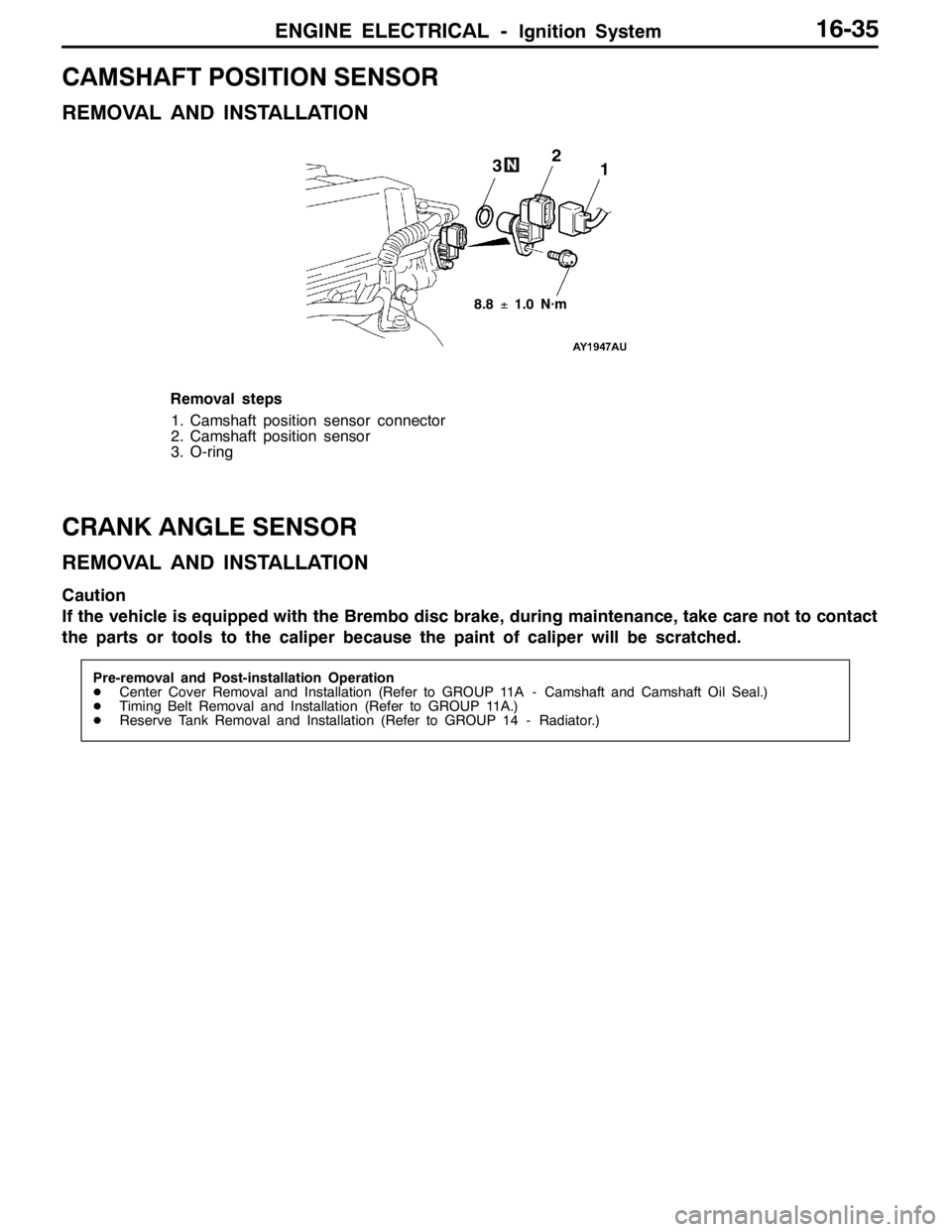

ENGINE ELECTRICAL -Ignition System16-35

CAMSHAFT POSITION SENSOR

REMOVAL AND INSTALLATION

1 2

3

8.8±1.0 N·m

Removal steps

1. Camshaft position sensor connector

2. Camshaft position sensor

3. O-ring

CRANK ANGLE SENSOR

REMOVAL AND INSTALLATION

Caution

If the vehicle is equipped with the Brembo disc brake, during maintenance, take care not to contact

the parts or tools to the caliper because the paint of caliper will be scratched.

Pre-removal and Post-installation Operation

DCenter Cover Removal and Installation (Refer to GROUP 11A - Camshaft and Camshaft Oil Seal.)

DTiming Belt Removal and Installation (Refer to GROUP 11A.)

DReserve Tank Removal and Installation (Refer to GROUP 14 - Radiator.)

Page 793 of 1449

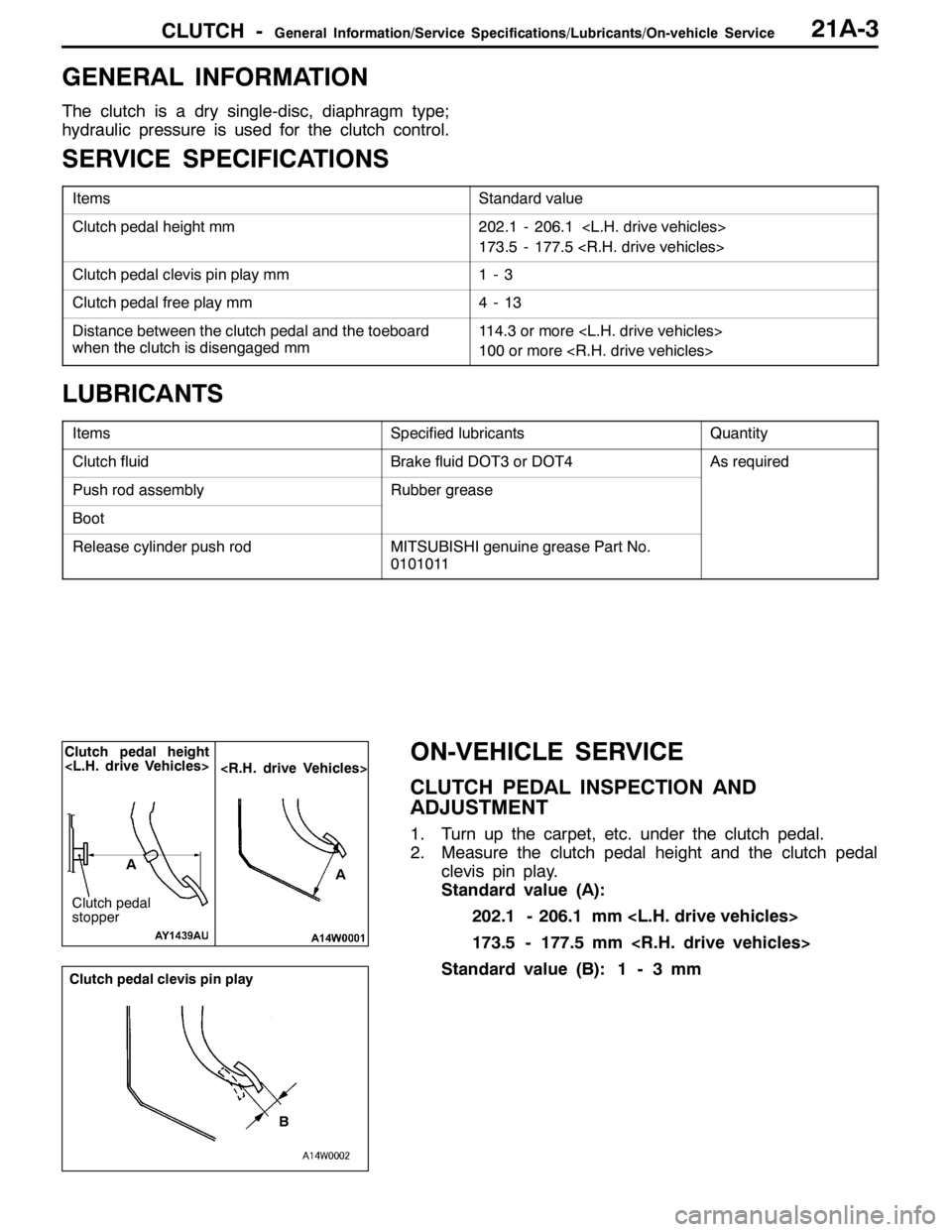

CLUTCH -General Information/Service Specifications/Lubricants/On-vehicle Service21A-3

GENERAL INFORMATION

The clutch is a dry single-disc, diaphragm type;

hydraulic pressure is used for the clutch control.

SERVICE SPECIFICATIONS

ItemsStandard value

Clutch pedal height mm202.1 - 206.1

173.5 - 177.5

Clutch pedal clevis pin play mm1-3

Clutch pedal free play mm4-13

Distance between the clutch pedal and the toeboard

when the clutch is disengaged mm114.3 or more

100 or more

LUBRICANTS

ItemsSpecified lubricantsQuantity

Clutch fluidBrake fluid DOT3 or DOT4As required

Push rod assemblyRubber grease

Boot

Release cylinder push rodMITSUBISHI genuine grease Part No.

0101011

ON-VEHICLE SERVICE

CLUTCH PEDAL INSPECTION AND

ADJUSTMENT

1. Turn up the carpet, etc. under the clutch pedal.

2. Measure the clutch pedal height and the clutch pedal

clevis pin play.

Standard value (A):

202.1 - 206.1 mm

173.5 - 177.5 mm

Standard value (B): 1 - 3 mm

Clutch pedal height

A

A

Clutch pedal

stopper

Clutch pedal clevis pin play

B