brake MITSUBISHI LANCER EVOLUTION 2007 Service Manual PDF

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 1032 of 1449

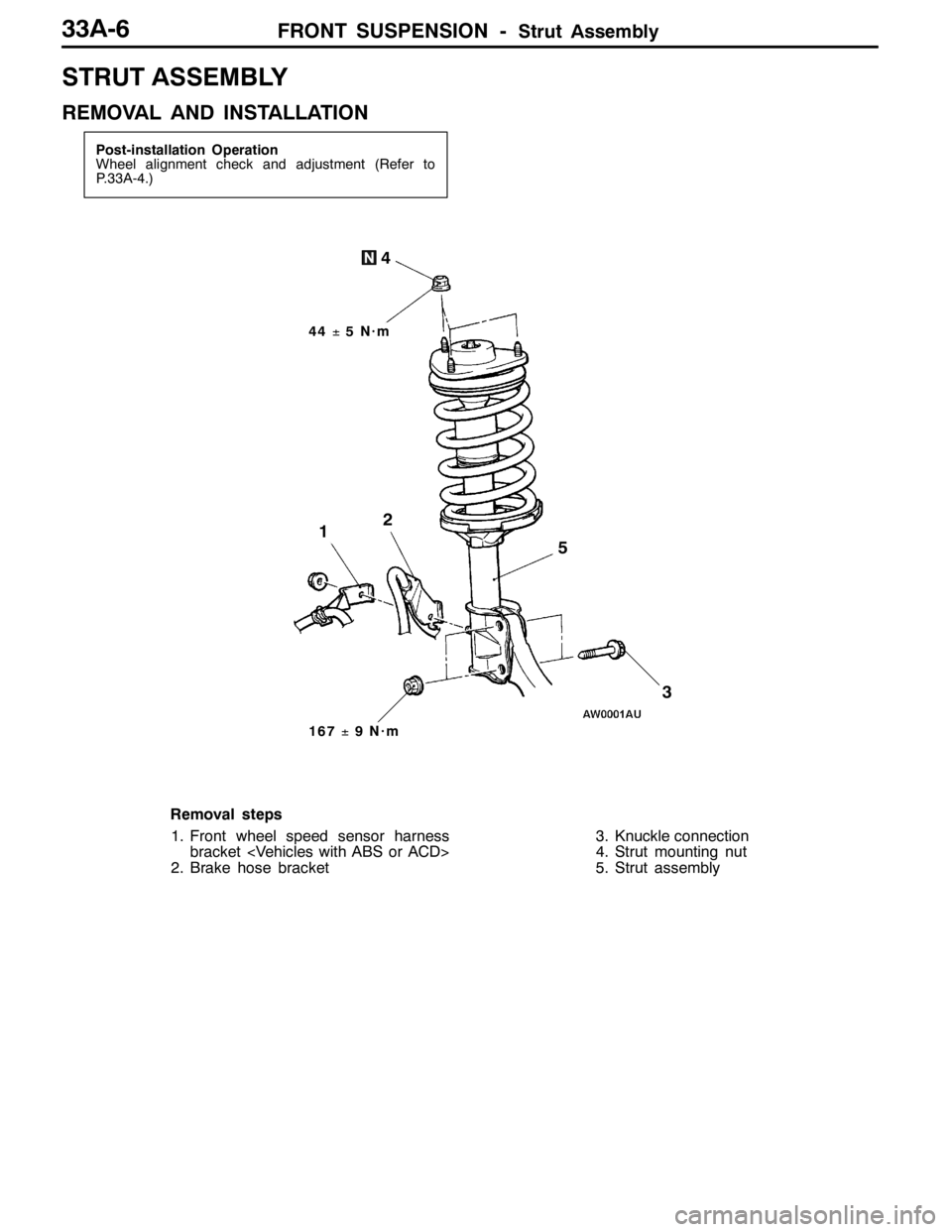

FRONT SUSPENSION -Strut Assembly33A-6

STRUT ASSEMBLY

REMOVAL AND INSTALLATION

Post-installation Operation

Wheel alignment check and adjustment (Refer to

P.33A-4.)

44±5N·m

3

21

167±9N·m

4

5

Removal steps

1. Front wheel speed sensor harness

bracket

2. Brake hose bracket3. Knuckle connection

4. Strut mounting nut

5. Strut assembly

Page 1035 of 1449

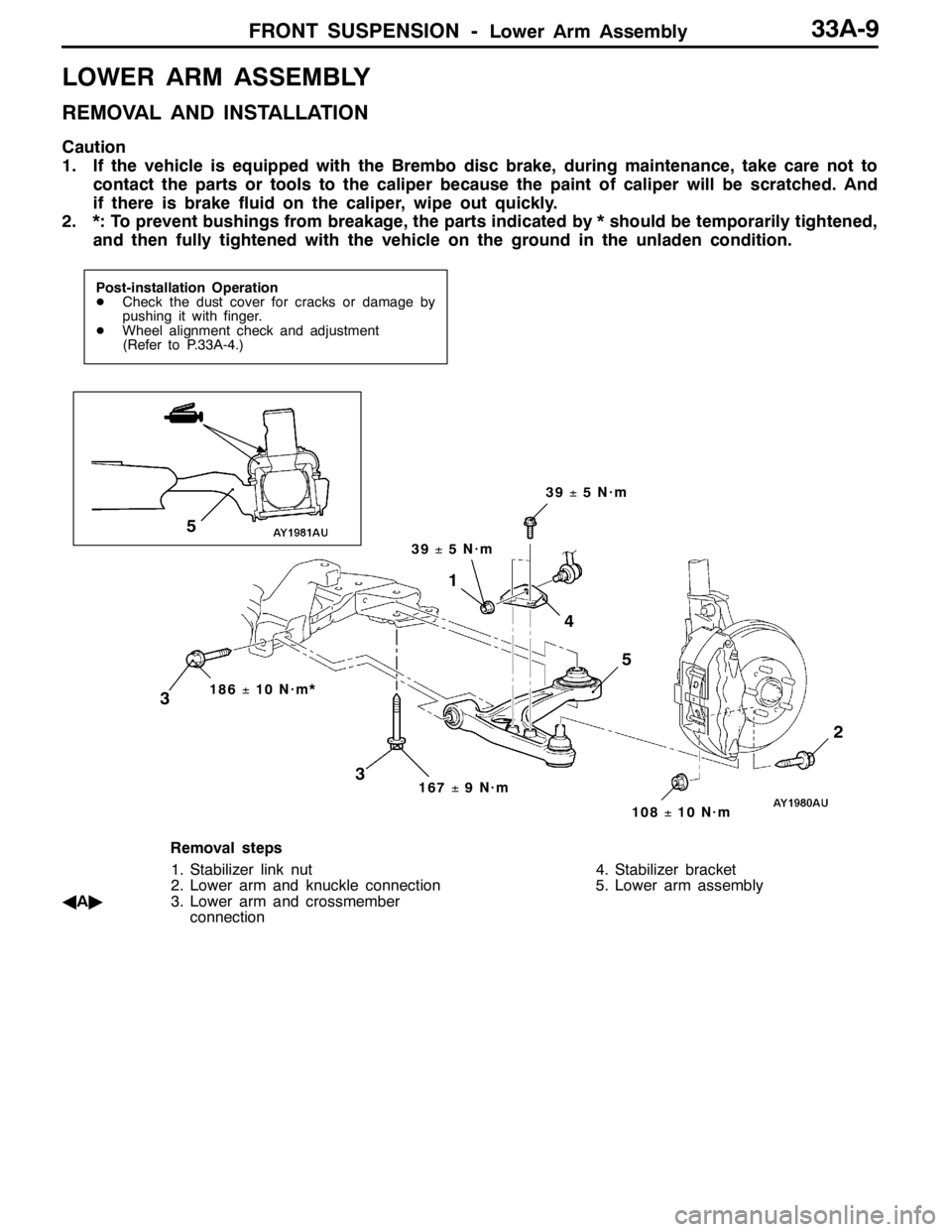

FRONT SUSPENSION -Lower Arm Assembly33A-9

LOWER ARM ASSEMBLY

REMOVAL AND INSTALLATION

Caution

1. If the vehicle is equipped with the Brembo disc brake, during maintenance, take care not to

contact the parts or tools to the caliper because the paint of caliper will be scratched. And

if there is brake fluid on the caliper, wipe out quickly.

2. *: To prevent bushings from breakage, the parts indicated by * should be temporarily tightened,

and then fully tightened with the vehicle on the ground in the unladen condition.

Post-installation Operation

DCheck the dust cover for cracks or damage by

pushing it with finger.

DWheel alignment check and adjustment

(Refer to P.33A-4.)

72

5

186±10 N·m*

3167±9N·m

5

1

3

4

108±10 N·m

39±5N·m

39±5N·m

Removal steps

1. Stabilizer link nut

2. Lower arm and knuckle connection

AA"3. Lower arm and crossmember

connection4. Stabilizer bracket

5. Lower arm assembly

Page 1038 of 1449

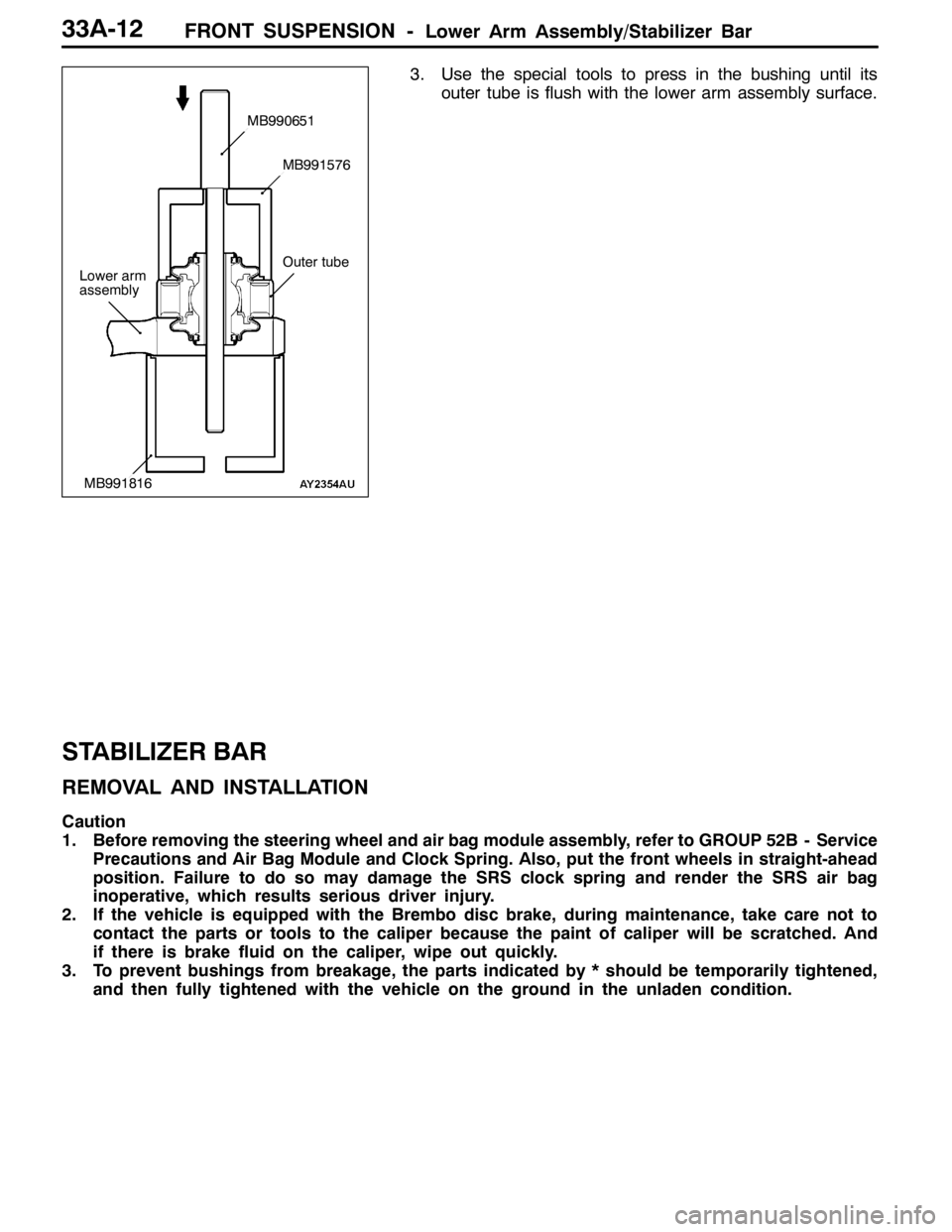

FRONT SUSPENSION -Lower Arm Assembly/Stabilizer Bar33A-12

3. Use the special tools to press in the bushing until its

outer tube is flush with the lower arm assembly surface.

STABILIZER BAR

REMOVAL AND INSTALLATION

Caution

1. Before removing the steering wheel and air bag module assembly, refer to GROUP 52B - Service

Precautions and Air Bag Module and Clock Spring. Also, put the front wheels in straight-ahead

position. Failure to do so may damage the SRS clock spring and render the SRS air bag

inoperative, which results serious driver injury.

2. If the vehicle is equipped with the Brembo disc brake, during maintenance, take care not to

contact the parts or tools to the caliper because the paint of caliper will be scratched. And

if there is brake fluid on the caliper, wipe out quickly.

3. To prevent bushings from breakage, the parts indicated by * should be temporarily tightened,

and then fully tightened with the vehicle on the ground in the unladen condition.

Lower arm

assembly

MB990651

MB991576

MB991816

Outer tube

Page 1043 of 1449

BASIC BRAKE SYSTEM 35A.........................................

ANTI-SKID BRAKING SYSTEM (ABS) <4WD> 35B......................

35A-1

SERVICE BRAKES

CONTENTS

Page 1044 of 1449

35A-2

BASIC BRAKE

SYSTEM

CONTENTS

GENERAL INFORMATION 3..................

SERVICE SPECIFICATIONS 5.................

LUBRICANTS 6..............................

SEALANT 6..................................

SPECIAL TOOLS 6...........................

ON-VEHICLE SERVICE 7.....................

Brake Pedal Check and Adjustment 7............

Brake Booster Operating Test 8.................

Check Valve Operation Check 9.................

Proportioning Valve Function Test

Brake Fluid Level Sensor Check 11.............

Disc Brake Pad Check and Replacement 11......

Disc Brake Rotor Check 13.....................

Brake Disc Thickness Check 14.................

Brake Disc Run-out Check and Correction 14....

BRAKE PEDAL 16...........................

PROPORTIONING VALVE, MASTER

CYLINDER AND BRAKE BOOSTER 17........

Master Cylinder 19.............................

DISC BRAKE 20.............................

Page 1045 of 1449

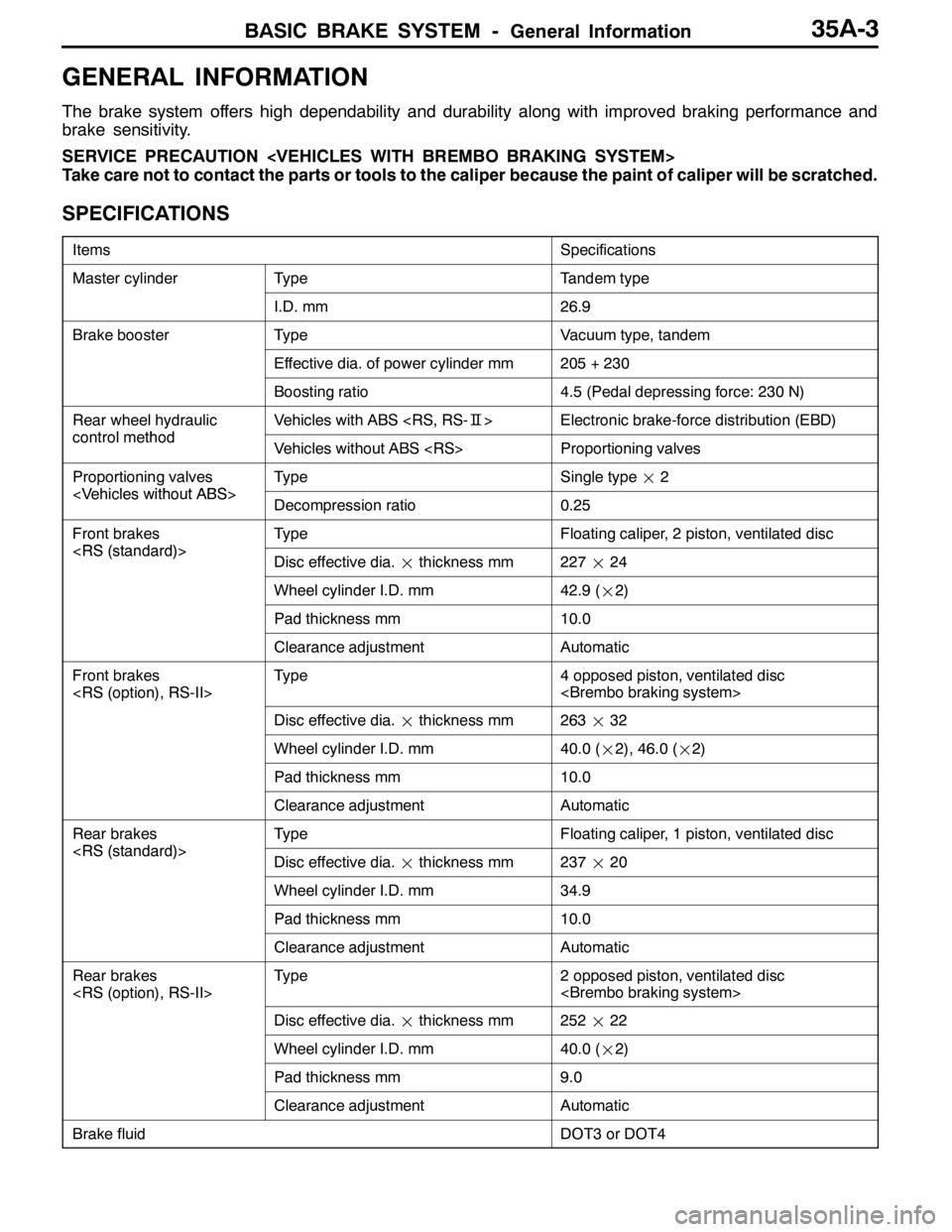

BASIC BRAKE SYSTEM -General Information35A-3

GENERAL INFORMATION

The brake system offers high dependability and durability along with improved braking performance and

brake sensitivity.

SERVICE PRECAUTION

Take care not to contact the parts or tools to the caliper because the paint of caliper will be scratched.

SPECIFICATIONS

ItemsSpecifications

Master cylinderTypeTandem type

I.D. mm26.9

Brake boosterTypeVacuum type, tandem

Effective dia. of power cylinder mm205 + 230

Boosting ratio4.5 (Pedal depressing force: 230 N)

Rear wheel hydraulic

controlmethod

Vehicles with ABS

control methodVehicles without ABS

Proportioning valves

VehicleswithoutABS

TypeSingle type¢2

Front brakes

RS(standard)

TypeFloating caliper, 2 piston, ventilated disc

Wheel cylinder I.D. mm42.9 (¢2)

Pad thickness mm10.0

Clearance adjustmentAutomatic

Front brakes

Disc effective dia.¢thickness mm263¢32

Wheel cylinder I.D. mm40.0 (¢2), 46.0 (¢2)

Pad thickness mm10.0

Clearance adjustmentAutomatic

Rear brakes

RS(standard)

TypeFloating caliper, 1 piston, ventilated disc

Wheel cylinder I.D. mm34.9

Pad thickness mm10.0

Clearance adjustmentAutomatic

Rear brakes

Disc effective dia.¢thickness mm252¢22

Wheel cylinder I.D. mm40.0 (¢2)

Pad thickness mm9.0

Clearance adjustmentAutomatic

Brake fluidDOT3 or DOT4

Page 1046 of 1449

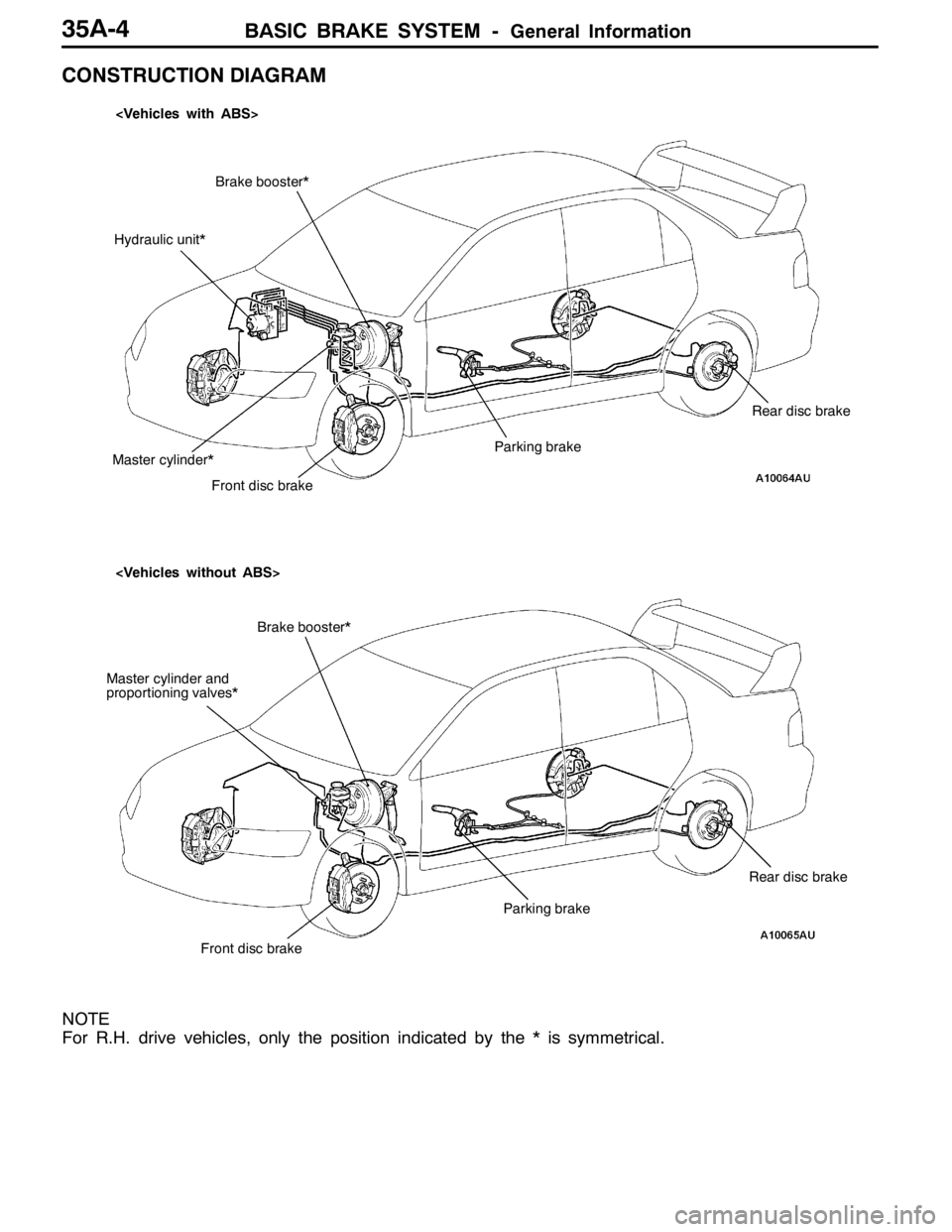

BASIC BRAKE SYSTEM -General Information35A-4

CONSTRUCTION DIAGRAM

Brake booster*

Rear disc brake

Parking brake

Front disc brake Master cylinder*Hydraulic unit*

Brake booster*

Rear disc brake

Parking brake

Front disc brake Master cylinder and

proportioning valves*

NOTE

For R.H. drive vehicles, only the position indicated by the * is symmetrical.

Page 1047 of 1449

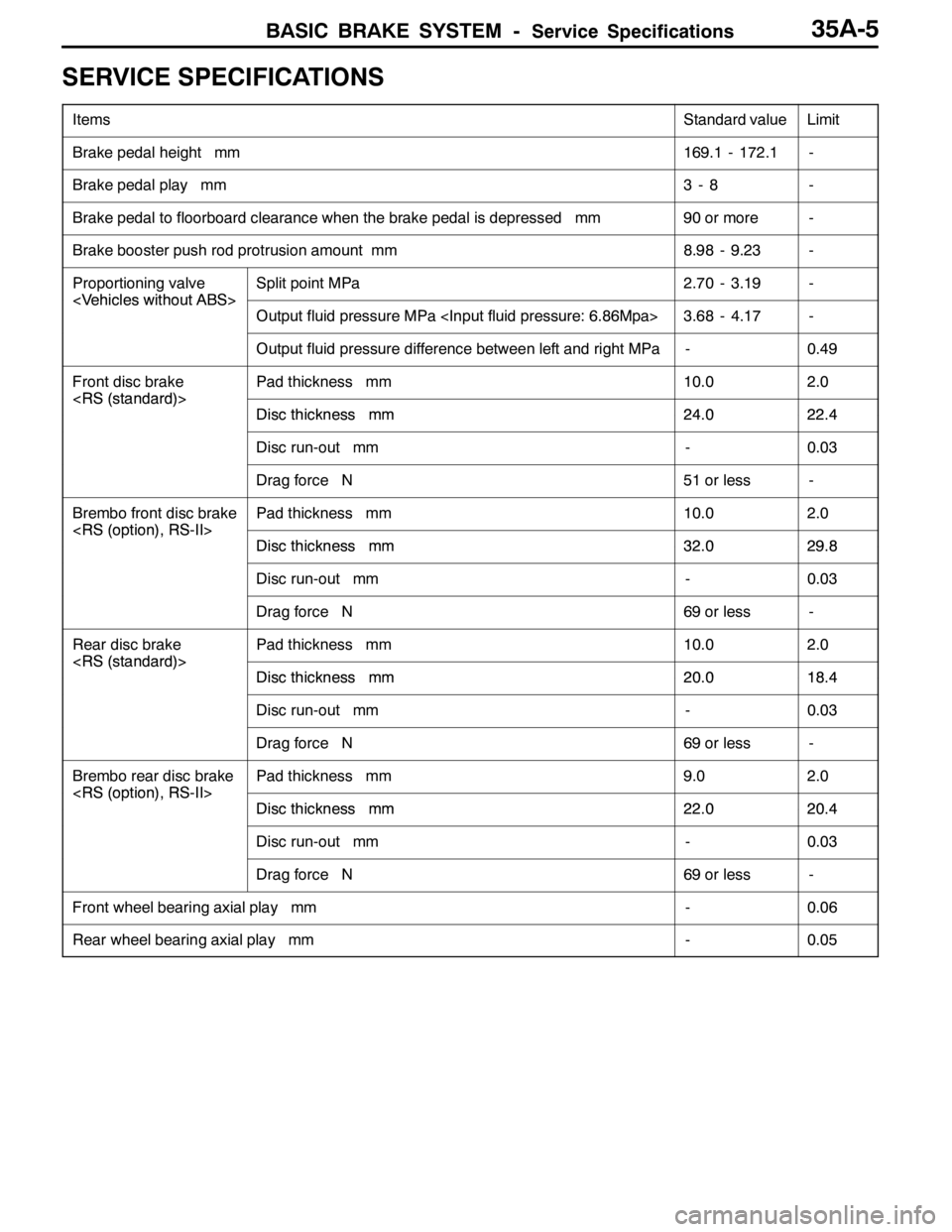

BASIC BRAKE SYSTEM -Service Specifications35A-5

SERVICE SPECIFICATIONS

ItemsStandard valueLimit

Brake pedal height mm169.1 - 172.1-

Brake pedal play mm3-8-

Brake pedal to floorboard clearance when the brake pedal is depressed mm90 or more-

Brake booster push rod protrusion amount mm8.98 - 9.23-

Proportioning valve

Split point MPa2.70 - 3.19-

Output fluid pressure MPa 3.68 - 4.17-

Output fluid pressure difference between left and right MPa-0.49

Front disc brake

Pad thickness mm10.02.0

Discthicknessmm24 022 4Discthickness mm24.022.4

Disc run-out mm-0.03

Drag force N51 or less-

Brembo front disc brake

Pad thickness mm10.02.0

Discthicknessmm32 029 8Discthickness mm32.029.8

Disc run-out mm-0.03

Drag force N69 or less-

Rear disc brake

Pad thickness mm10.02.0

Discthicknessmm20 018 4Discthickness mm20.018.4

Disc run-out mm-0.03

Drag force N69 or less-

Brembo rear disc brake

Pad thickness mm9.02.0

Discthicknessmm22 020 4Discthickness mm22.020.4

Disc run-out mm-0.03

Drag force N69 or less-

Front wheel bearing axial play mm-0.06

Rear wheel bearing axial play mm-0.05

Page 1048 of 1449

BASIC BRAKE SYSTEM -Lubricants/Sealant/Special Tools35A-6

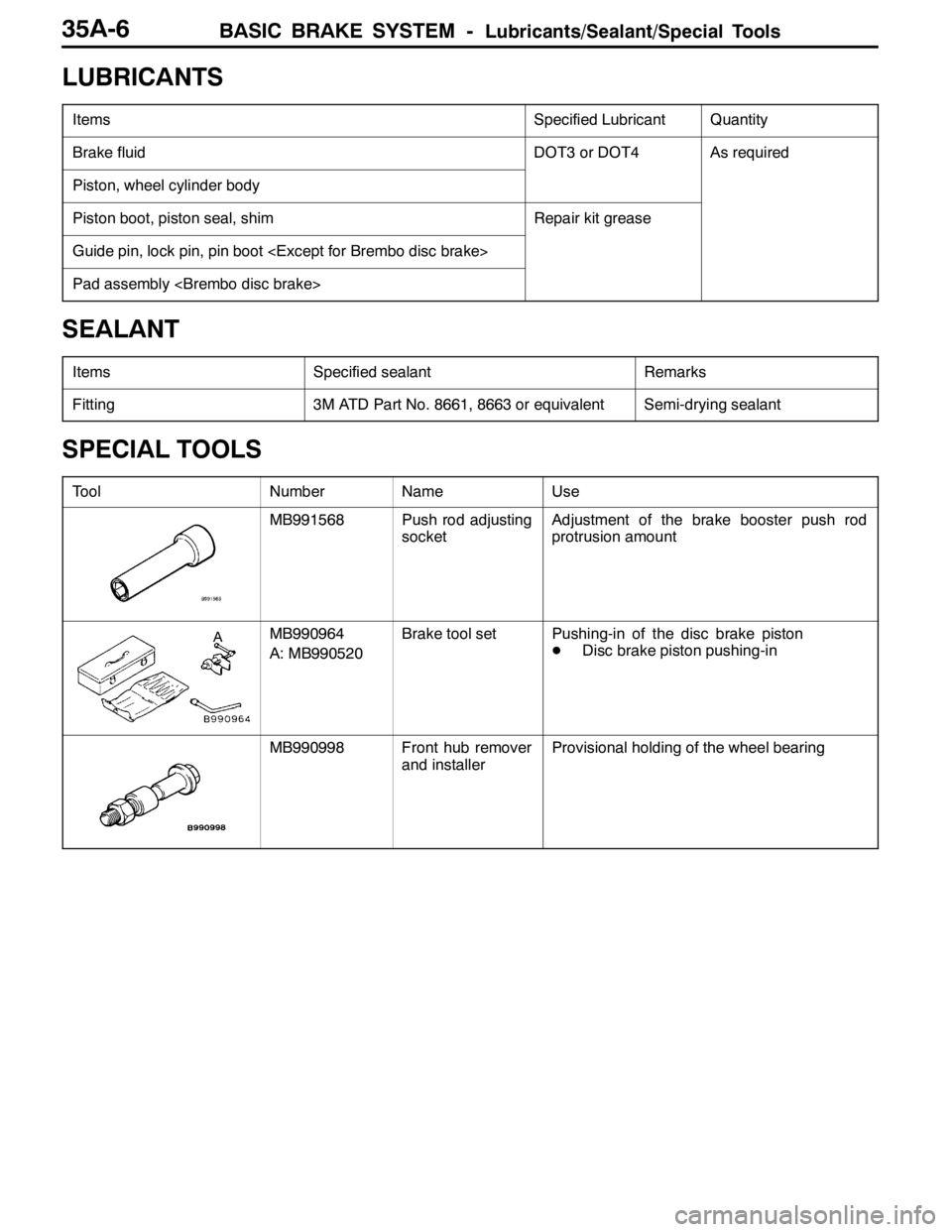

LUBRICANTS

ItemsSpecified LubricantQuantity

Brake fluidDOT3 or DOT4As required

Piston, wheel cylinder body

Piston boot, piston seal, shimRepair kit grease

Guide pin, lock pin, pin boot

Pad assembly

SEALANT

ItemsSpecified sealantRemarks

Fitting3M ATD Part No. 8661, 8663 or equivalentSemi-drying sealant

SPECIAL TOOLS

ToolNumberNameUse

MB991568Push rod adjusting

socketAdjustment of the brake booster push rod

protrusion amount

AMB990964

A: MB990520Brake tool setPushing-in of the disc brake piston

DDisc brake piston pushing-in

MB990998Front hub remover

and installerProvisional holding of the wheel bearing

Page 1049 of 1449

BASIC BRAKE SYSTEM -On-vehicle Service35A-7

ON-VEHICLE SERVICE

BRAKE PEDAL CHECK AND ADJUSTMENT

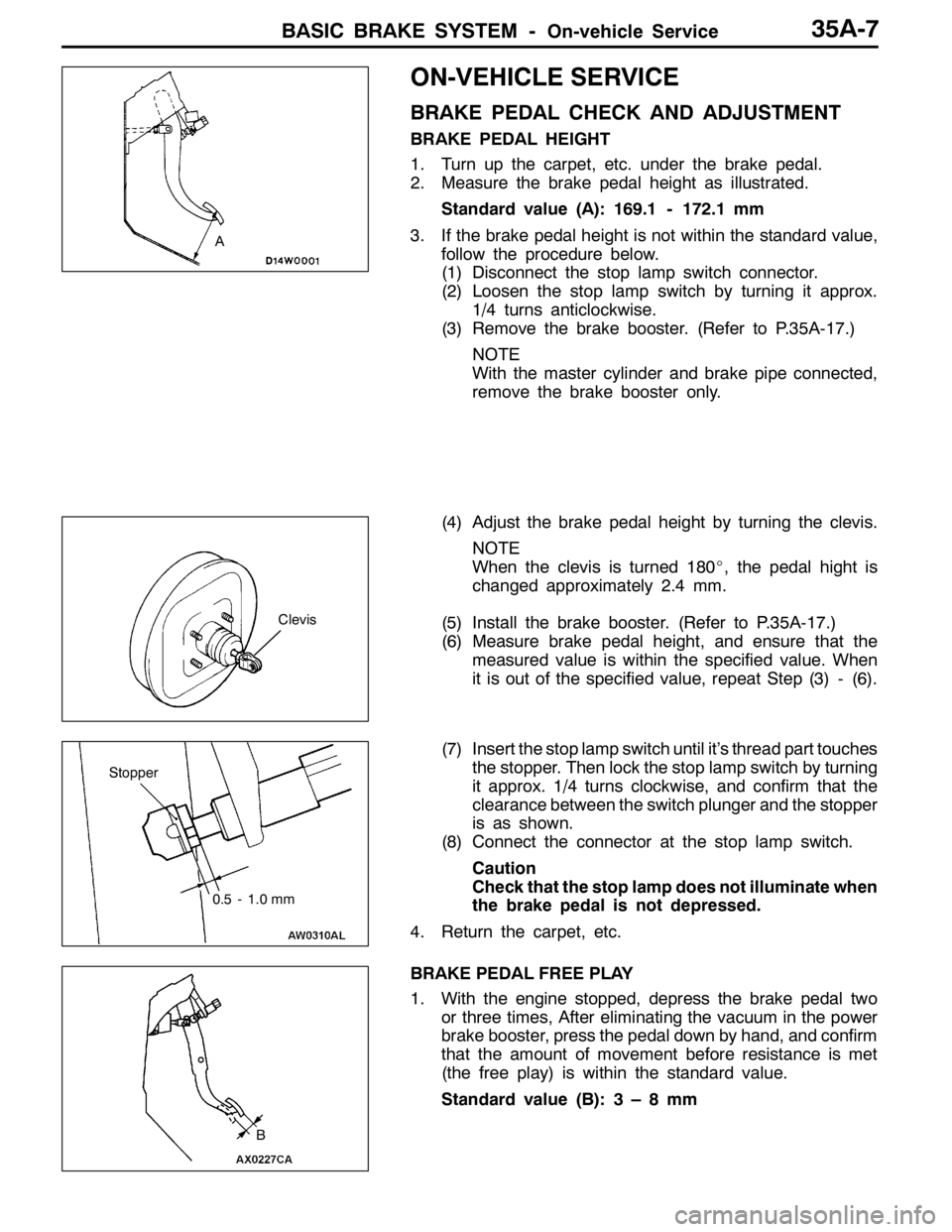

BRAKE PEDAL HEIGHT

1. Turn up the carpet, etc. under the brake pedal.

2. Measure the brake pedal height as illustrated.

Standard value (A): 169.1 - 172.1 mm

3. If the brake pedal height is not within the standard value,

follow the procedure below.

(1) Disconnect the stop lamp switch connector.

(2) Loosen the stop lamp switch by turning it approx.

1/4 turns anticlockwise.

(3) Remove the brake booster. (Refer to P.35A-17.)

NOTE

With the master cylinder and brake pipe connected,

remove the brake booster only.

(4) Adjust the brake pedal height by turning the clevis.

NOTE

When the clevis is turned 180_, the pedal hight is

changed approximately 2.4 mm.

(5) Install the brake booster. (Refer to P.35A-17.)

(6) Measure brake pedal height, and ensure that the

measured value is within the specified value. When

it is out of the specified value, repeat Step (3) - (6).

(7) Insert the stop lamp switch until it’s thread part touches

the stopper. Then lock the stop lamp switch by turning

it approx. 1/4 turns clockwise, and confirm that the

clearance between the switch plunger and the stopper

is as shown.

(8) Connect the connector at the stop lamp switch.

Caution

Check that the stop lamp does not illuminate when

the brake pedal is not depressed.

4. Return the carpet, etc.

BRAKE PEDAL FREE PLAY

1. With the engine stopped, depress the brake pedal two

or three times, After eliminating the vacuum in the power

brake booster, press the pedal down by hand, and confirm

that the amount of movement before resistance is met

(the free play) is within the standard value.

Standard value (B):3–8mm

A

Clevis

Stopper

0.5 - 1.0 mm

B