dimensions MITSUBISHI LANCER EVOLUTION 2007 Service Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 500 of 1449

ENGINE OVERHAUL -Cylinder Head and Valve11B-46

Valve Guide Replacement

1. Using a press, push the valve guide to the cylinder block

side.

2. Machine the valve guide hole on the cylinder head to

match the oversized valve guide into which it is to be

pressed in.

Caution

Do not use a valve guide having the same size as

the removed valve guide.

Valve guide hole diameter:

0.05 O.S. 12.05 - 12.07 mm

0.25 O.S. 12.25 - 12.27 mm

0.50 O.S. 12.50 - 12.52 mm

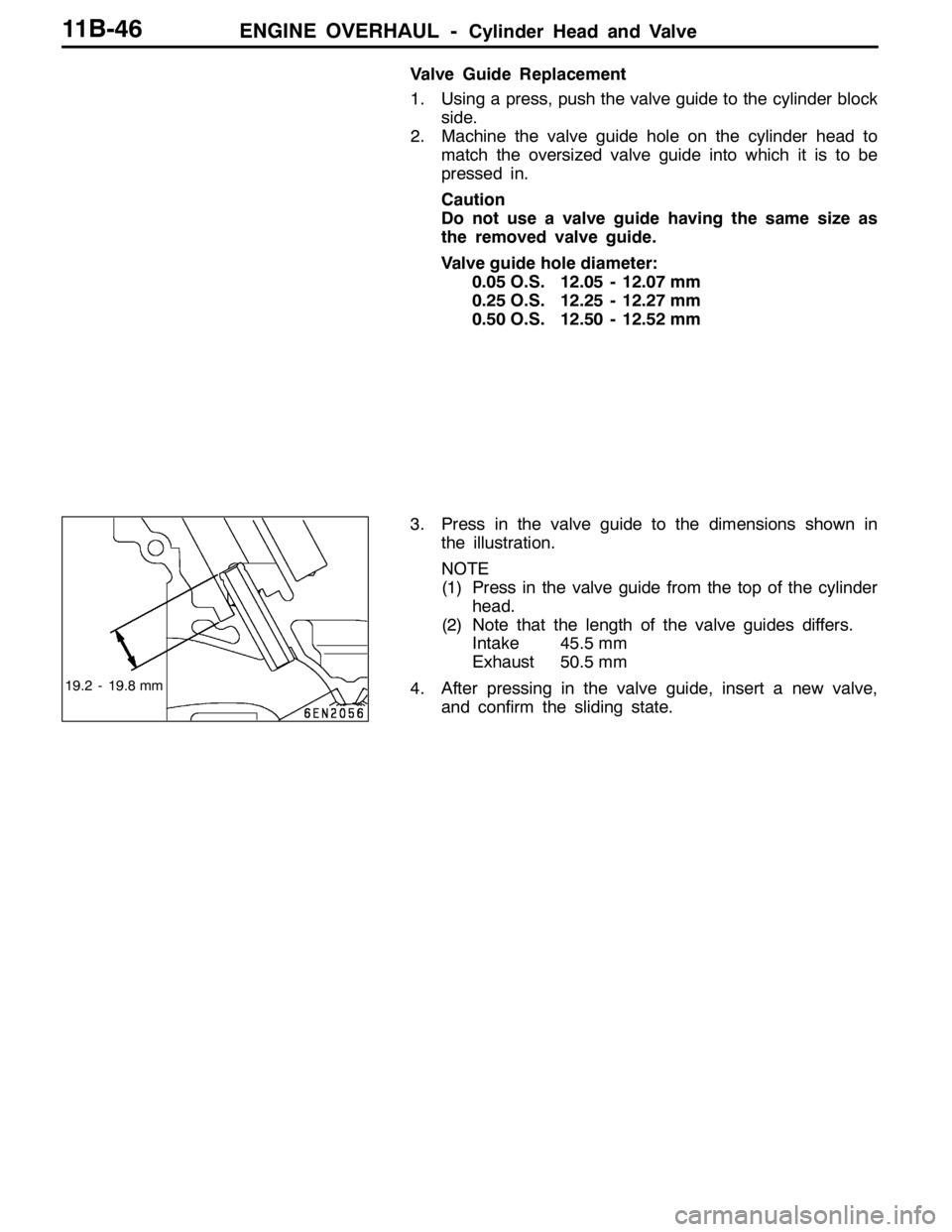

3. Press in the valve guide to the dimensions shown in

the illustration.

NOTE

(1) Press in the valve guide from the top of the cylinder

head.

(2) Note that the length of the valve guides differs.

Intake 45.5 mm

Exhaust 50.5 mm

4. After pressing in the valve guide, insert a new valve,

and confirm the sliding state.

19.2 - 19.8 mm

Page 508 of 1449

ENGINE OVERHAUL -Oil Pump and Oil Pan11B-54

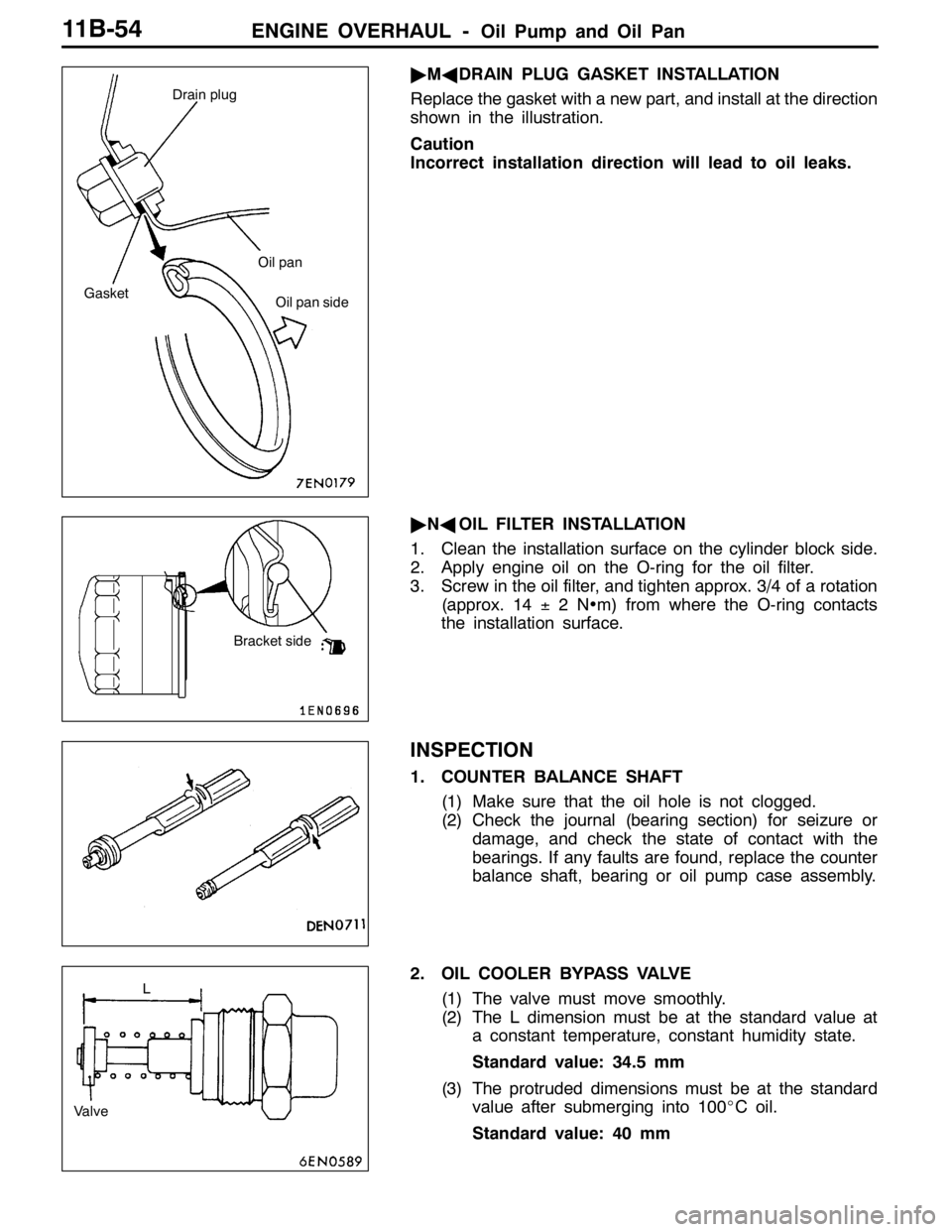

"MADRAIN PLUG GASKET INSTALLATION

Replace the gasket with a new part, and install at the direction

shown in the illustration.

Caution

Incorrect installation direction will lead to oil leaks.

"NAOIL FILTER INSTALLATION

1. Clean the installation surface on the cylinder block side.

2. Apply engine oil on the O-ring for the oil filter.

3. Screw in the oil filter, and tighten approx. 3/4 of a rotation

(approx. 14±2N•m) from where the O-ring contacts

the installation surface.

INSPECTION

1. COUNTER BALANCE SHAFT

(1) Make sure that the oil hole is not clogged.

(2) Check the journal (bearing section) for seizure or

damage, and check the state of contact with the

bearings. If any faults are found, replace the counter

balance shaft, bearing or oil pump case assembly.

2. OIL COOLER BYPASS VALVE

(1) The valve must move smoothly.

(2) The L dimension must be at the standard value at

a constant temperature, constant humidity state.

Standard value: 34.5 mm

(3) The protruded dimensions must be at the standard

value after submerging into 100_C oil.

Standard value: 40 mm

Drain plug

Oil pan

Oil pan side Gasket

Bracket side

L

Valve

Page 523 of 1449

ENGINE OVERHAUL -Crankshaft and Cylinder Block11B-69

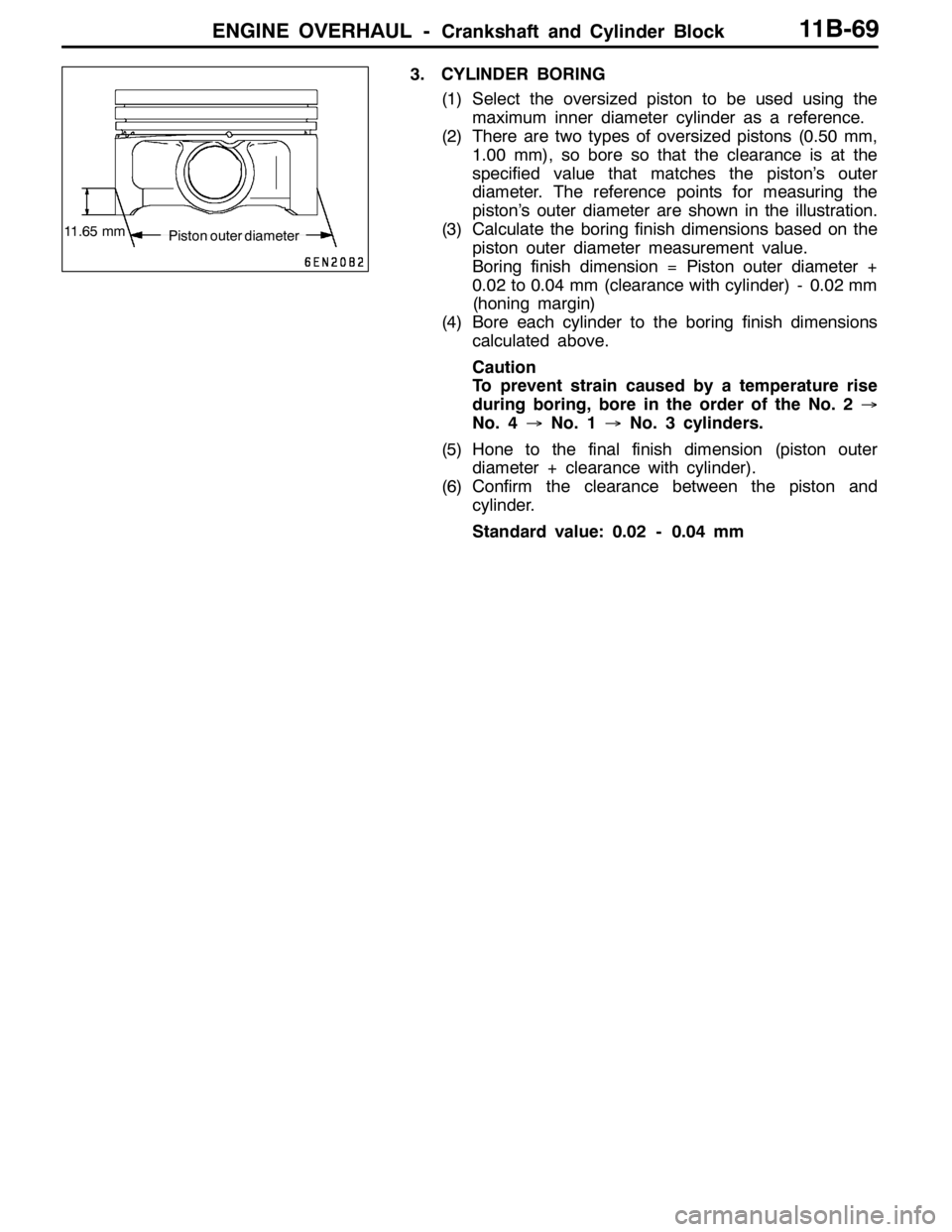

3. CYLINDER BORING

(1) Select the oversized piston to be used using the

maximum inner diameter cylinder as a reference.

(2) There are two types of oversized pistons (0.50 mm,

1.00 mm), so bore so that the clearance is at the

specified value that matches the piston’s outer

diameter. The reference points for measuring the

piston’s outer diameter are shown in the illustration.

(3) Calculate the boring finish dimensions based on the

piston outer diameter measurement value.

Boring finish dimension = Piston outer diameter +

0.02 to 0.04 mm (clearance with cylinder) - 0.02 mm

(honing margin)

(4) Bore each cylinder to the boring finish dimensions

calculated above.

Caution

To prevent strain caused by a temperature rise

during boring, bore in the order of the No. 2→

No. 4→No. 1→No. 3 cylinders.

(5) Hone to the final finish dimension (piston outer

diameter + clearance with cylinder).

(6) Confirm the clearance between the piston and

cylinder.

Standard value: 0.02 - 0.04 mm

Piston outer diameter 11.65 mm

Page 890 of 1449

MANUAL TRANSMISSION OVERHAUL -Input Shaft22B-24

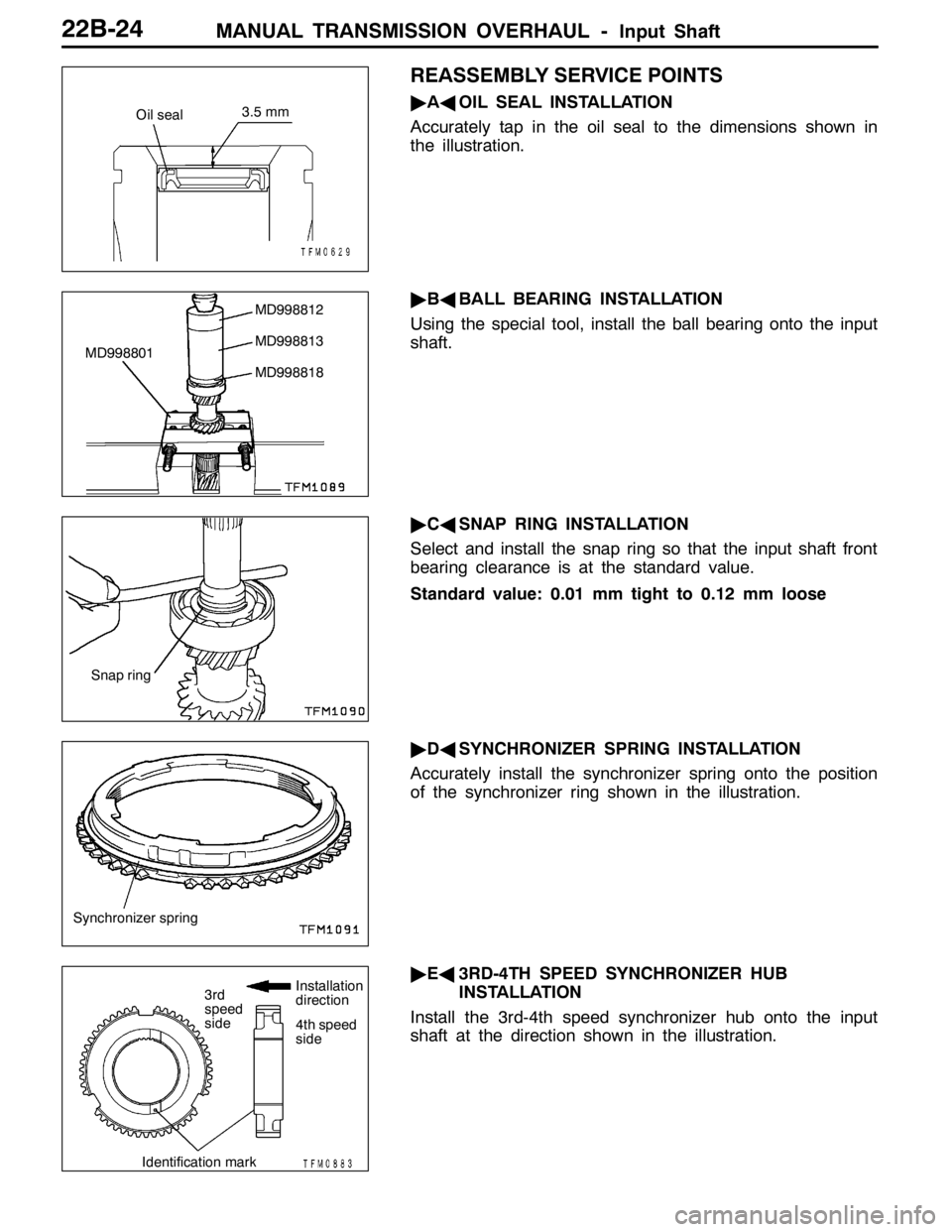

REASSEMBLY SERVICE POINTS

"AAOIL SEAL INSTALLATION

Accurately tap in the oil seal to the dimensions shown in

the illustration.

"BABALL BEARING INSTALLATION

Using the special tool, install the ball bearing onto the input

shaft.

"CASNAP RING INSTALLATION

Select and install the snap ring so that the input shaft front

bearing clearance is at the standard value.

Standard value: 0.01 mm tight to 0.12 mm loose

"DASYNCHRONIZER SPRING INSTALLATION

Accurately install the synchronizer spring onto the position

of the synchronizer ring shown in the illustration.

"EA3RD-4TH SPEED SYNCHRONIZER HUB

INSTALLATION

Install the 3rd-4th speed synchronizer hub onto the input

shaft at the direction shown in the illustration.Oil seal3.5 mm

MD998812

MD998813

MD998818 MD998801

Snap ring

Synchronizer spring

Identification mark3rd

speed

side

4th speed

side Installation

direction

Page 897 of 1449

MANUAL TRANSMISSION OVERHAUL -Output Shaft22B-31

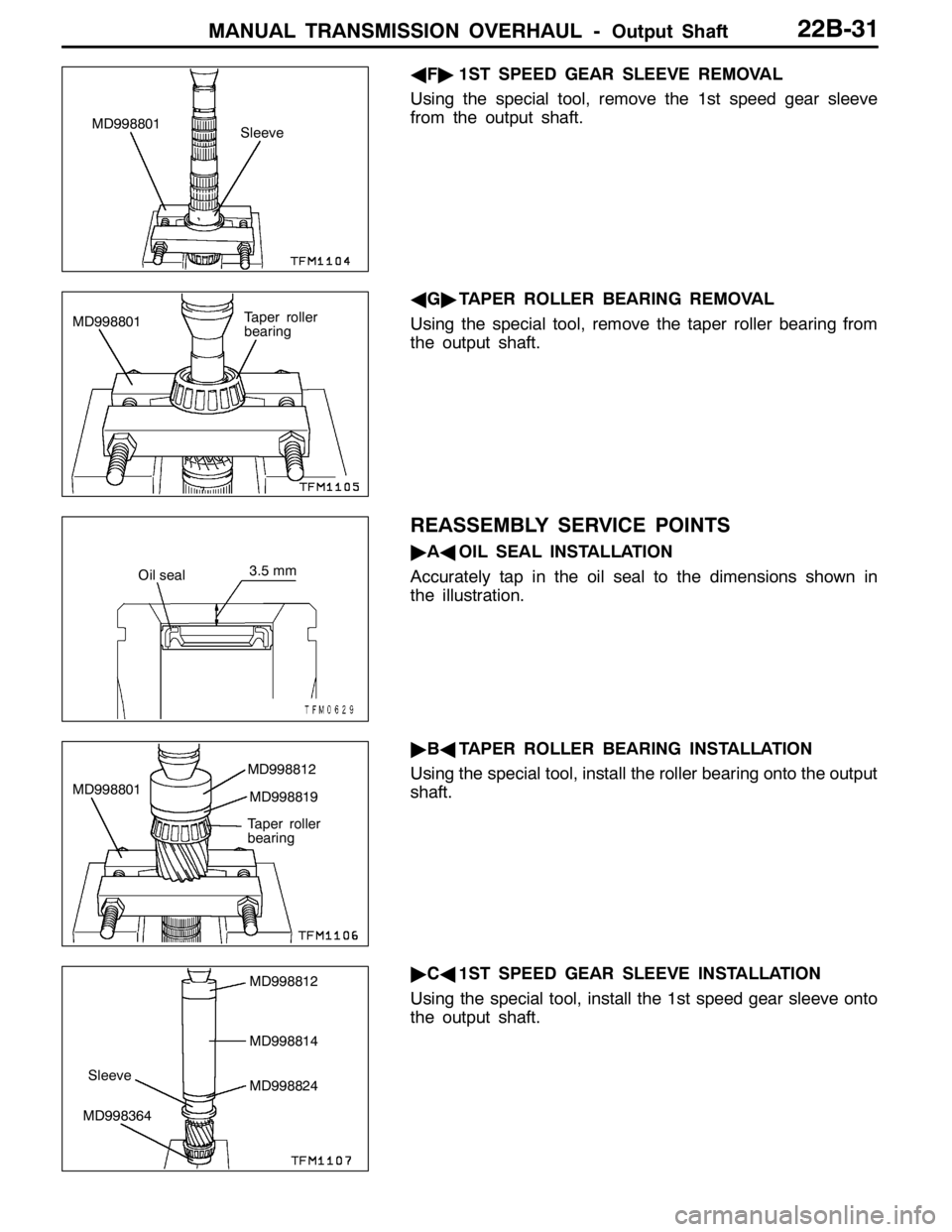

AF"1ST SPEED GEAR SLEEVE REMOVAL

Using the special tool, remove the 1st speed gear sleeve

from the output shaft.

AG"TAPER ROLLER BEARING REMOVAL

Using the special tool, remove the taper roller bearing from

the output shaft.

REASSEMBLY SERVICE POINTS

"AAOIL SEAL INSTALLATION

Accurately tap in the oil seal to the dimensions shown in

the illustration.

"BATAPER ROLLER BEARING INSTALLATION

Using the special tool, install the roller bearing onto the output

shaft.

"CA1ST SPEED GEAR SLEEVE INSTALLATION

Using the special tool, install the 1st speed gear sleeve onto

the output shaft.

MD998801

Sleeve

MD998801Taper roller

bearing

Oil seal3.5 mm

MD998801MD998812

MD998819

Taper roller

bearing

MD998364SleeveMD998812

MD998814

MD998824

Page 907 of 1449

MANUAL TRANSMISSION OVERHAUL -Control Housing22B-41

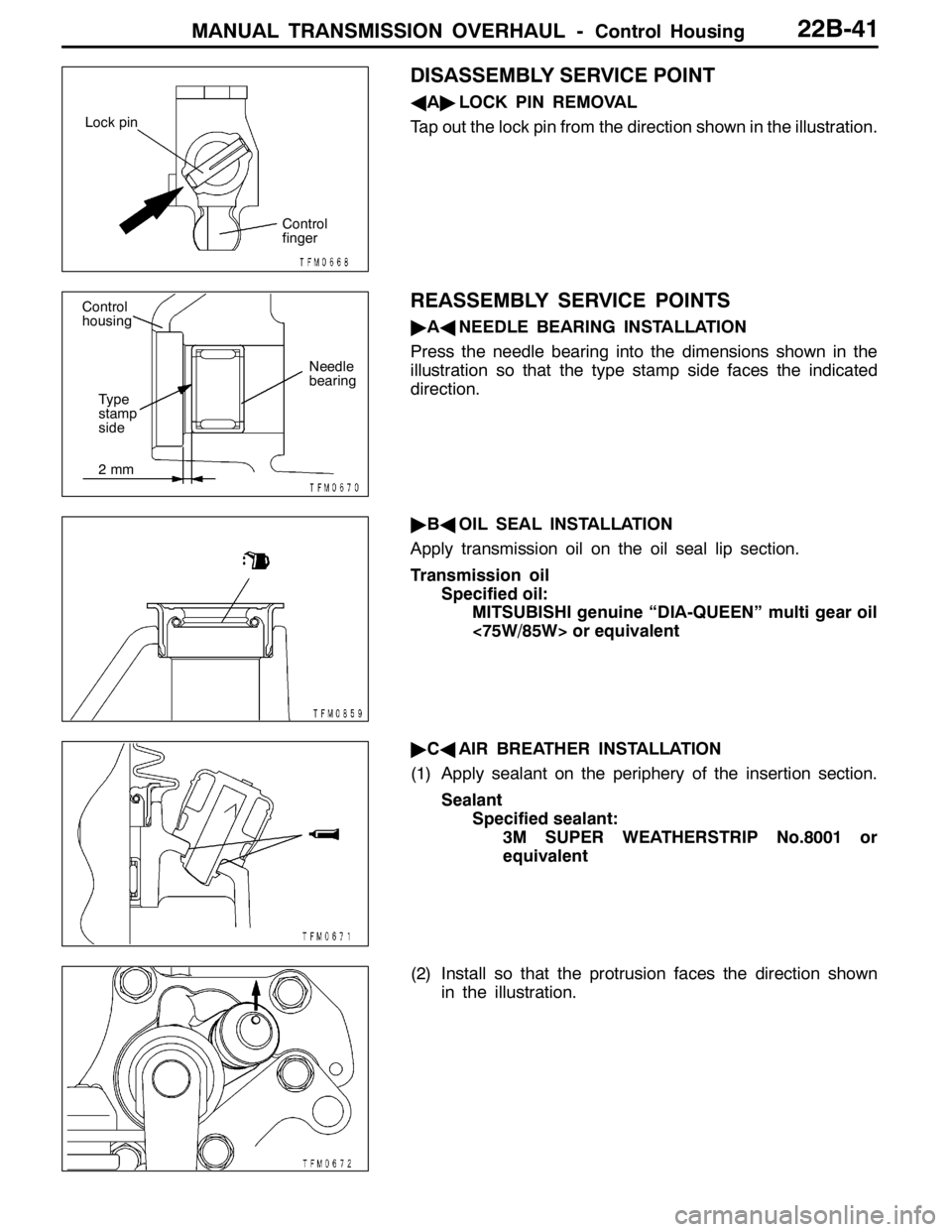

DISASSEMBLY SERVICE POINT

AA"LOCK PIN REMOVAL

Tap out the lock pin from the direction shown in the illustration.

REASSEMBLY SERVICE POINTS

"AANEEDLE BEARING INSTALLATION

Press the needle bearing into the dimensions shown in the

illustration so that the type stamp side faces the indicated

direction.

"BAOIL SEAL INSTALLATION

Apply transmission oil on the oil seal lip section.

Transmission oil

Specified oil:

MITSUBISHI genuine “DIA-QUEEN” multi gear oil

<75W/85W> or equivalent

"CAAIR BREATHER INSTALLATION

(1) Apply sealant on the periphery of the insertion section.

Sealant

Specified sealant:

3M SUPER WEATHERSTRIP No.8001 or

equivalent

(2) Install so that the protrusion faces the direction shown

in the illustration.

Lock pin

Control

finger

Control

housing

Needle

bearing

2mm Type

stamp

side

Page 992 of 1449

REAR AXLE -Differential Carrier

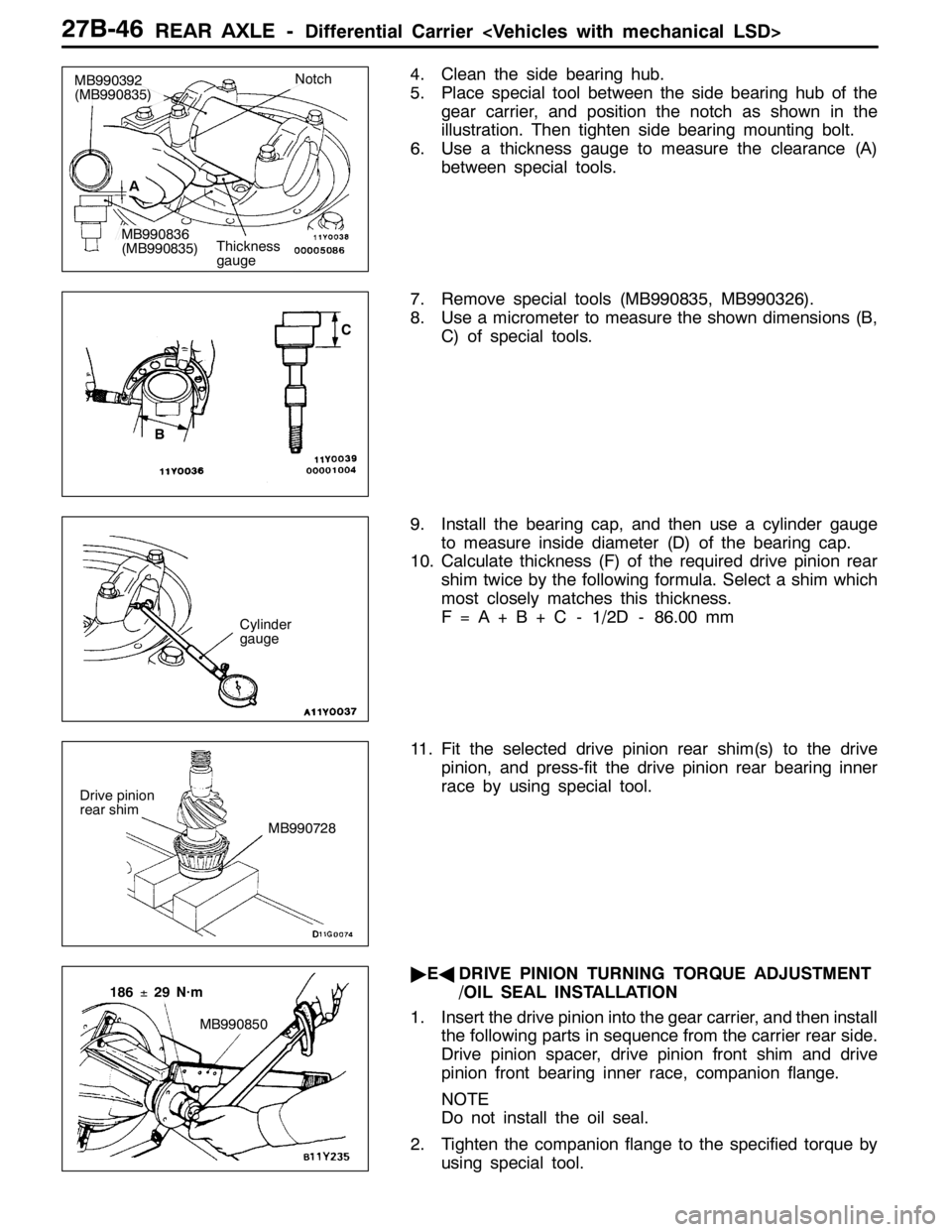

4. Clean the side bearing hub.

5. Place special tool between the side bearing hub of the

gear carrier, and position the notch as shown in the

illustration. Then tighten side bearing mounting bolt.

6. Use a thickness gauge to measure the clearance (A)

between special tools.

7. Remove special tools (MB990835, MB990326).

8. Use a micrometer to measure the shown dimensions (B,

C) of special tools.

9. Install the bearing cap, and then use a cylinder gauge

to measure inside diameter (D) of the bearing cap.

10. Calculate thickness (F) of the required drive pinion rear

shim twice by the following formula. Select a shim which

most closely matches this thickness.

F = A + B + C - 1/2D - 86.00 mm

11. Fit the selected drive pinion rear shim(s) to the drive

pinion, and press-fit the drive pinion rear bearing inner

race by using special tool.

"EADRIVE PINION TURNING TORQUE ADJUSTMENT

/OIL SEAL INSTALLATION

1. Insert the drive pinion into the gear carrier, and then install

the following parts in sequence from the carrier rear side.

Drive pinion spacer, drive pinion front shim and drive

pinion front bearing inner race, companion flange.

NOTE

Do not install the oil seal.

2. Tighten the companion flange to the specified torque by

using special tool.

Thickness

gauge

MB990392

(MB990835)Notch

MB990836

(MB990835)A

BC

Cylinder

gauge

Drive pinion

rear shim

MB990728

MB990850

186±29 N·m

Page 1221 of 1449

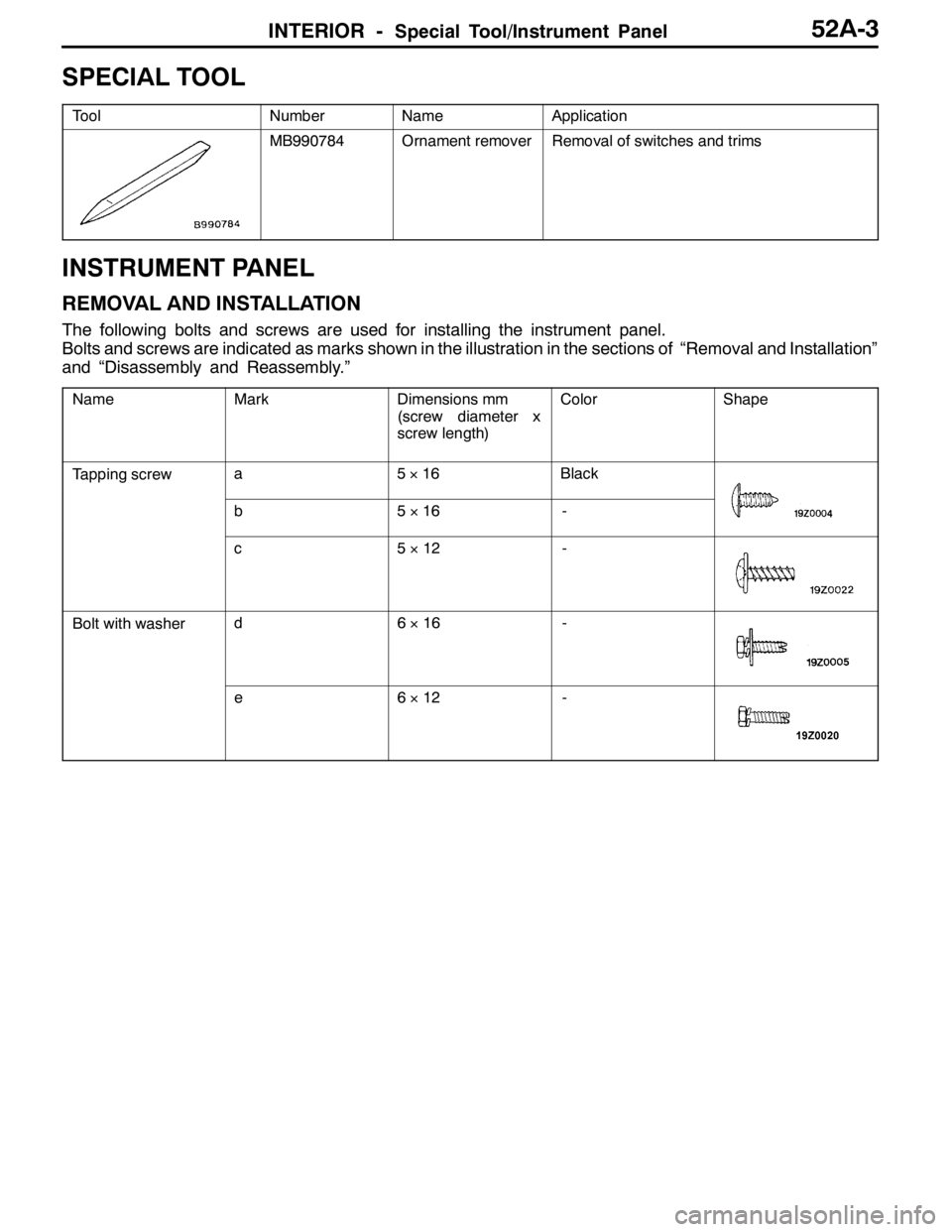

INTERIOR -Special Tool/Instrument Panel52A-3

SPECIAL TOOL

ToolNumberNameApplication

MB990784Ornament removerRemoval of switches and trims

INSTRUMENT PANEL

REMOVAL AND INSTALLATION

The following bolts and screws are used for installing the instrument panel.

Bolts and screws are indicated as marks shown in the illustration in the sections of “Removal and Installation”

and “Disassembly and Reassembly.”

NameMarkDimensions mm

(screw diameter x

screw length)ColorShape

Tapping screwa5×16Black

b5×16-

c5×12-

Bolt with washerd6×16-

e6×12-