height MITSUBISHI LANCER EVOLUTION 2007 Service Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 793 of 1449

CLUTCH -General Information/Service Specifications/Lubricants/On-vehicle Service21A-3

GENERAL INFORMATION

The clutch is a dry single-disc, diaphragm type;

hydraulic pressure is used for the clutch control.

SERVICE SPECIFICATIONS

ItemsStandard value

Clutch pedal height mm202.1 - 206.1

173.5 - 177.5

Clutch pedal clevis pin play mm1-3

Clutch pedal free play mm4-13

Distance between the clutch pedal and the toeboard

when the clutch is disengaged mm114.3 or more

100 or more

LUBRICANTS

ItemsSpecified lubricantsQuantity

Clutch fluidBrake fluid DOT3 or DOT4As required

Push rod assemblyRubber grease

Boot

Release cylinder push rodMITSUBISHI genuine grease Part No.

0101011

ON-VEHICLE SERVICE

CLUTCH PEDAL INSPECTION AND

ADJUSTMENT

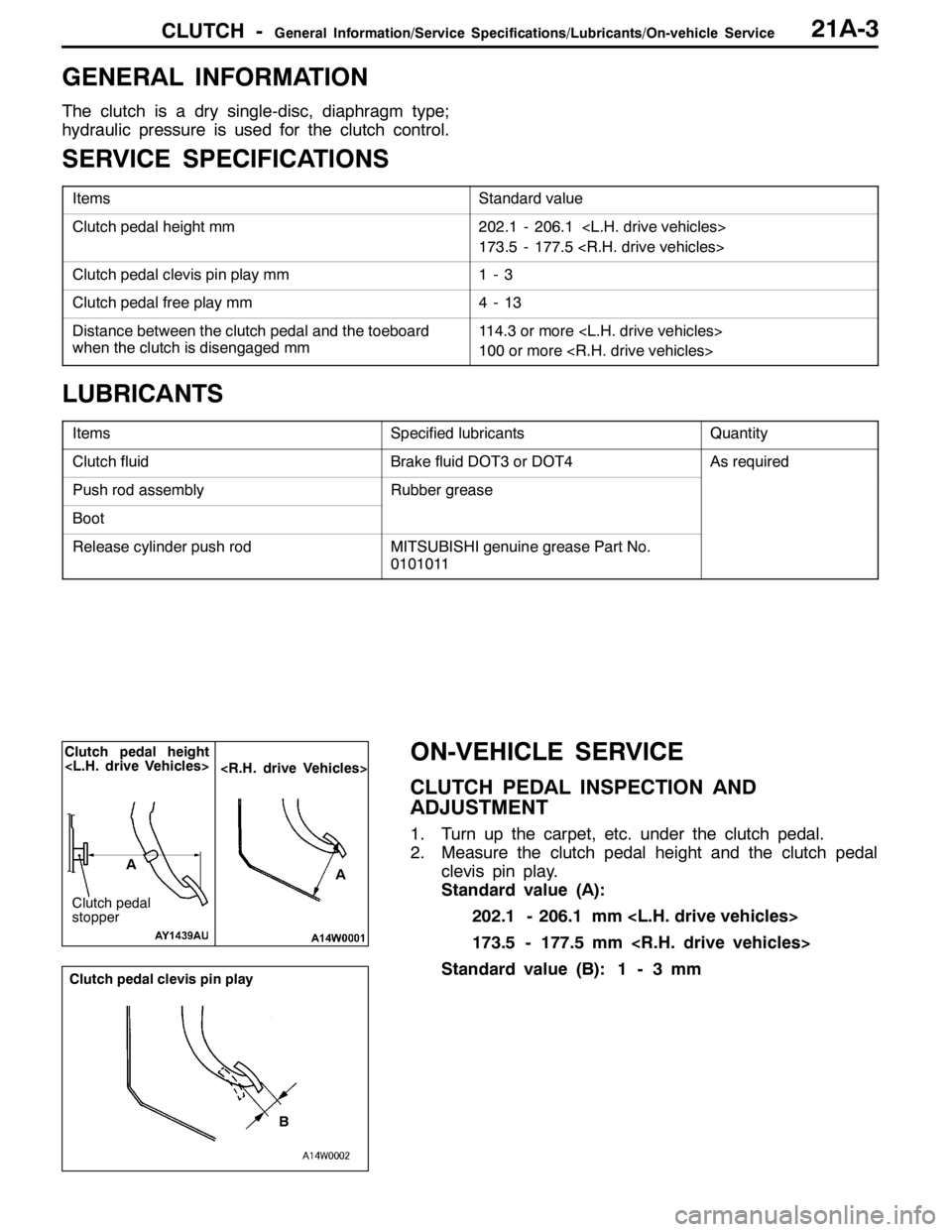

1. Turn up the carpet, etc. under the clutch pedal.

2. Measure the clutch pedal height and the clutch pedal

clevis pin play.

Standard value (A):

202.1 - 206.1 mm

173.5 - 177.5 mm

Standard value (B): 1 - 3 mm

Clutch pedal height

A

A

Clutch pedal

stopper

Clutch pedal clevis pin play

B

Page 794 of 1449

CLUTCH -On-Vehicle Service21A-4

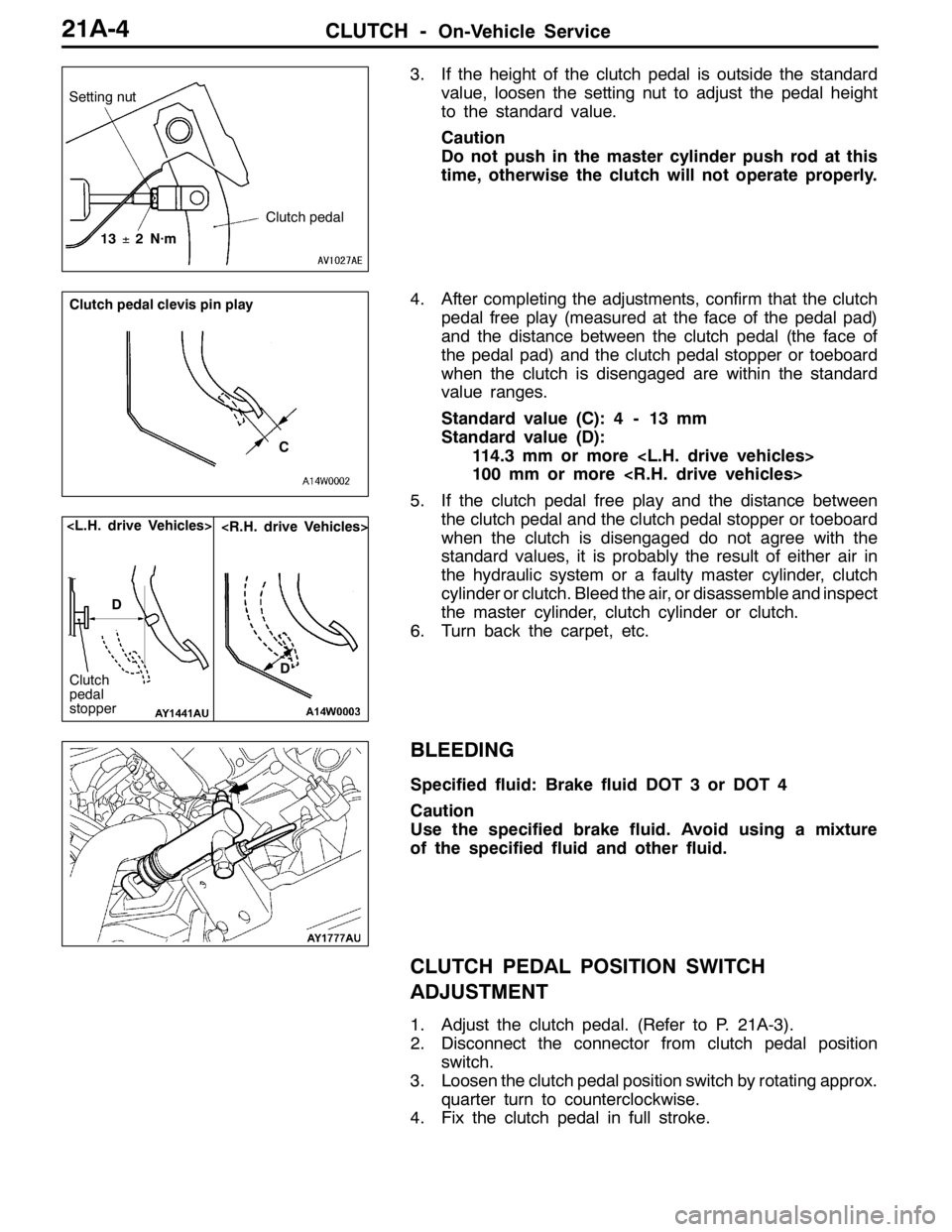

3. If the height of the clutch pedal is outside the standard

value, loosen the setting nut to adjust the pedal height

to the standard value.

Caution

Do not push in the master cylinder push rod at this

time, otherwise the clutch will not operate properly.

4. After completing the adjustments, confirm that the clutch

pedal free play (measured at the face of the pedal pad)

and the distance between the clutch pedal (the face of

the pedal pad) and the clutch pedal stopper or toeboard

when the clutch is disengaged are within the standard

value ranges.

Standard value (C): 4 - 13 mm

Standard value (D):

114.3 mm or more

100 mm or more

5. If the clutch pedal free play and the distance between

the clutch pedal and the clutch pedal stopper or toeboard

when the clutch is disengaged do not agree with the

standard values, it is probably the result of either air in

the hydraulic system or a faulty master cylinder, clutch

cylinder or clutch. Bleed the air, or disassemble and inspect

the master cylinder, clutch cylinder or clutch.

6. Turn back the carpet, etc.

BLEEDING

Specified fluid: Brake fluid DOT 3 or DOT 4

Caution

Use the specified brake fluid. Avoid using a mixture

of the specified fluid and other fluid.

CLUTCH PEDAL POSITION SWITCH

ADJUSTMENT

1. Adjust the clutch pedal. (Refer to P. 21A-3).

2. Disconnect the connector from clutch pedal position

switch.

3. Loosen the clutch pedal position switch by rotating approx.

quarter turn to counterclockwise.

4. Fix the clutch pedal in full stroke.

Clutch pedal Setting nut

13±2 N·m

Clutch pedal clevis pin play

C

Clutch

pedal

stopper

D D

Page 833 of 1449

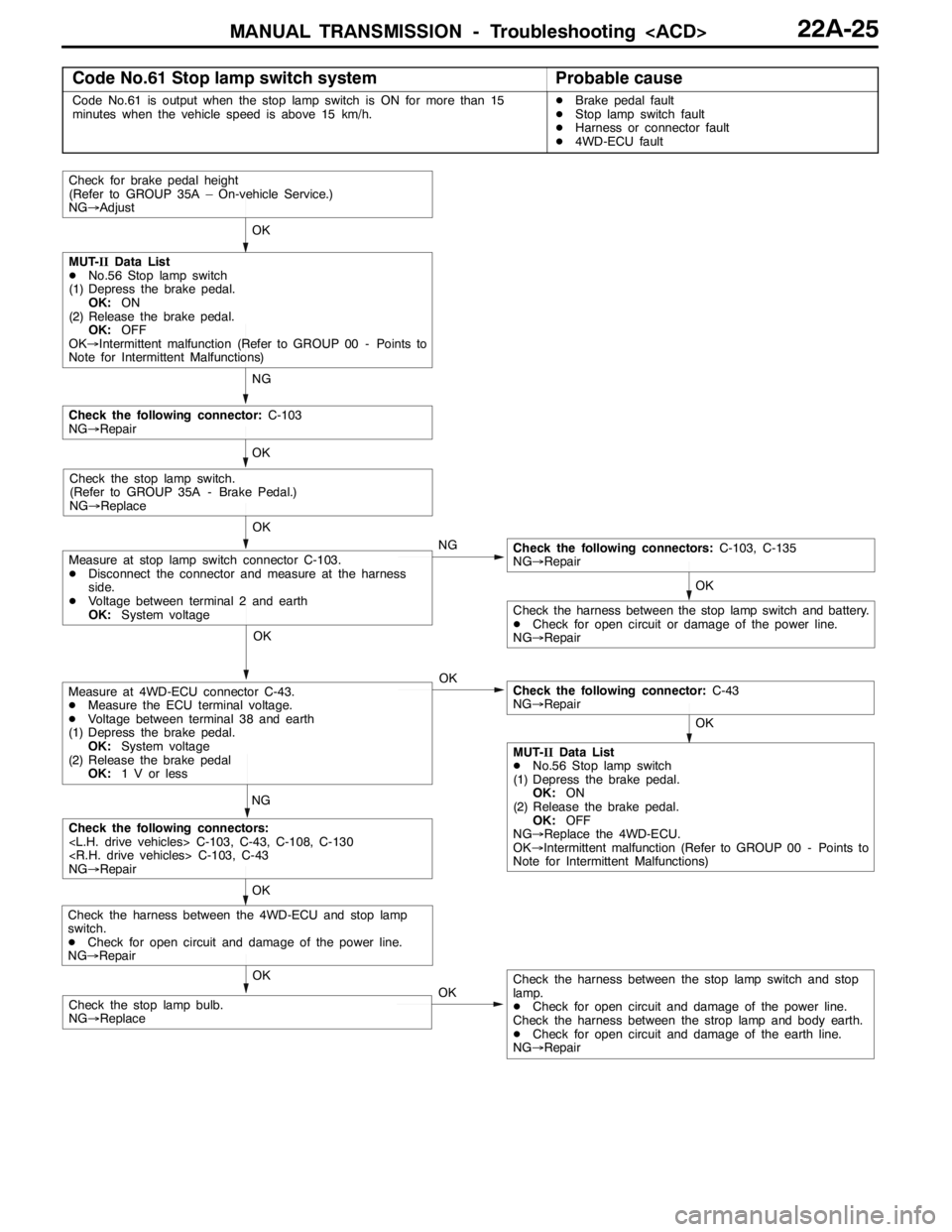

MANUAL TRANSMISSION - Troubleshooting

Code No.61 Stop lamp switch systemProbable cause

Code No.61 is output when the stop lamp switch is ON for more than 15

minutes when the vehicle speed is above 15 km/h.DBrake pedal fault

DStop lamp switch fault

DHarness or connector fault

D4WD-ECU fault

OK

OK

OK

NG

OK

Check for brake pedal height

(Refer to GROUP 35A – On-vehicle Service.)

NG→Adjust

NG

MUT-IIData List

DNo.56 Stop lamp switch

(1) Depress the brake pedal.

OK:ON

(2) Release the brake pedal.

OK:OFF

OK→Intermittent malfunction (Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions)

OK

Check the following connector:C-103

NG→Repair

Check the stop lamp switch.

(Refer to GROUP 35A - Brake Pedal.)

NG→Replace

NG

OK

Check the following connectors:C-103, C-135

NG→Repair

Check the harness between the stop lamp switch and battery.

DCheck for open circuit or damage of the power line.

NG→Repair

OK

Measure at stop lamp switch connector C-103.

DDisconnect the connector and measure at the harness

side.

DVoltage between terminal 2 and earth

OK:System voltage

Measure at 4WD-ECU connector C-43.

DMeasure the ECU terminal voltage.

DVoltage between terminal 38 and earth

(1) Depress the brake pedal.

OK:System voltage

(2) Release the brake pedal

OK:1 V or less

OK

Check the following connectors:

NG→Repair

OKCheck the harness between the stop lamp switch and stop

lamp.

DCheck for open circuit and damage of the power line.

Check the harness between the strop lamp and body earth.

DCheck for open circuit and damage of the earth line.

NG→Repair

Check the harness between the 4WD-ECU and stop lamp

switch.

DCheck for open circuit and damage of the power line.

NG→Repair

Check the following connector:C-43

NG→Repair

MUT-IIData List

DNo.56 Stop lamp switch

(1) Depress the brake pedal.

OK:ON

(2) Release the brake pedal.

OK:OFF

NG→Replace the 4WD-ECU.

OK→Intermittent malfunction (Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions)

OK

Check the stop lamp bulb.

NG→Replace

Page 953 of 1449

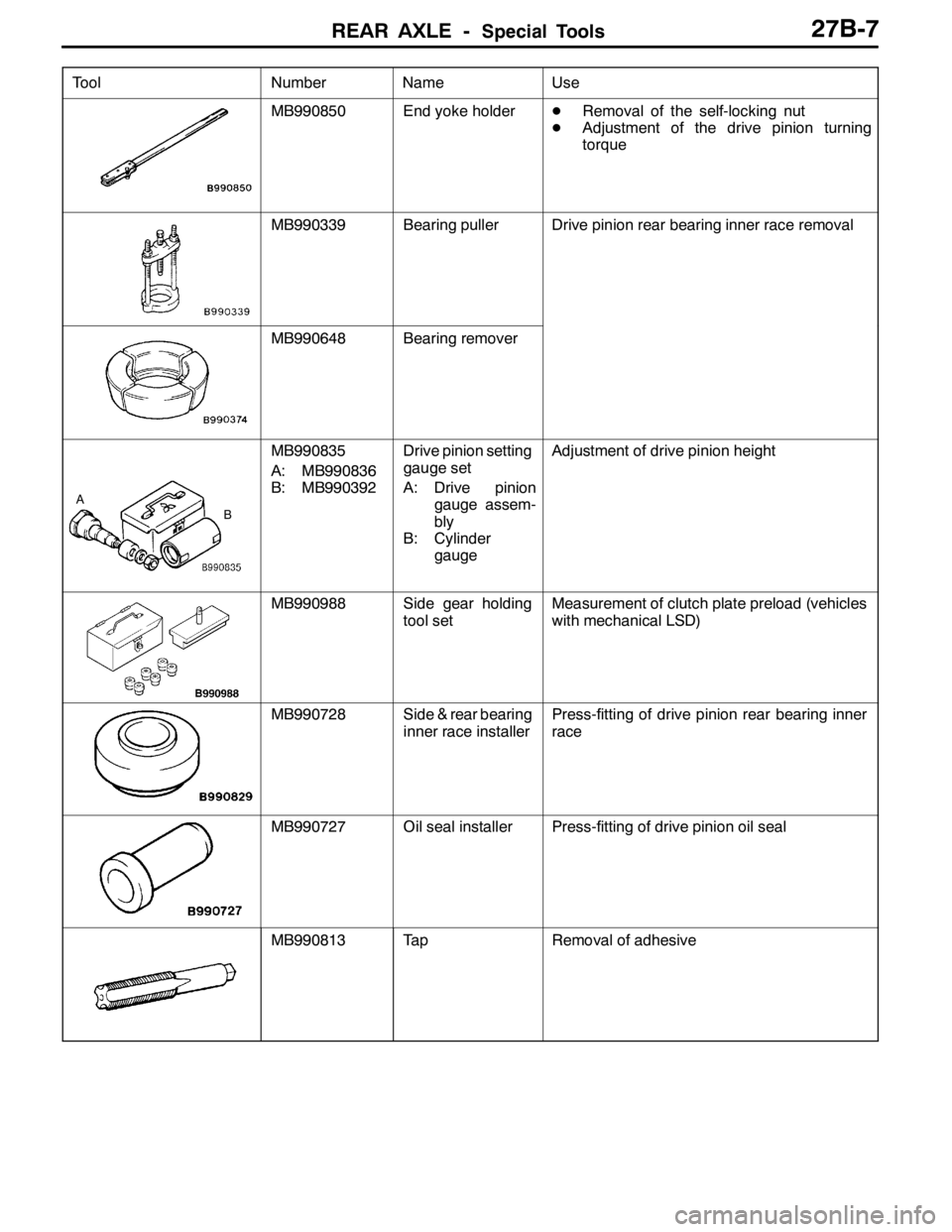

REAR AXLE -Special Tools27B-7

Tool UseName Number

MB990850End yoke holderDRemoval of the self-locking nut

DAdjustment of the drive pinion turning

torque

MB990339Bearing pullerDrive pinion rear bearing inner race removal

MB990648Bearing remover

B A

MB990835

A: MB990836

B: MB990392Drive pinion setting

gauge set

A: Drive pinion

gauge assem-

bly

B: Cylinder

gaugeAdjustment of drive pinion height

MB990988Side gear holding

tool setMeasurement of clutch plate preload (vehicles

with mechanical LSD)

MB990728Side & rear bearing

inner race installerPress-fitting of drive pinion rear bearing inner

race

MB990727Oil seal installerPress-fitting of drive pinion oil seal

MB990813Ta pRemoval of adhesive

Page 984 of 1449

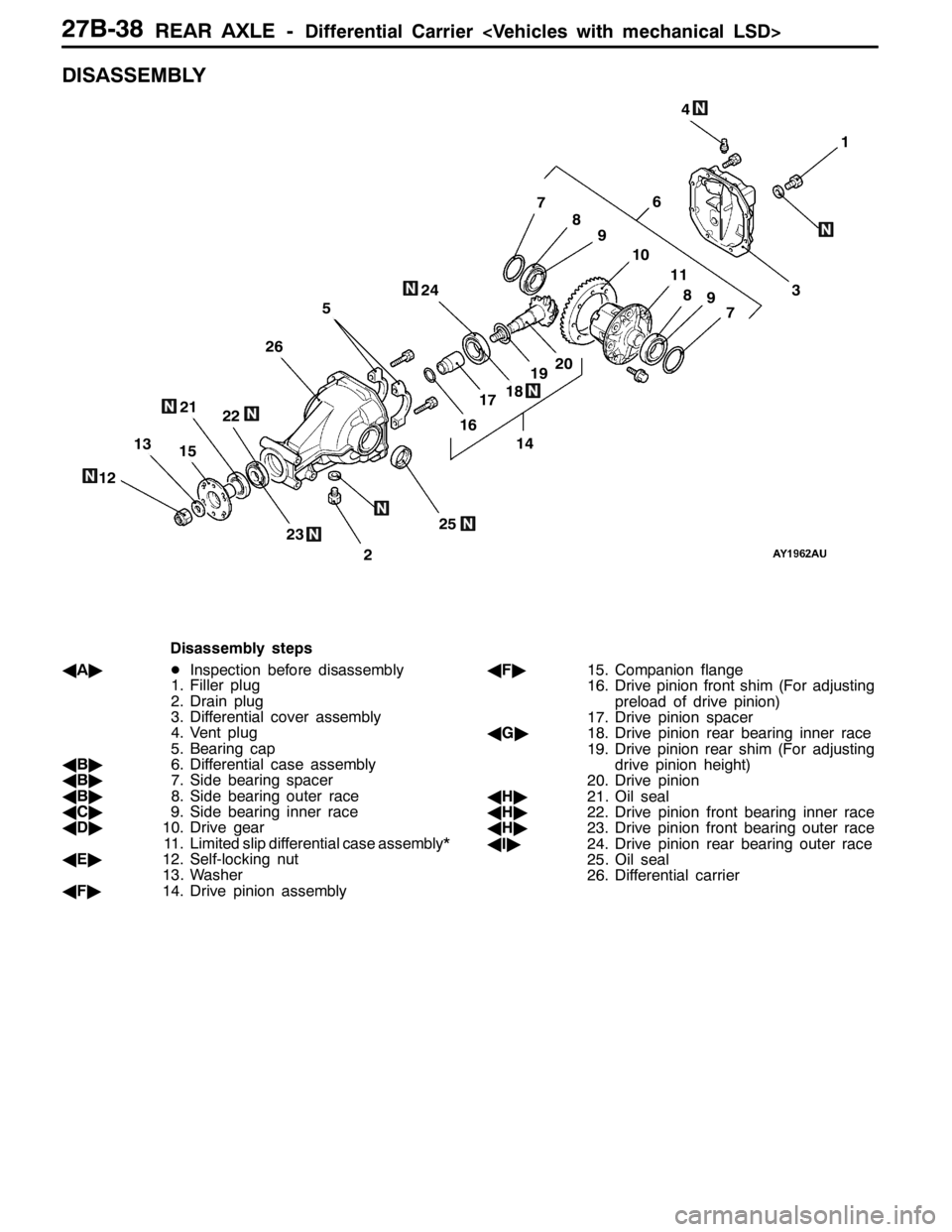

REAR AXLE -Differential Carrier

DISASSEMBLY

19

2

6

8

20

22

26

5

113

4

9

12

15

16

1314

10

21

1

23

24

25

18

17

7

897

Disassembly steps

AA"DInspection before disassembly

1. Filler plug

2. Drain plug

3. Differential cover assembly

4. Vent plug

5. Bearing cap

AB"6. Differential case assembly

AB"7. Side bearing spacer

AB"8. Side bearing outer race

AC"9. Side bearing inner race

AD"10. Drive gear

11. Limited slip differential case assembly*

AE"12. Self-locking nut

13. Washer

AF"14. Drive pinion assemblyAF"15. Companion flange

16. Drive pinion front shim (For adjusting

preload of drive pinion)

17. Drive pinion spacer

AG"18. Drive pinion rear bearing inner race

19. Drive pinion rear shim (For adjusting

drive pinion height)

20. Drive pinion

AH"21. Oil seal

AH"22. Drive pinion front bearing inner race

AH"23. Drive pinion front bearing outer race

AI"24. Drive pinion rear bearing outer race

25. Oil seal

26. Differential carrier

Page 986 of 1449

REAR AXLE -Differential Carrier

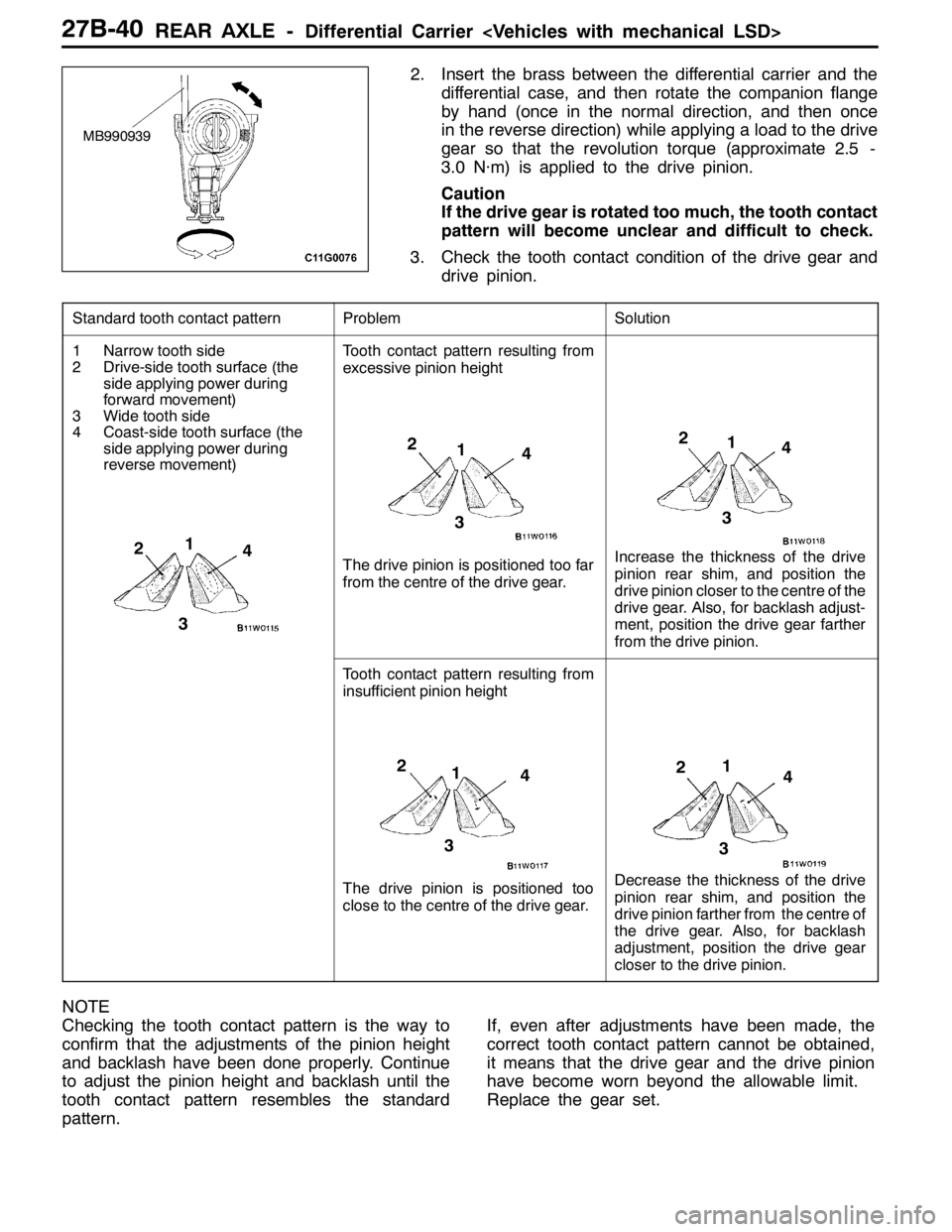

2. Insert the brass between the differential carrier and the

differential case, and then rotate the companion flange

by hand (once in the normal direction, and then once

in the reverse direction) while applying a load to the drive

gear so that the revolution torque (approximate 2.5 -

3.0 N·m) is applied to the drive pinion.

Caution

If the drive gear is rotated too much, the tooth contact

pattern will become unclear and difficult to check.

3. Check the tooth contact condition of the drive gear and

drive pinion.

Standard tooth contact patternProblemSolution

1 Narrow tooth side

2 Drive-side tooth surface (the

side applying power during

forward movement)

3 Wide tooth side

4 Coast-side tooth surface (the

side applying power during

reverse movement)

1

2

34

Tooth contact pattern resulting from

excessive pinion height

The drive pinion is positioned too far

from the centre of the drive gear.

1 2

34

Increase the thickness of the drive

pinion rear shim, and position the

drive pinion closer to the centre of the

drive gear. Also, for backlash adjust-

ment, position the drive gear farther

from the drive pinion.

1 2

34

Tooth contact pattern resulting from

insufficient pinion height

The drive pinion is positioned too

close to the centre of the drive gear.

1 2

34

Decrease the thickness of the drive

pinion rear shim, and position the

drive pinion farther from the centre of

the drive gear. Also, for backlash

adjustment, position the drive gear

closer to the drive pinion.

1

2

34

NOTE

Checking the tooth contact pattern is the way to

confirm that the adjustments of the pinion height

and backlash have been done properly. Continue

to adjust the pinion height and backlash until the

tooth contact pattern resembles the standard

pattern.If, even after adjustments have been made, the

correct tooth contact pattern cannot be obtained,

it means that the drive gear and the drive pinion

have become worn beyond the allowable limit.

Replace the gear set.

MB990939

Page 989 of 1449

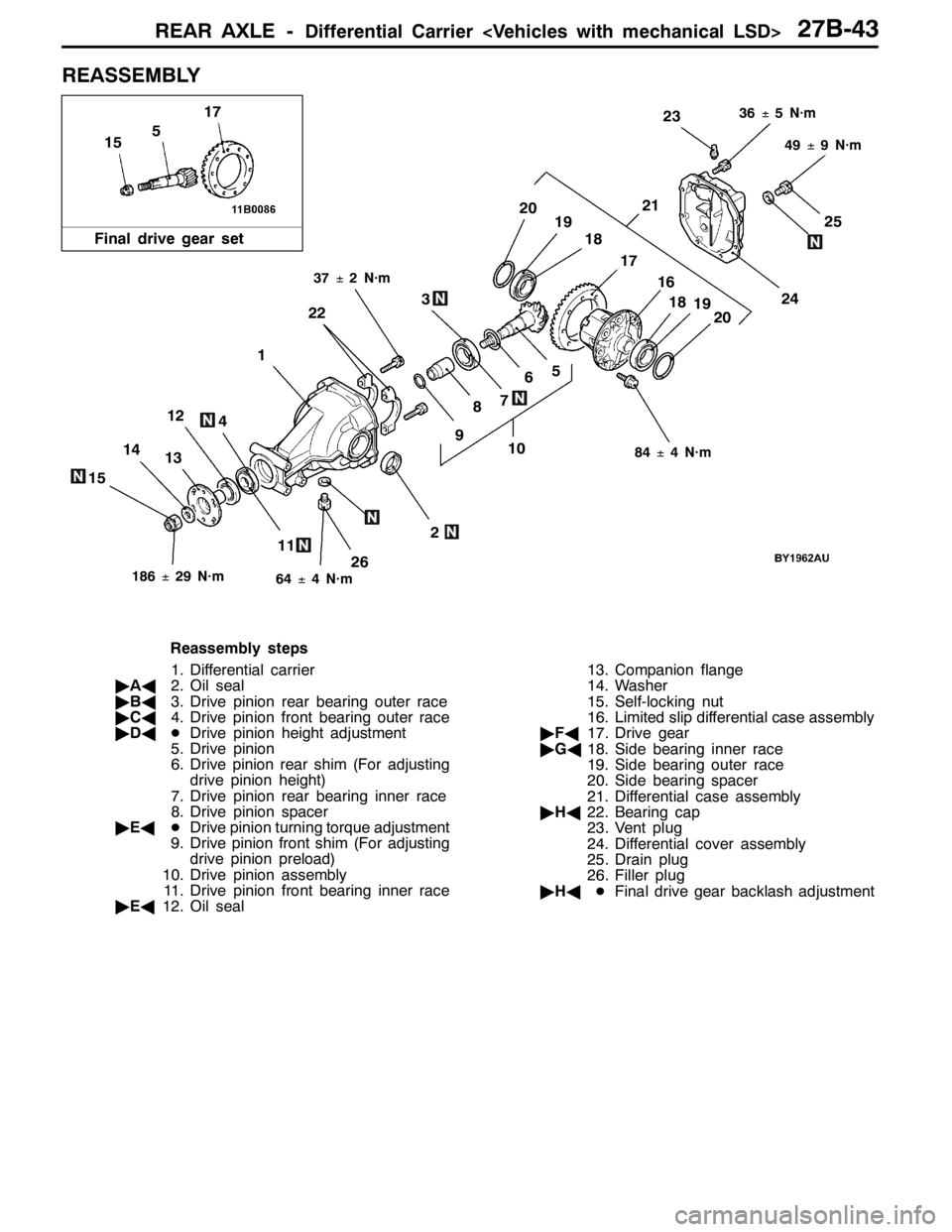

REAR AXLE -Differential Carrier

REASSEMBLY

11

14

26

25

1310

6

124

7

24

21

18

17

15

2019

9

3

8

5

2

1

22

23

16

191820

5

17

15

84±4 N·m

186±29 N·m64±4 N·m

49±9 N·m

37±2 N·m

36±5 N·m

Final drive gear set

Reassembly steps

1. Differential carrier

"AA2. Oil seal

"BA3. Drive pinion rear bearing outer race

"CA4. Drive pinion front bearing outer race

"DADDrive pinion height adjustment

5. Drive pinion

6. Drive pinion rear shim (For adjusting

drive pinion height)

7. Drive pinion rear bearing inner race

8. Drive pinion spacer

"EADDrive pinion turning torque adjustment

9. Drive pinion front shim (For adjusting

drive pinion preload)

10. Drive pinion assembly

11. Drive pinion front bearing inner race

"EA12. Oil seal13. Companion flange

14. Washer

15. Self-locking nut

16. Limited slip differential case assembly

"FA17. Drive gear

"GA18. Side bearing inner race

19. Side bearing outer race

20. Side bearing spacer

21. Differential case assembly

"HA22. Bearing cap

23. Vent plug

24. Differential cover assembly

25. Drain plug

26. Filler plug

"HADFinal drive gear backlash adjustment

Page 991 of 1449

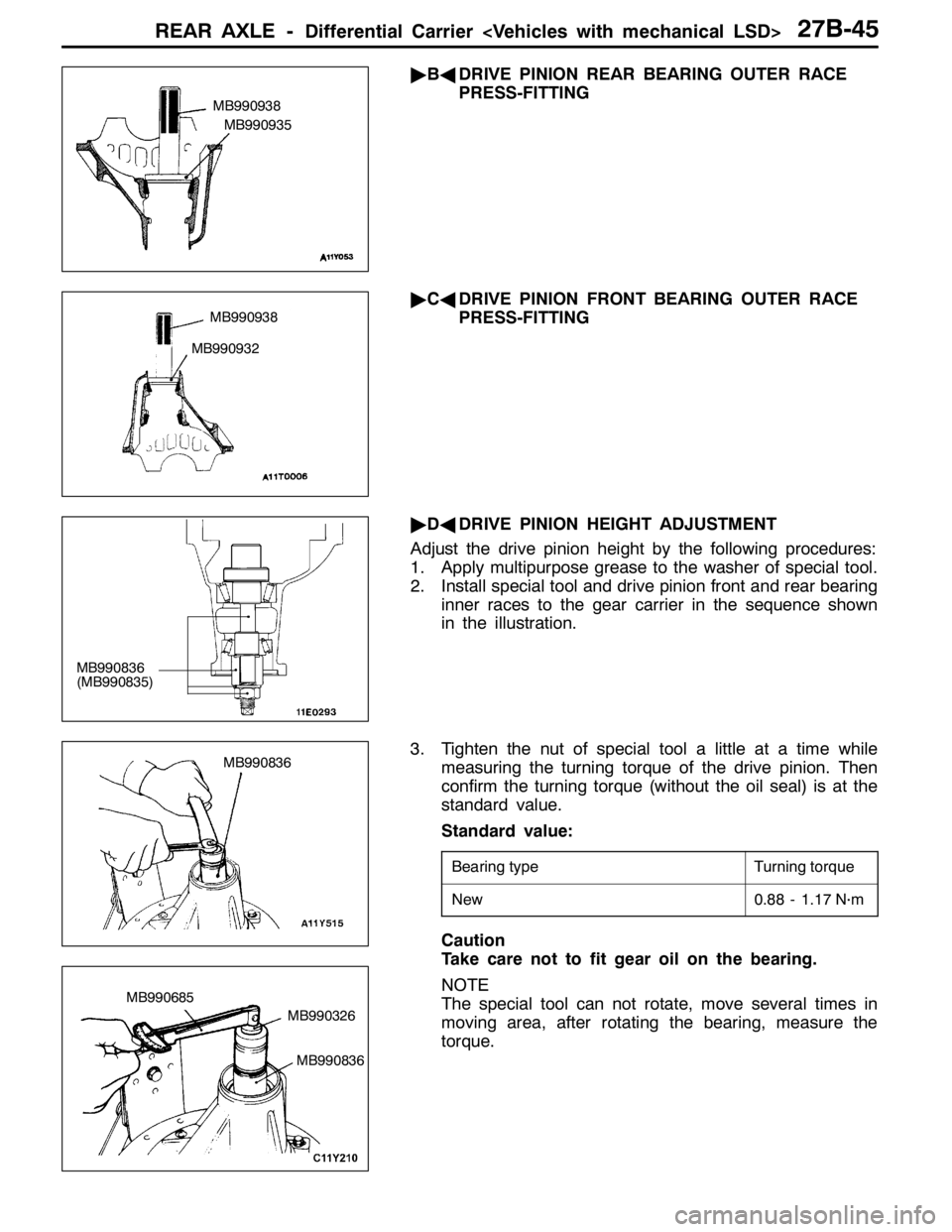

REAR AXLE -Differential Carrier

"BADRIVE PINION REAR BEARING OUTER RACE

PRESS-FITTING

"CADRIVE PINION FRONT BEARING OUTER RACE

PRESS-FITTING

"DADRIVE PINION HEIGHT ADJUSTMENT

Adjust the drive pinion height by the following procedures:

1. Apply multipurpose grease to the washer of special tool.

2. Install special tool and drive pinion front and rear bearing

inner races to the gear carrier in the sequence shown

in the illustration.

3. Tighten the nut of special tool a little at a time while

measuring the turning torque of the drive pinion. Then

confirm the turning torque (without the oil seal) is at the

standard value.

Standard value:

Bearing typeTurning torque

New0.88 - 1.17 N·m

Caution

Take care not to fit gear oil on the bearing.

NOTE

The special tool can not rotate, move several times in

moving area, after rotating the bearing, measure the

torque.

MB990938

MB990935

MB990938

MB990932

MB990836

(MB990835)

MB990836

MB990326 MB990685

MB990836

Page 993 of 1449

REAR AXLE -Differential Carrier

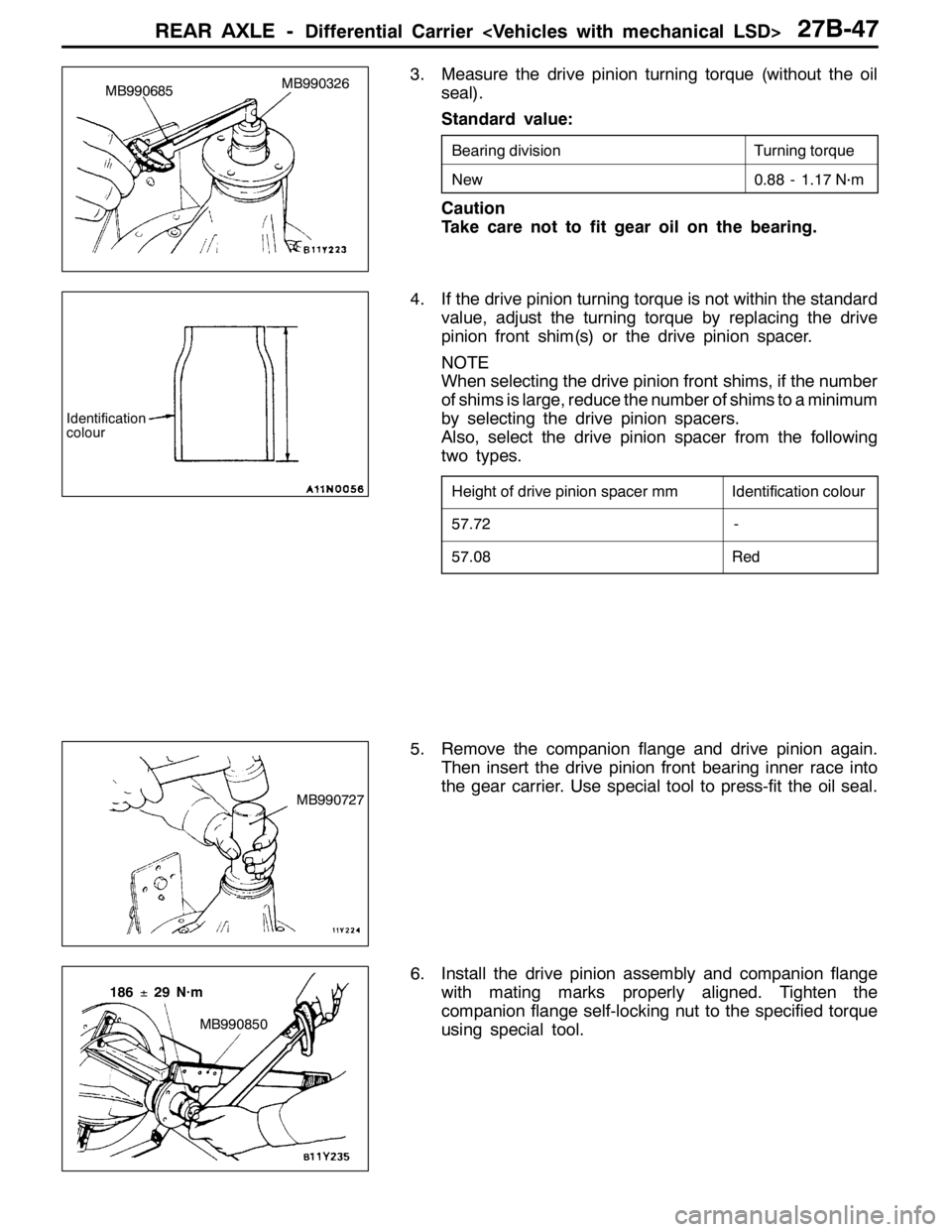

3. Measure the drive pinion turning torque (without the oil

seal).

Standard value:

Bearing divisionTurning torque

New0.88 - 1.17 N·m

Caution

Take care not to fit gear oil on the bearing.

4. If the drive pinion turning torque is not within the standard

value, adjust the turning torque by replacing the drive

pinion front shim(s) or the drive pinion spacer.

NOTE

When selecting the drive pinion front shims, if the number

of shims is large, reduce the number of shims to a minimum

by selecting the drive pinion spacers.

Also, select the drive pinion spacer from the following

two types.

Height of drive pinion spacer mmIdentification colour

57.72-

57.08Red

5. Remove the companion flange and drive pinion again.

Then insert the drive pinion front bearing inner race into

the gear carrier. Use special tool to press-fit the oil seal.

6. Install the drive pinion assembly and companion flange

with mating marks properly aligned. Tighten the

companion flange self-locking nut to the specified torque

using special tool.

MB990326

MB990685

Identification

colour

MB990727

MB990850

186±29 N·m

Page 1047 of 1449

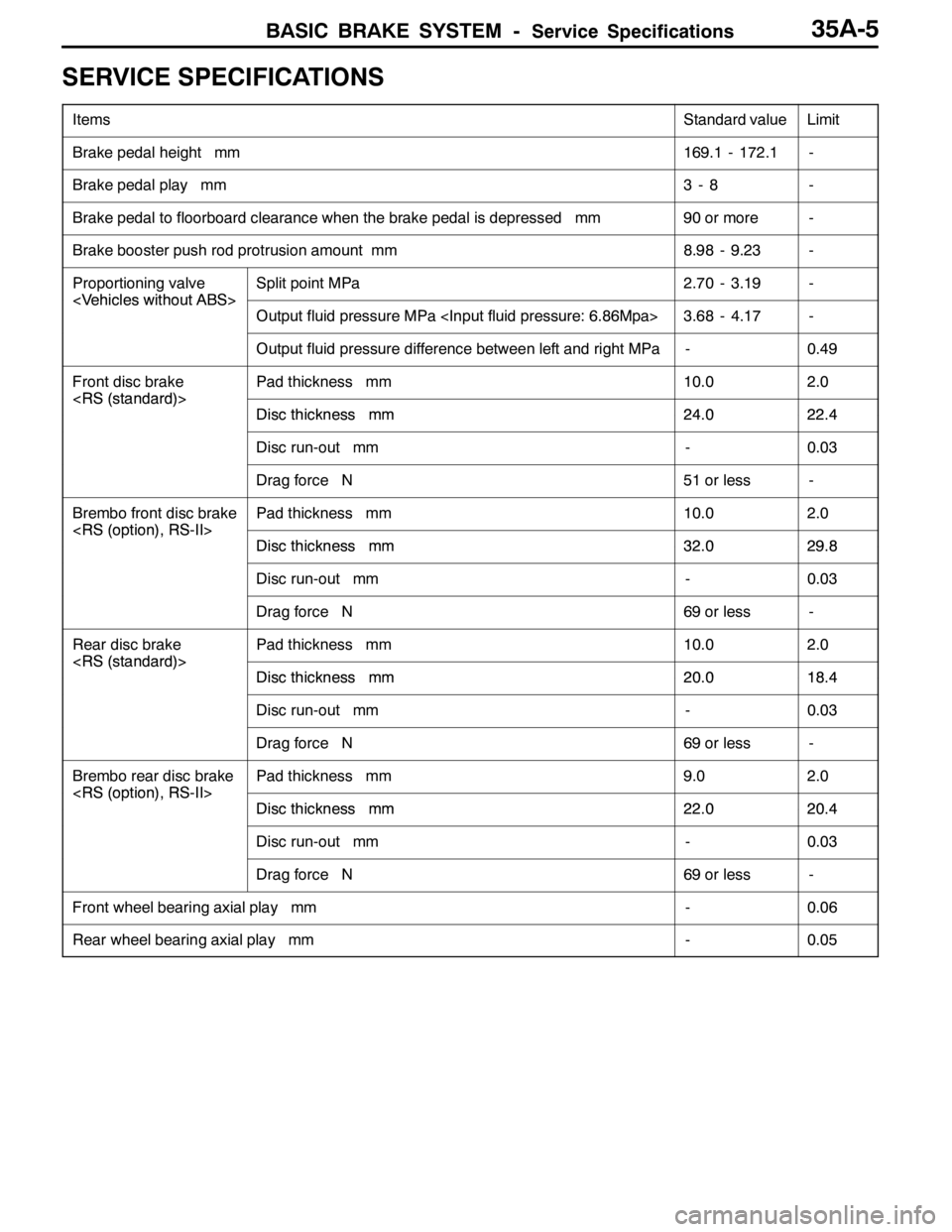

BASIC BRAKE SYSTEM -Service Specifications35A-5

SERVICE SPECIFICATIONS

ItemsStandard valueLimit

Brake pedal height mm169.1 - 172.1-

Brake pedal play mm3-8-

Brake pedal to floorboard clearance when the brake pedal is depressed mm90 or more-

Brake booster push rod protrusion amount mm8.98 - 9.23-

Proportioning valve

Split point MPa2.70 - 3.19-

Output fluid pressure MPa 3.68 - 4.17-

Output fluid pressure difference between left and right MPa-0.49

Front disc brake

Pad thickness mm10.02.0

Discthicknessmm24 022 4Discthickness mm24.022.4

Disc run-out mm-0.03

Drag force N51 or less-

Brembo front disc brake

Pad thickness mm10.02.0

Discthicknessmm32 029 8Discthickness mm32.029.8

Disc run-out mm-0.03

Drag force N69 or less-

Rear disc brake

Pad thickness mm10.02.0

Discthicknessmm20 018 4Discthickness mm20.018.4

Disc run-out mm-0.03

Drag force N69 or less-

Brembo rear disc brake

Pad thickness mm9.02.0

Discthicknessmm22 020 4Discthickness mm22.020.4

Disc run-out mm-0.03

Drag force N69 or less-

Front wheel bearing axial play mm-0.06

Rear wheel bearing axial play mm-0.05