height MITSUBISHI LANCER EVOLUTION 2007 Service Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 1049 of 1449

BASIC BRAKE SYSTEM -On-vehicle Service35A-7

ON-VEHICLE SERVICE

BRAKE PEDAL CHECK AND ADJUSTMENT

BRAKE PEDAL HEIGHT

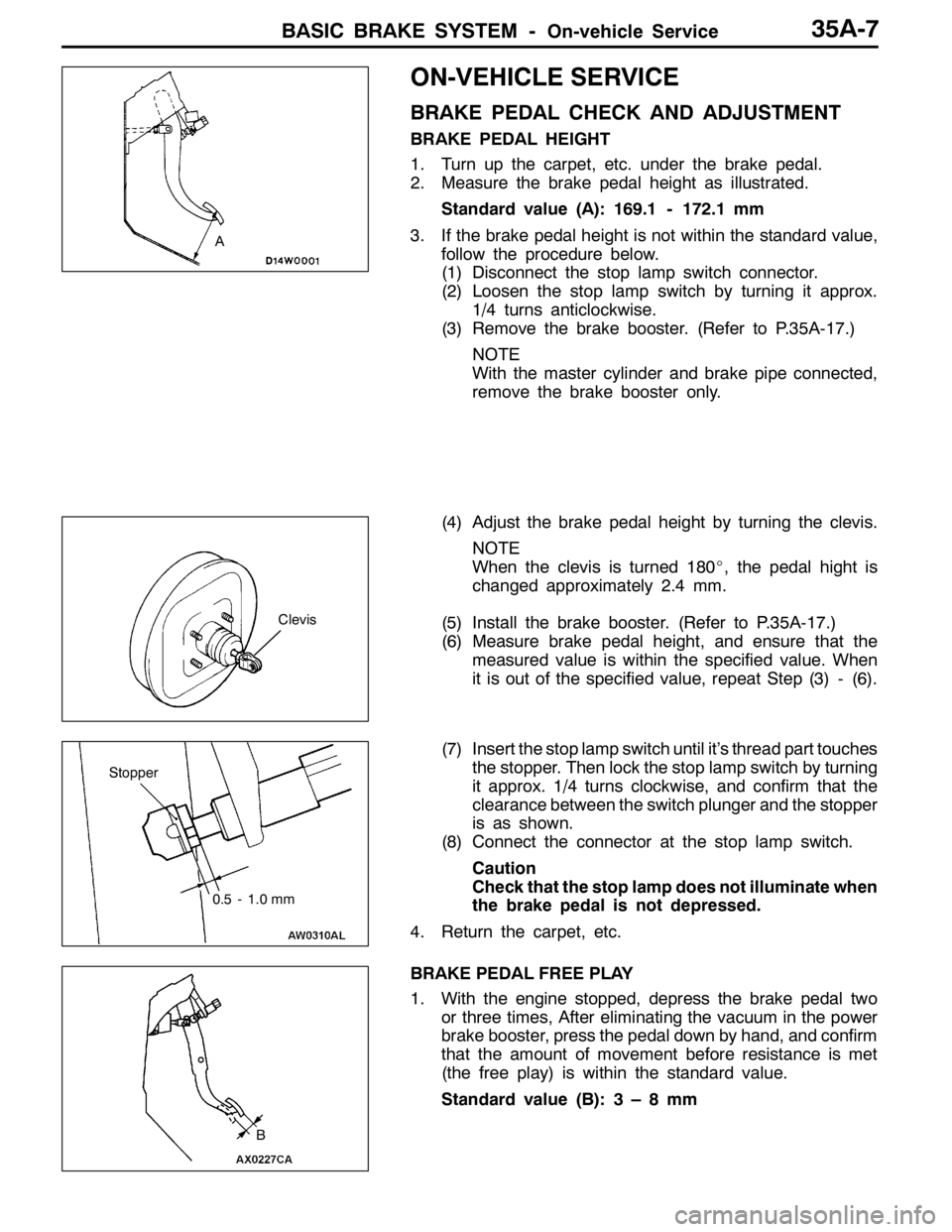

1. Turn up the carpet, etc. under the brake pedal.

2. Measure the brake pedal height as illustrated.

Standard value (A): 169.1 - 172.1 mm

3. If the brake pedal height is not within the standard value,

follow the procedure below.

(1) Disconnect the stop lamp switch connector.

(2) Loosen the stop lamp switch by turning it approx.

1/4 turns anticlockwise.

(3) Remove the brake booster. (Refer to P.35A-17.)

NOTE

With the master cylinder and brake pipe connected,

remove the brake booster only.

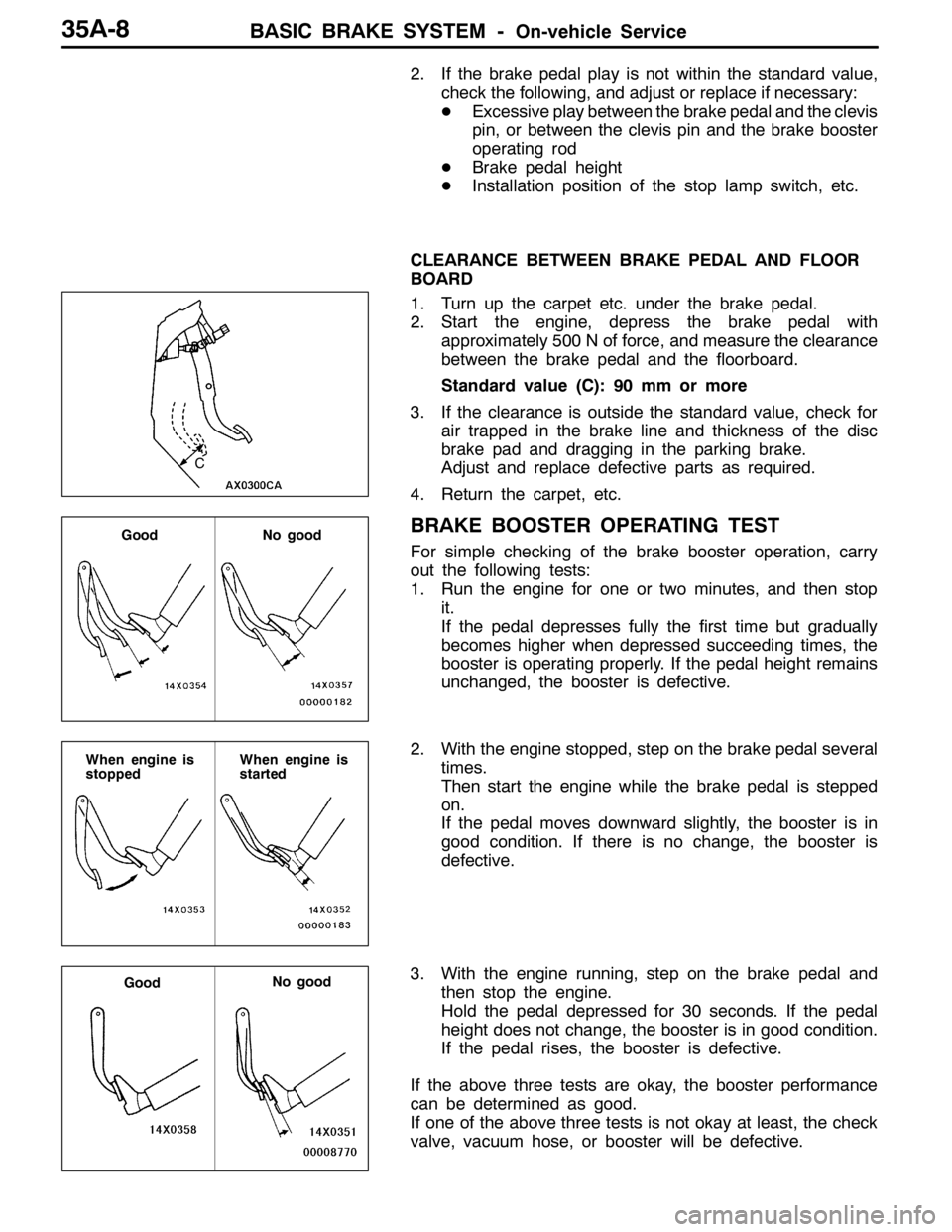

(4) Adjust the brake pedal height by turning the clevis.

NOTE

When the clevis is turned 180_, the pedal hight is

changed approximately 2.4 mm.

(5) Install the brake booster. (Refer to P.35A-17.)

(6) Measure brake pedal height, and ensure that the

measured value is within the specified value. When

it is out of the specified value, repeat Step (3) - (6).

(7) Insert the stop lamp switch until it’s thread part touches

the stopper. Then lock the stop lamp switch by turning

it approx. 1/4 turns clockwise, and confirm that the

clearance between the switch plunger and the stopper

is as shown.

(8) Connect the connector at the stop lamp switch.

Caution

Check that the stop lamp does not illuminate when

the brake pedal is not depressed.

4. Return the carpet, etc.

BRAKE PEDAL FREE PLAY

1. With the engine stopped, depress the brake pedal two

or three times, After eliminating the vacuum in the power

brake booster, press the pedal down by hand, and confirm

that the amount of movement before resistance is met

(the free play) is within the standard value.

Standard value (B):3–8mm

A

Clevis

Stopper

0.5 - 1.0 mm

B

Page 1050 of 1449

BASIC BRAKE SYSTEM -On-vehicle Service35A-8

2. If the brake pedal play is not within the standard value,

check the following, and adjust or replace if necessary:

DExcessive play between the brake pedal and the clevis

pin, or between the clevis pin and the brake booster

operating rod

DBrake pedal height

DInstallation position of the stop lamp switch, etc.

CLEARANCE BETWEEN BRAKE PEDAL AND FLOOR

BOARD

1. Turn up the carpet etc. under the brake pedal.

2. Start the engine, depress the brake pedal with

approximately 500 N of force, and measure the clearance

between the brake pedal and the floorboard.

Standard value (C): 90 mm or more

3. If the clearance is outside the standard value, check for

air trapped in the brake line and thickness of the disc

brake pad and dragging in the parking brake.

Adjust and replace defective parts as required.

4. Return the carpet, etc.

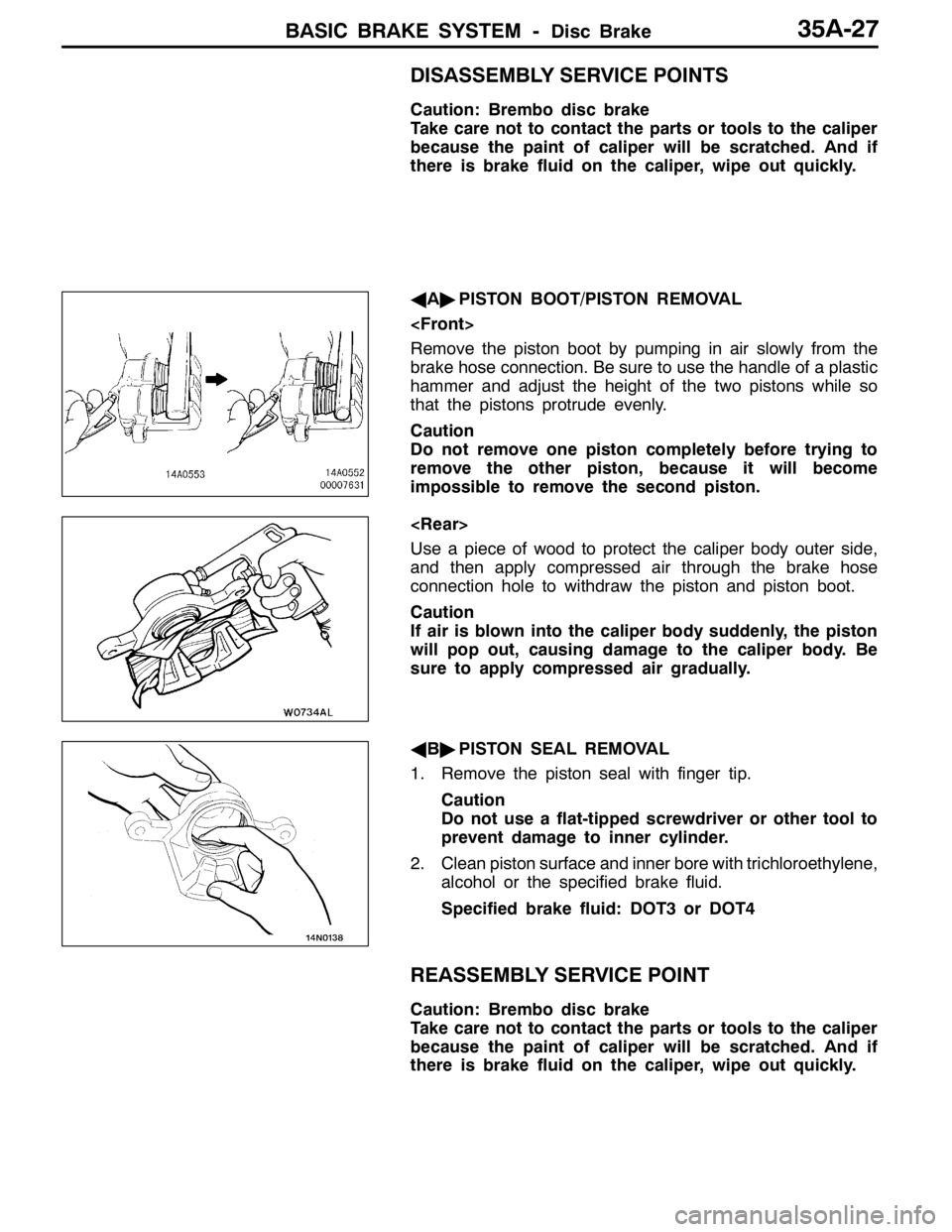

BRAKE BOOSTER OPERATING TEST

For simple checking of the brake booster operation, carry

out the following tests:

1. Run the engine for one or two minutes, and then stop

it.

If the pedal depresses fully the first time but gradually

becomes higher when depressed succeeding times, the

booster is operating properly. If the pedal height remains

unchanged, the booster is defective.

2. With the engine stopped, step on the brake pedal several

times.

Then start the engine while the brake pedal is stepped

on.

If the pedal moves downward slightly, the booster is in

good condition. If there is no change, the booster is

defective.

3. With the engine running, step on the brake pedal and

then stop the engine.

Hold the pedal depressed for 30 seconds. If the pedal

height does not change, the booster is in good condition.

If the pedal rises, the booster is defective.

If the above three tests are okay, the booster performance

can be determined as good.

If one of the above three tests is not okay at least, the check

valve, vacuum hose, or booster will be defective.

C

Good No good

When engine is

stoppedWhen engine is

started

GoodNo good

Page 1069 of 1449

BASIC BRAKE SYSTEM -Disc Brake35A-27

DISASSEMBLY SERVICE POINTS

Caution: Brembo disc brake

Take care not to contact the parts or tools to the caliper

because the paint of caliper will be scratched. And if

there is brake fluid on the caliper, wipe out quickly.

AA"PISTON BOOT/PISTON REMOVAL

Remove the piston boot by pumping in air slowly from the

brake hose connection. Be sure to use the handle of a plastic

hammer and adjust the height of the two pistons while so

that the pistons protrude evenly.

Caution

Do not remove one piston completely before trying to

remove the other piston, because it will become

impossible to remove the second piston.

Use a piece of wood to protect the caliper body outer side,

and then apply compressed air through the brake hose

connection hole to withdraw the piston and piston boot.

Caution

If air is blown into the caliper body suddenly, the piston

will pop out, causing damage to the caliper body. Be

sure to apply compressed air gradually.

AB"PISTON SEAL REMOVAL

1. Remove the piston seal with finger tip.

Caution

Do not use a flat-tipped screwdriver or other tool to

prevent damage to inner cylinder.

2. Clean piston surface and inner bore with trichloroethylene,

alcohol or the specified brake fluid.

Specified brake fluid: DOT3 or DOT4

REASSEMBLY SERVICE POINT

Caution: Brembo disc brake

Take care not to contact the parts or tools to the caliper

because the paint of caliper will be scratched. And if

there is brake fluid on the caliper, wipe out quickly.

Page 1149 of 1449

42-1

BODY

CONTENTS

HOOD2 .................................

ON-VEHICLE SERVICE 2..................

Adjustment of Clearance around Hood 2......

Adjustment of Alignment of Hood Stepped

Portion and Hood Striker 2..................

Adjustment of Hood Height 2.................

HOOD 3..................................

FENDER4 ..............................

SPECIAL TOOL 4.........................

FENDER 5................................

FUEL FILLER DOOR7 .................

STRUT TOWER BAR AND REAR END

CROSS BAR8 ...........................

WINDOW GLASS9 .....................

ADHESIVE 9..............................

SPECIAL TOOLS 9........................

WINDOW REPAIR 9.......................

WINDSHIELD 11...........................

REAR WINDOW GLASS 16................

DOORS19 ..............................

SERVICE SPECIFICATIONS 19.............ADHESIVES 19............................

SPECIAL TOOLS 19.......................

TROUBLESHOOTING 20...................

ON-VEHICLE SERVICE 20.................

Door Adjustment 20.........................

Door Window Glass Adjustment 21...........

Adjustment and Replacement during Power

Window Malfunction 22......................

Power Window Safety Mechanism Check 22..

Power Window Timer Function Check 22......

Door Outside Handle Looseness Check 23....

Power Window Operation Current Check 23...

Circuit Breaker Check 23....................

Power Window Check 23....................

Door Inside Handle Looseness Check and

Adjustment 24...............................

DOOR ASSEMBLY 25......................

DOOR TRIM AND

WATERPROOF FILM 27....................

DOOR GLASS AND REGULATOR 32.......

DOOR HANDLE AND LATCH 35...........

WINDOW GLASS RUNCHANNEL AND

DOOR OPENING WEATHERSTRIP 38.......

TRUNK LID41 ..........................

Page 1150 of 1449

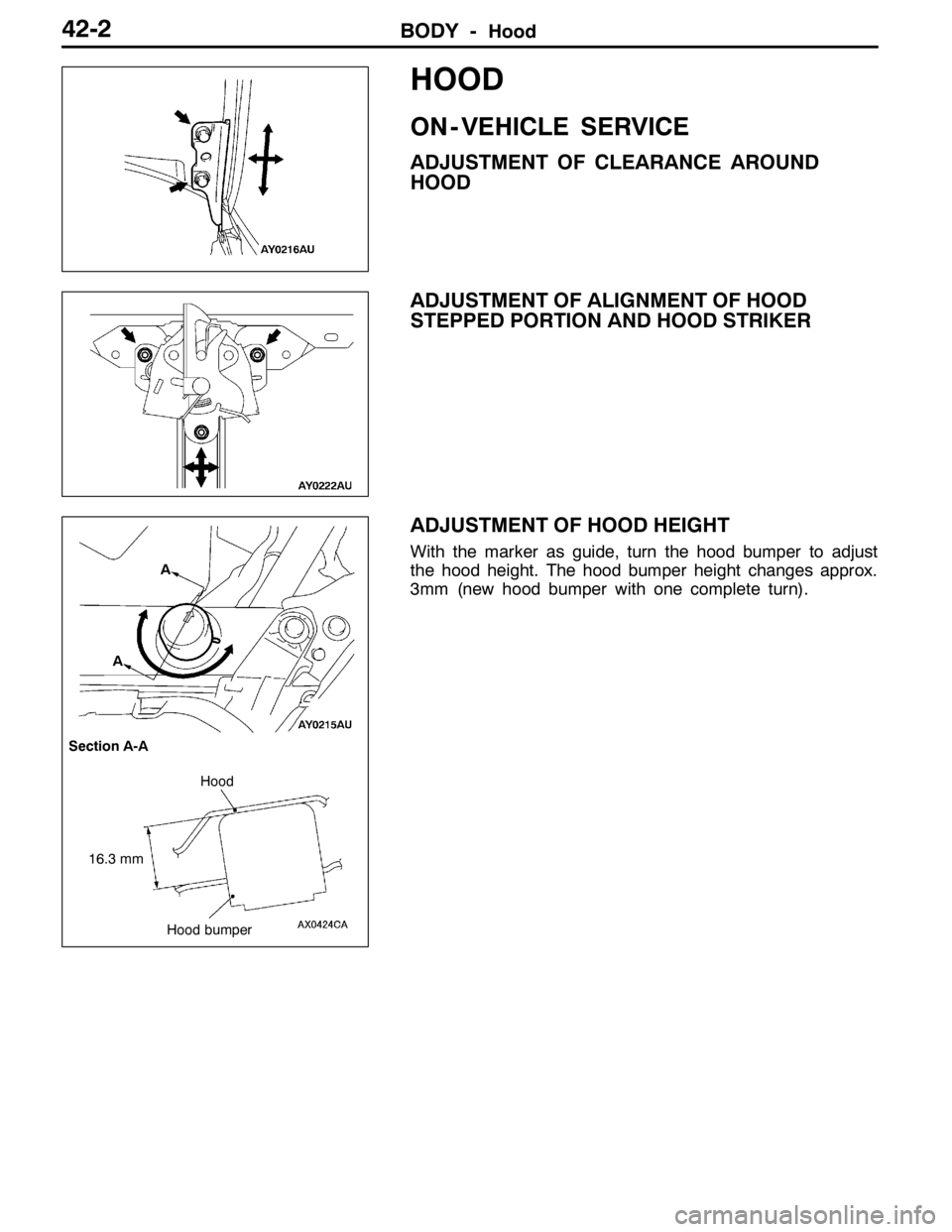

BODY -Hood42-2

HOOD

ON - VEHICLE SERVICE

ADJUSTMENT OF CLEARANCE AROUND

HOOD

ADJUSTMENT OF ALIGNMENT OF HOOD

STEPPED PORTION AND HOOD STRIKER

ADJUSTMENT OF HOOD HEIGHT

With the marker as guide, turn the hood bumper to adjust

the hood height. The hood bumper height changes approx.

3mm (new hood bumper with one complete turn).

A

A

Section A-A

16.3 mmHood

Hood bumper

Page 1238 of 1449

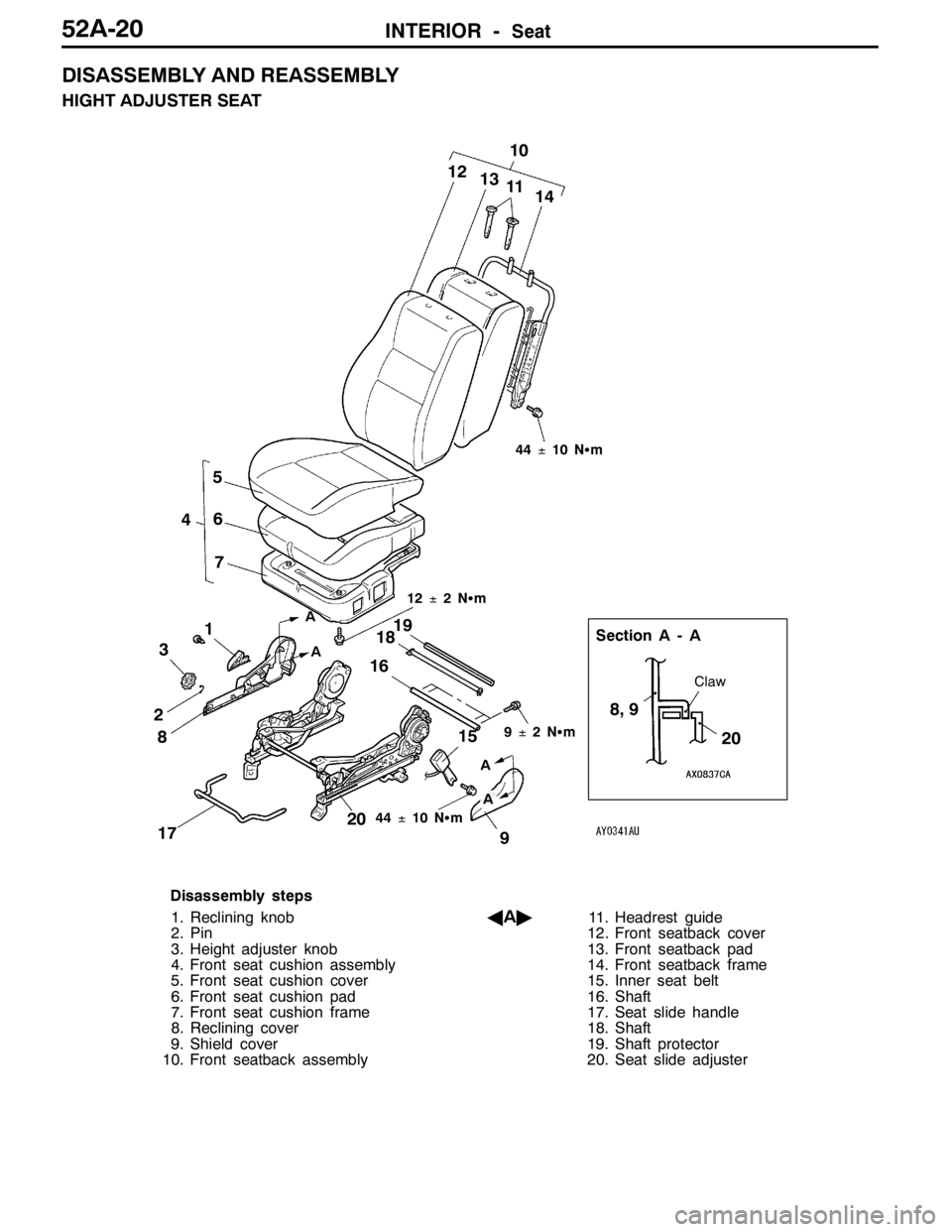

INTERIOR -Seat52A-20

DISASSEMBLY AND REASSEMBLY

HIGHT ADJUSTER SEAT

8, 9

20

Section A - A

Claw

1

2345

6

7

8

910

11 12

13

14

15

1720

44±10 NSm

44±10 NSm 12±2NSm

A

A

A9±2NSm

18

1619

A

Disassembly steps

1. Reclining knob

2. Pin

3. Height adjuster knob

4. Front seat cushion assembly

5. Front seat cushion cover

6. Front seat cushion pad

7. Front seat cushion frame

8. Reclining cover

9. Shield cover

10. Front seatback assembly

AA"11. Headrest guide

12. Front seatback cover

13. Front seatback pad

14. Front seatback frame

15. Inner seat belt

16. Shaft

17. Seat slide handle

18. Shaft

19. Shaft protector

20. Seat slide adjuster

Page 1334 of 1449

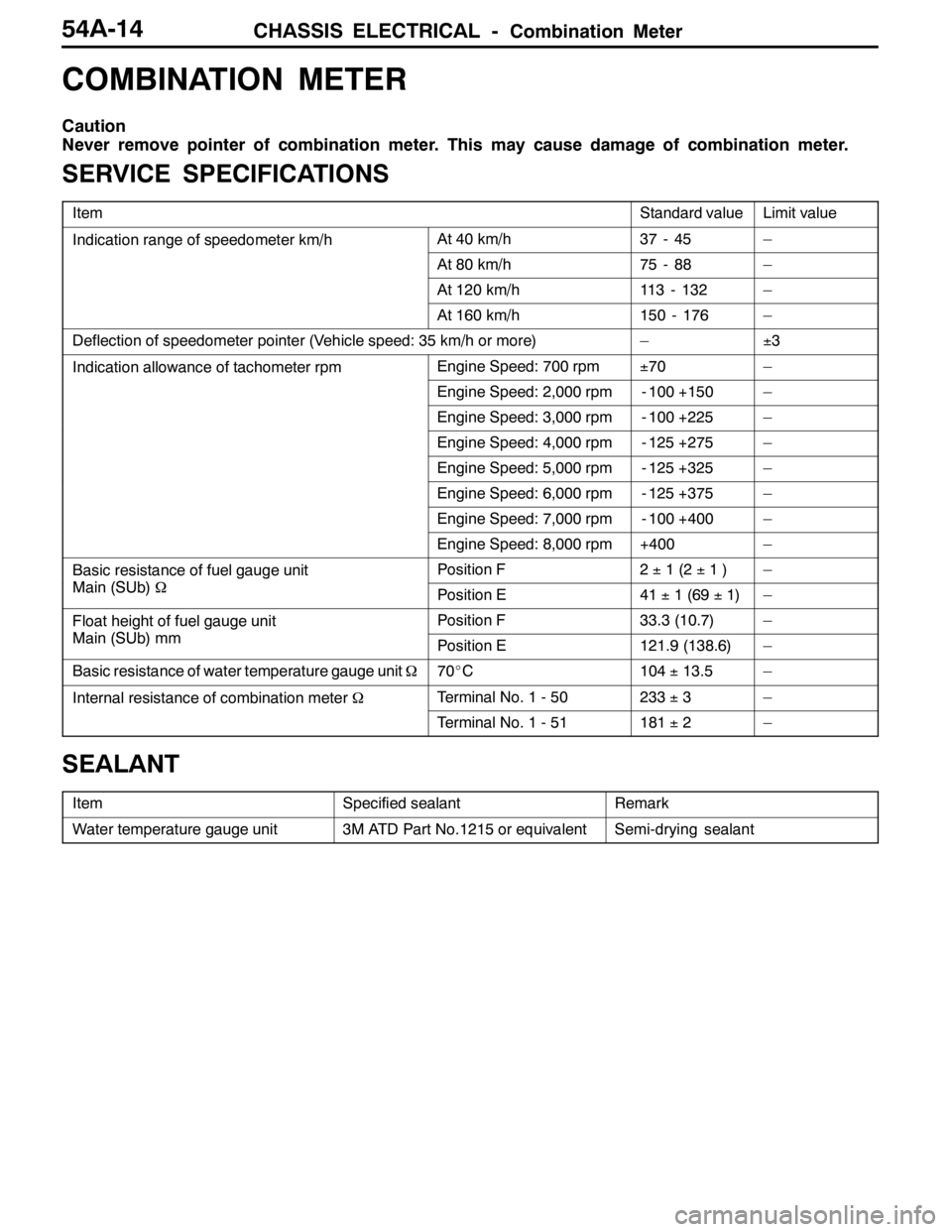

CHASSIS ELECTRICAL -Combination Meter54A-14

COMBINATION METER

Caution

Never remove pointer of combination meter. This may cause damage of combination meter.

SERVICE SPECIFICATIONS

ItemStandard valueLimit value

Indication range of speedometer km/hAt 40 km/h37 - 45–gp

At 80 km/h75 - 88–

At 120 km/h113 - 132–

At 160 km/h150 - 176–

Deflection of speedometer pointer (Vehicle speed: 35 km/h or more)–±3

Indication allowance of tachometer rpmEngine Speed: 700 rpm±70–p

Engine Speed: 2,000 rpm- 100 +150–

Engine Speed: 3,000 rpm- 100 +225–

Engine Speed: 4,000 rpm- 125 +275–

Engine Speed: 5,000 rpm- 125 +325–

Engine Speed: 6,000 rpm- 125 +375–

Engine Speed: 7,000 rpm- 100 +400–

Engine Speed: 8,000 rpm+400–

Basic resistance of fuel gauge unit

Mi(SUb)Ω

Position F2±1(2±1)–gg

Main (SUb)ΩPosition E41±1 (69±1)–

Float height of fuel gauge unit

Mi(SUb)

Position F33.3 (10.7)–ggg

Main (SUb) mmPosition E121.9 (138.6)–

Basic resistance of water temperature gauge unitΩ70_C104±13.5–

Internal resistance of combination meterΩTerminal No. 1 - 50233±3–

Terminal No. 1 - 51181±2–

SEALANT

ItemSpecified sealantRemark

Water temperature gauge unit3M ATD Part No.1215 or equivalentSemi-drying sealant

Page 1341 of 1449

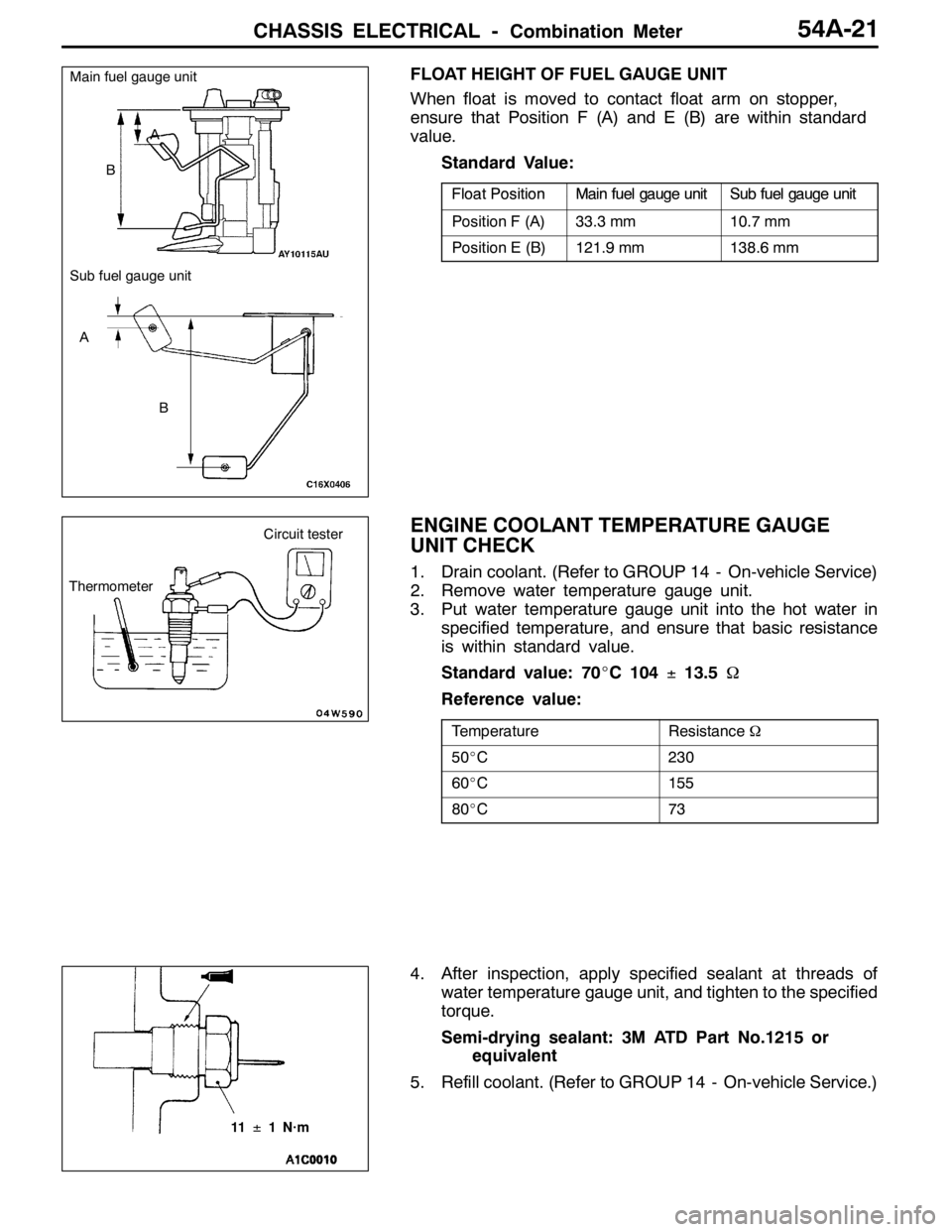

CHASSIS ELECTRICAL -Combination Meter54A-21

FLOAT HEIGHT OF FUEL GAUGE UNIT

When float is moved to contact float arm on stopper,

ensure that Position F (A) and E (B) are within standard

value.

Standard Value:

FloatPositionMainfuelgaugeunitSubfuelgaugeunitFloatPositionMainfuelgaugeunitSubfuelgaugeunit

Position F (A)33.3 mm10.7 mm

Position E (B)121.9 mm138.6 mm

ENGINE COOLANT TEMPERATURE GAUGE

UNIT CHECK

1. Drain coolant. (Refer to GROUP 14 - On-vehicle Service)

2. Remove water temperature gauge unit.

3. Put water temperature gauge unit into the hot water in

specified temperature, and ensure that basic resistance

is within standard value.

Standard value: 70_C 104±13.5Ω

Reference value:

TemperatureResistanceΩ

50_C230

60_C155

80_C73

4. After inspection, apply specified sealant at threads of

water temperature gauge unit, and tighten to the specified

torque.

Semi-drying sealant: 3M ATD Part No.1215 or

equivalent

5. Refill coolant. (Refer to GROUP 14 - On-vehicle Service.)

Main fuel gauge unit

Sub fuel gauge unit

A

B

A

B

ThermometerCircuit tester

11±1 N·m