ESP MITSUBISHI LANCER EVOLUTION 2007 Service Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 821 of 1449

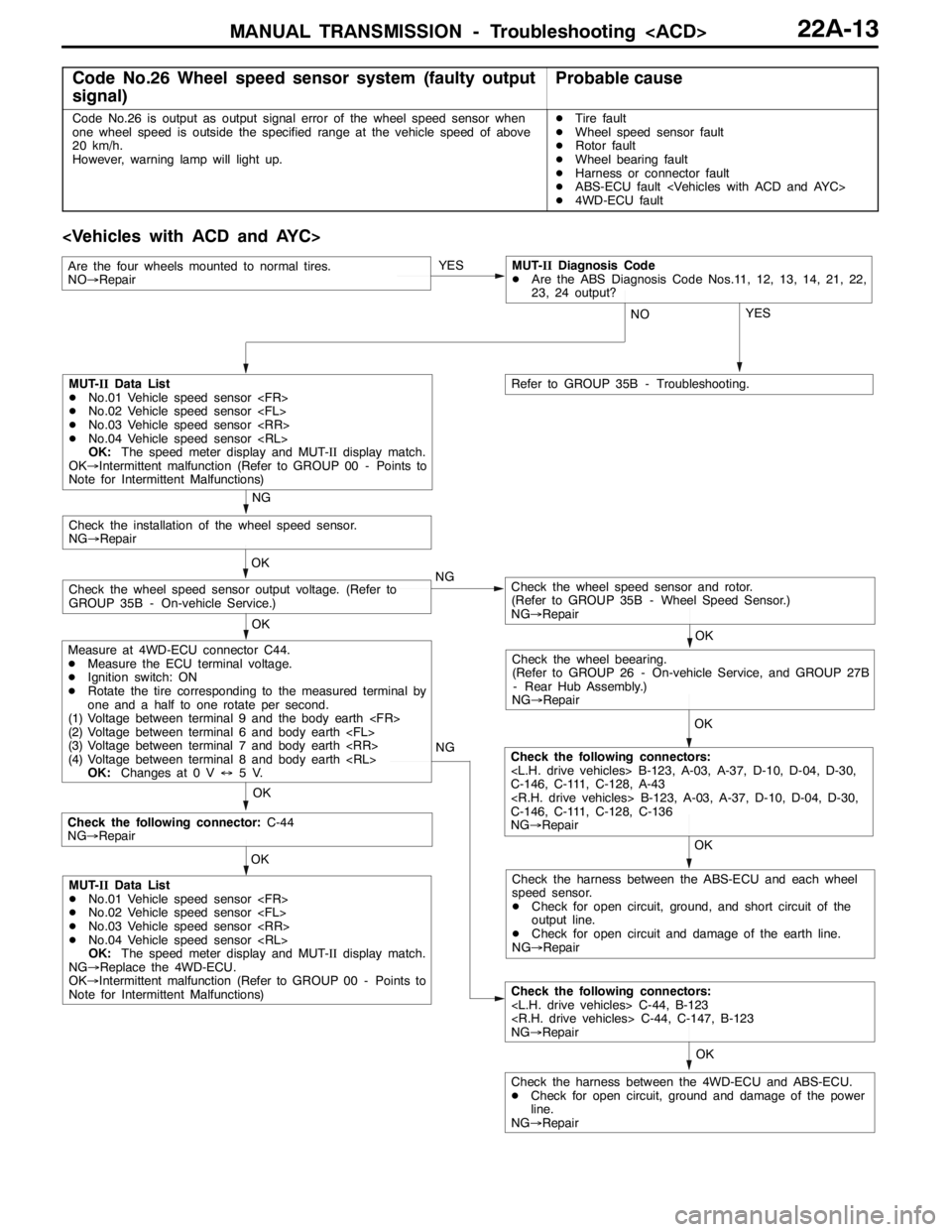

MANUAL TRANSMISSION - Troubleshooting

Code No.26 Wheel speed sensor system (faulty output

signal)Probable cause

Code No.26 is output as output signal error of the wheel speed sensor when

one wheel speed is outside the specified range at the vehicle speed of above

20 km/h.

However, warning lamp will light up.DTire fault

DWheel speed sensor fault

DRotor fault

DWheel bearing fault

DHarness or connector fault

DABS-ECU fault

D4WD-ECU fault

OK NG

OK

Check the following connector:C-44

NG→Repair

Check the following connectors:

NG→Repair OK

Check the harness between the 4WD-ECU and ABS-ECU.

DCheck for open circuit, ground and damage of the power

line.

NG→RepairYES

OK OK

Check the wheel speed sensor and rotor.

(Refer to GROUP 35B - Wheel Speed Sensor.)

NG→RepairCheck the wheel speed sensor output voltage. (Refer to

GROUP 35B - On-vehicle Service.)OK

Check the installation of the wheel speed sensor.

NG→Repair

NG

OK

Check the wheel beearing.

(Refer to GROUP 26 - On-vehicle Service, and GROUP 27B

- Rear Hub Assembly.)

NG→Repair

OK

Check the following connectors:

C-146, C-111, C-128, A-43

C-146, C-111, C-128, C-136

NG→Repair NG

MUT-IIData List

DNo.01 Vehicle speed sensor

DNo.02 Vehicle speed sensor

DNo.03 Vehicle speed sensor

DNo.04 Vehicle speed sensor

OK:The speed meter display and MUT-IIdisplay match.

OK→Intermittent malfunction (Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions)

Measure at 4WD-ECU connector C44.

DMeasure the ECU terminal voltage.

DIgnition switch: ON

DRotate the tire corresponding to the measured terminal by

one and a half to one rotate per second.

(1) Voltage between terminal 9 and the body earth

(2) Voltage between terminal 6 and body earth

(3) Voltage between terminal 7 and body earth

(4) Voltage between terminal 8 and body earth

OK:Changes at 0 V↔5V.

MUT-IIData List

DNo.01 Vehicle speed sensor

DNo.02 Vehicle speed sensor

DNo.03 Vehicle speed sensor

DNo.04 Vehicle speed sensor

OK:The speed meter display and MUT-IIdisplay match.

NG→Replace the 4WD-ECU.

OK→Intermittent malfunction (Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions)Check the harness between the ABS-ECU and each wheel

speed sensor.

DCheck for open circuit, ground, and short circuit of the

output line.

DCheck for open circuit and damage of the earth line.

NG→Repair YES

NO

Refer to GROUP 35B - Troubleshooting.

Are the four wheels mounted to normal tires.

NO→RepairMUT-IIDiagnosis Code

DAre the ABS Diagnosis Code Nos.11, 12, 13, 14, 21, 22,

23, 24 output?

Page 845 of 1449

MANUAL TRANSMISSION - Troubleshooting

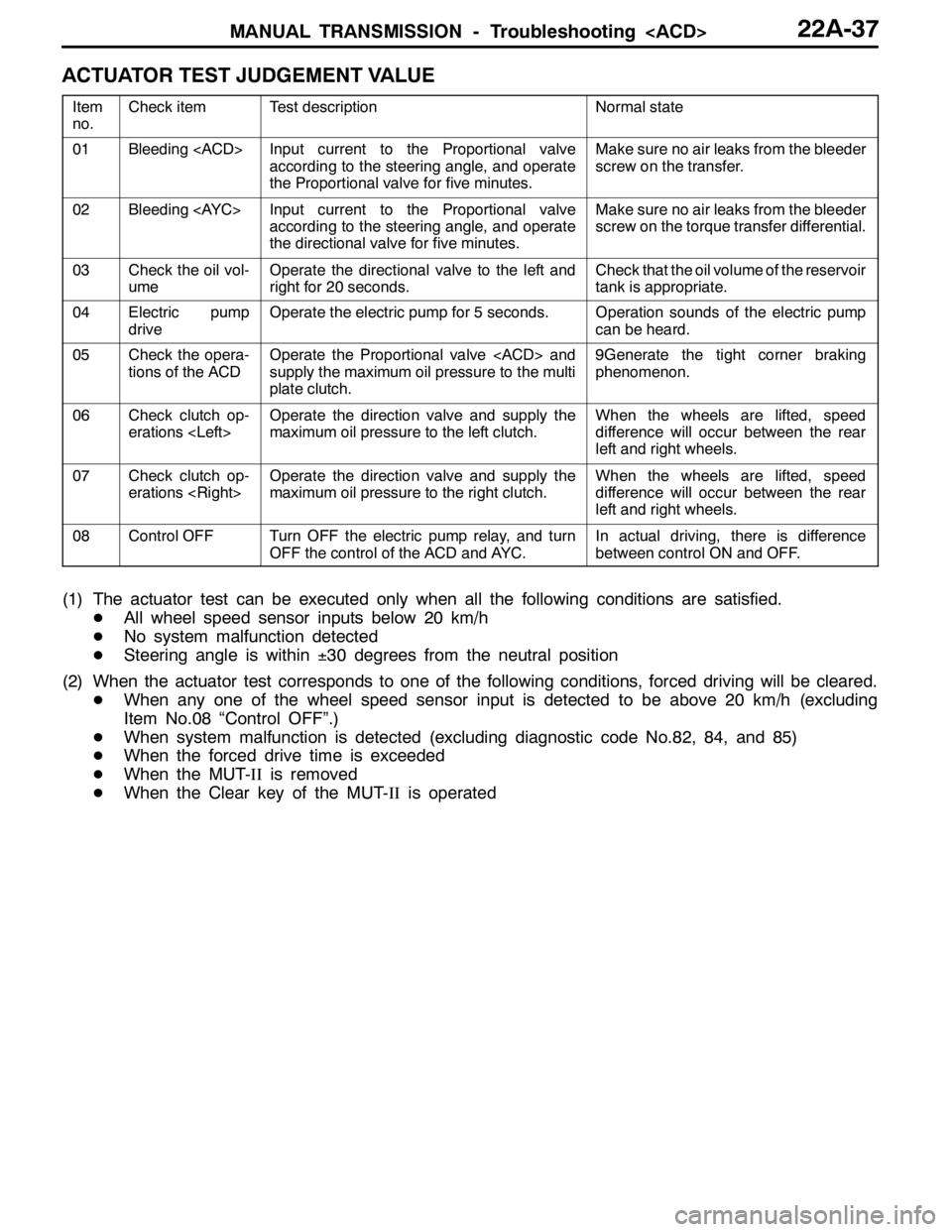

ACTUATOR TEST JUDGEMENT VALUE

Item

no.Check itemTest descriptionNormal state

01Bleeding

according to the steering angle, and operate

the Proportional valve for five minutes.Make sure no air leaks from the bleeder

screw on the transfer.

02Bleeding

according to the steering angle, and operate

the directional valve for five minutes.Make sure no air leaks from the bleeder

screw on the torque transfer differential.

03Check the oil vol-

umeOperate the directional valve to the left and

right for 20 seconds.Check that the oil volume of the reservoir

tank is appropriate.

04Electric pump

driveOperate the electric pump for 5 seconds.Operation sounds of the electric pump

can be heard.

05Check the opera-

tions of the ACDOperate the Proportional valve

supply the maximum oil pressure to the multi

plate clutch.9Generate the tight corner braking

phenomenon.

06Check clutch op-

erations

maximum oil pressure to the left clutch.When the wheels are lifted, speed

difference will occur between the rear

left and right wheels.

07Check clutch op-

erations

maximum oil pressure to the right clutch.When the wheels are lifted, speed

difference will occur between the rear

left and right wheels.

08Control OFFTurn OFF the electric pump relay, and turn

OFF the control of the ACD and AYC.In actual driving, there is difference

between control ON and OFF.

(1) The actuator test can be executed only when all the following conditions are satisfied.

DAll wheel speed sensor inputs below 20 km/h

DNo system malfunction detected

DSteering angle is within±30 degrees from the neutral position

(2) When the actuator test corresponds to one of the following conditions, forced driving will be cleared.

DWhen any one of the wheel speed sensor input is detected to be above 20 km/h (excluding

Item No.08 “Control OFF”.)

DWhen system malfunction is detected (excluding diagnostic code No.82, 84, and 85)

DWhen the forced drive time is exceeded

DWhen the MUT-IIis removed

DWhen the Clear key of the MUT-IIis operated

Page 942 of 1449

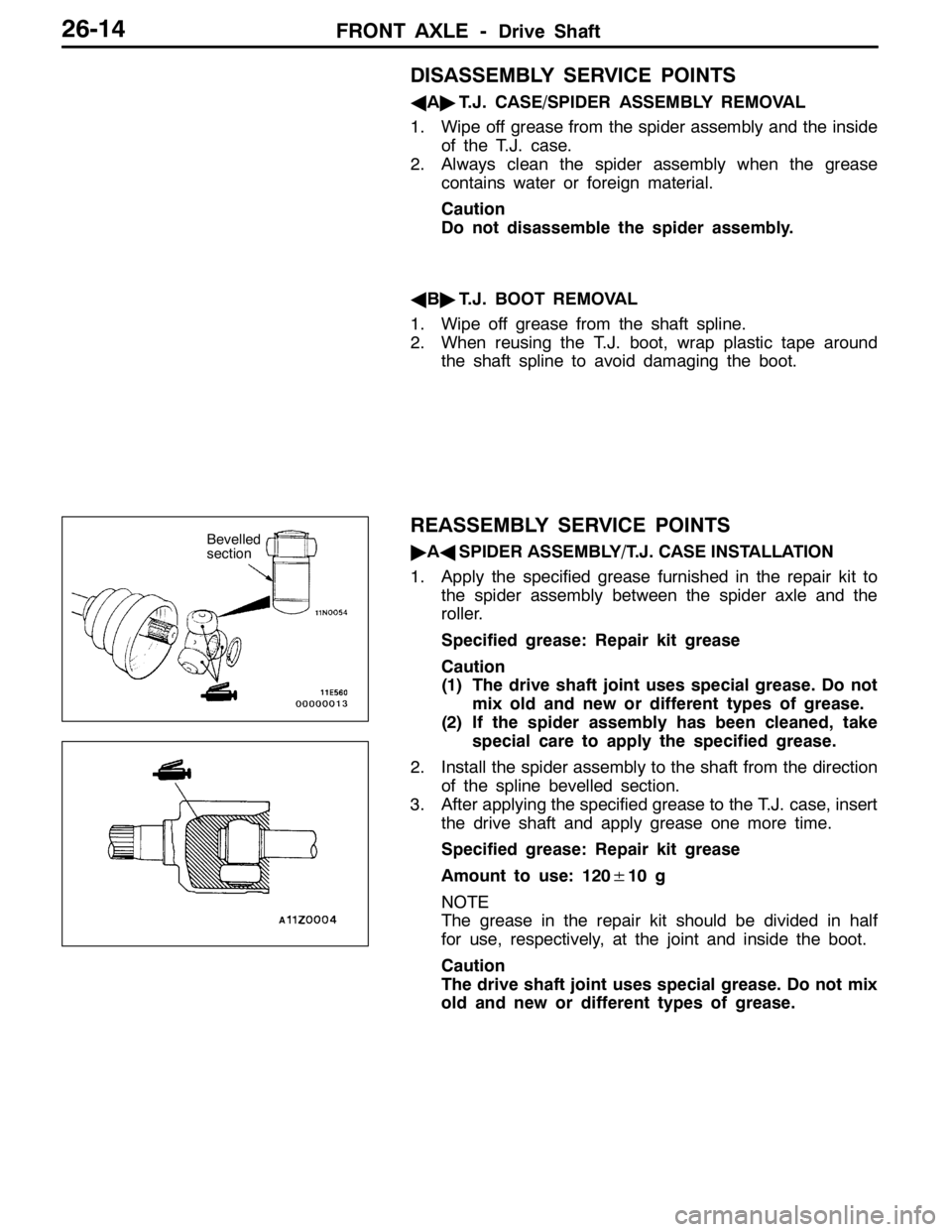

FRONT AXLE -Drive Shaft26-14

DISASSEMBLY SERVICE POINTS

AA"T.J. CASE/SPIDER ASSEMBLY REMOVAL

1. Wipe off grease from the spider assembly and the inside

of the T.J. case.

2. Always clean the spider assembly when the grease

contains water or foreign material.

Caution

Do not disassemble the spider assembly.

AB"T.J. BOOT REMOVAL

1. Wipe off grease from the shaft spline.

2. When reusing the T.J. boot, wrap plastic tape around

the shaft spline to avoid damaging the boot.

REASSEMBLY SERVICE POINTS

"AASPIDER ASSEMBLY/T.J. CASE INSTALLATION

1. Apply the specified grease furnished in the repair kit to

the spider assembly between the spider axle and the

roller.

Specified grease: Repair kit grease

Caution

(1) The drive shaft joint uses special grease. Do not

mix old and new or different types of grease.

(2) If the spider assembly has been cleaned, take

special care to apply the specified grease.

2. Install the spider assembly to the shaft from the direction

of the spline bevelled section.

3. After applying the specified grease to the T.J. case, insert

the drive shaft and apply grease one more time.

Specified grease: Repair kit grease

Amount to use: 120±10 g

NOTE

The grease in the repair kit should be divided in half

for use, respectively, at the joint and inside the boot.

Caution

The drive shaft joint uses special grease. Do not mix

old and new or different types of grease.Bevelled

section

Page 979 of 1449

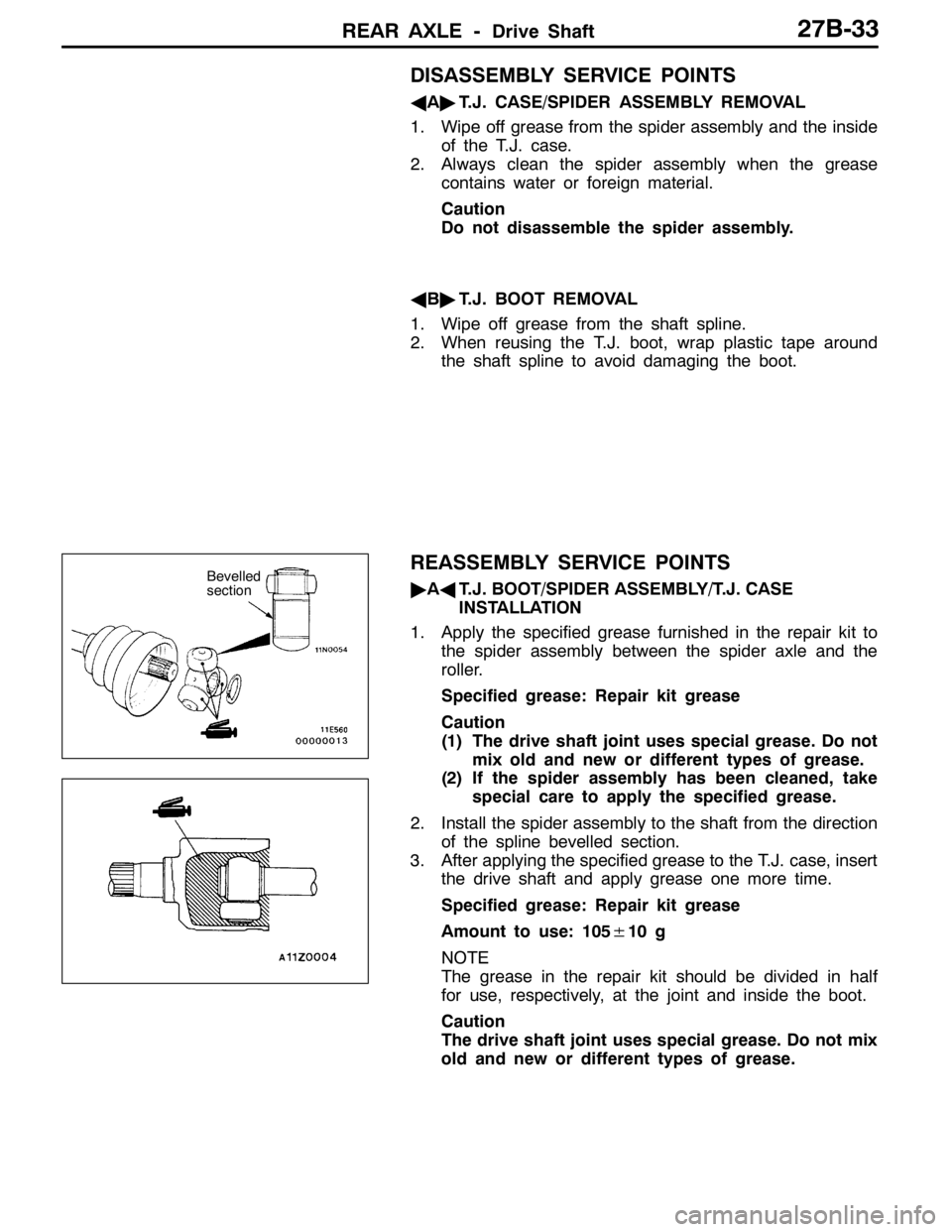

REAR AXLE -Drive Shaft27B-33

DISASSEMBLY SERVICE POINTS

AA"T.J. CASE/SPIDER ASSEMBLY REMOVAL

1. Wipe off grease from the spider assembly and the inside

of the T.J. case.

2. Always clean the spider assembly when the grease

contains water or foreign material.

Caution

Do not disassemble the spider assembly.

AB"T.J. BOOT REMOVAL

1. Wipe off grease from the shaft spline.

2. When reusing the T.J. boot, wrap plastic tape around

the shaft spline to avoid damaging the boot.

REASSEMBLY SERVICE POINTS

"AAT.J. BOOT/SPIDER ASSEMBLY/T.J. CASE

INSTALLATION

1. Apply the specified grease furnished in the repair kit to

the spider assembly between the spider axle and the

roller.

Specified grease: Repair kit grease

Caution

(1) The drive shaft joint uses special grease. Do not

mix old and new or different types of grease.

(2) If the spider assembly has been cleaned, take

special care to apply the specified grease.

2. Install the spider assembly to the shaft from the direction

of the spline bevelled section.

3. After applying the specified grease to the T.J. case, insert

the drive shaft and apply grease one more time.

Specified grease: Repair kit grease

Amount to use: 105±10 g

NOTE

The grease in the repair kit should be divided in half

for use, respectively, at the joint and inside the boot.

Caution

The drive shaft joint uses special grease. Do not mix

old and new or different types of grease.Bevelled

section

Page 1015 of 1449

32-1

POWER PLANT

MOUNT

CONTENTS

GENERAL INFORMATION 2..................

SPECIAL TOOL 3............................

ENGINE MOUNTING 4........................TRANSMISSION MOUNTING 5................

ENGINE ROLL STOPPER, CENTERMEMBER

6 ............................................

CROSSMEMBER* 8..........................

WARNING REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING!

(1) Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to personal

injury or death to service personnel (from inadvertent firing of the air bag) or to driver and passenger (from rendering

the SRS inoperative).

(2) Service or maintenance of any SRS component or SRS-related component must be performed only at an authorized

MITSUBISHI dealer.

(3) MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B - Supplemental

Restraint System (SRS) before beginning any service or maintenance of any component of the SRS or any SRS-related

component.

NOTE

The SRS includes the following components: SRS-ECU, SRS warning lamp, air bag module, clock spring, and interconnecting

wiring. Other SRS-related components (that may have to be removed/installed in connection with SRS service or maintenance) are

indicated in the table of contents by an asterisk (*).

Page 1031 of 1449

FRONT SUSPENSION -On-vehicle Service33A-5

Tightening torque: 52±2 N·m

3. Confirm that the toe-in is at the standard value.

4. Use a turning radius gauge to check that the steering

angle is at the standard value.

Standard value:

Inner wheels31_45’±1_30’

Outer wheels (for reference)27_15’

TOE-OUT ANGLE ON TURNS

To check the steering linkage, especially after the vehicle

has been involved in an accident or if an accident is presumed,

it is advisable to check the toe-out angle on turns in addition

to the wheel alignment.

Conduct this test on the left turn as well as on the right turn.

Standard value:

ItemsSpecifications

Toe-out angle on turns

(inner wheel when outer wheel at 20_)22_00’±1_30’

CAMBER, CASTER AND KINGPIN INCLINATION

Standard value:

ItemsSpecifications

Camber

(Selectable from 2 options)-1_00’±30’* or - 2_00’±30’*

Caster3_55’±30’*

Kingpin inclination13_45’±1_30’

NOTE

1. *: difference between right and left wheels must be less

than 30’

2. Caster and kingpin inclination are preset at the factory

and cannot be adjusted.

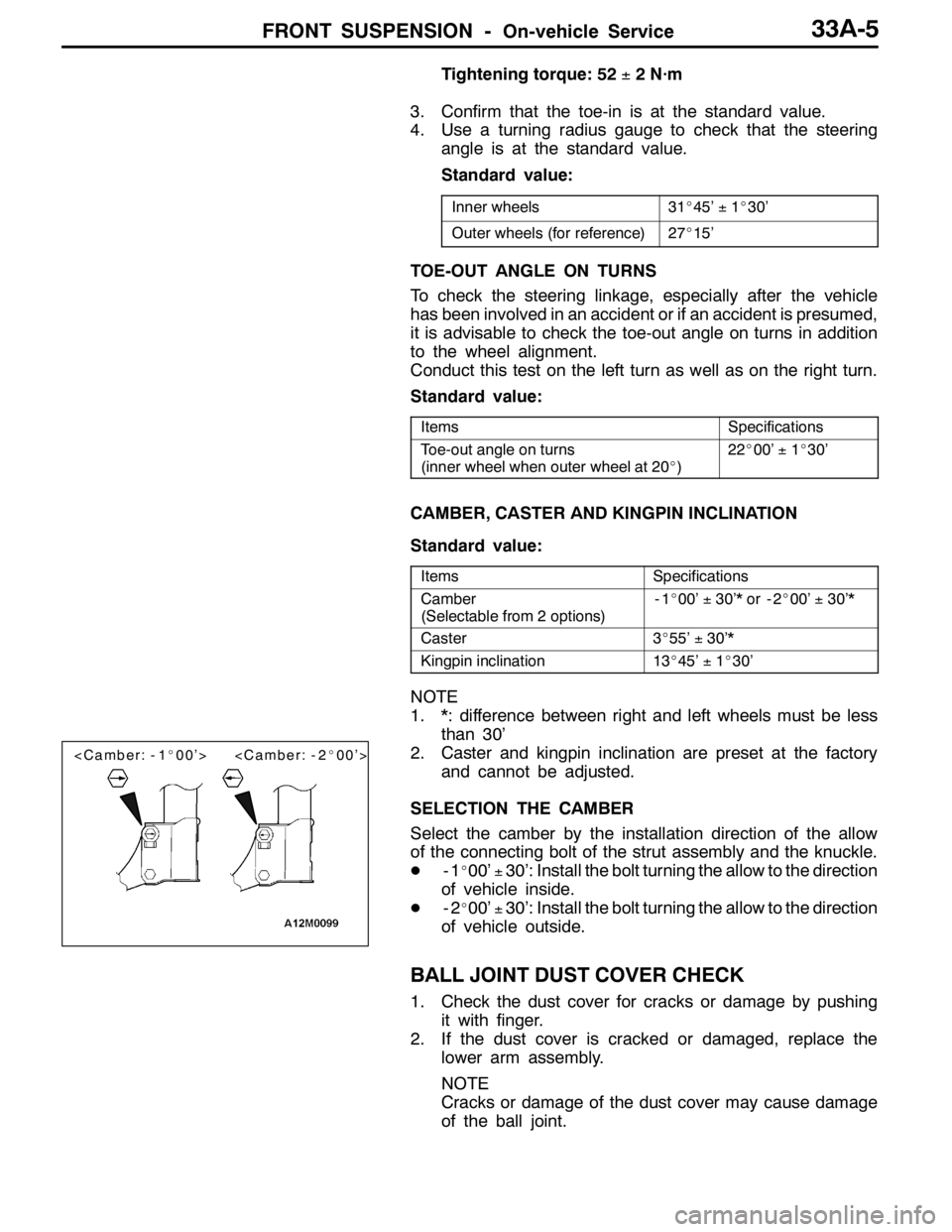

SELECTION THE CAMBER

Select the camber by the installation direction of the allow

of the connecting bolt of the strut assembly and the knuckle.

D-1

_00’±30’: Install the bolt turning the allow to the direction

of vehicle inside.

D-2

_00’±30’: Install the bolt turning the allow to the direction

of vehicle outside.

BALL JOINT DUST COVER CHECK

1. Check the dust cover for cracks or damage by pushing

it with finger.

2. If the dust cover is cracked or damaged, replace the

lower arm assembly.

NOTE

Cracks or damage of the dust cover may cause damage

of the ball joint.

Page 1051 of 1449

BASIC BRAKE SYSTEM -On-vehicle Service35A-9

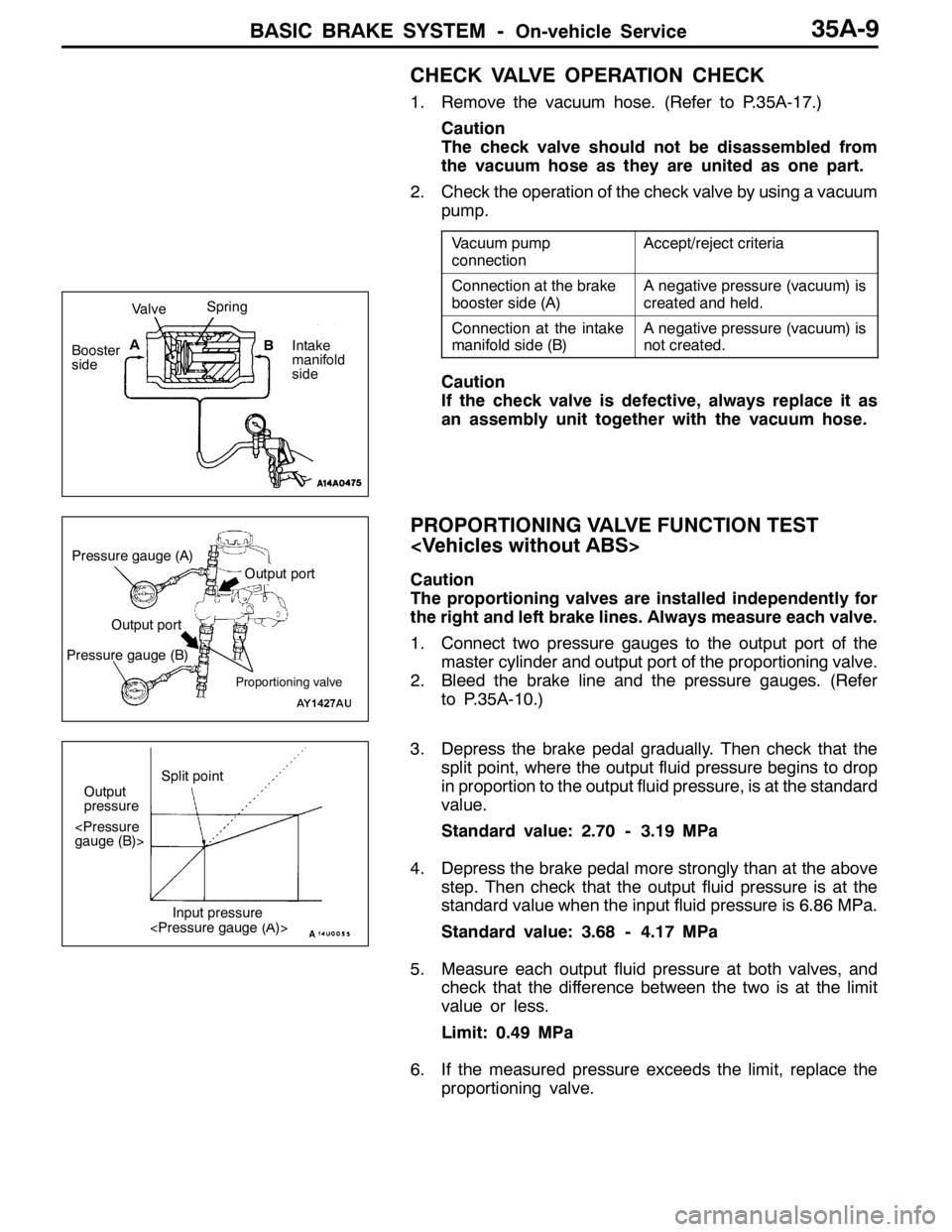

CHECK VALVE OPERATION CHECK

1. Remove the vacuum hose. (Refer to P.35A-17.)

Caution

The check valve should not be disassembled from

the vacuum hose as they are united as one part.

2. Check the operation of the check valve by using a vacuum

pump.

Vacuum pump

connectionAccept/reject criteria

Connection at the brake

booster side (A)A negative pressure (vacuum) is

created and held.

Connection at the intake

manifold side (B)A negative pressure (vacuum) is

not created.

Caution

If the check valve is defective, always replace it as

an assembly unit together with the vacuum hose.

PROPORTIONING VALVE FUNCTION TEST

Caution

The proportioning valves are installed independently for

the right and left brake lines. Always measure each valve.

1. Connect two pressure gauges to the output port of the

master cylinder and output port of the proportioning valve.

2. Bleed the brake line and the pressure gauges. (Refer

to P.35A-10.)

3. Depress the brake pedal gradually. Then check that the

split point, where the output fluid pressure begins to drop

in proportion to the output fluid pressure, is at the standard

value.

Standard value: 2.70 - 3.19 MPa

4. Depress the brake pedal more strongly than at the above

step. Then check that the output fluid pressure is at the

standard value when the input fluid pressure is 6.86 MPa.

Standard value: 3.68 - 4.17 MPa

5. Measure each output fluid pressure at both valves, and

check that the difference between the two is at the limit

value or less.

Limit: 0.49 MPa

6. If the measured pressure exceeds the limit, replace the

proportioning valve.

ValveSpring

Booster

sideA

B

Intake

manifold

side

Pressure gauge (A)

Proportioning valve

Output port

Output port

Pressure gauge (B)

Output

pressureSplit point

Page 1075 of 1449

ABS <4WD> -Troubleshooting35B-5

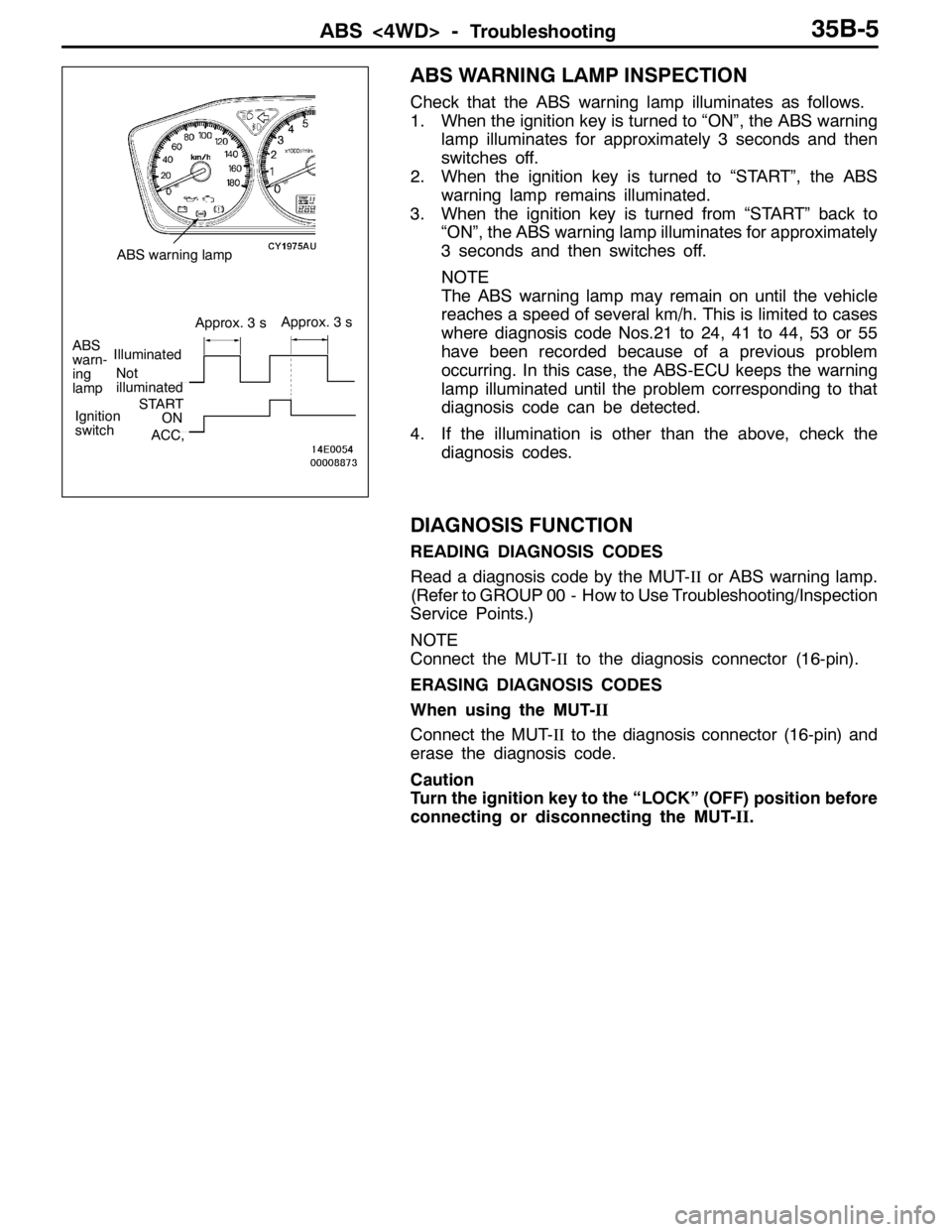

ABS WARNING LAMP INSPECTION

Check that the ABS warning lamp illuminates as follows.

1. When the ignition key is turned to “ON”, the ABS warning

lamp illuminates for approximately 3 seconds and then

switches off.

2. When the ignition key is turned to “START”, the ABS

warning lamp remains illuminated.

3. When the ignition key is turned from “START” back to

“ON”, the ABS warning lamp illuminates for approximately

3 seconds and then switches off.

NOTE

The ABS warning lamp may remain on until the vehicle

reaches a speed of several km/h. This is limited to cases

where diagnosis code Nos.21 to 24, 41 to 44, 53 or 55

have been recorded because of a previous problem

occurring. In this case, the ABS-ECU keeps the warning

lamp illuminated until the problem corresponding to that

diagnosis code can be detected.

4. If the illumination is other than the above, check the

diagnosis codes.

DIAGNOSIS FUNCTION

READING DIAGNOSIS CODES

Read a diagnosis code by the MUT-IIor ABS warning lamp.

(Refer to GROUP 00 - How to Use Troubleshooting/Inspection

Service Points.)

NOTE

Connect the MUT-IIto the diagnosis connector (16-pin).

ERASING DIAGNOSIS CODES

When using the MUT-II

Connect the MUT-IIto the diagnosis connector (16-pin) and

erase the diagnosis code.

Caution

Turn the ignition key to the “LOCK” (OFF) position before

connecting or disconnecting the MUT-II.

Not

illuminated

ABS

warn-

ing

lampIlluminated

Approx. 3 sApprox. 3 s

Ignition

switchSTARTON

ACC,

ABS warning lamp

Page 1077 of 1449

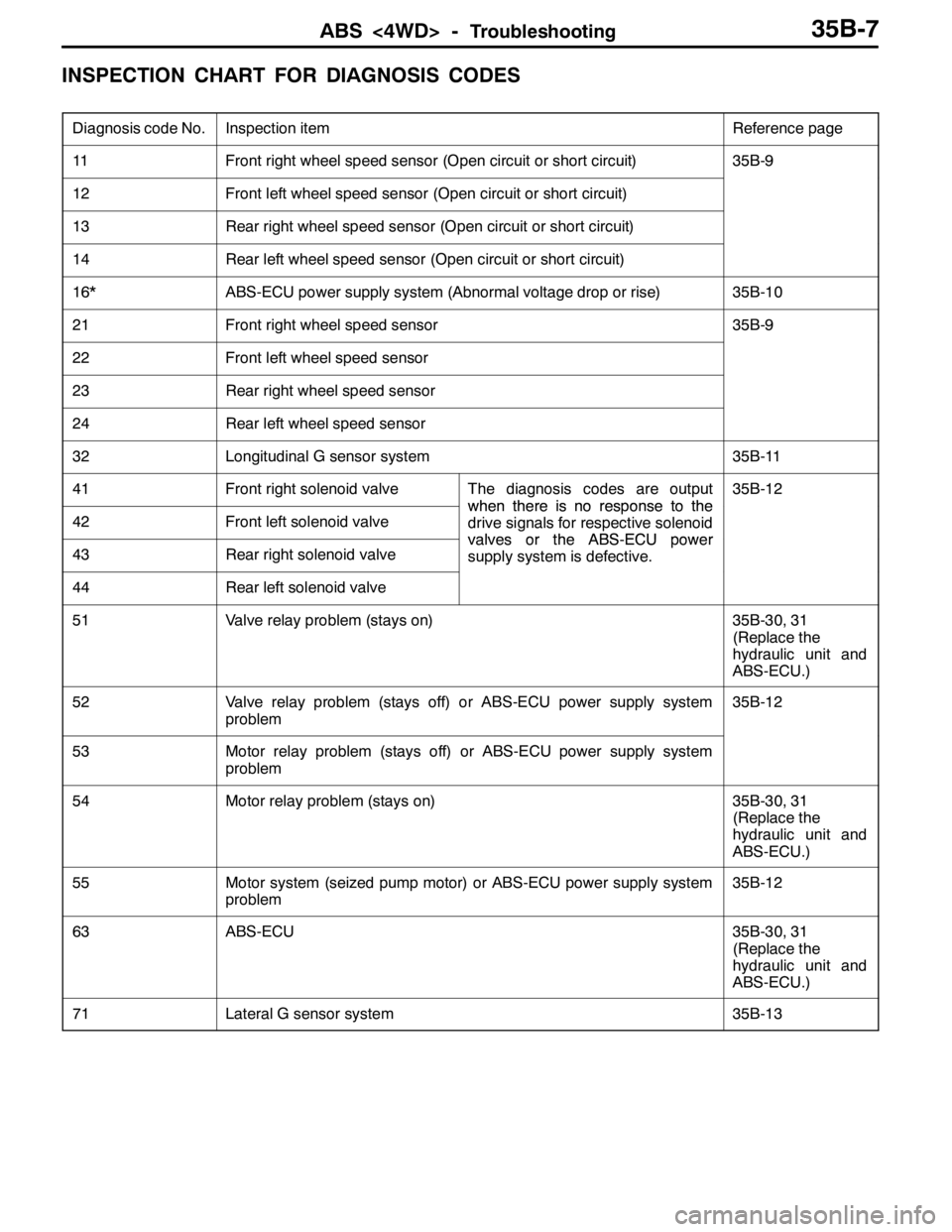

ABS <4WD> -Troubleshooting35B-7

INSPECTION CHART FOR DIAGNOSIS CODES

Diagnosis code No.Inspection itemReference page

11Front right wheel speed sensor (Open circuit or short circuit)35B-9

12Front left wheel speed sensor (Open circuit or short circuit)

13Rear right wheel speed sensor (Open circuit or short circuit)

14Rear left wheel speed sensor (Open circuit or short circuit)

16*ABS-ECU power supply system (Abnormal voltage drop or rise)35B-10

21Front right wheel speed sensor35B-9

22Front left wheel speed sensor

23Rear right wheel speed sensor

24Rear left wheel speed sensor

32Longitudinal G sensor system35B-11

41Front right solenoid valveThe diagnosis codes are output

whenthereisnoresponsetothe

35B-12

42Front left solenoid valve

whenthereis no responsetothe

drive signals for respective solenoid

valvesortheABS ECUpower43Rear right solenoid valvevalves or theABS-ECUpower

supply system is defective.

44Rear left solenoid valve

51Valve relay problem (stays on)35B-30, 31

(Replace the

hydraulic unit and

ABS-ECU.)

52Valve relay problem (stays off) or ABS-ECU power supply system

problem35B-12

53Motor relay problem (stays off) or ABS-ECU power supply system

problem

54Motor relay problem (stays on)35B-30, 31

(Replace the

hydraulic unit and

ABS-ECU.)

55Motor system (seized pump motor) or ABS-ECU power supply system

problem35B-12

63ABS-ECU35B-30, 31

(Replace the

hydraulic unit and

ABS-ECU.)

71Lateral G sensor system35B-13

Page 1115 of 1449

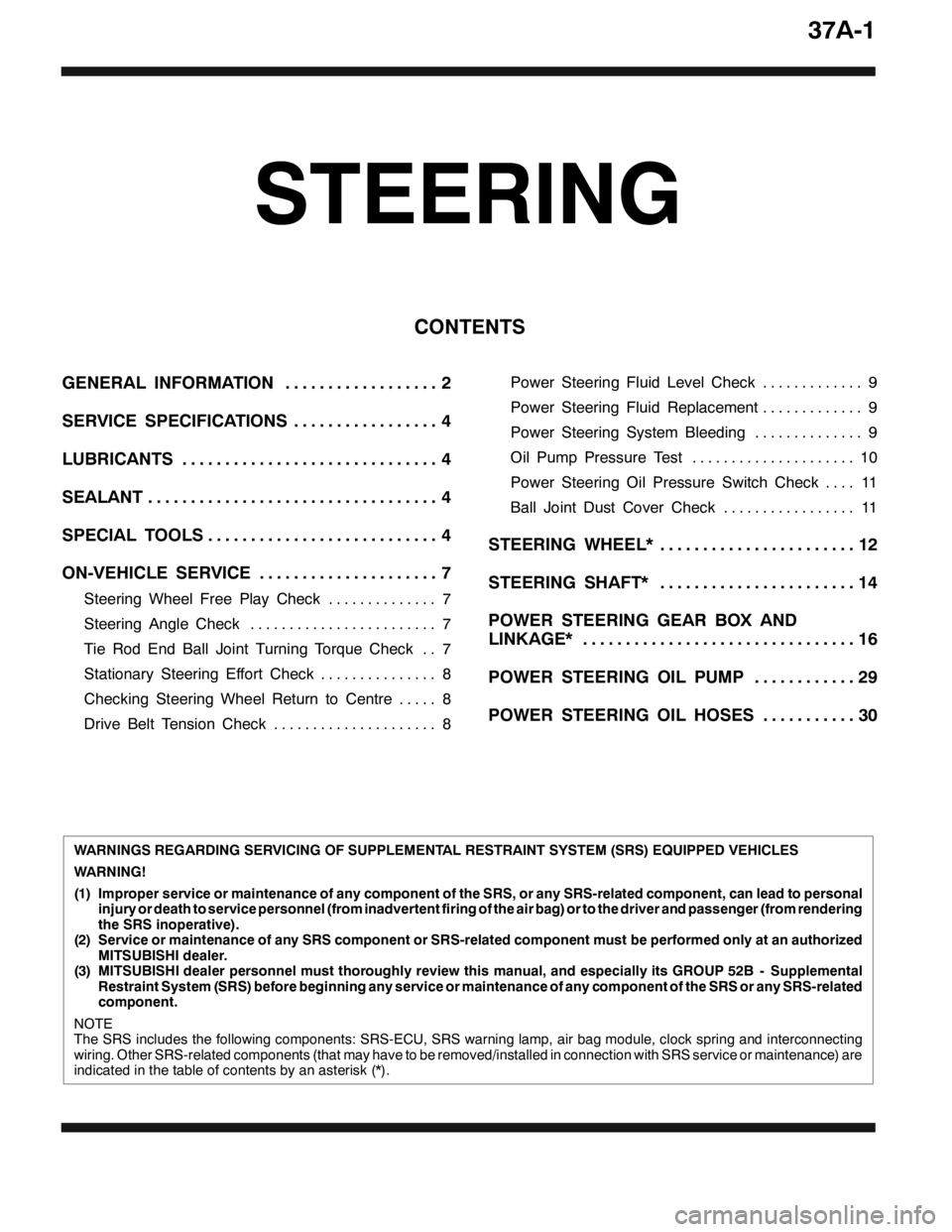

37A-1

STEERING

CONTENTS

GENERAL INFORMATION 2..................

SERVICE SPECIFICATIONS 4.................

LUBRICANTS 4..............................

SEALANT 4..................................

SPECIAL TOOLS 4...........................

ON-VEHICLE SERVICE 7.....................

Steering Wheel Free Play Check 7..............

Steering Angle Check 7........................

Tie Rod End Ball Joint Turning Torque Check 7..

Stationary Steering Effort Check 8...............

Checking Steering Wheel Return to Centre 8.....

Drive Belt Tension Check 8.....................Power Steering Fluid Level Check 9.............

Power Steering Fluid Replacement 9.............

Power Steering System Bleeding 9..............

Oil Pump Pressure Test 10.....................

Power Steering Oil Pressure Switch Check 11....

Ball Joint Dust Cover Check 11.................

STEERING WHEEL* 12.......................

STEERING SHAFT* 14.......................

POWER STEERING GEAR BOX AND

LINKAGE* 16................................

POWER STEERING OIL PUMP 29............

POWER STEERING OIL HOSES 30...........

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING!

(1) Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to personal

injury or death to service personnel (from inadvertent firing of the air bag) or to the driver and passenger (from rendering

the SRS inoperative).

(2) Service or maintenance of any SRS component or SRS-related component must be performed only at an authorized

MITSUBISHI dealer.

(3) MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B - Supplemental

Restraint System (SRS) before beginning any service or maintenance of any component of the SRS or any SRS-related

component.

NOTE

The SRS includes the following components: SRS-ECU, SRS warning lamp, air bag module, clock spring and interconnecting

wiring. Other SRS-related components (that may have to be removed/installed in connection with SRS service or maintenance) are

indicated in the table of contents by an asterisk (*).