ESP MITSUBISHI LANCER EVOLUTION 2007 Service Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 1336 of 1449

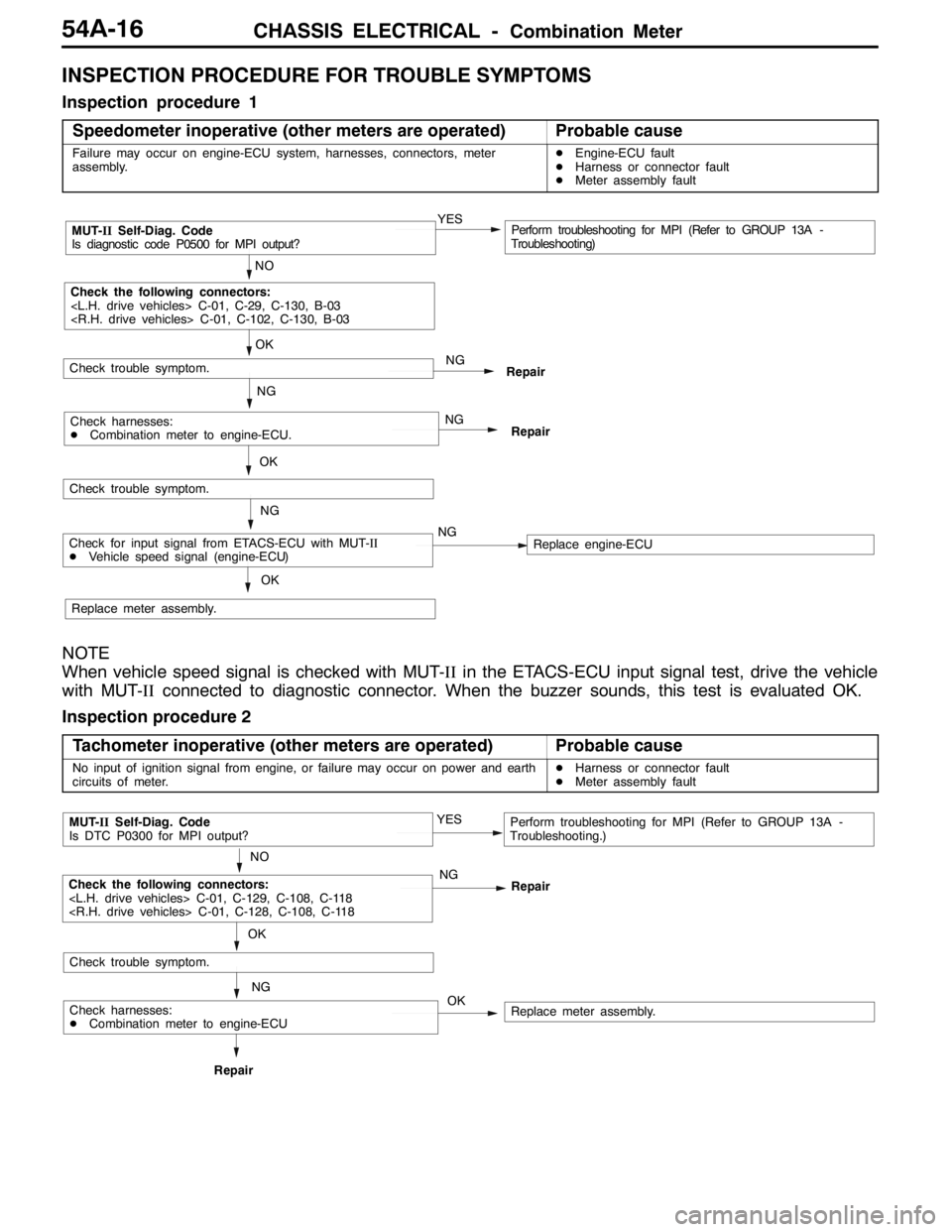

CHASSIS ELECTRICAL -Combination Meter54A-16

INSPECTION PROCEDURE FOR TROUBLE SYMPTOMS

Inspection procedure 1

Speedometer inoperative (other meters are operated)

Probable cause

Failure may occur on engine-ECU system, harnesses, connectors, meter

assembly.DEngine-ECU fault

DHarness or connector fault

DMeter assembly fault

NO

MUT-IISelf-Diag. Code

Is diagnostic code P0500 for MPI output?YESPerform troubleshooting for MPI (Refer to GROUP 13A -

Troubleshooting)

OK

NG

Check the following connectors:

Repair

OK

Check trouble symptom.

NG

NG

RepairCheck harnesses:

DCombination meter to engine-ECU.

Check trouble symptom.

NG

Replace meter assembly.

OK

Check for input signal from ETACS-ECU with MUT-II

DVehicle speed signal (engine-ECU)NGReplace engine-ECU

NOTE

When vehicle speed signal is checked with MUT-IIin the ETACS-ECU input signal test, drive the vehicle

with MUT-IIconnected to diagnostic connector. When the buzzer sounds, this test is evaluated OK.

Inspection procedure 2

Tachometer inoperative (other meters are operated)

Probable cause

No input of ignition signal from engine, or failure may occur on power and earth

circuits of meter.DHarness or connector fault

DMeter assembly fault

OK

NO

MUT-IISelf-Diag. Code

Is DTC P0300 for MPI output?YESPerform troubleshooting for MPI (Refer to GROUP 13A -

Troubleshooting.)

NG

NG

RepairRepair

Check trouble symptom.

OK

Check the following connectors:

Replace meter assembly.Check harnesses:

DCombination meter to engine-ECU

Page 1371 of 1449

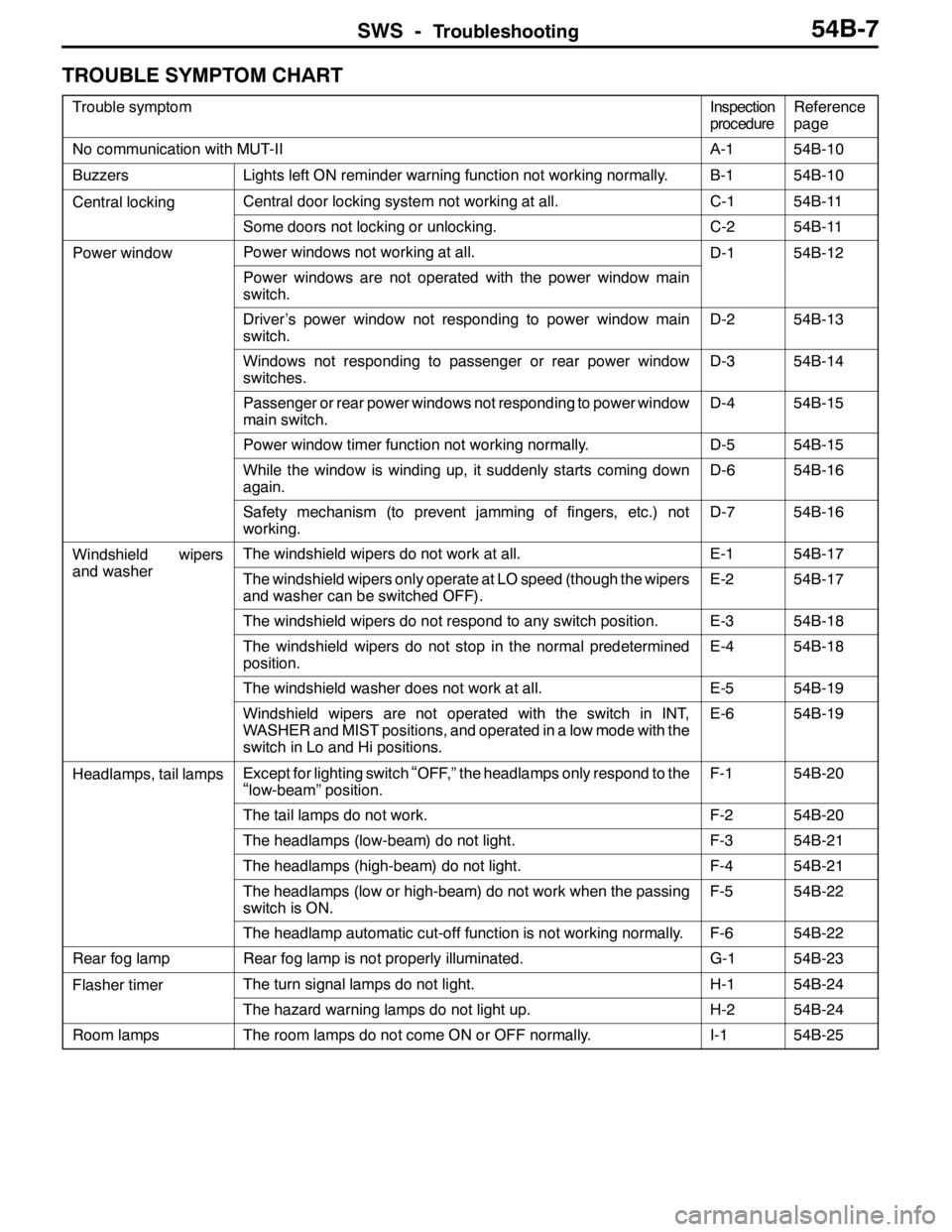

SWS -Troubleshooting54B-7

TROUBLE SYMPTOM CHART

Trouble symptomInspection

procedureReference

page

No communication with MUT-IIA-154B-10

BuzzersLights left ON reminder warning function not working normally.B-154B-10

Central lockingCentral door locking system not working at all.C-154B-11g

Some doors not locking or unlocking.C-254B-11

Power windowPower windows not working at all.D-154B-12

Power windows are not operated with the power window main

switch.

Driver’s power window not responding to power window main

switch.D-254B-13

Windows not responding to passenger or rear power window

switches.D-354B-14

Passenger or rear power windows not responding to power window

main switch.D-454B-15

Power window timer function not working normally.D-554B-15

While the window is winding up, it suddenly starts coming down

again.D-654B-16

Safety mechanism (to prevent jamming of fingers, etc.) not

working.D-754B-16

Windshield wipers

dh

The windshield wipers do not work at all.E-154B-17p

and washerThe windshield wipers only operate at LO speed (though the wipers

and washer can be switched OFF).E-254B-17

The windshield wipers do not respond to any switch position.E-354B-18

The windshield wipers do not stop in the normal predetermined

position.E-454B-18

The windshield washer does not work at all.E-554B-19

Windshield wipers are not operated with the switch in INT,

WASHER and MIST positions, and operated in a low mode with the

switch in Lo and Hi positions.E-654B-19

Headlamps, tail lampsExcept for lighting switch“OFF,” the headlamps only respond to the

“low-beam” position.

F-154B-20

The tail lamps do not work.F-254B-20

The headlamps (low-beam) do not light.F-354B-21

The headlamps (high-beam) do not light.F-454B-21

The headlamps (low or high-beam) do not work when the passing

switch is ON.F-554B-22

The headlamp automatic cut-off function is not working normally.F-654B-22

Rear fog lampRear fog lamp is not properly illuminated.G-154B-23

Flasher timerThe turn signal lamps do not light.H-154B-24

The hazard warning lamps do not light up.H-254B-24

Room lampsThe room lamps do not come ON or OFF normally.I-154B-25

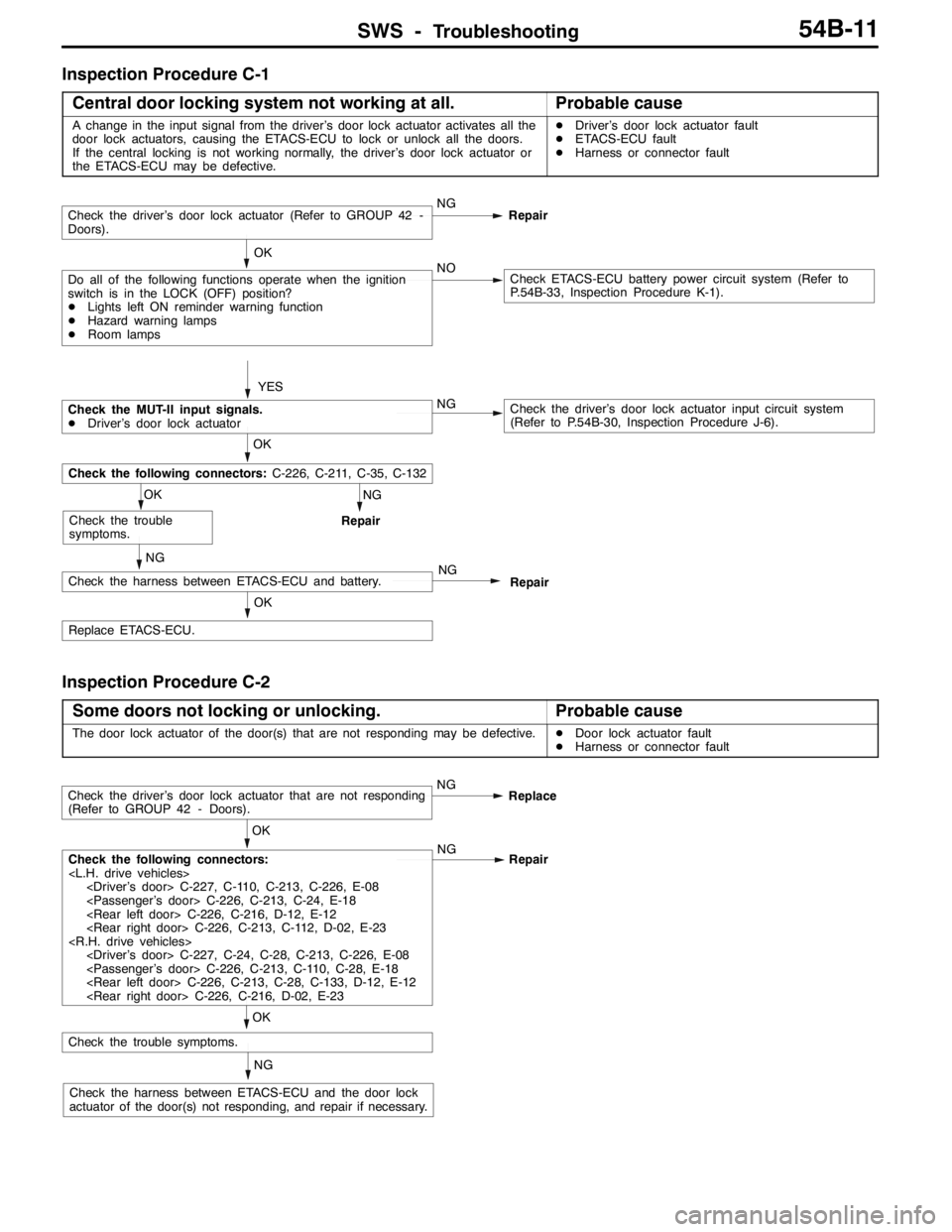

Page 1375 of 1449

SWS -Troubleshooting54B-11

Inspection Procedure C-1

Central door locking system not working at all.

Probable cause

A change in the input signal from the driver’s door lock actuator activates all the

door lock actuators, causing the ETACS-ECU to lock or unlock all the doors.

If the central locking is not working normally, the driver’s door lock actuator or

the ETACS-ECU may be defective.DDriver’s door lock actuator fault

DETACS-ECU fault

DHarness or connector fault

NG

Repair

OK

Replace ETACS-ECU.

NG

Check the harness between ETACS-ECU and battery.NG

Repair

OK

Check the trouble

symptoms.

OK

Check the following connectors:C-226, C-211, C-35, C-132

YES

Check the driver’s door lock actuator (Refer to GROUP 42 -

Doors).NG

Repair

Do all of the following functions operate when the ignition

switch is in the LOCK (OFF) position?

DLights left ON reminder warning function

DHazard warning lamps

DRoom lampsNOCheck ETACS-ECU battery power circuit system (Refer to

P.54B-33, Inspection Procedure K-1). OK

Check the MUT-II input signals.

DDriver’s door lock actuatorNGCheck the driver’s door lock actuator input circuit system

(Refer to P.54B-30, Inspection Procedure J-6).

Inspection Procedure C-2

Some doors not locking or unlocking.

Probable cause

The door lock actuator of the door(s) that are not responding may be defective.DDoor lock actuator fault

DHarness or connector fault

NG

Check the harness between ETACS-ECU and the door lock

actuator of the door(s) not responding, and repair if necessary.

OK

Check the trouble symptoms.

OK

Check the following connectors:

Repair

Check the driver’s door lock actuator that are not responding

(Refer to GROUP 42 - Doors).NG

Replace

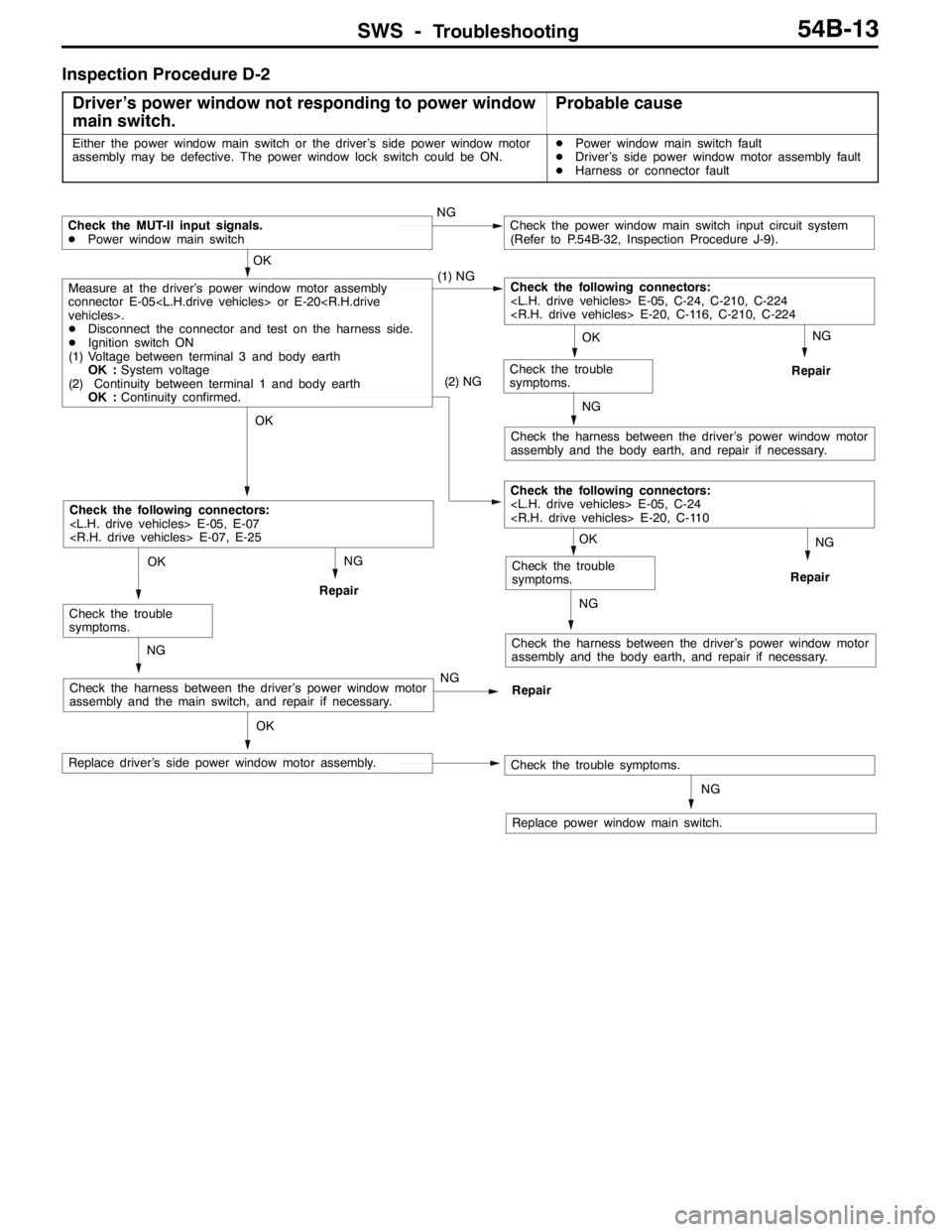

Page 1377 of 1449

SWS -Troubleshooting54B-13

Inspection Procedure D-2

Driver’s power window not responding to power window

main switch.

Probable cause

Either the power window main switch or the driver’s side power window motor

assembly may be defective. The power window lock switch could be ON.DPower window main switch fault

DDriver’s side power window motor assembly fault

DHarness or connector fault

NG

Replace power window main switch.

OK

Replace driver’s side power window motor assembly.

NG

Check the harness between the driver’s power window motor

assembly and the body earth, and repair if necessary.

NG

Repair

OK

Check the trouble

symptoms.

(2) NG

Check the following connectors:

NG

Repair

NG

Check the harness between the driver’s power window motor

assembly and the body earth, and repair if necessary.

NG

Repair

OK

Check the trouble

symptoms.

NG

Check the harness between the driver’s power window motor

assembly and the main switch, and repair if necessary.NG

Repair

OK

Check the trouble

symptoms.

OK

Check the following connectors:

OK

Measure at the driver’s power window motor assembly

connector E-05

DDisconnect the connector and test on the harness side.

DIgnition switch ON

(1) Voltage between terminal 3 and body earth

OK :System voltage

(2) Continuity between terminal 1 and body earth

OK :Continuity confirmed.(1) NGCheck the following connectors:

Check the MUT-II input signals.

DPower window main switchNGCheck the power window main switch input circuit system

(Refer to P.54B-32, Inspection Procedure J-9).

Check the trouble symptoms.

Page 1378 of 1449

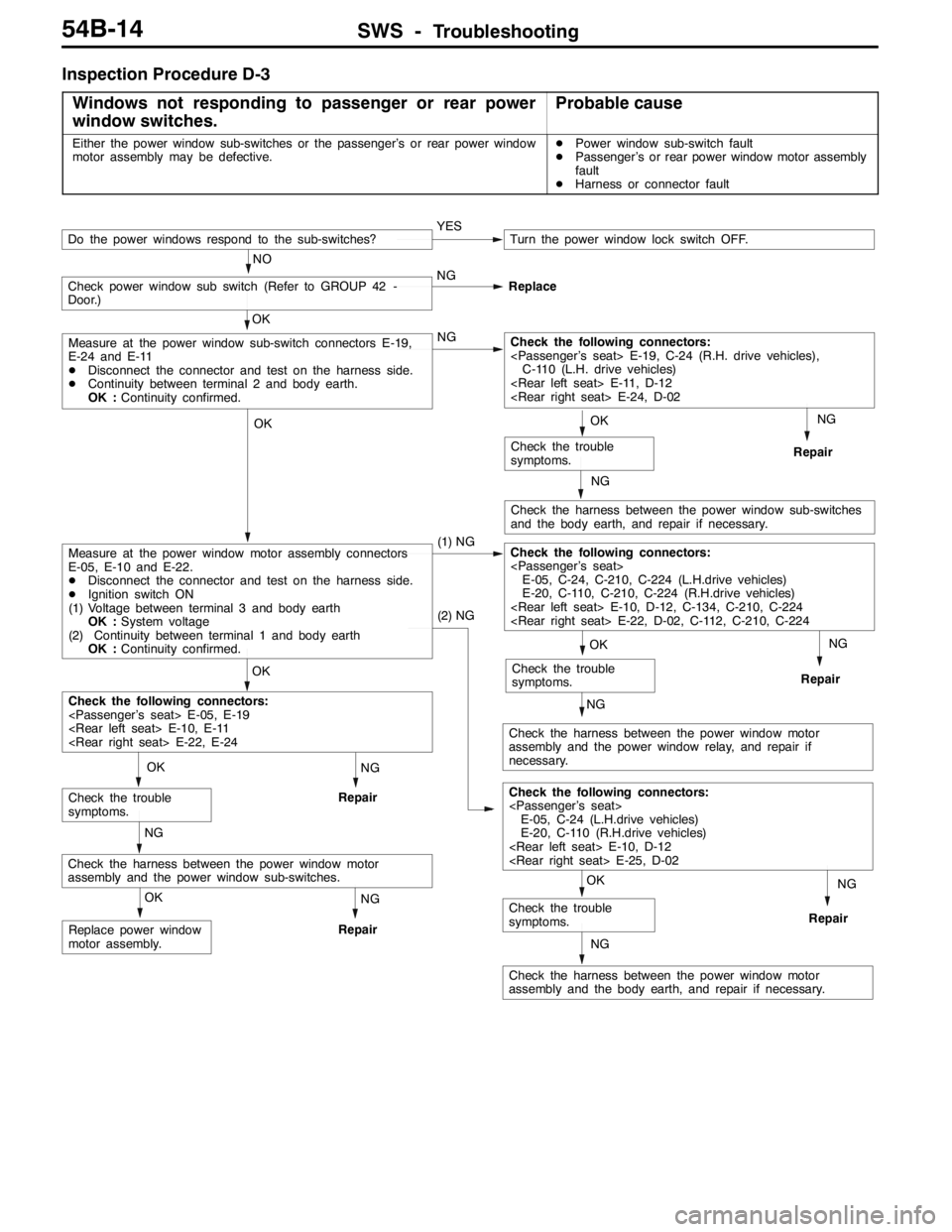

SWS -Troubleshooting54B-14

Inspection Procedure D-3

Windows not responding to passenger or rear power

window switches.

Probable cause

Either the power window sub-switches or the passenger’s or rear power window

motor assembly may be defective.DPower window sub-switch fault

DPassenger’s or rear power window motor assembly

fault

DHarness or connector fault

NG

Repair

NG

Check the harness between the power window sub-switches

and the body earth, and repair if necessary.

NG

Repair

NG

Check the harness between the power window motor

assembly and the power window relay, and repair if

necessary.NG

Repair

NG

Check the harness between the power window motor

assembly and the body earth, and repair if necessary.

NG

Repair

OK

Replace power window

motor assembly.

NG

Repair

NG

Check the harness between the power window motor

assembly and the power window sub-switches.

OK

Check the trouble

symptoms.

OK

Check the trouble

symptoms.

(2) NG

Check the following connectors:

E-05, C-24 (L.H.drive vehicles)

E-20, C-110 (R.H.drive vehicles)

OK

Check the trouble

symptoms.

OK

Check the trouble

symptoms.

OK

Check the following connectors:

OK

Measure at the power window motor assembly connectors

E-05, E-10 and E-22.

DDisconnect the connector and test on the harness side.

DIgnition switch ON

(1) Voltage between terminal 3 and body earth

OK :System voltage

(2) Continuity between terminal 1 and body earth

OK :Continuity confirmed.(1) NGCheck the following connectors:

E-05, C-24, C-210, C-224 (L.H.drive vehicles)

E-20, C-110, C-210, C-224 (R.H.drive vehicles)

OK

Measure at the power window sub-switch connectors E-19,

E-24 and E-11

DDisconnect the connector and test on the harness side.

DContinuity between terminal 2 and body earth.

OK :Continuity confirmed.NGCheck the following connectors:

C-110 (L.H. drive vehicles)

Check power window sub switch (Refer to GROUP 42 -

Door.)NG

Replace

YESTurn the power window lock switch OFF.

NO

Do the power windows respond to the sub-switches?

Page 1379 of 1449

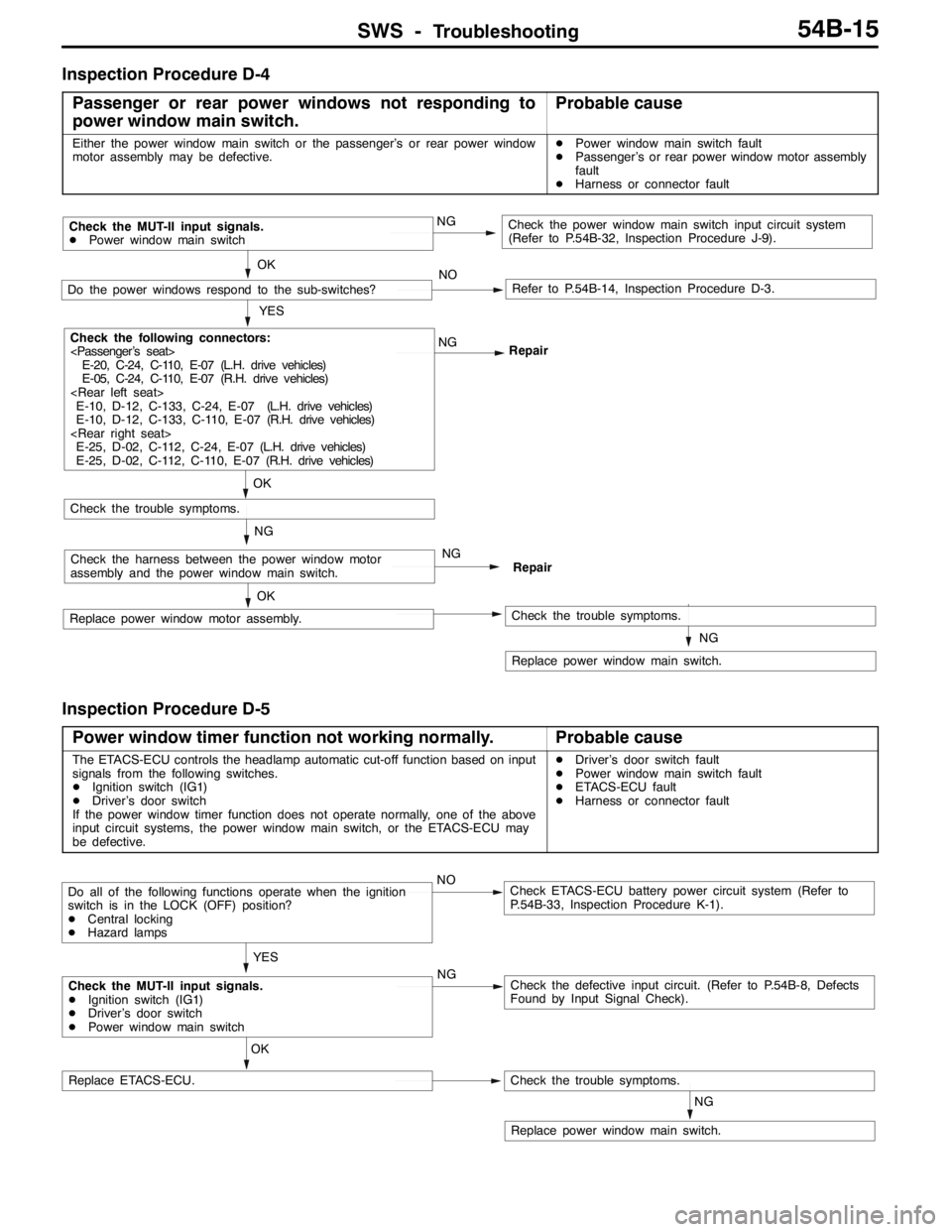

SWS -Troubleshooting54B-15

Inspection Procedure D-4

Passenger or rear power windows not responding to

power window main switch.

Probable cause

Either the power window main switch or the passenger’s or rear power window

motor assembly may be defective.DPower window main switch fault

DPassenger’s or rear power window motor assembly

fault

DHarness or connector fault

NG

Replace power window main switch.

OK

Replace power window motor assembly.Check the trouble symptoms.

NGCheck the harness between the power window motor

assembly and the power window main switch.NG

Repair

OK

Check the trouble symptoms.

YES

Check the following connectors:

E-20, C-24, C-110, E-07 (L.H. drive vehicles)

E-05, C-24, C-110, E-07 (R.H. drive vehicles)

E-10, D-12, C-133, C-24, E-07 (L.H. drive vehicles)

E-10, D-12, C-133, C-110, E-07 (R.H. drive vehicles)

E-25, D-02, C-112, C-24, E-07 (L.H. drive vehicles)

E-25, D-02, C-112, C-110, E-07 (R.H. drive vehicles)NG

Repair

OK

Do the power windows respond to the sub-switches?NORefer to P.54B-14, Inspection Procedure D-3.

Check the MUT-II input signals.

DPower window main switchNGCheck the power window main switch input circuit system

(Refer to P.54B-32, Inspection Procedure J-9).

Inspection Procedure D-5

Power window timer function not working normally.

Probable cause

The ETACS-ECU controls the headlamp automatic cut-off function based on input

signals from the following switches.

DIgnition switch (IG1)

DDriver’s door switch

If the power window timer function does not operate normally, one of the above

input circuit systems, the power window main switch, or the ETACS-ECU may

be defective.DDriver’s door switch fault

DPower window main switch fault

DETACS-ECU fault

DHarness or connector fault

NG

Replace power window main switch.

OK

Replace ETACS-ECU.Check the trouble symptoms.

Check the MUT-II input signals.

DIgnition switch (IG1)

DDriver’s door switch

DPower window main switchNGCheck the defective input circuit. (Refer to P.54B-8, Defects

Found by Input Signal Check).

Do all of the following functions operate when the ignition

switch is in the LOCK (OFF) position?

DCentral locking

DHazard lampsNOCheck ETACS-ECU battery power circuit system (Refer to

P.54B-33, Inspection Procedure K-1).

YES

Page 1381 of 1449

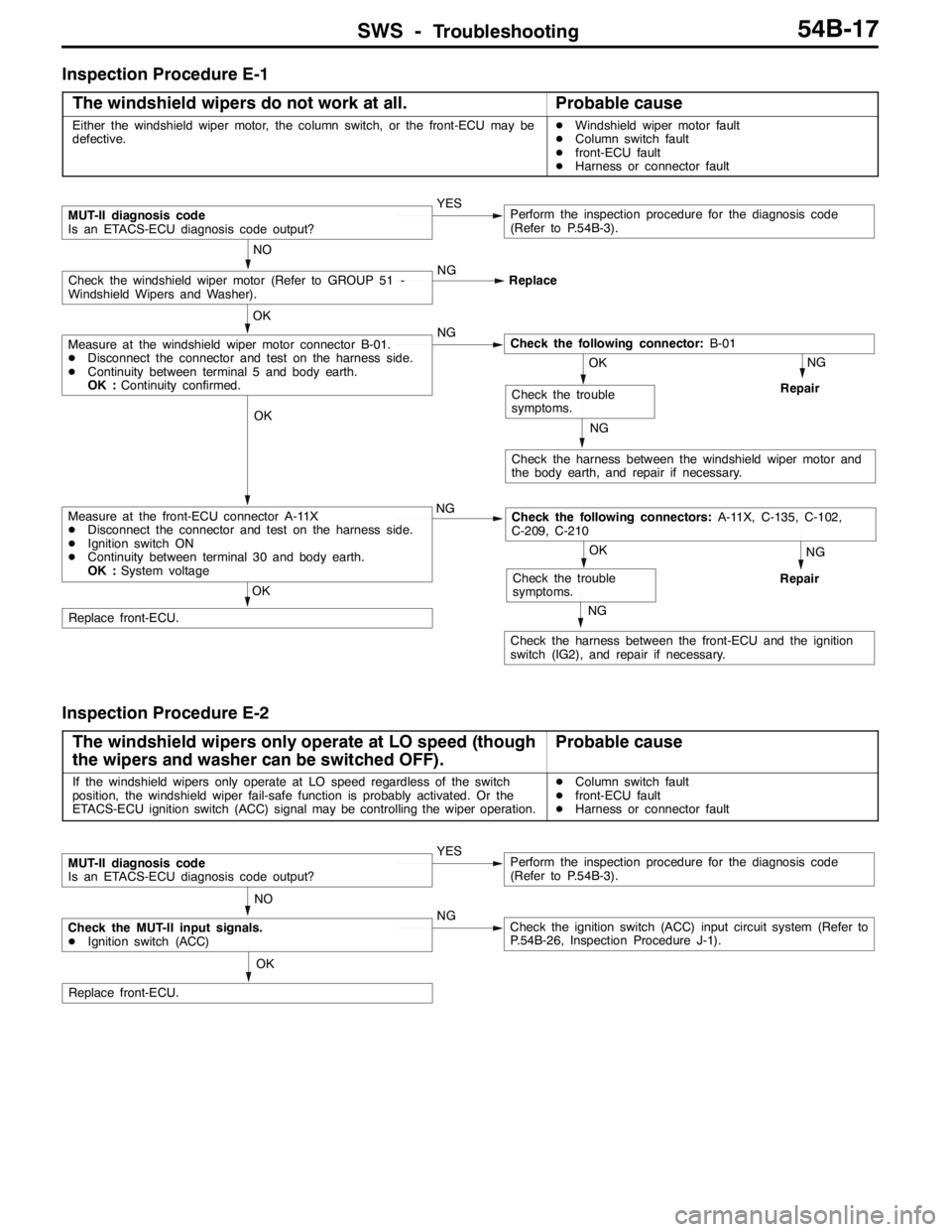

SWS -Troubleshooting54B-17

Inspection Procedure E-1

The windshield wipers do not work at all.

Probable cause

Either the windshield wiper motor, the column switch, or the front-ECU may be

defective.DWindshield wiper motor fault

DColumn switch fault

Dfront-ECU fault

DHarness or connector fault

OK

Replace front-ECU.

NO

NG

Replace

MUT-II diagnosis code

Is an ETACS-ECU diagnosis code output?YESPerform the inspection procedure for the diagnosis code

(Refer to P.54B-3).

NG

Repair

NG

Check the harness between the windshield wiper motor and

the body earth, and repair if necessary.

OK

Check the trouble

symptoms.

NG

Repair

NG

Check the harness between the front-ECU and the ignition

switch (IG2), and repair if necessary.

OK

Check the trouble

symptoms.

OK

Measure at the front-ECU connector A-11X

DDisconnect the connector and test on the harness side.

DIgnition switch ON

DContinuity between terminal 30 and body earth.

OK :System voltageNGCheck the following connectors:A-11X, C-135, C-102,

C-209, C-210

OK

Measure at the windshield wiper motor connector B-01.

DDisconnect the connector and test on the harness side.

DContinuity between terminal 5 and body earth.

OK :Continuity confirmed.NGCheck the following connector:B-01

Check the windshield wiper motor (Refer to GROUP 51 -

Windshield Wipers and Washer).

Inspection Procedure E-2

The windshield wipers only operate at LO speed (though

the wipers and washer can be switched OFF).

Probable cause

If the windshield wipers only operate at LO speed regardless of the switch

position, the windshield wiper fail-safe function is probably activated. Or the

ETACS-ECU ignition switch (ACC) signal may be controlling the wiper operation.DColumn switch fault

Dfront-ECU fault

DHarness or connector fault

OK

Replace front-ECU.

MUT-II diagnosis code

Is an ETACS-ECU diagnosis code output?YESPerform the inspection procedure for the diagnosis code

(Refer to P.54B-3).

Check the MUT-II input signals.

DIgnition switch (ACC)NGCheck the ignition switch (ACC) input circuit system (Refer to

P.54B-26, Inspection Procedure J-1). NO

Page 1382 of 1449

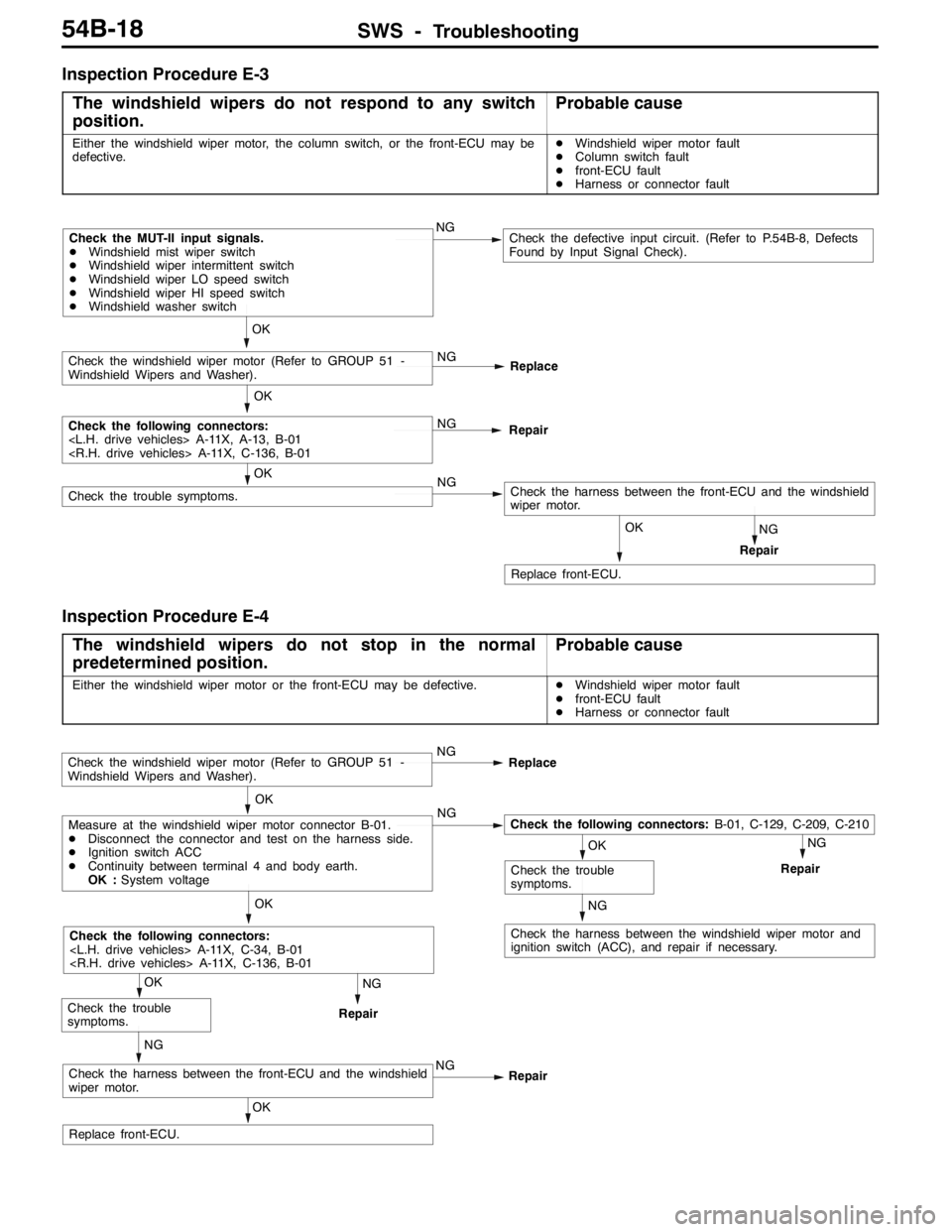

SWS -Troubleshooting54B-18

Inspection Procedure E-3

The windshield wipers do not respond to any switch

position.

Probable cause

Either the windshield wiper motor, the column switch, or the front-ECU may be

defective.DWindshield wiper motor fault

DColumn switch fault

Dfront-ECU fault

DHarness or connector fault

OK

Replace front-ECU.

NG

Check the harness between the front-ECU and the windshield

wiper motor. NG

Repair

OK

Check the trouble symptoms.

OK

Check the following connectors:

Repair

OK

Check the windshield wiper motor (Refer to GROUP 51 -

Windshield Wipers and Washer).NG

Replace

Check the MUT-II input signals.

DWindshield mist wiper switch

DWindshield wiper intermittent switch

DWindshield wiper LO speed switch

DWindshield wiper HI speed switch

DWindshield washer switchNGCheck the defective input circuit. (Refer to P.54B-8, Defects

Found by Input Signal Check).

Inspection Procedure E-4

The windshield wipers do not stop in the normal

predetermined position.

Probable cause

Either the windshield wiper motor or the front-ECU may be defective.DWindshield wiper motor fault

Dfront-ECU fault

DHarness or connector fault

NG

Repair

NG

Check the harness between the windshield wiper motor and

ignition switch (ACC), and repair if necessary.

NG

Repair

OK

Replace front-ECU.

NG

Check the harness between the front-ECU and the windshield

wiper motor.NG

Repair

OK

Check the trouble

symptoms.

OK

OK

Check the trouble

symptoms.

OK

Measure at the windshield wiper motor connector B-01.

DDisconnect the connector and test on the harness side.

DIgnition switch ACC

DContinuity between terminal 4 and body earth.

OK :System voltageNGCheck the following connectors:B-01, C-129, C-209, C-210

Check the windshield wiper motor (Refer to GROUP 51 -

Windshield Wipers and Washer).NG

Replace

Check the following connectors:

Page 1384 of 1449

SWS -Troubleshooting54B-20

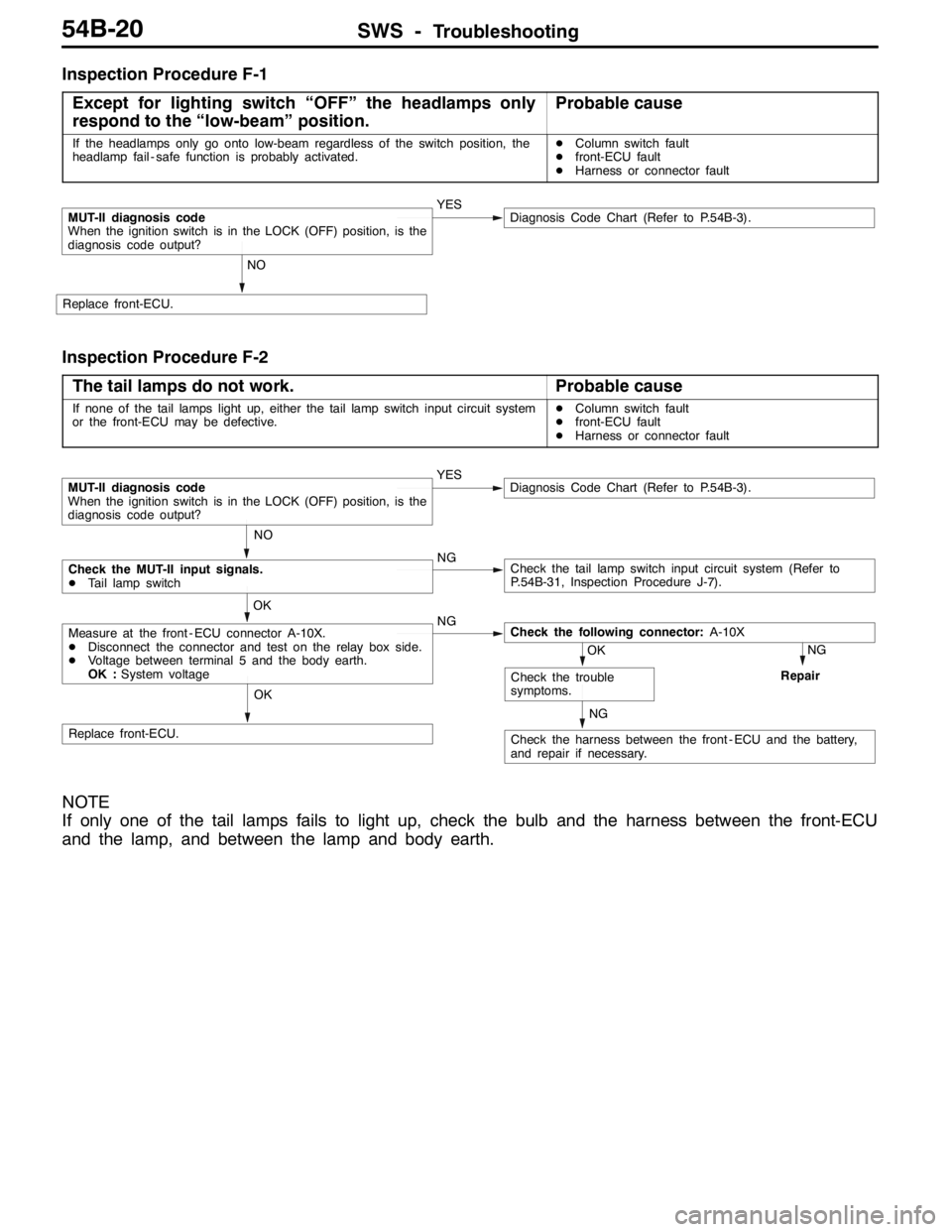

Inspection Procedure F-1

Except for lighting switch “OFF” the headlamps only

respond to the “low-beam” position.

Probable cause

If the headlamps only go onto low-beam regardless of the switch position, the

headlamp fail - safe function is probably activated.DColumn switch fault

Dfront-ECU fault

DHarness or connector fault

NO

Replace front-ECU.

MUT-II diagnosis code

When the ignition switch is in the LOCK (OFF) position, is the

diagnosis code output?YESDiagnosis Code Chart (Refer to P.54B-3).

Inspection Procedure F-2

The tail lamps do not work.

Probable cause

If none of the tail lamps light up, either the tail lamp switch input circuit system

or the front-ECU may be defective.DColumn switch fault

Dfront-ECU fault

DHarness or connector fault

NG

Repair

NG

Check the harness between the front - ECU and the battery,

and repair if necessary.

OK

Replace front-ECU.

OK

Check the trouble

symptoms.

OK

Measure at the front - ECU connector A-10X.

DDisconnect the connector and test on the relay box side.

DVoltage between terminal 5 and the body earth.

OK :System voltageNGCheck the following connector:A-10X

NO

Check the MUT-II input signals.

DTail lamp switchNGCheck the tail lamp switch input circuit system (Refer to

P.54B-31, Inspection Procedure J-7).

MUT-II diagnosis code

When the ignition switch is in the LOCK (OFF) position, is the

diagnosis code output?YESDiagnosis Code Chart (Refer to P.54B-3).

NOTE

If only one of the tail lamps fails to light up, check the bulb and the harness between the front-ECU

and the lamp, and between the lamp and body earth.

Page 1404 of 1449

ServiceSpecifications/Lubricants/

Special ToolsHEATER, AIR CONDITIONER AND VENTILATION-55-2

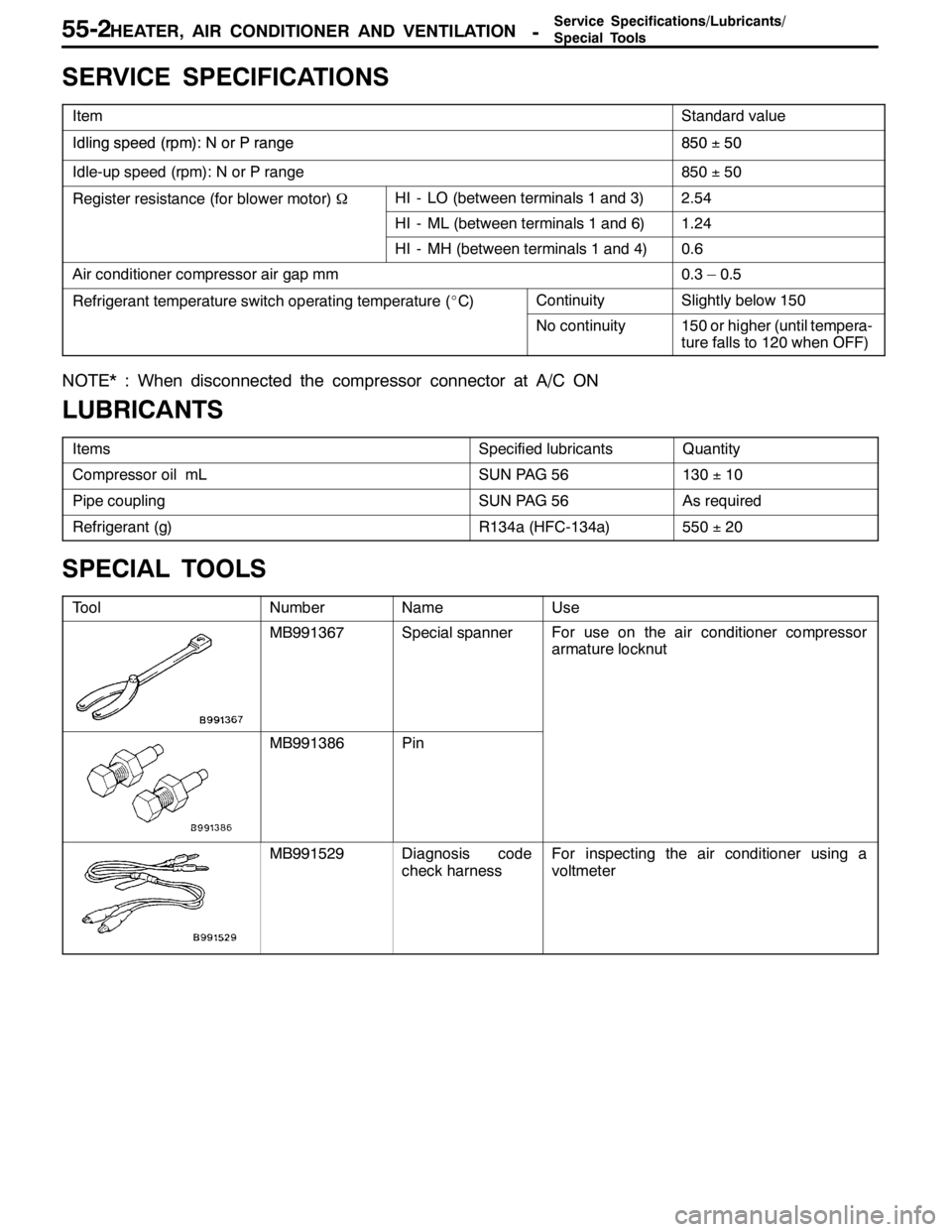

SERVICE SPECIFICATIONS

ItemStandard value

Idlid()NP85050Idlingspeed(rpm):NorPrange850±50Idlingspeed(rpm):NorPrange850±50Idlingspeed(rpm):NorPrange850�r50

Idle-up speed (rpm): N or P range850±50

Register resistance (for blower motor)ΩHI - LO (between terminals 1 and 3)2.54g()

HI - ML (between terminals 1 and 6)1.24

HI - MH (between terminals 1 and 4)0.6

Air conditioner compressor air gap mm0.3 – 0.5

Refrigerant temperature switch operating temperature (_C)ContinuitySlightly below 150gppgp()

No continuity150 or higher (until tempera-

ture falls to 120 when OFF)

NOTE* : When disconnected the compressor connector at A/C ON

LUBRICANTS

ItemsSpecified lubricantsQuantity

Compressor oil mLSUN PAG 56130±10

Pipe couplingSUN PAG 56As required

Refrigerant (g)R134a (HFC-134a)550±20

SPECIAL TOOLS

ToolNumberNameUse

MB991367Special spannerFor use on the air conditioner compressor

armature locknut

MB991386Pin

MB991529Diagnosis code

check harnessFor inspecting the air conditioner using a

voltmeter