brake sensor MITSUBISHI LANCER EVOLUTION 2007 Service Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 1071 of 1449

35B-1

ANTI-SKID

BRAKING SYSTEM

(ABS) <4WD>

CONTENTS

GENERAL INFORMATION 2..................

SERVICE SPECIFICATIONS 3.................

LUBRICANTS Refer to GROUP 35A..........

SEALANT Refer to GROUP 35A..............

SPECIAL TOOLS 4...........................

TROUBLESHOOTING 4.......................

ON-VEHICLE SERVICE 26....................

Brake Pedal Check and Adjustment

Refer to GROUP 35A ..........................

Brake Booster Operating Test

Refer to GROUP 35A ..........................

Check Valve Operation Check

Refer to GROUP 35A ..........................

Bleeding Refer to GROUP 35A..................

Brake Fluid Level Sensor Check

Refer to GROUP 35A ..........................

Disc Brake Pad Check and

Replacement Refer to GROUP 35A..............Disc Brake Rotor Check Refer to GROUP 35A...

Brake Disc Thickness Check

Refer to GROUP 35A ..........................

Brake Disc Run-out Check and Correction

Refer to GROUP 35A ..........................

Wheel Speed Sensor Output Voltage Check

26 ............................................

Hydraulic Unit Check 28........................

Remedy for a Flat Battery 29...................

BRAKE PEDAL Refer to GROUP 35A........

MASTER CYLINDER AND BRAKE

BOOSTER Refer to GROUP 35A............

DISC BRAKE Refer to GROUP 35A..........

HYDRAULIC UNIT AND ABS-ECU 30.........

WHEEL SPEED SENSOR 33..................

G SENSORS AND STEERING WHEEL

SENSOR 35..................................

Page 1072 of 1449

ABS <4WD> -General Information35B-2

GENERAL INFORMATION

ABS has been adopted as optional equipment in

RS-IIto maintain directional stability and steering

performance during sudden braking or braking on

slippery road surfaces.

The ABS control method is a 4-sensor, 4-channel

method which provides independent control for all

wheels.

Following system for Lancer EVOLUTION-VII has

been modified from Lancer EVOLUTION-VI Tommi

Makinen Edition.DBy adding lateral G sensor, longitudinal G

sensor and steering wheel sensor, optimized

ABS control at the time of cornering.

DBy inputting parking brake switch signal to

ABS-ECU with pulling parking brake lever, ABS

control has been optimized.

DABS-ECU outputs ABS signal to 4WD-ECU.

DG sensor (lateral), steering wheel sensor and

parking brake switch have been added to the

diagnosis and service data.

DABS-ECU connector has been changed.

EBD CONTROL

In ABS, electronic control method is used by which

the rear wheel brake hydraulic pressure during

braking is regulated by rear wheel control solenoid

valves in accordance with the vehicle’s rate of

deceleration and the front and rear wheel slippage

which are calculated from the each wheel speed

sensor’s signal. EBD control is a control system

which provides a high level of control for both vehicle

braking force and vehicle stability. The system has

the following features:

DBecause the system provides the optimum rear

wheel braking force regardless of the vehicleladen condition and the condition of the road

surface, the system reduces the required pedal

depression force, particularly when the vehicle

is heavily laden or driving on road surfaces

with high frictional coefficients.

DBecause the duty placed on the front brakes

has been reduced, the increases in pad

temperature can be controlled to improve the

wear resistance characteristics of the pad,

during front brakes applying.

DControl valves such as the proportioning valve

are no longer required.

SPECIFICATIONS

ItemSpecifications

ABS control method4-sensor, 4-channel

No. of ABS rotor teethFront43

Rear43

ABS speed sensorTypeMagnet coil typep

Gap between sensor and rotor mm0.85

Page 1073 of 1449

ABS <4WD> -General Information/Service Specifications35B-3

CONSTRUCTION DIAGRAM

Stop lamp

switch*Parking brake

switch

Diagnosis

connector*

Wheel speed sensorWheel speed sensor Hydraulic unit

assembly*

(integrated with

the ABS-ECU) ABS warning lamp

Lateral G sensor

Longitudinal G sensor Steering

wheel

sensor*

NOTE

For R.H. drive vehicles, only the position indicated by the * is symmetrical.

SERVICE SPECIFICATIONS

ItemsStandard value

Wheel speed sensor internal resistance kΩ1.24 - 1.64

Wheel speed sensor insulation resistance kΩ100 or more

Lateral G sensor/Longitudinal G

sensoroutputvoltageV

On stationary vehicle2.4 - 2.6

sensor outputvoltageV

With front mark downward3.4 - 3.6

Page 1074 of 1449

ABS <4WD> -Special Tools/Troubleshooting35B-4

SPECIAL TOOLS

ToolNumberNameUse

MB991502MUT-IIsub

assemblyFor checking of ABS

(Diagnosis code display when using the

MUT-II)

MB991529Diagnosis code

check harnessFor checking of ABS

(Diagnosis code display when using the ABS

warning lamp)

MB991348Test harness setFor checking of G sensor

TROUBLESHOOTING

STANDARD FLOW OF DIAGNOSTIC TROUBLESHOOTING

Refer to GROUP 00 - How to Use Troubleshooting/Inspection Service Points.

NOTES WITH REGARD TO DIAGNOSIS

1. The phenomena listed in the following table are not abnormal.

PhenomenonExplanation of phenomenon

System check soundWhen starting the engine, a thudding sound can sometimes be heard coming from inside

the engine compartment, but this is because the system operation check is being

performed, and is not an abnormality.

ABS operation sound1. Sound of the motor inside the ABS hydraulic unit operation. (whine)

2. Sound is the generated along with vibration of the brake pedal. (scraping)

3. When ABS operates, sound is generated from the vehicle chassis due to repeated

brake application and release.

(Thump: suspension; squeak: tyres)

System check soundWhen depressing the brake pedal during driving, a shock is sometime felt.

2. For road surfaces such as snow-covered roads and gravel roads, the braking distance for vehicles

with ABS can sometimes be longer than that for other vehicles. Accordingly, advise the customer

to drive safely on such roads by lowering the vehicle speed and not being too overconfident.

3. Diagnosis detection condition can vary depending on the diagnosis code.

Make sure that checking requirements listed in the “Comment” are satisfied when checking the trouble

symptom again.

Page 1085 of 1449

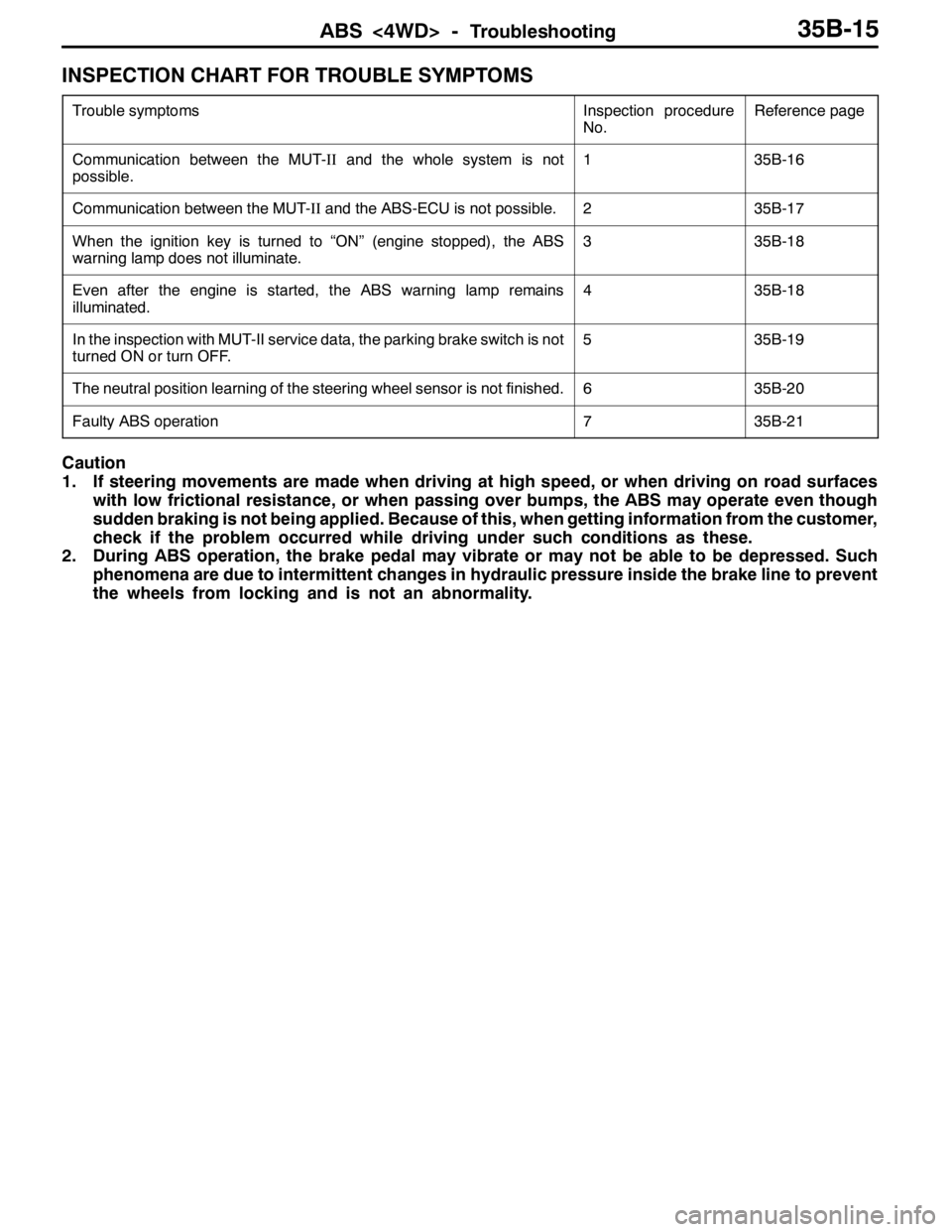

ABS <4WD> -Troubleshooting35B-15

INSPECTION CHART FOR TROUBLE SYMPTOMS

Trouble symptomsInspection procedure

No.Reference page

Communication between the MUT-IIand the whole system is not

possible.135B-16

Communication between the MUT-IIand the ABS-ECU is not possible.235B-17

When the ignition key is turned to “ON” (engine stopped), the ABS

warning lamp does not illuminate.335B-18

Even after the engine is started, the ABS warning lamp remains

illuminated.435B-18

In the inspection with MUT-II service data, the parking brake switch is not

turned ON or turn OFF.535B-19

The neutral position learning of the steering wheel sensor is not finished.635B-20

Faulty ABS operation735B-21

Caution

1. If steering movements are made when driving at high speed, or when driving on road surfaces

with low frictional resistance, or when passing over bumps, the ABS may operate even though

sudden braking is not being applied. Because of this, when getting information from the customer,

check if the problem occurred while driving under such conditions as these.

2. During ABS operation, the brake pedal may vibrate or may not be able to be depressed. Such

phenomena are due to intermittent changes in hydraulic pressure inside the brake line to prevent

the wheels from locking and is not an abnormality.

Page 1090 of 1449

ABS <4WD> -Troubleshooting35B-20

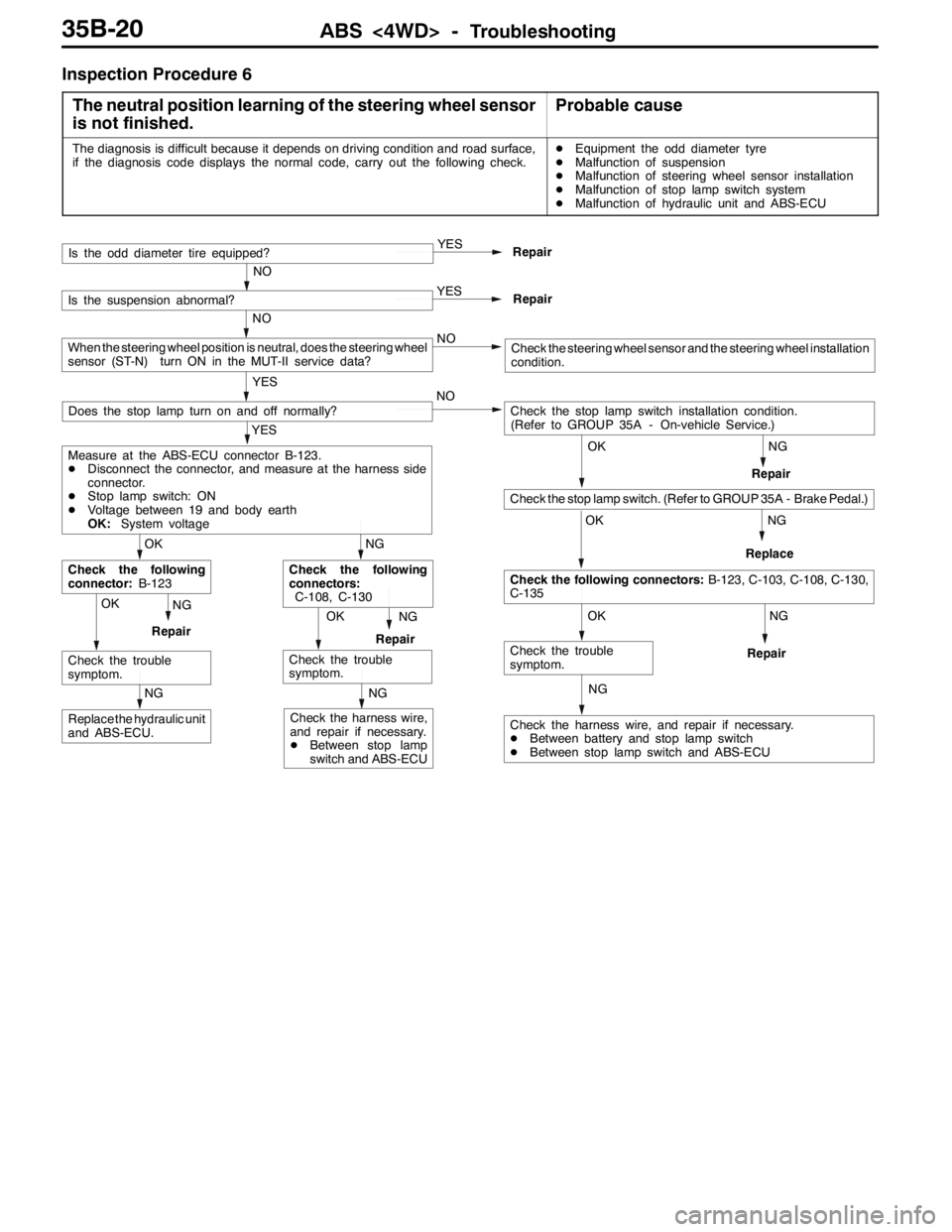

Inspection Procedure 6

The neutral position learning of the steering wheel sensor

is not finished.

Probable cause

The diagnosis is difficult because it depends on driving condition and road surface,

if the diagnosis code displays the normal code, carry out the following check.DEquipment the odd diameter tyre

DMalfunction of suspension

DMalfunction of steering wheel sensor installation

DMalfunction of stop lamp switch system

DMalfunction of hydraulic unit and ABS-ECU

NG

NG

NG

NG

Check the harness wire, and repair if necessary.

DBetween battery and stop lamp switch

DBetween stop lamp switch and ABS-ECU

OK

Check the trouble

symptom.

OK

Check the following connectors:B-123, C-103, C-108, C-130,

C-135

OK

Check the stop lamp switch. (Refer to GROUP 35A - Brake Pedal.)

Check the stop lamp switch installation condition.

(Refer to GROUP 35A - On-vehicle Service.) NO

Repair

OKNG

RepairOKNG

RepairReplace

NG

Replace the hydraulic unit

and ABS-ECU.

NG

Check the harness wire,

and repair if necessary.

DBetween stop lamp

switch and ABS-ECURepair

Check the trouble

symptom.

NG

Check the following

connectors:

C-108, C-130

Check the trouble

symptom.

OK

Check the following

connector:B-123

YES

Measure at the ABS-ECU connector B-123.

DDisconnect the connector, and measure at the harness side

connector.

DStop lamp switch: ON

DVoltage between 19 and body earth

OK:System voltage

Does the stop lamp turn on and off normally?

YES

Repair

NO

Is the odd diameter tire equipped?

YES

Repair

NO

Is the suspension abnormal?

NO

YES

When the steering wheel position is neutral, does the steering wheel

sensor (ST-N) turn ON in the MUT-II service data?Check the steering wheel sensor and the steering wheel installation

condition.

Page 1091 of 1449

ABS <4WD> -Troubleshooting35B-21

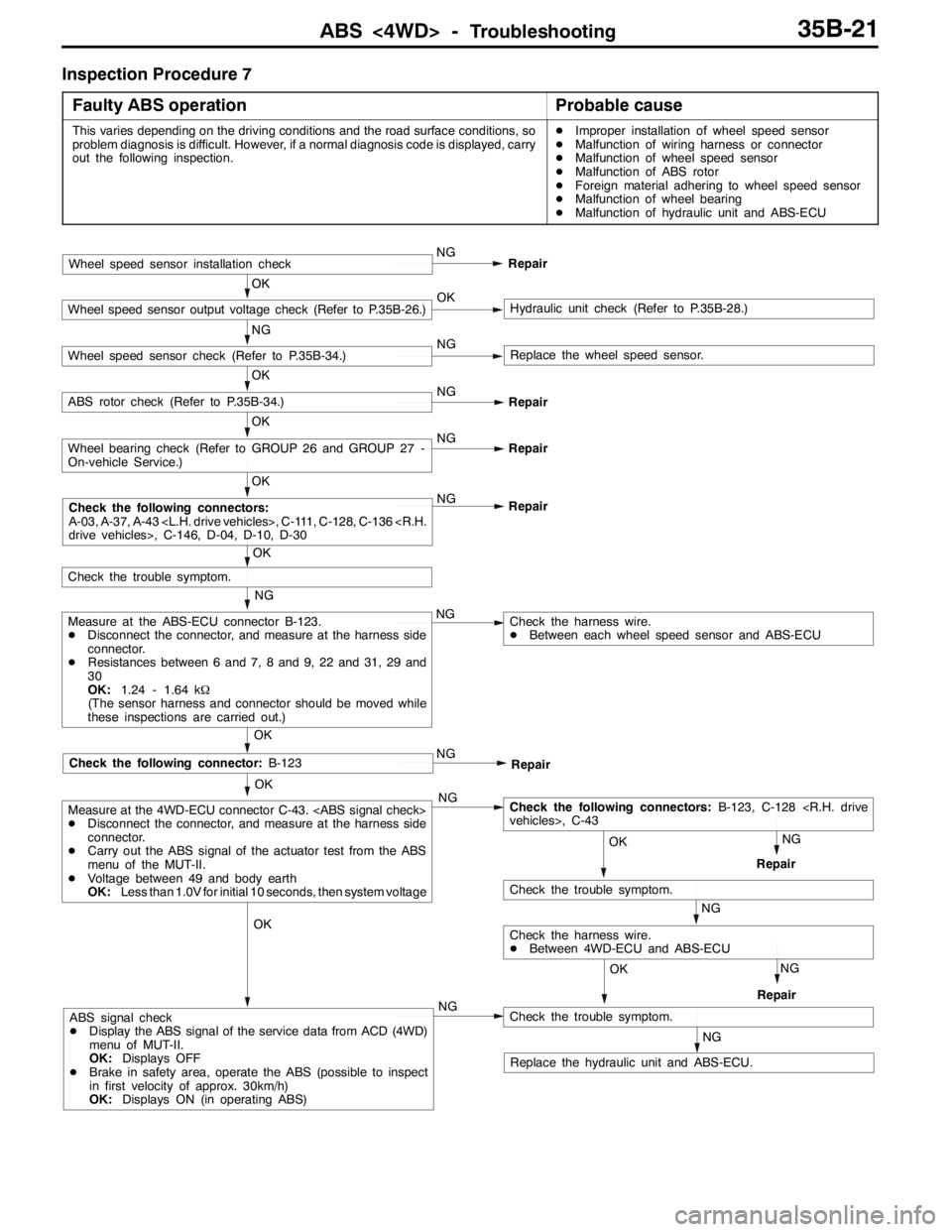

Inspection Procedure 7

Faulty ABS operation

Probable cause

This varies depending on the driving conditions and the road surface conditions, so

problem diagnosis is difficult. However, if a normal diagnosis code is displayed, carry

out the following inspection.DImproper installation of wheel speed sensor

DMalfunction of wiring harness or connector

DMalfunction of wheel speed sensor

DMalfunction of ABS rotor

DForeign material adhering to wheel speed sensor

DMalfunction of wheel bearing

DMalfunction of hydraulic unit and ABS-ECU

OK

OK

Check the following connector:B-123

NG

Measure at the ABS-ECU connector B-123.

DDisconnect the connector, and measure at the harness side

connector.

DResistances between 6 and 7, 8 and 9, 22 and 31, 29 and

30

OK:1.24 - 1.64 kΩ

(The sensor harness and connector should be moved while

these inspections are carried out.)NG

OK

Check the trouble symptom.

OK

NG

Repair

OK

Wheel bearing check (Refer to GROUP 26 and GROUP 27 -

On-vehicle Service.)NG

Repair

OK

ABS rotor check (Refer to P.35B-34.)NG

Repair

NG

Wheel speed sensor check (Refer to P.35B-34.)NGReplace the wheel speed sensor.

OK

Wheel speed sensor output voltage check (Refer to P.35B-26.)OKHydraulic unit check (Refer to P.35B-28.)

Wheel speed sensor installation checkNG

Repair

Check the harness wire.

DBetween each wheel speed sensor and ABS-ECU

NG

Repair

NG

NG

RepairOK

Check the following connectors:B-123, C-128

NG

Check the trouble symptom.

RepairNG

OK

Check the harness wire.

DBetween 4WD-ECU and ABS-ECU OK

Measure at the 4WD-ECU connector C-43.

DDisconnect the connector, and measure at the harness side

connector.

DCarry out the ABS signal of the actuator test from the ABS

menu of the MUT-II.

DVoltage between 49 and body earth

OK:Less than 1.0V for initial 10 seconds, then system voltage

NGABS signal check

DDisplay the ABS signal of the service data from ACD (4WD)

menu of MUT-II.

OK:Displays OFF

DBrake in safety area, operate the ABS (possible to inspect

in first velocity of approx. 30km/h)

OK:Displays ON (in operating ABS)

NG

Check the trouble symptom.

Replace the hydraulic unit and ABS-ECU.

Check the following connectors:

A-03, A-37, A-43

Page 1092 of 1449

ABS <4WD> -Troubleshooting35B-22

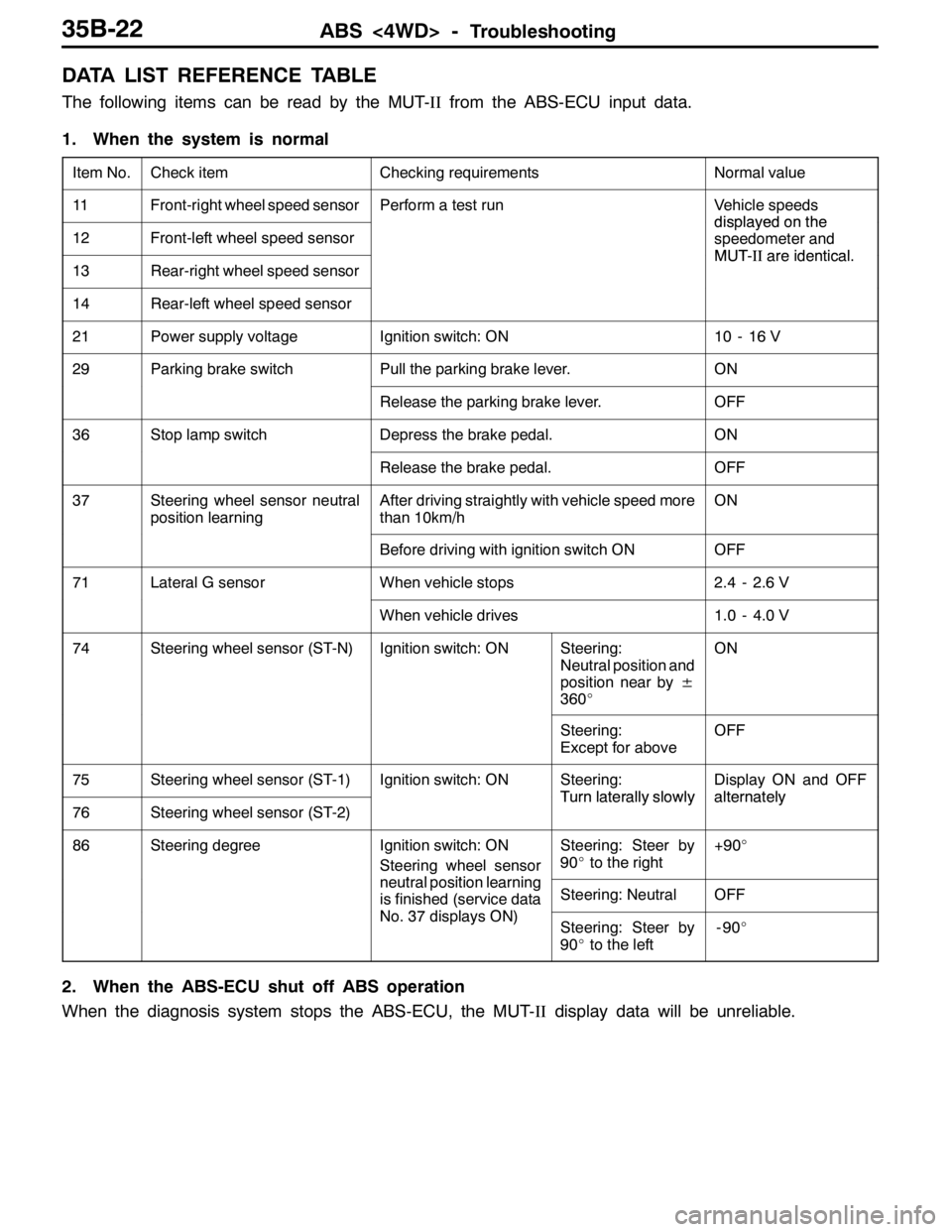

DATA LIST REFERENCE TABLE

The following items can be read by the MUT-IIfrom the ABS-ECU input data.

1. When the system is normal

Item No.Check itemChecking requirementsNormal value

11Front-right wheel speed sensorPerform a test runVehicle speeds

displayedonthe

12Front-left wheel speed sensor

displayedonthe

speedometer and

MUTIIareidentical13Rear-right wheel speed sensorMUT-IIareidentical.

14Rear-left wheel speed sensor

21Power supply voltageIgnition switch: ON10 - 16 V

29Parking brake switchPull the parking brake lever.ON

Release the parking brake lever.OFF

36Stop lamp switchDepress the brake pedal.ON

Release the brake pedal.OFF

37Steering wheel sensor neutral

position learningAfter driving straightly with vehicle speed more

than 10km/hON

Before driving with ignition switch ONOFF

71Lateral G sensorWhen vehicle stops2.4 - 2.6 V

When vehicle drives1.0 - 4.0 V

74Steering wheel sensor (ST-N)Ignition switch: ONSteering:

Neutral position and

position near by±

360_ON

Steering:

Except for aboveOFF

75Steering wheel sensor (ST-1)Ignition switch: ONSteering:

Turnlaterallyslowly

Display ON and OFF

alternately

76Steering wheel sensor (ST-2)

Turnlaterallyslowlyalternately

86Steering degreeIgnition switch: ON

Steering wheel sensor

tlitili

Steering: Steer by

90_to the right+90_

g

neutral position learning

is finished (service data

N37di lON)

Steering: NeutralOFF(

No. 37 displays ON)Steering: Steer by

90_to the left-90_

2. When the ABS-ECU shut off ABS operation

When the diagnosis system stops the ABS-ECU, the MUT-IIdisplay data will be unreliable.

Page 1094 of 1449

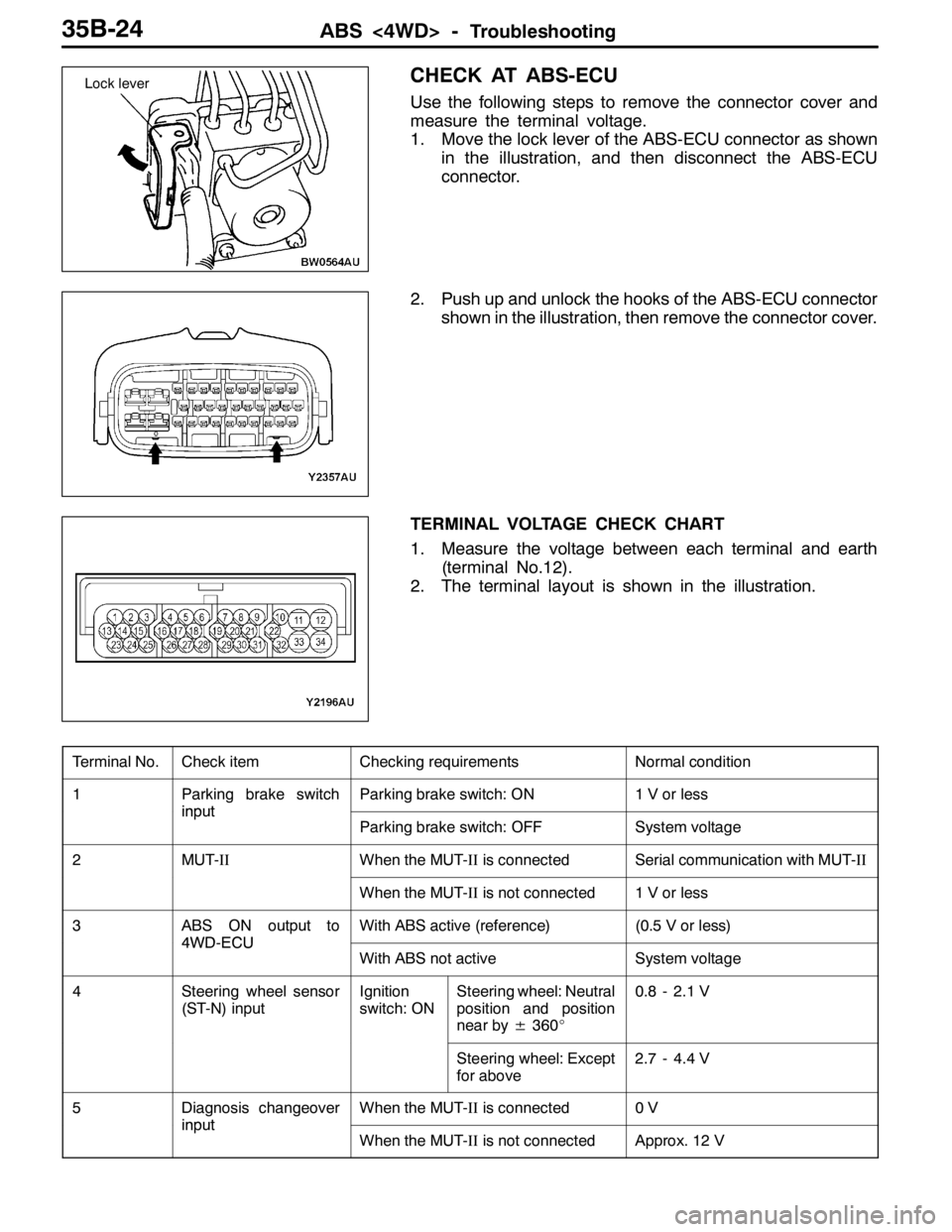

ABS <4WD> -Troubleshooting35B-24

CHECK AT ABS-ECU

Use the following steps to remove the connector cover and

measure the terminal voltage.

1. Move the lock lever of the ABS-ECU connector as shown

in the illustration, and then disconnect the ABS-ECU

connector.

2. Push up and unlock the hooks of the ABS-ECU connector

shown in the illustration, then remove the connector cover.

TERMINAL VOLTAGE CHECK CHART

1. Measure the voltage between each terminal and earth

(terminal No.12).

2. The terminal layout is shown in the illustration.

Terminal No.Check itemChecking requirementsNormal condition

1Parking brake switch

input

Parking brake switch: ON1 V or less

input

Parking brake switch: OFFSystem voltage

2MUT-IIWhen the MUT-IIis connectedSerial communication with MUT-II

When the MUT-IIis not connected1 V or less

3ABS ON output to

4WD ECU

With ABS active (reference)(0.5 V or less)

4WD-ECU

With ABS not activeSystem voltage

4Steering wheel sensor

(ST-N) inputIgnition

switch: ONSteering wheel: Neutral

position and position

near by±360_0.8 - 2.1 V

Steering wheel: Except

for above2.7 - 4.4 V

5Diagnosis changeover

input

When the MUT-IIis connected0V

input

When the MUT-IIis not connectedApprox. 12 V

Lock lever

Page 1096 of 1449

ABS <4WD> -Troubleshooting/On-vehicle Service35B-26

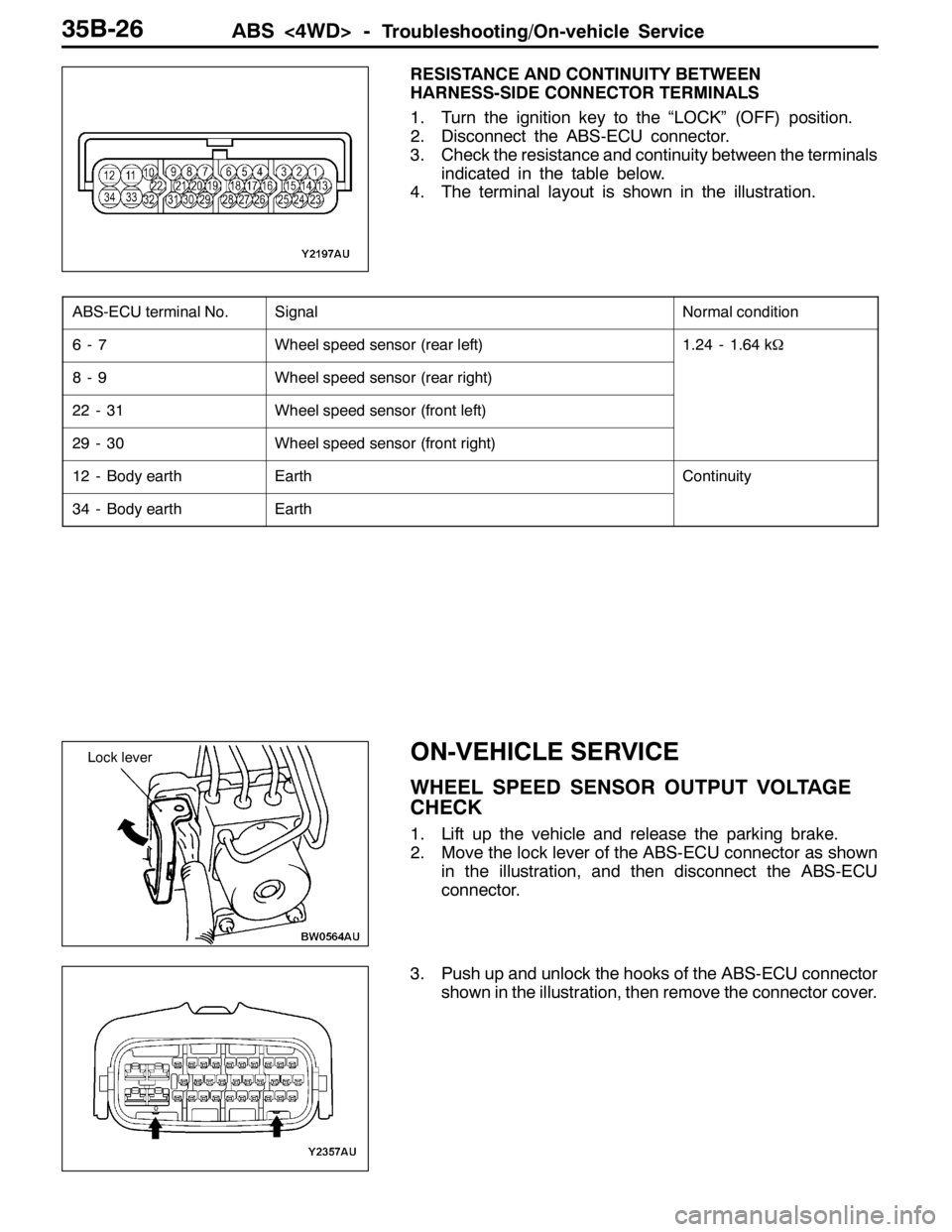

RESISTANCE AND CONTINUITY BETWEEN

HARNESS-SIDE CONNECTOR TERMINALS

1. Turn the ignition key to the “LOCK” (OFF) position.

2. Disconnect the ABS-ECU connector.

3. Check the resistance and continuity between the terminals

indicated in the table below.

4. The terminal layout is shown in the illustration.

ABS-ECU terminal No.SignalNormal condition

6-7Wheel speed sensor (rear left)1.24 - 1.64 kΩ

8-9Wheel speed sensor (rear right)

22 - 31Wheel speed sensor (front left)

29 - 30Wheel speed sensor (front right)

12 - Body earthEarthContinuity

34 - Body earthEarth

ON-VEHICLE SERVICE

WHEEL SPEED SENSOR OUTPUT VOLTAGE

CHECK

1. Lift up the vehicle and release the parking brake.

2. Move the lock lever of the ABS-ECU connector as shown

in the illustration, and then disconnect the ABS-ECU

connector.

3. Push up and unlock the hooks of the ABS-ECU connector

shown in the illustration, then remove the connector cover.

Lock lever