display MITSUBISHI LANCER EVOLUTION 2007 Service Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 1091 of 1449

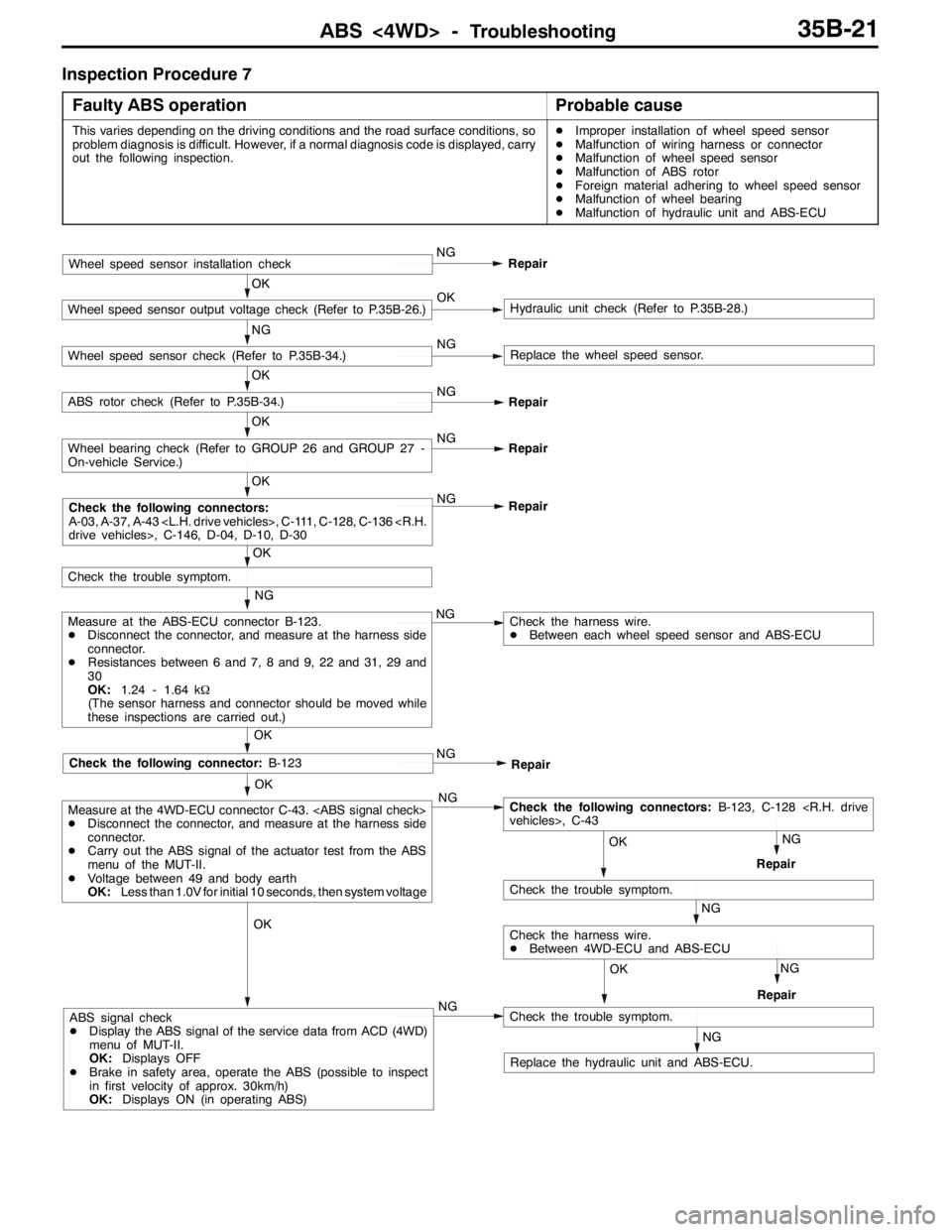

ABS <4WD> -Troubleshooting35B-21

Inspection Procedure 7

Faulty ABS operation

Probable cause

This varies depending on the driving conditions and the road surface conditions, so

problem diagnosis is difficult. However, if a normal diagnosis code is displayed, carry

out the following inspection.DImproper installation of wheel speed sensor

DMalfunction of wiring harness or connector

DMalfunction of wheel speed sensor

DMalfunction of ABS rotor

DForeign material adhering to wheel speed sensor

DMalfunction of wheel bearing

DMalfunction of hydraulic unit and ABS-ECU

OK

OK

Check the following connector:B-123

NG

Measure at the ABS-ECU connector B-123.

DDisconnect the connector, and measure at the harness side

connector.

DResistances between 6 and 7, 8 and 9, 22 and 31, 29 and

30

OK:1.24 - 1.64 kΩ

(The sensor harness and connector should be moved while

these inspections are carried out.)NG

OK

Check the trouble symptom.

OK

NG

Repair

OK

Wheel bearing check (Refer to GROUP 26 and GROUP 27 -

On-vehicle Service.)NG

Repair

OK

ABS rotor check (Refer to P.35B-34.)NG

Repair

NG

Wheel speed sensor check (Refer to P.35B-34.)NGReplace the wheel speed sensor.

OK

Wheel speed sensor output voltage check (Refer to P.35B-26.)OKHydraulic unit check (Refer to P.35B-28.)

Wheel speed sensor installation checkNG

Repair

Check the harness wire.

DBetween each wheel speed sensor and ABS-ECU

NG

Repair

NG

NG

RepairOK

Check the following connectors:B-123, C-128

NG

Check the trouble symptom.

RepairNG

OK

Check the harness wire.

DBetween 4WD-ECU and ABS-ECU OK

Measure at the 4WD-ECU connector C-43.

DDisconnect the connector, and measure at the harness side

connector.

DCarry out the ABS signal of the actuator test from the ABS

menu of the MUT-II.

DVoltage between 49 and body earth

OK:Less than 1.0V for initial 10 seconds, then system voltage

NGABS signal check

DDisplay the ABS signal of the service data from ACD (4WD)

menu of MUT-II.

OK:Displays OFF

DBrake in safety area, operate the ABS (possible to inspect

in first velocity of approx. 30km/h)

OK:Displays ON (in operating ABS)

NG

Check the trouble symptom.

Replace the hydraulic unit and ABS-ECU.

Check the following connectors:

A-03, A-37, A-43

Page 1092 of 1449

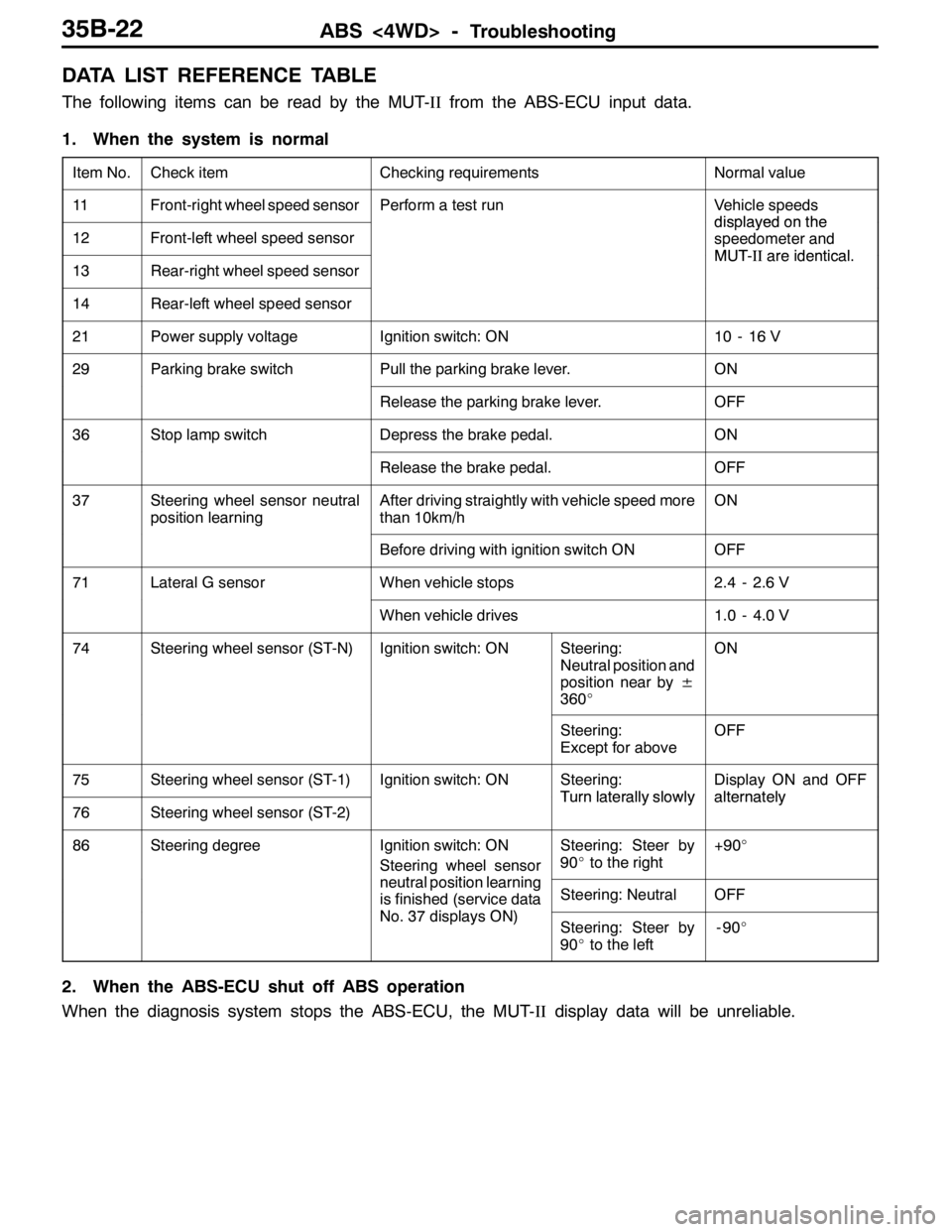

ABS <4WD> -Troubleshooting35B-22

DATA LIST REFERENCE TABLE

The following items can be read by the MUT-IIfrom the ABS-ECU input data.

1. When the system is normal

Item No.Check itemChecking requirementsNormal value

11Front-right wheel speed sensorPerform a test runVehicle speeds

displayedonthe

12Front-left wheel speed sensor

displayedonthe

speedometer and

MUTIIareidentical13Rear-right wheel speed sensorMUT-IIareidentical.

14Rear-left wheel speed sensor

21Power supply voltageIgnition switch: ON10 - 16 V

29Parking brake switchPull the parking brake lever.ON

Release the parking brake lever.OFF

36Stop lamp switchDepress the brake pedal.ON

Release the brake pedal.OFF

37Steering wheel sensor neutral

position learningAfter driving straightly with vehicle speed more

than 10km/hON

Before driving with ignition switch ONOFF

71Lateral G sensorWhen vehicle stops2.4 - 2.6 V

When vehicle drives1.0 - 4.0 V

74Steering wheel sensor (ST-N)Ignition switch: ONSteering:

Neutral position and

position near by±

360_ON

Steering:

Except for aboveOFF

75Steering wheel sensor (ST-1)Ignition switch: ONSteering:

Turnlaterallyslowly

Display ON and OFF

alternately

76Steering wheel sensor (ST-2)

Turnlaterallyslowlyalternately

86Steering degreeIgnition switch: ON

Steering wheel sensor

tlitili

Steering: Steer by

90_to the right+90_

g

neutral position learning

is finished (service data

N37di lON)

Steering: NeutralOFF(

No. 37 displays ON)Steering: Steer by

90_to the left-90_

2. When the ABS-ECU shut off ABS operation

When the diagnosis system stops the ABS-ECU, the MUT-IIdisplay data will be unreliable.

Page 1099 of 1449

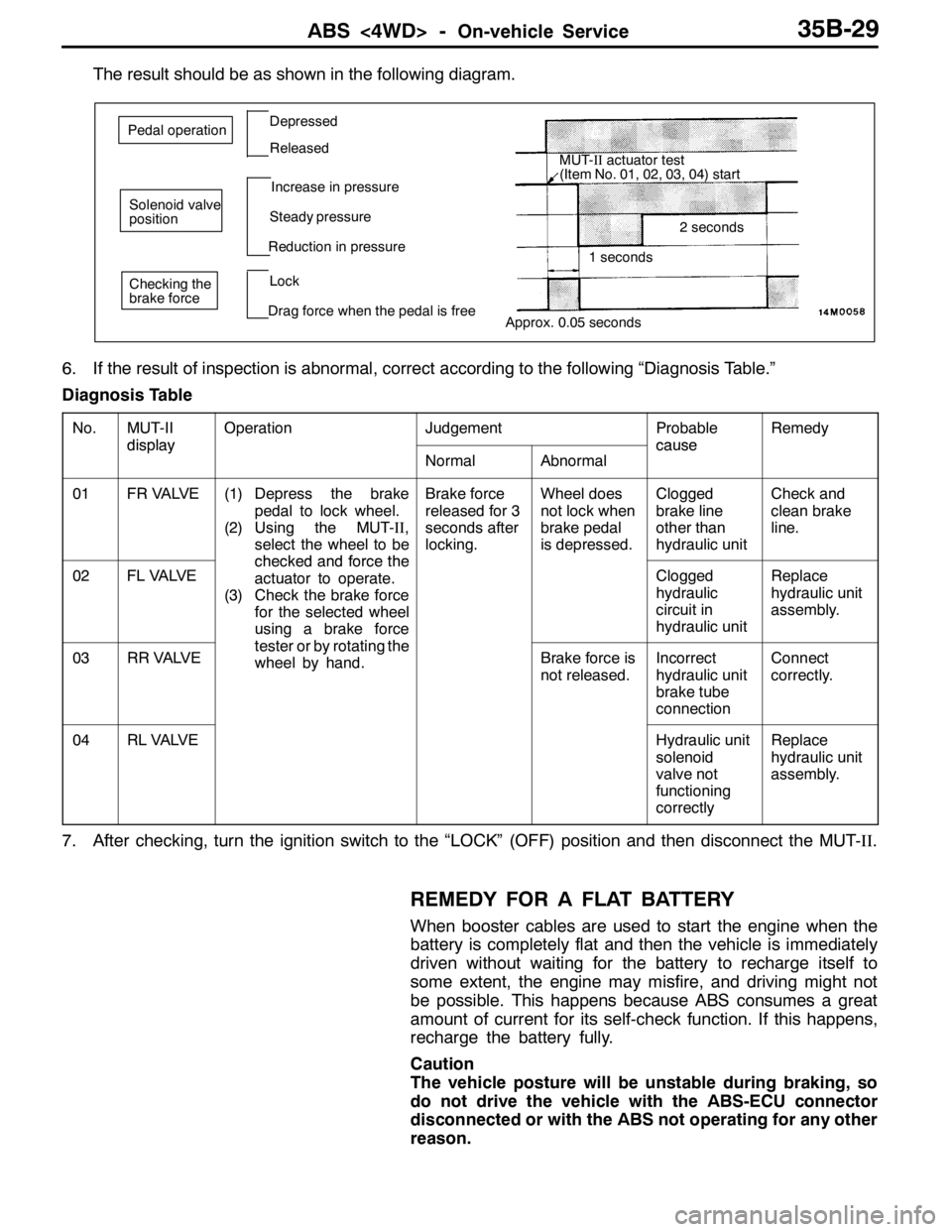

ABS <4WD> -On-vehicle Service35B-29

The result should be as shown in the following diagram.

Approx. 0.05 seconds

Pedal operationDepressed

Released

Solenoid valve

positionIncrease in pressure

Steady pressure

Reduction in pressure

Checking the

brake forceLock

Drag force when the pedal is freeMUT-IIactuator test

(Item No. 01, 02, 03, 04) start

2 seconds

1 seconds

6. If the result of inspection is abnormal, correct according to the following “Diagnosis Table.”

Diagnosis Table

No.MUT-II

display

OperationJudgementProbable

cause

Remedy

display

NormalAbnormal

cause

01FR VALVE(1) Depress the brake

pedal to lock wheel.

(2) Using the MUT-II,

select the wheel to be

checkedandforcethe

Brake force

released for 3

seconds after

locking.Wheel does

not lock when

brake pedal

is depressed.Clogged

brake line

other than

hydraulic unitCheck and

clean brake

line.

02FL VALVEchecked and force the

actuator to operate.

(3) Check the brake force

for the selected wheel

using a brake force

ttbttith

Clogged

hydraulic

circuit in

hydraulic unitReplace

hydraulic unit

assembly.

03RR VALVE

g

tester or by rotating the

wheel by hand.Brake force is

not released.Incorrect

hydraulic unit

brake tube

connectionConnect

correctly.

04RL VALVEHydraulic unit

solenoid

valve not

functioning

correctlyReplace

hydraulic unit

assembly.

7. After checking, turn the ignition switch to the “LOCK” (OFF) position and then disconnect the MUT-II.

REMEDY FOR A FLAT BATTERY

When booster cables are used to start the engine when the

battery is completely flat and then the vehicle is immediately

driven without waiting for the battery to recharge itself to

some extent, the engine may misfire, and driving might not

be possible. This happens because ABS consumes a great

amount of current for its self-check function. If this happens,

recharge the battery fully.

Caution

The vehicle posture will be unstable during braking, so

do not drive the vehicle with the ABS-ECU connector

disconnected or with the ABS not operating for any other

reason.

Page 1254 of 1449

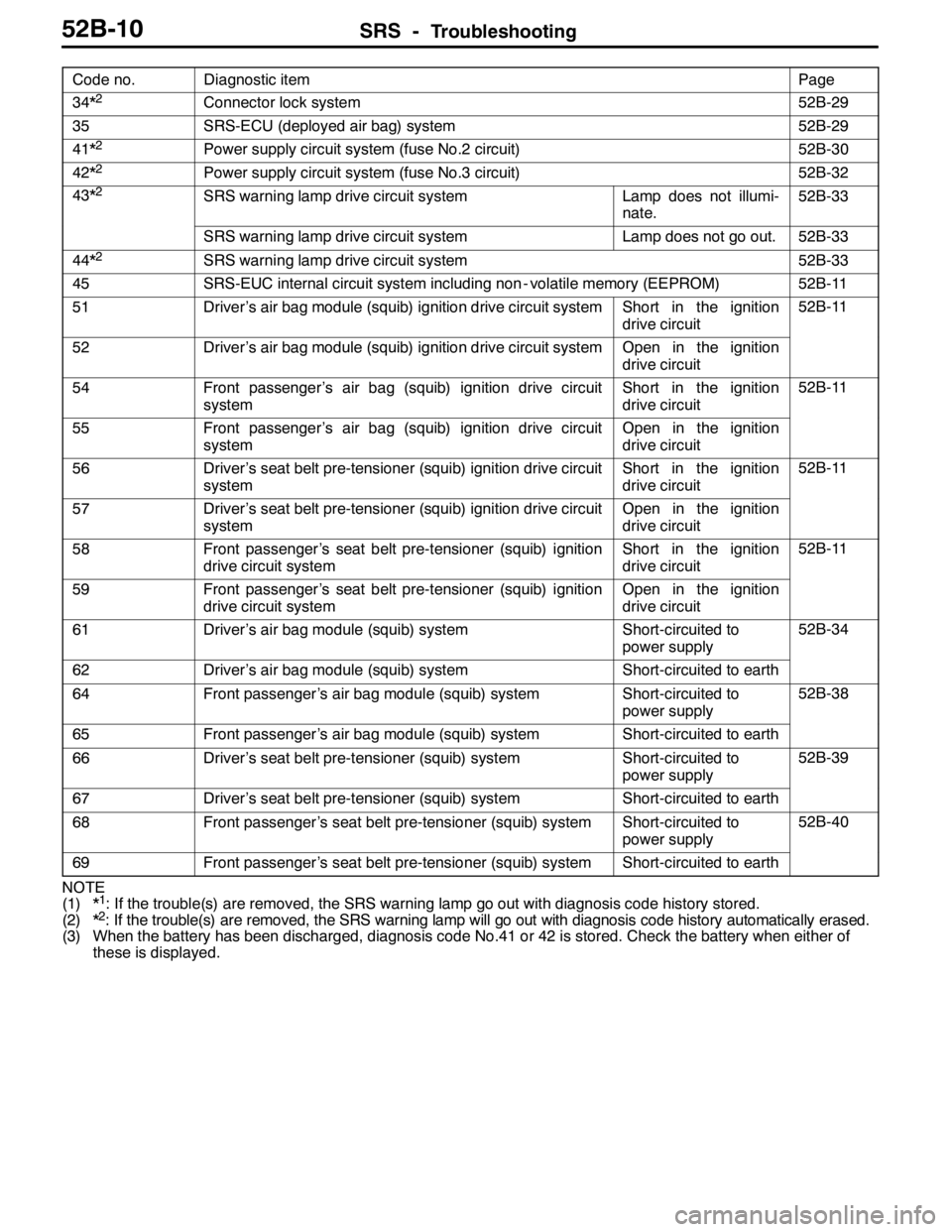

SRS -Troubleshooting52B-10

Code no.Page Diagnostic item

34*2Connector lock system52B-29

35SRS-ECU (deployed air bag) system52B-29

41*2Power supply circuit system (fuse No.2 circuit)52B-30

42*2Power supply circuit system (fuse No.3 circuit)52B-32

43*2SRS warning lamp drive circuit systemLamp does not illumi-

nate.52B-33

SRS warning lamp drive circuit systemLamp does not go out.52B-33

44*2SRS warning lamp drive circuit system52B-33

45SRS-EUC internal circuit system including non - volatile memory (EEPROM)52B-11

51Driver’s air bag module (squib) ignition drive circuit systemShort in the ignition

drive circuit52B-11

52Driver’s air bag module (squib) ignition drive circuit systemOpen in the ignition

drive circuit

54Front passenger’s air bag (squib) ignition drive circuit

systemShort in the ignition

drive circuit52B-11

55Front passenger’s air bag (squib) ignition drive circuit

systemOpen in the ignition

drive circuit

56Driver’s seat belt pre-tensioner (squib) ignition drive circuit

systemShort in the ignition

drive circuit52B-11

57Driver’s seat belt pre-tensioner (squib) ignition drive circuit

systemOpen in the ignition

drive circuit

58Front passenger’s seat belt pre-tensioner (squib) ignition

drive circuit systemShort in the ignition

drive circuit52B-11

59Front passenger’s seat belt pre-tensioner (squib) ignition

drive circuit systemOpen in the ignition

drive circuit

61Driver’s air bag module (squib) systemShort-circuited to

power supply52B-34

62Driver’s air bag module (squib) systemShort-circuited to earth

64Front passenger’s air bag module (squib) systemShort-circuited to

power supply52B-38

65Front passenger’s air bag module (squib) systemShort-circuited to earth

66Driver’s seat belt pre-tensioner (squib) systemShort-circuited to

power supply52B-39

67Driver’s seat belt pre-tensioner (squib) systemShort-circuited to earth

68Front passenger’s seat belt pre-tensioner (squib) systemShort-circuited to

power supply52B-40

69Front passenger’s seat belt pre-tensioner (squib) systemShort-circuited to earth

NOTE

(1) *1: If the trouble(s) are removed, the SRS warning lamp go out with diagnosis code history stored.

(2) *2: If the trouble(s) are removed, the SRS warning lamp will go out with diagnosis code history automatically erased.

(3) When the battery has been discharged, diagnosis code No.41 or 42 is stored. Check the battery when either of

these is displayed.

Page 1273 of 1449

SRS -Troubleshooting52B-29

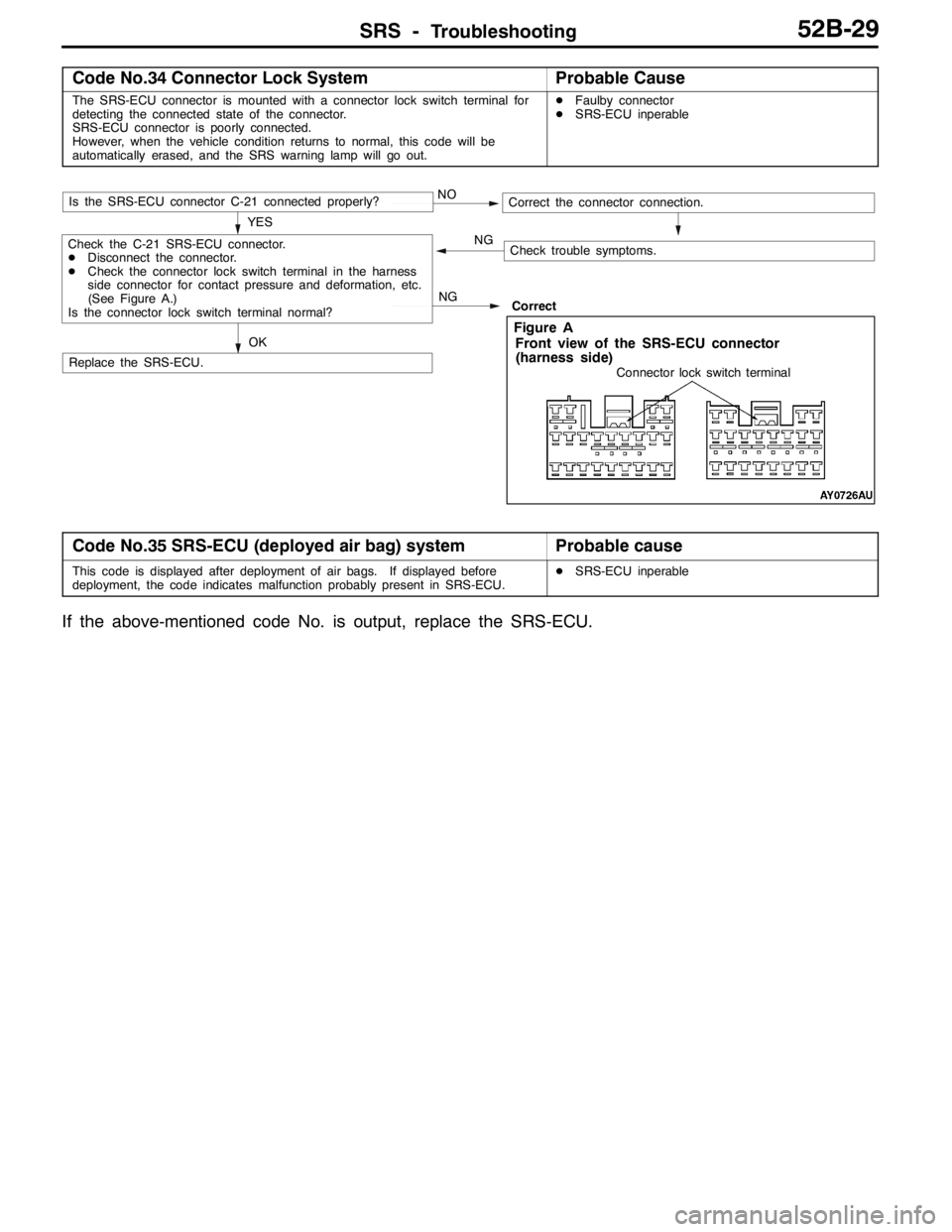

Code No.34 Connector Lock SystemProbable Cause

The SRS-ECU connector is mounted with a connector lock switch terminal for

detecting the connected state of the connector.

SRS-ECU connector is poorly connected.

However, when the vehicle condition returns to normal, this code will be

automatically erased, and the SRS warning lamp will go out.DFaulby connector

DSRS-ECU inperable

NOIs the SRS-ECU connector C-21 connected properly?

Replace the SRS-ECU.Correct YES

OK

Correct the connector connection.

Check trouble symptoms. NG

NGCheck the C-21 SRS-ECU connector.

DDisconnect the connector.

DCheck the connector lock switch terminal in the harness

side connector for contact pressure and deformation, etc.

(See Figure A.)

Is the connector lock switch terminal normal?

Connector lock switch terminal

Front view of the SRS-ECU connector

(harness side)

Figure A

Code No.35 SRS-ECU (deployed air bag) systemProbable cause

This code is displayed after deployment of air bags. If displayed before

deployment, the code indicates malfunction probably present in SRS-ECU.DSRS-ECU inperable

If the above-mentioned code No. is output, replace the SRS-ECU.

Page 1289 of 1449

SRS - Post-collision Diagnosis52B-45

POST-COLLISION DIAGNOSIS

Whether or not the air bags have deployed, check and service

the vehicle after collision as follows:

SRS-ECU MEMORY CHECK

1. Connect the MUT-IIto the diagnosis connector. (Refer

to GROUP 00 – How to Use Troubleshooting/Inspection

Service Points.)

Caution

Refer to that the ignition switch is LOCK(OFF) when

connecting or disconnecting MUT-II.

2. Read (and write down) all displayed diagnosis codes.

(Refer to P.52B-9.)

NOTE

If battery power supply has been shut down by the

collision, the MUT-IIcannot communicate with the

SRS-ECU. Check and, repair if necessary, the instrument

panel wiring harness before the next job.

3. Use the the MUT-IIto read the data list (how long trouble(s)

have continued and how often memory have been

erased).

Data list

NoService Data ItemApplicability

92Number indication how often the memory is cleared.Maximum time to be stored: 250

93How long problem have lasted (How long it takes

from the occurrence of the problem till the first air bag

squib igniting signal)Maximum time to be stored: 9999 minutes

(approximately 7 days)

94How long problem(s) have lasted (How long it takes

from the first air bag squib igniting signal till now.)

4. Erase the diagnosis codes and after waiting 5 seconds

or more read (and write down) all displayed diagnosis

codes. (Refer to P.52B-9.)

Page 1366 of 1449

SWS -Special Tools/Troubleshooting54B-2

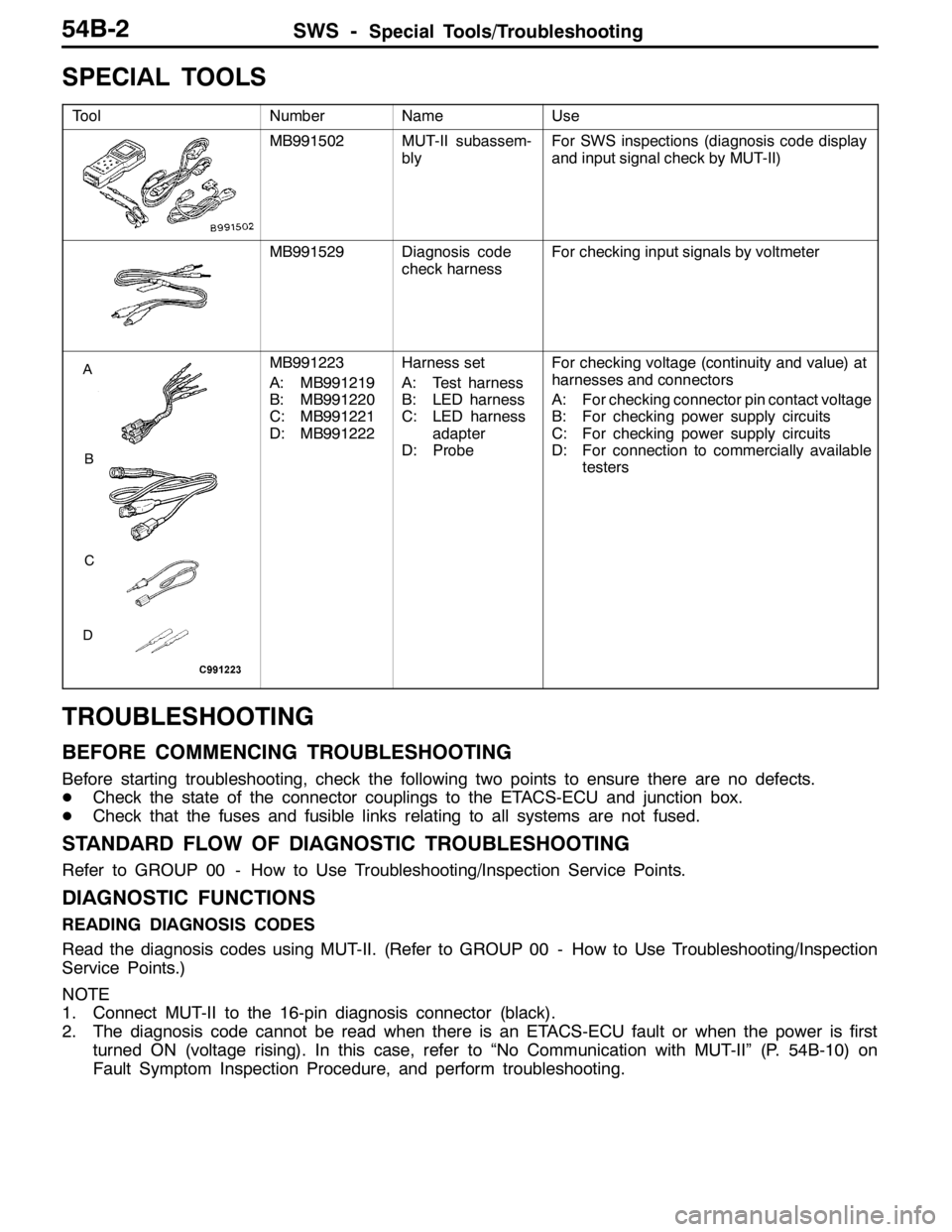

SPECIAL TOOLS

ToolNumberNameUse

MB991502MUT-II subassem-

blyFor SWS inspections (diagnosis code display

and input signal check by MUT-II)

MB991529Diagnosis code

check harnessFor checking input signals by voltmeter

A

B

C

D

MB991223

A: MB991219

B: MB991220

C: MB991221

D: MB991222Harness set

A: Test harness

B: LED harness

C: LED harness

adapter

D: ProbeFor checking voltage (continuity and value) at

harnesses and connectors

A: For checking connector pin contact voltage

B: For checking power supply circuits

C: For checking power supply circuits

D: For connection to commercially available

testers

TROUBLESHOOTING

BEFORE COMMENCING TROUBLESHOOTING

Before starting troubleshooting, check the following two points to ensure there are no defects.

DCheck the state of the connector couplings to the ETACS-ECU and junction box.

DCheck that the fuses and fusible links relating to all systems are not fused.

STANDARD FLOW OF DIAGNOSTIC TROUBLESHOOTING

Refer to GROUP 00 - How to Use Troubleshooting/Inspection Service Points.

DIAGNOSTIC FUNCTIONS

READING DIAGNOSIS CODES

Read the diagnosis codes using MUT-II. (Refer to GROUP 00 - How to Use Troubleshooting/Inspection

Service Points.)

NOTE

1. Connect MUT-II to the 16-pin diagnosis connector (black).

2. The diagnosis code cannot be read when there is an ETACS-ECU fault or when the power is first

turned ON (voltage rising). In this case, refer to “No Communication with MUT-II” (P. 54B-10) on

Fault Symptom Inspection Procedure, and perform troubleshooting.