length MITSUBISHI LANCER EVOLUTION 2007 Service Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 1157 of 1449

BODY -Window Glass42-9

WINDOW GLASS

ADHESIVE

ItemsSpecified adhesive

Windshield3M ATD Part No. 8609 Super Fast Urethane Auto Glass Sealant or

il tRear window glass

p

equivalent

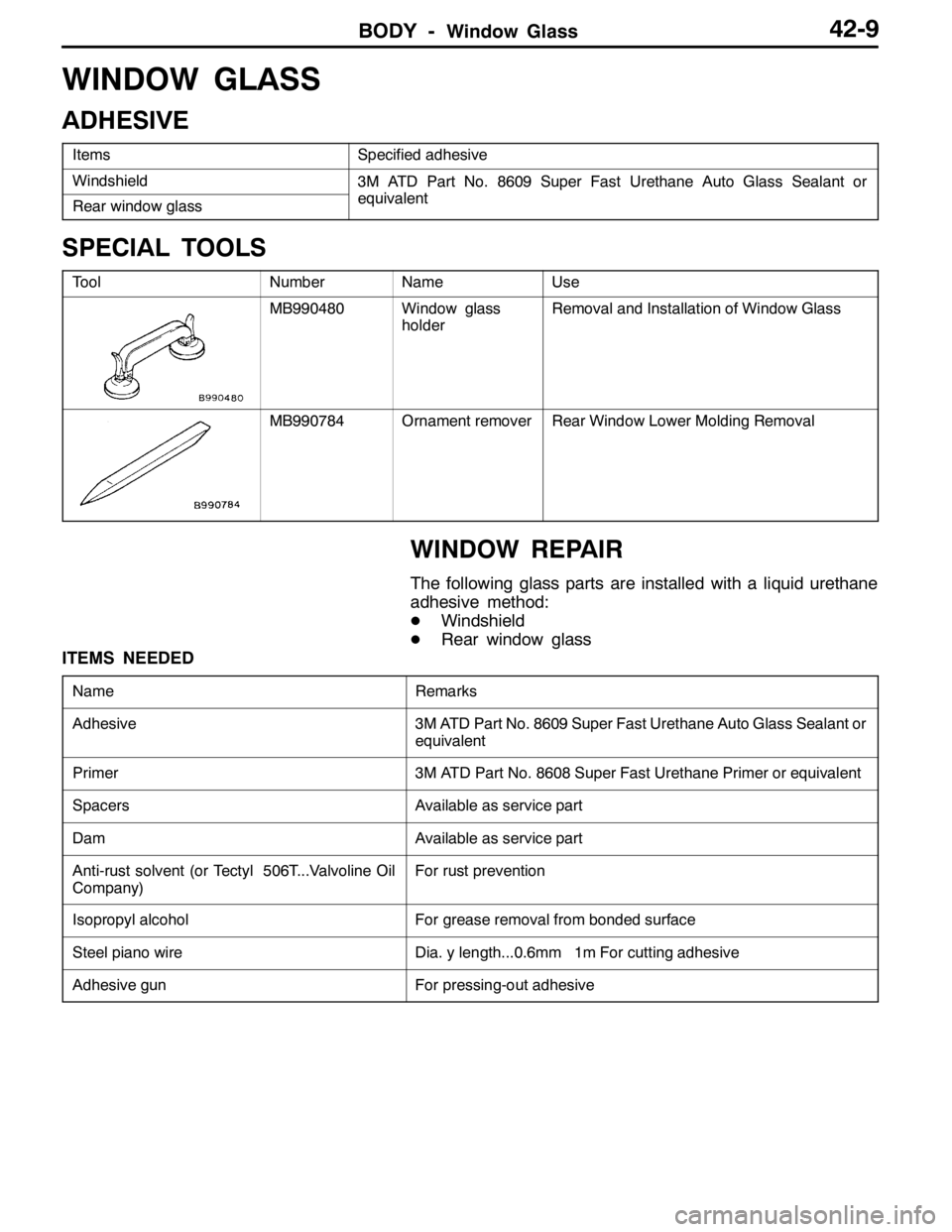

SPECIAL TOOLS

ToolNumberNameUse

MB990480Window glass

holderRemoval and Installation of Window Glass

MB990784Ornament removerRear Window Lower Molding Removal

WINDOW REPAIR

The following glass parts are installed with a liquid urethane

adhesive method:

DWindshield

DRear window glass

ITEMS NEEDED

NameRemarks

Adhesive3M ATD Part No. 8609 Super Fast Urethane Auto Glass Sealant or

equivalent

Primer3M ATD Part No. 8608 Super Fast Urethane Primer or equivalent

SpacersAvailable as service part

DamAvailable as service part

Anti-rust solvent (or Tectyl 506T...Valvoline Oil

Company)For rust prevention

Isopropyl alcoholFor grease removal from bonded surface

Steel piano wireDia. y length...0.6mm 1m For cutting adhesive

Adhesive gunFor pressing-out adhesive

Page 1189 of 1449

BODY -Trunk lid42-41

TRUNK LID

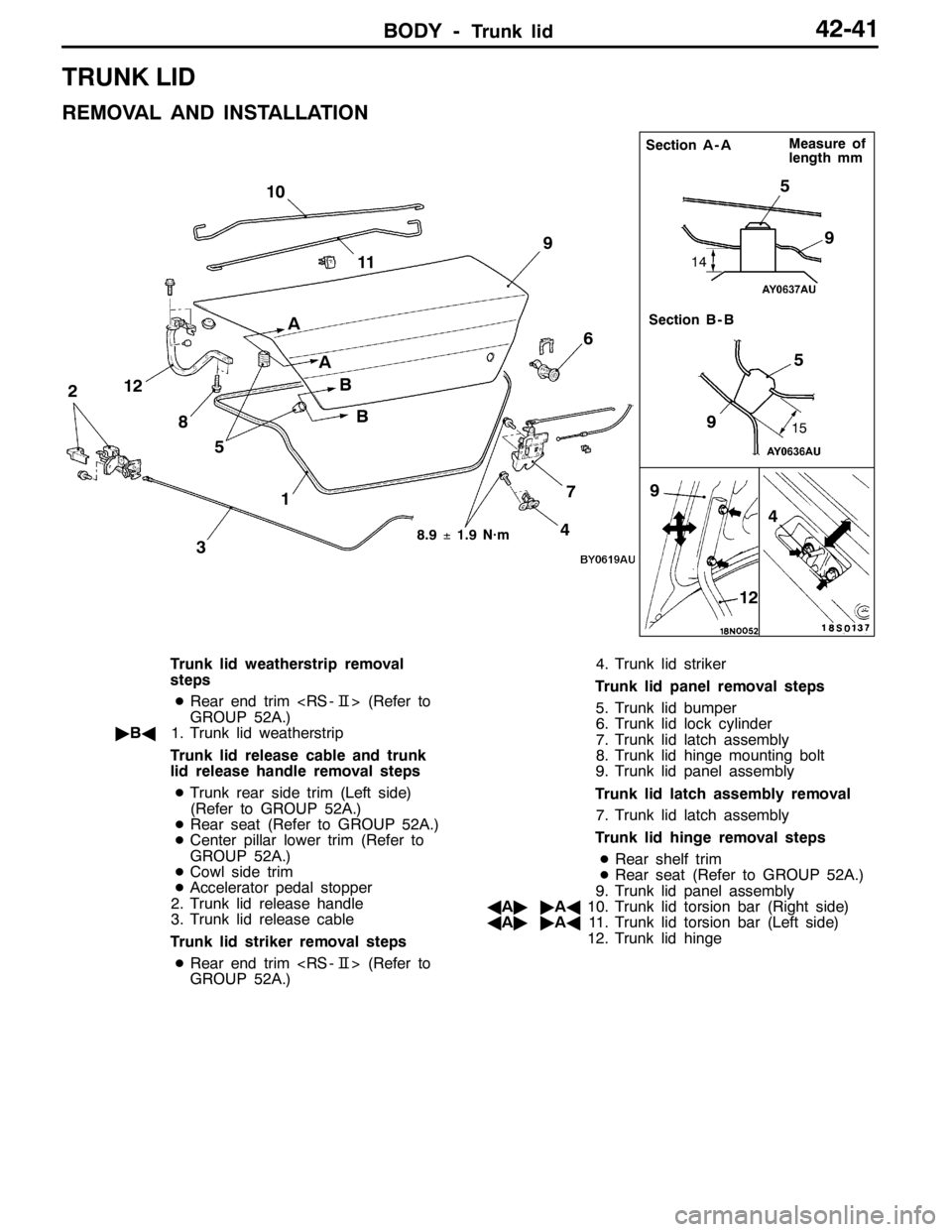

REMOVAL AND INSTALLATION

2

34 56

7 89 10

111

12A

A

B

B5 5

99

14Measure of

length mm

15

4 9

12

8.9±1.9 N·m

Section A - A

Section B - B

Trunk lid weatherstrip removal

steps

DRear end trim

GROUP 52A.)

"BA1. Trunk lid weatherstrip

Trunk lid release cable and trunk

lid release handle removal steps

DTrunk rear side trim (Left side)

(Refer to GROUP 52A.)

DRear seat (Refer to GROUP 52A.)

DCenter pillar lower trim (Refer to

GROUP 52A.)

DCowl side trim

DAccelerator pedal stopper

2. Trunk lid release handle

3. Trunk lid release cable

Trunk lid striker removal steps

DRear end trim

GROUP 52A.)4. Trunk lid striker

Trunk lid panel removal steps

5. Trunk lid bumper

6. Trunk lid lock cylinder

7. Trunk lid latch assembly

8. Trunk lid hinge mounting bolt

9. Trunk lid panel assembly

Trunk lid latch assembly removal

7. Trunk lid latch assembly

Trunk lid hinge removal steps

DRear shelf trim

DRear seat (Refer to GROUP 52A.)

9. Trunk lid panel assembly

AA""AA10. Trunk lid torsion bar (Right side)

AA""AA11. Trunk lid torsion bar (Left side)

12. Trunk lid hinge

Page 1221 of 1449

INTERIOR -Special Tool/Instrument Panel52A-3

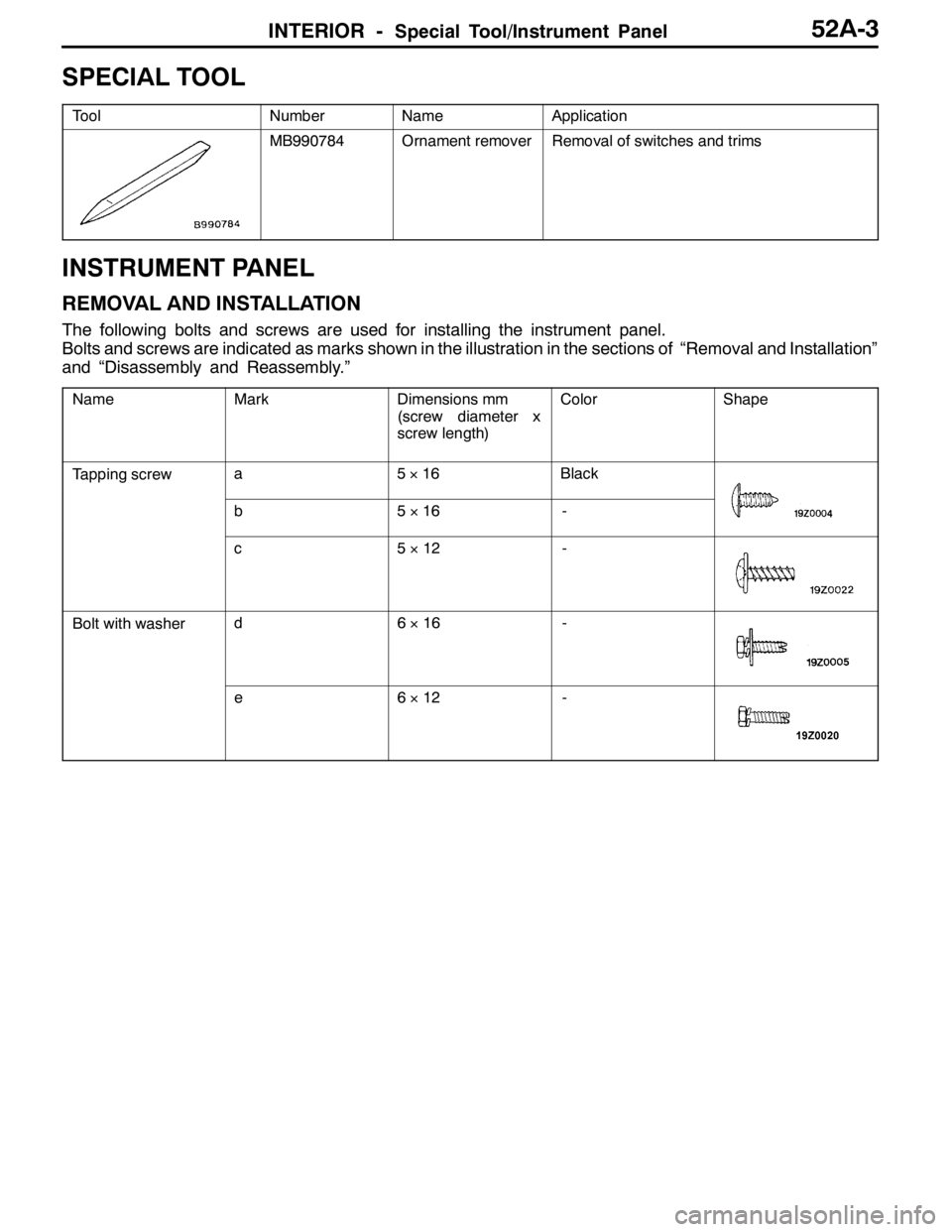

SPECIAL TOOL

ToolNumberNameApplication

MB990784Ornament removerRemoval of switches and trims

INSTRUMENT PANEL

REMOVAL AND INSTALLATION

The following bolts and screws are used for installing the instrument panel.

Bolts and screws are indicated as marks shown in the illustration in the sections of “Removal and Installation”

and “Disassembly and Reassembly.”

NameMarkDimensions mm

(screw diameter x

screw length)ColorShape

Tapping screwa5×16Black

b5×16-

c5×12-

Bolt with washerd6×16-

e6×12-

Page 1300 of 1449

SRS - Air Bag Modules and Clock Spring52B-56

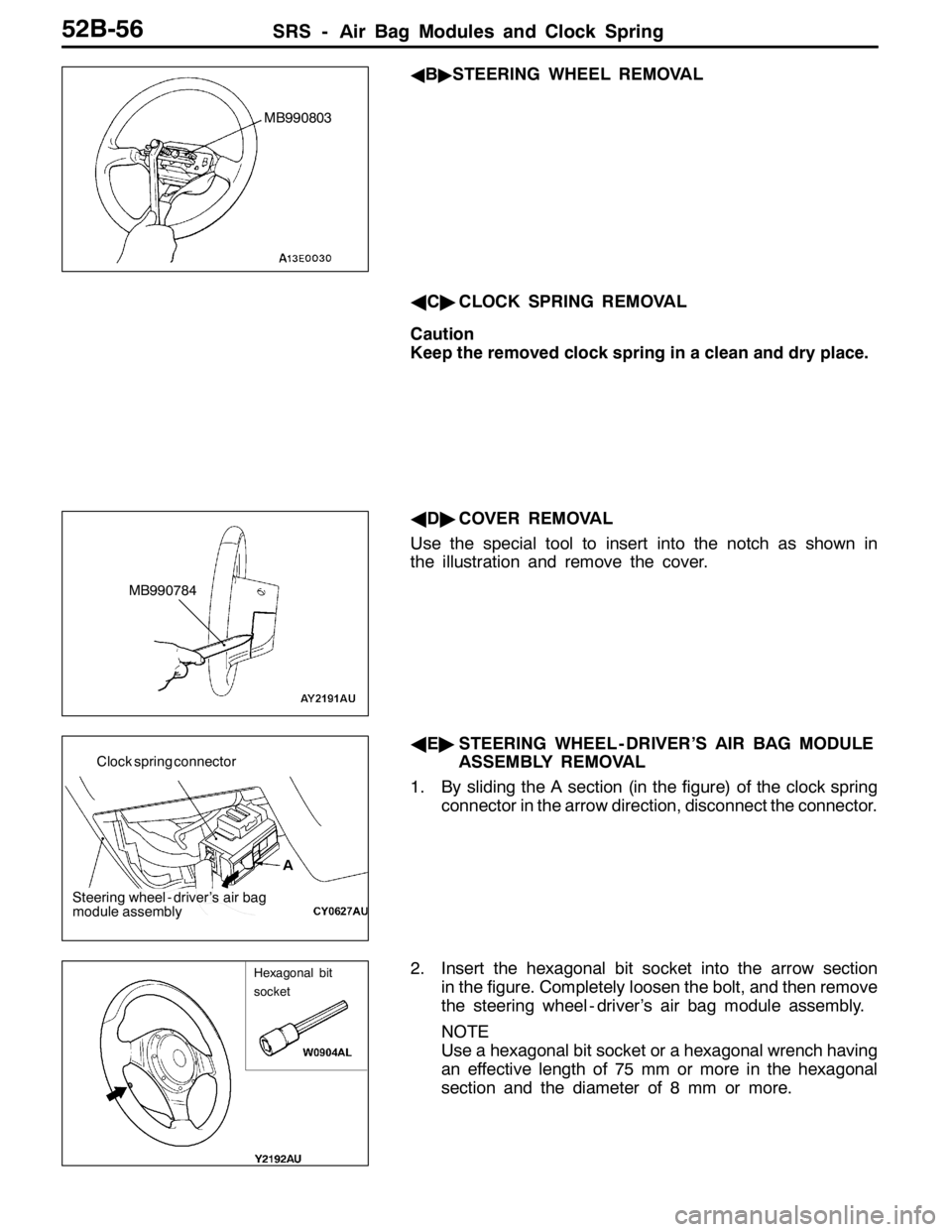

AB"STEERING WHEEL REMOVAL

AC"CLOCK SPRING REMOVAL

Caution

Keep the removed clock spring in a clean and dry place.

AD"COVER REMOVAL

Use the special tool to insert into the notch as shown in

the illustration and remove the cover.

AE"STEERING WHEEL - DRIVER’S AIR BAG MODULE

ASSEMBLY REMOVAL

1. By sliding the A section (in the figure) of the clock spring

connector in the arrow direction, disconnect the connector.

2. Insert the hexagonal bit socket into the arrow section

in the figure. Completely loosen the bolt, and then remove

the steering wheel - driver’s air bag module assembly.

NOTE

Use a hexagonal bit socket or a hexagonal wrench having

an effective length of 75 mm or more in the hexagonal

section and the diameter of 8 mm or more.

MB990803

MB990784

A Clock spring connector

Steering wheel - driver’s air bag

module assembly

Hexagonal bit

socket

Page 1363 of 1449

CHASSIS ELECTRICAL -Defogger54A-43

ON-VEHICLE SERVICE

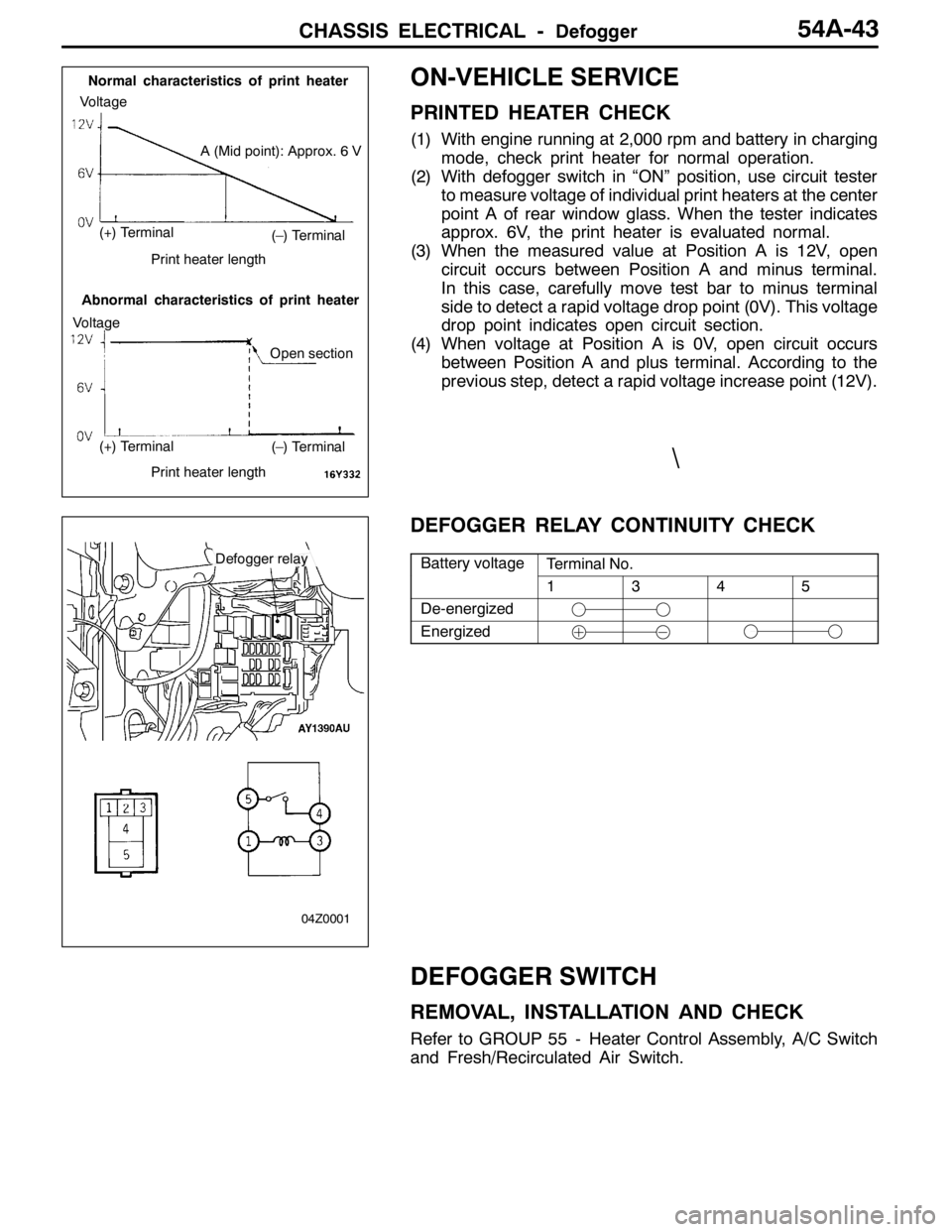

PRINTED HEATER CHECK

(1) With engine running at 2,000 rpm and battery in charging

mode, check print heater for normal operation.

(2) With defogger switch in “ON” position, use circuit tester

to measure voltage of individual print heaters at the center

point A of rear window glass. When the tester indicates

approx. 6V, the print heater is evaluated normal.

(3) When the measured value at Position A is 12V, open

circuit occurs between Position A and minus terminal.

In this case, carefully move test bar to minus terminal

side to detect a rapid voltage drop point (0V). This voltage

drop point indicates open circuit section.

(4) When voltage at Position A is 0V, open circuit occurs

between Position A and plus terminal. According to the

previous step, detect a rapid voltage increase point (12V).

DEFOGGER RELAY CONTINUITY CHECK

Battery voltageTerminal No.yg

1345

De-energized

Energized

DEFOGGER SWITCH

REMOVAL, INSTALLATION AND CHECK

Refer to GROUP 55 - Heater Control Assembly, A/C Switch

and Fresh/Recirculated Air Switch.

(–) Terminal

(–) Terminal

A (Mid point): Approx. 6 V

Normal characteristics of print heater

Abnormal characteristics of print heater

Voltage

Voltage

(+) Terminal

(+) Terminal

Print heater length

Print heater length

Open section

Defogger relay

04Z0001

\