length MITSUBISHI LANCER EVOLUTION 2007 Service User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 498 of 1449

ENGINE OVERHAUL -Cylinder Head and Valve11B-44

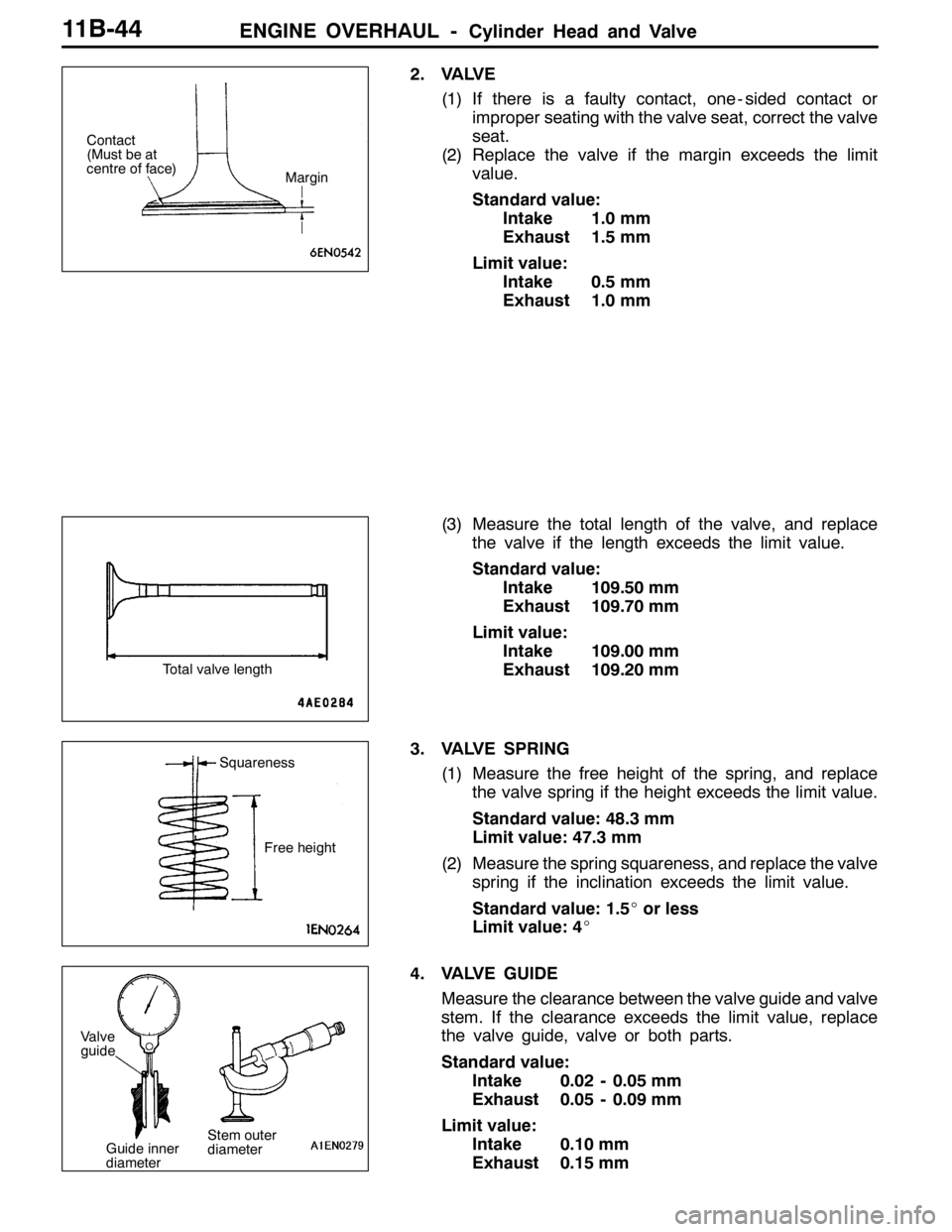

2. VALVE

(1) If there is a faulty contact, one - sided contact or

improper seating with the valve seat, correct the valve

seat.

(2) Replace the valve if the margin exceeds the limit

value.

Standard value:

Intake 1.0 mm

Exhaust 1.5 mm

Limit value:

Intake 0.5 mm

Exhaust 1.0 mm

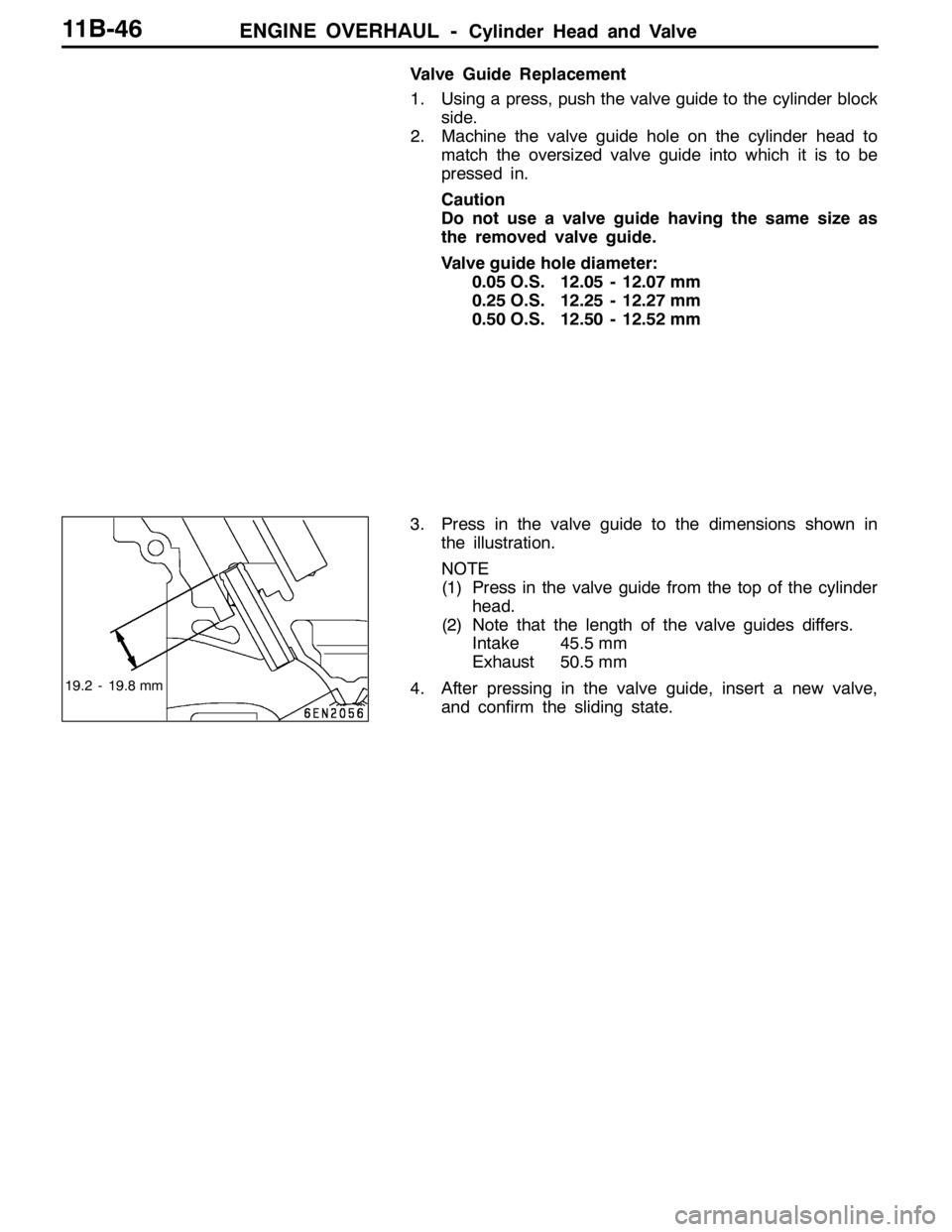

(3) Measure the total length of the valve, and replace

the valve if the length exceeds the limit value.

Standard value:

Intake 109.50 mm

Exhaust 109.70 mm

Limit value:

Intake 109.00 mm

Exhaust 109.20 mm

3. VALVE SPRING

(1) Measure the free height of the spring, and replace

the valve spring if the height exceeds the limit value.

Standard value: 48.3 mm

Limit value: 47.3 mm

(2) Measure the spring squareness, and replace the valve

spring if the inclination exceeds the limit value.

Standard value: 1.5_or less

Limit value: 4_

4. VALVE GUIDE

Measure the clearance between the valve guide and valve

stem. If the clearance exceeds the limit value, replace

the valve guide, valve or both parts.

Standard value:

Intake 0.02 - 0.05 mm

Exhaust 0.05 - 0.09 mm

Limit value:

Intake 0.10 mm

Exhaust 0.15 mm

Contact

(Must be at

centre of face)

Margin

Total valve length

Squareness

Free height

Valve

guide

Stem outer

diameter Guide inner

diameter

Page 500 of 1449

ENGINE OVERHAUL -Cylinder Head and Valve11B-46

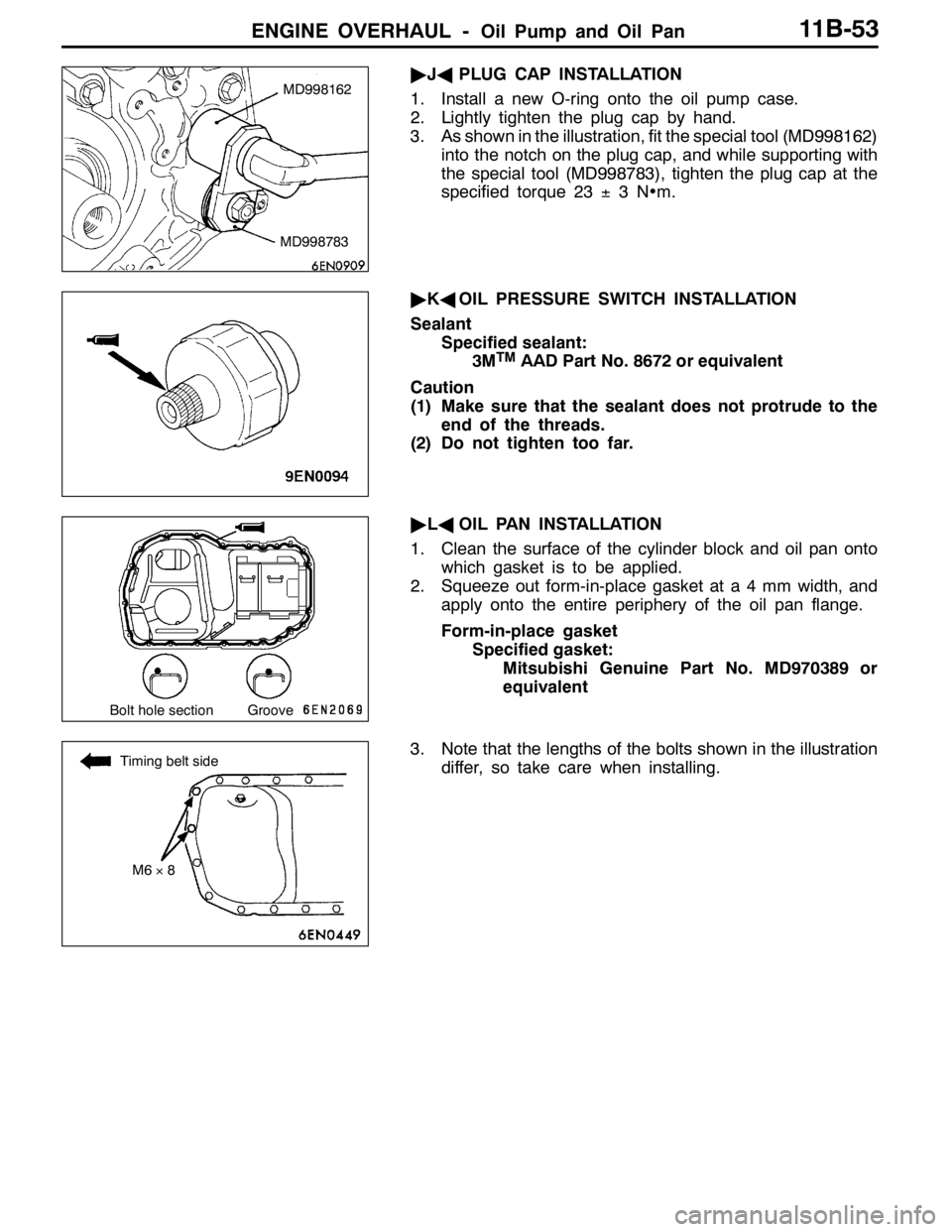

Valve Guide Replacement

1. Using a press, push the valve guide to the cylinder block

side.

2. Machine the valve guide hole on the cylinder head to

match the oversized valve guide into which it is to be

pressed in.

Caution

Do not use a valve guide having the same size as

the removed valve guide.

Valve guide hole diameter:

0.05 O.S. 12.05 - 12.07 mm

0.25 O.S. 12.25 - 12.27 mm

0.50 O.S. 12.50 - 12.52 mm

3. Press in the valve guide to the dimensions shown in

the illustration.

NOTE

(1) Press in the valve guide from the top of the cylinder

head.

(2) Note that the length of the valve guides differs.

Intake 45.5 mm

Exhaust 50.5 mm

4. After pressing in the valve guide, insert a new valve,

and confirm the sliding state.

19.2 - 19.8 mm

Page 507 of 1449

ENGINE OVERHAUL -Oil Pump and Oil Pan11B-53

"JAPLUG CAP INSTALLATION

1. Install a new O-ring onto the oil pump case.

2. Lightly tighten the plug cap by hand.

3. As shown in the illustration, fit the special tool (MD998162)

into the notch on the plug cap, and while supporting with

the special tool (MD998783), tighten the plug cap at the

specified torque 23±3N•m.

"KAOIL PRESSURE SWITCH INSTALLATION

Sealant

Specified sealant:

3M

TMAAD Part No. 8672 or equivalent

Caution

(1) Make sure that the sealant does not protrude to the

end of the threads.

(2) Do not tighten too far.

"LAOIL PAN INSTALLATION

1. Clean the surface of the cylinder block and oil pan onto

which gasket is to be applied.

2. Squeeze out form-in-place gasket at a 4 mm width, and

apply onto the entire periphery of the oil pan flange.

Form-in-place gasket

Specified gasket:

Mitsubishi Genuine Part No. MD970389 or

equivalent

3. Note that the lengths of the bolts shown in the illustration

differ, so take care when installing.

MD998162

MD998783

Bolt hole section Groove

Timing belt side

M6×8

Page 512 of 1449

ENGINE OVERHAUL -Piston and Connecting Rod11B-58

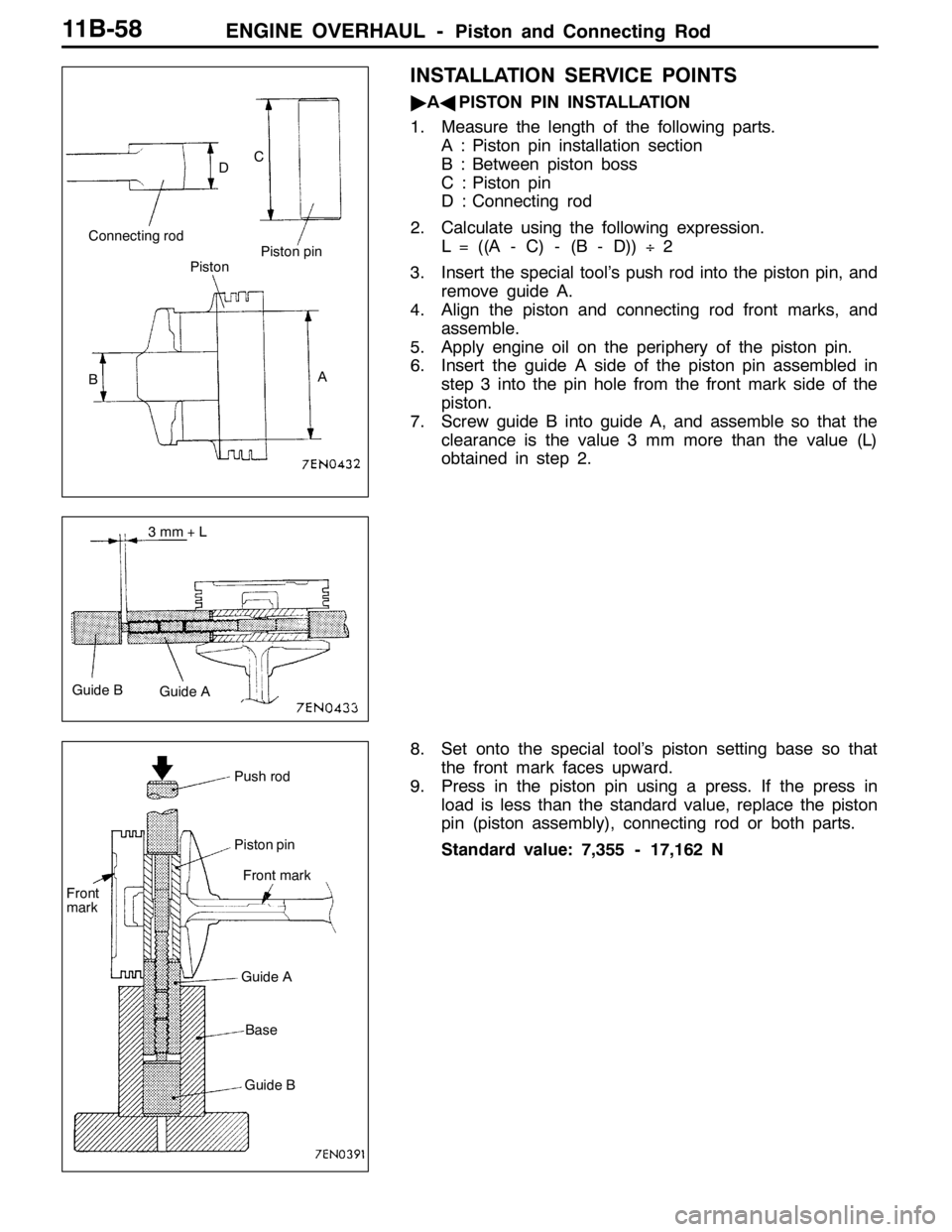

INSTALLATION SERVICE POINTS

"AAPISTON PIN INSTALLATION

1. Measure the length of the following parts.

A : Piston pin installation section

B : Between piston boss

C : Piston pin

D : Connecting rod

2. Calculate using the following expression.

L = ((A - C) - (B - D))÷2

3. Insert the special tool’s push rod into the piston pin, and

remove guide A.

4. Align the piston and connecting rod front marks, and

assemble.

5. Apply engine oil on the periphery of the piston pin.

6. Insert the guide A side of the piston pin assembled in

step 3 into the pin hole from the front mark side of the

piston.

7. Screw guide B into guide A, and assemble so that the

clearance is the value 3 mm more than the value (L)

obtained in step 2.

8. Set onto the special tool’s piston setting base so that

the front mark faces upward.

9. Press in the piston pin using a press. If the press in

load is less than the standard value, replace the piston

pin (piston assembly), connecting rod or both parts.

Standard value: 7,355 - 17,162 N

Connecting rod

PistonPiston pin

BA DC

3mm+L

Guide B

Guide A

Push rod

Piston pin

Front mark

Front

mark

Guide A

Guide BBase

Page 520 of 1449

![MITSUBISHI LANCER EVOLUTION 2007 Service User Guide ENGINE OVERHAUL -Crankshaft and Cylinder Block11B-66

3. Select the bearing from the above table according to

the identification confirmed in steps 1 and 2.

[Example of selecting bearing]

(1) If the me MITSUBISHI LANCER EVOLUTION 2007 Service User Guide ENGINE OVERHAUL -Crankshaft and Cylinder Block11B-66

3. Select the bearing from the above table according to

the identification confirmed in steps 1 and 2.

[Example of selecting bearing]

(1) If the me](/img/19/57084/w960_57084-519.png)

ENGINE OVERHAUL -Crankshaft and Cylinder Block11B-66

3. Select the bearing from the above table according to

the identification confirmed in steps 1 and 2.

[Example of selecting bearing]

(1) If the measured outer diameter of the crankshaft

journal is 57.000 mm, Class 1 applies, and the

identification colour is yellow.

(2) If the cylinder block bearing bore identification mark

is 0, select identification mark 0 in consideration of

step (1).

4. Install the grooved bearing on the cylinder block side.

5. Install the bearing with no oil groove onto the beam bearing

cap side.

"CABEAM BEARING CAP/BEARING CAP BOLT

INSTALLATION

1. Install the beam bearing cap with the arrow facing the

timing belt side.

2. Before installing the bearing cap bolt, confirm that the

bolt’s underhead length is less than the limit value.

Replace the bolt if it exceeds the limit value.

Limit value: 71.1 mm

3. Apply engine oil on the bolt threads and bolt surface.

4. Following the tightening order, tighten the bearing cap

bolt at 25±2N•m.

5. Make paint marks on the bolt head.

6. Using the position of the mark painted on the bolt head

as reference, make paint marks on the seat surface at

the 90_to 100_positions in the tightening direction.

7. Following the tightening order, tighten the bolt by 90_

to 100_, and confirm that the paint marks made on the

bolt and seat surface match.

Caution

(1) If the tightening angle is less than 90_, the

connection performance may not be attained, so

take special care when tightening.

(2) If the tightening angle exceeds 100_, completely

loosen the nut, and start again from step 1.Crankshaft bearing side

identification mark position

Identification

mark

Groove

Upper bearing

Lower bearing

Underhead length

Arrow

84159

732610

Paint marksPaint marks

90°- 100°

Page 701 of 1449

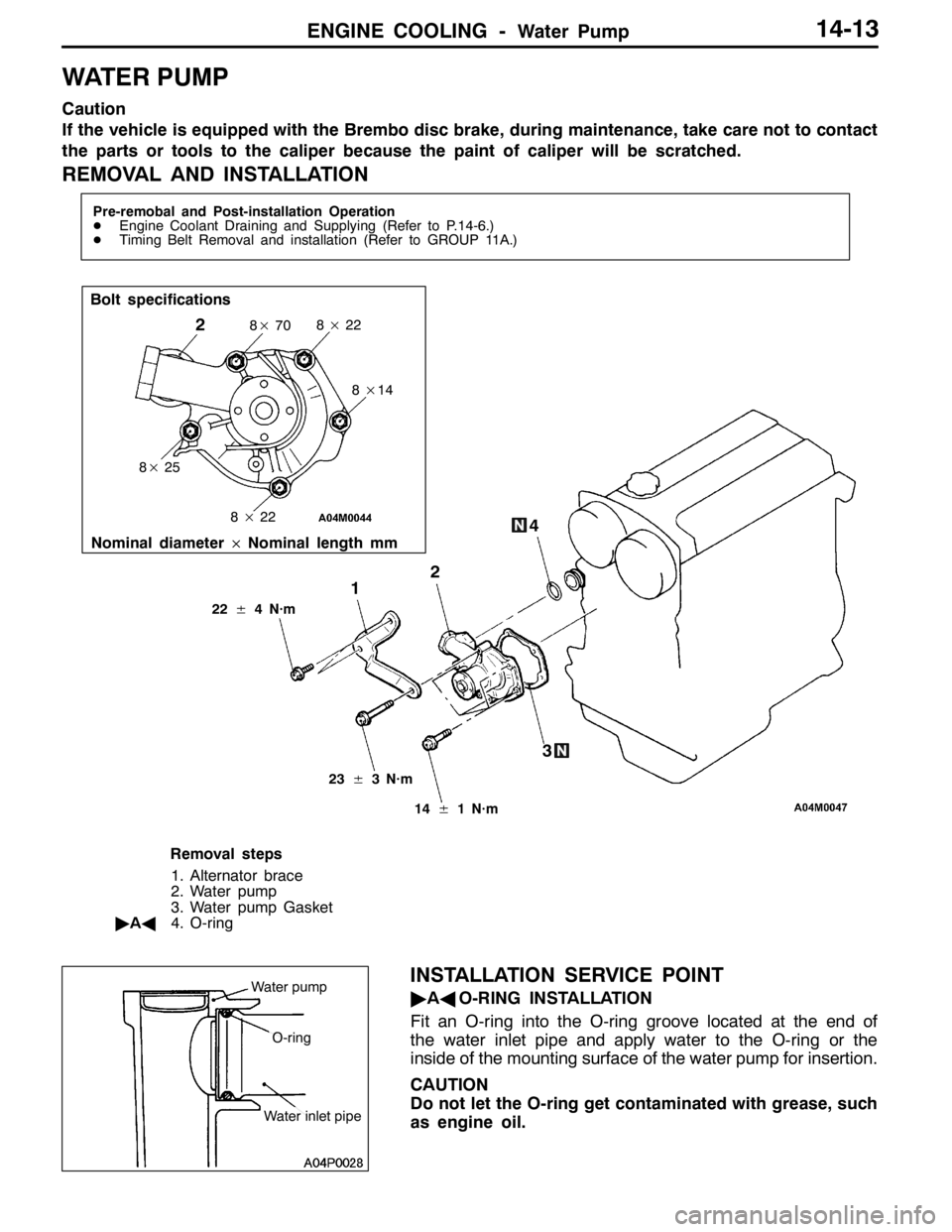

ENGINE COOLING -Water Pump14-13

WATER PUMP

Caution

If the vehicle is equipped with the Brembo disc brake, during maintenance, take care not to contact

the parts or tools to the caliper because the paint of caliper will be scratched.

REMOVAL AND INSTALLATION

Pre-remobal and Post-installation Operation

DEngine Coolant Draining and Supplying (Refer to P.14-6.)

DTiming Belt Removal and installation (Refer to GROUP 11A.)

1

Bolt specifications

28×22

2

23±3 N·m

14±1 N·m

Nominal diameter×Nominal length mm

8×70

8×14

8×22 8×25

3 4

22±4 N·m

Removal steps

1. Alternator brace

2. Water pump

3. Water pump Gasket

"AA4. O-ring

INSTALLATION SERVICE POINT

"AAO-RING INSTALLATION

Fit an O-ring into the O-ring groove located at the end of

the water inlet pipe and apply water to the O-ring or the

inside of the mounting surface of the water pump for insertion.

CAUTION

Do not let the O-ring get contaminated with grease, such

as engine oil.Water pump

O-ring

Water inlet pipe

Page 735 of 1449

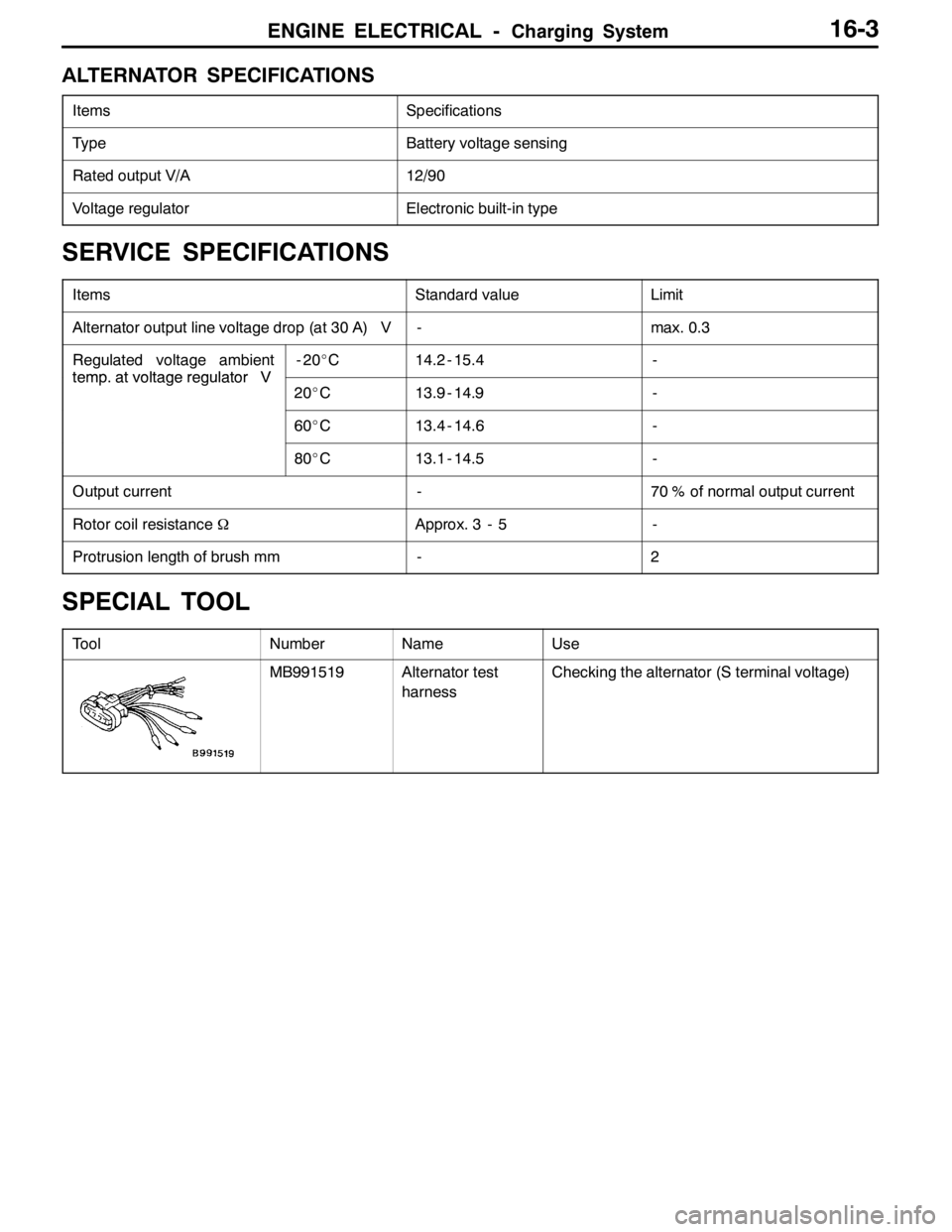

ENGINE ELECTRICAL -Charging System16-3

ALTERNATOR SPECIFICATIONS

ItemsSpecifications

TypeBattery voltage sensing

Rated output V/A12/90

Voltage regulatorElectronic built-in type

SERVICE SPECIFICATIONS

ItemsStandard valueLimit

Alternator output line voltage drop (at 30 A) V-max. 0.3

Regulated voltage ambient

tempatvoltageregulatorV

-20_C14.2 - 15.4-

temp. atvoltage regulatorV

20_C13.9 - 14.9-

60_C13.4 - 14.6-

80_C13.1 - 14.5-

Output current-70 % of normal output current

Rotor coil resistanceΩApprox. 3 - 5-

Protrusion length of brush mm-2

SPECIAL TOOL

ToolNumberNameUse

MB991519Alternator test

harnessChecking the alternator (S terminal voltage)

Page 748 of 1449

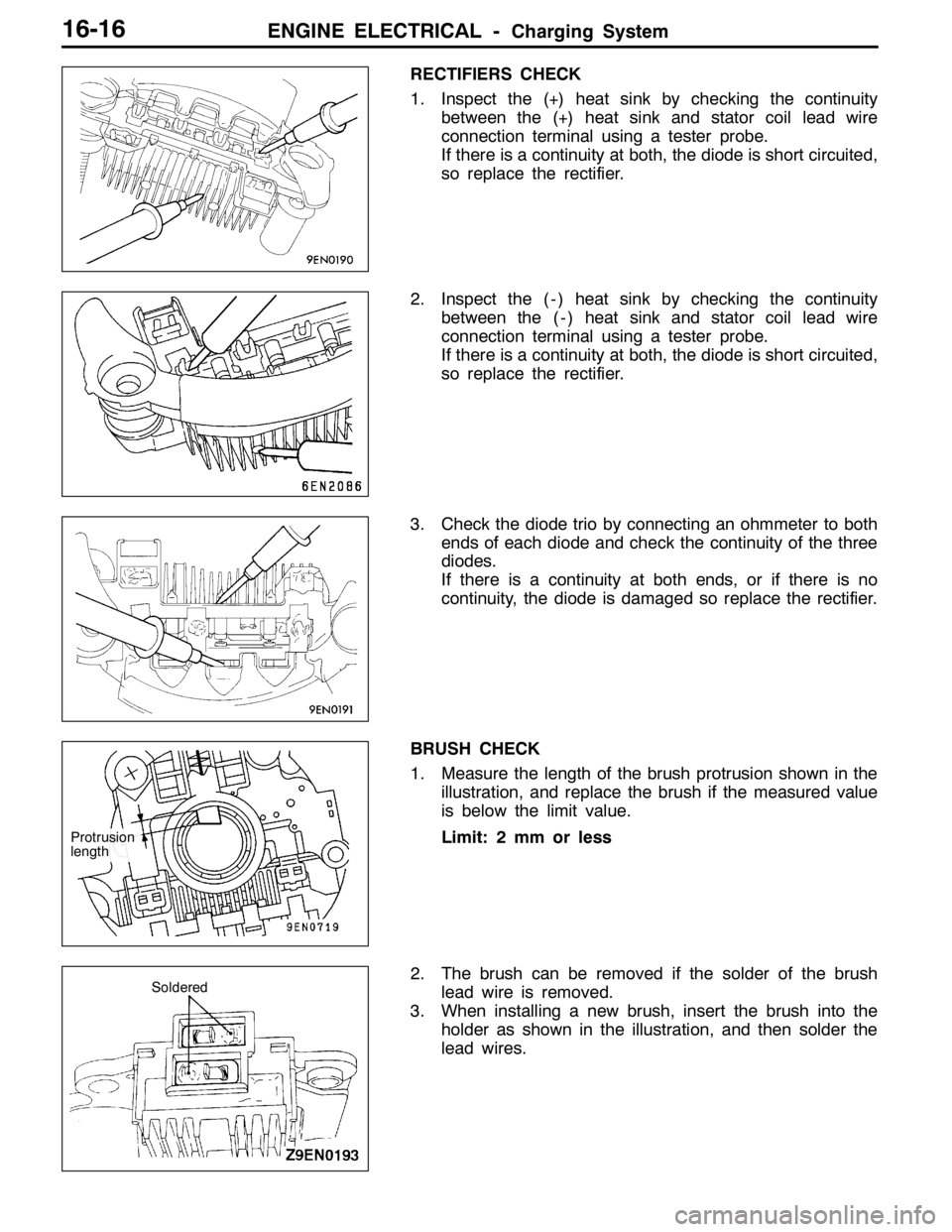

ENGINE ELECTRICAL -Charging System16-16

RECTIFIERS CHECK

1. Inspect the (+) heat sink by checking the continuity

between the (+) heat sink and stator coil lead wire

connection terminal using a tester probe.

If there is a continuity at both, the diode is short circuited,

so replace the rectifier.

2. Inspect the ( - ) heat sink by checking the continuity

between the ( - ) heat sink and stator coil lead wire

connection terminal using a tester probe.

If there is a continuity at both, the diode is short circuited,

so replace the rectifier.

3. Check the diode trio by connecting an ohmmeter to both

ends of each diode and check the continuity of the three

diodes.

If there is a continuity at both ends, or if there is no

continuity, the diode is damaged so replace the rectifier.

BRUSH CHECK

1. Measure the length of the brush protrusion shown in the

illustration, and replace the brush if the measured value

is below the limit value.

Limit: 2 mm or less

2. The brush can be removed if the solder of the brush

lead wire is removed.

3. When installing a new brush, insert the brush into the

holder as shown in the illustration, and then solder the

lead wires.

Protrusion

length

Soldered

Page 749 of 1449

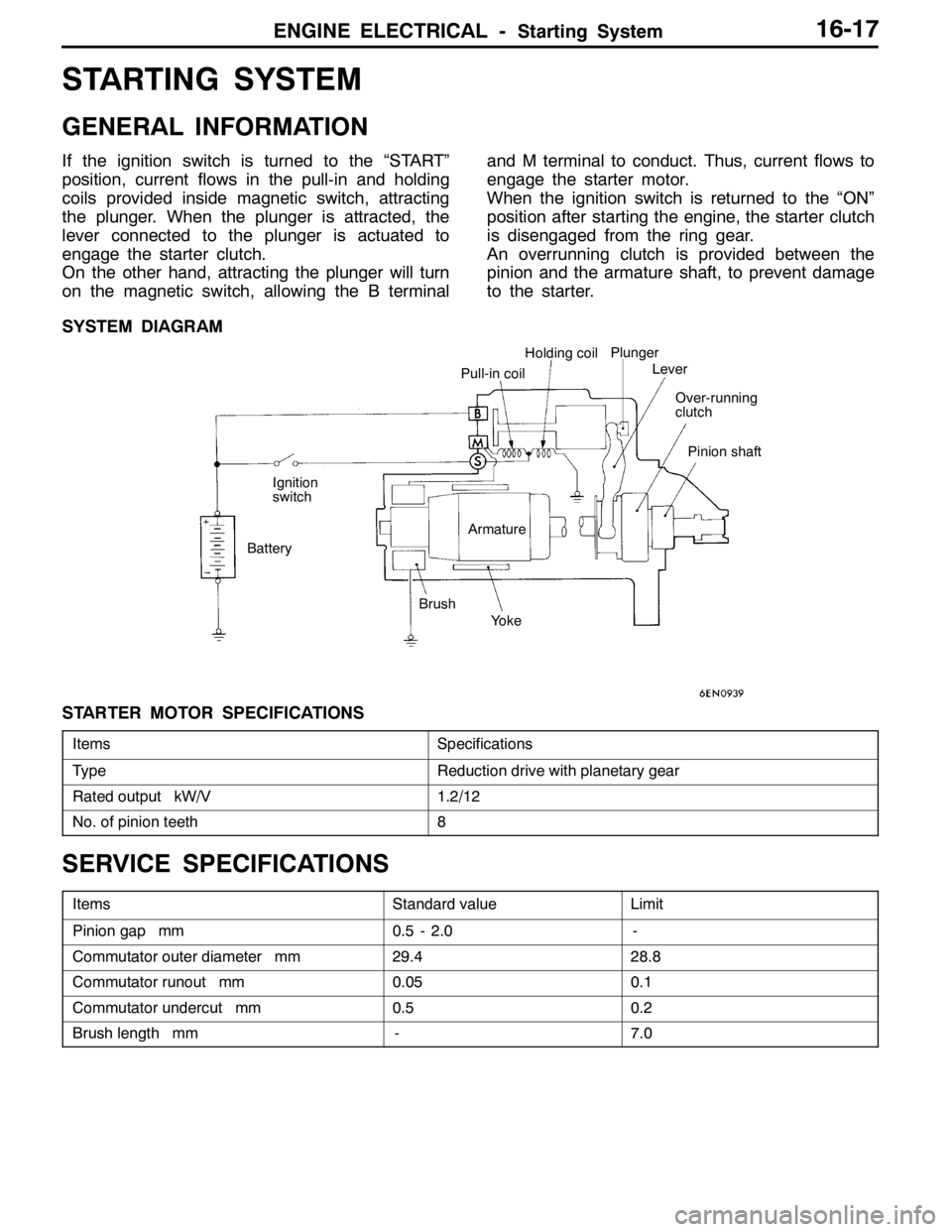

ENGINE ELECTRICAL -Starting System16-17

STARTING SYSTEM

GENERAL INFORMATION

If the ignition switch is turned to the “START”

position, current flows in the pull-in and holding

coils provided inside magnetic switch, attracting

the plunger. When the plunger is attracted, the

lever connected to the plunger is actuated to

engage the starter clutch.

On the other hand, attracting the plunger will turn

on the magnetic switch, allowing the B terminaland M terminal to conduct. Thus, current flows to

engage the starter motor.

When the ignition switch is returned to the “ON”

position after starting the engine, the starter clutch

is disengaged from the ring gear.

An overrunning clutch is provided between the

pinion and the armature shaft, to prevent damage

to the starter.

SYSTEM DIAGRAM

Pull-in coilHolding coil

Ignition

switch

BatteryArmature

Brush

YokePlunger

Lever

Over-running

clutch

Pinion shaft

STARTER MOTOR SPECIFICATIONS

ItemsSpecifications

TypeReduction drive with planetary gear

Rated output kW/V1.2/12

No. of pinion teeth8

SERVICE SPECIFICATIONS

ItemsStandard valueLimit

Pinion gap mm0.5 - 2.0-

Commutator outer diameter mm29.428.8

Commutator runout mm0.050.1

Commutator undercut mm0.50.2

Brush length mm-7.0

Page 756 of 1449

ENGINE ELECTRICAL -Starting System16-24

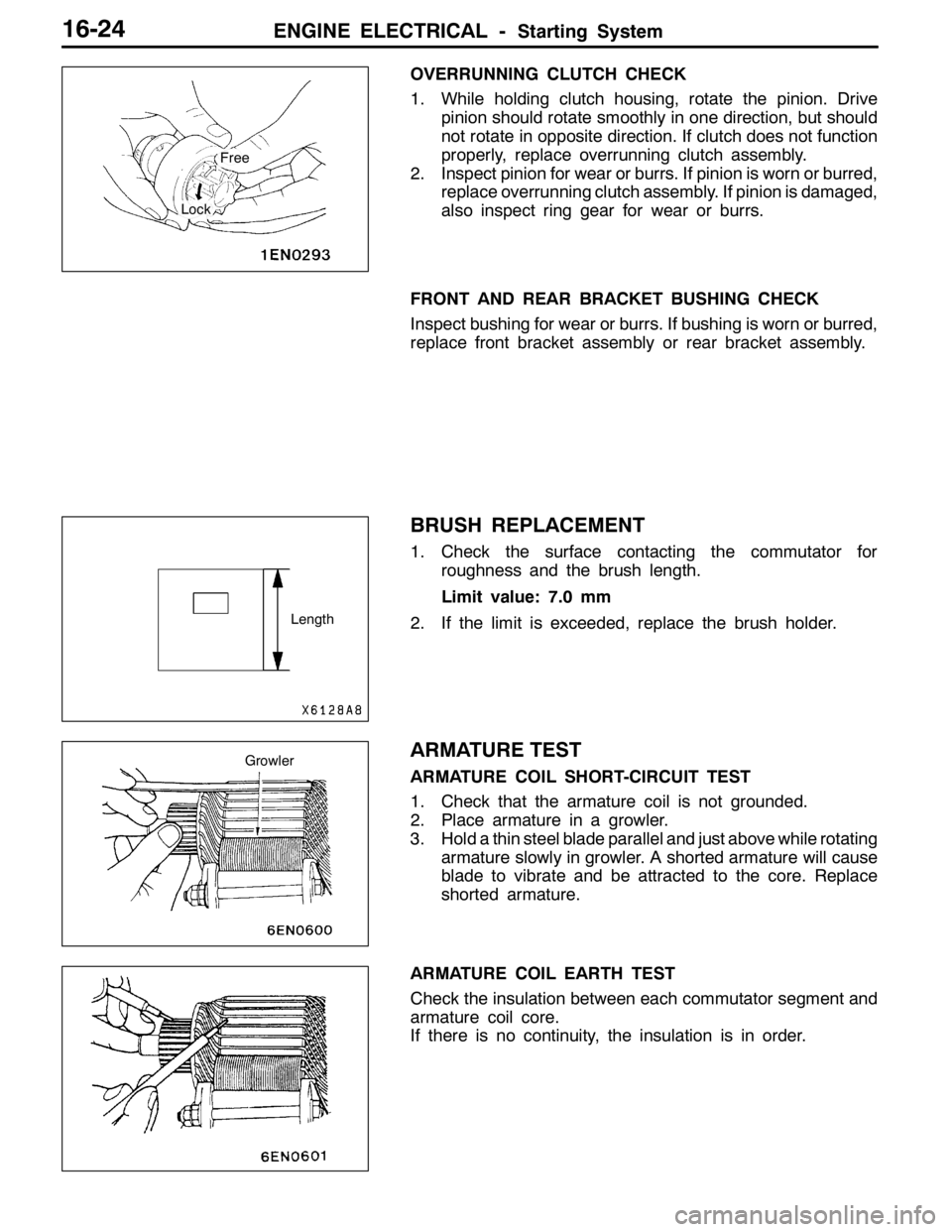

OVERRUNNING CLUTCH CHECK

1. While holding clutch housing, rotate the pinion. Drive

pinion should rotate smoothly in one direction, but should

not rotate in opposite direction. If clutch does not function

properly, replace overrunning clutch assembly.

2. Inspect pinion for wear or burrs. If pinion is worn or burred,

replace overrunning clutch assembly. If pinion is damaged,

also inspect ring gear for wear or burrs.

FRONT AND REAR BRACKET BUSHING CHECK

Inspect bushing for wear or burrs. If bushing is worn or burred,

replace front bracket assembly or rear bracket assembly.

BRUSH REPLACEMENT

1. Check the surface contacting the commutator for

roughness and the brush length.

Limit value: 7.0 mm

2. If the limit is exceeded, replace the brush holder.

ARMATURE TEST

ARMATURE COIL SHORT-CIRCUIT TEST

1. Check that the armature coil is not grounded.

2. Place armature in a growler.

3. Hold a thin steel blade parallel and just above while rotating

armature slowly in growler. A shorted armature will cause

blade to vibrate and be attracted to the core. Replace

shorted armature.

ARMATURE COIL EARTH TEST

Check the insulation between each commutator segment and

armature coil core.

If there is no continuity, the insulation is in order.

Free

Lock

Length

Growler